Figure 1.

Framework of the contents.

Figure 1.

Framework of the contents.

Figure 2.

One example of a bidirectional projection between the task space and the configuration space, both of which are discretized. For each reachable configuration of the robot, its occupied cells (in red) in task space can be calculated and stored first.

Figure 2.

One example of a bidirectional projection between the task space and the configuration space, both of which are discretized. For each reachable configuration of the robot, its occupied cells (in red) in task space can be calculated and stored first.

Figure 3.

The process of path planning in DC-space. (a) C-space map. Grid nodes can be categorized into three types, boundary nodes (orange), free nodes (green), occupied nodes (blue). Occupied cells are colored in red, the start point (red star), and the target point (blue star) locate at the geometric center of the start cell and the target cell separately. (b) Obstacles collapse. The blue point is the collapse position for all the nodes in one obstacle. The free nodes are displaced accordingly. (c) Path generation in the DC-space. The start point and the target point are connected with one straight path (in red) directly. (d) Path restoration in the C-space. A feasible path (dark blue) that avoids the obstacle is built after projecting the straight path in DC-space back to the C-space.

Figure 3.

The process of path planning in DC-space. (a) C-space map. Grid nodes can be categorized into three types, boundary nodes (orange), free nodes (green), occupied nodes (blue). Occupied cells are colored in red, the start point (red star), and the target point (blue star) locate at the geometric center of the start cell and the target cell separately. (b) Obstacles collapse. The blue point is the collapse position for all the nodes in one obstacle. The free nodes are displaced accordingly. (c) Path generation in the DC-space. The start point and the target point are connected with one straight path (in red) directly. (d) Path restoration in the C-space. A feasible path (dark blue) that avoids the obstacle is built after projecting the straight path in DC-space back to the C-space.

Figure 4.

One 2D example of path planning failure in DC-space when improper distortion points are chosen for obstacles. (a) Initial C-space with obstacles ( and ), the start point (red star), and the target point (green star). (b) The DC-space after the obstacles collapse, the upper-right obstacle is distorted to the lower-left position , and the lower-left obstacle is distorted to the upper-right position . Penetration between grids is observed. (c) The generated path (blue) in C-space falls into infinite loops and cannot achieve the target.

Figure 4.

One 2D example of path planning failure in DC-space when improper distortion points are chosen for obstacles. (a) Initial C-space with obstacles ( and ), the start point (red star), and the target point (green star). (b) The DC-space after the obstacles collapse, the upper-right obstacle is distorted to the lower-left position , and the lower-left obstacle is distorted to the upper-right position . Penetration between grids is observed. (c) The generated path (blue) in C-space falls into infinite loops and cannot achieve the target.

Figure 5.

Non-convex DC-space situation. (a) The obstacle is connected with one boundary of C-space. (b) The generated DC-space after deforming the obstacle, and one path (red line) connects the start point (red star) and the target point (green). (c) The path is generated in C-space after mapping back from DC-space. The path stops extending when reaching the boundary.

Figure 5.

Non-convex DC-space situation. (a) The obstacle is connected with one boundary of C-space. (b) The generated DC-space after deforming the obstacle, and one path (red line) connects the start point (red star) and the target point (green). (c) The path is generated in C-space after mapping back from DC-space. The path stops extending when reaching the boundary.

Figure 6.

One example of the tortuous path by the original DC-space method. A red star denotes the start point, and a green star denotes the target point.

Figure 6.

One example of the tortuous path by the original DC-space method. A red star denotes the start point, and a green star denotes the target point.

Figure 7.

(

a) The resulted DC-space for the situation in

Figure 4. The start position and the target position are connected with one straight line directly. (

b) The effective path after projecting the path back to C-space.

Figure 7.

(

a) The resulted DC-space for the situation in

Figure 4. The start position and the target position are connected with one straight line directly. (

b) The effective path after projecting the path back to C-space.

Figure 8.

Some examples with floating obstacles. The first row is the initial C-space with obstacles. The second row presents the resulted DC-space after applying ACPG method. The start point (red star) and the target point (green star) are connected with one straight line directly. The third row is the generated path after projecting the path back to the C-space.

Figure 8.

Some examples with floating obstacles. The first row is the initial C-space with obstacles. The second row presents the resulted DC-space after applying ACPG method. The start point (red star) and the target point (green star) are connected with one straight line directly. The third row is the generated path after projecting the path back to the C-space.

Figure 9.

The process of iterations for growing from root nodes. The number in the picture is the index of the root node. The child nodes grow in the same iteration are in the same color.

Figure 9.

The process of iterations for growing from root nodes. The number in the picture is the index of the root node. The child nodes grow in the same iteration are in the same color.

Figure 10.

The hieratical relationship between the root nodes and the child nodes for the example in

Figure 9. The child nodes generated from the same root node will be collapsed at that root node. The child node that has several parent nodes (in red) will be deformed into the middle position of the trajectory generated by its all parent nodes along the boundary.

Figure 10.

The hieratical relationship between the root nodes and the child nodes for the example in

Figure 9. The child nodes generated from the same root node will be collapsed at that root node. The child node that has several parent nodes (in red) will be deformed into the middle position of the trajectory generated by its all parent nodes along the boundary.

Figure 11.

The examples of C-space with mixed types of obstacles. The first column is the initial C-space. The second column is the generated DC-space with the ACPG and NGA methods. The start position (red star) and the target position (green star) are connected with the red line. The third column is the generated path after projecting the path back to the C-space.

Figure 11.

The examples of C-space with mixed types of obstacles. The first column is the initial C-space. The second column is the generated DC-space with the ACPG and NGA methods. The start position (red star) and the target position (green star) are connected with the red line. The third column is the generated path after projecting the path back to the C-space.

Figure 12.

A 2D example of the path optimization process. (a) The projected back path (in blue) and the obstacle (in red) in C-space. (b) Connecting the start cell (red star) and temporary target cell (green star) until the path conflicts with the obstacle. (c) Taking the last cell before the temporary target cell as the new start cell and repeating the step (b). (d,e) Repeating the above two steps until the temporary target cell reaches the final target cell. (f) The final optimized trajectory (in orange).

Figure 12.

A 2D example of the path optimization process. (a) The projected back path (in blue) and the obstacle (in red) in C-space. (b) Connecting the start cell (red star) and temporary target cell (green star) until the path conflicts with the obstacle. (c) Taking the last cell before the temporary target cell as the new start cell and repeating the step (b). (d,e) Repeating the above two steps until the temporary target cell reaches the final target cell. (f) The final optimized trajectory (in orange).

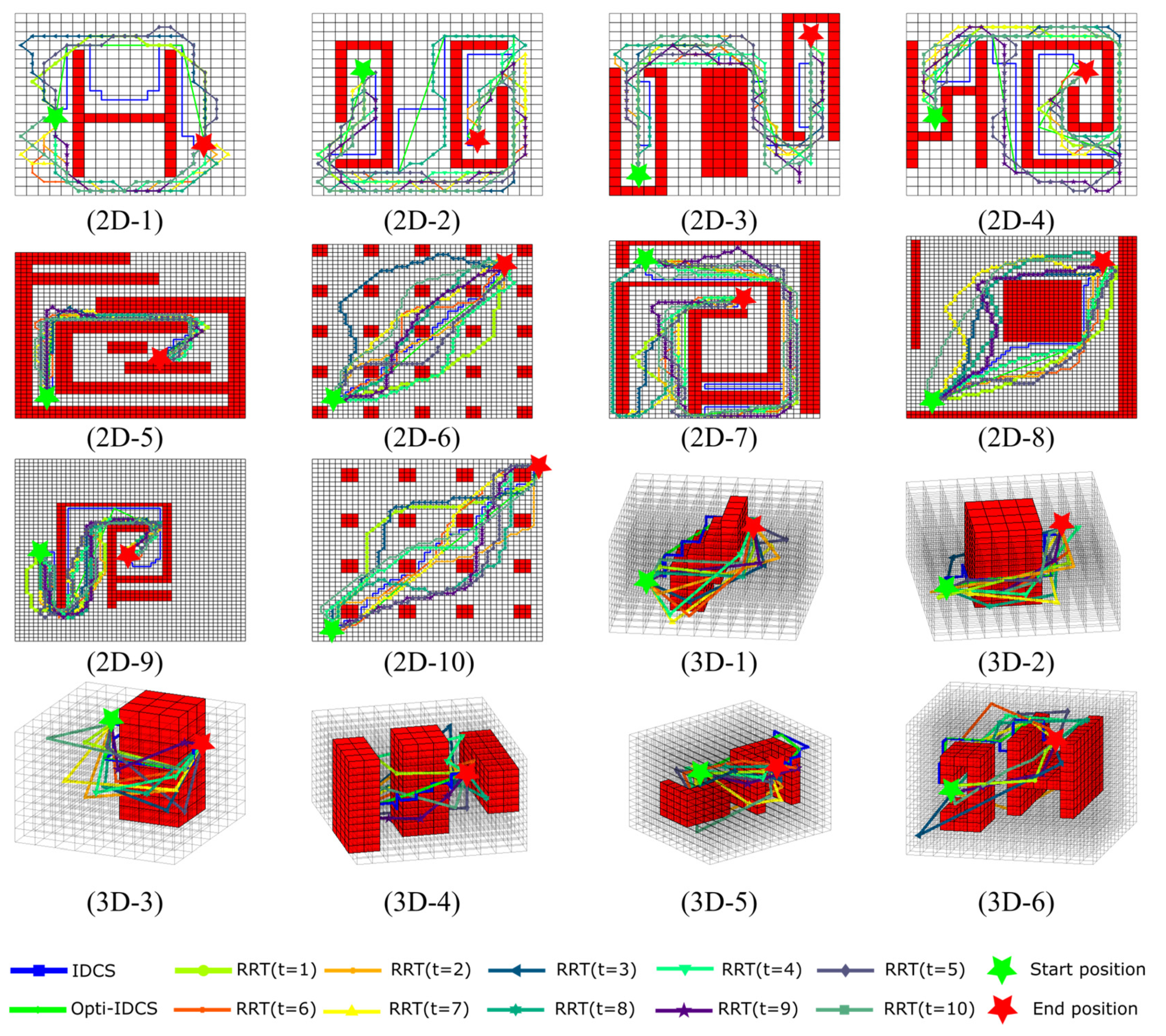

Figure 13.

The planned path for various maps. The results generated by the IDCS and Opti-IDCS methods keep the same for each experiment; the path generated by the RRT method is different for each experiment.

Figure 13.

The planned path for various maps. The results generated by the IDCS and Opti-IDCS methods keep the same for each experiment; the path generated by the RRT method is different for each experiment.

Figure 14.

Relationships between the map size and calculation time. The first three columns are the maps with different resolutions, and the fourth column shows the relationship between the number of cells in the map and the time cost.

Figure 14.

Relationships between the map size and calculation time. The first three columns are the maps with different resolutions, and the fourth column shows the relationship between the number of cells in the map and the time cost.

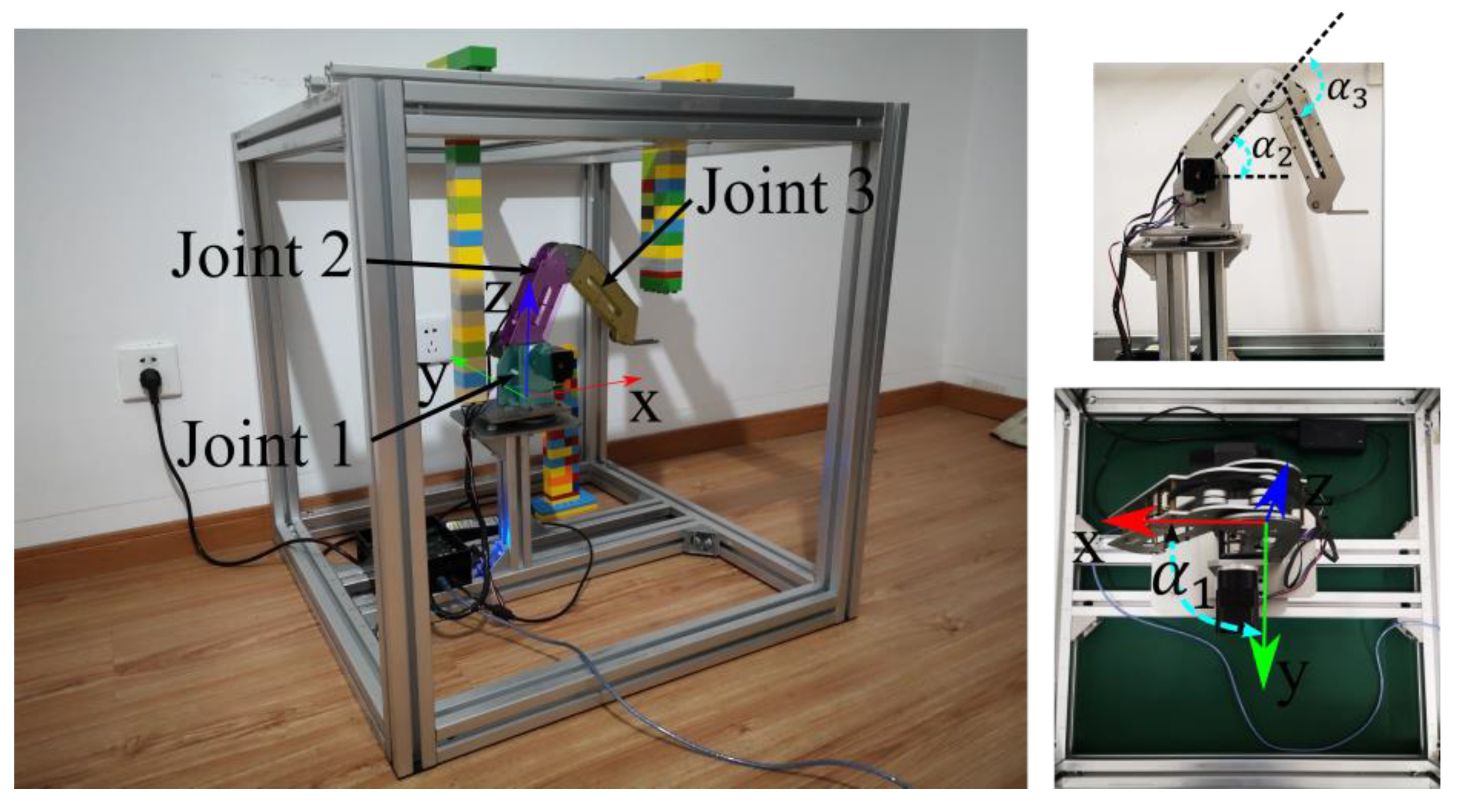

Figure 15.

The experimental platform for demonstration purpose.

Figure 15.

The experimental platform for demonstration purpose.

Figure 16.

(a) The range of Joint 3 changes at different angles of Joint 2. Two extreme positions of Joint 3 are illustrated when the Joint 2 is at 85 degrees. (b) The task space without obstacles and the corresponding configuration space.

Figure 16.

(a) The range of Joint 3 changes at different angles of Joint 2. Two extreme positions of Joint 3 are illustrated when the Joint 2 is at 85 degrees. (b) The task space without obstacles and the corresponding configuration space.

Figure 17.

The setup of the first experimental environment, O1, O2, and O3 respond to the corresponding obstacles. (a) The setup of the environment. (b) The configuration space of the first environment. (c) The distorted configuration space. The start point is colored by green, and the target point is colored by yellow. Two passing points are colored by purple and blue, respectively.

Figure 17.

The setup of the first experimental environment, O1, O2, and O3 respond to the corresponding obstacles. (a) The setup of the environment. (b) The configuration space of the first environment. (c) The distorted configuration space. The start point is colored by green, and the target point is colored by yellow. Two passing points are colored by purple and blue, respectively.

Figure 18.

The path generated with the IDCS method (dark blue) and the Opti-IDCS method (green) for the first experiment. The robot poses when it reaches the specified positions are shown as well.

Figure 18.

The path generated with the IDCS method (dark blue) and the Opti-IDCS method (green) for the first experiment. The robot poses when it reaches the specified positions are shown as well.

Figure 19.

The setup of the second experimental environment. (a) The setup of the environment. (b) The configuration space of the second environment. (c) The distorted configuration space. The start point is colored by green, and the target point is colored by yellow. One passing point is colored by purple.

Figure 19.

The setup of the second experimental environment. (a) The setup of the environment. (b) The configuration space of the second environment. (c) The distorted configuration space. The start point is colored by green, and the target point is colored by yellow. One passing point is colored by purple.

Figure 20.

The path generated with the IDCS method (dark blue) and the Opti-IDCS method (green) for the second experiment. The robot pose when it reaches the specified position is shown as well.

Figure 20.

The path generated with the IDCS method (dark blue) and the Opti-IDCS method (green) for the second experiment. The robot pose when it reaches the specified position is shown as well.

Table 1.

Path generation time in 2D map (s).

Table 1.

Path generation time in 2D map (s).

| | 1 | 2 | 3 | 4 | 5 |

| IDCS | 0.040 ± 0.004 | 0.051 ± 0.002 | 0.050 ± 0.002 | 0.052 ± 0.002 | 0.049 ± 0.003 |

| Opti-IDCS | 0.070 ± 0.003 | 0.113 ± 0.005 | 0.094 ± 0.016 | 0.123 ± 0.013 | 0.128 ± 0.005 |

| RRT | 0.194 ± 0.036 | 1.145 ± 0.383 | 0.824 ± 0.107 | 1.289 ± 0.233 | 0.514 ± 0.155 |

| | 6 | 7 | 8 | 9 | 10 |

| IDCS | 0.040 ± 0.002 | 0.044 ± 0.002 | 0.043 ± 0.004 | 0.014 ± 0.003 | 0.043 ± 0.003 |

| Opti-IDCS | 0.115 ± 0.009 | 0.156 ± 0.006 | 0.161 ± 0.008 | 0.106 ± 0.012 | 0.094 ± 0.004 |

| RRT | 0.267 ± 0.060 | 2.315 ± 0.375 | 0.301 ± 0.050 | 15.076 ± 2.297 | 1.409 ± 0.380 |

Table 2.

Path generation time in 3D maps (s).

Table 2.

Path generation time in 3D maps (s).

| | 1 | 2 | 3 | 4 | 5 | 6 |

|---|

| IDCS | 0.042 ± 0.006 | 0.046 ± 0.011 | 0.067 ± 0.006 | 0.063 ± 0.012 | 0.071 ± 0.006 | 0.079 ± 0.010 |

| Opti-IDCS | 0.066 ± 0.010 | 0.071 ± 0.013 | 0.083 ± 0.008 | 0.093 ± 0.011 | 0.157 ± 0.008 | 0.126 ± 0.016 |

| RRT | 0.113 ± 0.021 | 0.113 ± 0.024 | 0.086 ± 0.014 | 0.114 ± 0.015 | 0.158 ± 0.013 | 0.170 ± 0.034 |

Table 3.

Path length in 2D maps.

Table 3.

Path length in 2D maps.

| | 1 | 2 | 3 | 4 | 5 |

| IDCS | 44 ± 0.0 | 64 ± 0.0 | 54 ± 0.0 | 66 ± 0.0 | 60 ± 0.0 |

| Opti-IDCS | 29.242 ± 0.0 | 51.835 ± 0.0 | 46.220 ± 0.0 | 54.610 ± 0.0 | 55.835 ± 0.0 |

| RRT | 27.762 ± 4.921 | 52.951 ± 3.401 | 52.181 ± 3.075 | 50.858 ± 3.485 | 60.536 ± 1.738 |

| | 6 | 7 | 8 | 9 | 10 |

| IDCS | 66 ± 0.0 | 129 ± 0.0 | 76 ± 0.0 | 98 ± 0.0 | 72 ± 0.0 |

| Opti-IDCS | 47.045 ± 0.0 | 97.730 ± 0.0 | 59.261 ± 0.0 | 70.673 ± 0.0 | 51.698 ± 0.0 |

| RRT | 55.537 ± 3.651 | 97.830 ± 15.114 | 67.917 ± 4.274 | 75.795 ± 3.185 | 60.596 ± 3.236 |

Table 4.

Path length in 3D maps.

Table 4.

Path length in 3D maps.

| | 1 | 2 | 3 | 4 | 5 | 6 |

|---|

| IDCS | 21 ± 0.0 | 20 ± 0.0 | 12 ± 0.0 | 21 ± 0.0 | 39 ± 0.0 | 23 ± 0.0 |

| Opti-IDCS | 13.555 ± 0.0 | 13.998 ± 0.0 | 9.553 ± 0.0 | 13.303 ± 0.0 | 24.895 ± 0.0 | 15.381 ± 0.0 |

| RRT | 16.722 ± 1.72 | 16.728 ± 1.51 | 13.111 ± 1.76 | 19.156 ± 2.28 | 19.220 ± 1.80 | 18.650 ± 3.93 |

Table 5.

Path generation time in maps of different sizes.

Table 5.

Path generation time in maps of different sizes.

| | Map Size | IDCS | Opti-IDCS | RRT |

|---|

| Map 1 | 64 | 0.040 ± 0.003 | 0.065 ± 0.004 | 0.069 ± 0.011 |

| 256 | 0.041 ± 0.003 | 0.072 ± 0.003 | 0.103 ± 0.020 |

| 1024 | 0.042 ± 0.003 | 0.106 ± 0.006 | 0.153 ± 0.023 |

| Map 2 | 196 | 0.042 ± 0.002 | 0.067 ± 0.003 | 0.099 ± 0.022 |

| 784 | 0.043 ± 0.001 | 0.071 ± 0.003 | 0.135 ± 0.029 |

| 3136 | 0.046 ± 0.003 | 0.098 ± 0.004 | 0.449 ± 0.168 |

| Map 3 | 676 | 0.044 ± 0.002 | 0.074 ± 0.004 | 0.187 ± 0.061 |

| 2704 | 0.047 ± 0.005 | 0.096 ± 0.006 | 0.374 ± 0.127 |

| 10,816 | 0.053 ± 0.004 | 0.272 ± 0.015 | 1.069 ± 0.464 |

| Map 4 | 216 | 0.015 ± 0.003 | 0.024 ± 0.004 | 0.030 ± 0.010 |

| 1728 | 0.022 ± 0.005 | 0.044 ± 0.008 | 0.077 ± 0.020 |

| 5832 | 0.025 ± 0.003 | 0.060 ± 0.007 | 0.108 ± 0.031 |

| Map 5 | 216 | 0.021 ± 0.005 | 0.028 ± 0.005 | 0.044 ± 0.011 |

| 1728 | 0.025 ± 0.005 | 0.039 ± 0.007 | 0.108 ± 0.032 |

| 5832 | 0.029 ± 0.006 | 0.057 ± 0.005 | 0.136 ± 0.024 |

| Map 6 | 343 | 0.025 ± 0.005 | 0.033 ± 0.005 | 0.042 ± 0.011 |

| 2744 | 0.032 ± 0.006 | 0.065 ± 0.005 | 0.078 ± 0.014 |

| 9261 | 0.043 ± 0.010 | 0.080 ± 0.014 | 0.140 ± 0.048 |