Application of Scikit and Keras Libraries for the Classification of Iron Ore Data Acquired by Laser-Induced Breakdown Spectroscopy (LIBS)

Abstract

:1. Introduction

2. Experiments and Methods

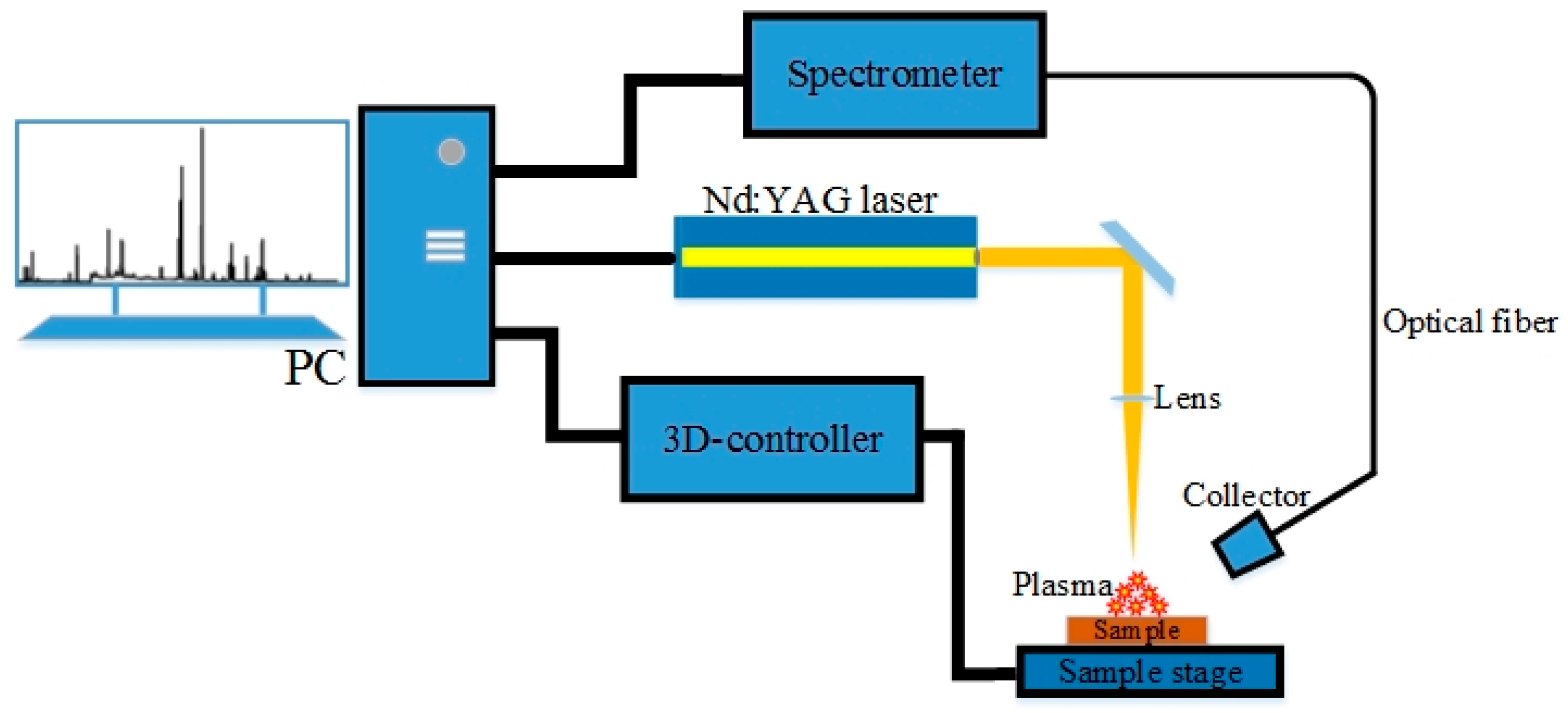

2.1. Instrumental Setup

2.2. Methods

3. Results and Discussion

3.1. LIBS Spectra of Iron Ore

3.2. Dimension Reduction with PCA

3.3. Classification with Machine Learning Techniques

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zeng, Q.; Deng, F.; Zhu, Z.; Tang, Y.; Wang, B.; Xiao, Y.; Xiong, L.; Yu, H.; Guo, L.; Li, X. Portable fiber-optic laser-induced breakdown spectroscopy system for the quantitative analysis of minor elements in steel. Plasma Sci. Technol. 2019, 21, 50–55. [Google Scholar] [CrossRef]

- ElFaham, M.M.; Okil, M.; Mostafa, A.M. Limit of detection and hardness evaluation of some steel alloys utilizing optical emission spectroscopic techniques. Plasma Sci. Technol. 2018, 108, 634–641. [Google Scholar] [CrossRef]

- Al-Khafif, G.D.; El-Banna, R. Reconstructing Ancient Egyptian Diet through Bone Elemental Analysis Using LIBS (Qubbet el Hawa Cemetery). BioMed Res. Int. 2015, 2015, 281056. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, D.C.; Hu, Z.Q.; Su, Y.B.; Hai, B.; Zhu, X.L.; Zhu, J.F.; Ma, X. Simple method for liquid analysis by laser-induced breakdown spectroscopy (LIBS). Opt. Express 2018, 26, 18794–18802. [Google Scholar] [CrossRef]

- Choi, S.U.; Han, S.C.; Yun, J.I. Hydrogen isotopic analysis using molecular emission from laser-induced plasma on liquid and frozen water. Spectrochim. Acta Part B At. Spectrosc. 2019, 162, 105716. [Google Scholar] [CrossRef]

- Vanselow, C.; Stöbener, D.; Kiefer, J.; Fischer, A. Revealing the impact of laser-induced breakdown on a gas flow. Meas. Sci. Technol. 2019, 31, 027001. [Google Scholar] [CrossRef]

- Wan, X.; Wang, P. Analysis of heavy metals in organisms based on an optimized quantitative LIBS. Opt. Int. J. Light Electron Opt. 2015, 126, 1930–1934. [Google Scholar] [CrossRef]

- Swain, B. Cost effective recovery of lithium from lithium ion battery by reverse osmosis and precipitation: A perspective. J. Chem. Technol. Biotechnol. 2018, 93, 311–319. [Google Scholar] [CrossRef]

- Jinjia GU, O.; Mahmoud, A.S.; Nan, L.I.; Jiaojian SO, N.G.; Zheng, R. Study of pressure effects on ocean in-situ detection using laser-induced breakdown spectroscopy. Plasma Sci. Technol. 2019, 21, 186–191. [Google Scholar]

- Nespeca, M.G.; Vieira, A.L.; Júnior, D.S.; Neto JA, G.; Ferreira, E.C. Detection and quantification of adulterants in honey by LIBS. Food Chem. 2019, 311, 125886. [Google Scholar] [CrossRef]

- Tiwari, P.K.; Awasthi, S.; Kumar, R.; Anand, R.K.; Rai, P.K.; Rai, A.K. Rapid analysis of pharmaceutical drugs using LIBS coupled with multivariate analysis. Lasers Med Sci. 2017, 33, 263–270. [Google Scholar] [CrossRef] [PubMed]

- Cama-Moncunill, X.; Markiewicz-Keszycka, M.; Cullen, P.J.; Sullivan, C.; Casado-Gavalda, M.P. Direct analysis of calcium in liquid infant formula via laser-induced breakdown spectroscopy (LIBS). Food Chem. 2020, 309, 125754. [Google Scholar] [CrossRef]

- Zhang, T.; Yan, C.; Qi, J.; Tang, H.; Li, H. Classification and discrimination of coal ash by laser-induced breakdown spectroscopy (LIBS) coupled with advanced chemometric methods. J. Anal. At. Spectrom. 2017, 32, 1960–1965. [Google Scholar] [CrossRef]

- Li, W.; Dong, M.; Lu, S.; Li, S.; Wei, L.; Huang, J.; Lu, J. Improved measurement of the calorific value of pulverized coal particle flow by laser-induced breakdown spectroscopy (LIBS). Anal. Methods 2019, 11, 4471–4480. [Google Scholar] [CrossRef]

- Jabbar, A.; Akhtar, M.; Mehmmod, S.; Iqbal, M.; Ahmed, R.; Baig, M.A. Quantitative analysis of Fe content in iron ore via external calibration in conjunction with internal standardization method coupled with LIBS. Chem. Res. Chin. Univ. 2015, 31, 107–111. [Google Scholar]

- Jabbar, A.; Akhtar, M.; Mehmmod, S.; Iqbal, M.; Ahmed, R.; Baig, M.A. Quantification of copper remediation in the Allium cepa L. leaves using electric field assisted laser induced breakdown spectroscopy. Spectrochim. Acta Part B At. Spectrosc. 2019, 162, 105719. [Google Scholar] [CrossRef]

- Liang, D.; Du, C.; Ma, F.; Shen, Y.; Wu, K.; Zhou, J. Degradation of Polyacrylate in the Outdoor Agricultural Soil Measured by FTIR-PAS and LIBS. Polymers 2018, 10, 1296. [Google Scholar] [CrossRef] [Green Version]

- Yao, S.; Zhang, L.; Zhu, Y.; Wu, J.; Lu, Z.; Lu, J. Evaluation of heavy metal element detection in municipal solid waste incineration fly ash based on LIBS sensor. Waste Manag. 2020, 102, 492–498. [Google Scholar] [CrossRef]

- Erler, A.; Riebe, D.; Beitz, T.; Löhmannsröben, H.G.; Gebbers, R. Soil Nutrient Detection for Precision Agriculture Using Handheld Laser-Induced Breakdown Spectroscopy (LIBS) and Multivariate Regression Methods (PLSR, Lasso and GPR). Sensors 2020, 20, 418. [Google Scholar] [CrossRef] [Green Version]

- Purohit, P.; Fortes, F.J.; Laserna, J. Spectral identification in the attogram regime through laser-induced emission of single optically-trapped nanoparticles in air. Angew. Chem. Int. Ed. Engl. 2017, 56, 14178–14182. [Google Scholar] [CrossRef]

- Serrano, J.; Moros, J.; Laserna, J.J. Molecular Signatures in Femtosecond Laser-Induced Organic Plasmas. Comparison with Nanosecond Laser Ablation. Phys. Chem. Chem. Phys. 2015, 18, 2398–2408. [Google Scholar] [CrossRef] [PubMed]

- Samuels, A.C.; DeLucia, F.C.; McNesby, K.L.; Miziolek, A.W. Laser-Induced Breakdown Spectroscopy of Bacterial Spores, Molds, Pollens, and Protein: Initial Studies of Discrimination Potential. Appl. Opt. 2003, 42, 6205–6209. [Google Scholar] [CrossRef] [PubMed]

- Gottfried, L.; de Lucia, F.C., Jr.; Munson, C.A.; Miziolek, A.W. Strategies for residue explosives detection using laser-induced breakdown spectroscopy. J. Anal. At. Spectrom. 2008, 23, 205–216. [Google Scholar] [CrossRef]

- Portnov, A.; Rosenwaks, S.; Bar, I. Emission following laser-induced breakdown spectroscopy of organic compounds in ambient air. Appl. Opt. 2003, 42, 2835–2842. [Google Scholar] [CrossRef]

- Sreedhar, S.; Rao, S.V.; Kiran, P.P.; Tewari, S.P.; Kumar, G.M. Stoichiometric analysis of ammonium nitrate and ammonium perchlorate with nanosecond laser induced breakdown spectroscopy. Chem. Biol. Radiol. Nucl. Explos. Sens. XI 2010, 7665, 76650. [Google Scholar]

- Stefas, D.; Gyftokostas, N.; Bellou, E.; Couris, S. Laser-induced breakdown spectroscopy assisted by machine learning for olive oils classification: The effect of the experimental parameters. Spectrochim. Acta Part B At. Spectrosc. 2019, 7, 79. [Google Scholar]

- Peng, H.; Chen, G.; Chen, X.; Lu, Z.; Yao, S. Hybrid classification of coal and biomass by laser-induced breakdown spectroscopy combined with K-means and SVM. Plasma Sci. Technol. 2019, 21, 64–72. [Google Scholar] [CrossRef]

- Diaz, D.; Molina, A.; Hahn, D.W. Laser-Induced Breakdown Spectroscopy and Principal Component Analysis for the Classification of Spectra from Gold-Bearing Ores. Appl. Spectrosc. 2019, 0003702819881444. [Google Scholar] [CrossRef]

- Li, X.; Yang, S.; Fan, R.; Yu, X.; Chen, D. Discrimination of soft tissues using laser-induced breakdown spectroscopy in combination with k nearest neighbors (kNN) and support vector machine (SVM) classifiers. Opt. Laser Technol. 2018, 102, 233–239. [Google Scholar] [CrossRef]

- Sha, W.; Li, J.; Xiao, W.; Ling, P.; Lu, C. Quantitative Analysis of Elements in Fertilizer Using Laser-Induced Breakdown Spectroscopy Coupled with Support Vector Regression Model. Sensors 2019, 19, 3277. [Google Scholar] [CrossRef] [Green Version]

- Sheng, L.; Zhang, T.; Niu, G.; Wang, K.; Tang, H.; Duan, Y.; Li, H. Classification of iron ores by laser-induced breakdown spectroscopy (LIBS) combined with random forest (RF). J. Anal. At. Spectrom. 2015, 30, 453–458. [Google Scholar] [CrossRef]

- Wang, P.; Li, N.; Yan, C.; Feng, Y.; Ding, Y.; Zhang, T.; Li, H. Rapid quantitative analysis of the acidity of iron ore by laser-induced breakdown spectroscopy (LIBS) technique coupled with variable importance measurement-random forest (VIM-RF). Anal. Methods 2019, 11, 3419–3428. [Google Scholar] [CrossRef]

- Liu, K.; Tian, D.; Xu, H.; Wang, H.; Yang, G. Quantitative analysis of toxic elements in polypropylene (PP) via laser-induced breakdown spectroscopy (LIBS) coupled with random forest regression based on variable importance (VI-RFR). Anal. Methods 2019, 11, 4769–4774. [Google Scholar] [CrossRef]

- Zhao, Y.; Lamine Guindo, M.; Xu, X.; Sun, M.; Peng, J.; Liu, F.; He, Y. Deep Learning Associated with Laser-Induced Breakdown Spectroscopy (LIBS) for the Prediction of Lead in Soil. Appl. Spectrosc. 2019, 73, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Pavel, P.; Jakub, K.; Erik, K.; David, P.; David, W.; Hahn, J. On the utilization of principal component analysis in laser-induced breakdown spectroscopy data analysis, a review. Spectrochim. Acta Part B At. Spectrosc. 2018, 148, 65–82. [Google Scholar]

- Wan, Q.; Teng, G.; Li, C.; Zhao, Y.; Peng, Z. Identification and classification of explosives using semi-supervised learning and laser-induced breakdown spectroscopy. J. Hazard. Mater. 2019, 369, 423–429. [Google Scholar]

- Cisewski, J.; Snyder, E.; Hannig, J.; Oudejans, L. Support vector machine classification of suspect powders using laser-induced breakdownspectroscopy (LIBS) spectral data. J. Chemom. 2012, 26, 143–149. [Google Scholar] [CrossRef]

- Kramida, A.; Ralchenko, Y.; Reader, J.; Team, N.A. NIST Atomic Spectra Database (Version 5.7.1); National Institute of Standards and Technology: Gaithersburg, MD, USA. Available online: http://physics.nist.gov/asd (accessed on 18 October 2019).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Hao, X.; Zhang, L.; Ren, L. Application of Scikit and Keras Libraries for the Classification of Iron Ore Data Acquired by Laser-Induced Breakdown Spectroscopy (LIBS). Sensors 2020, 20, 1393. https://doi.org/10.3390/s20051393

Yang Y, Hao X, Zhang L, Ren L. Application of Scikit and Keras Libraries for the Classification of Iron Ore Data Acquired by Laser-Induced Breakdown Spectroscopy (LIBS). Sensors. 2020; 20(5):1393. https://doi.org/10.3390/s20051393

Chicago/Turabian StyleYang, Yanwei, Xiaojian Hao, Lili Zhang, and Long Ren. 2020. "Application of Scikit and Keras Libraries for the Classification of Iron Ore Data Acquired by Laser-Induced Breakdown Spectroscopy (LIBS)" Sensors 20, no. 5: 1393. https://doi.org/10.3390/s20051393