SAW Chemical Array Device Coated with Polymeric Sensing Materials for the Detection of Nerve Agents

Abstract

:1. Introduction

2. Experiment

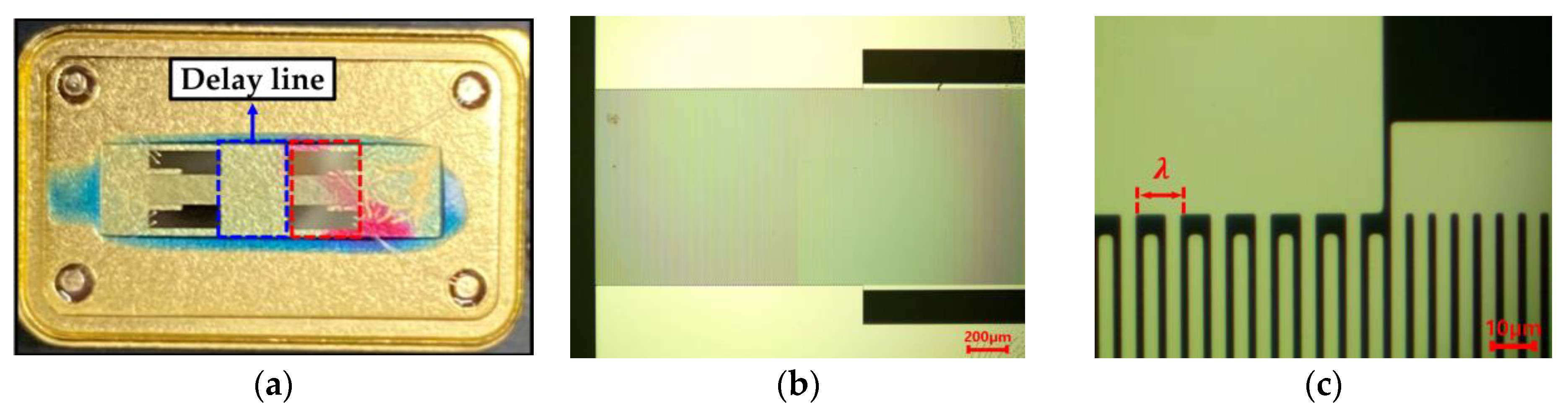

2.1. Design of SAW Array Sensor

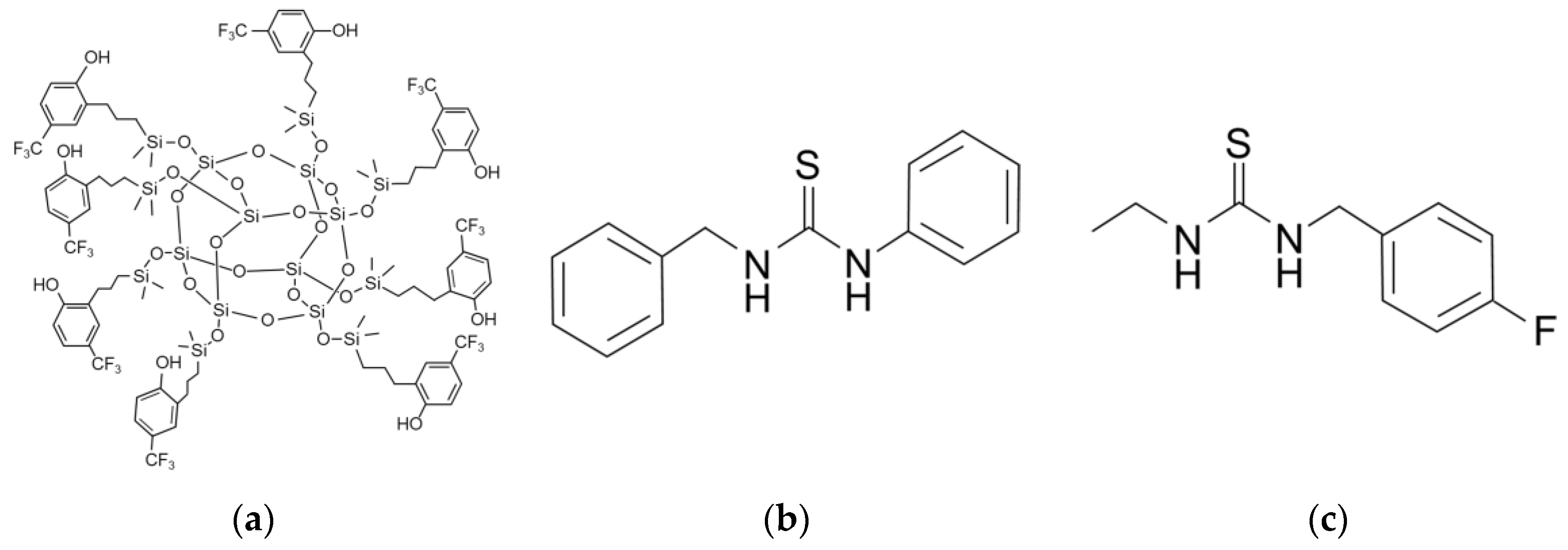

2.2. Materials Synthesis and Coating Process

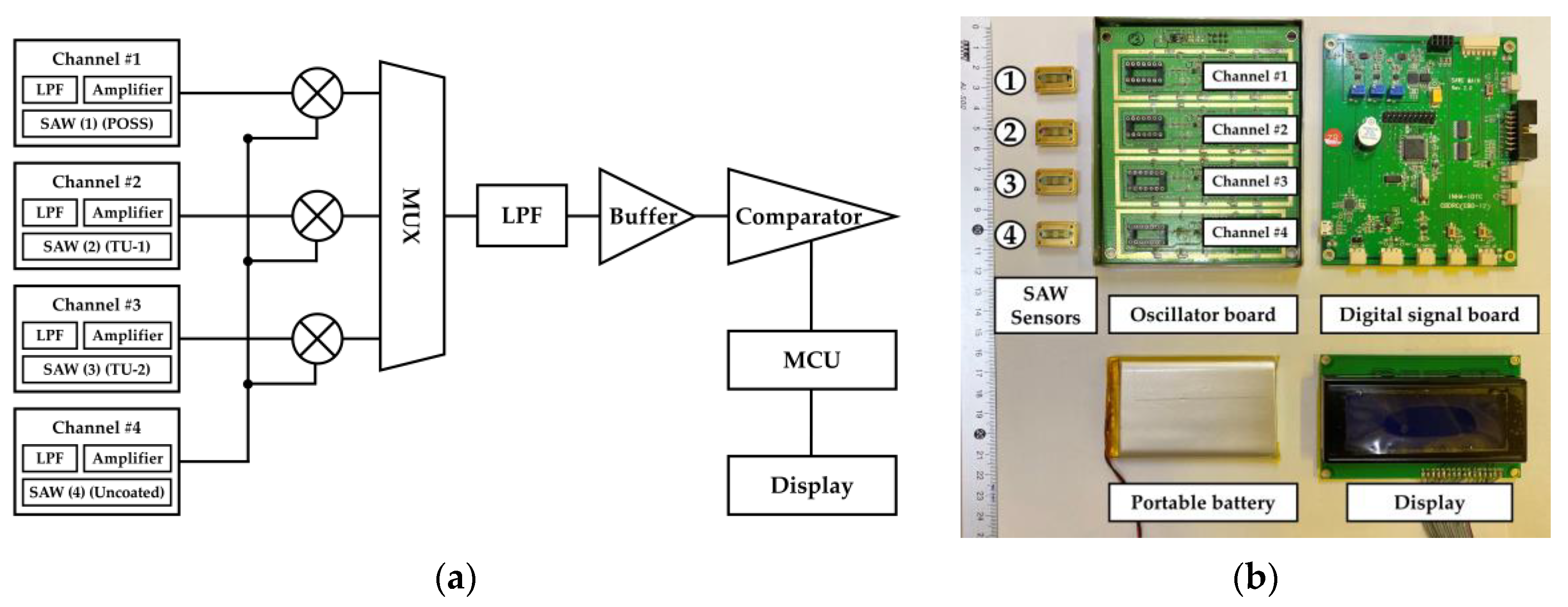

2.3. Experimental Apparatus

3. Results

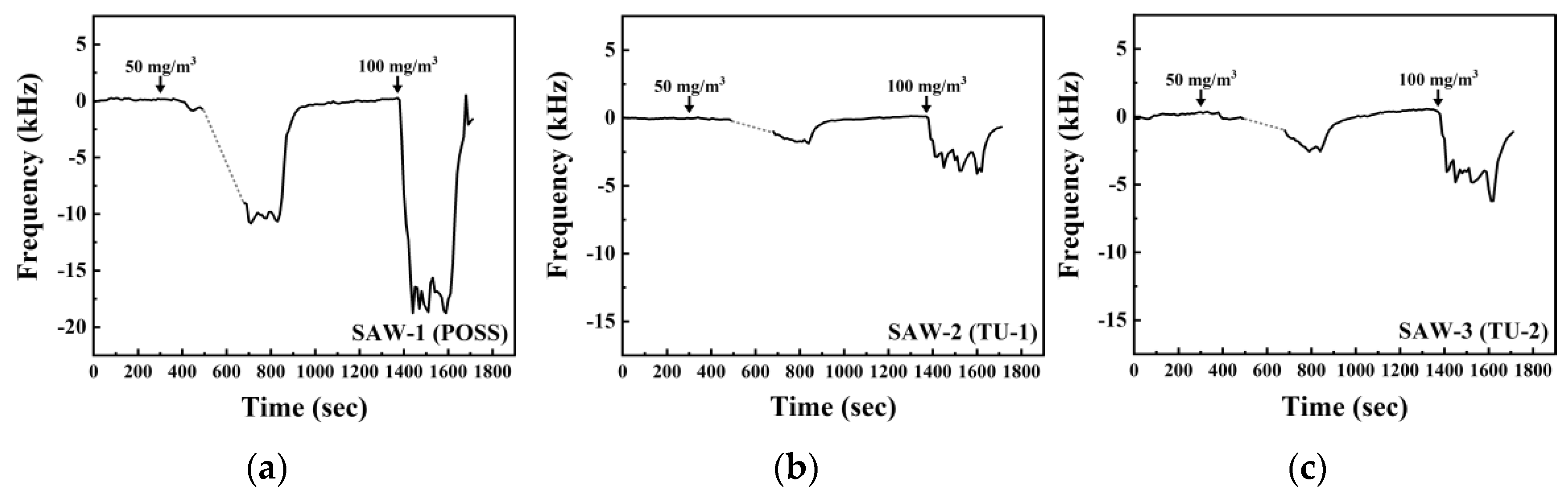

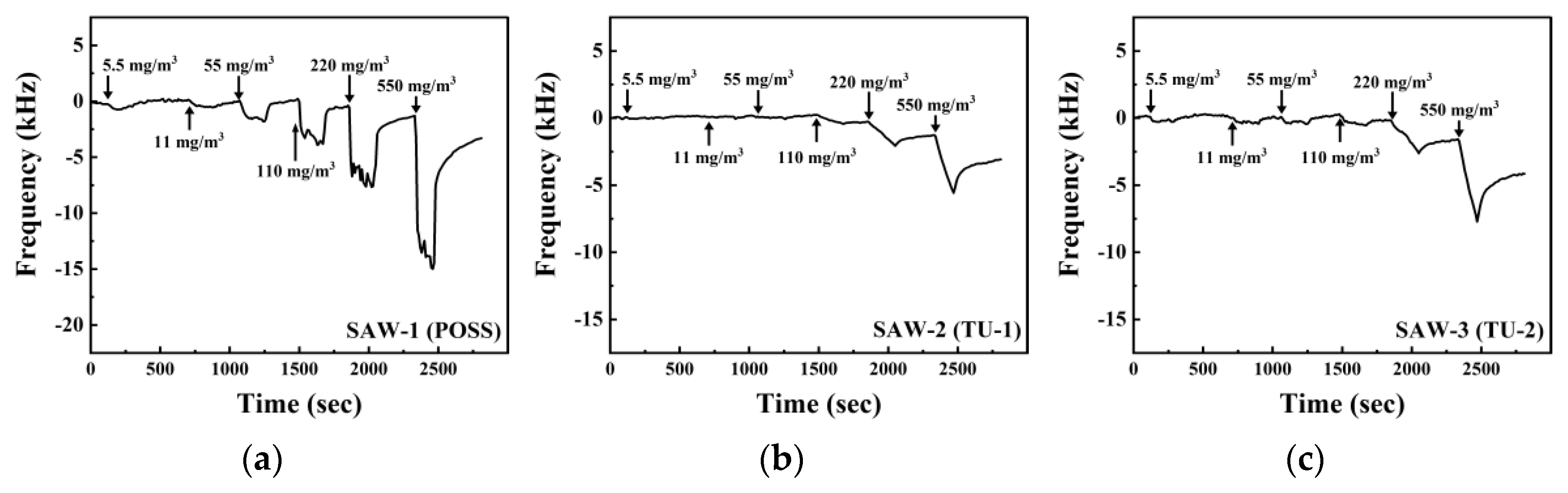

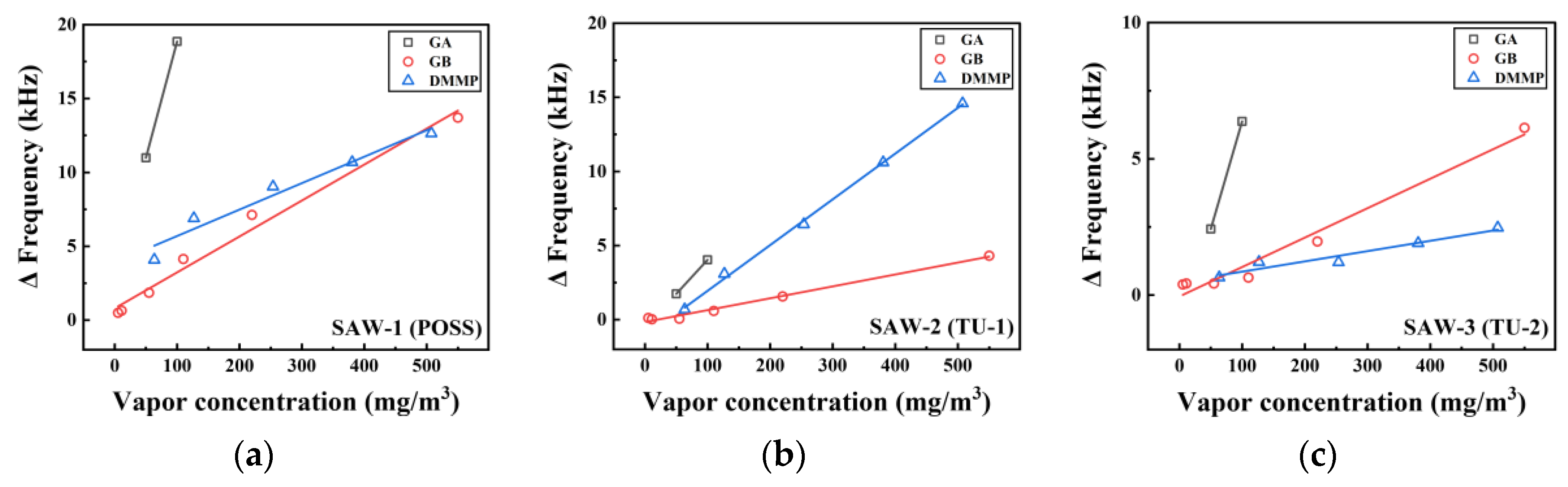

3.1. Sensitivity to GA Vapor

3.2. Sensitivity to GB Vapor

3.3. Sensitivity to DMMP Vapor

3.4. Regression to Frequency Response of the Sensors

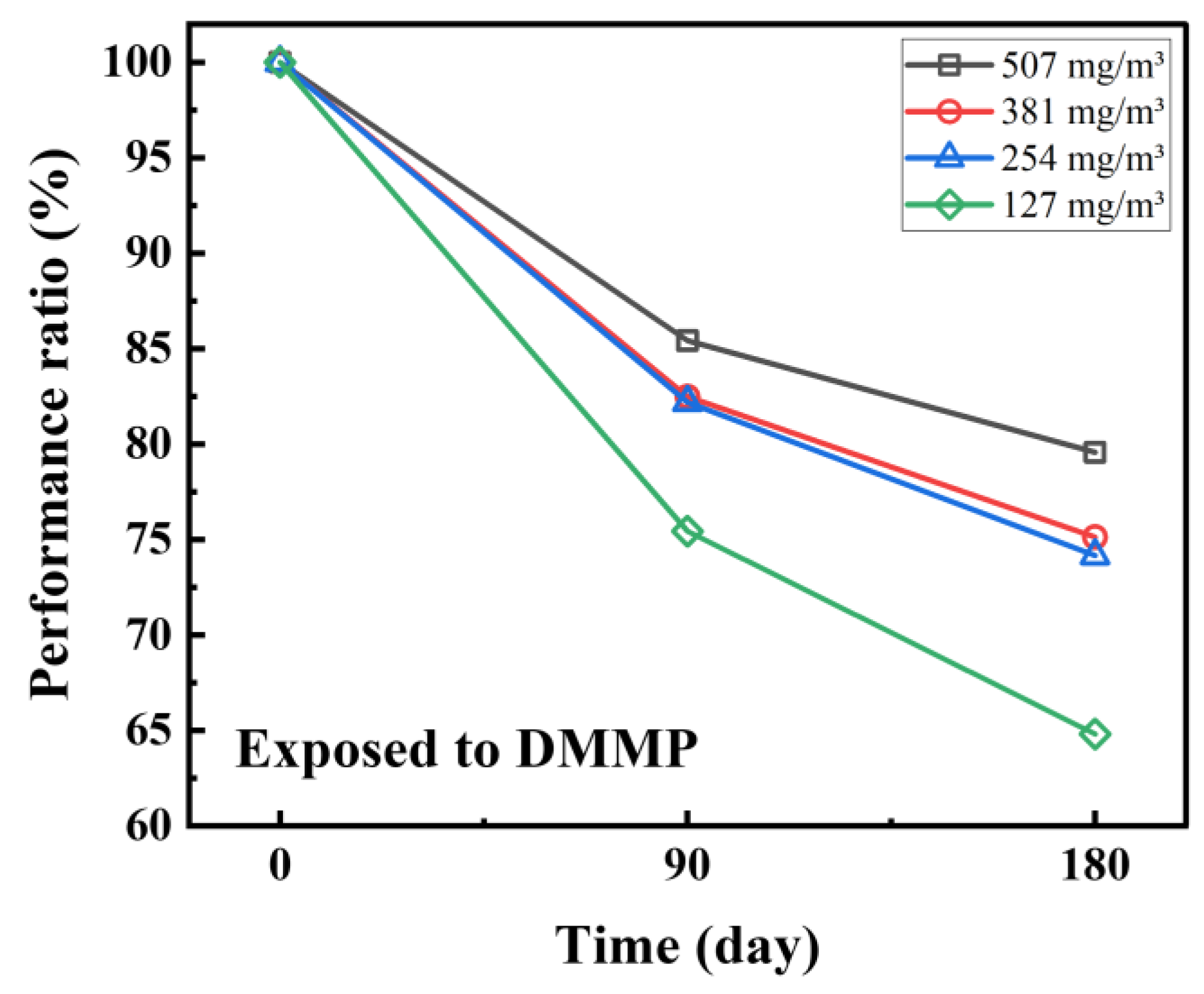

3.5. Long-Term SAW Response: Reliability of the POSS as a Sensing Material

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Salem, H.; Sidell, F.R. Nerve Agents. Encycl. Toxicol. 2005, 201–206. [Google Scholar] [CrossRef]

- Chauhan, S.; Chauhan, S.; D’Cruz, R.; Faruqi, S.; Singh, K.K.; Varma, S.; Singh, M.; Karthik, V. Chemical Warfare Agents. Environ. Toxicol. Pharmacol. 2008, 26, 113–122. [Google Scholar] [CrossRef] [PubMed]

- Abdollahi, M.; Mostafalou, S. G-Series Nerve Agents, 3rd ed.; Elsevier: New York, NY, USA, 2014; Volume 2. [Google Scholar] [CrossRef]

- Smith, P.A.; Lepage, C.J.; Harrer, K.L.; Brochu, P.J. Hand-Held Photoionization Instruments for Quantitative Detection of Sarin Vapor and for Rapid Qualitative Screening of Contaminated Objects. J. Occup. Environ. Hyg. 2007, 4, 729–738. [Google Scholar] [CrossRef] [PubMed]

- Satoh, T.; Kishi, S.; Nagashima, H.; Tachikawa, M.; Kanamori-Kataoka, M.; Nakagawa, T.; Kitagawa, N.; Tokita, K.; Yamamoto, S.; Seto, Y. Ion Mobility Spectrometric Analysis of Vaporous Chemical Warfare Agents by the Instrument with Corona Discharge Ionization Ammonia Dopant Ambient Temperature Operation. Anal. Chim. Acta 2015, 865, 39–52. [Google Scholar] [CrossRef] [PubMed]

- Puton, J.; Namieśnik, J. Ion Mobility Spectrometry: Current Status and Application for Chemical Warfare Agents Detection. TrAC Trends Anal. Chem. 2016, 85, 10–20. [Google Scholar] [CrossRef]

- Pascual, L.; Campos, I.; Bataller, R.; Olguín, C.; García-Breijo, E.; Martínez-Mañez, R.; Soto, J. A “Humid Electronic Nose” for the Detection of Nerve Agent Mimics; A Case of Selective Sensing of DCNP (a Tabun Mimic). Sens. Actuators B Chem. 2014, 192, 134–142. [Google Scholar] [CrossRef]

- Olguín, C.; Laguarda-Miró, N.; Pascual, L.; García-Breijo, E.; Martínez-Mañez, R.; Soto, J. An Electronic Nose for the Detection of Sarin, Soman and Tabun Mimics and Interfering Agents. Sens. Actuators B Chem. 2014, 202, 31–37. [Google Scholar] [CrossRef]

- Logan, T.; Allen, E.; Way, M.; Swift, A.; Soni, S.D.; Koplovitz, I. A Method for the Analysis of Tabun in Multisol Using Gas Chromatographic Flame Photometric Detection. Toxicol. Mech. Methods 2006, 16, 359–363. [Google Scholar] [CrossRef]

- Seto, Y.; Kanamori-Kataoka, M.; Tsuge, K.; Ohsawa, I.; Maruko, H.; Sekiguchi, H.; Sano, Y.; Yamashiro, S.; Matsushita, K.; Sekiguchi, H.; et al. Development of an On-Site Detection Method for Chemical and Biological Warfare Agents. Toxin Rev. 2007, 26, 299–312. [Google Scholar] [CrossRef]

- Pacsial-Ong, E.J.; Aguilar, Z.P. Chemical Warfare Agent Detection: A Review of Current Trends and Future Perspective. Front. Biosci. 2013, 5, 516–543. [Google Scholar] [CrossRef]

- Holdren, S.; Tsyshevsky, R.; Fears, K.; Owrutsky, J.; Wu, T.; Wang, X.; Eichhorn, B.W.; Kuklja, M.M.; Zachariah, M.R. Adsorption and Destruction of the G-Series Nerve Agent Simulant Dimethyl Methylphosphonate on Zinc Oxide. ACS Catal. 2019, 9, 902–911. [Google Scholar] [CrossRef]

- Wilmsmeyer, A.R.; Gordon, W.O.; Davis, E.D.; Troya, D.; Mantooth, B.A.; Lalain, T.A.; Morris, J.R. Infrared Spectra and Binding Energies of Chemical Warfare Nerve Agent Simulants on the Surface of Amorphous Silica. J. Phys. Chem. C 2013, 117, 15685–15697. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, G.; Guo, T.; Liu, X.; Zhang, C.; Yang, J.; Cao, B.; Zhang, C.; Wang, W. Environmental Characteristics of Surface Acoustic Wave Devices for Sensing Organophosphorus Vapor. Sens. Actuators B Chem. 2020, 315, 127986. [Google Scholar] [CrossRef]

- Nimal, A.T.; Mittal, U.; Singh, M.; Khaneja, M.; Kannan, G.K.; Kapoor, J.C.; Dubey, V.; Gutch, P.K.; Lal, G.; Vyas, K.D.; et al. Development of Handheld SAW Vapor Sensors for Explosives and CW Agents. Sens. Actuators B Chem. 2009, 135, 399–410. [Google Scholar] [CrossRef]

- Drafts, B. Acoustic Wave Technology Sensors—Microwave Theory and Techniques. IEEE Trans. Microw. Theory Tech. 2001, 49, 795–802. [Google Scholar] [CrossRef]

- Kirschner, J. Surface Acoustic Wave Sensors (SAWS): Design for Application. Microelectromech. Syst. 2010, 12, 1–11. [Google Scholar]

- Wang, W.; Lee, K.; Kim, T.; Park, I.; Yang, S. A Novel Wireless, Passive CO2 Sensor Incorporating a Surface Acoustic Wave Reflective Delay Line. Smart Mater. Struct. 2007, 16, 1382–1389. [Google Scholar] [CrossRef]

- Ramakrishnan, N.; Nemade, H.B.; Palathinkal, R.P. Resonant Frequency Characteristics of a SAW Device Attached to Resonating Micropillars. Sensors 2012, 12, 3789–3797. [Google Scholar] [CrossRef]

- Ricco, A.J.; Martin, S.J.; Zipperian, T.E. Surface Acoustic Wave Gas Sensor Based on Film Conductivity Changes. Sens. Actuators 1985, 8, 319–333. [Google Scholar] [CrossRef]

- Wang, Y.; Du, X.; Long, Y.; Tang, X.; Tai, H.; Jiang, Y. The Response Comparison of a Hydrogen-Bond Acidic Polymer to Sarin, Soman and Dimethyl Methyl Phosphonate Based on a Surface Acoustic Wave Sensor. Anal. Methods 2014, 6, 1951–1955. [Google Scholar] [CrossRef]

- Bielecki, M.; Witkiewicz, Z.; Rogala, P. Sensors to Detect Sarin Simulant. Crit. Rev. Anal. Chem. 2020, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization Behavior of Poly(ε-Caprolactone)/Layered Double Hydroxide Nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Higgins, B.A.; Simonson, D.L.; Houser, E.J.; Kohl, J.G.; Andrew Mcgill, R. Synthesis and Characterization of a Hyperbranched Hydrogen Bond Acidic Carbosilane Sorbent Polymer. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 3000–3009. [Google Scholar] [CrossRef]

- Lee, Y.-J.; Kim, J.-G.; Kim, J.-H.; Yun, J.; Jang, W.J. Detection of Dimethyl Methylphosphonate (DMMP) Using Polyhedral Oligomeric Silsesquioxane (POSS). J. Nanosci. Nanotechnol. 2018, 18, 6565–6569. [Google Scholar] [CrossRef]

- Ha, S.; Lee, M.; Seo, H.O.; Song, S.G.; Kim, K.S.; Park, C.H.; Kim, I.H.; Kim, Y.D.; Song, C. Structural Effect of Thioureas on the Detection of Chemical Warfare Agent Simulants. ACS Sens. 2017, 2, 1146–1151. [Google Scholar] [CrossRef]

- Devkota, J.; Ohodnicki, P.R.; Greve, D.W. SAW Sensors for Chemical Vapors and Gases. Sensors 2017, 17, 801. [Google Scholar] [CrossRef] [Green Version]

- Länge, K. Bulk and Surface Acoustic Wave Sensor Arrays for Multi-Analyte Detection: A Review. Sensors 2019, 19, 5382. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.H.; Chang, D.H.; Yoon, Y.S.; Lee, T.J.; Kang, S.J. Study on the Optimization of a Temperature Sensor Based on SAW Delay Line. J. Kor. Phys. Soc. 2004, 45, 1366–1371. [Google Scholar]

- Kim, E.; Kim, J.; Ha, S.; Song, C.; Kim, J.-H. Improved Performance of Surface Acoustic Wave Sensors by Plasma Treatments for Chemical Warfare Agents Monitoring. J. Nanosci. Nanotechnol. 2020, 20, 7145–7150. [Google Scholar] [CrossRef]

- Wohltjen, H. Mechanism of Operation and Design Considerations for Surface Acoustic Wave Device Vapour Sensors. Sens. Actuators 1984, 5, 307–325. [Google Scholar] [CrossRef]

- Kim, J.; Kim, E.; Kim, J.; Kim, J.-H.; Ha, S.; Song, C.; Jang, W.J.; Yun, J. Four-Channel Monitoring System with Surface Acoustic Wave Sensors for Detection of Chemical Warfare Agents. J. Nanosci. Nanotechnol. 2020, 20, 7151–7157. [Google Scholar] [CrossRef]

- Grate, J.W. Hydrogen-Bond Acidic Polymers for Chemical Vapor Sensing. Chem. Rev. 2008, 108, 726–745. [Google Scholar] [CrossRef] [PubMed]

- Hartmann-Thompson, C.; Hu, J.; Kaganove, S.N.; Keinath, S.E.; Keeley, D.L.; Dvornic, P.R. Hydrogen-Bond Acidic Hyperbranched Polymers for Surface Acoustic Wave (SAW) Sensors. Chem. Mater. 2004, 16, 5357–5364. [Google Scholar] [CrossRef]

- Kuo, S.W.; Chang, F.C. POSS Related Polymer Nanocomposites. Prog. Polym. Sci. 2011, 36, 1649–1696. [Google Scholar] [CrossRef]

- Lavoie, J.; Srinivasan, S.; Nagarajan, R. Using Cheminformatics to Find Simulants for Chemical Warfare Agents. J. Hazard. Mater. 2011, 194, 85–91. [Google Scholar] [CrossRef] [PubMed]

| a | b | R2 | |

|---|---|---|---|

| SAW-1 (POSS) | |||

| GA | 0.157 | 3.118 | - |

| GB | 0.024 | 0.803 | 0.984 |

| DMMP | 0.018 | 3.906 | 0.957 |

| SAW-2 (TU-1) | |||

| GA | 0.046 | −0.563 | - |

| GB | 0.008 | −0.157 | 0.991 |

| DMMP | 0.031 | −1.138 | 0.999 |

| SAW-3 (TU-2) | |||

| GA | 0.079 | −1.527 | - |

| GB | 0.011 | 0.048 | 0.972 |

| DMMP | 0.004 | 0.485 | 0.935 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Park, H.; Kim, J.; Seo, B.-I.; Kim, J.-H. SAW Chemical Array Device Coated with Polymeric Sensing Materials for the Detection of Nerve Agents. Sensors 2020, 20, 7028. https://doi.org/10.3390/s20247028

Kim J, Park H, Kim J, Seo B-I, Kim J-H. SAW Chemical Array Device Coated with Polymeric Sensing Materials for the Detection of Nerve Agents. Sensors. 2020; 20(24):7028. https://doi.org/10.3390/s20247028

Chicago/Turabian StyleKim, Jinuk, Hyewon Park, Jihyun Kim, Byung-Il Seo, and Joo-Hyung Kim. 2020. "SAW Chemical Array Device Coated with Polymeric Sensing Materials for the Detection of Nerve Agents" Sensors 20, no. 24: 7028. https://doi.org/10.3390/s20247028