Development of a Real-Time Tillage Depth Measurement System for Agricultural Tractors: Application to the Effect Analysis of Tillage Depth on Draft Force during Plow Tillage

Abstract

1. Introduction

2. Materials and Methods

2.1. Agricultural Tractor and Tillage Implement

2.2. Measurement of Soil Parameters

2.3. Tillage Depth Measurement

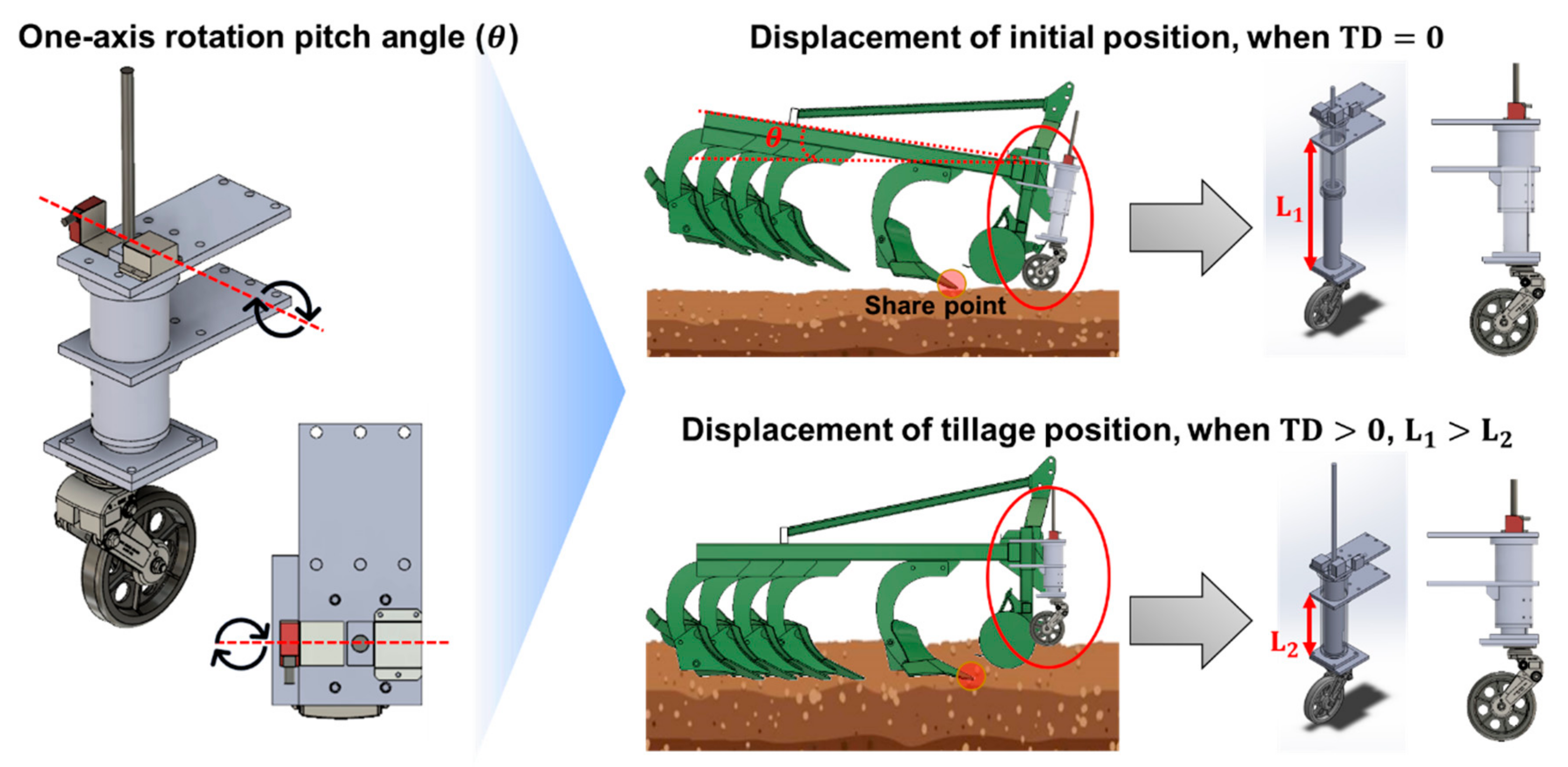

2.3.1. Tillage Depth Measurement Principle

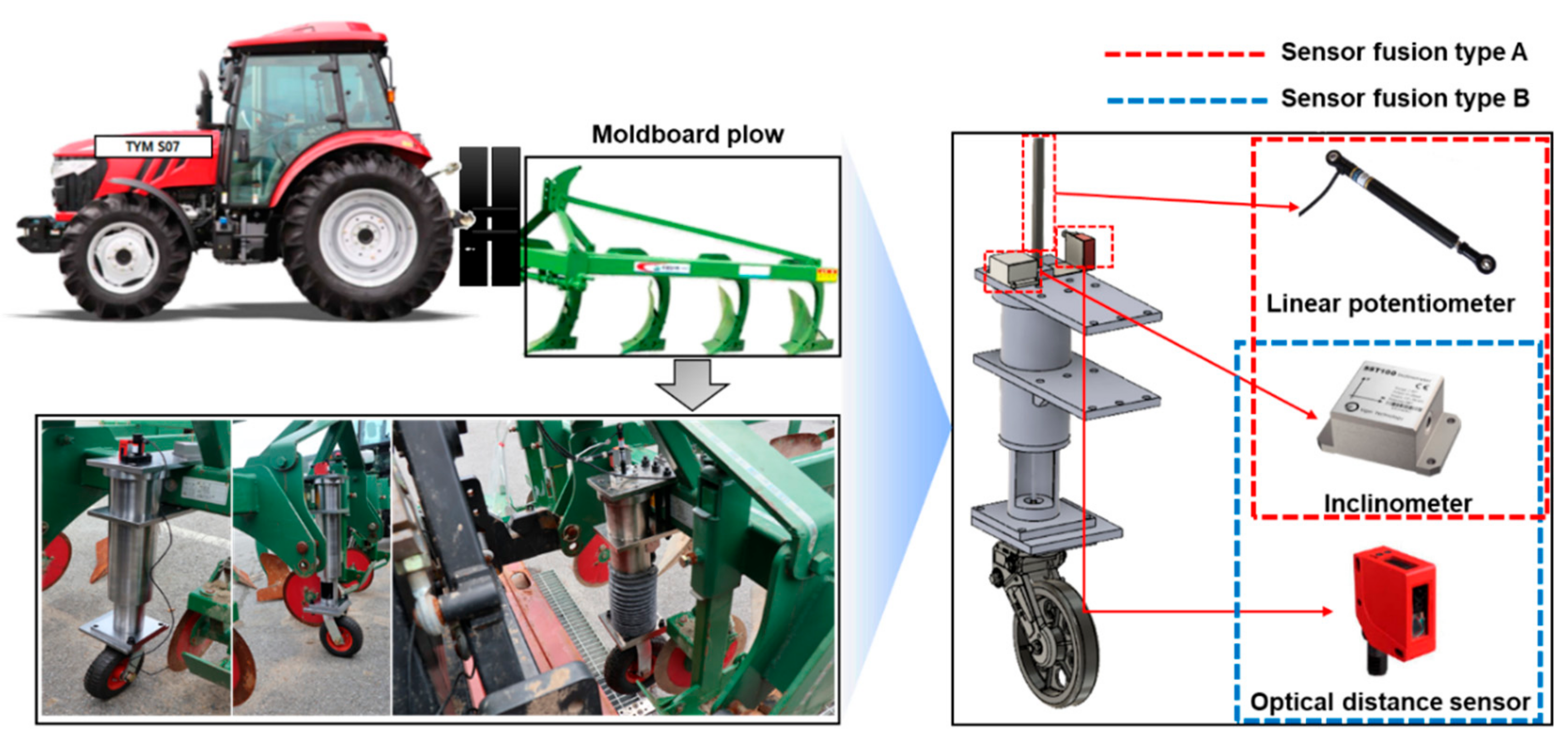

2.3.2. Development of a Real-Time Tillage Depth Measurement System

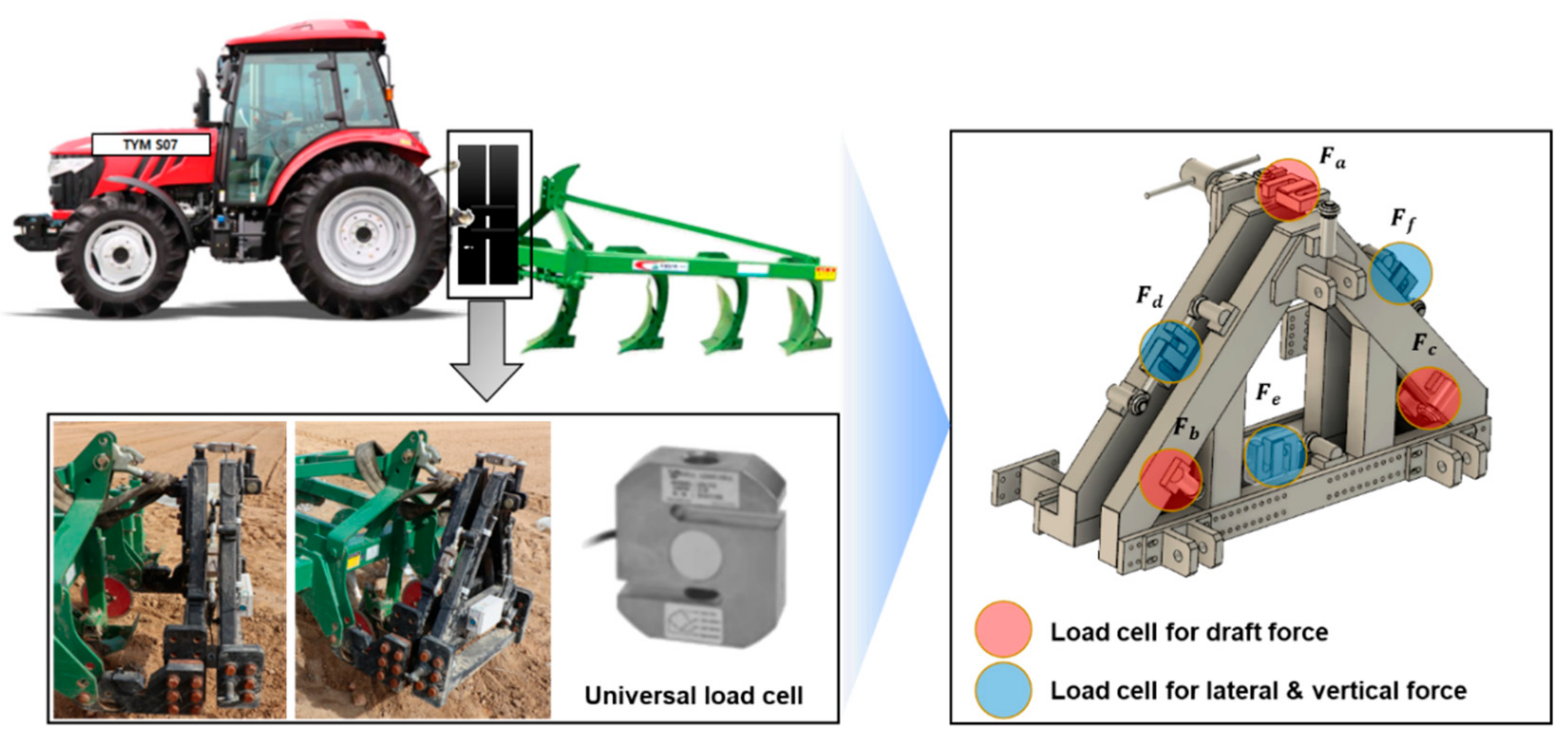

2.4. Draft Force Measurement System

2.5. Test Procedure

2.5.1. Soil Non-Penetration Test Using Two Sensor Fusion Type

2.5.2. Field Experiments

2.6. Analysis Method

3. Results and Discussion

3.1. Soil Non-Penetration Test

3.2. Soil Properties

3.3. Analysis of Field Experiment Data

3.3.1. Tillage Depth

3.3.2. Traveling Speed

3.3.3. Draft Force

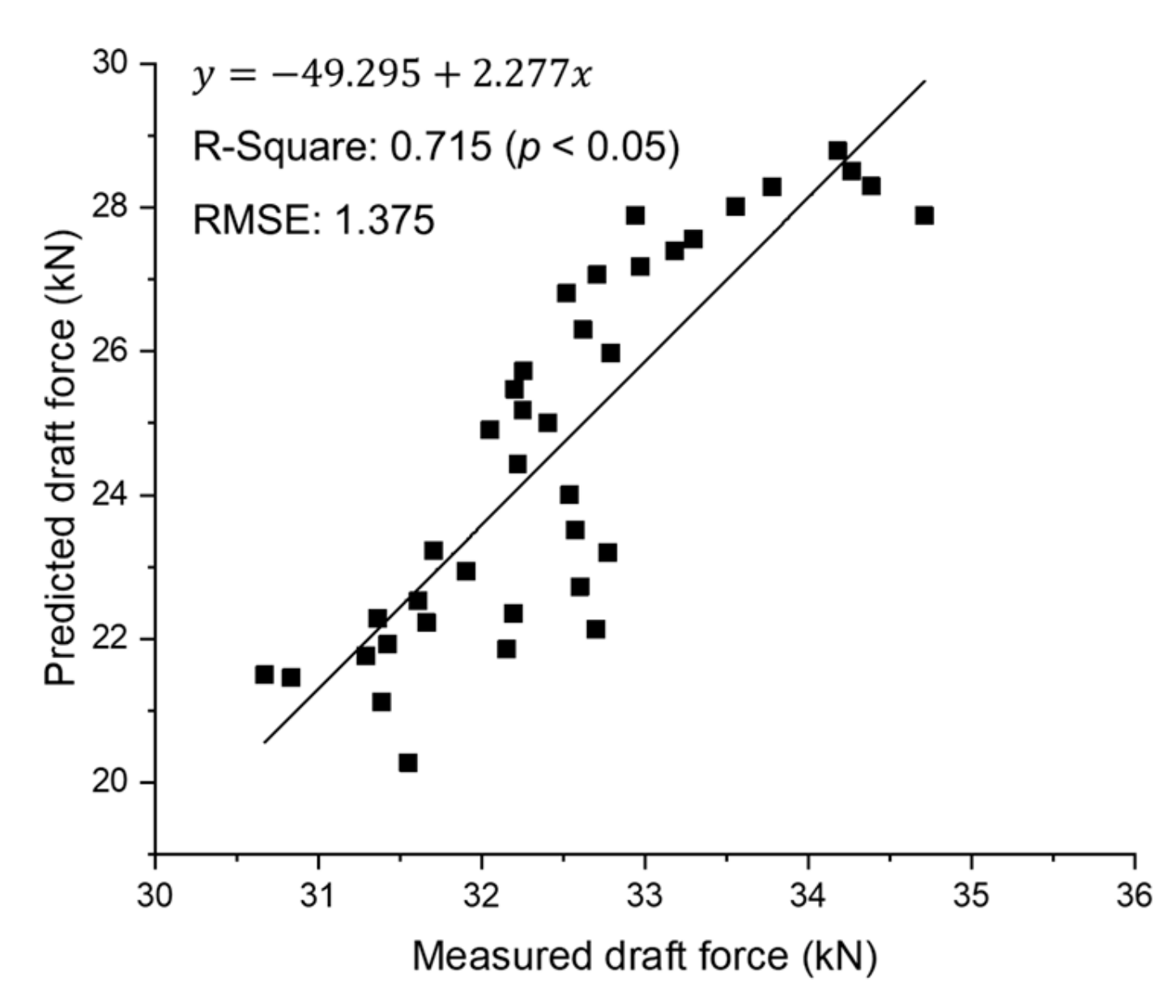

4. Discussion

5. Conclusions

- (1)

- The real-time tillage depth measurement system was developed through sensor fusion consisting of a linear potentiometer, an optical distance sensor, and an inclinometer. A simple soil non-penetration test bed was constructed considering the actual tillage depth of moldboard plow. As a result of the accuracy verification test, sensor fusion type A showed a 2% measurement error, which was 9% lower than the sensor fusion type B, using the optical distance sensor and the inclinometer, which had an 11% measurement error. In addition, sensor fusion type A showed only about 3% measurement error in actual moldboard plow operations. Therefore, sensor fusion type A is a suitable method for measuring the tillage depth during actual tillage operations. In addition, the system can only be measured with relative vertical displacement, which makes it possible to use it for any type of tillage operation.

- (2)

- To verify the accuracy of the real-time tillage depth measurement system in the plow tillage, a comparative test between the measured draft force and the predicted values based on the ASABE standard equation was conducted. In addition, soil texture analysis of the test field was performed to select Fi (dimensionless soil texture adjustment parameter), a key factor used in the draft force prediction. As a result of the soil texture analysis, the soil of the test field was classified as loam, and it was confirmed that the Fi value of 0.7 should be used when using the draft force prediction equation of ASABE standard as the soil texture of the medium texture group.

- (3)

- Field test results showed that the overall average traveling speed and draft force values of the two gear stages were similar, but are greatly affected by the tillage depth. Overall, the higher the gear selection, the deeper the tillage depths, which will result in greater soil resistance, slowing the traveling speed while increasing the average draft force. The regression analysis for system accuracy analysis showed that the deeper the tillage depth in each gear, the closer the coefficient of determination was to 1. Specifically, the lower the gear selection and the deeper the tillage depth during plow tillage, the higher the coefficient of determination as a result of the regression analysis of the measured values. This is thought to be influenced by the relatively rapid decrease in traveling speed due to greater soil resistance in the deep tillage depth section of the high gear stage M3–high. Therefore, in the case of no reduction in traveling speed due to soil resistance even in the deep tillage depth section during plow tillage, it was seen that the deeper the tillage depth and the greater the draft force, the higher the accuracy of the draft force prediction using the real-time tillage depth measurement system.

Author Contributions

Funding

Conflicts of Interest

References

- Zoz, F.M.; Turner, R.J.; Shell, L.R. Power Delivery Efficiency: A Valid Measure of Belt and Tire Tractor Performance. Trans. ASAE 2002, 45, 509–518. [Google Scholar]

- Lee, N.-H.; Lee, K.-S.; Park, W.-Y. A Study on Traction Prediction of Agricultural Tractor by Empirical Method. J. Biosyst. Eng. 2009, 34, 297–304. [Google Scholar] [CrossRef]

- Wong, J.Y. Theory of ground vehicles; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Naderloo, L.; Alimadani, R.; Akram, A.; Javadikia, P.; Zeinali Khanghah, H. Tillage depth and forward speed effects on draft of three primary tillage implements in clay loam soil. J. Food Agric. Environ. 2009, 7, 382–385. [Google Scholar]

- Arvidsson, J.; Keller, T.; Gustafsson, K. Specific draught for mouldboard plough, chisel plough and disc harrow at different water contents. Soil Tillage Res. 2004, 79, 221–231. [Google Scholar] [CrossRef]

- Servadio, P.; Bergonzoli, S.; Beni, C. Soil Tillage Systems and Wheat Yield under Climate Change Scenarios. Agronomy 2016, 6, 43. [Google Scholar] [CrossRef]

- Upadhyay, G.; Raheman, H. Specific draft estimation model for offset disc harrows. Soil Tillage Res. 2019, 191, 75–84. [Google Scholar] [CrossRef]

- Kichler, C.; Fulton, J.; Raper, R.; McDonald, T.; Zech, W. Effects of transmission gear selection on tractor performance and fuel costs during deep tillage operations. Soil Tillage Res. 2011, 113, 105–111. [Google Scholar] [CrossRef]

- Tianmanee, K.; Wongpichet, S.; Taira, E.; Ueno, M. The study of the soil texture parameter in the upland of Khon Kaen province; Thailand. Eng. Appl. Sci. Res. 2016, 43, 354–358. [Google Scholar]

- Barzegar, M.; Hashemi, S.; Nazokdast, H.; Karimi, R. Evaluating the draft force and soil-tool adhesion of a UHMW-PE coated furrower. Soil Tillage Res. 2016, 163, 160–167. [Google Scholar] [CrossRef]

- Jabro, J.D.; Stevens, W.B.; Iversen, W.M.; Evans, R.G. Tillage Depth Effects on Soil Physical Properties, Sugarbeet Yield, and Sugarbeet Quality. Commun. Soil Sci. Plant Anal. 2010, 41, 908–916. [Google Scholar] [CrossRef]

- Arvidsson, J.; Westlin, A.; Sörensson, F. Working depth in non-inversion tillage—Effects on soil physical properties and crop yield in Swedish field experiments. Soil Tillage Res. 2013, 126, 259–266. [Google Scholar] [CrossRef]

- Rasmussen, K. Impact of ploughless soil tillage on yield and soil quality: A Scandinavian review. Soil Tillage Res. 1999, 53, 3–14. [Google Scholar] [CrossRef]

- Condon, S.F.; Ward, S.M.; Holden, N.M.; McGee, A. The development of a depth control system for a peat milling machine, part I: Sensor development. J. Agric. Eng. Res. 2001, 80, 7–15. [Google Scholar] [CrossRef]

- Lee, K.S.; Park, J.G.; Cho, S.C.; Noh, K.M.; Chang, Y.C. Physical Properties of Hardpan in Paddy Fields. J. Biosyst. Eng. 2007, 32, 207–214. [Google Scholar]

- Tekeste, M.Z.; Raper, R.L.; Schwab, E.B. Soil Drying Effects on Soil Strength and Depth of Hardpan Layers as Determined from Cone Index Data. Agric. Eng. Int. CIGR J. 2008, X, 1–17. [Google Scholar]

- Chung, S.O.; Sudduth, K.A.; Plouffe, C.; Kitchen, N.R. Soil Bin and Field Tests of an On-The-Go Soil Strength Profile Sensor. Trans. ASABE 2008, 51, 5–18. [Google Scholar] [CrossRef]

- Marakoglu, T.; Carma, K. Effects of Design Parameters of a Cultivator Share on Draft Force and Soil Loosening in a Soil Bin. J. Agron. 2009, 8, 21–26. [Google Scholar] [CrossRef][Green Version]

- Tagar, A.; Ji, C.; Ding, Q.; Adamowski, J.; Chandio, F.; Mari, I. Soil failure patterns and draft as influenced by consistency limits: An evaluation of the remolded soil cutting test. Soil Tillage Res. 2014, 137, 58–66. [Google Scholar] [CrossRef]

- Taghavifar, H.; Mardani, A. Investigating the effect of velocity, inflation pressure, and vertical load on rolling resistance of a radial ply tire. J. Terramech. 2013, 50, 99–106. [Google Scholar] [CrossRef]

- Way, T.R. Three Single Wheel Machines for Traction and Soil Compaction Research. Agric. Eng. Int. CIGR J. 2019, 11, 1–24. [Google Scholar]

- Raper, R.L. The Influence of Implement Type, Tillage Depth, and Tillage Timing on Residue Burial. Trans. ASAE 2002, 45, 1281–1286. [Google Scholar] [CrossRef]

- Raper, R.L.; Reeves, D.W.; Burmester, C.H.; Schwab, E.B. Tillage Depth, Tillage Timing, and Cover Crop Effects on Cotton Yield, Soil Strength, and Tillage Energy Requirements. Appl. Eng. Agric. 2000, 16, 379–385. [Google Scholar] [CrossRef]

- Etana, A. Effects of tillage depth on organic carbon content and physical properties in five Swedish soils. Soil Tillage Res. 1999, 52, 129–139. [Google Scholar] [CrossRef]

- Park, J.G. Bio-Production Machinery Engineering, 1st ed.; CIR: Seoul, Korea, 2008. [Google Scholar]

- Shierlaw, J.; Alston, A.M. Effect of soil compaction on root growth and uptake of phosphorus. Plant Soil 1984, 77, 15–28. [Google Scholar] [CrossRef]

- Czyż, E.A. Effects of traffic on soil aeration, bulk density and growth of spring barley. Soil Tillage Res. 2004, 79, 153–166. [Google Scholar] [CrossRef]

- Imhoff, S.; Da Silva, A.P.; Ghiberto, P.J.; Tormena, C.A.; Pilatti, M.A.; Libardi, P.L. Physical quality indicators and mechanical behavior of agricultural soils of Argentina. PLoS ONE 2016, 11, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Oduma, O.; Oluka, S.I.; Eze, P.C. Effect of soil physical properties on performance of agricultural field machinery in south eastern Nigeria. Cigr. 2018, 20, 25–31. [Google Scholar]

- Ani, O.A.; Uzoejinwa, B.; Ezeama, A.; Onwualu, A.; Ugwu, S.; Ohagwu, C. Overview of soil-machine interaction studies in soil bins. Soil Tillage Res. 2018, 175, 13–27. [Google Scholar] [CrossRef]

- ASABE Standards S313.3. Soil Cone Penetrometer. Available online: https://elibrary.asabe.org/abstract.asp?aid=44232&t=2&redir=&redirType= (accessed on 10 October 2019).

- ASABE Standards EP542. Procedure for Using and Reporting Data Obtained with the Soil Cone Penetrometer. Available online: https://standards.globalspec.com/std/13163484/ASABE%20EP542 (accessed on 10 October 2019).

- Joo, J.; Na, K.; Kang, D. Design and evaluation of a six-component load cell. Measurement 2002, 32, 125–133. [Google Scholar] [CrossRef]

- Vellidis, G.; Tucker, M.; Perry, C.; Reckford, D.; Butts, C.; Henry, H.; Liakos, V.; Hill, R.W.; Edwards, W. A soil moisture sensor-based variable rate irrigation scheduling system. In Precision agriculture ’13; Wageningen Academic Publishers: Wageningen, The Netherlands, 2013; ISBN 9789086862245. [Google Scholar]

- Tsiropoulos, Z.; Fountas, S.; Gravalos, I.; Augoustis, A.; Arslan, S.; Misiewicz, P.; Gemtos, T. Importance of measuring tillage implement forces for reduced fuel consumption and increased efficiency without affecting tillage depth. In Precision agriculture ’15; Wageningen Academic Publishers: Wageningen, The Netherlands, 2015; pp. 353–360. [Google Scholar]

- Kim, E.K.; Moon, S.G.; Oh, C.M.; Han, J.W. Working Load Measurement using 6-Component Load Cell and Fatigue Damage Analysis of Composite Working Implement. J. Agric. Life Environ. Sci. 2017, 29, 225–236. [Google Scholar]

- ASABE Standards Standard ASAE D497.4. Agricultural Machinery Management Data. Available online: http://www.khuisf.ac.ir/prof/images/Uploaded_files/ASAE[4154667].PDF (accessed on 10 October 2019).

- Chen, Y.; Munkholm, L.J.; Nyord, T. A discrete element model for soil–sweep interaction in three different soils. Soil Tillage Res. 2013, 126, 34–41. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Discrete element modelling of tillage forces and soil movement of a one-third scale mouldboard plough. Biosyst. Eng. 2017, 155, 44–45. [Google Scholar]

- Thien, S.J. A flow diagram for teaching texture by feel analysis. J. Agron. Edu. 1979, 8, 54–55. [Google Scholar]

- USDA Natural Resources Conservation Service Soils. Available online: https://www.nrcs.usda.gov/wps/portal/nrcs/detail/soils/ref/?cid=nrcs142p2_054253 (accessed on 15 September 2019).

| Item | Specification |

|---|---|

| Mass (kg) | 790 |

| Length Width Height (m) | 2.8 2.15 1.25 |

| Required power (kW) | 67–89 |

| Working depth (m) | Up to 0.2 |

| Working speed (km/h) | 5–8 |

| Share type | Gunnel-type/Plain coulter with spring |

| Item | Draft | Lateral | Vertical |

|---|---|---|---|

| Applied force (kN) | 14.7 | 9.8 | 4.9 |

| Measured force (kN) | 14.5 | 9.7 | 5 |

| Accuracy (%) | 98.9 | 99.2 | 97.4 |

| Target Tillage Depth (m) | Sensor Fusion Type A | Sensor Fusion Type B | ||||

|---|---|---|---|---|---|---|

| 0.05 | 0.1 | 0.15 | 0.05 | 0.1 | 0.15 | |

| RMSE (m) | 0.00111 | 0.00328 | 0.00138 | 0.00555 | 0.00962 | 0.019 |

| Accuracy (%) | 97.76 | 96.72 | 99.08 | 88.88 | 90.38 | 87.32 |

| Gear Selection | Max. | Mean | Std. |

|---|---|---|---|

| M3–low | 0.188 | 0.168 | 0.0088 |

| M3–high | 0.194 | 0.157 | 0.0013 |

| Gear Selection | Grouped Frequency of Tillage Depth (m) | ||||||

|---|---|---|---|---|---|---|---|

| 0.14 | 0.15 | 0.16 | 0.17 | 0.18 | 0.19 | Average | |

| M3–low | 5.45 A | 5.68 B | 5.8 C | 5.73 BC | 5.51 A | 5.44 A | 5.69 |

| M3–high | 5.74 e | 5.9 f | 5.63 d | 5.36 c | 5.03 b | 4.1 a | 5.58 |

| Gear Selection | Grouped Frequency of Tillage Depth (m) | ||||||

|---|---|---|---|---|---|---|---|

| 0.14 | 0.15 | 0.16 | 0.17 | 0.18 | 0.19 | Average | |

| M3–low | 31.79 A | 32.08 AB | 32.31 B | 32.8 C | 33.4 D | 34.1 E | 32.76 |

| M3–high | 32.2 a | 32.36 ab | 32.54 b | 33.49 c | 34.43 d | 36.51 e | 32.91 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.-S.; Kim, T.-J.; Kim, Y.-J.; Lee, S.-D.; Park, S.-U.; Kim, W.-S. Development of a Real-Time Tillage Depth Measurement System for Agricultural Tractors: Application to the Effect Analysis of Tillage Depth on Draft Force during Plow Tillage. Sensors 2020, 20, 912. https://doi.org/10.3390/s20030912

Kim Y-S, Kim T-J, Kim Y-J, Lee S-D, Park S-U, Kim W-S. Development of a Real-Time Tillage Depth Measurement System for Agricultural Tractors: Application to the Effect Analysis of Tillage Depth on Draft Force during Plow Tillage. Sensors. 2020; 20(3):912. https://doi.org/10.3390/s20030912

Chicago/Turabian StyleKim, Yeon-Soo, Taek-Jin Kim, Yong-Joo Kim, Sang-Dae Lee, Seong-Un Park, and Wan-Soo Kim. 2020. "Development of a Real-Time Tillage Depth Measurement System for Agricultural Tractors: Application to the Effect Analysis of Tillage Depth on Draft Force during Plow Tillage" Sensors 20, no. 3: 912. https://doi.org/10.3390/s20030912

APA StyleKim, Y.-S., Kim, T.-J., Kim, Y.-J., Lee, S.-D., Park, S.-U., & Kim, W.-S. (2020). Development of a Real-Time Tillage Depth Measurement System for Agricultural Tractors: Application to the Effect Analysis of Tillage Depth on Draft Force during Plow Tillage. Sensors, 20(3), 912. https://doi.org/10.3390/s20030912