Design and Testing of Inertial System for Landslide Displacement Distribution Measurement

Abstract

:1. Introduction

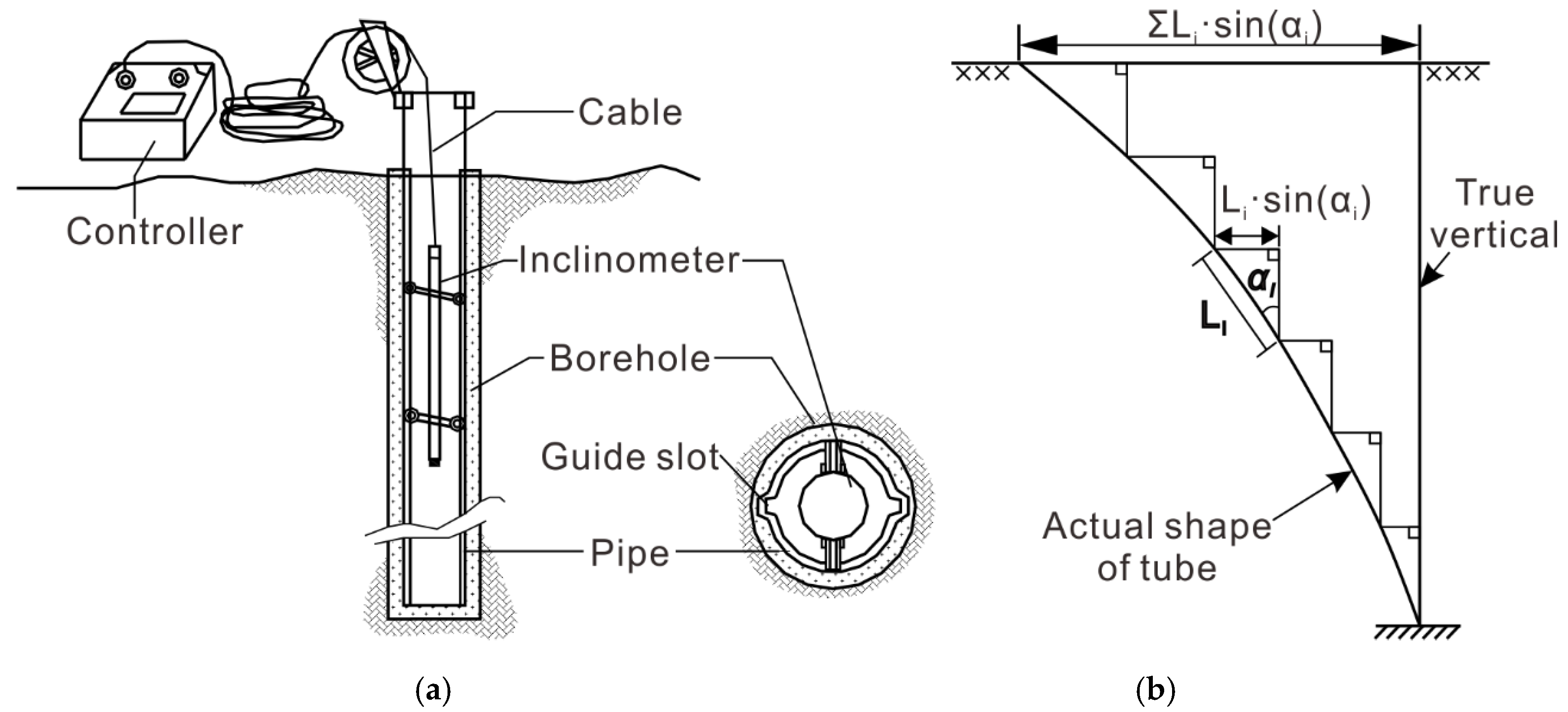

2. Introduction of Inertial Measurement in Landslide Displacement Measurement

2.1. Matching of Inertial System

2.2. Establishment of Measurement Method

3. Measuring Instrument Design

3.1. Overall Design Scheme

3.2. Mechanical Structure

3.3. Measuring Circuit Design

3.4. Pipeline Trajectory and Landslide Displacement Solution

3.4.1. Trajectory Attitude Solution

3.4.2. Dynamic Correction of Attitude Angle

Effect of the -axis Acceleration on the Pitch

Effect of the -axis and -axis Angular Velocities and on

3.4.3. Pipeline Trajectory Curve Calculation

3.4.4. Landslide Displacement Calculation

4. Test Results and Application

4.1. Test Results

4.2. Application

5. Discussion

6. Conclusions

- (1)

- Combination of sensor. Considering the engineering geological conditions, contact measurements were applied to measure the axial linear velocity of the pipeline, a single-axis gyro was adopted to measure the azimuth, and gravitational acceleration was selected as the reference physical variable of the roll angle and pitch angle. Therefore, the final combination of sensors was presented as a “single-axis gyro + two accelerometers + external roller coded program” and made up a simplified semiplatform-semistrap inertial measurement model.

- (2)

- Configuration of mechanical structure. The instrument was enclosed in a modular cabin. The cabin was mainly comprised of the sensor compartment, circuit compartment, battery compartment, and console, and all were sealed in the cylinder sleeve. Additionally, two sets of support claws formed by six uniformly distributed rollers were assembled at both ends of the instrument, and a two-phase electromagnetic encoder was assembled on the roller for velocity measurement.

- (3)

- Calculation of displacement distribution. The attitude angle, e.g., pitch angle, roll angle and azimuth angle at each measurement moment, was calculated by the monitoring results of the two-axis accelerometer and one-axis gyro. Then, according to an Eulerian transformation with regard to the attitude angle, the axial linear velocity was projected to a reference frame. Finally, the pipeline trajectory was calculated by the integration of three-axes-projected linear velocity, and the difference of trajectory monitored at each measurement moment was considered as the displacement distribution of a landslide. It is stressed that the accumulation of axial linear acceleration will affect the precision of the pitch angle when unavoidably added to the pitch angle accelerometer, which, however, should be removed in the calculation.

- (4)

- Verification and application. Compared with the results of the total station and trajectory measurements applied in a simulating pipeline, the instrument exhibited a high precision of 3 cm/100 m in multiple singly periodic measurements, which meets the displacement measurement requirement of landslides with medium precision. Conversely, the instrument was successfully applied to the deformation monitoring of the Majiagou I# landslide when fully considering the engineering geological conditions.

Author Contributions

Funding

Conflicts of Interest

References

- Cruden, D.M.; Varnes, D.J. Landslides: Investigation and Mitigation. Chapter 3-Landslide Types and Processes; Transportation Research Board Special Report, Issue Number 247; Transportation Research Board: Washington, DC, USA, 1996; pp. 36–75, ISSN 0360-859X. [Google Scholar]

- Guzzetti, F. Landslide Hazard and Risk Assessment. Ph.D. Thesis, University of Bonn, Bonn, Germany, 2006; pp. 25–30. [Google Scholar]

- Tang, H.; Wasowski, J.; Juang, C.H. Geohazards in the three Gorges Reservoir Area, China—Lessons learned from decades of research. Eng. Geol. 2019, 261, 105267. [Google Scholar] [CrossRef]

- Yao, W.; Li, C.; Zhan, H.; Zhou, J.-Q.; Criss, R.E.; Xiong, S.; Jiang, X. Multiscale Study of Physical and Mechanical Properties of Sandstone in Three Gorges Reservoir Region Subjected to Cyclic Wetting-Drying of Yangtze River Water. Rock Mech. Rock Eng. 2020, 53, 2215–2231. [Google Scholar] [CrossRef]

- Li, C.; Fu, Z.; Wang, Y.; Tang, H.; Yan, J.; Gong, W.; Yao, W.; Criss, R.E. Susceptibility of reservoir-induced landslides and strategies for increasing the slope stability in the Three Gorges Reservoir Area: Zigui Basin as an example. Eng. Geol. 2019, 261, 105279. [Google Scholar] [CrossRef]

- Simeoni, L.; Ronchetti, F.; Costa, C.; Joris, P.; Corsini, A. Redundancy and coherence of multi-method displacement monitoring data as key issues for the analysis of extremely slow landslides (Isarco valley, Eastern Alps, Italy). Eng. Geol. 2020, 267, 105504. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, C.; Huang, B.; Ren, X.; Liu, C.; Hu, B.; Chen, Z. Landslide displacement prediction based on multi-source data fusion and sensitivity states. Eng. Geol. 2020, 271, 105608. [Google Scholar] [CrossRef]

- Huntley, D.; Bobrowsky, P.; Hendry, M.; Macciotta, R.; Best, M. Multi-technique geophysical investigation of a very slow-moving landslide near Ashcroft, British Columbia, Canada. J. Environ. Eng. Geophys. 2019, 24, 87–110. [Google Scholar] [CrossRef]

- Sun, Y.-J.; Zhang, D.; Shi, B.; Tong, H.-J.; Wei, G.-Q.; Wang, X. Distributed acquisition, characterization and process analysis of multi-field information in slopes. Eng. Geol. 2014, 182, 49–62. [Google Scholar] [CrossRef]

- Squarzoni, C.; Delacourt, C.; Allemand, P. Differential single-frequency GPS monitoring of the La Valette landslide (French Alps). Eng. Geol. 2005, 79, 215–229. [Google Scholar] [CrossRef]

- Schlögel, R.; Doubre, C.; Malet, J.-P.; Masson, F. Landslide deformation monitoring with ALOS/PALSAR imagery: A D-InSAR geomorphological interpretation method. Geomorphology 2015, 231, 314–330. [Google Scholar] [CrossRef]

- Jaboyedoff, M.; Oppikofer, T.; Abellán, A.; Derron, M.-H.; Loye, A.; Metzger, R.; Pedrazzini, A. Use of LIDAR in landslide investigations: A review. Nat. Hazards 2012, 61, 5–28. [Google Scholar] [CrossRef] [Green Version]

- Corsini, A.; Bonacini, F.; Mulas, M.; Petitta, M.; Ronchetti, F.; Truffelli, G. Long-Term Continuous Monitoring of a Deep-Seated Compound Rock Slide in the Northern Apennines; Springer International Publishing: Cham, Switzerland, 2015; pp. 1337–1340. [Google Scholar]

- Simeoni, L.; Mongiovì, L. Inclinometer monitoring of the Castelrotto landslide in Italy. J. Geotech. Geoenviron. Eng. 2007, 133, 653–666. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Tang, H.M.; Li, C.D.; Lu, G.Y.; Cai, Y.; Zhang, J.R.; Tan, F.L. Design and Testing of a Flexible Inclinometer Probe for Model Tests of Landslide Deep Displacement Measurement. Sensors 2018, 18, 224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iten, M.; Puzrin, A.M.; Schmid, A. Landslide monitoring using a road-embedded optical fiber sensor. In Proceedings of the SPIE Smart Structures and Materials and Nondestructive Evaluation and Health Monitoring Symposium, San Diego, CA, USA, 9–13 March 2008. [Google Scholar]

- Zhu, H.-H.; Shi, B.; Zhang, C.-C. FBG-based monitoring of geohazards: Current status and trends. Sensors 2017, 17, 452. [Google Scholar] [CrossRef] [PubMed]

- Stangl, R.; Buchan, G.; Loiskandl, W. Field use and calibration of a TDR-based probe for monitoring water content in a high-clay landslide soil in Austria. Geoderma 2009, 150, 23–31. [Google Scholar] [CrossRef]

- Bellas, M.; Voulgaridis, G. Study of the major landslide at the community of Ropoto, Central Greece, mitigation and FBG early warning system design. Innov. Infrastruct. Solut. 2018, 3, 30. [Google Scholar] [CrossRef]

- Su, M.-B.; Chen, I.-H.; Liao, C.-H. Using TDR cables and GPS for landslide monitoring in high mountain area. J. Geotech. Geoenviron. Eng. 2009, 135, 1113–1121. [Google Scholar] [CrossRef] [Green Version]

- Stark, T.D.; Choi, H. Slope inclinometers for landslides. Landslides 2008, 5, 339. [Google Scholar] [CrossRef]

- Segalini, A.; Carini, C. Underground landslide displacement monitoring: A new MMES based device. In Landslide Science and Practice: Volume 2: Early Warning, Instrumentation and Monitoring; Margottini, C., Canuti, P., Sassa, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 87–93. [Google Scholar]

- Dost, B.; Gronz, O.; Casper, M.; Krein, A. The Potential of Smartstone Probes in Landslide Experiments: How to Read Motion Data. Nat. Hazards Earth Syst. Sci. Discuss. 2020. [Google Scholar] [CrossRef]

- Cina, A.; Manzino, A.M.; Bendea, I.H. Improving GNSS Landslide Monitoring with the Use of Low-Cost MEMS Accelerometers. Appl. Sci. 2019, 9, 5075. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Yin, Y.; Song, S. Use of micro-electromechanical systems inertial sensors as a geotechnical monitoring method for slope deformation. In Proceedings of the IAEG/AEG Annual Meeting, San Francisco, CA, USA, 17–21 September 2018; pp. 253–258. [Google Scholar]

- Harding, M.J.; Fussell, B.K.; Gullison, M.A.; Benoit, J.; de Alba, P.A. Design and Testing of a Debris Flow ‘Smart Rock’. Geotech. Test. J. 2014, 37, 20130172. [Google Scholar] [CrossRef]

- Mihalić Arbanas, S.; Arbanas, Ž. Landslide mapping and monitoring: Review of conventional and advanced techniques. In Proceedings of the 4th Symposium of Macedonian Association for Geotechnics (MAG), Struga, Macedonia, 25–28 June 2014; p. 57. [Google Scholar]

- Yao, W.; Li, C.; Zuo, Q.; Zhan, H.; Criss, R.E. Spatiotemporal deformation characteristics and triggering factors of Baijiabao landslide in Three Gorges Reservoir region, China. Geomorphology 2019, 343, 34–47. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Lu, G.Y.; Wu, X.M. A simplified model of inertial navigation system for underground pipeline track instrument. Adv. Mater. Res. 2012, 542–543, 895–900. [Google Scholar] [CrossRef]

- Khanh, D.Q.; Suh, Y.S. Mobile Robot Destination Generation by Tracking a Remote Controller Using a Vision-aided Inertial Navigation Algorithm. J. Electr. Eng. Technol. 2013, 8, 613–620. [Google Scholar]

- Hyun, D.; Yang, H.S.; Park, H.S.; Kim, H.J. Dead-reckoning sensor system and tracking algorithm for 3-D pipeline mapping. Mechatronics 2010, 20, 213–223. [Google Scholar] [CrossRef]

| Type of Movement | Axis | Physical Quantity | Measuring Device | Limiting Condition | Selection |

|---|---|---|---|---|---|

| Line motion | Linear acceleration | Accelerometer | None | ||

| Linear velocity | Encoder | Contact measurement | √ | ||

| Angular rotation | Angular velocity | Gyroscope | None | ||

| Angle | Gravity accelerometer | Cannot be 90° | √ | ||

| Angular velocity | Gyroscope | None | |||

| Angle | Gravity accelerometer | Cannot be 90° | √ | ||

| Angular velocity | Gyroscope | Cannot be 90° | √ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Tang, H.; Lu, G.; Wang, Y.; Li, C.; Zhang, J.; An, P.; Shen, P. Design and Testing of Inertial System for Landslide Displacement Distribution Measurement. Sensors 2020, 20, 7154. https://doi.org/10.3390/s20247154

Zhang Y, Tang H, Lu G, Wang Y, Li C, Zhang J, An P, Shen P. Design and Testing of Inertial System for Landslide Displacement Distribution Measurement. Sensors. 2020; 20(24):7154. https://doi.org/10.3390/s20247154

Chicago/Turabian StyleZhang, Yongquan, Huiming Tang, Guiying Lu, Yuansheng Wang, Changdong Li, Junrong Zhang, Pengju An, and Peiwu Shen. 2020. "Design and Testing of Inertial System for Landslide Displacement Distribution Measurement" Sensors 20, no. 24: 7154. https://doi.org/10.3390/s20247154

APA StyleZhang, Y., Tang, H., Lu, G., Wang, Y., Li, C., Zhang, J., An, P., & Shen, P. (2020). Design and Testing of Inertial System for Landslide Displacement Distribution Measurement. Sensors, 20(24), 7154. https://doi.org/10.3390/s20247154