Battery-Free and Noninvasive Estimation of Food pH and CO2 Concentration for Food Monitoring Based on Pressure Measurement

Abstract

:1. Introduction

2. Methods

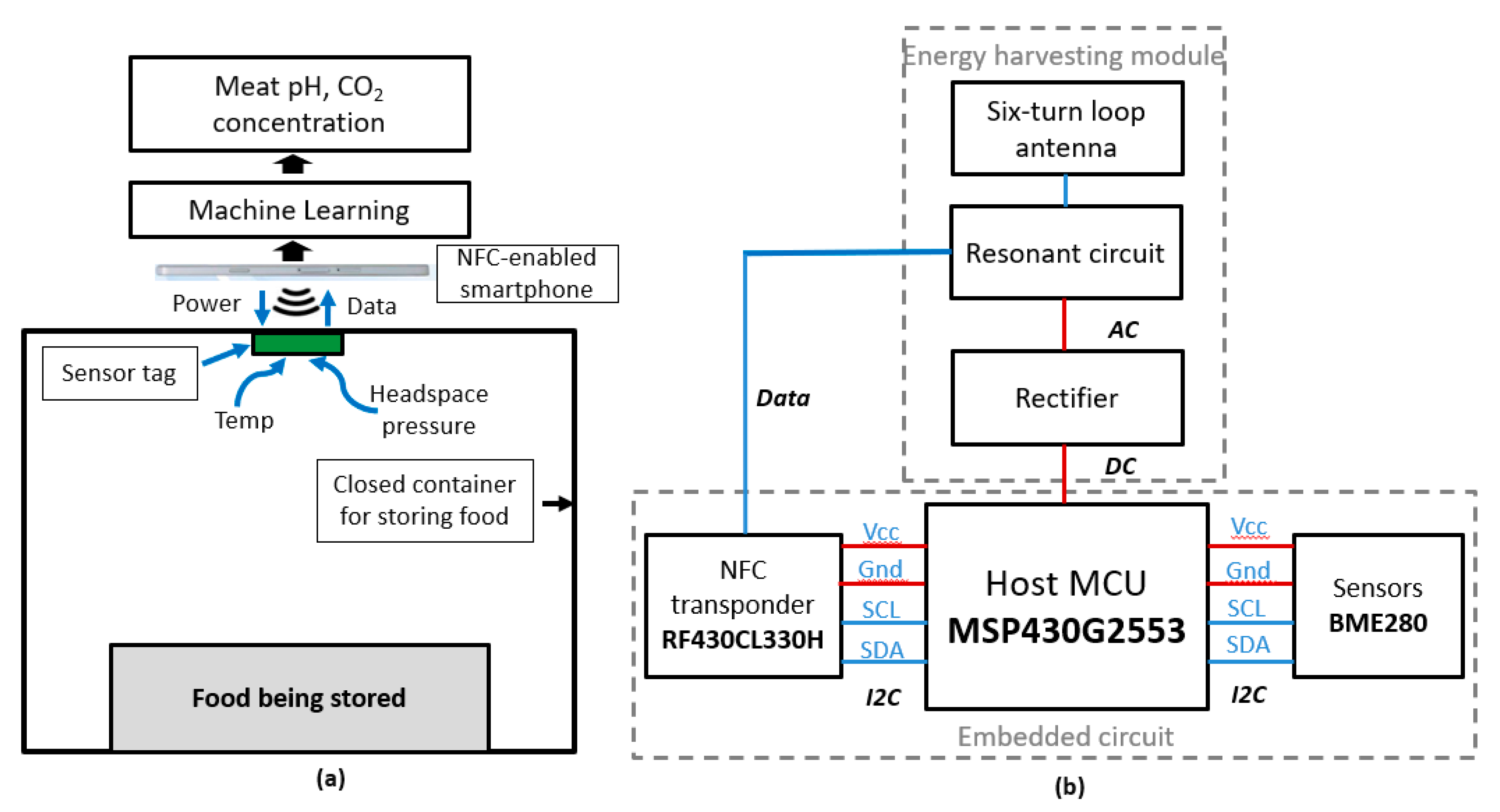

2.1. Proposed Method for Battery-Free Food Monitoring

2.2. Techniques for Self-Powered Operation

3. Results

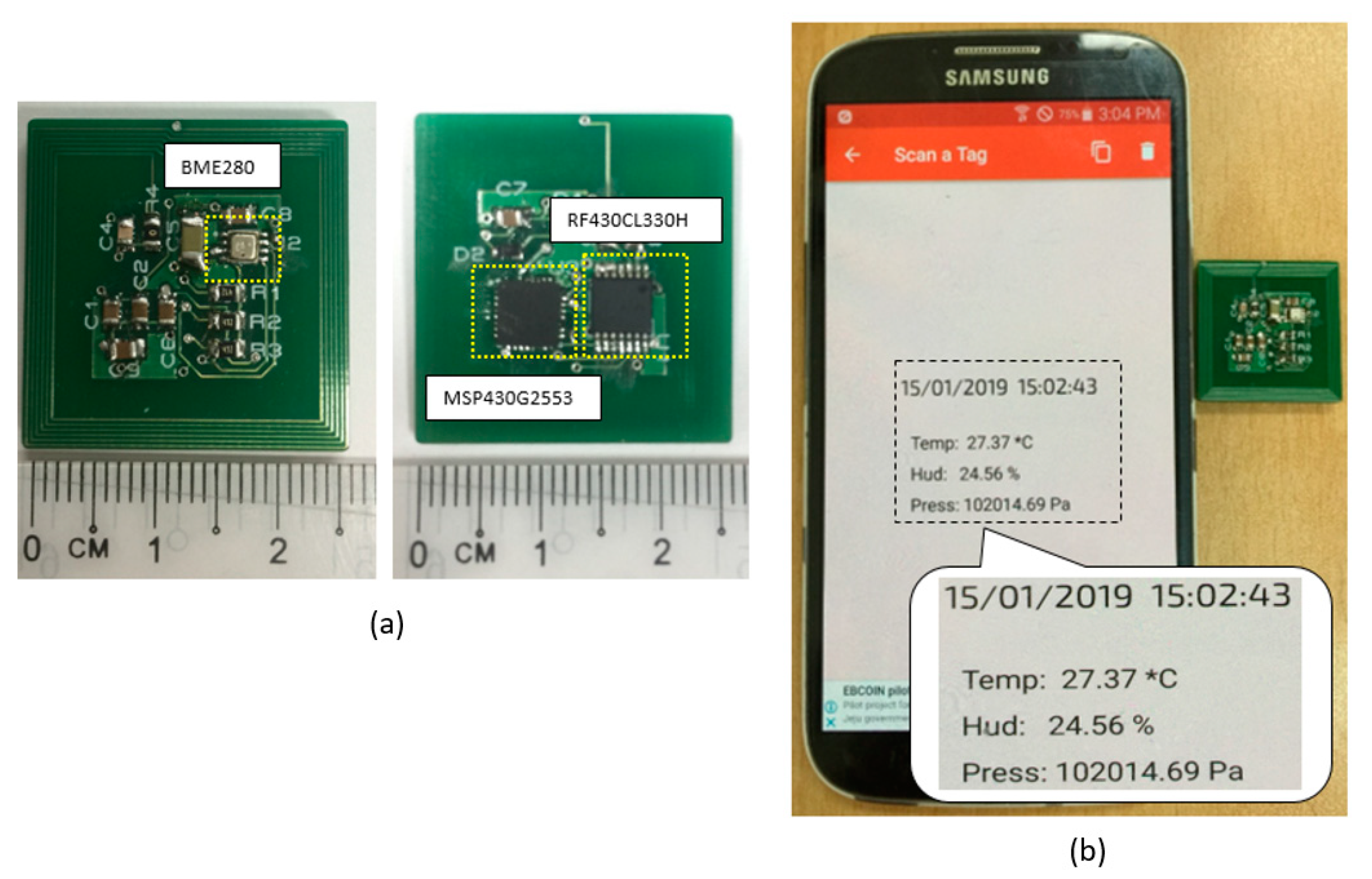

3.1. Sensor Tag Operation Analysis

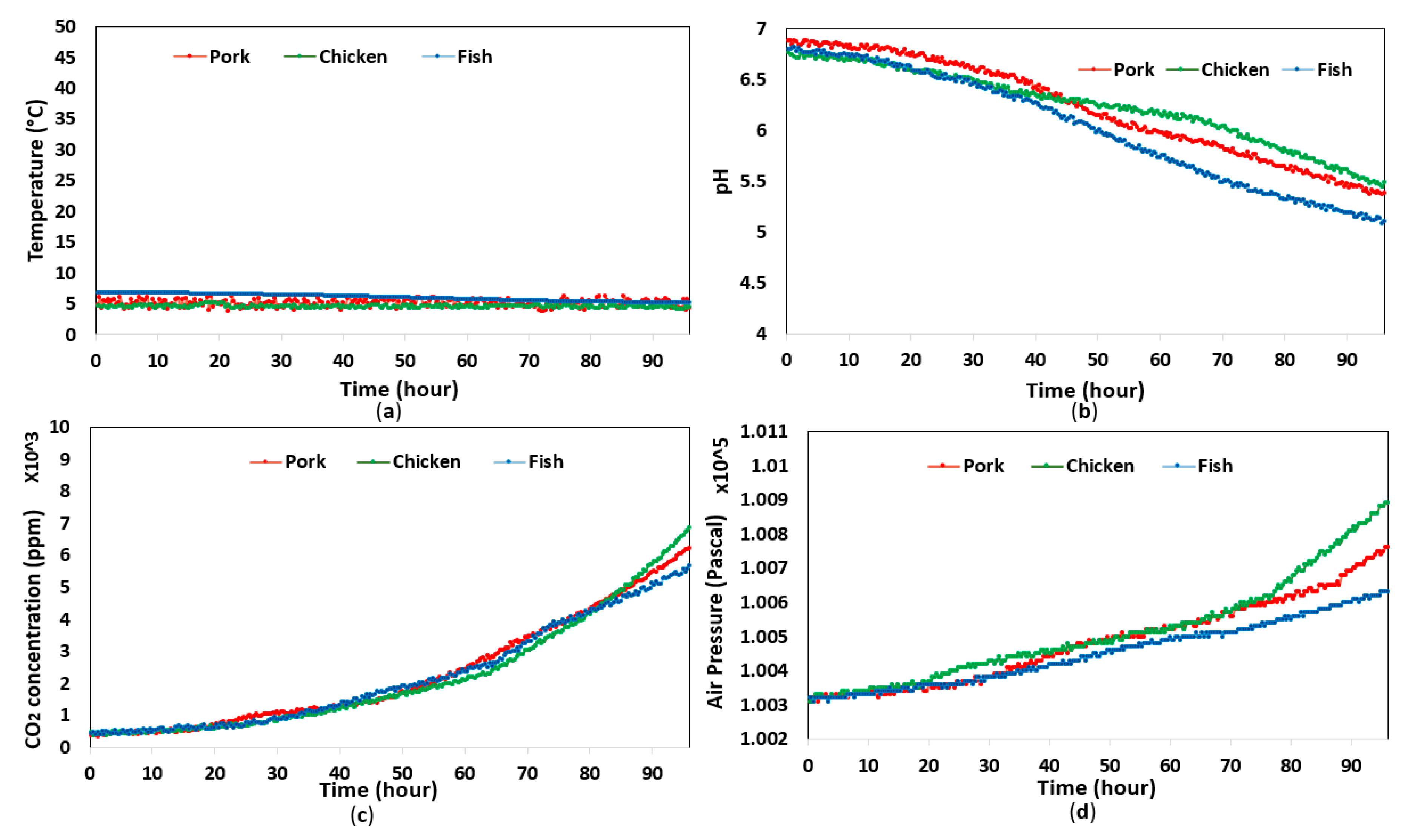

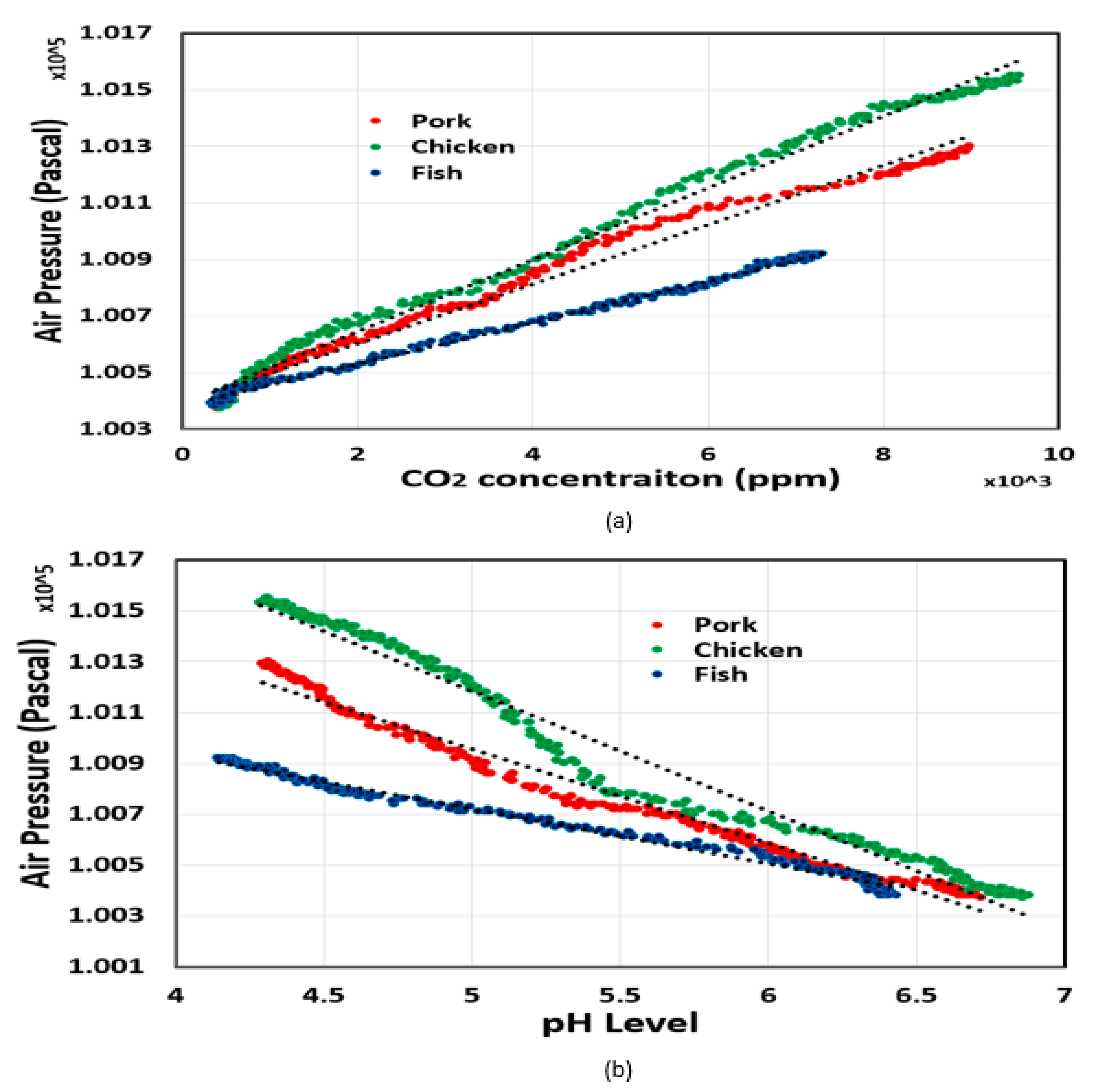

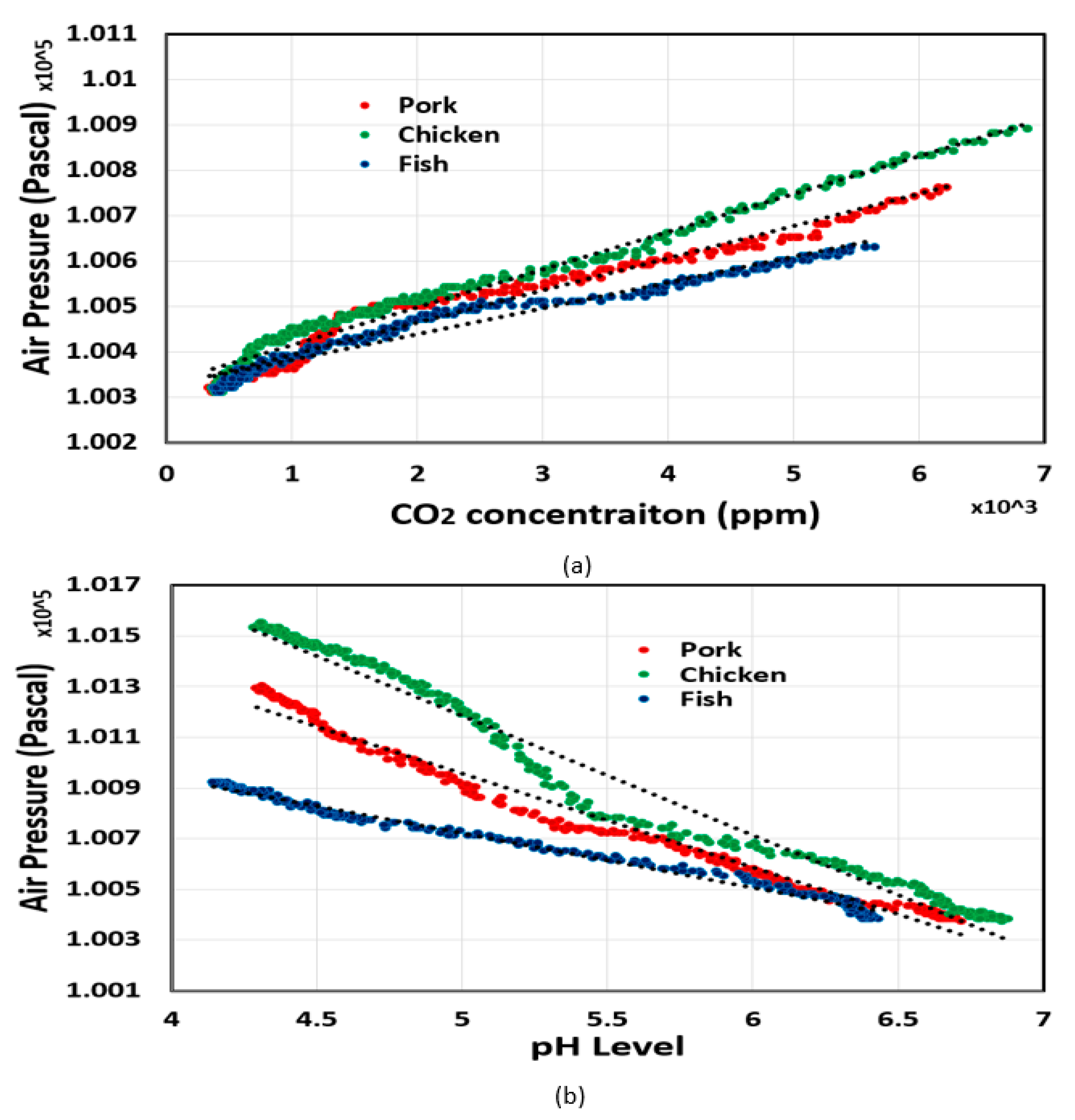

3.2. Data Collection from Experiments with Food

3.3. Mobile Application Development

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Near Field Communications Forum. Available online: http://nfc-forum.org (accessed on 20 December 2019).

- Passive NFC Temperature Patch Reference Design. Available online: http://www.ti.com/tool/TIDA00721?keyMatch=tida%2000721&tisearch=Search-EN-Everything (accessed on 20 November 2019).

- Dynamic Field-Powered NFC for Data Logging Access Control & Security Applications Reference Design. Available online: http://www.ti.com/tool/TIDA-00217?keyMatch=tida%2000217&tisearch=Search-EN-Everything (accessed on 20 November 2019).

- Rahimi, R.; Brener, U.; Ochoa, M.; Ziaie, B. Flexible and transparent pH monitoring system with NFC communication for wound monitoring applications. In Proceedings of the 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 125–128. [Google Scholar]

- Boada, M.; Lázaro, A.; Villarino, R.; Girbau, D. Battery-Less Soil Moisture Measurement System Based on a NFC Device with Energy Harvesting Capability. IEEE Sens. J. Eng. 2018, 18, 5541–5549. [Google Scholar] [CrossRef]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- World Health Organization. Available online: https://www.who.int/news-room/detail/03-12-2015-who-s-first-ever-global-estimates-of-foodborne-diseases-find-children-under-5-account-for-almost-one-third-of-deaths (accessed on 15 August 2019).

- Gram, L.; Ravn, L.; Rasch, M.; Bruhn, J.B.; Christensen, A.B.; Givskov, M. Food spoilage—interactions between food spoilage bacteria. Int. J. Food Microbiol. 2002, 78, 79–97. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Makino, Y.; Oshita, S. Online monitoring of red meat color using hyperspectral imaging. Meat Sci. 2016, 116, 110–117. [Google Scholar] [CrossRef]

- Zhang, H.; Hou, A.; Xie, K.; Gao, A. Smart color-changing paper packaging sensors with pH sensitive chromophores based on azo-anthraquinone reactive dyes. Sens. Actuators B Chem. 2019, 286, 362–369. [Google Scholar] [CrossRef]

- Chen, Y.; Fu, G.; Zilberman, Y.; Ruan, W.; Ameri, S.K.; Miller, E.; Sonkusale, S. Disposable colorimetric geometric barcode sensor for food quality monitoring. In Proceedings of the 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 1422–1424. [Google Scholar]

- Shi, C.; Qian, J.; Han, S.; Fan, B.; Yang, X.; Wu, X. Developing a machine vision system for simultaneous prediction of freshness indicators based on tilapia (Oreochromis niloticus) pupil and gill color during storage at 4 °C. Food Chem. 2018, 243, 134–140. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.Z.; Zhang, M.; Bhandari, B.; Yang, C.H. Development of a novel colorimetric food package label for monitoring lean pork freshness. LWT 2019, 99, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Gao, F.; Wu, Q.; Zhang, J.; Xue, Y.; Wan, H.; Wang, P. Real-time assessment of food freshness in refrigerators based on a miniaturized electronic nose. Anal. Methods 2018, 10, 4741–4749. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S.; Lee, K.; Baek, S.; Seo, J. Development of a pH indicator composed of high moisture-absorbing materials for real-time monitoring of chicken breast freshness. Food Sci. Biotechnol. 2017, 26, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Lam, M.B.; Dang, N.T.; Nguyen, T.H.; Chung, W.Y. A Neural Network-Based Model of Radio Frequency Energy Harvesting Characteristics in a Self-Powered Food Monitoring System. IEEE Sens. J. 2001, 19, 8813–8823. [Google Scholar] [CrossRef]

- Cao, X.T.; Chung, W.Y. An Enhanced Multiplication of RF Energy Harvesting Efficiency Using Relay Resonator for Food Monitoring. Sensors 2019, 19, 1963. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chung, W.Y.; Le, G.T.; Tran, T.V.; Nguyen, N.H. Novel proximal fish freshness monitoring using batteryless smart sensor tag. Sens. Actuators B Chem. 2017, 248, 910–916. [Google Scholar] [CrossRef]

- Nguyen, N.H.; Chung, W.Y. Battery-less pork freshness real-time monitoring system with high efficient RF energy scavenging. In Proceedings of the 2017 International Conference on Applied System Innovation (ICASI), Sapporo, Japan, 13–17 May 2017; pp. 235–238. [Google Scholar]

- Le, G.T.; Tran, T.V.; Lee, H.S.; Chung, W.Y. Long-range batteryless RF sensor for monitoring the freshness of packaged vegetables. Sens. Actuators A Phys. 2016, 237, 20–28. [Google Scholar] [CrossRef]

- Sun, H.; Guo, Y.-X.; He, M.; Zhong, Z. A dual-band rectenna using broadband Yagi antenna array for ambient RF power harvesting. IEEE Antennas Wirel. Propa. Lett. 2013, 12, 918–921. [Google Scholar] [CrossRef]

- Masotti, D.; Costanzo, A.; Prete, M.D.; Rizzoli, V. Genetic-based design of a tetra-band high-efficiency radio-frequency energy system. Microw. Antennas Propag. 2013, 7, 1254–1263. [Google Scholar] [CrossRef]

- Niotaki, K.; Kim, S.; Jeong, S.; Collado, A.; Georgiadis, A.; Tentzeris, M. A compact dual-band rectenna using slot-loaded dual band folded dipole antenna. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 1634–1637. [Google Scholar] [CrossRef]

- Piñuela, M.; Mitcheson, P.D.; Lucyszyn, S. Ambient RF energy harvesting in urban and semi-urban environments. IEEE Trans. Microw. Theory Tech. 2013, 61, 2715–2726. [Google Scholar] [CrossRef]

- Niotaki, K.; Georgiadis, A.; Collado, A.; Vardakas, J.S. Dual-band resistance compression networks for improved rectifier performance. IEEE Trans. Microw. Theory Tech. 2015, 62, 3512–3521. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Shinohara, N.; Mitani, T. A constant efficiency of rectifying circuit in an extremely wide load range. IEEE Trans. Microw. Theory Tech. 2014, 62, 986–993. [Google Scholar] [CrossRef]

- Kuhn, V.; Lahuec, C.; Seguin, F.; Person, C. A multi-band stacked RF energy harvester with rf-to-dc efficiency up to 84%. IEEE Trans. Microw. Theory Tech. 2015, 63, 1768–1778. [Google Scholar] [CrossRef]

- Atkins, P.; Jones, L. Chemical Principles: The Quest for Insight; Macmillan: New York, NY, USA, 2007. [Google Scholar]

- Texas Intruments. Available online: http://www.ti.com/product/RF430CL330H (accessed on 20 August 2019).

- Texas Intruments. Available online: http://www.ti.com/product/MSP430G2553 (accessed on 20 August 2019).

- Bosh Sensortec. Available online: https://www.bosch-sensortec.com/bst/products/all_products/bme280 (accessed on 20 August 2019).

| Reference | Frequency (GHz) | Input Power Level of Interest (dBm) | Maximum RF–DC Conversion Efficiency at a Single Frequency (%) | Measured/Simulated Harvested DC Power at the Outdoor Ambient Input Power Level (−15 dBm) |

|---|---|---|---|---|

| [21] | Dual-band 1.8, 2.2 | −30 to −5 | 55 at −5 dBm | 28 µW (measured) |

| [22] | Four-band 0.9, 1.75, 2.15, 2.45 | −15 to 0 | 60 at 0 dBm | 13 µW (measured) |

| [23] | Dual-band 0.915, 2.45 | 15 to 0 | 50 at 0 dBm | 17 µW (measured) |

| [24] | Four-band 0.55, 0.9, 1.85, 2.15 | −29 to −10 | 40 at −12 dBm | 38 µW (measured) |

| [25] | Dual-band 0.915, 2.45 | −30 to 0 | 70 at 0 dBm | 26 µW (simulated) |

| [26] | Single-band 2.45 | 13 to 20 | 80 at 13 dBm | Not reported |

| [27] | Four-band 0.9, 1.8, 2.1, 2.4 | −25 to 0 | 65 at 0 dBm | 70 µW (measured) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.-B.; Nguyen, T.-H.; Chung, W.-Y. Battery-Free and Noninvasive Estimation of Food pH and CO2 Concentration for Food Monitoring Based on Pressure Measurement. Sensors 2020, 20, 5853. https://doi.org/10.3390/s20205853

Nguyen T-B, Nguyen T-H, Chung W-Y. Battery-Free and Noninvasive Estimation of Food pH and CO2 Concentration for Food Monitoring Based on Pressure Measurement. Sensors. 2020; 20(20):5853. https://doi.org/10.3390/s20205853

Chicago/Turabian StyleNguyen, Thanh-Binh, Trung-Hau Nguyen, and Wan-Young Chung. 2020. "Battery-Free and Noninvasive Estimation of Food pH and CO2 Concentration for Food Monitoring Based on Pressure Measurement" Sensors 20, no. 20: 5853. https://doi.org/10.3390/s20205853

APA StyleNguyen, T.-B., Nguyen, T.-H., & Chung, W.-Y. (2020). Battery-Free and Noninvasive Estimation of Food pH and CO2 Concentration for Food Monitoring Based on Pressure Measurement. Sensors, 20(20), 5853. https://doi.org/10.3390/s20205853