Robust Fault Estimation Using the Intermediate Observer: Application to the Quadcopter

Abstract

:1. Introduction

- An intermediate estimator is provided in the quadcopter system to estimate states and faults in the presence of uncertainties. The proposed method aims to relax the matching conditions or equation constraints.

- Stability analysis is described to validate the convergence of the error system.

- The experimental works on the quadcopter are demonstrated to validate the proposed algorithm.

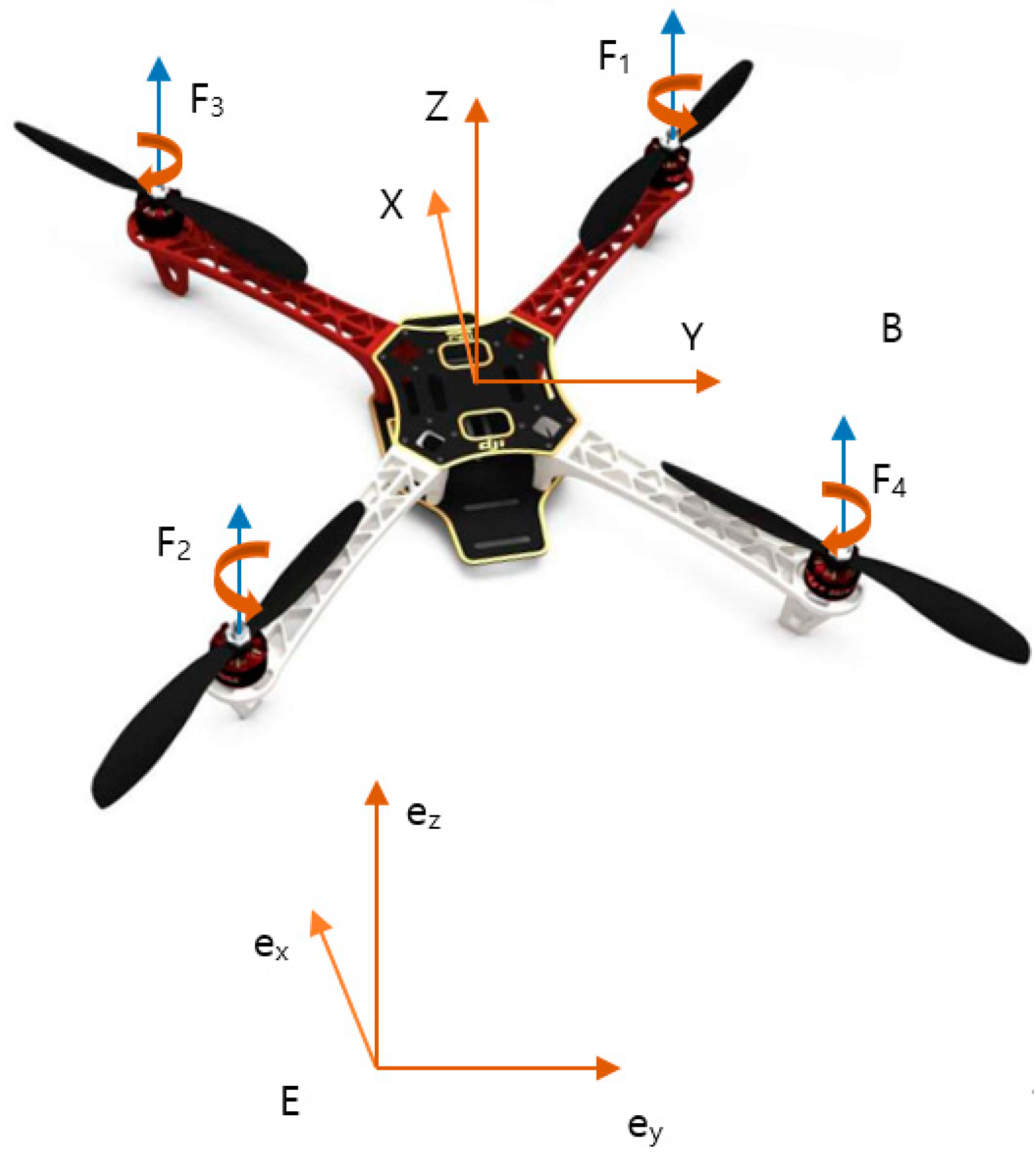

2. Mathematical Model of the Quadcopter

3. Methodology

3.1. Design of the Intermediate Observer

3.2. Magnitude Order Balance and Fault Estimation of Each Actuator

4. Experimental Results and Discussion

4.1. Experiment Setup

4.2. Experimental Results

4.2.1. LoCE in One Actuator without Using Magnitude Order Unbalance

4.2.2. LoCE in One Actuator Using the Magnitude Order Balance Method

4.2.3. LoCE in the Three Actuators Using Magnitude Order Unbalance

4.2.4. Loss of Control Effectiveness in Four Motors Using Magnitude Order Unbalance

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gordon, O.; Arinze, O.; James, O.; Nnaemeka, O. Design and Implementation of a Real Time Wireless Quadcopter for Rescue Operations. Am. J. Eng. Res. 2016, 5, 130–138. [Google Scholar]

- Eid, S.E.; Dol, S.S. Design and development of lightweight-high endurance unmanned aerial vehicle for offshore search and rescue operation. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conference, Dubai, UAE, 26 March–10 April 2019. [Google Scholar]

- Ian, L.T.; Mitchell, D.H.; Christopher, D.D. UAVs for coastal surveying. Coast. Eng. 2016, 114, 19–24. [Google Scholar]

- Kingston, D.; Rasmussen, S.; Humphrey, L. Automated UAV tasks for search and surveillance. In Proceedings of the 2016 IEEE Conference on Control Applications Part of 2016 IEEE Multi-Conference on Systems and Control, Buenos Aires, Argentina, 19–22 September 2016. [Google Scholar]

- Tenmuulen, S.; Jonathan, D.; Jason, M.; Joel, B.S. UAV lidar and hyperspectral fusion for forest monitoring in the southwestern USA. Remote Sens. Environ. 2017, 195, 30–43. [Google Scholar]

- Krause, S.; Sanders, T.G.; Mund, J.-P.; Greve, K. UAV-Based Photogrammetric Tree Height Measurement for Intensive Forest Monitoring. Remote Sens. 2019, 11, 758. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Li, H.; Xia, G.; Zhao, W.; Rem, S.; Wang, C. Research on the Application of Deep Learning Target Detection of Engineering Vehicles in the Patrol and Inspection for Military Optical Cable Lines by UAV. In Proceedings of the 2018 11th International Symposium on Computational Intelligence and Design (ISCID), Hangzhou, China, 8–9 December 2018. [Google Scholar]

- Butt, A.; Shah, S.I.A.; Zaheer, Q. Weapon Launch System Design of Anti-Terrorist UAV. In Proceedings of the 2019 International Conference on Engineering and Emerging Technologies, Lahore, Pakistan, 21–22 February 2019. [Google Scholar]

- Brossard, J.; Bensoussan, D.; Landry, R.; Hammami, M. Robustness studies on quadrotor control. In Proceedings of the 2019 International Conference on Unmanned Aircraft Systems, Atlanta, GA, USA, 11–14 June 2019. [Google Scholar]

- Mystkowski, A. An application of mu-synthesis for control of a small air vehicle and simulation results. J. Vibroeng. 2012, 14, 79–86. [Google Scholar]

- Tunik, A.A.; Nadsadnaya, O.I. A Flight Control System for Small Unmanned Aerial Vehicle. Int. Appl. Mech. 2018, 54, 239–247. [Google Scholar] [CrossRef]

- Xu, D.; Whidborne, J.F.; Cooke, A. Fault tolerant control of a quadrotor using L1 adaptive control. Int. J. Intell. Unmanned Syst. 2016, 4, 1–20. [Google Scholar]

- Ghandour, J.; Aberkane, S.; Ponsart, J.C. Feedback linearization approach for standard and fault tolerant control: Application to a quadrotor UAV testbed. J. Phys. Conf. Ser. 2014, 570, 082003. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Zhang, Y.; Gordon, B.W. Nonlinear fault-tolerant control of a quadrotor UAV based on sliding mode control technique. In Proceedings of the 8th IFAC Symposium of Fault Detection, Supervision and Safety of Technical Processes, Mexico city, Mexico, 29–31 August 2012. [Google Scholar]

- Freddi, A.; Longhi, S.; Monteriù, A. A diagnostic thau observer for a class of unmanned vehicles. J. Intell. Robot. Syst. 2012, 67, 1–13. [Google Scholar] [CrossRef]

- Freddi, A.; Longhi, S.; Monteriù, A. A model-based fault diagnosis system for a mini-quadrotor. In Proceedings of the 7th Workshop on Advanced Control and Diagnosis, Zielona Gora, Poland, 19–20 November 2009. [Google Scholar]

- Freddi, A.; Longhi, S.; Monteriu, A. Actuator fault detection system for a mini-quadrotor. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2020. [Google Scholar]

- Aguilar-Sierra, H.; Flores, G.; Salazar, S.; Lozano, R. Fault estimation for a quad-rotor MAV using a polynominal observer. In Proceedings of the 2013 International Conference on Unmanned Aircraft Systems, Atlanta, GA, USA, 28–31 May 2013. [Google Scholar]

- Amoozgar, M.H.; Chamseddine, A.; Zhang, Y. Experimental test of a two-stage Kalman filter for actuator fault detection and diagnosis of an unmanned quadrotor helicopter. J. Intell. Robot. Syst. 2013, 70, 107–117. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, C.; Zhang, Y. Active fault-tolerant control of unmanned quadrotor helicopter using linear parameter varying technique. J. Intell. Robot. Syst. 2017, 88, 415–436. [Google Scholar] [CrossRef]

- Cen, Z.; Noura, H.; Susilo Younes, Y.A. Robust fault diagnosis for quadrotor UAVs using adaptive Thau observer. J. Intell. Robot. Syst. 2014, 73, 573–588. [Google Scholar] [CrossRef]

- Cen, Z.; Noura, H. An Adaptive Thau Observer for estimating the time-varying LOE fault of quadrotor actuators. In Proceedings of the 2013 Conference on Control and Fault-Tolerant Systems (SysTol), Nice, France, 9–11 October 2013. [Google Scholar]

- Ma, H.; Liu, Y.; Li, T.; Yang, G. Nonlinear High-Gain Observer-Based Diagnosis and Compensation for Actuator and Sensor Faults in a Quadrotor Unmanned Aerial Vehicle. IEEE Trans. Ind. Inform. 2019, 15, 550–562. [Google Scholar] [CrossRef]

- Witczak, P.; Patan, K.; Witcak, M.; Mrugalski, M. A neural network approach to simultaneous state and actuator fault estimation under unknown input decoupling. Neurocomputing 2017, 250, 65–75. [Google Scholar] [CrossRef]

- Cho, C.N.; Hong, J.T.; Kim, H.J. Neural Network Based Adaptive Actuator Fault Detection Algorithm for Robot Manipulators. J. Intell. Robot. Syst. 2019, 95, 137–147. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, Y.; Zhang, X. Actuator fault estimation for a class of nonlinear descriptor systems. Int. J. Syst. Sci. 2014, 45, 487–496. [Google Scholar] [CrossRef]

- Mallavalli, S.; Fekih, A. A fault tolerant tracking control for a quadrotor UAV subject to simultaneous actuator faults and exogenous disturbances. Int. J. Control 2018, 93, 655–668. [Google Scholar] [CrossRef]

- Chen, F.; Lei, W.; Tao, G.; Jiang, B. Actuator fault estimation and reconfiguration control for quad-rotor helicopter. Int. J. Adv. Robot. Syst. 2016, 13, 33. [Google Scholar] [CrossRef] [Green Version]

- Bharani, K.P.; Alwi, H.; Edwards, C. Fault reconstruction for a quadrotor using an LPV sliding mode observer. In Proceedings of the 9th IFAC Symposium on Fault Detection Supervision and Safety for Technical Processes SAFEPROCESS 2015, Paris, France, 2–4 September 2015. [Google Scholar]

- Nguyen, N.P.; Hong, S.K. Sliding Mode Thau Observer for Actuator Fault Diagnosis of Quadcopter UAVs. Appl. Sci. 2018, 8, 1893. [Google Scholar] [CrossRef] [Green Version]

- Dong, W.; Gu, G.-Y.; Zhu, X.; Ding, H. Modeling and Control of a Quadrotor UAV with Aerodynamics Concepts. World Acad. Sci. Eng. Technol. 2013, 7, 901–906. [Google Scholar]

- Zhang, Y.; Chamseddine, A. Fault tolerant flight control techniques with application to a quadrotor UAV testbed. In Automatic Flight Control Systems-Latest Developments; Thomas Lombaerts, IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.-W.; Yang, G.-H.; Wang, H.; Wang, F. Fault estimation for a class of nonlinear systems based on intermediate estimator. IEEE Trans. Autom. Control 2016, 61, 2518–2524. [Google Scholar] [CrossRef]

- Editing/Building with Eclipse on Windows. Available online: http://ardupilot.org/dev/docs/editing-the-code-with-eclipse.html (accessed on 31 August 2018).

- Telemetry. Available online: http://ardupilot.org/copter/docs/common-telemetry-landingpage.html (accessed on 31 August 2018).

| Input: The control inputs and system matrices in (5) satisfying Assumptions 1–4. |

| Step 1: Choose small positive parameters of Step 2: Solving the LMI matrix to obtain matrix and . Step 3: Fault estimation for roll, pitch, yaw, thrust motion in (14). |

| Step 4: Choose adjustment gain for magnitude order balance. |

| Step 5: Loss of control effectiveness of each actuator (Fault estimation of each actuator) in (38) is obtained. |

| Parameter | Description | Value |

|---|---|---|

| Arm length | ||

| Thrust coefficient | ||

| Drag coefficient | ||

| Total mass | ||

| Moments of inertia | ||

| Rotor inertia | ||

| Adjustment gain | 10 | |

| Constant | 1 | |

| Constant | 0.02 | |

| Constant | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, N.P.; Huynh, T.T.; Do, X.P.; Xuan Mung, N.; Hong, S.K. Robust Fault Estimation Using the Intermediate Observer: Application to the Quadcopter. Sensors 2020, 20, 4917. https://doi.org/10.3390/s20174917

Nguyen NP, Huynh TT, Do XP, Xuan Mung N, Hong SK. Robust Fault Estimation Using the Intermediate Observer: Application to the Quadcopter. Sensors. 2020; 20(17):4917. https://doi.org/10.3390/s20174917

Chicago/Turabian StyleNguyen, Ngoc Phi, Tuan Tu Huynh, Xuan Phu Do, Nguyen Xuan Mung, and Sung Kyung Hong. 2020. "Robust Fault Estimation Using the Intermediate Observer: Application to the Quadcopter" Sensors 20, no. 17: 4917. https://doi.org/10.3390/s20174917