Electrical Resistivity Measurements of Reinforced Concrete Slabs with Delamination Defects

Abstract

:1. Introduction

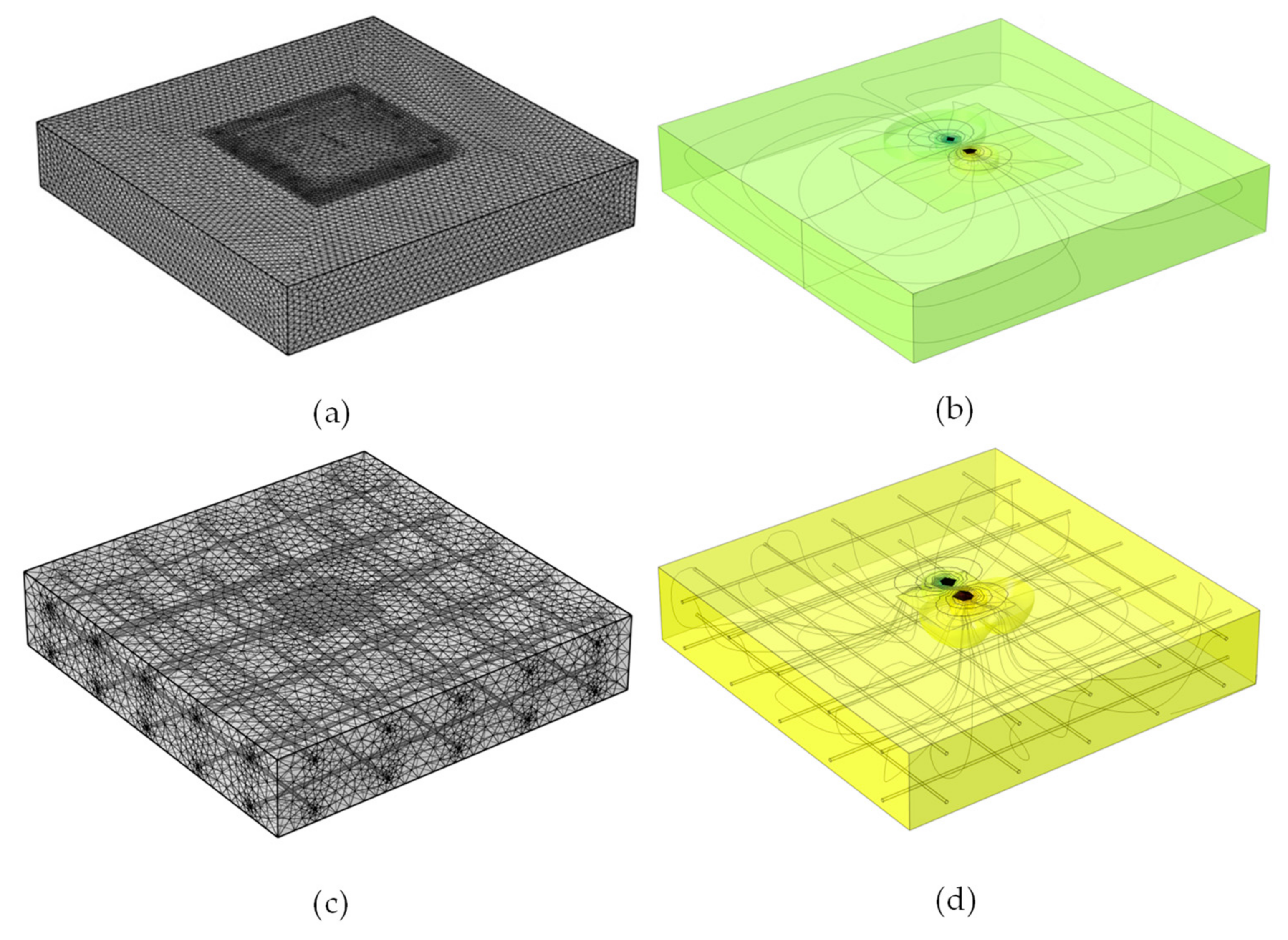

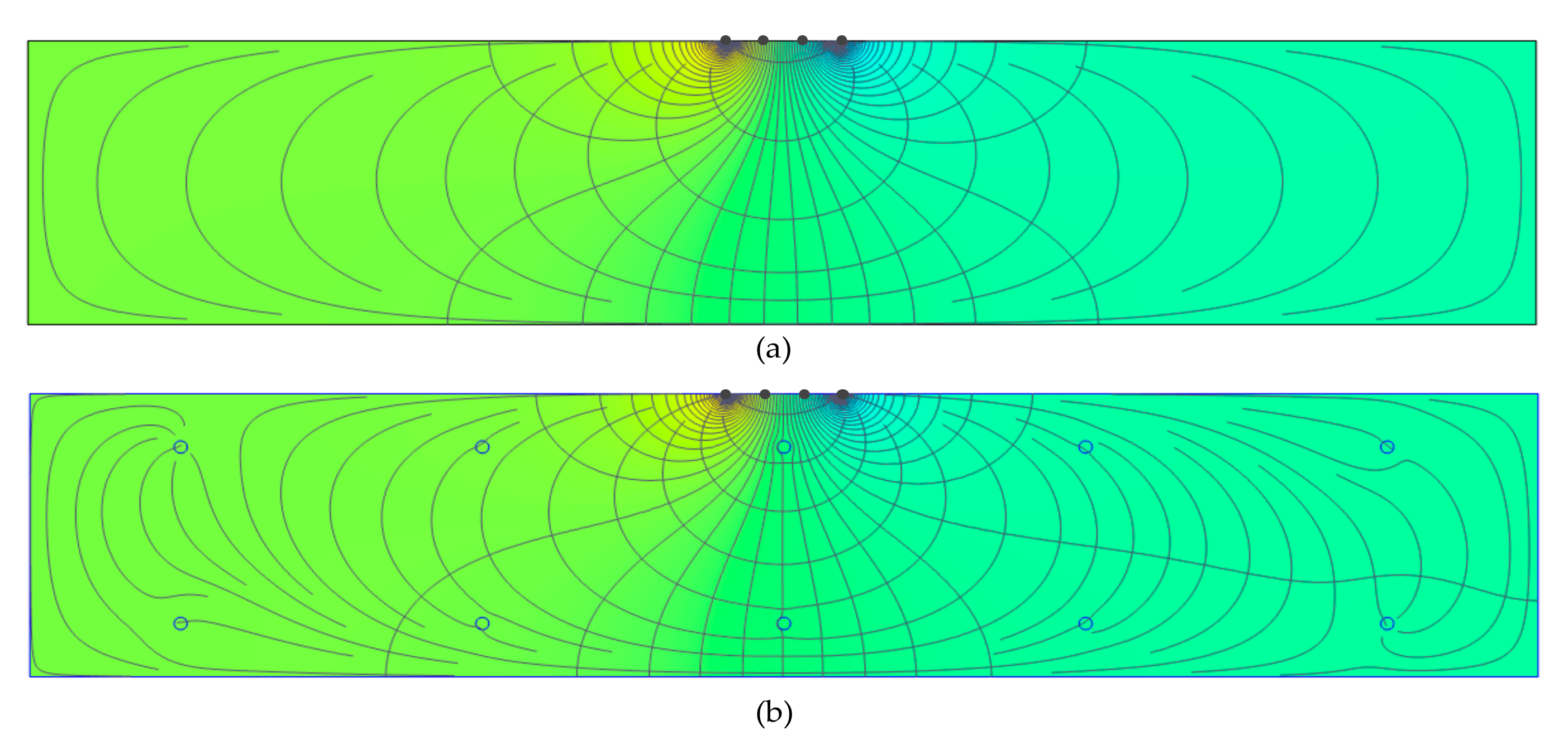

2. Numerical Simulation

Model Description

3. Experimental Study

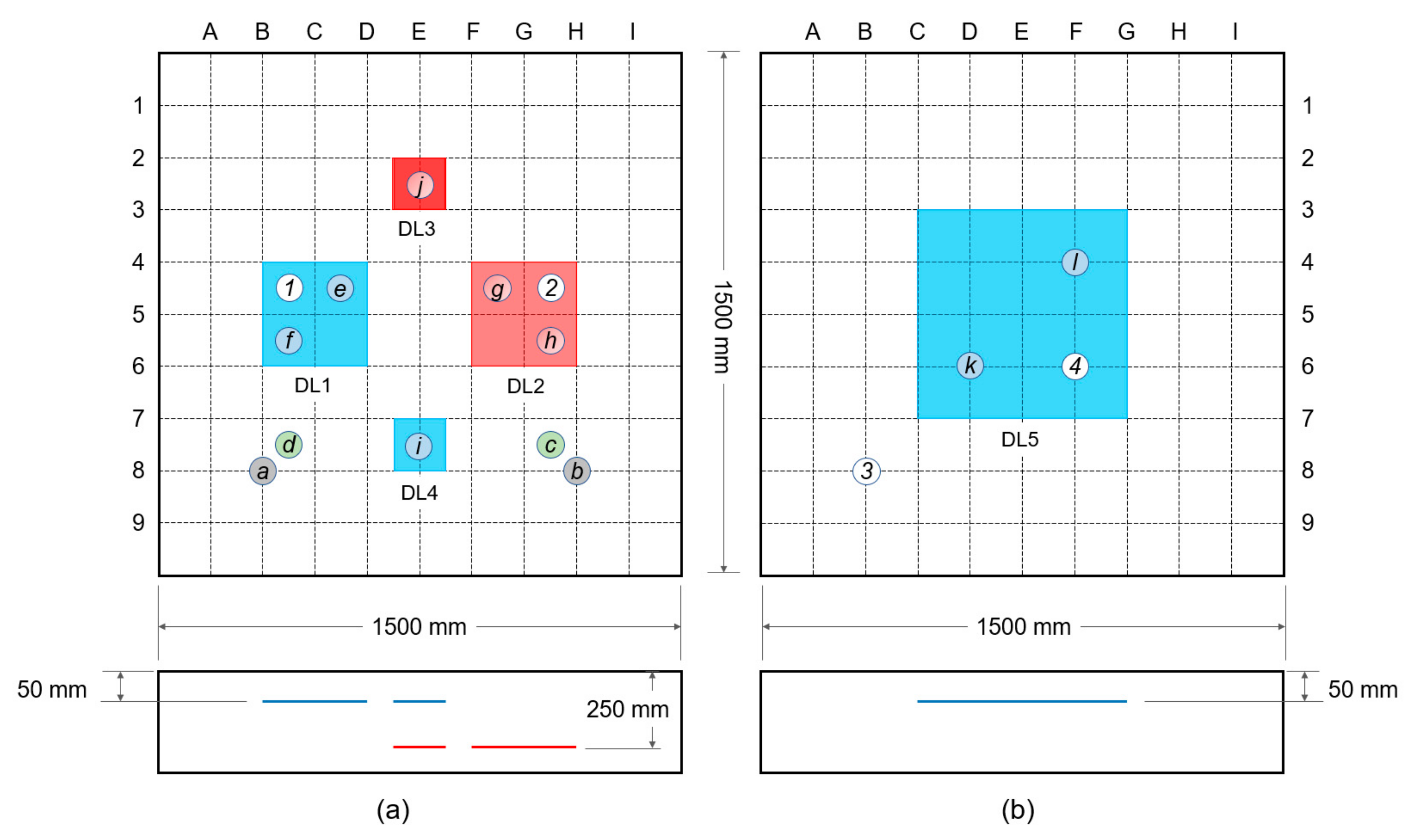

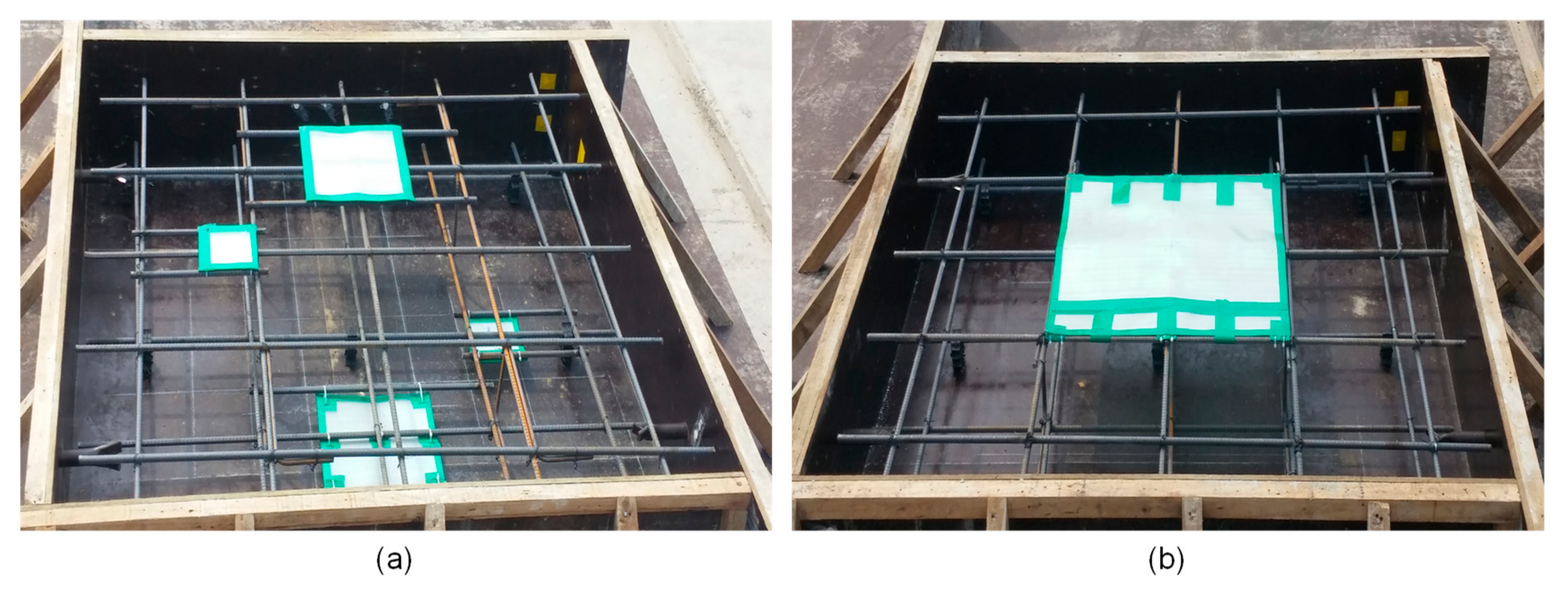

3.1. Preparation of Concrete Slab Specimens

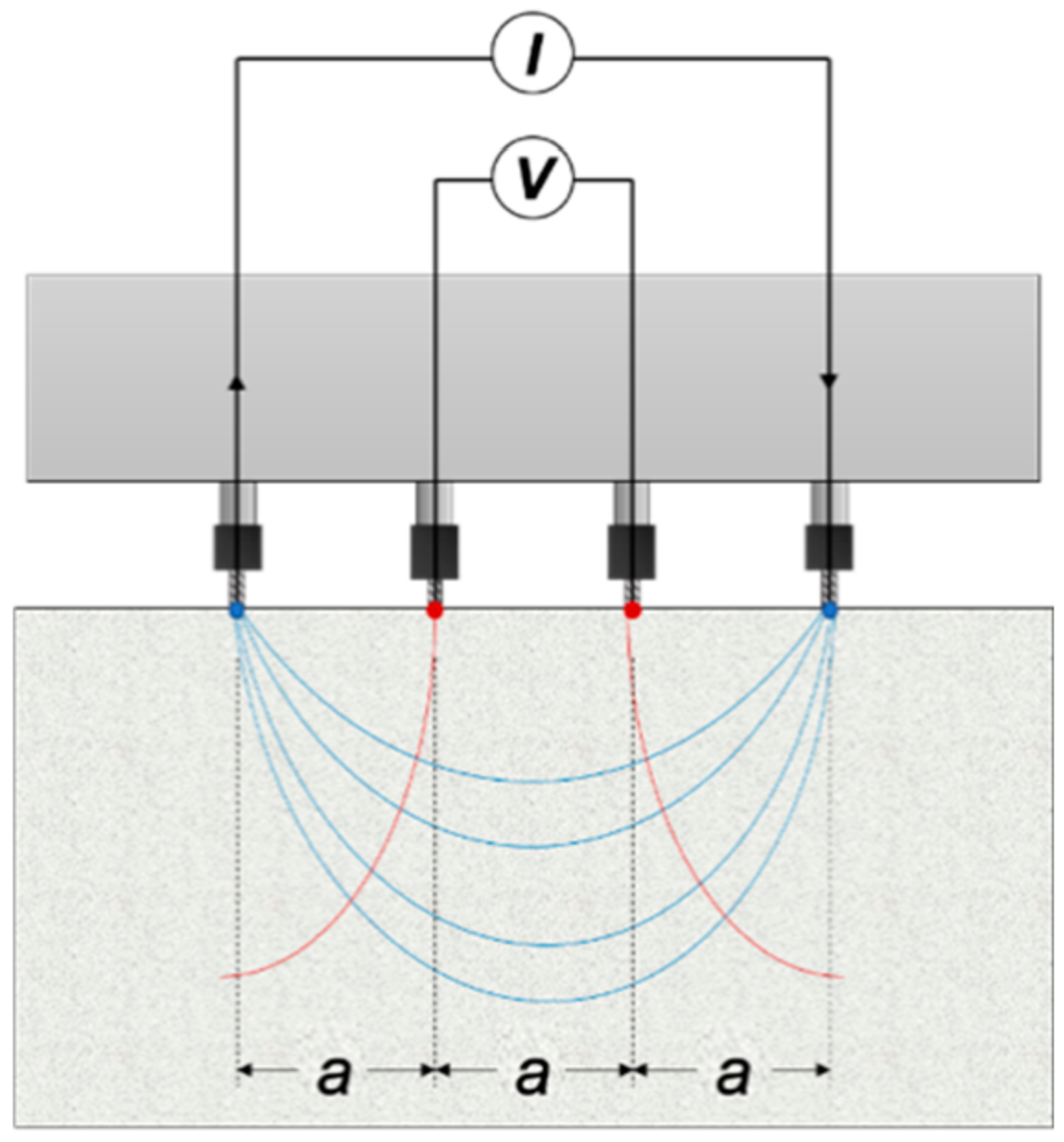

3.2. Electrical Resistivity Measurements

3.2.1. Test Setup

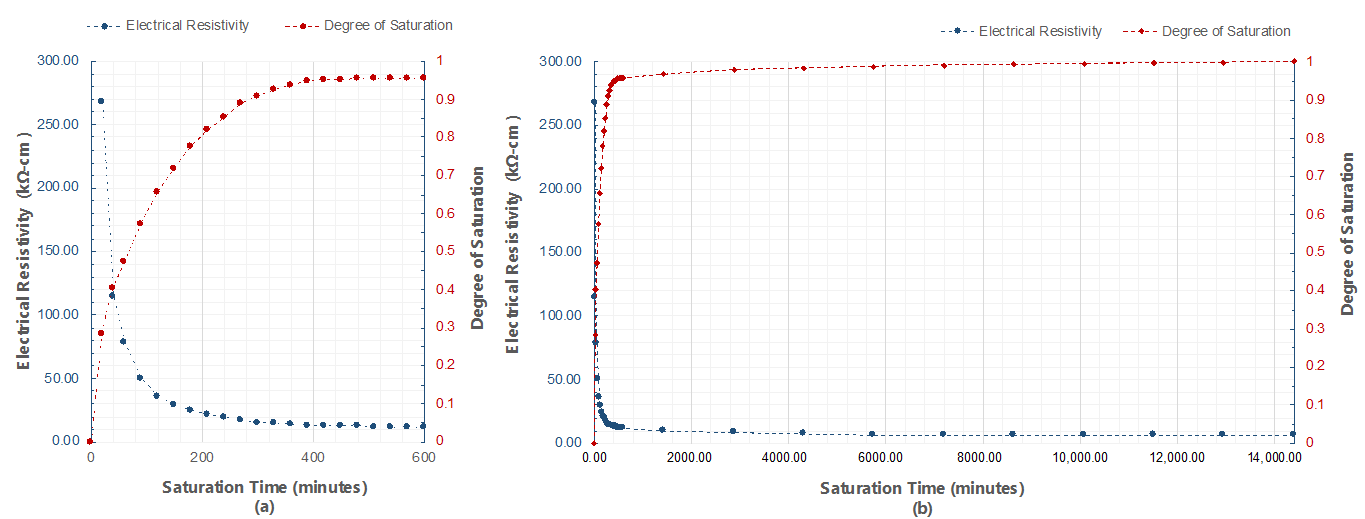

3.2.2. ER Measurements with Various Concrete Saturation Conditions

3.2.3. ER Measurements over Various Delamination Defects

4. Results and Discussion

4.1. Experimental Variability of Electrical Resistivity Measurements

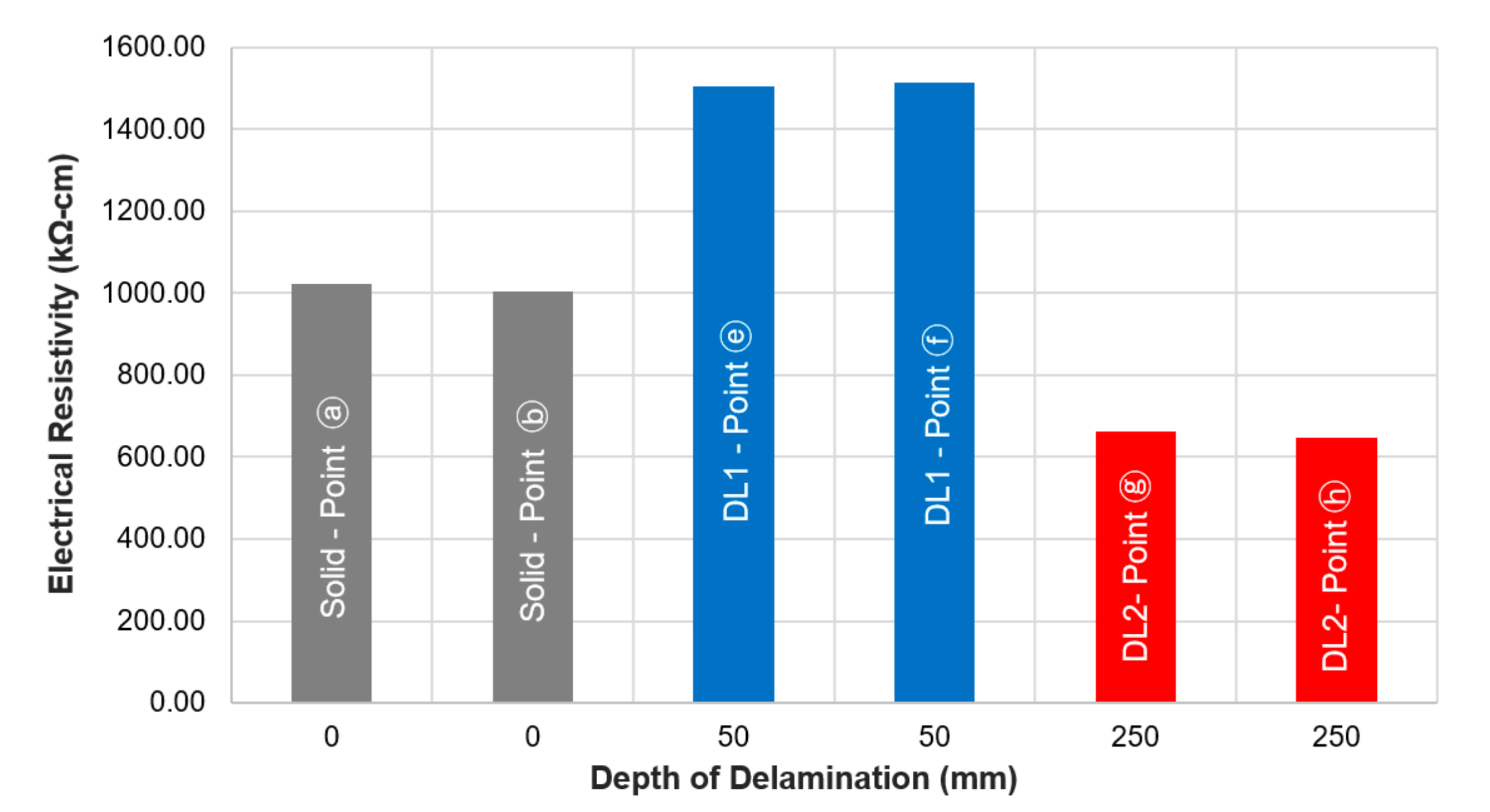

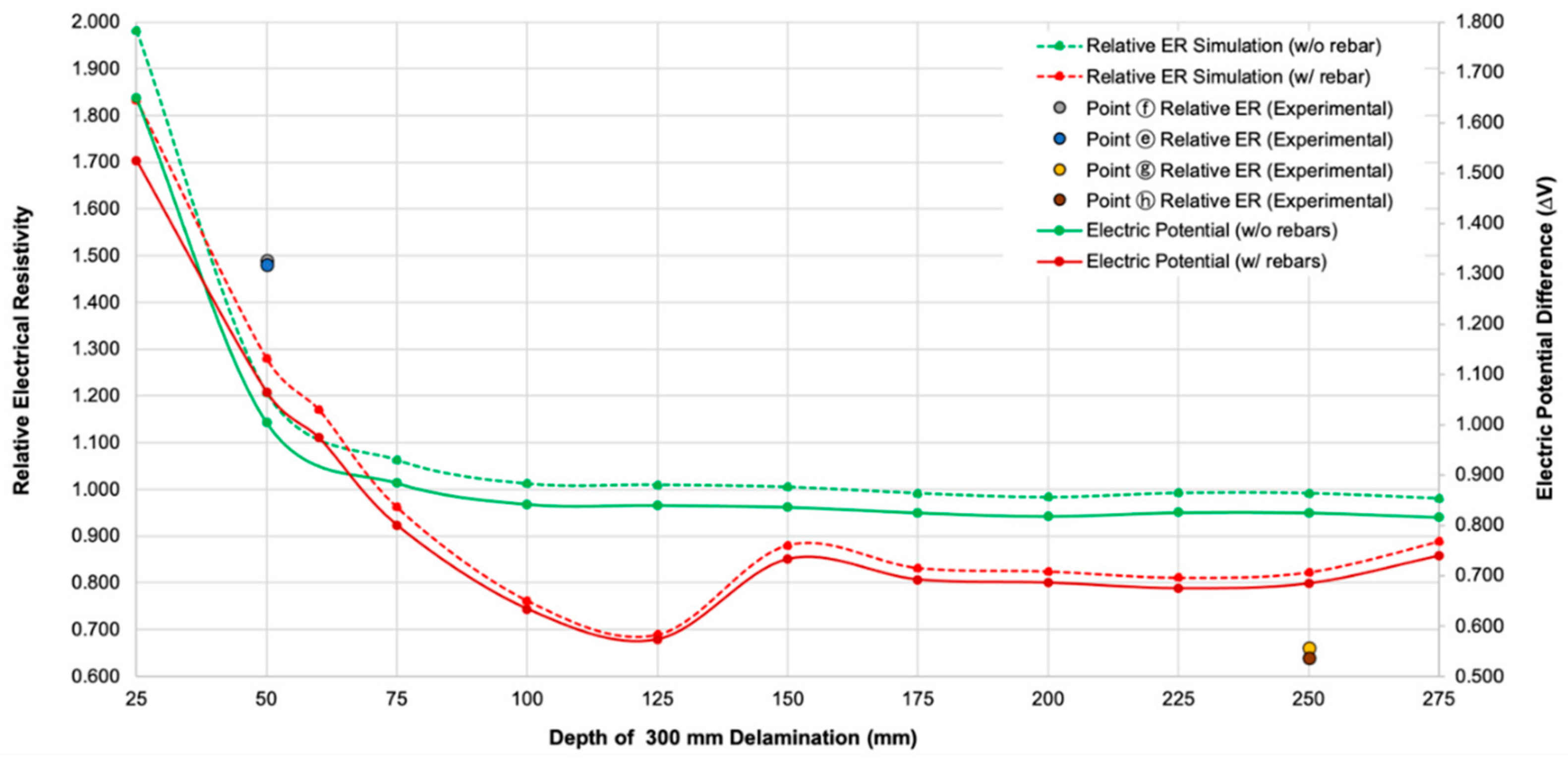

4.2. Effect of the Depth of Delamination Defects

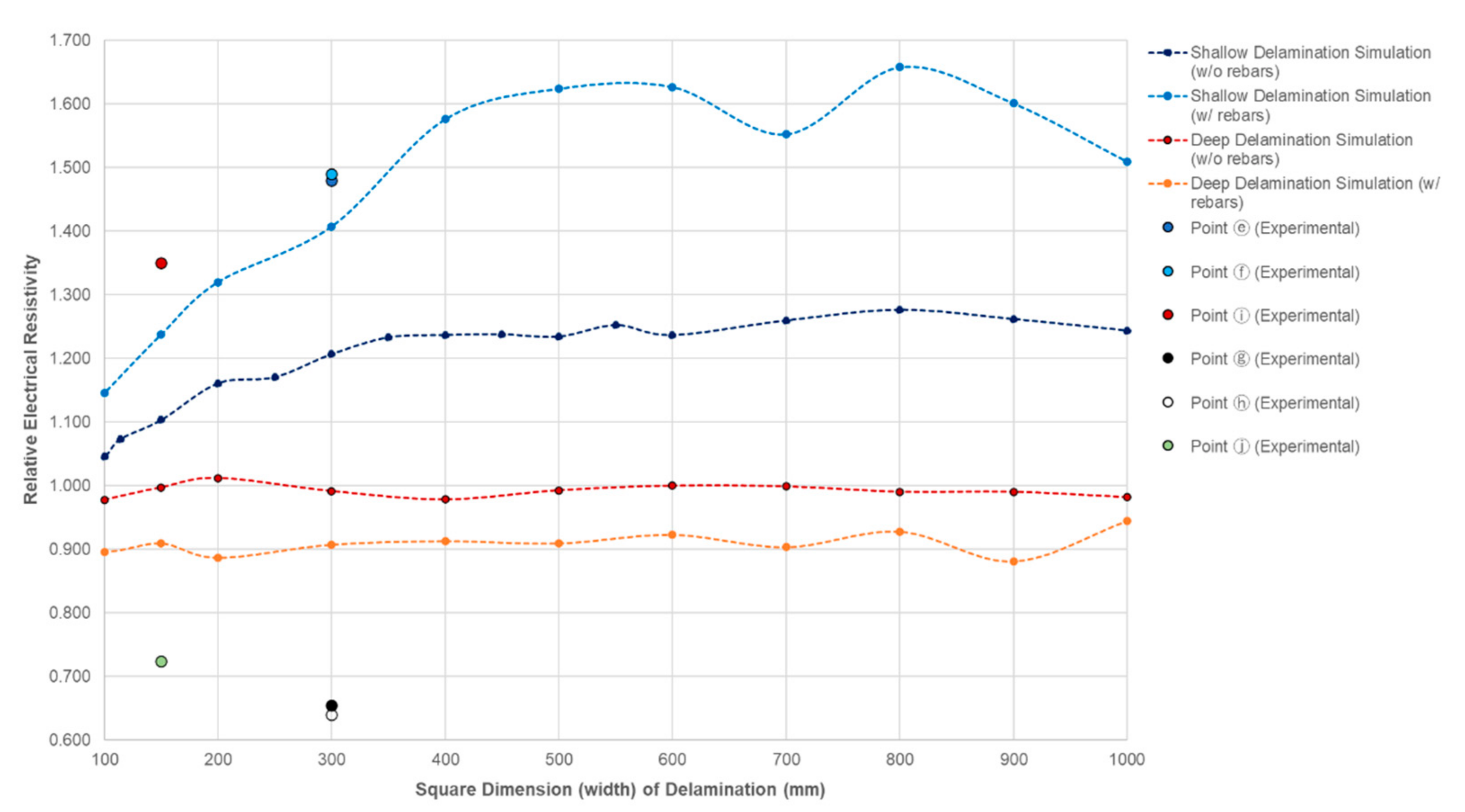

4.3. Effect of the Width of Delamination Defects

4.4. Effect of Configuration of Wenner Probe Device

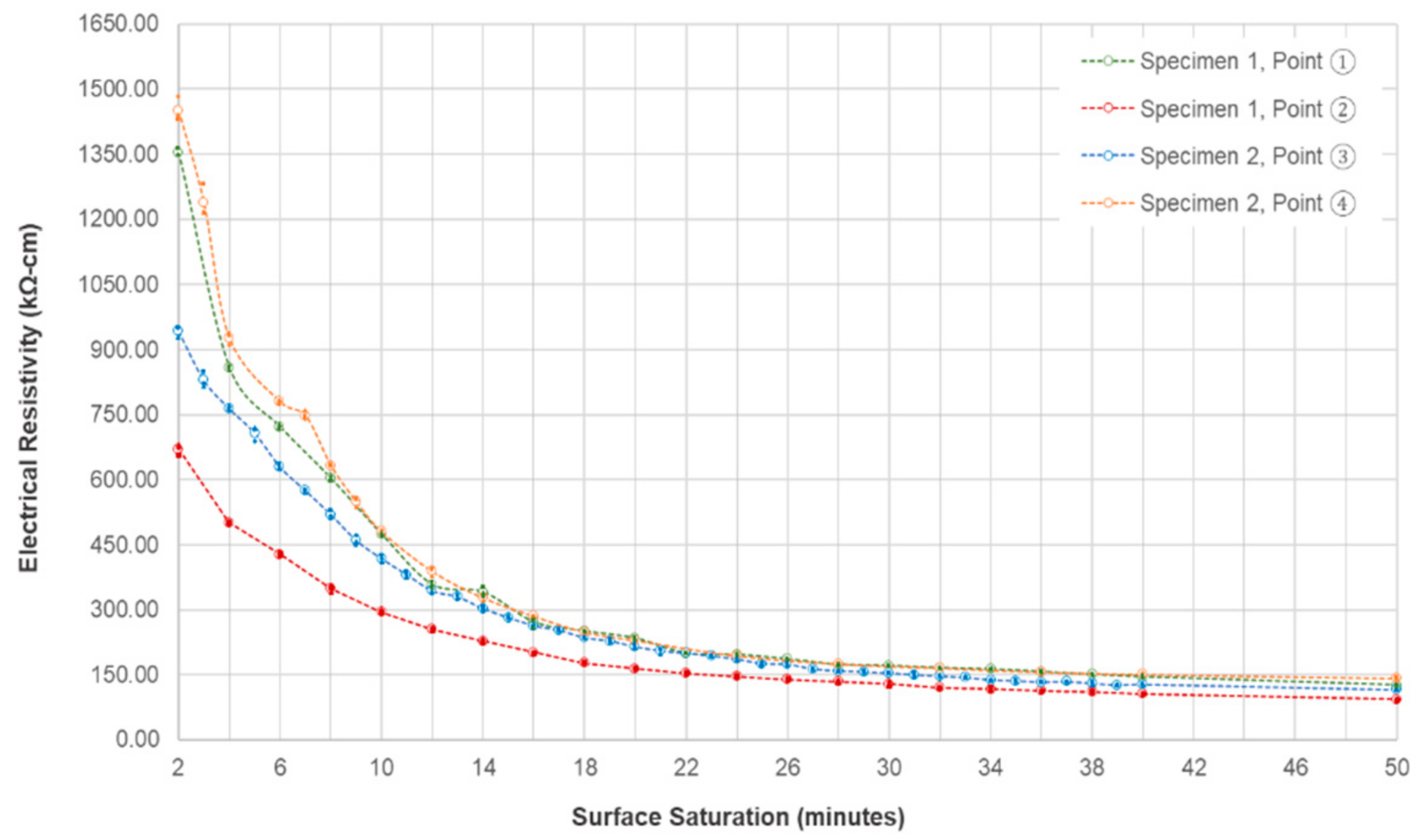

4.5. Effect of Surface Saturation

5. Conclusions

- (1)

- ER measurements conducted in this paper are variably controlled and precise considering that the COV computed are lower or near the values set by AASHTO TP358-15. ER values gathered also follow a normal distribution curve, which means that the measured ER data in this study can be represented by two statistical parameters (i.e., mean value and standard deviation).

- (2)

- The delamination defects in this study are divided into shallow delamination and deep delamination defects. Based on the experimental data gathered and the analysis of data conducted, it is deduced that shallow delamination defects (with depth of 50 mm), both small and large, contributes to a higher ER. On the other hand, small and large deep delamination defects (with depth of 250 mm) lead to a lower measured ER. The values gathered were compared to the ER of solid concrete. With reference to the average ER of solid concrete, the percent differences of shallow and deep delamination range from 26.90% to 49.35% and −17.19% to −47.19%, respectively.

- (3)

- It is observed in this study that the size of the delamination also affects the value of ER. As the size of the shallow delamination defects increases, the measured ER increases. On the other hand, the size of deep delamination defects is inversely proportional with the measured ER. It should be taken into consideration that measurements are done with the presence of steel reinforcement that may influence the values of ER, specifically for deep delamination defects, which are located below two layers of rebars.

- (4)

- It was concluded from the numerical simulation and experimental studies that ER values decrease with depth of delamination defects. For a plain concrete model, the relative ER closes to 1.0, whereas for reinforced concrete, relative ER decreases to 0.7. For the increase in size of delamination defects, shallow delamination defects in both plain and reinforced concrete models resulted in the increase in ER values. For deep delamination defects, the increase in size is negligible. Limitations are found in the numerical simulation, since other concrete properties and environmental factors such as degree of saturation, and the porous property of concrete were not included in the analysis. A more detailed and more systematic study of the effect of the presence of rebars, and/or the combination of the effect of the presence of reinforcements and delamination should be investigated both experimentally and numerically.

- (5)

- The presence of steel reinforcement has an effect on the measurements, resulting in a lower value of ER. Among the probe configurations used, the configuration C5, where the device was placed directly on top of the rebar, produced the smallest ER, whereas measurements made using C4 (the probe is perpendicular to the rebar), and C6 (probe is placed diagonally to the mesh) were within the range of the first three configurations. It can be inferred in this study that the presence of rebar near locations of measurements leads to a lower resistivity value. Measurements done at DL5, in which rebars are farther as compared to the points considered in shallow delamination of the concrete slab specimen 1, have overflowing (OF), or very high measurements.

- (6)

- It is established in this research that constant surface saturation decreases the value of ER. It is also established in this experiment that the gap of the ER measured along solid concrete locations and delaminated zones decreases due to the constant surface saturation of concrete. It is recommended in this study that in actual field measurements, to minimize the effect of delamination defects, saturation of the concrete surface should be done for at least 20–30 min. However, for measurements that are done right away (approximately at the first two minutes), delamination defects will greatly affect the ER measurements.

Author Contributions

Funding

Conflicts of Interest

References

- Valipour, M.; Yekkalar, M.; Shekarchi, M.; Panahi, S. Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J. Clean. Prod. 2014, 65, 418–423. [Google Scholar] [CrossRef]

- Damtoft, J.S.; Lukasik, J.; Herfort, D.; Sorrentino, D.; Gartner, E.M. Sustainable development and climate change initiatives. Cem. Concr. Res. 2008, 38, 115–127. [Google Scholar] [CrossRef]

- Gagg, C.R. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- IPCC. Carbon Dioxide Capture and Storage: Special Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Yekkalar, M.; Sabour, M.R.; Nikravan, M. The environmental impacts of concrete containing Nano-SiO2 and typical concrete on global warming and fossil fuel depletion: A comparison. In Proceedings of the 3rd International Symposium on Life-Cycle Civil Engineering, Vienna, Austria, 3–6 October 2012. [Google Scholar]

- Abduljabbar, R.A. Nondestructive Evaluation of Corrosion Damage in Reinforced Concrete Aged Slab Specimen. Ph.D. Thesis, University of South Carolina, Columbia, SC, USA, 2018; p. 95. [Google Scholar]

- Davalos, J.F. Advanced Materials for Civil Infrastructure Rehabilitation and Protection. In FCLU Public Seminar; The Hong Kong Polytechnic University: Hongkong, China, 2010; p. 1. [Google Scholar]

- Pacheco-Torgal, F. Introduction. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–12. [Google Scholar]

- Hussain, R.R.; Ishida, T. Enhanced electro-chemical corrosion model for reinforced concrete under severe coupled action of chloride and temperature. Constr. Build. Mater. 2011, 25, 1305–1315. [Google Scholar] [CrossRef]

- Markeset, G.; Mytdal, R. Modelling of reinforcement corrosion in concrete-State of the art. SINTEF Build. Infrastuct. 2008, 1891–1978. [Google Scholar] [CrossRef]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Monitoring Corrosion of Steel Bars in Reinforced Concrete Structures. Sci. World J. 2014, 2014, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Otieno, M.; Beushausen, H.; Alexander, M. Resistivity-based chloride-induced corrosion rate prediction models and hypothetical framework for interpretation of resistivity measurements in cracked RC structures. Mater. Struct. 2016, 49, 2349–2366. [Google Scholar] [CrossRef]

- Yu, B.; Liu, J.; Chen, Z. Probabilistic evaluation method for corrosion risk of steel reinforcement based on concrete resistivity. Constr. Build. Mater. 2017, 138, 101–113. [Google Scholar] [CrossRef]

- Morris, W.; Vico, A.; Vázquez, M. Chloride induced corrosion of reinforcing steel evaluated by concrete resistivity measurements. Electrochim. Acta 2004, 49, 4447–4453. [Google Scholar] [CrossRef]

- González, J.; Miranda, J.; Feliu, S. Considerations on reproducibility of potential and corrosion rate measurements in reinforced concrete. Corros. Sci. 2004, 46, 2467–2485. [Google Scholar] [CrossRef]

- Ahmad, S. An experimental study on correlation between concrete resistivity and reinforcement corrosion rate. Anti-Corros. Methods Mater. 2014, 61, 158–165. [Google Scholar] [CrossRef]

- Sengul, O. Use of electrical resistivity as an indicator for durability. Constr. Build. Mater. 2014, 73, 434–441. [Google Scholar] [CrossRef]

- Van Noort, R.; Hunger, M.; Spiesz, P.P. Long-term chloride migration coefficient in slag cement-based concrete and resistivity as an alternative test method. Constr. Build. Mater. 2016, 115, 746–759. [Google Scholar] [CrossRef]

- Isfahani, F.T.; Redaelli, E.; Lollini, F.; Li, W.; Bertolini, L. Effects of Nanosilica on Compressive Strength and Durability Properties of Concrete with Different Water to Binder Ratios. Adv. Mater. Sci. Eng. 2016, 2016, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Pilvar, A.; Ramezanianpour, A.A.; Rajaie, H. Comparison of Four Electrical Measurement Methods with Bulk Diffusion for Assessing the Chloride Resistance of Concretes. Iran. J. Sci. Technol. Trans. Civ. Eng. 2016, 40, 327–336. [Google Scholar] [CrossRef]

- Presuel-Moreno, F.J. Effect of w/cm and Composition on Correlations of Concrete Electrical Resistivity and Chloride Migration Coefficients. Key Eng. Mater. 2016, 711, 21–28. [Google Scholar] [CrossRef]

- Wei, X.; Xiao, L. Influence of the aggregate volume on the electrical resistivity and properties of portland cement concretes. J. Wuhan Univ. Technol. Sci. Ed. 2011, 26, 965–971. [Google Scholar] [CrossRef]

- Priou, J.; Lecieux, Y.; Chevreuil, M.; Gaillard, V.; Lupi, C.; LeDuc, D.; Rozière, E.; Guyard, R.; Schoefs, F. In situ DC electrical resistivity mapping performed in a reinforced concrete wharf using embedded sensors. Constr. Build. Mater. 2019, 211, 244–260. [Google Scholar] [CrossRef]

- Mendes, S.E.; Oliveira, R.L.; Cremonez, C.; Pereira, E.; Pereira, E.; Medeiros-Junior, R.A. Electrical resistivity as a durability parameter for concrete design: Experimental data versus estimation by mathematical model. Constr. Build. Mater. 2018, 192, 610–620. [Google Scholar] [CrossRef]

- Mishra, R.K. Early Age Strength and Electrical Resistivity of Concrete as Durability Indicator through Maturity. Int. J. Earth Sci. Eng. 2017, 10, 677–682. [Google Scholar] [CrossRef]

- De Bem, D.H.; Lima, D.P.B.; Medeiros-Junior, R.A. Effect of chemical admixtures on concrete’s electrical resistivity. Int. J. Build. Pathol. Adapt. 2018, 36, 174–187. [Google Scholar] [CrossRef]

- Presuel-Moreno, F.J.; Liu, Y.; Suares, A. Final Report: Characterization of New and Old Concrete Structures Using Surface Resistivity Measurements; ROSA P: Washington, DC, USA, 2010; p. 263. [Google Scholar]

- Gucunski, N.; Maher, A.; Basily, B.; La, H.; Lim, R.; Parvardeh, H.; Kee, S.H. Robotic platform rabit for condition assessment of concrete bridge decks using multiple nde technologies. HDKBR INFO Mag. 2013, 3, 5–12. [Google Scholar]

- Yoon, I.-S.; Nam, J.-W. Effect of water and chloride content on electrical resistivity in concrete. Comput. Concr. 2016, 18, 565–575. [Google Scholar] [CrossRef] [Green Version]

- [Hnin, S.W.; Sancharoen, P.; Tangtermsirikul, S. Effects of Concrete Mix Proportion on Electrical Resistivity of Concrete. Mater. Sci. Forum 2016, 866, 68–72. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Li, X.; Tan, J.; Li, J. Electrical resistivity of fly ash and metakaolin based geopolymers. Constr. Build. Mater. 2020, 234, 117868. [Google Scholar] [CrossRef]

- Lim, T.Y.D.; Teng, S.; Bahador, S.D.; Gjørv, O.E. Durability of Very-High-Strength Concrete with Supplementary Cementitious Materials for Marine Environments. ACI Mater. J. 2016, 113, 95–103. [Google Scholar] [CrossRef]

- AASHTO. AASHTO TP 95-11-Standard Test Method for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration; AASHTO: Washington, DC, USA, 2011; pp. 1–6. [Google Scholar]

- Taillet, E.; Lataste, J.; Rivard, P.; Denis, A. Non-destructive evaluation of cracks in massive concrete using normal dc resistivity logging. NDT E Int. 2014, 63, 11–20. [Google Scholar] [CrossRef]

- Silva, J.; Jalali, S.; Ferreira, R.M. Estimating Long-Term Durability Parameters Based on Electrical Resistivity Measurements. In Proceedings of the International Conference on Energy Efficient Technologies for Sustainability (ICEETS), Nagercoil, India, 7–8 April 2016. [Google Scholar] [CrossRef]

- Liu, Y.; Presuel-Moreno, F.J. Normalization of Temperature Effect on Concrete Resistivity by Method Using Arrhenius Law. ACI Mater. J. 2014, 111, 433–442. [Google Scholar] [CrossRef]

- Effect of Embedded Steel on Electrical Resistivity Measurements on Concrete Structures. ACI Mater. J. 2009, 106, 11–18. [CrossRef]

- Azarsa, P.; Gupta, R. Electrical Resistivity of Concrete for Durability Evaluation: A Review. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef] [Green Version]

- Alhajj, M.A.; Palma-Lopes, S.; Villain, G. Accounting for steel rebar effect on resistivity profiles in view of reinforced concrete structure survey. Constr. Build. Mater. 2019, 223, 898–909. [Google Scholar] [CrossRef]

- Chouteau, M.; Beaulieu, S. An Investigation on Application of the Electrical Resistivity Tomography Method to Concrete Structures. In Proceedings of the 2nd Annual Conference on the Application of Geophysical and NDT Methodologies to Transportation Facilities and Infrastructure, Los Angeles, CA, USA, 15–19 April 1998; pp. 3–10. [Google Scholar]

- Lataste, J.; Sirieix, C.; Breysse, D.; Frappa, M. Electrical resistivity measurement applied to cracking assessment on reinforced concrete structures in civil engineering. NDT E Int. 2003, 36, 383–394. [Google Scholar] [CrossRef]

- Huh, J.; Mac, V.H.; Tran, Q.H.; Lee, G.-Y.; Lee, J.-I.; Kang, C. Detectability of Delamination in Concrete Structure Using Active Infrared Thermography in Terms of Signal-to-Noise Ratio. Appl. Sci. 2018, 8, 1986. [Google Scholar] [CrossRef] [Green Version]

- Kee, S.-H.; Lee, J.-W.; Candelaria, M.D. Evaluation of Delamination in Concrete by IE Testing Using Multi-Channel Elastic Wave Data. Sensors 2019, 20, 201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nathan, A.J.; Scobell, A. How China sees America. Foreign Aff. 2012, 91, 32–47. [Google Scholar]

- Proceq. Resipod Family: Operating Instructions; Proceq: Schwerzenbach, Switzerland, 2013; p. 25. [Google Scholar]

- Bertolini, L.; Polder, R.B. Concrete resistivity and reinforcement corrosion rate as a function of temperature and humidity of the environment. TNO Build. Constr. Res. TNO Rep. 1997, 273, 12466–12475. [Google Scholar]

- Veselý, V.; Konený, P.; Konečný, P.; Pieszka, D.; Žídek, L. Electrical resistivity and ultrasonic measurements during sequential fracture test of cementitious composite. Frattura ed Integrità Strutturale 2014, 8, 263–272. [Google Scholar] [CrossRef] [Green Version]

- Feliu, S.; González, J.A.; Andrade, C. Relationship between conductivity of concrete and corrosion of reinforcing bars. Br. Corros. J. 1989, 24, 195–198. [Google Scholar] [CrossRef]

- Hamed, L.; Pouria Ghods, P.; Alizadeh, A.R.; Salehi, M. Electrical Resistivity of Concrete. Concr. Int. 2015, 37, 41–46. [Google Scholar]

- Polder, R.; Andrade, C.; Elsener, B.; Vennesland, Ø.; Gulikers, J.; Weidert, R.; Raupach, M. Rilem Technical Committees, Rilem Tc 154-Emc: Electrochemical Techniques for Measuring. Mater. Struct. Constr. 2001, 33, 603–611. [Google Scholar] [CrossRef]

- Alhozaimy, A.; Hussain, R.R.; Al-Negheimish, A. Electro-chemical investigation for the effect of rebar source and surface condition on the corrosion rate of reinforced concrete structures under varying corrosive environments. Constr. Build. Mater. 2020, 244, 118317. [Google Scholar] [CrossRef]

- Weydert, R.; Gehlen, C. Electrolytic resistivity of cover concrete: Relevance, measurement and interpretation. Durab. Build. Mater. Compon. 1999, 8, 409–419. [Google Scholar]

- Millard, S.G.; Wenner. REINFORCED CONCRETE RESISTIVITY MEASUREMENT TECHNIQUES. Proc. Inst. Civ. Eng. 1991, 91, 71–88. [Google Scholar] [CrossRef]

- Salehi, M.; Ghods, P.; Isgor, O.B. Numerical investigation of the role of embedded reinforcement mesh on electrical resistivity measurements of concrete using the Wenner probe technique. Mater. Struct. 2014, 49, 301–316. [Google Scholar] [CrossRef]

- Sengul, O.; Gjørv, O.E. Electrical resistivity measurements for quality control during concrete construction. ACI Mater. J. 2008, 105, 541–547. [Google Scholar] [CrossRef]

- AASHTO. AASHTO Designation: T 358-15 - Standard Method of Test for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration; American Association of State Highway and Transportation Officials: Washington DC, USA, 2015. [Google Scholar]

- Larsen, C.K.; Østvik, J.-M.; Bjøntegaard, Ø. Compilation of 5 papers on (1) Electrical resistivity as a durability indicator and (2) Cracking tendency in hardening concrete. In Teknologirapport; no. 2482; Statens Vegvesen: Oslo, Norway, 2007; pp. 1–67. [Google Scholar]

- Charmchi, G. The Role of Concrete Maturity in Resistivity-Based Performance Specifications. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2015; p. 85. [Google Scholar]

- Chen, C.T.; Chang, J.J.; Yeih, W.C. The effects of specimen parameters on the resistivity of concrete. Constr. Build. Mater. 2014, 71, 35–43. [Google Scholar] [CrossRef]

- Djuric, Z.; Müller, H.S. Modelling of the saturation behaviour of cement stone during freezing and thawing action. In Proceedings of the 9th fib International PhD Symposium in Civil Engineering, Karlsruhe, Germany, 22–25 July 2012; pp. 529–534. [Google Scholar]

| Measured Location | Configuration | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | ||||||||

| μ | COV | μ | COV | μ | COV | μ | COV | μ | COV | μ | COV | ||

| ⓐ | Solid 1 | 1021 | 6.06 | 1084 | 4.97 | 1023 | 4.36 | -4 | - | - | |||

| ⓑ | 1003 | 1.37 | 1086 | 1.48 | 1020 | 4.19 | |||||||

| ⓒ | Solid 2 | 1028 | 3.19 | 1123 | 5.26 | 929 | 5.69 | 1093 | 4.80 | 856 | 2.81 | 1009 | 4.46 |

| ⓓ | 1021 | 3.10 | 970 | 3.50 | 980 | 2.24 | 995 | 1.92 | 821 | 4.72 | 1054 | 3.30 | |

| ⓔ | DL1 | 1504 | 1.15 | 1474 | 2.16 | 1457 | 1.73 | 1439 | 2.19 | 1427 | 3.04 | 1471 | 1.49 |

| ⓕ | 1512 | 1.03 | 1449 | 2.64 | 1452 | 2.45 | 1477 | 3.40 | 1377 | 1.74 | 1414 | 1.95 | |

| ⓖ | DL2 | 663 | 3.80 | 699 | 6.69 | 678 | 5.59 | 656 | 7.08 | 573 | 4.48 | 635 | 6.47 |

| ⓗ | 646 | 6.41 | 676 | 2.48 | 651 | 3.67 | 708 | 2.54 | 588 | 6.01 | 686 | 5.12 | |

| ⓛ | DL5 | OF 3 | -5 | OF | - | OF | - | OF | - | OF | - | OF | - |

| ⓚ | OF | - | OF | - | OF | - | OF | - | OF | - | OF | - | |

| Measured Location | Configuration | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C7 | C8 | C9 | C10 | ||||||

| μ | COV | μ | COV | μ | COV | μ | COV | ||

| ⓘ | DL3 | 1419 | 3.11 | 1362 | 3.35 | 1392 | 1.28 | 1384 | 5.64 |

| ⓙ | DL4 | 838 | 2.72 | 733 | 3.76 | 615 | 5.94 | 746 | 5.31 |

| Measured Location | Probe Configuration | ||||||

|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | ||

| ⓐ | Solid 1 | 0.0904 | 0.0983 | 0.0723 | - | - | - |

| ⓑ | 0.0885 | 0.1039 | 0.0731 | - | - | - | |

| ⓒ | Solid 2 | 0.1369 | 0.0793 | 0.1122 | 0.1499 | 0.0930 | 0.1530 |

| ⓓ | 0.1511 | 0.1072 | 0.1457 | 0.1087 | 0.0630 | 0.0664 | |

| ⓔ | DL1 | 0.1276 | 0.1182 | 0.0839 | 0.0814 | 0.1248 | 0.0737 |

| ⓕ | 0.0891 | 0.0735 | 0.0000 | 0.1010 | 0.1319 | 0.1345 | |

| ⓖ | DL2 | 0.1275 | 0.0923 | 0.1886 | 0.0804 | 0.1209 | 0.0934 |

| ⓗ | 0.0835 | 0.1073 | 0.1147 | 0.0779 | 0.2785 | 0.0766 | |

| Measurement Points | Probe Configuration | ||||

|---|---|---|---|---|---|

| C7 | C8 | C9 | C10 | ||

| ⓘ | DL3 | 0.0971 | 0.1006 | 0.1281 | 0.1811 |

| ⓙ | DL4 | 0.0841 | 0.0813 | 0.1286 | 0.1173 |

| Square Dimension of Delamination (mm) | Electrical Resistivity [kΩ-cm] | |

|---|---|---|

| Shallow | Deep | |

| 150 | 1362.0 | 733.4 |

| 300 | 1504.4 | 663.6 |

| 600 | OF | Not available |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robles, K.P.V.; Kim, D.-W.; Yee, J.-J.; Lee, J.-W.; Kee, S.-H. Electrical Resistivity Measurements of Reinforced Concrete Slabs with Delamination Defects. Sensors 2020, 20, 7113. https://doi.org/10.3390/s20247113

Robles KPV, Kim D-W, Yee J-J, Lee J-W, Kee S-H. Electrical Resistivity Measurements of Reinforced Concrete Slabs with Delamination Defects. Sensors. 2020; 20(24):7113. https://doi.org/10.3390/s20247113

Chicago/Turabian StyleRobles, Kevin Paolo V., Dong-Won Kim, Jurng-Jae Yee, Jin-Wook Lee, and Seong-Hoon Kee. 2020. "Electrical Resistivity Measurements of Reinforced Concrete Slabs with Delamination Defects" Sensors 20, no. 24: 7113. https://doi.org/10.3390/s20247113

APA StyleRobles, K. P. V., Kim, D.-W., Yee, J.-J., Lee, J.-W., & Kee, S.-H. (2020). Electrical Resistivity Measurements of Reinforced Concrete Slabs with Delamination Defects. Sensors, 20(24), 7113. https://doi.org/10.3390/s20247113