3.1. Datapath

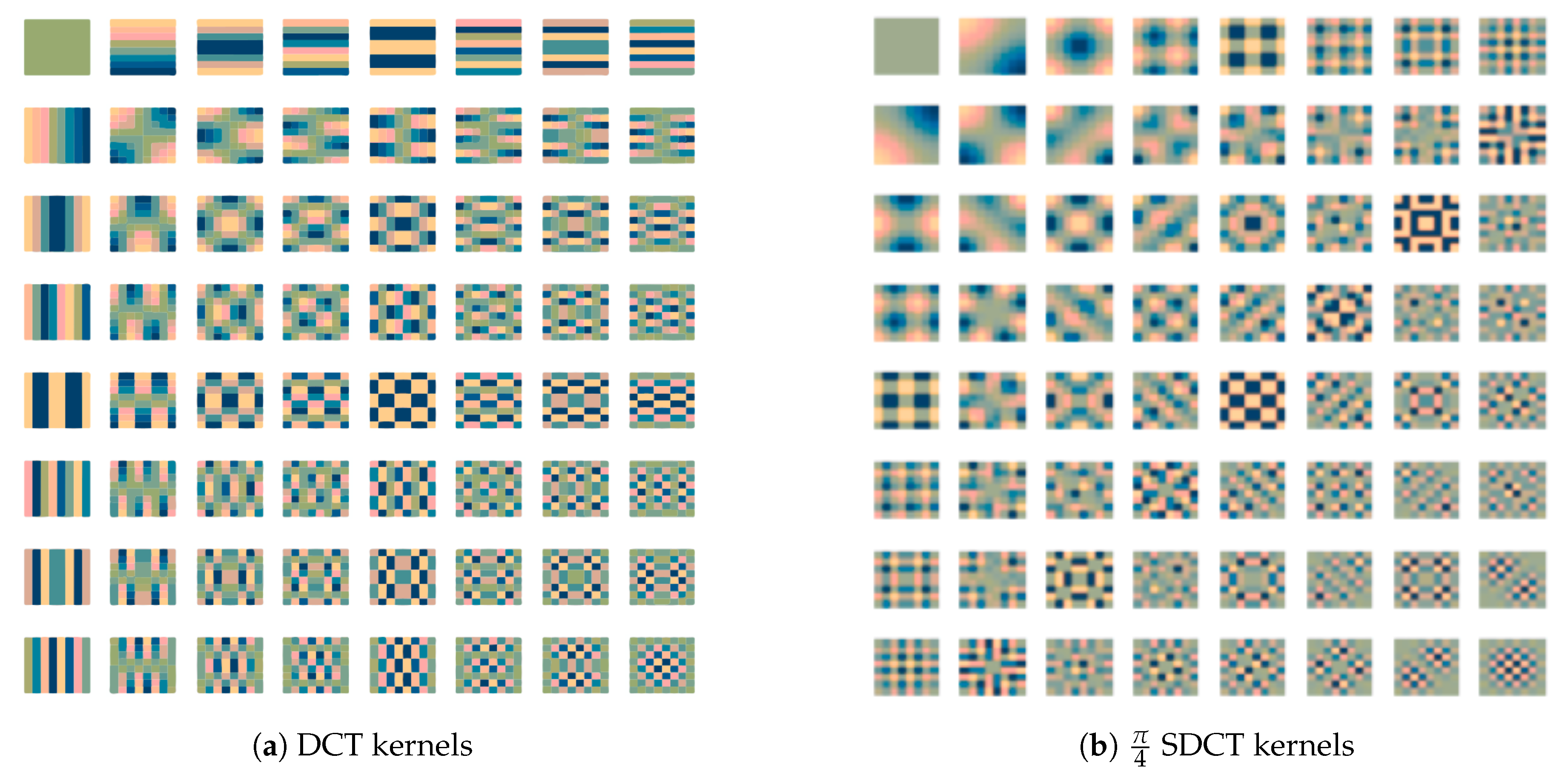

While the 2D-DCT employed in HEVC is an inherently separable operation, the SDCT must be computed all at once. The complexity of a transform that is not separable is far greater than a separable one, so this may be a big drawback for the implementation. However, the complexity can be decreased drastically by splitting the SDCT into two parts, namely, a separable 2D DCT followed by some rotations, and then by computing the separable transform before applying rotations, as reported in [

8]:

where

are the input samples,

are the results obtained by applying the

T transform matrix,

is the rotation matrix, while

is the result of the SDCT. Thus, the SDCT can be decomposed in a DCT followed by a steering transformation. The DCT part can be implemented as suggested in the literature using a folded architecture [

13]. When all the samples returned by the 2D-DCT are available, the rotations must be applied to obtain a steering transform. Since the DCT works exploiting a sliding window approach on the data, the process takes several steps to complete. However, the results will be provided all at once. This means that the steering part of the architecture has to work faster than the DCT. This issue has been tackled in this work by defining two clock regimes, one for the 2D-DCT and one, four times faster, for the steering part, to comply with the throughput offered by the 2D-DCT transform block. A FIFO memory between the two parts acts as a buffer memory. The whole structure is depicted in

Figure 3.

The 2D-DCT block is based on the architecture proposed in [

13] by Meher et al., which is very flexible and efficient, especially when dealing with folded transforms of size 4, 8, 16 and 32. The steerable part is shown in

Figure 4. It is composed of an input memory (IM), an output memory (OM) and the lifting blocks that perform the rotation [

14]. Some multiplexers are used to bypass the lifting blocks for the case of no rotation, returning directly the result given by the DCT. Despite the possiblity to bypass the IM and OM blocks when no rotation has to be applied, such an alternative leads to different latency of the architecture as a function of the rotation angle. Thus, in order to simplify the interface of the architecture, we decided to only bypass the lifting blocks. The IM is required also to reorder the samples as the steering process is computed on the custom zig-zag order given in

Figure 5; this is different from the classic zig-zag ordering, as the vectors are rotated in pairs with respect to the diagonal elements. Rotation by lifting scheme:

The rotation matrix is decomposed in the multiplication of three other rotation matrices, in such a way that the resulting structure shown in

Figure 6, presents a lower complexity. Indeed, this implementation requires only three multipliers, one less concerning the original implementation, leading to a reduction of the 25% of the computational area, shorter latency and less power consumption. To further simplify the architecture, the multiplication for P and U coefficients from Equation (

3)

in

Figure 6 are implemented as shift and add, as the number of possible rotation angles has been fixed to 8 (from 0, no rotation, to 7), as reported as optimum in [

8] by M. Masera et al. The steerable block thus introduces

clock cycles of latency for the reordering stage plus 4 clock cycles due to the internal pipeline. Therefore, in the event that all the SDCTs have a length N = 32, the latency is equal to 68 clock cycles, which corresponds to the worst case.

3.2. Control Unit

The design requires two Control Units (CUs), one for the DCT part and one for the steering part. The 2D-DCT block is managed by its control unit, which generates all the control signals and the required memory addresses. It is composed of a Finite State Machine (FSM) and a counter. The FSM is composed of two states (FWR1 and FWC1), plus an IDLE state. When the external starting input signal is received, the FSM switches from IDLE to FWR1. The counter starts to increase its value and the write_enable signal is raised so that the partial 1D-DCT results are stored in the transposition buffer at the position indicated by the counter address value. The input signal itself encapsulates the length of the current DCT and consequently the value to be reached by the counter. Once the maximum counter value (cnt_max) is reached, the FSM switches from FWR1 to FWC1. In this state, the FSM is responsible for the read memory address generation and the assertion of the data_out_valid signal. The maximum counter value in this state remains the same as the previous one. Once cnt_max is reached, the two-dimensional transformation is completed, and the FSM evolves to a new FWR1 state if the start signal is asserted again, otherwise, it returns to the IDLE state.

For what concerns the steerable block, its control unit generates all the signals needed to manage the datapath and to address the two buffers. This unit is made up of an FSM and four counters. The FSM is composed of 14 states and an IDLE state, divided into 5 functional groups.

Table 1 reports all groups functionalities. All the states belonging to the same group are similar, they are distinguished only by the different behavior of the output signals and the counter threshold.

State A coincides with the start of the steering process. Here, the 2D-DCT results are written into the input buffer. After that, the FSM switches to the B state, where the data is read from the input buffer and is written to the output one after being rotated. Then the results must be removed from the output buffer. However, as the video coding application requires to process a continuous stream of data, every time the previous results are completely written in the output buffer, new values need to be fetched and stored in the input one. State C handles such a situation, allowing the architecture to provide uninterrupted input/output data flow.

In principle, these three states plus E are enough to execute the steerable operation but the execution of multiple steerable with different lengths must be considered. The FSM complexity grows with the number of different supported SDCT lengths. As stated before, this unit supports lengths of N = 4, 8, 16 and 32. Consequently, many different states are required. For instance,

Table 2 shows one simple FSM execution, in which a steerable operation with length N = 16 is followed by a new operation with a length of N = 8. In this case, after the eight columns of new data are written in the input buffer, it is necessary to read and rotate them. The first N = 16 columns of the output buffer are filled with previous data, but not all of them have been read. Thus, the FSM introduces an offset in the writing address to avoid the overwrite of previous results. At this point, new data can be stored in the output buffer, while the old ones are read at the same time. In the opposite situation there are no problems: the new execution is longer than the previous one, so temporary storage is not needed.

The four counters are responsible for the generation of the double buffer addresses and to control the FSM evolution from state to state. Two counters are necessary to decide the next state: while the first one takes into account the previous SDCT length, the second one deals with the current SDCT length. A third counter generates the addresses for the input buffer and the coefficients Read-Only Memory (ROM). Finally, the last counter is used to point to the SDCT results in the output memory.

Figure 7 visually represents the simplified evolution of states in the control unit. The states are grouped as in

Table 1:

START: write input buffer

WAIT: read input & write output buffer

WB (Write Buffer): write input & read output buffer

RWB (Read and Write Buffer): read input & write output & read output buffer

RB (Read Buffer): read output buffer

The decision about which will be the next state depends on the the current SDCT computation phase and the size of the next SDCT to be computed, this is why the states RB, RWB and RB are so thightly interconnected.

3.3. Reduced SDCT Architectures

The unit presented so far can compute SDCT of lengths 4, 8, 16 and 32. This type of structure has been designed to be implemented inside the HEVC standard while providing maximum flexibility. This algorithm could be also used for video compression standards with lower constraints and image compression algorithms, such as JPEG. As these cases do not require the whole range of SDCT lengths, two reduced SDCT units have also been developed. The first can compute SDCT of length 4, 8 and 16 (called SDCT-16), while the second is capable of computing SDCT of length 4 and 8 (called SDCT-8). These two units have a reduced throughput of 50% and 75%, respectively, with a parallelism of 16 or 8 data samples instead of 32. This leads to a consistent reduction of the memory sizes. In particular, the length of both rows and columns of all memories is halved in the SDCT-16 unit, while it is four times lower in the SDCT-8 unit with respect to SDCT-32. As a result, the area occupation of these units is much lower than the SDCT-32 one, providing suitable solutions tailored to the final application. Moreover, since the throughput is reduced, just one clock domain has been used for both DCT and steerable block. In this way it is possible to remove the FIFO memory interface and lower the design complexity.