Classification of Variable Foundation Properties Based on Vehicle–Pavement–Foundation Interaction Dynamics

Abstract

1. Introduction

2. Model Formulation

2.1. Overview

2.2. Basic Equations

2.3. Augmented Equations of Motion

3. Stochastic Vehicle Response

4. Illustrative Examples

4.1. Vehicle and Pavement Model Properties

4.2. Validation of the Solution Approach

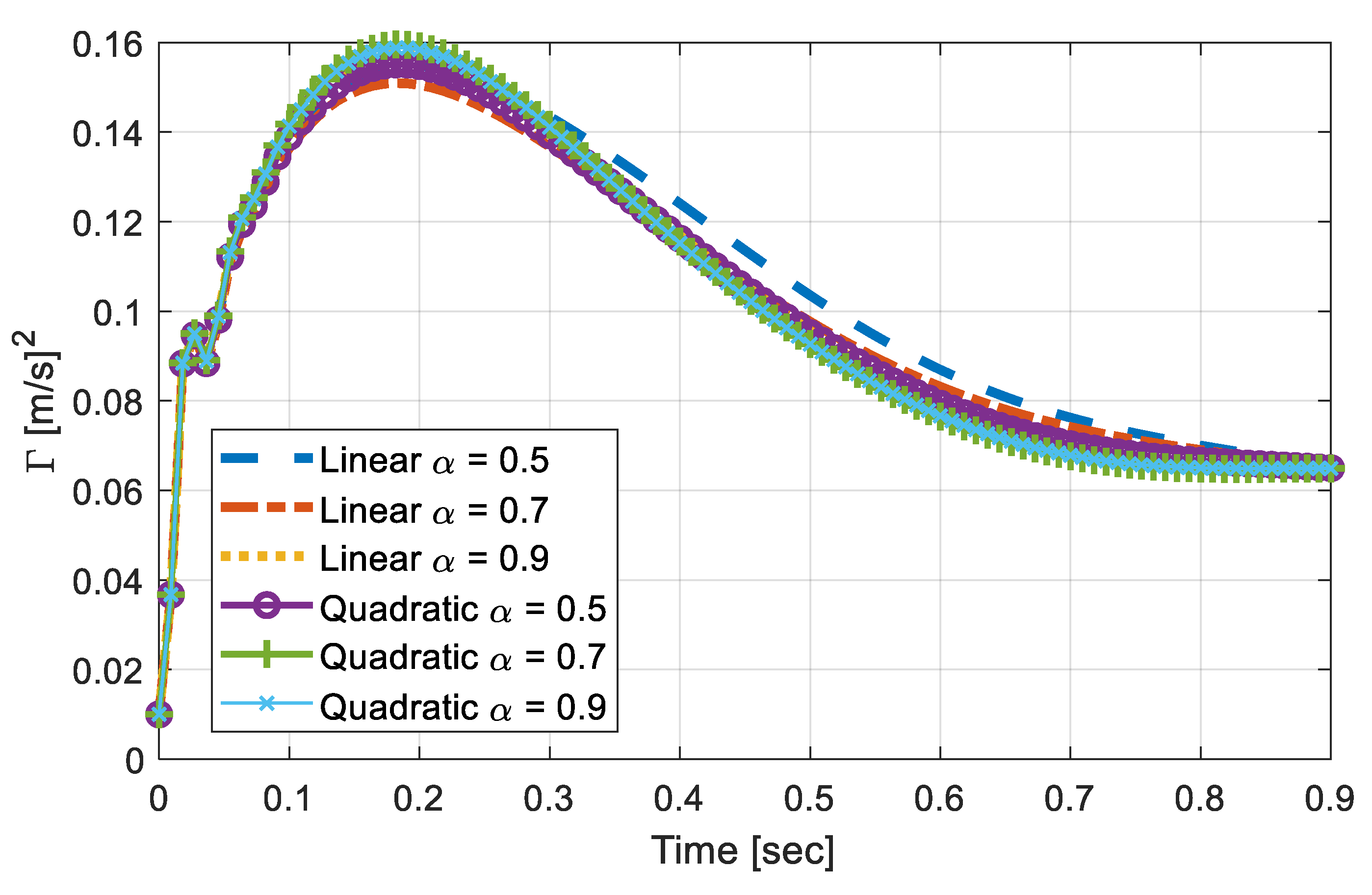

4.3. Time-Varying Covariance Responses

- Variations in profiles and differed the maximum response and rate of convergence, while a general shape of the responses was preserved.

- A larger maximum value was obtained in quadratically varying profiles, compared to the linear case when the same was used.

- Within the same profile, a larger tended to increase the rate of convergence. However, the responses exhibit highly nonlinear relationships between the variables, making the prediction of subgrade’s property change difficult.

- Although the vehicle responses were somewhat deterministic, once the foundation and vehicle parameters were determined, the analytical approach in the prediction was not realistic, due to the noises in the measured signal.

5. Machine-Learning Based Classification

6. Conclusions

- The introduced vehicle–pavement–foundation model and nonstationary solution approach allow the investigation of the impact of nonuniform foundation characteristics on vehicle responses.

- Due to the non-stationary stochastic solution approach described, which examined the second-order statistics of the process, efficient estimation was available, where the response was determinate and unaffected by the zero-mean noises.

- The proposed approach could efficiently handle various types of vehicles, roughness, and nonlinearity of foundations.

- Based on the theoretical evaluation, a machine-learning-based classification of non-uniform foundation properties was demonstrated, which included irremovable measured noises.

- In addition to the physical realization of the presented results, future research must ensure to provide high accuracy of identification when the location of the weakened foundation is unknown, and should consider the lateral movement at the left support.

- Overall, based on the outcome of the study, the vehicle responses could be used in conjunction with machine-learning technologies for classifying the properties and types of the subgrade.

Author Contributions

Funding

Conflicts of Interest

References

- Federal Highway Administration (US); Federal Transit Administration (US) (Eds.) 2015 Status of the Nation’s Highways, Bridges, and Transit Conditions & Performance Report to Congress; Government Printing Office: Washington, DC, USA, 2017.

- Rada, G.R.; Perera, R.W.; Prabhakar, V.C.; Wiser, L.J. Relating ride quality and structural adequacy for pavement rehabilitation and management decisions. Transp. Res. Rec. 2012, 2304, 28–36. [Google Scholar] [CrossRef]

- Shahin, M.Y.; Michael, I.D.; Starr, D.K. Development of a Pavement Condition Index for Roads and Streets; No. CERL-IR-M-232; Construction Engineering Research Lab (Army) Champaign Illinois: Champaign, IL, USA, 1978. [Google Scholar]

- Chung, H.C.; Girardello, R.; Soeller, T.; Shinozuka, M. Automated management for pavement inspection system (AMPIS). In Smart Structures and Materials 2003: Smart Systems and Nondestructive Evaluation for Civil Infrastructures; International Society for Optics and Photonics: San Diego, CA, USA, 2003; Volume 5057. [Google Scholar]

- Huang, Y.; Xu, B. Automatic inspection of pavement cracking distress. J. Electron. Imaging 2006, 15, 013017. [Google Scholar] [CrossRef]

- Chen, Y.L.; Jahanshahi, M.R.; Manjunatha, P.; Gan, W.; Abdelbarr, M.; Masri, S.F.; Becerik-Gerber, B.; Caffrey, J.P. Inexpensive multimodal sensor fusion system for autonomous data acquisition of road surface conditions. IEEE Sens. J. 2016, 16, 7731–7743. [Google Scholar] [CrossRef]

- Al-Suleiman, T.I.; Hamici, Z.M.; Bazlamit, S.M.; Ahmad, H.S. Assessment of the effect of alligator cracking on pavement condition using WSN-image processing. In International Conference on Engineering, Project, and Product Management; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Lee, Y.J.; Kim, R.E.; Suh, W.; Park, K. Probabilistic fatigue life updating for railway bridges based on local inspection and repair. Sensors 2017, 17, 936. [Google Scholar] [CrossRef] [PubMed]

- Silva, N.; Shah, V.; Soares, J.; Rodrigues, H. Road anomalies detection system evaluation. Sensors 2018, 18, 1984. [Google Scholar] [CrossRef]

- Sebaaly, P.; Tabatabaee, N.; Bonaquist, R.; Anderson, D. Evaluating structural damage of flexible pavements using cracking and falling weight deflectometer data. Transp. Res. Rec. 1989, 1227, 115–127. [Google Scholar]

- Chen, D.H.; Fernando, E.; Murphy, M. Application of falling weight deflectometer data for analysis of superheavy loads. Transp. Res. Rec. 1996, 1540, 83–90. [Google Scholar] [CrossRef]

- Vyas, V.; Singh, A.P.; Srivastava, A. Prediction of asphalt pavement condition using FWD deflection basin parameters and artificial neural networks. Road Mater. Pavement Des. 2020, 1–19. [Google Scholar] [CrossRef]

- Spencer, B.F., Jr.; Hoskere, V.; Narazaki, Y. Advances in computer vision-based civil infrastructure inspection and monitoring. Engineering 2019, 5, 199–222. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, W.; Ding, H.; Kim, R.E.; Spencer, B.F. Autonomous evaluation of ambient vibration of underground spaces induced by adjacent subway trains using high-sensitivity wireless smart sensors. Smart Struct. Syst. 2017, 19, 1–10. [Google Scholar] [CrossRef]

- Kim, R.E.; Li, J.; Spencer, B.F.; Nagayama, T.; Mechitov, K.A. Synchronized sensing for wireless monitoring of large structures. Smart Struct. Syst. 2016, 18, 885–909. [Google Scholar] [CrossRef]

- Cebon, D. Handbook of vehicle-road interaction; CRC Press: Boca Raton, FL, USA, 1999; ISBN 9789026515545. [Google Scholar]

- Sun, L.; Luo, F. Nonstationary dynamic pavement loads generated by vehicles traveling at varying speed. J. Transp. Eng. 2007, 133, 252–263. [Google Scholar] [CrossRef]

- Sun, L. A closed-form solution of beam on viscoelastic subgrade subjected to moving loads. Comput. Struct. 2002, 80, 1–8. [Google Scholar] [CrossRef]

- Wedig, W.V. Dynamics of Half-Car Models under Stochastic Road Excitations. In Proceedings of the ASME 2003 International Mechanical Engineering Congress and Exposition American Society of Mechanical Engineers Digital Collection, Washington, DC, USA, 15–21 November 2003; pp. 269–275, ISBN 0-7918-3709-2. [Google Scholar]

- Hardy, M.S.A.; Cebon, D. Response of continuous pavements to moving dynamic loads. J. Eng. Mech. 1993, 119, 1762–1780. [Google Scholar] [CrossRef]

- Hardy, M.S.A.; Cebon, D. Importance of speed and frequency in flexible pavement response. J. Eng. Mech. 1994, 120, 463–482. [Google Scholar] [CrossRef]

- Yongchen, L.; Li, S.; Kun, L.; Lichao, X. A method of acquiring dynamic road roughness based on vehicle-road vertical coupling. Open Autom. Control Syst. J. 2014, 6, 616–620. [Google Scholar] [CrossRef]

- Akbarian, M.; Moeini-Ardakani, S.S.; Ulm, F.J.; Nazzal, M. Mechanistic approach to pavement–vehicle interaction and its impact on life-cycle assessment. Transp. Res. Rec. 2012, 2306, 171–179. [Google Scholar] [CrossRef]

- Kim, R.E.; Kang, S.; Spencer, B.F.; Al-Qadi, I.L.; Ozer, H. Impact of Pavement Roughness and Deflection on Fuel Consumption Using Energy Dissipation. J. Eng. Mech. 2019, 145, 04019080. [Google Scholar] [CrossRef]

- Franklin, J.N.; Scott, R.F. Beam equation with variable foundation coefficient. J. Eng. Mech. Div. 1979, 105, 811–827. [Google Scholar]

- Lentini, M. Numerical solution of the beam equation with nonuniform foundation coefficient. J. Appl. Mech. 1979, 46, 901–904. [Google Scholar] [CrossRef]

- Clastornik, J.; Eisenberger, M.; Yankelevsky, D.Z.; Adin, M.A. Beams on Variable Winkler Elastic Foundation. J. Appl. Mech. 1986, 53, 925–928. [Google Scholar] [CrossRef]

- Lee, S.Y.; Ke, H.Y. Free vibrations of non-uniform beams resting on non-uniform elastic foundation with general elastic end restraints. Comput. Struct. 1990, 34, 421–429. [Google Scholar]

- Kacar, A.; Tan, H.T.; Kaya, M.O. Free vibration analysis of beams on variable winkler elastic foundation by using the differential transform method. Math. Comput. Appl. 2011, 16, 773–783. [Google Scholar] [CrossRef]

- Kumar, Y. Free vibration analysis of isotropic rectangular plates on winkler foundation using differential transform method. Int. J. Appl. Mech. Eng. 2013, 18, 589–597. [Google Scholar] [CrossRef][Green Version]

- Abdelghany, S.M.; Ewis, K.M.; Mahmoud, A.A.; Nassar, M.M. Dynamic response of non-uniform beam subjected to moving load and resting on non-linear viscoelastic foundation. Beni-Suef Univ. J. Basic Appl. Sci. 2015, 4, 192–199. [Google Scholar] [CrossRef][Green Version]

- Ansari, M.; Esmailzadeh, E.; Younesian, D. Internal-external resonance of beams on non-linear viscoelastic foundation traversed by moving load. Nonlinear Dyn. 2010, 61, 163–182. [Google Scholar] [CrossRef]

- Ansari, M.; Esmailzadeh, E.; Younesian, D. Frequency analysis of finite beams on nonlinear Kelvin–Voight foundation under moving loads. J. Sound Vib. 2011, 330, 1455–1471. [Google Scholar] [CrossRef]

- Oni, S.T.; Awodola, T.O. Dynamic behaviour under moving concentrated masses of simply supported rectangular plates resting on variable Winkler elastic foundation. Lat. Am. J. Solids Struct. 2011, 8, 373–392. [Google Scholar] [CrossRef]

- Kim, R.E.; Kang, S.; Spencer, B.F.; Al-Qadi, I.L.; Ozer, H. New stochastic approach of vehicle energy dissipation on nondeformable rough pavements. J. Eng. Mech. 2017, 143, 04016118. [Google Scholar] [CrossRef]

- Kim, R.E.; Kang, S.; Spencer, B.F.; Ozer, H.; Al-Qadi, I.L. Stochastic analysis of energy dissipation of a half-car model on nondeformable rough pavement. J. Transp. Eng. Part B Pavements 2017, 143, 04017016. [Google Scholar] [CrossRef]

- Soong, T.T.; Grigoriu, M. Random Vibration of Mechanical and Structural Systems; Prentice-Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- Wachspress, E.L. Iterative solution of the Lyapunov matrix equation. Appl. Math. Lett. 1988, 1, 87–90. [Google Scholar] [CrossRef]

- Louhghalam, A.; Akbarian, M.; Ulm, F.J. Roughness-induced pavement–vehicle interactions: key parameters and impact on vehicle fuel consumption. Transp. Res. Rec. 2015, 2525, 62–70. [Google Scholar] [CrossRef]

- Louhghalam, A.; Tootkaboni, M.; Ulm, F.J. Roughness-induced vehicle energy dissipation: Statistical analysis and scaling. J. Eng. Mech. 2015, 141, 04015046. [Google Scholar] [CrossRef]

- Chatti, K.; Zaabar, I. Estimating the Effects of Pavement Condition on Vehicle Operating Costs; Transportation Research Board: Washington, DC, USA, 2012; Volume 720. [Google Scholar]

- Kropáč, O.; Múčka, P. Deterioration model of longitudinal road unevenness based on its power spectral density indices. Road Mater. Pavement Des. 2008, 9, 389–420. [Google Scholar] [CrossRef]

- Gillespie, T.D.; Sayers, M.W.; Segal, L. Calibration of Response-Type Road Roughness Measuring Systems; NCHRP Rep. 228; Transportation Research Board: Washington, DC, USA, 1980. [Google Scholar]

- Xu, L. Typical Values of Young’s Elastic Modulus and Poisson’s Ratio for Pavement Materials. 2015. Available online: https://www.academia.edu/15702729/Typical_Values_of_Youngs_Elastic_Modulus_and_Poissons_Ratio_for_Pavement_Materials.PDF (accessed on 6 May 2018).

- Farrar, C.R.; Worden, K. Structural Health Monitoring: A Machine Learning Perspective; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Matlab. Statistics and Machine Learning Toolbox. Available online: https://mathworks.com/products/statistics.html (accessed on 10 December 2017).

- Gorban, A.N.; Golubkov, A.; Grechuk, B.; Mirkes, E.M.; Tyukin, I.Y. Correction of AI systems by linear discriminants: Probabilistic foundations. Inf. Sci. 2018, 466, 303–322. [Google Scholar] [CrossRef]

- Fisher, R.A. The use of multiple measurements in taxonomic problems. Ann. Eugen. 1936, 7, 179–188. [Google Scholar] [CrossRef]

| Symbol | Components | Value |

|---|---|---|

| Sprung mass | 1460 kg | |

| Unsprung mass | 80 kg | |

| Suspension Damping | 8760 Ns/m | |

| Tire Damping | 700 Ns/m | |

| Suspension Stiffness | 29.44 kN/m | |

| Tire Stiffness | 2500 kN/m | |

| V | Velocity | 20 km/h (stated otherwise) |

| Symbol | Components | Value |

|---|---|---|

| Thickness | 200 mm | |

| Width | 1.8 m | |

| Elastic modulus | 8760 Ns/m | |

| Density | 700 Ns/m | |

| L | Length | 5 m |

| Actual Properties | Assessed Properties | |||||

|---|---|---|---|---|---|---|

| L50 | L70 | L90 | Q50 | Q70 | Q90 | |

| L50 | 0.82 | 0.00 | 0.00 | 0.00 | 0.18 | 0.00 |

| L70 | 0.00 | 1.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| L90 | 0.00 | 0.00 | 1.00 | 0.00 | 0.00 | 0.00 |

| Q50 | 0.00 | 0.00 | 0.00 | 1.00 | 0.00 | 0.00 |

| Q70 | 0.18 | 0.00 | 0.00 | 0.00 | 0.82 | 0.00 |

| Q90 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, R.E. Classification of Variable Foundation Properties Based on Vehicle–Pavement–Foundation Interaction Dynamics. Sensors 2020, 20, 6263. https://doi.org/10.3390/s20216263

Kim RE. Classification of Variable Foundation Properties Based on Vehicle–Pavement–Foundation Interaction Dynamics. Sensors. 2020; 20(21):6263. https://doi.org/10.3390/s20216263

Chicago/Turabian StyleKim, Robin Eunju. 2020. "Classification of Variable Foundation Properties Based on Vehicle–Pavement–Foundation Interaction Dynamics" Sensors 20, no. 21: 6263. https://doi.org/10.3390/s20216263

APA StyleKim, R. E. (2020). Classification of Variable Foundation Properties Based on Vehicle–Pavement–Foundation Interaction Dynamics. Sensors, 20(21), 6263. https://doi.org/10.3390/s20216263