Classification of Copper Minerals by Handheld Laser-Induced Breakdown Spectroscopy and Nonnegative Tensor Factorisation

Abstract

:1. Introduction

2. Materials

2.1. Overview

2.2. Element Composition

3. Experimental

4. Method

4.1. Latent Spectrum Extraction

4.2. Regression Model Using Latent Spectra

4.3. Determining the Number of Latent Spectra per Mineral

5. Results

5.1. Setup

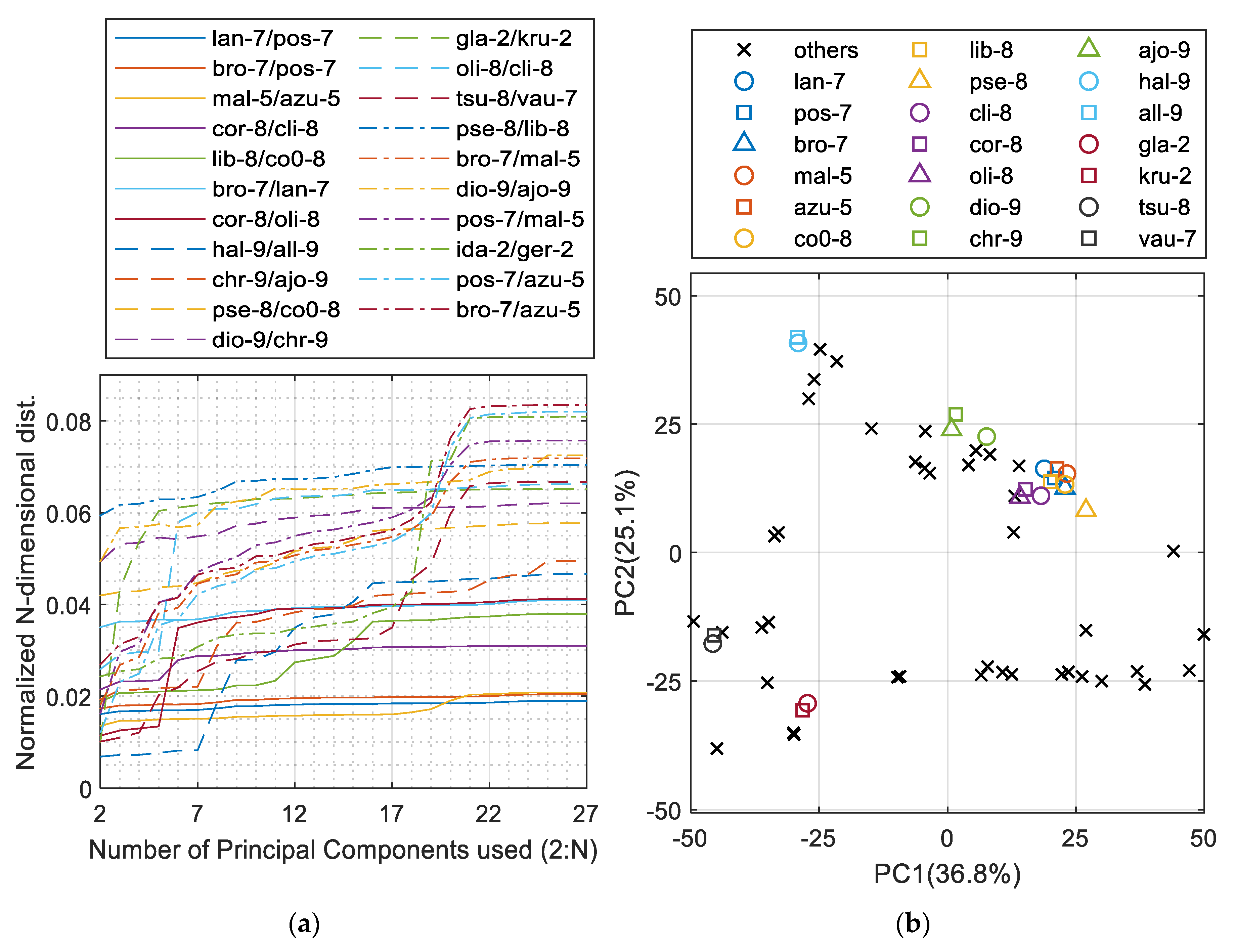

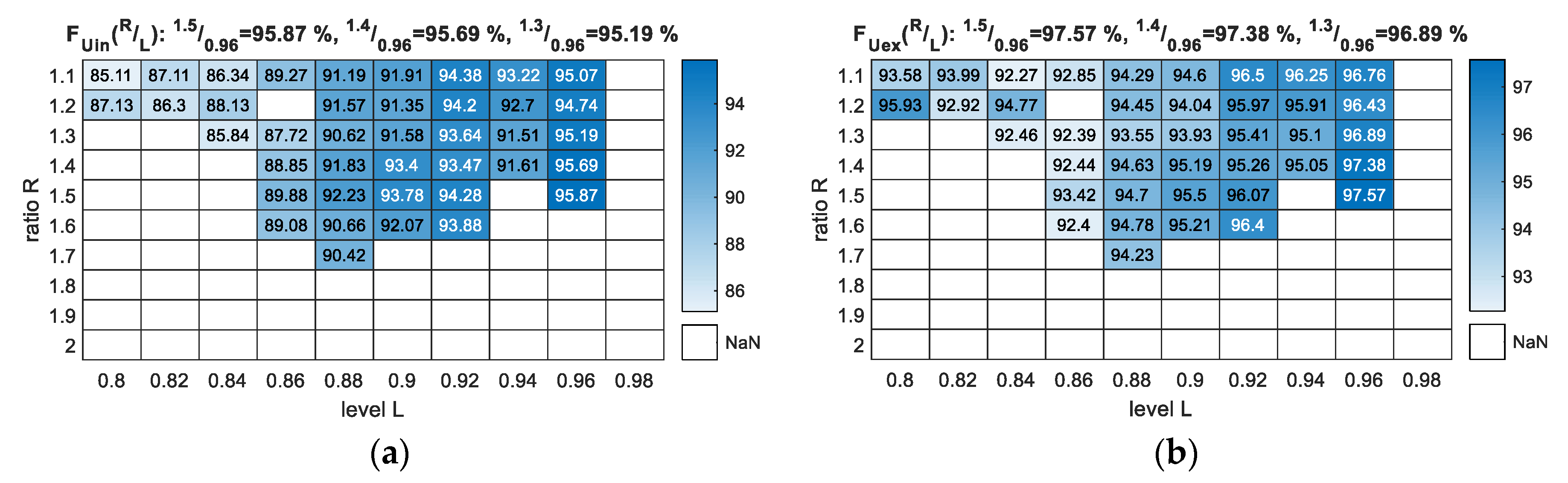

5.2. Analysis of Training Data

5.3. Analysis of Validation Data

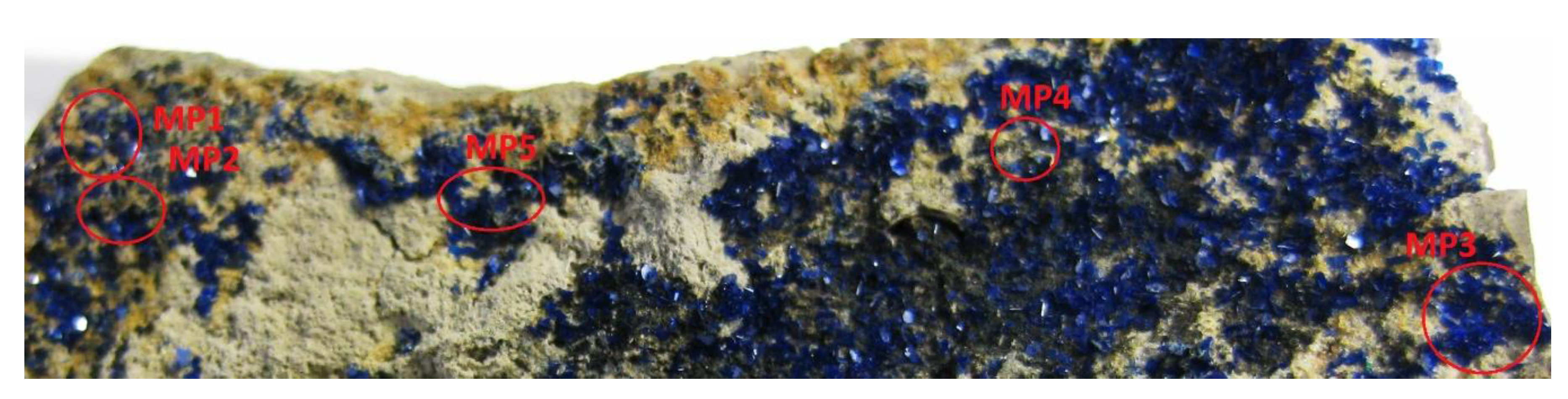

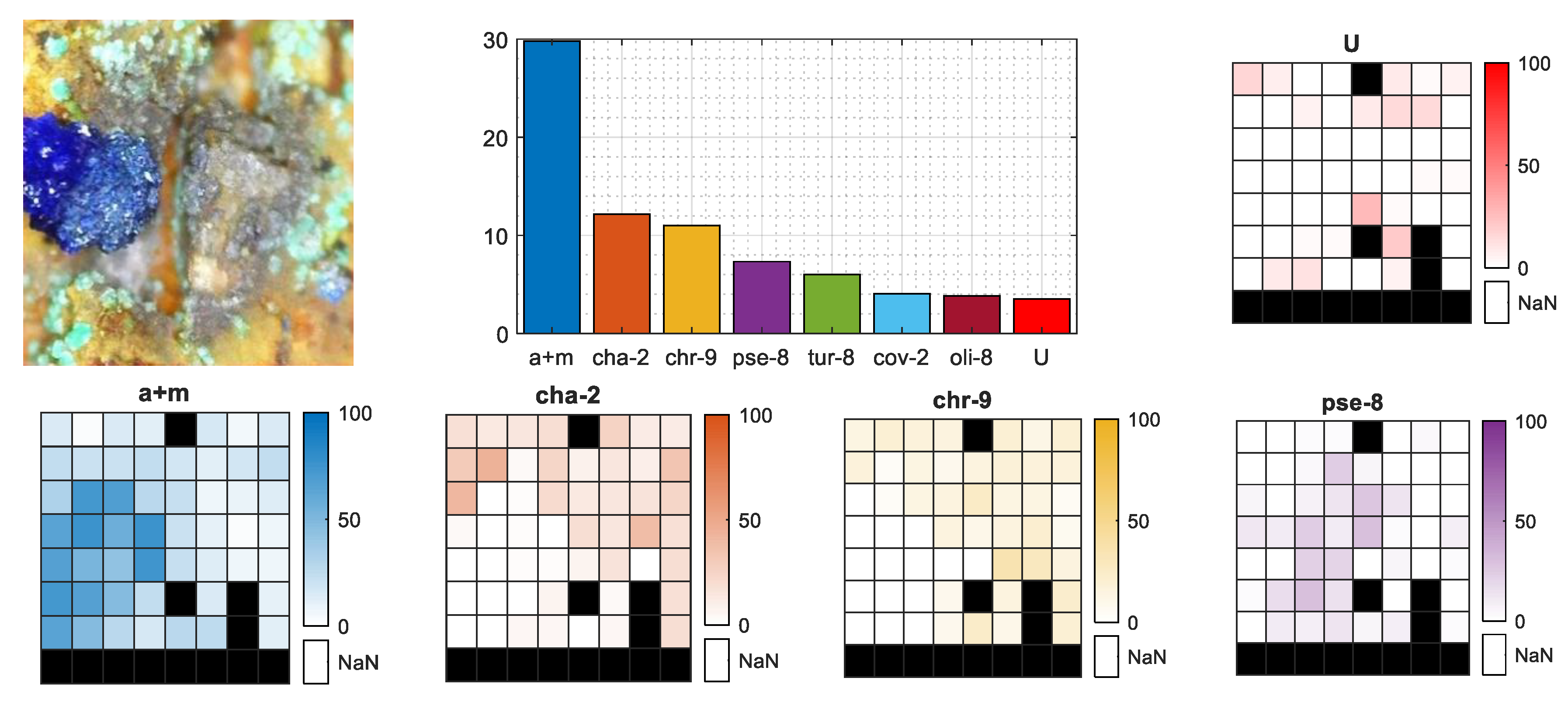

5.4. Example of Mineral Contribution for Selected MPs

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Cremers, D.A.; Multari, R.A.; Knight, A.K. Laser-Induced Breakdown Spectroscopy. In Encyclopedia of Analytical Chemistry; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; pp. 1–28. ISBN 9780470027318. [Google Scholar]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Elements of Statistical Learning: Data Mining, Inference, and Prediction, 2nd ed.; Springer Series in Statistics; Springer: New York, NY, USA, 2009; ISBN 9780387848587. [Google Scholar]

- Alpaydin, E. Introduction to Machine Learning; Adaptive Computation and Machine Learning Series; MIT Press: Cambridge, MA, USA, 2014; ISBN 9780262325752. [Google Scholar]

- Pontes, M.J.C.; Cortez, J.; Galvão, R.K.H.; Pasquini, C.; Araújo, M.C.U.; Coelho, R.M.; Chiba, M.K.; de Abreu, M.F.; Madari, B.E. Classification of Brazilian soils by using LIBS and variable selection in the wavelet domain. Anal. Chim. Acta 2009, 642, 12–18. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Wu, S.; Dong, J.; Wei, J.; Wang, K.; Tang, H.; Yang, X.; Li, H. Quantitative and classification analysis of slag samples by laser induced breakdown spectroscopy (LIBS) coupled with support vector machine (SVM) and partial least square (PLS) methods. J. Anal. At. Spectrom. 2015, 30, 368–374. [Google Scholar] [CrossRef]

- Li, X.; Yang, S.; Fan, R.; Yu, X.; Chen, D. Discrimination of soft tissues using laser-induced breakdown spectroscopy in combination with k nearest neighbors (kNN) and support vector machine (SVM) classifiers. Opt. Laser Technol. 2018, 102, 233–239. [Google Scholar] [CrossRef]

- Feng, J.; Wang, Z.; West, L.; Li, Z.; Ni, W. A PLS model based on dominant factor for coal analysis using laser-induced breakdown spectroscopy. Anal. Bioanal. Chem. 2011, 400, 3261–3271. [Google Scholar] [CrossRef] [PubMed]

- Bricklemyer, R.S.; Brown, D.J.; Turk, P.J.; Clegg, S. Comparing vis-NIRS, LIBS, and Combined vis-NIRS-LIBS for Intact Soil Core Soil Carbon Measurement. Soil Sci. Soc. Am. J. 2018, 82, 1482–1496. [Google Scholar] [CrossRef]

- Menking-Hoggatt, K.; Arroyo, L.; Curran, J.; Trejos, T. Novel LIBS method for micro-spatial chemical analysis of inorganic gunshot residues. J. Chemom. 2019, e3208. [Google Scholar] [CrossRef]

- Wójcik, M.R.; Zdunek, R.; Antończak, A.J. Unsupervised verification of laser-induced breakdown spectroscopy dataset clustering. Spectrochim. Acta Part B At. Spectrosc. 2016, 126, 84–92. [Google Scholar] [CrossRef]

- Ramil, A.; López, A.J.; Yáñez, A. Application of artificial neural networks for the rapid classification of archaeological ceramics by means of laser induced breakdown spectroscopy (LIBS). Appl. Phys. A Mater. Sci. Process. 2008, 92, 197–202. [Google Scholar] [CrossRef]

- Hahn, D.W.; Omenetto, N. Laser-Induced Breakdown Spectroscopy (LIBS), Part II: Review of Instrumental and Methodological Approaches to Material Analysis and Applications to Different Fields. Appl. Spectrosc. 2012, 66, 347–419. [Google Scholar] [CrossRef]

- Merk, S.; Scholz, C.; Florek, S.; Mory, D. Increased identification rate of scrap metal using Laser Induced Breakdown Spectroscopy Echelle spectra. Spectrochim. Acta—Part B At. Spectrosc. 2015, 112, 10–15. [Google Scholar] [CrossRef]

- Herrera, K.K.; Tognoni, E.; Gornushkin, I.B.; Omenetto, N.; Smith, B.W.; Winefordner, J.D. Comparative study of two standard-free approaches in laser-induced breakdown spectroscopy as applied to the quantitative analysis of aluminum alloy standards under vacuum conditions. J. Anal. At. Spectrom. 2009, 24, 426–438. [Google Scholar] [CrossRef]

- Kuhn, K.; Meima, J.A.; Rammlmair, D.; Ohlendorf, C. Chemical mapping of mine waste drill cores with laser-induced breakdown spectroscopy (LIBS) and energy dispersive X-ray fluorescence (EDXRF) for mineral resource exploration. J. Geochem. Explor. 2015, 161, 72–84. [Google Scholar] [CrossRef]

- Moncayo, S.; Manzoor, S.; Rosales, J.D.; Anzano, J.; Caceres, J.O. Qualitative and quantitative analysis of milk for the detection of adulteration by Laser Induced Breakdown Spectroscopy (LIBS). Food Chem. 2017, 232, 322–328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ji, G.; Ye, P.; Shi, Y.; Yuan, L.; Chen, X.; Yuan, M.; Zhu, D.; Chen, X.; Hu, X.; Jiang, J. Laser-induced breakdown spectroscopy for rapid discrimination of heavy-metal-contaminated seafood Tegillarca granosa. Sensors 2017, 17, 2655. [Google Scholar] [CrossRef] [Green Version]

- Hamzaoui, S.; Khleifia, R.; Jaïdane, N.; Ben Lakhdar, Z. Quantitative analysis of pathological nails using laser-induced breakdown spectroscopy (LIBS) technique. Lasers Med. Sci. 2011, 26, 79–83. [Google Scholar] [CrossRef] [PubMed]

- Erler, A.; Riebe, D.; Beitz, T.; Löhmannsröben, H.G.; Gebbers, R. Soil nutrient detection for precision agriculture using handheld laser-induced breakdown spectroscopy (LIBS) and multivariate regression methods (PLSR, lasso and GPR). Sensors 2020, 20, 418. [Google Scholar] [CrossRef] [Green Version]

- Cremers, D.A. Space Applications of LIBS. In Laser-Induced Breakdown Spectroscopy: Theory and Applications; Musazzi, S., Perini, U., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 257–291. ISBN 978-3-642-45085-3. [Google Scholar]

- DeLucia, F.C.; Samuels, A.C.; Harmon, R.S.; Walters, R.A.; McNesby, K.L.; LaPointe, A.; Winkel, R.J.; Miziolek, A.W. Laser-induced breakdown spectroscopy (LIBS): A promising versatile chemical sensor technology for hazardous material detection. IEEE Sens. J. 2005, 5, 681–689. [Google Scholar] [CrossRef]

- Shashua, A.; Hazan, T. Non-negative tensor factorization with applications to statistics and computer vision. In Proceedings of the 22nd International Conference on Machine Learning, Bonn, Germany, 7–11 August 2005; pp. 792–799. [Google Scholar]

- Nickel, H.S.E. Strunz Mineralogical Tables, 9th ed.; Schweizerbart Science Publishers: Stuttgart, Germany, 2001; ISBN 9783510651887. [Google Scholar]

- Mineralogy Database. Available online: http://webmineral.com/ (accessed on 1 July 2020).

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- MathWorks Pdist—Pairwise Distance between Pairs of Observations. Available online: https://www.mathworks.com/help/stats/pdist.html (accessed on 27 July 2020).

- Carroll, J.D.; Chang, J.J. Analysis of individual differences in multidimensional scaling via an n-way generalization of “Eckart-Young” decomposition. Psychometrika 1970, 35, 283–319. [Google Scholar] [CrossRef]

- Harshman, R.A. Foundations of the PARAFAC procedure: Models and conditions for an “explanatory” multimodal factor analysis. UCLA Work Pap. Phon. 1970, 16, 1–84. [Google Scholar]

- Cichocki, A.; Zdunek, R.; Amari, S.I. Hierarchical ALS algorithms for nonnegative matrix and 3D tensor factorization. Lect. Notes Comput. Sci. 2007, 4666 LNCS, 169–176. [Google Scholar] [CrossRef]

- Phan, A.-H.; Cichocki, A. Multi-Way Nonnegative Tensor Factorization Using Fast Hierarchical Alternating Least Squares Algorithm (HALS). In Proceedings of the 2008 International Symposium on Nonlinear Theory and Its Applications, Budapest, Hungary, 7–10 September 2008; pp. 41–44. [Google Scholar]

- Sokolova, M.; Lapalme, G. A systematic analysis of performance measures for classification tasks. Inf. Process. Manag. 2009, 45, 427–437. [Google Scholar] [CrossRef]

| Mineral Class Name | Class Number C |

|---|---|

| Sulfides | 2 |

| Halides | 3 |

| Oxides and Hydroxides | 4 |

| Carbonates and Nitrates | 5 |

| Sulfates | 7 |

| Phosphates | 8 |

| Silicates | 9 |

| MP | Mineral | Reference | Coverage |

|---|---|---|---|

| 1 | azurite | 0 | 80 |

| 2 | azurite | 0 | 20 |

| 3 | azurite | 1 | 90 |

| 4 | azurite | 0 | 30 |

| 5 | azurite | 0 | 60 |

| Measure | SVM | KNN | LDA | NTFUin | NTFUex |

|---|---|---|---|---|---|

| Precision (%) | 71.76 | 51.77 | 52.01 | 74.74 (+2.98) | 74.74 (+2.98) |

| Recall (%) | 68.48 | 54.97 | 54.16 | 70.13 (+1.65) | 75.40 (+6.92) |

| F-Measure (%) | 67.22 | 49.48 | 49.77 | 69.09 (+1.87) | 72.24 (+5.02) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wójcik, M.; Brinkmann, P.; Zdunek, R.; Riebe, D.; Beitz, T.; Merk, S.; Cieślik, K.; Mory, D.; Antończak, A. Classification of Copper Minerals by Handheld Laser-Induced Breakdown Spectroscopy and Nonnegative Tensor Factorisation. Sensors 2020, 20, 5152. https://doi.org/10.3390/s20185152

Wójcik M, Brinkmann P, Zdunek R, Riebe D, Beitz T, Merk S, Cieślik K, Mory D, Antończak A. Classification of Copper Minerals by Handheld Laser-Induced Breakdown Spectroscopy and Nonnegative Tensor Factorisation. Sensors. 2020; 20(18):5152. https://doi.org/10.3390/s20185152

Chicago/Turabian StyleWójcik, Michał, Pia Brinkmann, Rafał Zdunek, Daniel Riebe, Toralf Beitz, Sven Merk, Katarzyna Cieślik, David Mory, and Arkadiusz Antończak. 2020. "Classification of Copper Minerals by Handheld Laser-Induced Breakdown Spectroscopy and Nonnegative Tensor Factorisation" Sensors 20, no. 18: 5152. https://doi.org/10.3390/s20185152

APA StyleWójcik, M., Brinkmann, P., Zdunek, R., Riebe, D., Beitz, T., Merk, S., Cieślik, K., Mory, D., & Antończak, A. (2020). Classification of Copper Minerals by Handheld Laser-Induced Breakdown Spectroscopy and Nonnegative Tensor Factorisation. Sensors, 20(18), 5152. https://doi.org/10.3390/s20185152