Improving Just-in-Time Delivery Performance of IoT-Enabled Flexible Manufacturing Systems with AGV Based Material Transportation

Abstract

1. Introduction

2. Literature Review

3. Smart AGV Management System (SAMS)

3.1. Physical and Data-Transaction Layers

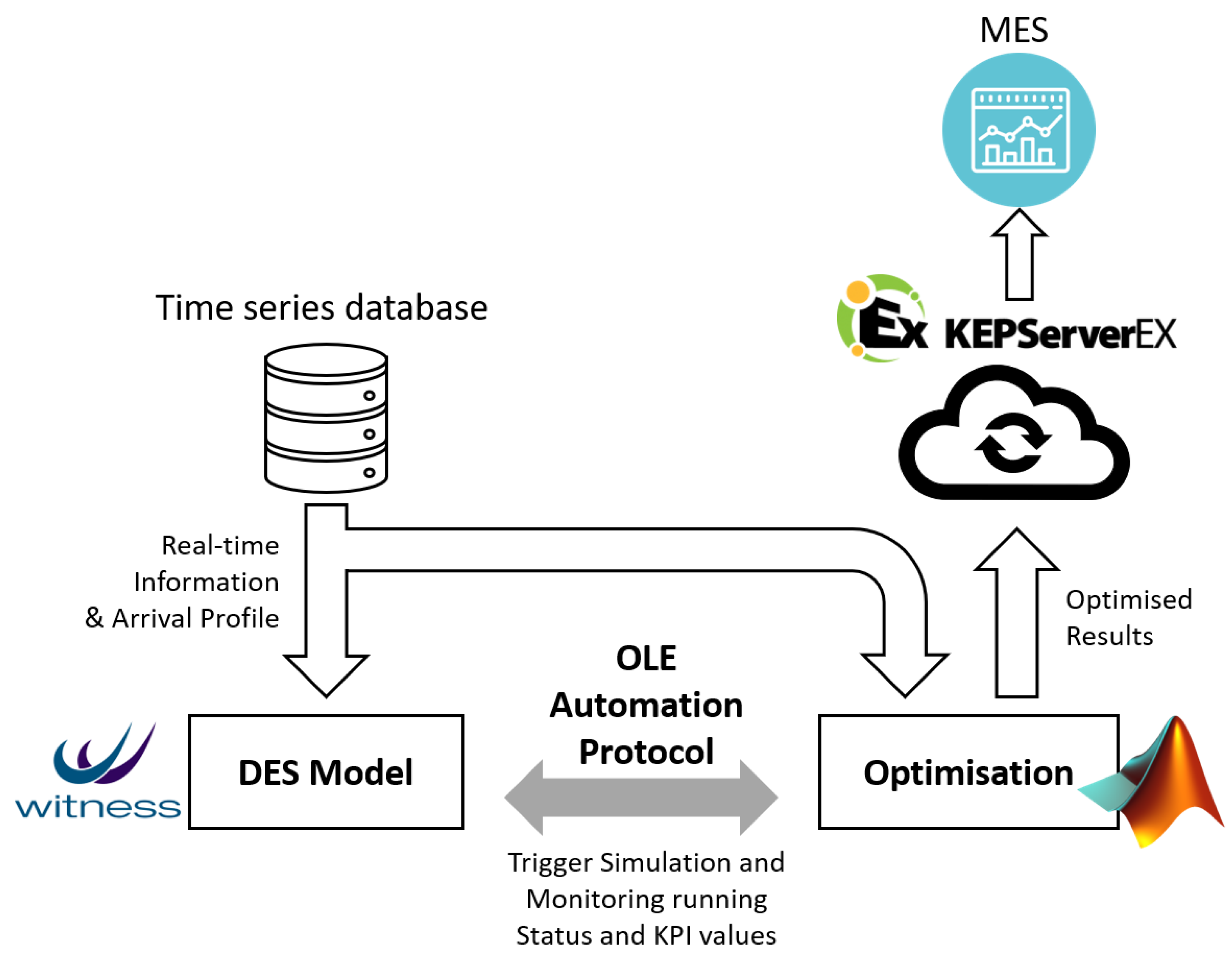

3.2. Digital Layer

3.3. Shop-Floor Decision-Support

4. Optimisation Approach

4.1. Problem Formulation

- Objective function 1: aims to minimise the total cost associated with the earliness and lateness of the scheduled jobs, and formulated as below.Please note that the authors report based on their project experiences from seat and car manufacturing projects that, overall manufacturing performance, in general, tends to be more affected by the lateness of the jobs. Hence, it is often penalised more than the earliness of the jobs. However, the penalty costs for both earliness and lateness should be configured based on the factory and user requirements.

- Objective function 2: stands for the minimisation of the total energy consumption associated with the AGV loading and cumulative travel distances, and formulated as follows:where represents the energy consumption rate related to AGV weights and travel distance.

- These objectives are subjected to the following constraints:In the above equations, constraint (4) is used to ensure that the precedence relations between stages of a job for every AGVs is not breached. Constraint (5) ensures that multiple jobs cannot be performed by a machine at a time. Constraint (6) is used to fulfil the requirement that a job cannot be performed more than one machine in a stage. Constraint (7) enforces the time difference between start time of machine in the first stage and the release time of the jobs that are assigned to them must be equal or greater zero. Constraint (8) ensures that an AGV cannot perform more than one material transportation task at a time. Constraint (9) states the variables’ binary nature.

4.2. Assumptions

- The parameters of machines, including: set up time and processing time are known and based on continuously updated historical production data;

- The parameters of AGVs, including: energy consumption rate, battery capacity and travelling speed are known and based on continuously updated historical production data;

- The demand information is continuously updated in real time;

- Machine output buffers have a fixed capacity limit;

- The AGV fleet capacity is enough to cover all transportation jobs;

- The AGV will not be called by the machine when the machine output buffer is empty.

4.3. Genetic Algorithm Based Solving Method

4.4. Genetic Algorithm

| Algorithm 1. Genetic Algorithm pseudo-code. |

Pseudo-code of the GA

|

4.4.1. Initialising Parameter

4.4.2. Initialising Population

4.4.3. The New Generate Population Generating

- Selection: The stochastic universal selection strategy (see [75]) is used to select parents for producing the next generators. In the stochastic uniform selection, all parents are laid on a line. The algorithm follows the line, and moves to the next point at an equal step size. At each movement, the algorithm chooses the current point as the parent for the next generation. The first step is also a uniform random number, which is smaller than the step size.

- Elitism:All the individuals are sorted based on the fitness values. The first (Equation(10)) best individuals are chosen and passed to the next generation directly. This step guarantees that the best fitness values can survive in the next generation:

- Crossover: Crossover is generated by combining the two parents together. The genes from parents are chosen randomly for crossover, and genes coordinates are the same for both parents, and the crossover children population is specified by the crossover fraction . These rules are applied into both parts of parents. Figure 8 shows an example of crossover strategy.

4.4.4. Evaluation and Iteration

5. Case Study

5.1. Overview of the Experiments

- The shop-floor layout and AGV routing paths were fixed.

- Charging threshold for AGV is set at 20%. If the battery level is lower than 20%, the AGV needs to park at the charging station for re-charge. When AGV battery is fully charged, it will be ready for the new task.

5.2. Results

5.3. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chryssolouris, G. Manufacturing Systems: Theory and Practice; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Ahmad, M.; Ahmad, B.; Harrison, R.; Alkan, B.; Vera, D.; Meredith, J.; Bindel, A. A framework for automatically realizing assembly sequence changes in a virtual manufacturing environment. Procedia CIRP 2016, 50, 129–134. [Google Scholar] [CrossRef][Green Version]

- Chinnathai, M.K.; Alkan, B.; Vera, D.; Harrison, R. Pilot to full-scale production: A battery module assembly case study. Procedia CIRP 2018, 72, 796–801. [Google Scholar] [CrossRef]

- Baruwa, O.T.; Piera, M.A. A coloured Petri net-based hybrid heuristic search approach to simultaneous scheduling of machines and automated guided vehicles. Int. J. Prod. Res. 2016, 54, 4773–4792. [Google Scholar] [CrossRef]

- Espinouse, M.L.; Pawlak, G.; Sterna, M. Complexity of scheduling problem in single-machine flexible manufacturing system with cyclic transportation and unlimited buffers. J. Optim. Theory Appl. 2017, 173, 1042–1054. [Google Scholar] [CrossRef]

- Barenji, A.V.; Barenji, R.V.; Roudi, D.; Hashemipour, M. A dynamic multi-agent-based scheduling approach for SMEs. Int. J. Adv. Manuf. Technol. 2017, 89, 3123–3137. [Google Scholar] [CrossRef]

- Alkan, B.; Bullock, S. Assessing operational complexity of manufacturing systems based on algorithmic complexity of key performance indicator time-series. J. Oper. Res. Soc. 2020. [Google Scholar] [CrossRef]

- Mehrabian, A.; Tavakkoli-Moghaddam, R.; Khalili-Damaghani, K. Multi-objective routing and scheduling in flexible manufacturing systems under uncertainty. Iran. J. Fuzzy Syst. 2017, 14, 45–77. [Google Scholar]

- Fazlollahtabar, H.; Saidi-Mehrabad, M.; Balakrishnan, J. Mathematical optimization for earliness/tardiness minimization in a multiple automated guided vehicle manufacturing system via integrated heuristic algorithms. Robt. Autom. Syst. 2015, 72, 131–138. [Google Scholar] [CrossRef]

- Behrje, U.; Himstedt, M.; Maehle, E. An Autonomous Forklift with 3D Time-of-Flight Camera-Based Localization and Navigation. In Proceedings of the 2018 15th International Conference on Control, Automation, Robotics and Vision (ICARCV), Singapore, 18–21 November 2018; pp. 1739–1746. [Google Scholar]

- Alkan, B.; Vera, D.A.; Ahmad, M.; Ahmad, B.; Harrison, R. Complexity in manufacturing systems and its measures: a literature review. Eur. J. Ind. Eng. 2018, 12, 116–150. [Google Scholar] [CrossRef]

- Alkan, B.; Vera, D.; Ahmad, M.; Ahmad, B.; Harrison, R. Design evaluation of automated manufacturing processes based on complexity of control logic. Procedia CIRP 2016, 50, 141–146. [Google Scholar] [CrossRef]

- Alkan, B.; Vera, D.; Ahmad, B.; Harrison, R. A Method to Assess Assembly Complexity of Industrial Products in Early Design Phase. IEEE Access 2018, 6, 989–999. [Google Scholar] [CrossRef]

- Zhang, S.; Wong, T.N. Flexible job-shop scheduling/rescheduling in dynamic environment: A hybrid MAS/ACO approach. Int. J. Prod. Res. 2017, 55, 3173–3196. [Google Scholar] [CrossRef]

- Alkan, B.; Harrison, R. A virtual engineering based approach to verify structural complexity of component-based automation systems in early design phase. J. Manuf. Syst. 2019, 53, 18–31. [Google Scholar] [CrossRef]

- Chinnathai, M.K.; Al-Mowafy, Z.; Alkan, B.; Vera, D.; Harrison, R. A Framework for Pilot Line Scale-up using Digital Manufacturing. Procedia CIRP 2019, 81, 962–967. [Google Scholar] [CrossRef]

- Yao, F.; Keller, A.; Ahmad, M.; Ahmad, B.; Harrison, R.; Colombo, A.W. Optimizing the Scheduling of Autonomous Guided Vehicle in a Manufacturing Process. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 264–269. [Google Scholar]

- Eksioglu, B.; Vural, A.V.; Reisman, A. The vehicle routing problem: A taxonomic review. Comput. Ind. Eng. 2009, 57, 1472–1483. [Google Scholar] [CrossRef]

- Braekers, K.; Ramaekers, K.; Van Nieuwenhuyse, I. The vehicle routing problem: State of the art classification and review. Comput. Ind. Eng. 2016, 99, 300–313. [Google Scholar] [CrossRef]

- Demesure, G.; Defoort, M.; Bekrar, A.; Trentesaux, D.; Djemaï, M. Navigation scheme with priority-based scheduling of mobile agents: Application to AGV-based flexible manufacturing system. J. Intell. Robt. Syst. 2016, 82, 495–512. [Google Scholar] [CrossRef]

- Fontes, D.B.M.; Homayouni, S.M. Joint production and transportation scheduling in flexible manufacturing systems. J. Glob. Optim. 2019, 74, 879–908. [Google Scholar] [CrossRef]

- Fazlollahtabar, H. Scheduling of Multiple Autonomous Guided Vehicles for an Assembly Line using Minimum Cost Network Flow. J. Glob. Optim. 2018, 11, 185–193. [Google Scholar]

- Dang, Q.V.; Nielsen, I. Simultaneous scheduling of machines and mobile robots. In International Conference on Practical Applications of Agents and Multi-Agent Systems; Springer: Berlin/Heidelberg, Germany, 2013; pp. 118–128. [Google Scholar]

- Nageswararao, M.; Narayanarao, K.; Ranagajanardhana, G. Simultaneous scheduling of machines and AGVs in flexible manufacturing system with minimization of tardiness criterion. Procedia Mater. Sci. 2014, 5, 1492–1501. [Google Scholar] [CrossRef]

- Huang, B.; Jiang, R.; Zhang, G. Heuristic Search for Scheduling Flexible Manufacturing Systems Using Multiple Heuristic Functions. In International Conference on Industrial, Engineering and Other Applications of Applied Intelligent Systems; Springer: Berlin/Heidelberg, Germany, 2014; pp. 178–187. [Google Scholar]

- Sanches, D.S.; da Silva Rocha, J.; Castoldi, M.F.; Morandin, O.; Kato, E.R.R. An adaptive genetic algorithm for production scheduling on manufacturing systems with simultaneous use of machines and agvs. J. Control Autom. Electr. Syst. 2015, 26, 225–234. [Google Scholar] [CrossRef]

- Mousavi, M.; Yap, H.J.; Musa, S.N.; Tahriri, F.; Dawal, S.Z.M. Multi-objective AGV scheduling in an FMS using a hybrid of genetic algorithm and particle swarm optimization. PLoS ONE 2017, 12, e0169817. [Google Scholar] [CrossRef] [PubMed]

- Zhong, M.; Yang, Y.; Dessouky, Y.; Postolache, O. Multi-AGV scheduling for conflict-free path planning in automated container terminals. Comput. Ind. Eng. 2020, 142, 106371. [Google Scholar] [CrossRef]

- Rahman, H.F.; Janardhanan, M.N.; Nielsen, P. An integrated approach for line balancing and AGV scheduling towards smart assembly systems. Assembly Autom. 2020, 40, 219–234. [Google Scholar] [CrossRef]

- Wang, C.; Jin, C.; Li, Z. Bilevel programming model of low energy consumption AGV scheduling problem at automated container terminal. In Proceedings of the 2019 IEEE International Conference on Smart Manufacturing, Industrial & Logistics Engineering (SMILE), Hangzhou, China, 20–21 April 2019; pp. 195–199. [Google Scholar]

- Liu, Y.; Ji, S.; Su, Z.; Guo, D. Multi-objective AGV scheduling in an automatic sorting system of an unmanned (intelligent) warehouse by using two adaptive genetic algorithms and a multi-adaptive genetic algorithm. PLoS ONE 2019, 14, e0226161. [Google Scholar] [CrossRef] [PubMed]

- Weyns, D.; Boucké, N.; Holvoet, T.; Demarsin, B. Dyncnet: A protocol for dynamic task assignment in multiagent systems. In Proceedings of the First International Conference on Self-Adaptive and Self-Organizing Systems (SASO 2007), Cambridge, MA, USA, 9–11 July 2007; pp. 281–284. [Google Scholar]

- Smith, R.G. The contract net protocol: High-level communication and control in a distributed problem solver. IEEE Trans. Comput. 1980, C-29, 1104–1113. [Google Scholar] [CrossRef]

- Chan, F.T.; Chan, H.K.; Kazerooni, A. Real time fuzzy scheduling rules in FMS. J. Intell. Manuf. 2003, 14, 341–350. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Liu, Y.; Wu, N. Multiagent and Bargaining-Game-Based Real-Time Scheduling for Internet of Things-Enabled Flexible Job Shop. IEEE Internet Things J. 2018, 6, 2518–2531. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Z.; Lv, J. CPS-based smart control model for shopfloor material handling. IEEE Trans. Ind. Inf. 2017, 14, 1764–1775. [Google Scholar] [CrossRef]

- Xue, T.; Zeng, P.; Yu, H. A reinforcement learning method for multi-AGV scheduling in manufacturing. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018. [Google Scholar]

- Zhao, X.; Liu, H.; Lin, S.; Chen, Y. Design and implementation of a multiple agv scheduling algorithm for a job-shop. Int. J. Simul. Modell. (IJSIMM) 2020, 19, 134–145. [Google Scholar] [CrossRef]

- Sahin, C.; Demirtas, M.; Erol, R.; Baykasoğlu, A.; Kaplanoğlu, V. A multi-agent based approach to dynamic scheduling with flexible processing capabilities. J. Intell. Manuf. 2017, 28, 1827–1845. [Google Scholar] [CrossRef]

- Padgham, L.; Winikoff, M. Developing Intelligent Agent Systems: A Practical Guide; John Wiley & Sons: Hoboken, NJ, USA, 2005; Volume 13. [Google Scholar]

- Xu, W.; Guo, S.; Li, X.; Guo, C.; Wu, R.; Peng, Z. A Dynamic Scheduling Method for Logistics Tasks Oriented to Intelligent Manufacturing Workshop. Math. Prob. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Lenstra, J.K.; Kan, A.R. Complexity of vehicle routing and scheduling problems. Networks 1981, 11, 221–227. [Google Scholar] [CrossRef]

- Defoort, M.; Kokosy, A.; Floquet, T.; Perruquetti, W.; Palos, J. Motion planning for cooperative unicycle-type mobile robots with limited sensing ranges: A distributed receding horizon approach. Robt. Autom. Syst. 2009, 57, 1094–1106. [Google Scholar] [CrossRef]

- Corréa, A.I.; Rousseau, L.M.; Langevin, A. A Scheduling and Conflict-Free Routing Problem Solved with a Hybrid Constraint Programming: Mixed Integer Programming Approach; Groupe D’études et de Recherche en Analyse des Décisions, Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Oboth, C.; Batta, R.; Karwan, M. Dynamic conflict-free routing of automated guided vehicles. Int. J. Prod. Res. 1999, 37, 2003–2030. [Google Scholar] [CrossRef]

- Jin, J.; Zhang, X.H. Multi agv scheduling problem in automated container terminal. J. Mar. Sci. Technol. 2016, 24, 32–38. [Google Scholar]

- Demesure, G.; Defoort, M.; Bekrar, A.; Trentesaux, D.; Djemai, M. Decentralized motion planning and scheduling of AGVs in an FMS. IEEE Trans. Ind. Inf. 2017, 14, 1744–1752. [Google Scholar] [CrossRef]

- Nouri, H.E.; Driss, O.B.; Ghédira, K. Simultaneous Scheduling of Machines and a Single Moving Robot in a Job Shop Environment by Metaheuristics based Clustered Holonic Multiagent Model. In Proceedings of the 8th International Conference on Agents and Artificial Intelligence ICAART, Rome, Italy, 24–26 February 2016; pp. 51–62. [Google Scholar]

- He, Y.; Stecke, K.E.; Smith, M.L. Robot and machine scheduling with state-dependent part input sequencing in flexible manufacturing systems. Int. J. Prod. Res. 2016, 54, 6736–6746. [Google Scholar] [CrossRef]

- Mousavi, M.; Yap, H.; Musa, S.; Dawal, S. A fuzzy hybrid GA-PSO algorithm for multi-objective AGV scheduling in FMS. Int. J. Simul. Modell. 2017, 16, 58–71. [Google Scholar] [CrossRef]

- Li, G.; Zeng, B.; Liao, W.; Li, X.; Gao, L. A new AGV scheduling algorithm based on harmony search for material transfer in a real-world manufacturing system. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Zou, W.Q.; Pan, Q.K.; Tasgetiren, M.F. An Effective Discrete Artificial Bee Colony Algorithm for Scheduling an Automatic-Guided-Vehicle in a Linear Manufacturing Workshop. IEEE Access 2020, 8, 35063–35076. [Google Scholar] [CrossRef]

- Zhang, F.; Li, J. An Improved Particle Swarm Optimization Algorithm for Integrated Scheduling Model in AGV-Served Manufacturing Systems. J. Adv. Manuf. Syst. 2018, 17, 375–390. [Google Scholar] [CrossRef]

- Chawla, V.; Chanda, A.; Angra, S. Scheduling of multi load AGVs in FMS by modified memetic particle swarm optimization algorithm. J. Project Manag. 2018, 3, 39–54. [Google Scholar] [CrossRef]

- Chen, C.; Tiong, L.K.; Chen, I.M. Using a genetic algorithm to schedule the space-constrained AGV-based prefabricated bathroom units manufacturing system. Int. J. Prod. Res. 2019, 57, 3003–3019. [Google Scholar] [CrossRef]

- Riazi, S.; Diding, T.; Falkman, P.; Bengtsson, K.; Lennartson, B. Scheduling and Routing of AGVs for Large-scale Flexible Manufacturing Systems. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 891–896. [Google Scholar]

- Hooker, J.N. Planning and scheduling by logic-based Benders decomposition. Oper. Res. 2007, 55, 588–602. [Google Scholar] [CrossRef]

- Eckhardt, A.; Müller, S.; Leurs, L. An evaluation of the applicability of OPC UA Publish Subscribe on factory automation use cases. In Proceedings of the 2018 IEEE 23rd International Conference on Emerging Technologies and Factory Automation (ETFA), Turin, Italy, 4–7 September 2018; Volume 1, pp. 1071–1074. [Google Scholar]

- Ioana, A.; Korodi, A. OPC UA Publish-Subscribe and VSOME/IP Notify-Subscribe Based Gateway Application in the Context of Car to Infrastructure Communication. Sensors 2020, 20, 4624. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Efthymiou, K.; Papakostas, N.; Mourtzis, D.; Pagoropoulos, A. Flexibility and complexity: Is it a trade-off? Int. J. Prod. Res. 2013, 51, 6788–6802. [Google Scholar] [CrossRef]

- Lanner Group. WITNESS Simulation Software. 2003. Available online: https://www.addlink.es/images/pdf/WITNESS_Simulation_Software_Paper_lr.pdf (accessed on 10 September 2020).

- Barlas, P.; Heavey, C. Automation of input data to discrete event simulation for manufacturing: A review. Int. J. Model. Simul. Sci. Comput. 2016, 7, 1630001. [Google Scholar] [CrossRef]

- Gore Kumkum, A.; Jalwadi, S.; Natarajan, S. Systematic Efficiency Improvement by Optimizing the Assembly Line Using Witness Simulation Software. Available online: https://journalnx.com/papers/20150547-optimizing-assembly-line.pdf (accessed on 10 September 2020).

- Mensah, P.; Merkuryev, Y.; Longo, F. Using ICT in developing a resilient supply chain strategy. Procedia Comput. Sci. 2015, 43, 101–108. [Google Scholar] [CrossRef]

- Vitanov, I.V.; Vitanov, V.I.; Harrison, D.K. Buffer capacity allocation using ant colony optimisation algorithm. In Proceedings of the 2009 Winter Simulation Conference (WSC), Austin, TX, USA, 13–16 December 2009; pp. 3158–3168. [Google Scholar]

- Anbumalar, V.; Raja Chandra Sekar, M. Methods for solving cell formation, static layout and dynamic layout cellular manufacturing system problems: A review. Asian Int. J. Sci. Technol. 2015, 6, 2107–2112. [Google Scholar]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Jerald, J.; Asokan, P.; Saravanan, R.; Rani, A.D.C. Simultaneous scheduling of parts and automated guided vehicles in an FMS environment using adaptive genetic algorithm. Int. J. Adv. Manuf. Technol. 2006, 29, 584–589. [Google Scholar] [CrossRef]

- Choi, H.R.; Park, B.K.; Lee, J.; Park, C. Dispatching of container trucks using genetic algorithm. In Proceedings of the 4th International Conference on Interaction Sciences, Busan, Korea, 16–18 August 2011; pp. 146–151. [Google Scholar]

- Udhayakumar, P.; Kumanan, S. Task scheduling of AGV in FMS using non-traditional optimization techniques. Int. J. Simul. Modell. 2010, 9, 28–39. [Google Scholar] [CrossRef]

- Umar, U.A.; Ariffin, M.; Ismail, N.; Tang, S. Hybrid multiobjective genetic algorithms for integrated dynamic scheduling and routing of jobs and automated-guided vehicle (AGV) in flexible manufacturing systems (FMS) environment. Int. J. Adv. Manuf. Technol. 2015, 81, 2123–2141. [Google Scholar] [CrossRef]

- Grunow, M.; Günther, H.O.; Lehmann, M. Dispatching multi-load AGVs in highly automated seaport container terminals. In Container Terminals and Automated Transport Systems; Springer: Berlin/Heidelberg, Germany, 2005; pp. 231–255. [Google Scholar]

- Bose, J.; Reiners, T.; Steenken, D.; Voß, S. Vehicle dispatching at seaport container terminals using evolutionary algorithms. In Proceedings of the 33rd Annual Hawaii International Conference on System Sciences, Maui, HI, USA, 7 January 2000; p. 10. [Google Scholar]

- Deep, K.; Singh, K.P.; Kansal, M.L.; Mohan, C. A real coded genetic algorithm for solving integer and mixed integer optimization problems. Appl. Math. Comput. 2009, 212, 505–518. [Google Scholar] [CrossRef]

- Baldovino, R.G.; Bautista, M.G.A.C.; Aquino, A.U.; Calilung, E.J.; Sybingco, E.; Dadios, E.P. GA Optimization of coconut sugar cooking process: a preliminary study using stochastic universal sampling (SUS) technique. In Proceedings of the 9th International Conference on Computer and Automation Engineering, Sydney, Australia, 18–21 February 2017; pp. 346–349. [Google Scholar]

- Cicirello, V. Genetic algorithm parameter control: Application to scheduling with sequence-dependent setups. In Proceedings of the 9th EAI International Conference on Bio-inspired Information and Communications Technologies (formerly BIONETICS), New York, NY, USA, 3–5 December 2015; pp. 136–143. [Google Scholar]

- Ferrari, G.; Corinna, A. Application of an AGV System for Material Handling to a Cellular Manufacturing Environment: The Valeo Case. Master’s Thesis, Politecnico di Torino, Torino, Italy, 2018. [Google Scholar]

- Vafeiadis, T.; Kalatzis, D.; Nizamis, A.; Ioannidis, D.; Apostolou, K.; Metaxa, I.; Charisi, V.; Beecks, C.; Insolvibile, G.; Pardi, M.; et al. Data analysis and visualization framework in the manufacturing decision support system of COMPOSITION project. Procedia Manuf. 2019, 28, 57–62. [Google Scholar] [CrossRef]

- Sadeghian, R.; Sadeghian, M.R. A decision support system based on artificial neural network and fuzzy analytic network process for selection of machine tools in a flexible manufacturing system. Int. J. Adv. Manuf. Technol. 2016, 82, 1795–1803. [Google Scholar] [CrossRef]

- Salama, S.; Eltawil, A.B. A decision support system architecture based on simulation optimization for cyber-physical systems. Procedia Manuf. 2018, 26, 1147–1158. [Google Scholar] [CrossRef]

- Karlsson, I.; Bernedixen, J.; Ng, A.H.; Pehrsson, L. Combining augmented reality and simulation-based optimization for decision support in manufacturing. In Proceedings of the 2017 Winter Simulation Conference (WSC), Las Vegas, NV, USA, 3–6 December 2017; pp. 3988–3999. [Google Scholar]

- Prajapat, N.; Tiwari, A. A review of assembly optimisation applications using discrete event simulation. Int. J. Comput. Integr. Manuf. 2017, 30, 215–228. [Google Scholar] [CrossRef]

- Wu, N.; Zhou, M. Modeling and deadlock avoidance of automated manufacturing systems with multiple automated guided vehicles. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2005, 35, 1193–1202. [Google Scholar] [CrossRef]

- Fanti, M.P.; Zhou, M. Deadlock control methods in automated manufacturing systems. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2004, 34, 5–22. [Google Scholar] [CrossRef]

- Fanti, M.P. Event-based controller to avoid deadlock and collisions in zone-control AGVS. Int. J. Prod. Res. 2002, 40, 1453–1478. [Google Scholar] [CrossRef]

- Luo, J.; Wan, Y.; Wu, W.; Li, Z. Optimal Petri-Net Controller for Avoiding Collisions in a Class of Automated Guided Vehicle Systems. IEEE Trans. Intell. Transp. Syst. 2019. [Google Scholar] [CrossRef]

- Banaszak, Z.A.; Krogh, B.H. Deadlock avoidance in flexible manufacturing systems with concurrently competing process flows. IEEE Trans. Robt. Autom. 1990, 6, 724–734. [Google Scholar] [CrossRef]

| Type | Examples | Strengths | Weaknesses |

|---|---|---|---|

| Offline | [4,8,20,21,22,23,24,25,26,27,28,29,30,31,44,45,46,47,48,49,50,51,52,53,54,55,56,57,57] | Handles scheduling complexity | Inflexibility |

| scheduling | Low CPU overloads | Deterministic behaviours | |

| Requires task arrival information | |||

| Subjected to a limited execution time | |||

| Online | [32,33,34,35,37,38,39,41] | Handles unpredictable workloads | Reduced utilisation of resources |

| scheduling | CPU overloads are harder to detect |

| Notation | Description |

|---|---|

| Sets | |

| S | Set of stations |

| T | Set of production jobs |

| Set of AGVs | |

| W | Set of workstages |

| Number of stations in stage w | |

| Indices | |

| s | Index of station, |

| t | Index of production job, |

| n | Index of AGV, |

| w | Index of workstage, |

| Index of station in stage w, | |

| Parameters | |

| The weight of no load AGV n | |

| The weight of AGV n loaded, when travelling between station i and j for job t | |

| Earliness cost penalty coefficient | |

| Lateness cost penalty coefficient | |

| Processing time of job t allocated to s in stage w | |

| Due date of job t | |

| Completion date of job t | |

| Starting time of job t at station s in stage w | |

| Completion time of job t at station s in stage w | |

| Distance between station i and j, also, | |

| Release time of the job t into the system | |

| Decision Variables | |

| 1 if machine working on job t, else 0 | |

| 1 if AGV n travels between station i and j for job t, else 0 |

| Solutions | Normal Events | Two Machines Breakdown | ||

|---|---|---|---|---|

| Tardiness | EC | Tardiness | EC | |

| Proposed Scheduling | 300.4484 (Earliness) | 701.4404 | 218.6914 (Earliness) | 704.9327 |

| FIFO Scheduling | 1575.7169 (Earliness) | 577.4241 | 4657.8487 (Lateness) | 701.1848 |

| SPT based on 1st Stage | 1103.9 (Earliness) | 585.7565 | 14,968 (Lateness) | 997.0096 |

| SPT based on 2nd Stage | 679.377 (Earliness) | 607.6007 | 13,708 (Lateness) | 923.2472 |

| SPT based on 3rd Stage | 1223.6 (Earliness) | 612.8167 | 9681.7 (Lateness) | 833.9795 |

| SPT based on 4th Stage | 1179.2 (Earliness) | 613.1612 | 15,750 (Lateness) | 1150.4 |

| SPT based on overall Stage | 1710.9 (Earliness) | 576.6980 | 13,956 (Lateness) | 944.900 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, F.; Alkan, B.; Ahmad, B.; Harrison, R. Improving Just-in-Time Delivery Performance of IoT-Enabled Flexible Manufacturing Systems with AGV Based Material Transportation. Sensors 2020, 20, 6333. https://doi.org/10.3390/s20216333

Yao F, Alkan B, Ahmad B, Harrison R. Improving Just-in-Time Delivery Performance of IoT-Enabled Flexible Manufacturing Systems with AGV Based Material Transportation. Sensors. 2020; 20(21):6333. https://doi.org/10.3390/s20216333

Chicago/Turabian StyleYao, Fengjia, Bugra Alkan, Bilal Ahmad, and Robert Harrison. 2020. "Improving Just-in-Time Delivery Performance of IoT-Enabled Flexible Manufacturing Systems with AGV Based Material Transportation" Sensors 20, no. 21: 6333. https://doi.org/10.3390/s20216333

APA StyleYao, F., Alkan, B., Ahmad, B., & Harrison, R. (2020). Improving Just-in-Time Delivery Performance of IoT-Enabled Flexible Manufacturing Systems with AGV Based Material Transportation. Sensors, 20(21), 6333. https://doi.org/10.3390/s20216333