Review of Measuring Microenvironmental Changes at the Body–Seat Interface and the Relationship between Object Measurement and Subjective Evaluation

Abstract

:1. Introduction

2. Materials and Methods

- be published in peer-reviewed journals from January 2000 to December 2019;

- be written in the English language;

- include objectively measured parameters (using electronic devices) at the body–seat interface;

- be either cohort studies, cross-sectional studies, case series or case reports; and

- include human participants (not manikins).

3. Results

3.1. Microclimate Measurement

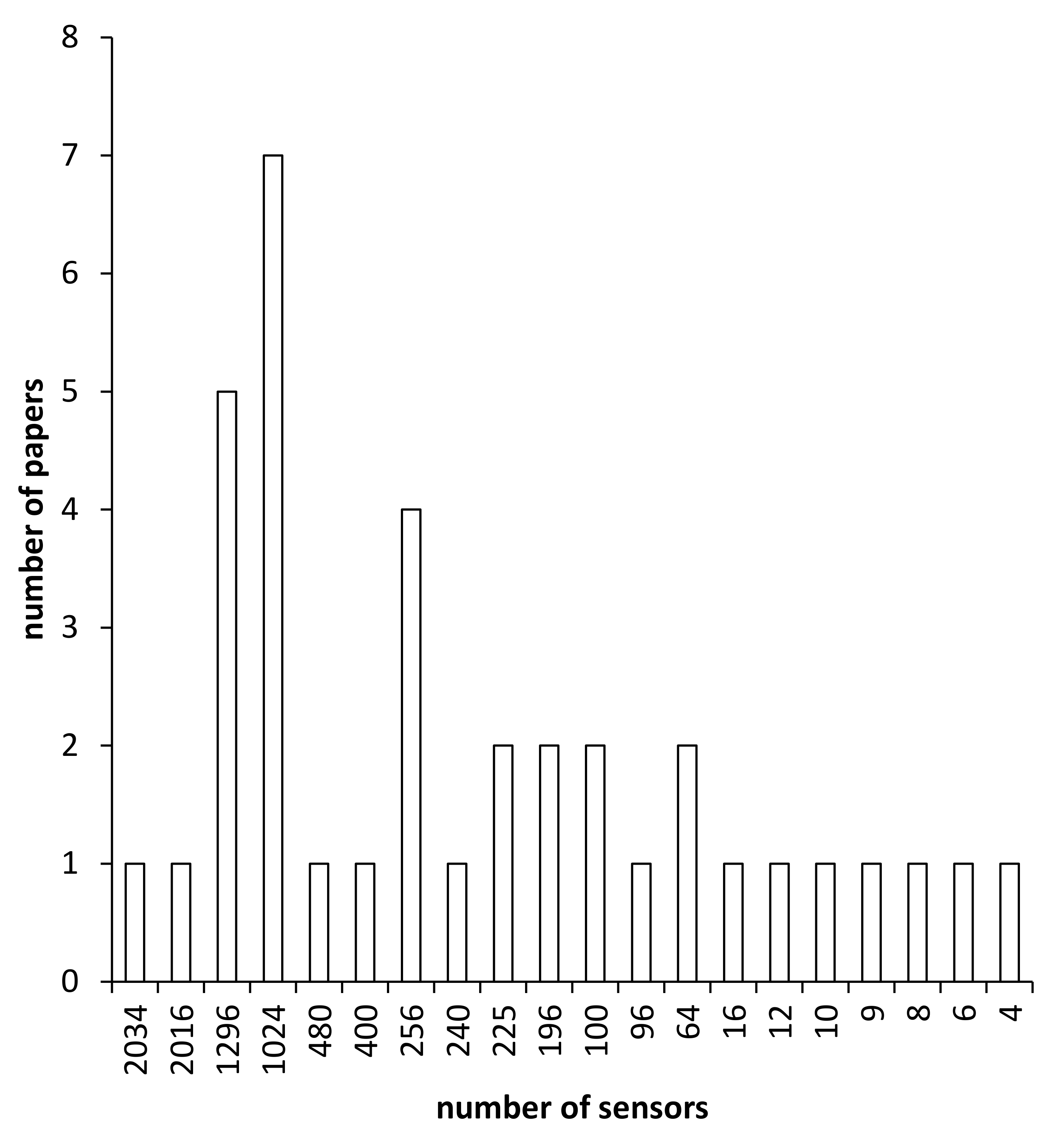

3.2. Pressure Measurement

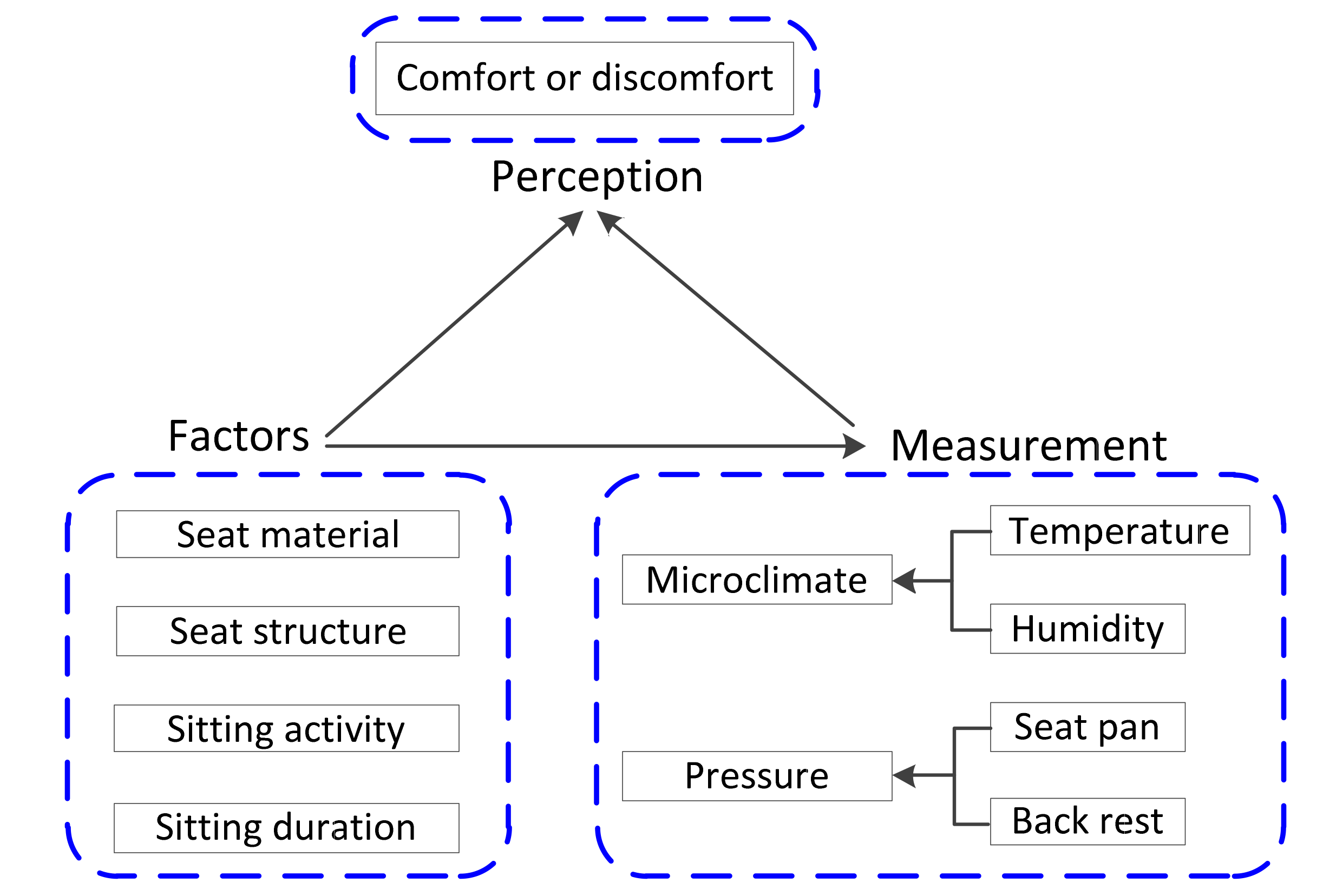

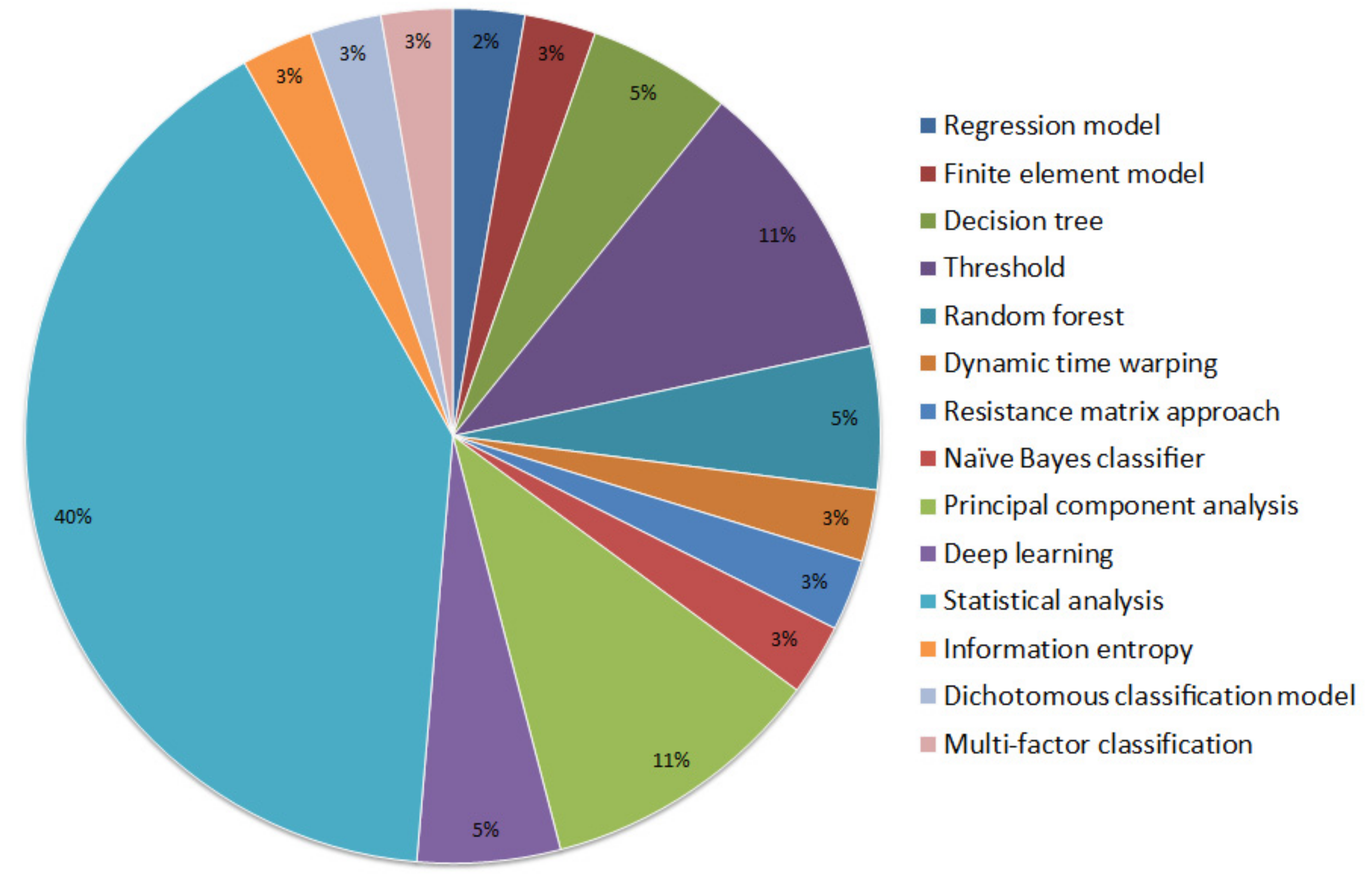

4. Discussion

4.1. Relationship between Microclimatic Factors, Comfort and Discomfort

4.2. Relationship between Interface Pressure, Comfort and Discomfort

4.3. Objective Measurements Using Different Types of Instruments

4.4. Reliability and Validity of Sensors

4.5. Future Work

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thosar, S.S.; Bielko, S.L.; Mather, K.J.; Johnston, J.D.; Wallace, J.P. Effect of prolonged sitting and breaks in sitting time on endothelial function. Med. Sci. Sport Exerc. 2014, 47, 843–849. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mastrigt, H.V.; Groenesteijn, L.; Vink, P.; Kuijt-Evers, L.F.M. Predicting passenger seat comfort and discomfort on the basis of human, context and seat characteristics: A literature review. Ergonomics 2016, 60, 1–44. [Google Scholar] [CrossRef]

- De Looze, M.P.; Kuijt-Evers, L.F.M.; Van Dieen, J. Sitting comfort and discomfort and the relationships with objective measures. Ergonomics 2003, 46, 985–997. [Google Scholar] [CrossRef] [PubMed]

- Zemp, R.; Taylor, W.R.; Lorenzetti, S. Are pressure measurements effective in the assessment of officechair comfort/discomfort? A review. Appl. Ergon. 2015, 48, 273–282. [Google Scholar] [CrossRef] [PubMed]

- Kang, N.; Burnap, A.; Kim, K.H.; Reed, M.P.; Papalambros, P.Y. Influence of automobile seat form and comfort rating on willingness-to-pay. Int. J. Veh. Des. 2017, 75, 75–90. [Google Scholar] [CrossRef]

- Kolich, M. Predicting automobile seat comfort using a neural network. Int. J. Ind. Ergonom. 2004, 33, 285–293. [Google Scholar] [CrossRef]

- Bauer, K.; Rock, K.; Nazzal, M.; Jones, O.; Qu, W. Pressure Ulcers in the United States’ Inpatient Population From 2008 to 2012: Results of a Retrospective Nationwide Study. Ostomy Wound Manag. 2016, 62, 30. [Google Scholar]

- Helander, M.G.; Zhang, L. Field studies of comfort and discomfort in sitting. Ergonomics 1997, 40, 895–915. [Google Scholar] [CrossRef]

- Mitsuya, R.; Kato, K.; Kou, N.; Nakamura, T.; Sugawara, K.; Dobashi, H.; Sugita, T.; Kawai, T. Analysis of body pressure distribution on car seats by using deep learning. Appl. Ergon. 2019, 75, 283–287. [Google Scholar] [CrossRef]

- Olney, C.M.; Simone, A.; Hanowski, K.; Rector, T.S.; Goldish, G.D.; Hansen, A.H.; Ferguson, J.E. Microclimate evaluation of strap-based wheelchair seating systems for persons with spinal cord injury: A pilot study. J. Tissue Viability 2018, 27, 181–187. [Google Scholar] [CrossRef]

- Yang, Y.S.; Pan, C.T.; Ho, W.H. Sensor-based remote temperature and humidity monitoring device embedded in wheelchair cushion. Sens. Mater. 2018, 30, 1807–1814. [Google Scholar] [CrossRef]

- Gefen, A. How do microclimate factors affect the risk for superficial pressure ulcers: A mathematical modeling study. J. Tissue Viability 2011, 20, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Cheng, H.; Luo, Z.; Cascioli, V.; Heusch, A.; Nadia, N.; Mccarthy, P.W. Performance assessment of a humidity measurement system and its use to evaluate moisture characteristics of wheelchair cushions at the user–seat interface. Sensors 2017, 17, 775. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hodges, G.J.; Mallette, M.M.; Rigby, A.; Klentrou, P.; Falk, B. Comparison of different wheelchair seating on thermoregulation and perceptual responses in thermoneutral and hot conditions in children. J. Tissue Viability 2019, 28, 144–151. [Google Scholar] [CrossRef]

- Stockton, L.; Rithalia, S. Pressure-reducing cushions: Perceptions of comfort from the wheelchair users’ perspective using interface pressure, temperature and humidity measurements. J. Tissue Viability 2009, 18, 28–35. [Google Scholar] [CrossRef]

- Gefen, A. How much time does it take to get a pressure ulcer? Integrated evidence from human, animal, and in vitro studies. Ostomy Wound Manag. 2008, 54, 26–35. [Google Scholar]

- Brienza, D.M.; Karg, P.E.; Geyer, M.J.; Kelsey, S.; Trefler, E. The relationship between pressure ulcer incidence and buttock-seat cushion interface pressure in at-risk elderly wheelchair users. Arch. Phys. Med. Rehabil. 2001, 82, 529–533. [Google Scholar] [CrossRef]

- Hamilton, M.T.; Hamilton, D.G.; Zderic, T.W. Role of low energy expenditure and sitting in obesity, metabolic syndrome, type 2 diabetes, and cardiovascular disease. Diabetes 2007, 56, 2655–2667. [Google Scholar] [CrossRef] [Green Version]

- Schuch, F.; Vancampfort, D.; Firth, J.; Rosenbaum, S.; Stubbs, B. Physical activity and sedentary behavior in people with major depressive disorder: A systematic review and meta-analysis. J. Affect. Disord. 2017, 210, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Vancampfort, D.; Firth, J.; Schuch, F.B.; Rosenbaum, S.; Mugisha, J.; Hallgren, M. Sedentary behavior and physical activity levels in people with schizophrenia, bipolar disorder and major depressive disorder: A global systematic review and meta-analysis. World Psychiatry 2017, 16, 308–315. [Google Scholar] [CrossRef]

- Hosking, J. A pilot study comparing custom contoured and planar support surfaces for pressure ulcer risk over the heels for night time postural management using interface pressure mapping and discomfort scores. J. Tissue Viability 2017, 26, 189–195. [Google Scholar] [CrossRef]

- Stephens, M.; Bartley, C. Understanding the association between pressure ulcers and sitting in adults what does it mean for me and my carers? Seating guidelines for people, carers and health & social care professionals. J. Tissue Viability 2018, 27, 59–73. [Google Scholar] [CrossRef] [PubMed]

- Koskelo, R.; Zaproudina, N.; Vuorikari, K. High scrotal temperatures and chairs in the pathophysiology of poor semen quality. Pathophysiology 2005, 11, 221–224. [Google Scholar] [CrossRef] [PubMed]

- Jurewicz, J.; Radwan, M.; Sobala, W.; Radwan, P.; Bochenek, M.; Hanke, W. Effects of occupational exposure—Is there a link between exposure based on an occupational questionnaire and semen quality? Syst. Biol. Reprod. Med. 2014, 60, 227–233. [Google Scholar] [CrossRef] [PubMed]

- Kottner, J.; Black, J.; Call, E.; Gefen, E.; Santamaria, N. Microclimate: A critical review in the context of pressure ulcer prevention. Clin. Biomech. 2018, 59, 62–70. [Google Scholar] [CrossRef]

- Liu, Z.; Li, J.; Liu, M.; Cascioli, V.; Mccarthy, P.W. In-depth investigation into the transient humidity response at the body-seat interface on initial contact using a dual temperature and humidity sensor. Sensors 2019, 19, 1471. [Google Scholar] [CrossRef] [Green Version]

- Havelka, A.; Nagy, L.; Tunák, M.; Antoch, J. Testing the effect of textile materials on car seat comfort in real traffic. J. Ind. Text 2019, 1–28. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, Y.; Liu, M.; Cascioli, V.; Mccarthy, P.W. Investigating thermal performance of different chairs at the user-seat interface by a temperature sensor array system while participants perform office work. J. Tissue Viability 2018, 27, 83–89. [Google Scholar] [CrossRef]

- Sales, R.B.C.; Pereira, R.R.; Aguilar, M.T.P.; Cardoso, A.V. Thermal comfort of seats as visualized by infrared thermography. Appl. Ergon. 2017, 62, 142–149. [Google Scholar] [CrossRef]

- Pron, H.; Taiar, R.; Bui, H.T.; Lestriez, P.; Polidori, G. Infrared thermography applied to the study of the thermal behavior of wheelchair cushion. Comput. Methods Biomech. Biomed. Eng. 2017, 20, 167–168. [Google Scholar] [CrossRef] [Green Version]

- Hsu, T.; Yang, S.; Liu, J.; Pan, C.Y. The effect of cushion properties on skin temperature and humidity at the body-support interface. Assist. Technol. 2018, 30, 1–8. [Google Scholar] [CrossRef]

- Kumar, A.R.; Butt, S.E.; Fredericks, T.K. Using a psychophysical approach to identify a user’s self-selected thermal comfort on a task chair. Int. J. Ind. Ergon. 2015, 46, 36–43. [Google Scholar] [CrossRef]

- Vlaovic, Z.; Domljan, D.; Grbac, I. Research of temperature and moisture during sitting on office chairs. Drvna Ind. 2012, 63, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Cascioli, V.; Heusch, A.; Mccarthy, P.W. Studying thermal characteristics of seating materials by recording temperature from 3 positions at the seat-subject interface. J. Tissue Viability 2011, 20, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Cengiz, T.G.; Babalik, F.C. The effects of ramie blended car seat covers on thermal comfort during road trials. Int. J. Ind. Ergon. 2009, 39, 287–294. [Google Scholar] [CrossRef]

- McCarthy, P.W.; Liu, Z.; Heusch, A.; Cascioli, V. Assessment of humidity and temperature sensors and their application to seating. J. Med. Eng. Technol. 2009, 33, 449–453. [Google Scholar] [CrossRef]

- Cengiz, T.G.; Babalik, F.C. An on-the-road experiment into the thermal comfort of car seats. Appl. Ergon. 2007, 38, 337–347. [Google Scholar] [CrossRef]

- Bartels, V.T. Thermal comfort of aeroplane seats: Influence of different seat materials and the use of laboratory test methods. Appl. Ergon. 2003, 34, 393–399. [Google Scholar] [CrossRef]

- Ferrarin, M.; Ludwig, N. Analysis of thermal properties of wheelchair cushions with thermography. Med. Biol. Eng. Comput. 2000, 38, 31–34. [Google Scholar] [CrossRef]

- Lee, B.W.; Shin, H. Feasibility study of sitting posture monitoring based on piezoresistive conductive film-based flexible force sensor. IEEE Sens. J. 2016, 16, 15–16. [Google Scholar] [CrossRef]

- Zemp, R.; Fliesser, M.; Wippert, P.M.; Taylor, W.; Lorenzetti, S. Occupational sitting behaviour and its relationship with back pain—A pilot study. Appl. Ergon. 2016, 56, 84–91. [Google Scholar] [CrossRef] [Green Version]

- Kyung, G.; Nussbaum, M.A. Age-related difference in perceptual responses and interface pressure requirements for driver seat design. Ergonomics 2013, 56, 1795–1805. [Google Scholar] [CrossRef] [PubMed]

- Meyer, A.B.; Schumm, J.; Troster, G. Design and modeling of a textile pressure sensor for sitting posture classification. IEEE Sens. J. 2010, 10, 1391–1398. [Google Scholar] [CrossRef]

- Carcone, S.M.; Keir, P.J. Effects of backrest design on biomechanics and comfort during seated work. Appl. Ergon. 2007, 38, 755–764. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Yu, S.; Yang, H.; Pei, H.; Zhao, C. Effects of long-duration sitting with limited space on discomfort, body flexibility, and surface pressure. Int. J. Ind. Ergon. 2017, 58, 12–24. [Google Scholar] [CrossRef]

- Groenesteijn, L.; Vink, P.; Looze, M.D.; Krause, F. Effects of differences in office chair controls, seat and backrest angle design in relation to tasks. Appl. Ergon. 2009, 40, 362–370. [Google Scholar] [CrossRef] [PubMed]

- Tewari, V.K.; Prasad, N. Optimum seat pan and back-rest parameters for a comfortable tractor seat. Ergonomics 2000, 43, 167–186. [Google Scholar] [CrossRef] [PubMed]

- Cascioli, V.; Liu, Z.; Heusch, A.; McCarthy, P.W. A methodology using in-chair movements as an objective measure of discomfort for the purpose of statistically distinguishing between similar seat surfaces. Appl. Ergon. 2016, 54, 100–109. [Google Scholar] [CrossRef] [PubMed]

- Bontrup, C.; Taylor, W.R.; Fliesser, M.; Visscher, R.; Zemp, R. Low back pain and its relationship with sitting behaviour among sedentary office workers. Appl. Ergon. 2019, 81, 102894. [Google Scholar] [CrossRef]

- Fasulo, L.; Naddeo, A.; Cappetti, N. A study of classroom seat (dis)comfort: Relationships between body movements, center of pressure on the seat, and lower limbs’ sensations. Appl. Ergon. 2019, 74, 233–240. [Google Scholar] [CrossRef]

- Ahmad, J.; Andersson, H.; Siden, J. Screen-printed piezoresistive sensors for monitoring pressure distribution in wheelchair. IEEE Sens. J. 2019, 19, 2055–2063. [Google Scholar] [CrossRef]

- Cardoso, M.; Mckinnon, C.; Viggiani, D.; Johnson, M.J.; Callaghan, J.P.; Albert, W.J. Biomechanical investigation of prolonged driving in an ergonomically designed truck seat prototype. Ergonomics 2018, 61, 367–380. [Google Scholar] [CrossRef] [PubMed]

- Worsley, P.R.; Rebolledo, D.; Web, S.; Caggiari, S.; Bader, D.L. Monitoring the biomechanical and physiological effects of postural changes during leisure chair sitting. J. Tissue Viability 2018, 27, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Li, W.; Gravina, R.; Fortino, G. Posture detection based on smart cushion for wheelchair users. Sensors 2017, 17, 719. [Google Scholar] [CrossRef] [PubMed]

- Stinson, M.; Ferguson, R.; Porter-Armstrong, A. Exploring repositioning movements in sitting with ′at risk′ groups using accelerometry and interface pressure mapping technologies. J. Tissue Viability 2017, 27, 10–15. [Google Scholar] [CrossRef]

- Ma, C.; Li, W.; Raffaele, G.; Cao, J.; Li, Q.; Fortino, G. Activity level assessment using a smart cushion for people with a sedentary lifestyle. Sensors 2017, 17, 2269. [Google Scholar] [CrossRef] [Green Version]

- Zemp, R.; Tanadini, M.; Pluss, S.; Schnuriger, K.; Singh, N.B.; Taylor, W.R.; Lorenzetti, S. Application of machine learning approaches for classifying sitting posture based on force and acceleration sensors. Biomed Res. Int. 2016, 2016, 5978489. [Google Scholar] [CrossRef] [Green Version]

- Zemp, R.; Taylor, W.R.; Lorenzetti, S. Seat pan and backrest pressure distribution while sitting in office chairs. Appl. Ergon. 2016, 53, 1–9. [Google Scholar] [CrossRef]

- Shu, L.; Tao, X.; Feng, D.D. A new approach for readout of resistive sensor arrays for wearable electronic applications. IEEE Sens. J. 2015, 15, 442–452. [Google Scholar] [CrossRef]

- Fredericks, T.K.; Butt, S.E.; Kumar, A.R.; Bellingar, T. Do users desire symmetrical lumbar supports in task seating? Ergonomics 2016, 59, 901–912. [Google Scholar] [CrossRef]

- Barba, R.; Madrid, P.; Boticario, G. Development of an inexpensive sensor network for recognition of sitting posture. Int. J. Distrib. Sens. Netw. 2015, 11, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Yoo, W. Effect of a suspension seat support chair on the trunk flexion angle and gluteal pressure during computer work. J. Phys. Ther. Sci. 2015, 27, 2989–2990. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Le, P.; Rose, J.; Knapik, G.; Marras, W.S. Objective classification of vehicle seat discomfort. Ergonomics 2014, 57, 536–544. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Huang, M.; Navid, A.; Lei, H.; Majid, S. eCushion: A textile pressure sensor array design and calibration for sitting posture analysis. IEEE Sens. J. 2013, 13, 3926–3934. [Google Scholar] [CrossRef]

- Noro, K.; Naruse, T.; Lueder, R.; Nao-i, N.; Kozawa, M. Application of Zen sitting principles to microscopic surgery seating. Appl. Ergon. 2012, 43, 308–319. [Google Scholar] [CrossRef]

- Paul, G.; Daniell, N.; Fraysse, F. Patterns of correlation between vehicle occupant seat pressure and anthropometry. Work 2012, 41, 2226–2231. [Google Scholar] [CrossRef] [Green Version]

- Kyung, G.; Nussbaum, M.A. Driver sitting comfort and discomfort (part II): Relationships with and prediction from interface pressure. Int. J. Ind. Ergon. 2008, 38, 526–538. [Google Scholar] [CrossRef]

- Vos, G.A.; Congleton, J.J.; Moore, J.S.; Amendola, A.A.; Ringer, L. Postural versus chair design impacts upon interface pressure. Appl. Ergon. 2006, 37, 619–628. [Google Scholar] [CrossRef]

- Na, S.; Lim, S.; Choi, H.S.; Chung, M.K. Evaluation of driver’s discomfort and postural change using dynamic body pressure distribution. Int. J. Ind. Ergon. 2005, 35, 1085–1096. [Google Scholar] [CrossRef]

- Porter, J.M.; Gyi, D.E.; Tait, H.A. Interface pressure data and the prediction of driver discomfort in road trials. Appl. Ergon. 2003, 34, 207–214. [Google Scholar] [CrossRef] [Green Version]

- Andreoni, G.; Santambrogio, G.C.; Rabuffetti, M.; Pedotti, A. Method for the analysis of posture and interface pressure of car drivers. Appl. Ergon. 2002, 33, 511–522. [Google Scholar] [CrossRef]

- Hostens, I.; Papajoannou, G.; Spaepen, A.; Ramon, H. Buttock and back pressure distribution tests on seats of mobile agricultural machinery. Appl. Ergon. 2001, 32, 347–355. [Google Scholar] [CrossRef]

- Fenety, P.A.; Putnam, C.; Walker, J.M. In-chair movement: Validity, reliability and implications for measuring sitting discomfort. Appl. Ergon. 2000, 31, 383–393. [Google Scholar] [CrossRef]

- Marenzi, E.; Bertolotti, G.M.; Cristiani, A. Design and development of a monitoring system for the interface pressure measurement of seated people. IEEE Trans. Instrum. Meas. 2013, 62, 570–577. [Google Scholar] [CrossRef]

- Mattmann, C.; Clemens, F.; Troster, G. Sensor for measuring strain in textile. Sensors 2008, 8, 3719–3732. [Google Scholar] [CrossRef]

- Merritt, C.R.; Nagle, H.T.; Grant, E. Textile-based capacitive sensors for respiration monitoring. IEEE Sens. J. 2009, 9, 71–78. [Google Scholar] [CrossRef]

- Liu, Z.; Chang, L.; Luo, Z.; Cascioli, V.; Heusch, A.; McCarthy, P.W. Design and development of a thermal imaging system based on a temperature sensor array for temperature measurements of enclosed surfaces and its use at the body-seat interface. Measurement 2017, 104, 123–131. [Google Scholar] [CrossRef] [Green Version]

- Vergara, M.; Page, A. System to measure the use of the back rest in sitting-posture office tasks. Appl. Ergon. 2000, 31, 247–254. [Google Scholar] [CrossRef]

- Bendix, T.; Winkel, J.; Jessen, F. Comparison of office chairs with fixed forwards or backwards inclining, or tiltable seats. Eur. J. Appl. Physiol. 1985, 54, 378–385. [Google Scholar] [CrossRef] [PubMed]

- Bendix, T.; Poulsen, V.; Klausen, K.; Jensen, C.V. What does a backrest actually do to the lumbar spine? Ergonomics 1996, 39, 533–542. [Google Scholar] [CrossRef] [PubMed]

- Kamp, I.; Kilincsoy, U.; Vink, P. Chosen postures during specific sitting activities. Ergonomics 2011, 54, 1029–1042. [Google Scholar] [CrossRef]

- Groenesteijn, L.; Ellegast, R.P.; Keller, K.; Krause, F.; Berger, H.; De Looze, M. Office task effects on comfort and body dynamics in five dynamic office chairs. Appl. Ergon. 2012, 43, 320–328. [Google Scholar] [CrossRef] [PubMed]

- Ciaccia, F.; Sznelwar, L. An approach to aircraft seat comfort using interface pressure mapping. Work 2012, 41, 240–245. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goossens, R.H.M.; Teeuw, R.; Snijders, C.J. Sensitivity for pressure difference on the ischial tuberosity. Ergonomics 2005, 48, 895–902. [Google Scholar] [CrossRef]

- Fujimaki, G.; Mitsuya, R. Study of the seated posture for VDT work. Displays 2002, 23, 17–24. [Google Scholar] [CrossRef]

- Greene, R.D.; Frey, M.; Attarsharghi, S.; Snow, J.C.; Barrett, M.; Carvalho, D. Transient perceived back pain induced by prolonged sitting in a backless office chair: Are biomechanical factors involved? Ergonomics 2019, 62, 1415–1425. [Google Scholar] [CrossRef]

- Jia, B.; Nussbaum, M.A. Influences of continuous sitting and psychosocial stress on low back kinematics, discomfort, and localized muscle fatigue during unsupported sitting activities. Ergonomics 2018, 61, 1671–1684. [Google Scholar] [CrossRef] [PubMed]

- Ellegast, R.P.; Kraft, K.; Groenesteijn, L.; Krause, F.; Berger, H.; Vink, P. Comparison of four specific dynamic office chairs with a conventional office chair: Impact upon muscle activation, physical activity and posture. Appl. Ergon. 2012, 43, 296–307. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Weiss, K.J.; Haggerty, M.C.; Heath, J.E. The effect of active sitting on trunk motion. J. Sport Health Sci. 2014, 4, 333–337. [Google Scholar] [CrossRef] [Green Version]

- Thosar, S.; Johnson, B.D.; Johnston, J.D.; Wallace, J.P. Sitting and endothelial function: The role of shear stress. Med. Sci. Monit. 2012, 18, 173–180. [Google Scholar] [CrossRef] [Green Version]

- López-Nava, I.H.; Muñoz-Meléndez, A. Wearable inertial sensors for human motion analysis: A review. IEEE Sens. J. 2016, 16, 7821–7834. [Google Scholar] [CrossRef]

- Vink, P.; Hallbeck, S. Comfort and discomfort studies demonstrate the need for a new model. Appl. Ergon. 2012, 43, 271–276. [Google Scholar] [CrossRef] [PubMed]

- Vergara, M.; Page, A. Relationship between comfort and back posture and mobility in sitting-posture. Appl. Ergon. 2002, 33, 1–8. [Google Scholar] [CrossRef]

- Bishu, R.R.; Hallbeck, M.S.; Riley, M.W. Seating comfort and its relationship to spinal profile: A pilot study. Int. J. Ind. Ergon. 1991, 8, 89–101. [Google Scholar] [CrossRef]

- Mehta, C.R.; Tewari, V.K. Biomechanical model to predict loads on lumbar vertebra of a tractor operator. Int. J. Ind. Ergon. 2015, 47, 104–116. [Google Scholar] [CrossRef]

- De, C.D.; Grondin, D.; Callaghan, J. The impact of office chair features on lumbar lordosis, intervertebral joint and sacral tilt angles: A radiographic assessment. Ergonomics 2016, 60, 1393–1404. [Google Scholar] [CrossRef]

- Gabison, S.; Hayes, K.; Campbell, K.E.; Swaine, J.M.; Craven, B.C. Ultrasound imaging of tissue overlying the ischial tuberosity: Does patient position matter? J. Tissue Viability 2019, 28, 179–185. [Google Scholar] [CrossRef]

- Russell, L.; Goubran, R.; Kwamena, F. Posture detection using sounds and temperature: Lms-based approach to enable sensory substitution. IEEE Trans. Instrum. Meas. 2018, 67, 1543–1554. [Google Scholar] [CrossRef]

- Brienza, D.; Vallely, J.; Karg, P.; Akins, J.; Gefen, A. An MRI investigation of the effects of user anatomy and wheelchair cushion type on tissue deformation. J. Tissue Viability 2018, 27, 42–53. [Google Scholar] [CrossRef]

- Sonenblum, S.E.; Ma, J.; Sprigle, S.H.; Hetzel, T.; McKay, C.J. Measuring the impact of cushion design on buttocks tissue deformation: An MRI approach. J. Tissue Viability. 2018, 27, 162–172. [Google Scholar] [CrossRef]

- Call, E.; Hetzel, T.; McLean, C.; Burton, J.N.; Oberg, C. Off-loading wheelchair cushion provides best case reduction in tissue deformation as indicated by MRI. J. Tissue Viability 2017, 26, 172–179. [Google Scholar] [CrossRef]

- Arrogi, A.; Boen, F.; Seghers, J. Validation of a smart chair and corresponding smartphone app as an objective measure of desk-based sitting. J. Occup. Health 2019, 61, 121–127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Author (Year) | Participant Information | Research Methodology | Objective Measurement | Subjective Evaluation ** | Conclusions |

|---|---|---|---|---|---|

| Liu et al. (2019) [26] | Single healthy university student Height = 1.74 m Weight = 58 kg | Approach to the foam cushion at two different speeds (slowly or rapidly). | Three HTU21D (TE Connectivity Ltd., Rheinstrasse, Schaffhausen, Switzerland) sensors placed at left mid-thigh, right mid-thigh and coccyx. | N/A | Transient increase in RH at the onset of sitting was an artefact due to moisture from a warmer environment interacting with a colder sensor. |

| Havelka et al. (2019) [27] | N = 16 (detailed information not available due to commercial sensitivity) | 60-min relaxation 180-min on-road driving 60-min break 180-min on-road driving (changeover between drivers and co-drivers) Compare the following seats: Seat 1 (standard): top–woven fabric (twill), middle–reticulated foam, bottom–jersey knitted layer Seat 2 (standard+): top—woven fabric (twill), middle–nonwoven, bottom–3D spacer knitwear | 15 SHT21 (Sensirion AG, Staefa, Switzerland) sensors in five sequences with three sensors per row | Five-level Likert-type scale for comfort evaluation. Use the redefined subjective evaluation scoring system (4, 6, 8, 10) to better distinguish between categories. | Seat 2 had better thermal and ventilating performance than Seat 1. Possible to resolve differences between similar seat formulations. |

| Olney et al. (2018) [10] | N = 6 (M = 6, F = 0), wheelchair users with spinal cord injury at C5 or below Age = 60 ± 10.7 years BMI = 24.75 ± 3.58 kg/m2 | 100-min sitting on four wheelchair seating systems: (1) solid strap cushion (2) perforated strap cushion (3) foam cushion (4) air cell cushion | One capsule-shaped temperature-humidity integrated sensor (FH2, MSR Electronics GmbH, Seuzach, Switzerland) placed under the right medial thigh Infrared thermal camera (T450sc, FLIR Systems Inc., Wilsonville, OR, USA) measures heating and cooling characteristics three times: Preseating (room temperature), after 100-min sitting and 5 min after the subject being transferred out of the seat | N/A | Strap-based wheelchair cushions had better thermal emission capability as both solid and perforate strap-based seating systems cooled down faster than foam/air cell cushions when vacated. Based on the single point measurement at the skin-seat interface, no significant difference existed in RH. |

| Yang et al. (2018) [11] | N = 26 Age = 20–26 years BMI = 18.33–28.09 kg/m2 | Two-hour sitting on two commercially available pressure-relief wheelchair cushions: (1) air-filled rubber cushion (2) foam-fluid hybrid cushion | Four SH15 (Sensirion AG, Staefa, Switzerland) attached to the skin fastened by a single strip of surgical tape at the locations of ischial tuberosities and thighs | N/A | Temperature significantly differed between the measured locations, while RH showed no significant difference. |

| Liu et al. (2018) [28] | N = 8 (M = 4, F = 4) Age = 23.6 ± 1.3 years Height = 1.69 ± 0.08 m Body mass = 56.2 ± 10.3 kg | 20-min sitting on the following chairs: Chair 1: fabric cover + foam, Chair 2: wood, Chair 3: leatherette cover + foam | 64 digital temperature sensors (18B20, Maxim Integrated, San Jose, CA, USA) forming an 8 × 8 thermal measurement matrix | Questions related to thermal comfort, for example, “Did you feel any difference when sitting on the test chair compared to the chair used while you were waiting?” | Created a sensor-array-based body–seat interface temperature measurement system. Thermal performance of three chair compositions were measured and compared without disrupting participants. Temperature field at the contact surface was not uniformly distributed |

| Sales et al. (2017) [29] | Single healthy participant | 15-min sitting on eight types of chairs: lyptus wood, plywood, polypropylene, synthetic leather, melamine laminate, polyester fabric, metal and medium-density fibre board | RTD temperature probe (on the seat surface) Infrared camera (ThermaCAMP640, FLIR Systems Inc., Wilsonville, OR, USA) | N/A | All seats exhibited a higher cooling rate within the first five minutes of being vacated by participants. There was a significant variation at the beginning of cooling stage, but at the end of 15 min, all the seats reached environmental temperature, except for lyptus wood and plywood. |

| Pron et al. (2017) [30] | Single healthy participant Age = 34 years Height = 173 cm Body mass = 75 kg | 35-min sitting on the honeycomb-structured cushion | CEDIP (CEDIP Infrared Systems, Croissy, Beaubourg, France) Titanium infrared camera (The first infrared image was taken on the upper side of the cushion, the second one on the lower side, and the last one on the canvas of the wheelchair) | N/A | Cushion structure had impact on heat loss and dissipation |

| Liu et al. (2017) [13] | N = 11 (M = 6, F = 5) Age = 21–40 years BMI = 19.31–26.44 kg/m2 | 20-min sitting on either foam or gel cushion | Three HIH4000 (Honeywell Co., Morristown, NJ, USA) sensors under the left mid-thigh, the right mid-thigh and coccyx | N/A | Different cushion materials had a significant effect on RH profiles at the body–seat interface |

| Hsu et al. (2016) [31] | N = 78 (M = 39, F = 39) Participants equally divided into three groups (n = 26) Group 1 Age = 21.9 ± 1.8 years BMI = 21.6 ± 2.8 kg/m2 Group 2 Age = 22.5 ± 2.4 years BMI = 22.2 ± 3.8 kg/m2 Group 3 Age = 22.2 ± 3.8 years BMI = 21.7 ± 2.1 kg/m2 | Two-hour sitting on the following three cushions: air-filled rubber, foam–fluid hybrid and medium density foam | Skin temperature and RH were measured with four digital sensors (SH15, Sensirion AG, Staefa, Switzerland) placed under the ischial tuberosities and thighs bilaterally | N/A | Foam-fluid hybrid cushions exhibited the slowest temperature rise in comparison with standard foam and air-filled rubber cushions. No significant difference in RH between different cushions and RH reached a plateau during the two-hour sitting period. |

| Kumar et al. (2015) [32] | N = 10 (M = 0, F = 10) Age = 36.0 ± 5.56 years Height = 162.36 ± 5.57 cm Body mass = 65.59 ± 9.25 kg | 25-min sitting on foam cushion | 16 NTC-type medical grade sensors (General Electric Sensors, Fairfield, Connecticut, USA) placed around the ischial and thigh regions. (four on each ischial area, two on each thigh and two on skin-seat pan interface on each side) | Participants were allowed to adjust the temperature by regulating the seat air conditioning system. User’s self-selected comfort was attained when there was no further request for any change between two adjustment periods (5 min each). | Thermal comfort was achieved when the seating interface temperature was lower than the body temperature |

| Vlaovic et al. (2012) [33] | N = 6 (M = 3, F = 3) Age = 35 ± 4.3 years BMI = 23.9 ± 2.4 kg/m2 | 90-min sitting on the following office chairs: Model 1: A notch for coccyx and prostate, 2-layer ploy urethane Model 2: 3-layer ploy urethane Model 3: mobile in 3D, 2-layer ploy urethane Model 4: Mobile in all directions, 1-layer ploy urethane Model 5: Standard, 1-layer ploy urethane | Six S-THB-M008 (Onset Computer Corporation, Bourne, MA, USA) probes (three on seat surface, two in seat and one to monitor room conditions) | N/A | Seat surface temperature was always higher than its interior temperature. Surface moisture on a seat was different from that inside the seat. |

| Liu et al. (2011) [34] | N = 11 (M = 6, F = 5) Age = 21–40 years BMI = 19.3–26.4 kg/m2 | 20-min sitting on three seats: (foam, gel mould and solid wood) | Three temperature sensors (LM35, National Semiconductor Corporation, CA, USA) placed under left mid-thigh, right mid-thigh and coccyx | N/A | The significant difference between the three measurement locations indicated more sensors would be needed to accurately represent the thermal characteristics at the body–seat interface |

| Cengiz et al. (2009) [35] | N = 10 (M = 7, F = 3) Age = 30–34 years Height = 155–189 cm Body mass = 51–87 kg | 60-min on-road driving while sitting on seats with either ramie blended seat cover or polyester seat cover | Skin temperatures (PAR Medizintechnik GmbH & Co. KG Sachsendamm, Berlin, Germany) recorded at four places (thigh, waist, back and right bottom) Skin wittedness (PAR Medizintechnik GmbH & Co. KG Sachsendamm, Berlin, Germany) recorded on the torso back | A seven-point scale for thermal sensation and four scale for body moisture | Subjective evaluation and objective measurements were positively correlated in terms of thermal comfort. Waist and back areas had the highest temperature values. Ramie blended seat covers were preferable to polyester seat covers due to reduced skin moisture and improved thermal regulation. |

| McCarthy et al. (2009) [36] | N = 10 (M = 5, F = 5) Age = 19–41 years BMI = 18.67–27.33 kg/m2 | 60-min sitting on foam cushions | Five LM35 temperature sensors (National Semiconductor Corporation, CA, USA) and five HIH4000 sensors (Honeywell Co., Morristown, NJ, USA) placed under front and middle parts of each thigh and ischia tuberosity | N/A | Various measurement positions showed different temperature and RH responses. |

| Cengiz et al. (2007) [37] | N = 10 (M = 3, F = 7) Age = 31.8 ± 2.2 years BMI = 22.95 ± 4.1 kg/m2 | 60-min on-road driving while sitting on three different seat covers (velvet, jacquard and micro fibre), respectively | Eight locations for temperature (PAR Medizintechnik GmbH & Co. KG Sachsendamm, Berlin, Germany) measurement (under thigh, inner thigh, stomach, side of body, chest, waist, back and right bottom) Two locations (torso front and torso back) for the skin RH (PAR Medizintechnik GmbH & Co. KG Sachsendamm, Berlin, Germany) | Seven-point scale for thermal sensation, four-point scale for body moisture, three-point scale for comfort on seat back and seat cushion and four-point scale for sweat level. | Three seat cover materials showed no significant difference in subjective thermal evaluation and objective temperature measurement. Objective measurement had a positive relationship with subjective evaluation. Skin wettedness on the posterior torso was significantly different across the three cushions, while skin wettedness on the anterior torso did not. Skin wettedness played more important role in comfort evaluation than skin temperature. |

| Stockton and Rithalia * (2007) [15] | N = 5 (M = 1, F = 4) Wheelchair users Age = 63.8 ± 15.1 years | 10–16 h sitting (mean = 14.00, SD = 2.83 h) a day for continuous seven days. Four types of cushion: Airlite, Kombat, Primagel and Systam | Temperature and RH probes (Gemini Data Loggers, West Sussex, UK) inserted into the core of the cushion | Four-point scale comfort rating | Subjective sensation of comfort was not linked with temperature and RH. |

| Bartels et al. (2003) [38] | N = 4 (M = 4, F = 0) Mean age = 25 years Mean height = 177 cm Mean weight = 70 kg | 180-min sitting on either leather cover + foam cushion or fabric cover + spacer knit cushion | Temperature and RH sensors (detailed information is not available) | Four-point scale for heat, moisture and comfort sensations. | Textile cover and cushion type can improve sitting comfort |

| Ferrarin and Ludwig (2000) [39] | A health male Age = 32 years Height = 185 cm Weight = 70 kg | 15-min sitting on four cushions: silicone gel pad, air-filled rubber cells, gel-filled bubble and foam-filled bubble | Infrared camera (TVS-2000, Nippon Avionics Co., Tokyo, Japan) | N/A | Nonflat surface cushions (air-filled cells and bubble-shaped surfaces) showed lower peak temperatures than a flat surface cushion. Gel-filled bubble cushions had lower maximum temperatures than foam-filled bubble cushions. Temperatures at the thighs were higher than at the ischial regions. |

| Author (Year) | Participant | Measured Parameter | Seat Type | Sensor Unit | Subjective Evaluation | Conclusions |

|---|---|---|---|---|---|---|

| Mitsuya et al. (2019) [9] | N = 18 (M = 11, F = 7) | 2D pressure map at the seat and backrest converted into 1D data | 19 types of car seats | Pressure mat (LX100, XSENSOR Technology Co., Calgary, Alberta, Canada) | 7-level score questionnaire included three aspects: scale feeling, body pressure feeling, and fitting feeling. | Subjective evaluation appeared strongly related to objective measurement. Body size and car seat types were associated with body pressure distribution. |

| Bontrup et al. (2019) [49] | N = 62 (M = 23, F = 40) Age = 43 ± 13 years Height = 170 ± 10 cm Body mass = 78 ± 21 kg; | Mean number of movements per working hour Mean number of positional changes per working hour Mean time period of stable sitting Percentage of transient periods during the whole working period | Call-centre office seat | Textile pressure mat (Sensomative GmbH, Rothenburg, Switzerland) | Questionnaire on acute and chronic low back pain. Chronic pain questionnaire consisted of two parts: Korff characteristic pain intensity and Korff disability. Acute pain questionnaire included: pain severity and pain-related interference of daily functions | Sitting behavior was associated with chronic back-pain. Seven sitting postures were studied (Upright, reclined, forward inclined, laterally tilted right/left, crossed legs right over left/left over right). |

| Fasulo et al. (2019) [50] | N = 25 (M = 13, F = 12) Age = 21.4 ± 0.5 years BMI = 22.3 ± 2.3 kg/m2 | Centre of pressure | Classroom chair/combo desk (an hour test) | Sensor array (T&T medilogic Medizintechnik GmbH, Schönefeld, Germany) | 5-point Likert scale Questionnaire on comfort and discomfort evaluation | The perceived lower-body comfort had a relationship with movement |

| Ahmad et al. (2019) [51] | N = 5 (F = 3, M = 2) Age = 33 ± 8 years Height = 180 ± 10 cm Body mass = 70 ± 21 kg | Total number of activated sensors Single sensing element values Sum of all sensing element values Average of sensing element values | Wheelchair | Flexible screen-printed piezo-resistive sensors (customized) | N/A | Cost-effective and flexible screen-printed sensors for large area pressure measurement. Four sitting postures (forward leaning, backward leaning, right leaning and left leaning) were recognized with an accuracy of 80%. |

| Cardoso et al. (2018) [52] | N = 20 (M = 10, F = 10) Age = 22.3 ± 2.16 years (M), 22.1 ± 0.8 years (F) Height = 179.4 ± 7.0 cm (M), 165.3 ± 7.27 cm (F) Body mass = 79.6 ± 11.3 kg (M), 61.1 ± 6.5 kg (F) | Peak pressure, average pressure, and centre of pressure trunk angle, neck angle and shoulder angle Lumbar spinal angle and thoracic angle | Two truck seats: a “Force-3” seat and “industry standard” seat | Xsensor (X2, XSENSOR Technology Co., Calgary, Alberta, Canada) pressure pad Four Optotrak motion capture cameras (Optotrak Certus, NDI Inc., Waterloo, Canada) Three triaxial accelerometers (ADXL320, Analog Devices, Norwood, Massachusetts, USA) | 100 mm-scale RPD (ratings of perceived discomfort) and ASD (automotive seating discomfort) questionnaires | The Force-3 seat outperformed the industry standard seat. Reported to be due to adjustability in the seat height, pan length and backrest angle. |

| Worsley et al. (2018) [53] | N = 13 (M = 8, F = 5) BMI = 22.9 ± 2.7 kg/m2 | Peak interface pressure Trunk movement Oxygen and carbon dioxide tensions | Leisure chairs with foam cushion and air cushion | Tekscan pressure mat (Tekscan Co., South Boston, MA, USA) Triaxial accelerometer (Shimmer Platform, Realtime Technologies Ltd., Dublin, Ireland) Transcutaneous gas electrodes (Model 841, Radiometer A/S, Denmark) | Five-point comfort score | Interface pressure and trunk movement provided information to remind sitters to adjust their positions during prolonged sitting. Bony prominences contacted with the cushions remained at risk during sedentary activities. |

| Li et al. (2017) [45] | N = 18 (M = 12, F = 6) Age = 23.89 ± 1.49 years BMI = 21.51 ± 2.92 kg/m2 | Average contact pressure Mean peak pressure Mean contact area | Three different seat pitches (32 inches, 30 inches and 28 inches) | Two Tekscan (Tekscan Co., South Boston, MA, USA) thin-resistive- sensor pressure mats (seat pan and backrest) | Discomfort questionnaire using 5-point body part rating scale | The pitch of the seat and interface pressure had an impact on prolonged sitting comfort. |

| Ma et al. (2017) [54] | N = 12 (M = 7, F = 5) Age = 22–36 years BMI = 16–34 kg/m2 | Mean and standard deviation Five sitting postures | Wheelchair | FSR (Interlink FSR-406, Interlink Electronics, CA, USA) sensors (seven on seat pan and 5 on backrest) | N/A | Compared five classification algorithms whereby the decision tree was capable of achieving an accuracy of 96.85%. |

| Stinson et al. (2017) [55] | N = 14 (M = 12, F = 2) patients with spinal cord injury (trial 1) N = 7 old patients (trial 2) | Interface pressure Trunk tilt angle | Wheelchair Hospital chair | X3 interface pressure mat (XSENSOR Technology Co., Calgary, Alberta, Canada) ActivPAL3 accelerometer (PAL Technologies, Glasgow, UK) | N/A | Interface pressure and body movement information facilitated occupational therapists and healthcare professionals to minimize the risk of developing sitting acquired pressure ulcers through correct interventions. |

| Ma et al. (2017) [56] | N = 12 (M = 7, F = 5) Age = 22–36 years BMI = 16–34 kg/m2 | Centre of Pressure Angular velocities of anterior-posterior and medial-lateral swings | Wheelchair | FSR (Interlink FSR-406, Interlink Electronics, CA, USA) sensors (n = 6, equally placed on front, left/right and rear sides) IMU placed on the centre of the cushion (MPU9250, InvenSense Co., Tokyo, Japan) | N/A | Achieved an accuracy of (>89%) for activity recognition and (>98%) for activity level (quantified activity) recognition |

| Zemp et al. (2016) [57] | N = 41 (M = 25, F = 16) Age = 24–64 years Height = 160–200 cm Body mass = 53–126 kg | Median value of pressure Inclination angles of the backrest | Office chair | FSR (Interlink FSR-406, Interlink Electronics, CA, USA) sensors (n = 16, 10 on seat pan 4 on backrest, 2 on armrest) | N/A | The accuracy of classifying seven different sitting positions was between 81% and 98%. |

| Cascioli et al. (2016) [48] | N = 21 (M = 12, F = 9) Age = 25 ± 5 years Height = 1.73 ± 0.10 m BMI = 25 ± 4 kg/m2 | In-chair movement (ICM) | Contoured foam Straight foam Wood | FSR (Interlink FSR-406, Interlink Electronics, CA, USA) sensors | Questionnaires using 11-point numerical rating scale | Discomfort was associated with increased ICMs, while fewer ICMs indicated increasing comfort. |

| Lee and Shin (2016) [40] | N = 7 (M = 2, F = 5) Age = 22 ± 0.58 years Height = 168.9 ± 6.57 cm Body mass = 59.14 ± 4.35 kg | Ratio of the average pressure | Office chair | Piezo-resistive conductive film sensor array (customized) | N/A | Pressure distribution was related with sitting posture (upright, forward leaning, and backward leaning) |

| Zemp et al. (2016) [41] | N = 20 (M = 13, F = 7) Age = 27–57 years Height = 1.60–1.89 m Body mass = 50–105 kg | Averaged movements of one working hour Averaged positional changes during one working hour Mean time period of stable sitting Mean duration in the same sitting positions Percentage of transient periods during the whole working time | Office chair | Pressure sensor mat (PST04, SensingTex, Barcelona, Spain) | Standardized questionnaires (KPI and BPI) were used to assess short and long-term back pain | Classification of seven sitting positions (upright, reclined, forward inclined, laterally tilted right/left, crossed legs right over left/left over right) with an accuracy >80% Subjects with slight back pain exhibited a more static sitting behavior compared to subjects without any discomfort |

| Zemp et al. (2016) [58] | N = 20 (M = 15, F = 5) Age = 20–37 years Height = 1.64–1.90 m Body mass = 52–99 kg | Peak pressure Mean pressure Standard deviation of the pressure distribution Total contact area Force Maximum pressure gradient Mean Pressure gradient Standard deviation of the pressure gradient | Nine office chairs | Two pressure mats (Pliance-x 32 Expert, Novel GmbH, Munich, Germany: seat pan and backrest) | N/A | The material properties of chairs strongly influenced pressure distribution. |

| Shu et al. (2015) [59] | A male subject Age = 30 years Height = 174 cm Body mass = 70 kg | Pressure value Contact area | 90-min continuous working while sitting on office chairs | Textile resistive sensor arrays (customized) | N/A | The resistance matrix approach improved the measurement accuracy with lower hardware complexity and crosstalk error. Three sitting postures of sit-up, backward and forward were identified. |

| Fredericks et al. (2015) [60] | N = 201 (M = 100, F = 101) Age = 29.1 ± 11.1 years (M), 31.9 ± 12.4 years (F) Height = 1750.3 ± 77.9 mm (M), 1638.1 ± 69.6 mm (F) Body mass = 76.5 ± 13.1 kg (M), 66.8 ± 12.4 kg (F) | Standardized pressure map of seat pan and back rest | Customized chair with adjustable back rest support 15 min sitting while complete the task of typing/and using the mouse | FSA pressure mapping system (FSA Industrial Seat and Back Systems, Verg Inc., USA) | Optimal location and magnitude of backrest selected by users | Participants preferred asymmetric support in the lower back region which was contrary to popular practice |

| Barba et al. (2015) [61] | N = 9 Age = 59.7 ± 24.2 years Height = 1.76 ± 0.10 m Body mass = 38.78 ± 4.94 kg | 12 posture recognition based on pressure values | Office chair | Customized piezo-resistive sensors (eight sensors on seat pan and eight on backrest) | N/A | Developed a simple and inexpensive hardware system to monitor different sitting postures |

| Yoo (2015) [62] | N = 10 (M = 10, F = 0) Age = 28.2 ± 3.9 years Height = 175.7 ± 4.7 cm Body mass = 68.1 ± 6.3 kg | Gluteal peak pressure Trunk flexion angle | A general chair A suspension seat support chair | TekScan system (Tekscan Co., South Boston, MA, USA) | N/A | Suspension seat support chair was shown to reduce pressure at gluteal and thigh areas and prevented a slumped sitting posture |

| Le et al. (2014) [63] | N = 12 (M = 6, F = 6) Age = 33.0 ± 13.4 years Height = 169.8 ± 9.5 cm Body mass = 69.2 ± 13.2 kg | Seat pan distribution Pan and back high pressure point percentages Pan and back oscillations EMG cycling muscle oxygenation | Car seats (Audi A8 seat and Chrysler Sebring seat) | Two piezoelectric X3 (XSENSOR Technology Co., Calgary, Alberta, Canada) pressure sensor mat (seat pan and seat back) EMG (Delsysw Inc., Bagnolie-16, Boston, MA, USA) Custom-made 16-channel near-infrared spectroscopy system | 100mm-scale subjective discomfort for several body regions (neck, upper back, lower back, hip, buttock, upper leg and knee) | Body mass and stature had an impact on sitting discomfort. |

| Kyung and Nussbaum (2013) [42] | N = 22 (Y = 11, O = 11) Young group: Age = 21.8 ± 3.2 years Height = 168.9 ± 11.2 cm Body mass = 67.9 ± 11.1 kg Older group: Age = 71.4 ± 8.6 years Height = 168.2 ± 11.7 cm Body mass = 73.5 ± 22.0 kg | Contact area Contact pressure Peak pressure Ratio of local to global of contact area Ratio of local to global of contact pressure Ratio of local to global of peak pressure Local areas of seat: bilateral thighs and buttocks Local areas of seat back: low back and upper back | Two car seats (Sedan and Sport utility vehicle) | Two Tekscan pressure mats (Tekscan Co., South Boston, MA, USA) | Three subjective ratings (comfort, discomfort and overall). The comfort Scale ranged from 0 to 10, Whereas the discomfort scale ranged from 0 to −10. | Young and old subjects had different perceptions of comfort rating for the same car seats |

| Xu et al. (2013) [64] | N = 25 (M = 15, F = 10) | Canny edge detector Extract the outline curve of the binary image Measure the distance between every point and an image centre | Office chair | Customized textile pressure sensor (a fibre-based yarn coated with piezoelectric polymer) | N/A | The system appeared capable of resolving between seven sitting postures (sitting up, forward, backward, left lean, right lean, right foot over left and left foot over right) with an accuracy of 85.9% A resampling method reduced uncertain factors including offset, scaling, crosstalk and rotation effects |

| Noro et al. (2012) [65] | N = 11 (M = 7, F = 4) Height percentile information | Peak pressure Contact area Pelvic rotation | Two different surgery seats: a conventional seat and a prototype of a new seat (seat pan with sacral support) | Pressure sensitive mat (waiting for the corresponding author’s reply) Patented gyroscope (Patent no. 3,928,103 2004) | Five-point comfort rating | The newly designed chair was considered more comfortable than the traditional chair because it reduced the pressure and prevented posterior pelvic rotation |

| Paul et al. (2012) [66] | N = 64 (M = 64, F = 0) Age = 38 ± 6 years Height = 1730 ± 55 mm Body mass = 75.9 ± 11.7 kg | Contact areas (total seat, upper and lower seat back) Rear/front cushion force | Three vehicle seats | Tekscan (Tekscan Co., South Boston, MA, USA) sensor system | N/A | Anthropometric characteristics (e.g., body mass, shoulder breadth and hip circumference) were correlated with cushion contact areas and cushion front and rear force. |

| Meyer et al. (2010) [43] | N = 9 (M = 6, F = 3) | Centre of force Pressure at aggregated areas | Office chair | Customized textile pressure sensors | N/A | Classification accuracy for 16 sitting postures was almost the same as the commercially available products |

| Groenesteijn et al. (2009) [46] | N = 20 (M = 10, F = 10) Age = 43 ± 10.8 years Height = 1.77 ± 0.1 m Body mass = 75 ± 11.3 kg | Seat pan pressure: peak Pressure and pressure distribution | Office chair | Pressure sensitive mat (Pliance-x system, Novel Gmbh, Munich, Germany) | Six-point comfort rating | Comfort was related to task. Easily adjustable back rest was preferred by users. |

| Kyung and Nussbaum (2008) [67] | N = 27 (M = 12, F = 15) Age = 20–35 years Height = 170.7 ± 11.7 cm Body mass = 69.1 ± 13.1 kg | 36 interface pressure variables (pressure levels, contact areas and ratios of local to global pressure) | Two car (sedan and SUV) + two seats + two test conditions (lab + field) | Two Tekscan (Tekscan Co., South Boston, MA, USA) pressure mat (seat and back) | Comfort and discomfort ratings of the whole body and six local parts. Rating scales ranged from 0 to −10, and from 0 to 10, for discomfort and comfort, respectively. | Pressure measurement was considered more suitable for short-time comfort/discomfort evaluation than long-term. Pressure ratios at buttocks were lower than for upper/lower back. 20 out of 36 pressure variables were correlated with either overall or whole body comfort ratings. No pressure variable had significant correlation with whole body discomfort. |

| Stockton and Rithalia * (2007) [15] | N = 5 (M = 1, F = 4) Wheelchair users Age = 63.8 ± 15.1 years | Mean ± SD | Four types of wheelchair cushions: Airlite, Kombat, Primagel and Systam | Interface pressure measured by Oxford Pressure Monitor II (Talley Group, Hants, UK) | Four-point scale comfort rating | Cushions with the lowest interface pressures were rated the most comfortable. |

| Carcone and Keir (2007) [44] | N = 30 (F = 15, M = 15) Age = 23 ± 3.1 years Height = 1.71 ± 0.09 m Body mass = 69.7 ± 15.3 kg | Mean of average pressure Mean peak pressure Mean contact area Centre of pressure | Office chair with different backrest pads | Capacitive pressure-sensing system (X236, XSENSOR Technology Co., Calgary, Alberta, Canada) | Five-point Likert scale. | Higher ranked backrest was associated with lower peak backrest pressure, greater seat pan contact area and smaller backrest area. |

| Vos et al. (2006) [68] | N = 24 (M = 12, F = 12) | Peak and average pressure Contact area | 12 office chairs | X-Sensor pressure sensor mat (XSENSOR Technology Co., Calgary, Alberta, Canada) Four scales (under two arms and two feet) | N/A | Chair design had greater impact on sitting pressure than sitting posture, though both factors had significant relationships with pressure distribution. |

| Na et al. (2005) [69] | N = 16 (M = 16, F = 0) Age = 25.5 ± 2.6 years Height = 172.8 ± 5.4 cm Body mass = 72.3 ± 9.8 kg | Four body pressure ratio variables and two body pressure change variables | 45-min simulated driving (15 laps of 3 min per lap) while sitting on mid-size sedan seat | FSR (FSA Industrial Seat and Back Systems, Verg Inc., USA) pressure mats (seat pan and back rest) | Seven-point comfort rating for six body parts (neck, shoulder, back, lumbar, hip and thigh) | Body pressure ratio variables can be used to evaluate driving posture. Body pressure distribution variables were associated with discomfort ratings. |

| Porter et al. (2003) [70] | N = 18 (M = 8, F = 10) Age = 40 ± 12 years | Mean and maximum interface pressure acquired from left and right ischial tuberosities, left and right thighs, upper back and lower back Eight angle parameters: ankle angle, arm flexion, elbow angle, knee angle, neck inclination, thigh from horizontal, trunk from vertical and trunk–thigh angle | Three types of cars equipped with two different seats on road trial | Capacitive sensor matrix (Novel, Munich, Germany) placed on seat and backrest Goniometer | Seven point discomfort rating | Interface pressure appeared to have no strong correlation with subjective discomfort during road trials. |

| Andreoni et al. (2002) [71] | N = 8 (M = 7, F = 1) Age = 25 ± 2 years Height = 1.80 ± 0.06 m Body mass = 74 ± 13 kg | Mean and peak pressures lumbar flexion angle | Car seat | Tekscan (Tekscan Co., South Boston, MA, USA) pressure mats (cushion and backrest) Motion cameras (Elite Image Inc., New York, NY, USA) | User self-selected comfortable position | Pressure sensor + motion capture were suitable to classify car driver postures |

| Hostens et al. (2001) [72] | N = 10 (M = 10, F = 0) Age = 26.5 ± 4.43 years Height = 174.98 ± 6.8 cm Body mass = 67.86 ± 8.9 kg | Maximum and mean buttocks Back support pressure | Four foam air-based seats for agricultural machinery | Capacitive pressure sensor (XSENSOR Technology Co., Calgary, Alberta, Canada) mats (seat and back rest) | Participants choose the most comfortable sitting position | A linear relationship presented between mean pressure and body mass index. The air-based seat had lower maximum pressure than the foam seat. |

| Brienza et al. (2001) [17] | N = 32 Age = 85 ± 7.6 years | Mean and peak pressure | Generic foam seat cushion and pressure-reducing seat cushion placed on wheelchair | Pressure sensitive mats (FSA Industrial Seat and Back Systems, Verg Inc., USA) | National Pressure Ulcer Advisory Panel staging method | Buttock-cushion interface pressure was associated with pressure ulcer development |

| Fenety et al. (2000) [73] | N = 8 (M = 1, F = 7) Age = 23–45 years Height = 158.5–170 cm Body mass = 59.3–85.5 kg | ICM centre of pressure | Working chair used by telecommunication directory assistance Operators for two hours | Force sensing resistors pressure mat (Force Sensing Systems, Winnipeg, MN, Canada) | Preferred chair and screen position were chosen by participants before trials | ICM and centre of pressure can represent objective sitting comfort/discomfort |

| Tewari and Prasad (2000) [47] | N = 3 Height = 164.5–172.5 cm Body mass = 51.4–75.5 kg | Mean pressure on the seat pan and back rest | Tractor seat (four back-rests with different radius and three back-rest inclination angles) | Pressure sensitive mats (waiting for the corresponding author’s reply) | General comfort 6-point scale | Lower mean pressures on the seat pan were associated with higher comfort scores. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Cascioli, V.; McCarthy, P.W. Review of Measuring Microenvironmental Changes at the Body–Seat Interface and the Relationship between Object Measurement and Subjective Evaluation. Sensors 2020, 20, 6715. https://doi.org/10.3390/s20236715

Liu Z, Cascioli V, McCarthy PW. Review of Measuring Microenvironmental Changes at the Body–Seat Interface and the Relationship between Object Measurement and Subjective Evaluation. Sensors. 2020; 20(23):6715. https://doi.org/10.3390/s20236715

Chicago/Turabian StyleLiu, Zhuofu, Vincenzo Cascioli, and Peter W. McCarthy. 2020. "Review of Measuring Microenvironmental Changes at the Body–Seat Interface and the Relationship between Object Measurement and Subjective Evaluation" Sensors 20, no. 23: 6715. https://doi.org/10.3390/s20236715

APA StyleLiu, Z., Cascioli, V., & McCarthy, P. W. (2020). Review of Measuring Microenvironmental Changes at the Body–Seat Interface and the Relationship between Object Measurement and Subjective Evaluation. Sensors, 20(23), 6715. https://doi.org/10.3390/s20236715