An Unobstructive Sensing Method for Indoor Air Quality Optimization and Metabolic Assessment within Vehicles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Characterization

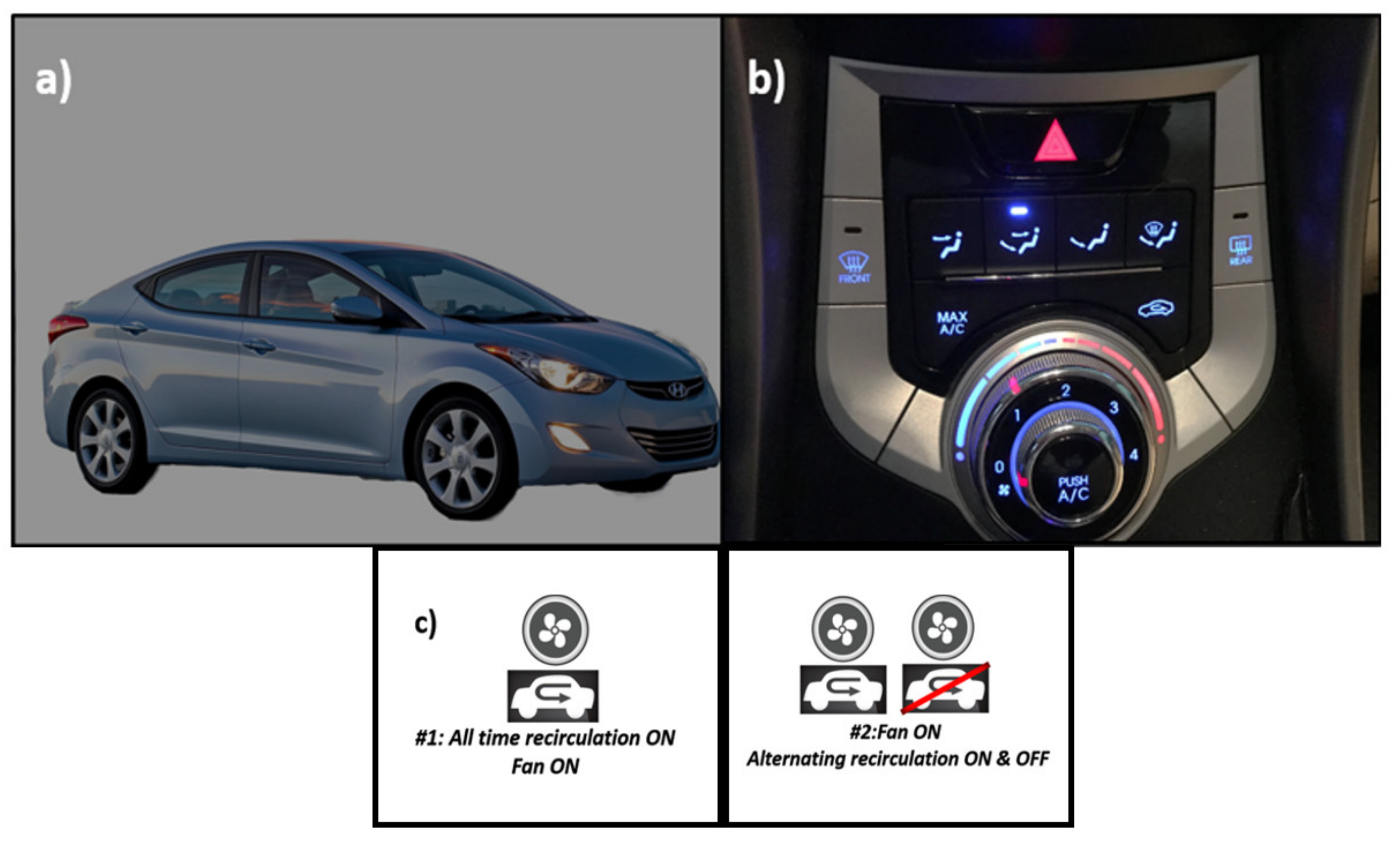

2.1.1. Experimental Setup

2.1.2. Sensing System

2.1.3. Measurements and Sensing Methods

2.1.4. Local Concentration Gradients within Vehicle

2.2. Simulation and Data Analysis

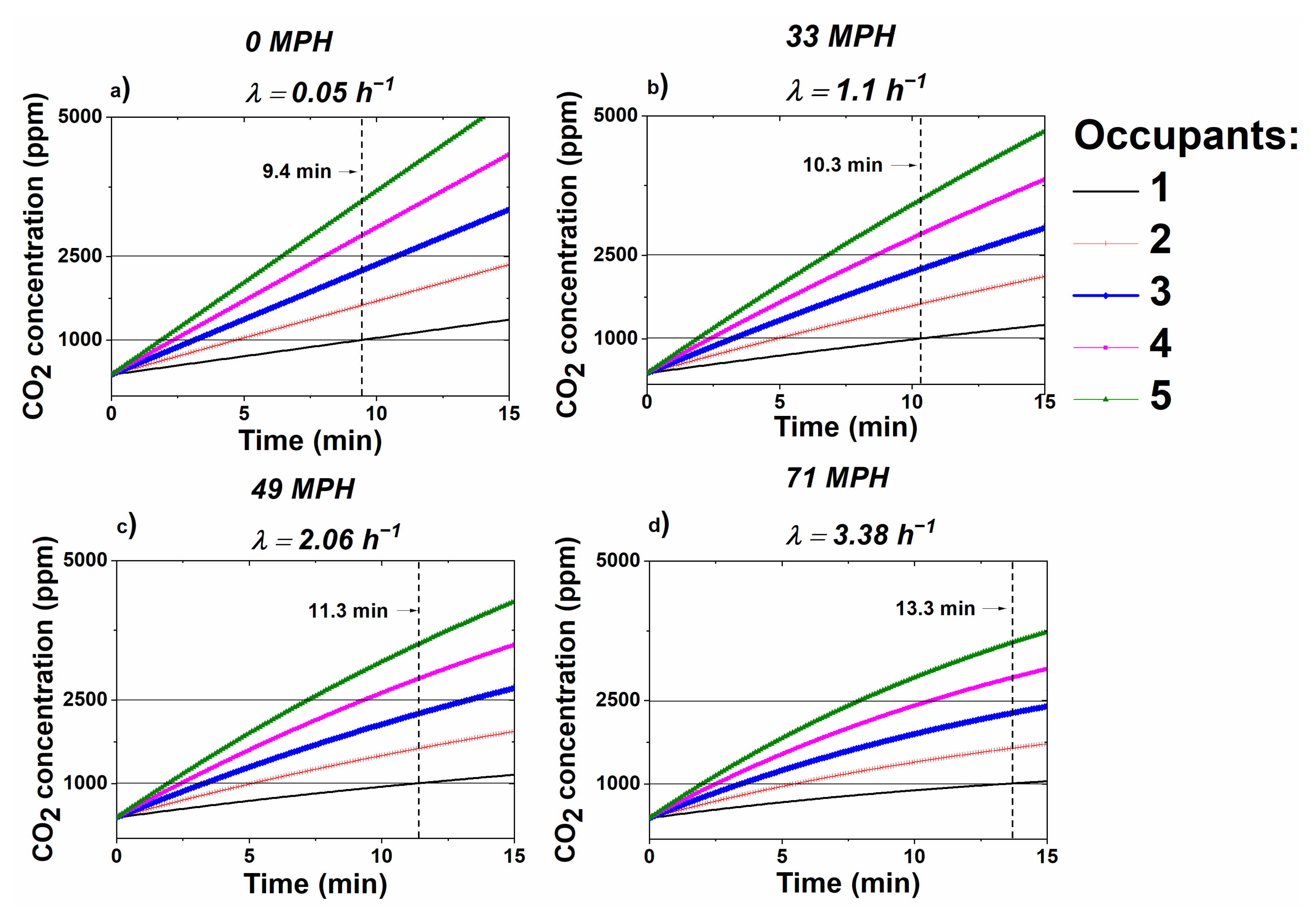

2.2.1. Carbon Dioxide Accumulation Analysis

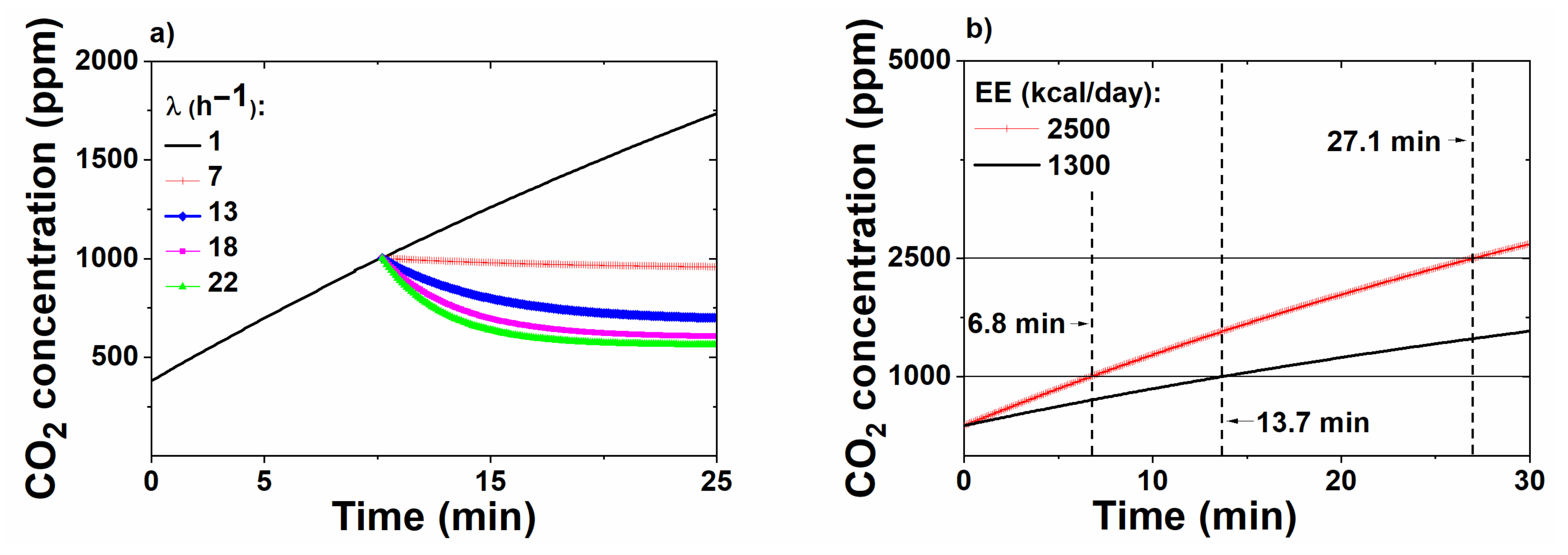

2.2.2. Effect of Car Occupant’s Metabolic Rate

2.2.3. Simulation Parameters

3. Results

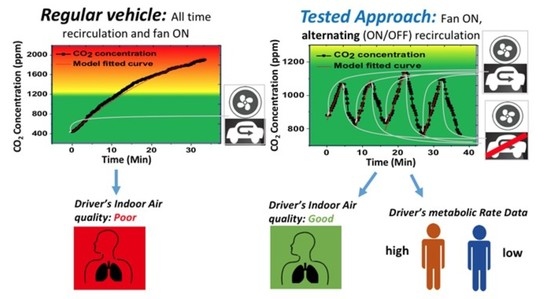

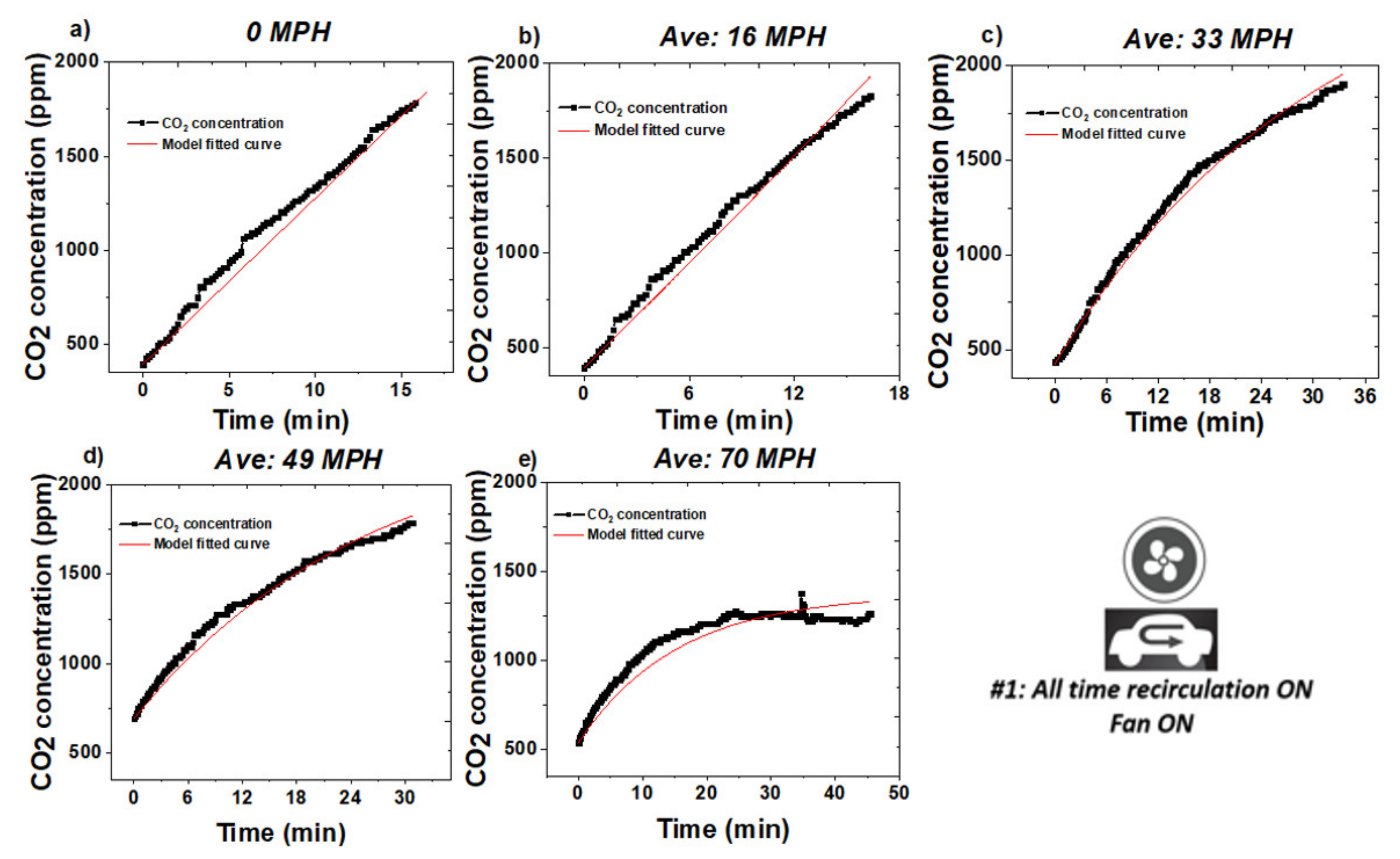

3.1. Experiments under Method #1—Continuous RC (Recirculation) Mode

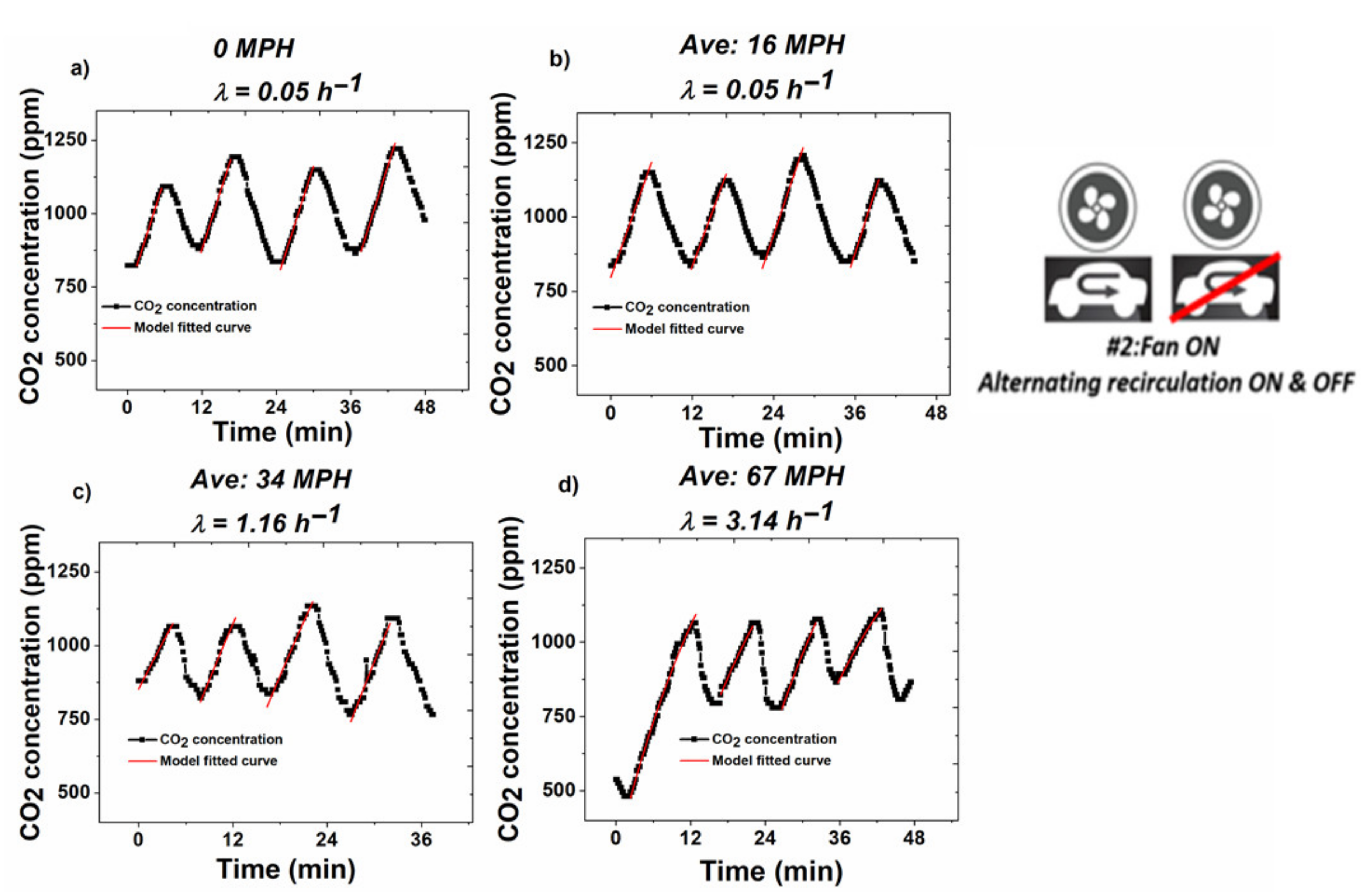

3.2. Experiments under Method #2—Continuous Ventilation and Intermittent RC Mode

3.3. CO2 Concentration Profile Modeling

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- NHTSA. National Highway Traffic Safety Administration. Quick Facts. 2016. Available online: https://crashstats.nhtsa.dot.gov/Api/Public/Publication/812451 (accessed on 14 July 2020).

- CDC. Center for Disease Control and Prevention. National Health Report Highlights. 2013. Available online: https://www.cdc.gov/healthreport/publications/compendium.pdf (accessed on 2 June 2020).

- Barnes, N.M.; Ng, T.W.; Ma, K.K.; Lai, K.-M. In-Cabin Air Quality during Driving and Engine Idling in Air-Conditioned Private Vehicles in Hong Kong. Int. J. Environ. Res. Public Health 2018, 15, 611. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hudda, N.; Fruin, S. Carbon dioxide accumulation inside vehicles: The effect of ventilation and driving conditions. Sci. Total. Environ. 2018, 610–611, 1448–1456. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.; Grady, M.L.; Victoroff, T.; Miller, A.L. Simultaneously reducing CO2 and particulate exposures via fractional recirculation of vehicle cabin air. Atmos. Environ. 2017, 160, 77–88. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gładyszewska-Fiedoruk, K. Concentrations of carbon dioxide in a car. Transp. Res. Part D Transp. Environ. 2011, 16, 166–171. [Google Scholar] [CrossRef]

- Gładyszewska-Fiedoruk, K. Concentrations of carbon dioxide in the cabin of a small passenger car. Transp. Res. Part D Transp. Environ. 2011, 16, 327–331. [Google Scholar] [CrossRef]

- Allen, J.G.; Macnaughton, P.; Satish, U.; Santanam, S.; Vallarino, J.; Spengler, J.D. Associations of Cognitive Function Scores with Carbon Dioxide, Ventilation, and Volatile Organic Compound Exposures in Office Workers: A Controlled Exposure Study of Green and Conventional Office Environments. Environ. Health Perspect. 2016, 124, 805–812. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Wargocki, P.; Lian, Z. Effects of Exposure to Carbon Dioxide and Human Bioeffluents on Cognitive Performance. Procedia Eng. 2015, 121, 138–142. [Google Scholar] [CrossRef] [Green Version]

- Satish, U.; Mendell, M.J.; Shekhar, K.; Hotchi, T.; Sullivan, D.; Streufert, S.; Fisk, W.J. Is CO2 an Indoor Pollutant? Direct Effects of Low-to-Moderate CO2 Concentrations on Human Decision-Making Performance. Environ. Health Perspect. 2012, 120, 1671–1677. [Google Scholar] [CrossRef] [Green Version]

- Norbäck, D.; Nordström, K.; Zhao, Z. Carbon dioxide (CO2) demand-controlled ventilation in university computer classrooms and possible effects on headache, fatigue and perceived indoor environment: an intervention study. Int. Arch. Occup. Environ. Health 2013, 86, 199–209. [Google Scholar] [CrossRef]

- Allen, J.G.; Macnaughton, P.; Cedeno-Laurent, J.G.; Cao, X.; Flanigan, S.; Vallarino, J.; Rueda, F.; Donnelly-McLay, D.; Spengler, J.D. Airplane pilot flight performance on 21 maneuvers in a flight simulator under varying carbon dioxide concentrations. J. Expo. Sci. Environ. Epidemiol. 2018, 29, 457–468. [Google Scholar] [CrossRef]

- Fruin, S.A.; Hudda, N.; Sioutas, C.; Delfino, R.J. Predictive Model for Vehicle Air Exchange Rates Based on a Large, Representative Sample. Environ. Sci. Technol. 2011, 45, 3569–3575. [Google Scholar] [CrossRef] [Green Version]

- Knibbs, L.D.; De Dear, R.J.; Atkinson, S.E. Field study of air change and flow rate in six automobiles. Indoor Air 2009, 19, 303–313. [Google Scholar] [CrossRef] [Green Version]

- Hudda, N.; Eckel, S.P.; Knibbs, L.D.; Sioutas, C.; Delfino, R.J.; Fruin, S. Linking in-vehicle ultrafine particle exposures to on-road concentrations. Atmos. Environ. 2012, 59, 578–586. [Google Scholar] [CrossRef] [Green Version]

- Ott, W.R.; Klepeis, N.E.; Switzer, P.V. Air change rates of motor vehicles and in-vehicle pollutant concentrations from secondhand smoke. J. Expo. Sci. Environ. Epidemiol. 2007, 18, 312–325. [Google Scholar] [CrossRef]

- Fletcher, B.; Saunders, C.J. Air change rates in stationary and moving motor vehicles. J. Hazard. Mater. 1994, 38, 243–256. [Google Scholar] [CrossRef]

- Jiang, C.; Masood, M.K.; Soh, Y.C.; Li, H. Indoor occupancy estimation from carbon dioxide concentration. Energy Build. 2016, 131, 132–141. [Google Scholar] [CrossRef] [Green Version]

- Ruiz, I.; Sprowls, M.; Deng, Y.; Kulick, D.; Destaillats, H.; Forzani, E. Assessing metabolic rate and indoor air quality with passive environmental sensors. J. Breath Res. 2018, 12, 036012. [Google Scholar] [CrossRef]

- Mehta, N.M.; Smallwood, C.D.; Joosten, K.F.; Hulst, J.M.; Tasker, R.C.; Duggan, C.P. Accuracy of a simplified equation for energy expenditure based on bedside volumetric carbon dioxide elimination measurement—A two-center study. Clin. Nutr. 2015, 34, 151–155. [Google Scholar] [CrossRef] [Green Version]

- Levine, J.A. Measurement of energy expenditure. Public Health Nutr. 2005, 8, 1123–1132. [Google Scholar] [CrossRef]

- Grunwald, G.K.; Melanson, E.L.; Forster, J.E.; Seagle, H.M.; Sharp, T.A.; Hill, J.O. Comparison of Methods for Achieving 24-Hour Energy Balance in a Whole-Room Indirect Calorimeter. Obes. Res. 2003, 11, 752–759. [Google Scholar] [CrossRef] [Green Version]

- Simonson, D.C.; DeFronzo, R.A. Indirect calorimetry: Methodological and interpretative problems. Am. J. Physiol. Metab. 1990, 258, E399–E412. [Google Scholar] [CrossRef]

- Fan, J.F.; Yin, Y.H.; Xu, L.D.; Zeng, Y.; Wu, F. IoT-Based Smart Rehabilitation System. IEEE Trans. Ind. Inform. 2014, 10, 1568–1577. [Google Scholar] [CrossRef]

- Al-Makhadmeh, Z.; Tolba, A. Utilizing IoT wearable medical device for heart disease prediction using higher order Boltzmann model: A classification approach. Measurment 2019, 147, 106815. [Google Scholar] [CrossRef]

- Meng, K.; Chen, J.; Li, X.; Wu, Y.; Fan, W.; Zhou, Z.; He, Q.; Wang, X.; Fan, X.; Zhang, Y.; et al. Flexible Weaving Constructed Self-Powered Pressure Sensor Enabling Continuous Diagnosis of Cardiovascular Disease and Measurement of Cuffless Blood Pressure. Adv. Funct. Mater. 2018, 29, 1806388. [Google Scholar] [CrossRef]

- Lin, Z.; Yang, J.; Li, X.; Wu, Y.; Wei, W.; Liu, J.; Chen, J.; Yang, J. Large-Scale and Washable Smart Textiles Based on Triboelectric Nanogenerator Arrays for Self-Powered Sleeping Monitoring. Adv. Funct. Mater. 2018, 28, 1704112. [Google Scholar] [CrossRef]

- Su, Y.; Wang, J.; Wang, B.; Yang, T.; Yang, B.; Xie, G.; Zhou, Y.; Zhang, S.; Tai, H.; Cai, Z.; et al. Alveolus-Inspired Active Membrane Sensors for Self-Powered Wearable Chemical Sensing and Breath Analysis. ACS Nano 2020, 14, 6067–6075. [Google Scholar] [CrossRef]

- Su, Y.; Xie, G.; Tai, H.; Li, S.; Yang, B.; Wang, S.; Zhang, Q.; Du, H.; Zhang, H.; Du, X.; et al. Self-powered room temperature NO2 detection driven by triboelectric nanogenerator under UV illumination. Nano Energy 2018, 47, 316–324. [Google Scholar] [CrossRef]

- Chang, T.-B.; Sheu, J.-J.; Huang, J.-W.; Lin, Y.-S.; Chang, C.-C. Development of a CFD model for simulating vehicle cabin indoor air quality. Transp. Res. Part D Transp. Environ. 2018, 62, 433–440. [Google Scholar] [CrossRef]

- Ji, W.; Luo, M.; Cao, B.; Zhu, Y.; Geng, Y.; Lin, B. A new method to study human metabolic rate changes and thermal comfort in physical exercise by CO2 measurement in an airtight chamber. Energy Build. 2018, 177, 402–412. [Google Scholar] [CrossRef]

- Matarese, L.E. Indirect Calorimetry: Technical Aspects. J. Am. Diet. Assoc. 1997, 97, S154–S160. [Google Scholar] [CrossRef]

- Weir, J.B.D.V. New methods for calculating metabolic rate with special reference to protein metabolism. J. Physiol. 1949, 109, 1–9. [Google Scholar] [CrossRef]

- Toubro, S.; Sørensen, T.I.; Hindsberger, C.; Christensen, N.J.; Astrup, A. Twenty-Four-Hour Respiratory Quotient: The Role of Diet and Familial Resemblance1. J. Clin. Endocrinol. Metab. 1998, 83, 2758–2764. [Google Scholar] [CrossRef] [Green Version]

- Stapel, S.N.; De Grooth, H.-J.; Alimohamad, H.; Elbers, P.W.; Girbes, A.R.J.; Weijs, P.J.M.; Straaten, H.M.O.-V. Ventilator-derived carbon dioxide production to assess energy expenditure in critically ill patients: Proof of concept. Crit. Care 2015, 19, 370. [Google Scholar] [CrossRef] [Green Version]

- Widmaier, E.P.; Raff, H.; Strang, K.T.; Vander, A.J. Human Physiology: The Mechanisms of Body Function, 8th ed.; McGraw-Hill Higher Education: Boston, MA, USA, 2001. [Google Scholar]

- Li, C.; Brewer, E.; Pham, L.; Jung, H. Reducing Mobile Air Conditioner (MAC) Power Consumption Using Active Cabin-Air-Recirculation in A Plug-In Hybrid Electric Vehicle (PHEV). World Electr. Veh. J. 2018, 9, 51. [Google Scholar] [CrossRef] [Green Version]

- McArdle, W.D.; Katch, F.I.; Katch, V.L. Exercise Physiology: Nutrition, Energy, and Human Performance; Lippincott Williams & Wilkins: Philadelphia, PA, USA, 2010. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Y.; Sprowls, M.; Mora, S.J.; Kulick, D.; Tao, N.; Destaillats, H.; Forzani, E. An Unobstructive Sensing Method for Indoor Air Quality Optimization and Metabolic Assessment within Vehicles. Sensors 2020, 20, 7202. https://doi.org/10.3390/s20247202

Deng Y, Sprowls M, Mora SJ, Kulick D, Tao N, Destaillats H, Forzani E. An Unobstructive Sensing Method for Indoor Air Quality Optimization and Metabolic Assessment within Vehicles. Sensors. 2020; 20(24):7202. https://doi.org/10.3390/s20247202

Chicago/Turabian StyleDeng, Yue, Mark Sprowls, S. Jimena Mora, Doina Kulick, Nongjian Tao, Hugo Destaillats, and Erica Forzani. 2020. "An Unobstructive Sensing Method for Indoor Air Quality Optimization and Metabolic Assessment within Vehicles" Sensors 20, no. 24: 7202. https://doi.org/10.3390/s20247202

APA StyleDeng, Y., Sprowls, M., Mora, S. J., Kulick, D., Tao, N., Destaillats, H., & Forzani, E. (2020). An Unobstructive Sensing Method for Indoor Air Quality Optimization and Metabolic Assessment within Vehicles. Sensors, 20(24), 7202. https://doi.org/10.3390/s20247202