Soft Bimodal Sensor Array Based on Conductive Hydrogel for Driving Status Monitoring

Abstract

:1. Introduction

- (1)

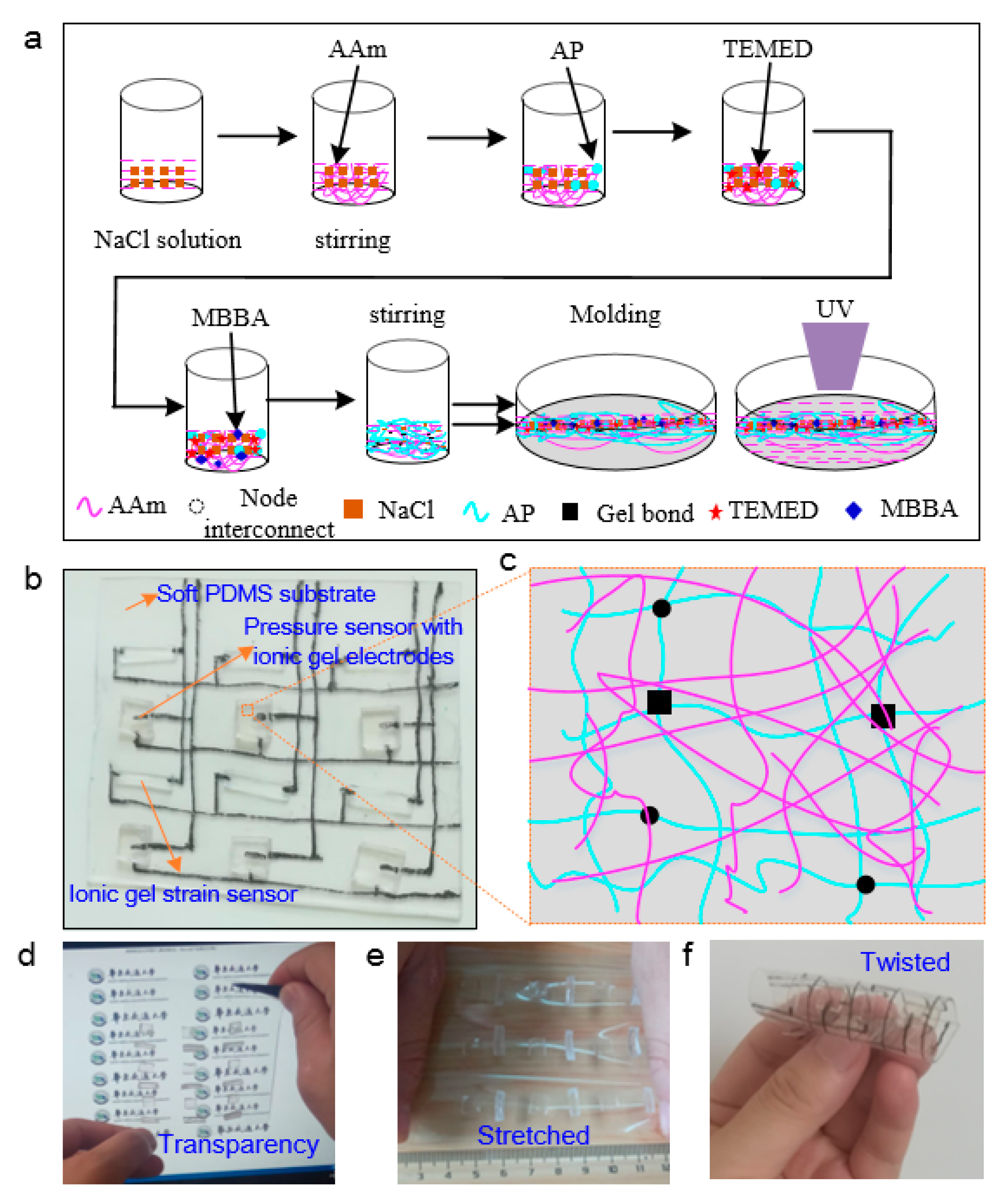

- Bimodal design and easy fabrication method of SBSA. SBSA is designed with a strain sensor based on ionic conductive gels and the capacitive pressure is based on ionic gel electrodes. The highly stretchable and transparent hydrogel is prepared through a low-cost, simple, and easy-fabricated sol–gel process. The sensor array is fabricated by the stretchable functional and structural materials to guarantee the overall softness of SBSA, which conformally contacts with the surface of the skin for stable, continuous, long-term drivers’ status monitoring.

- (2)

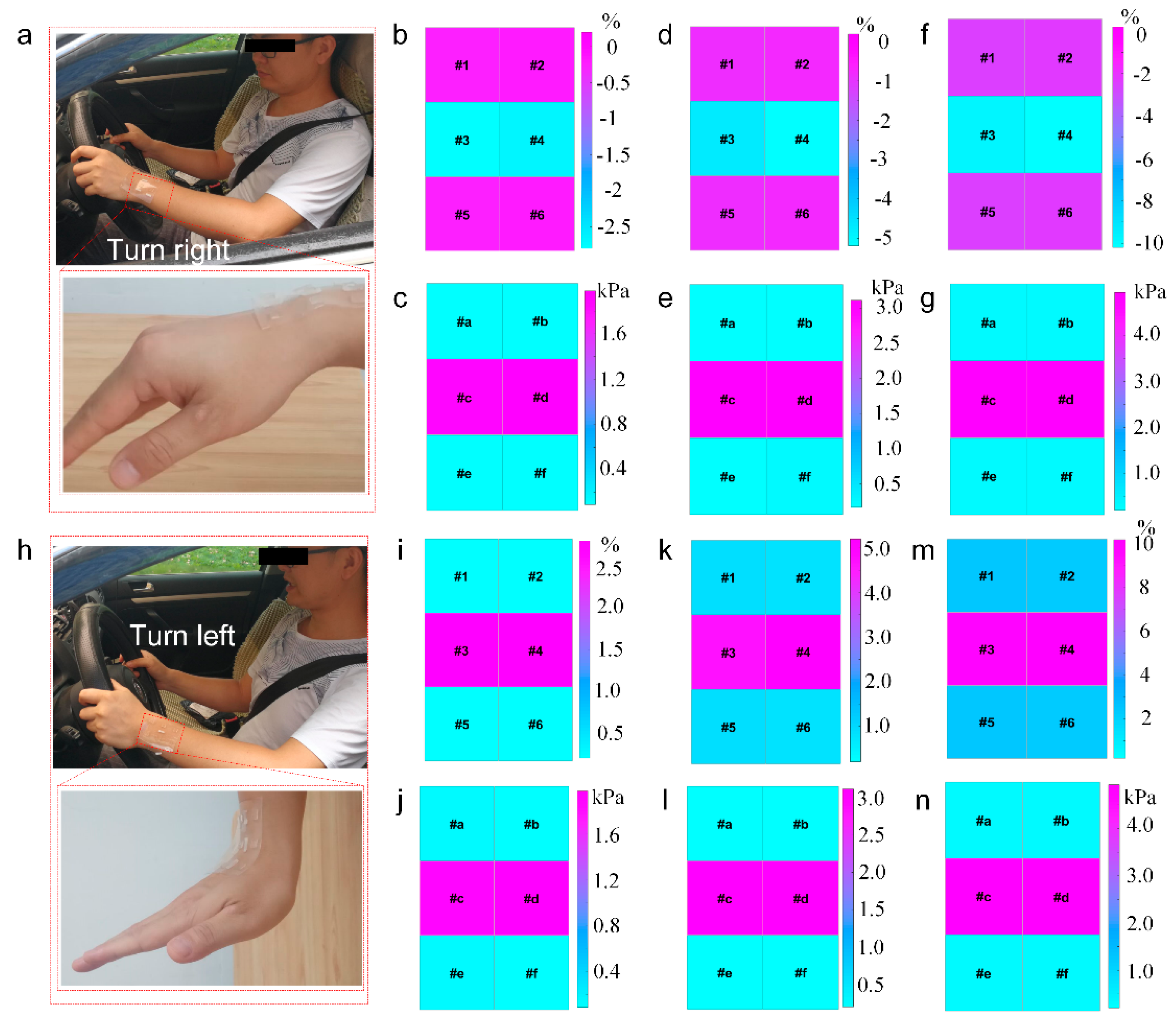

- Simple recognition method for the driver’s behaviors with the properties of conductive polymers. SBSA integrated with the strain and pressure sensor based on ionic gels is to identify the driver’s behaviors. A simple method is proposed to distinguish the turning right or left behaviors with negative and positive strain data from conductive ionic gels of SBSA. It would build up the relationship between the driving status and the strain/pressure data from SBSA. Combined with strain and pressure data values from SBSA, the responding bending angles could be computed to evaluate the driving behaviors.

2. Materials Selection and Structural Design

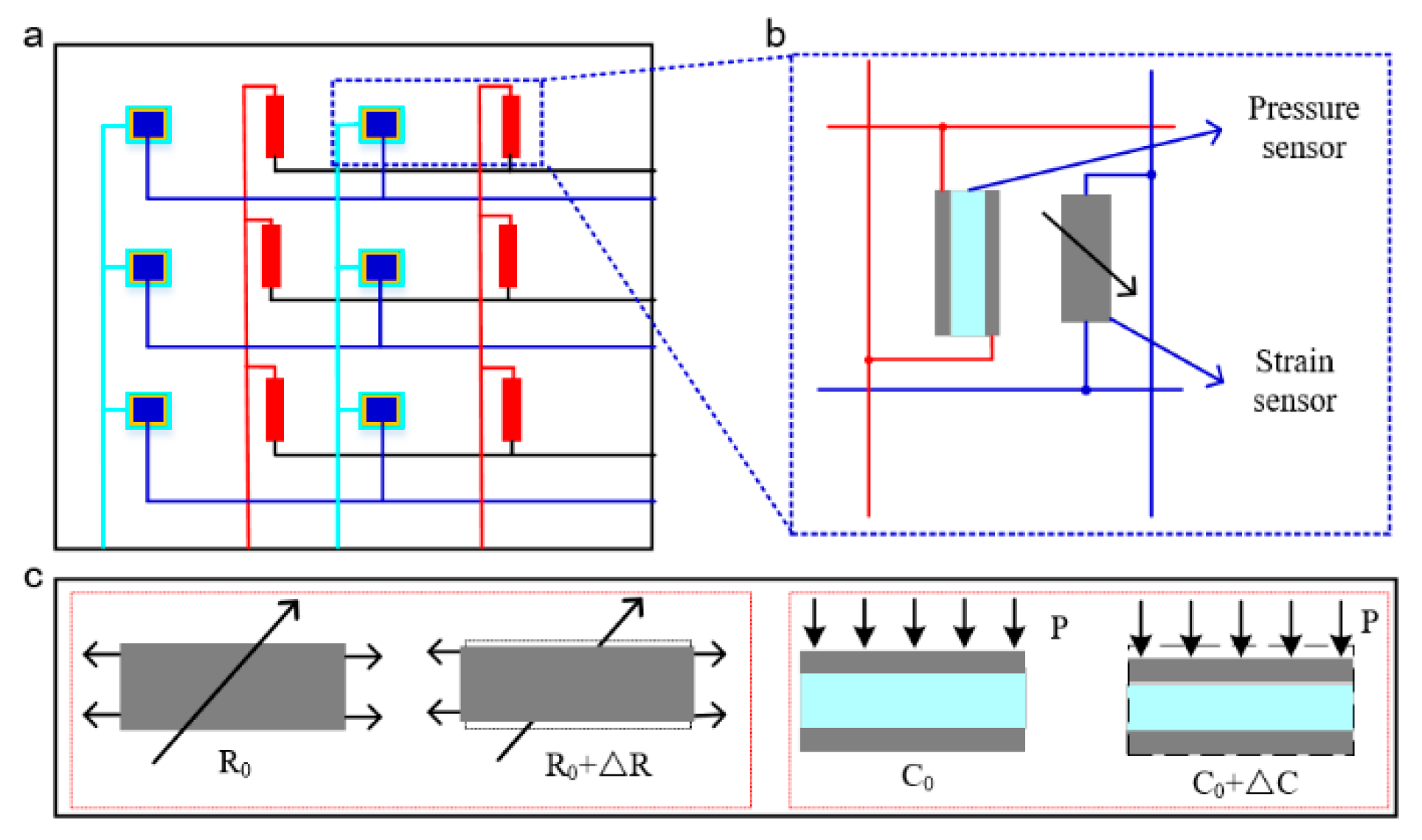

2.1. Design Strategy

2.2. Fabrication

3. Results and Application

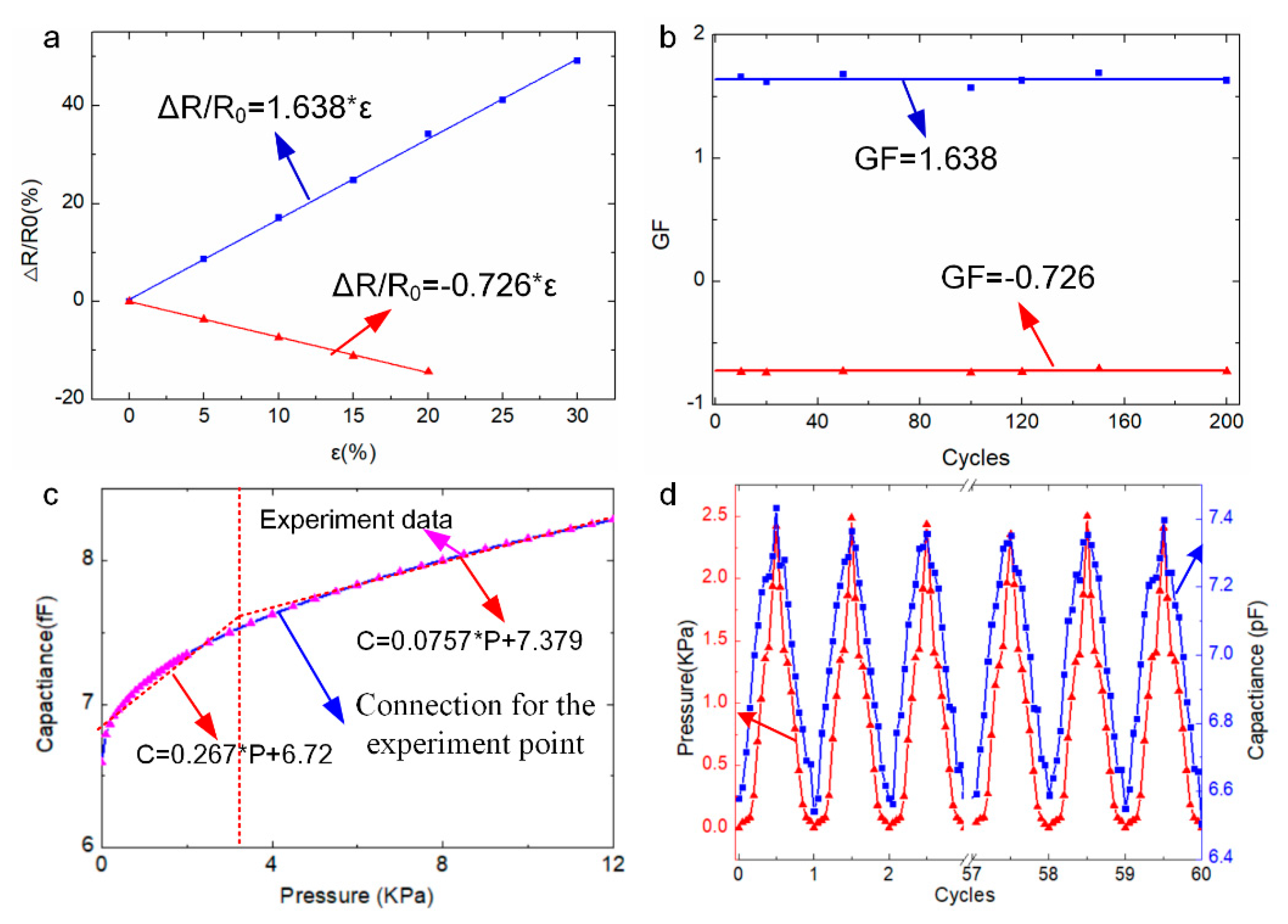

3.1. Electrical Performance

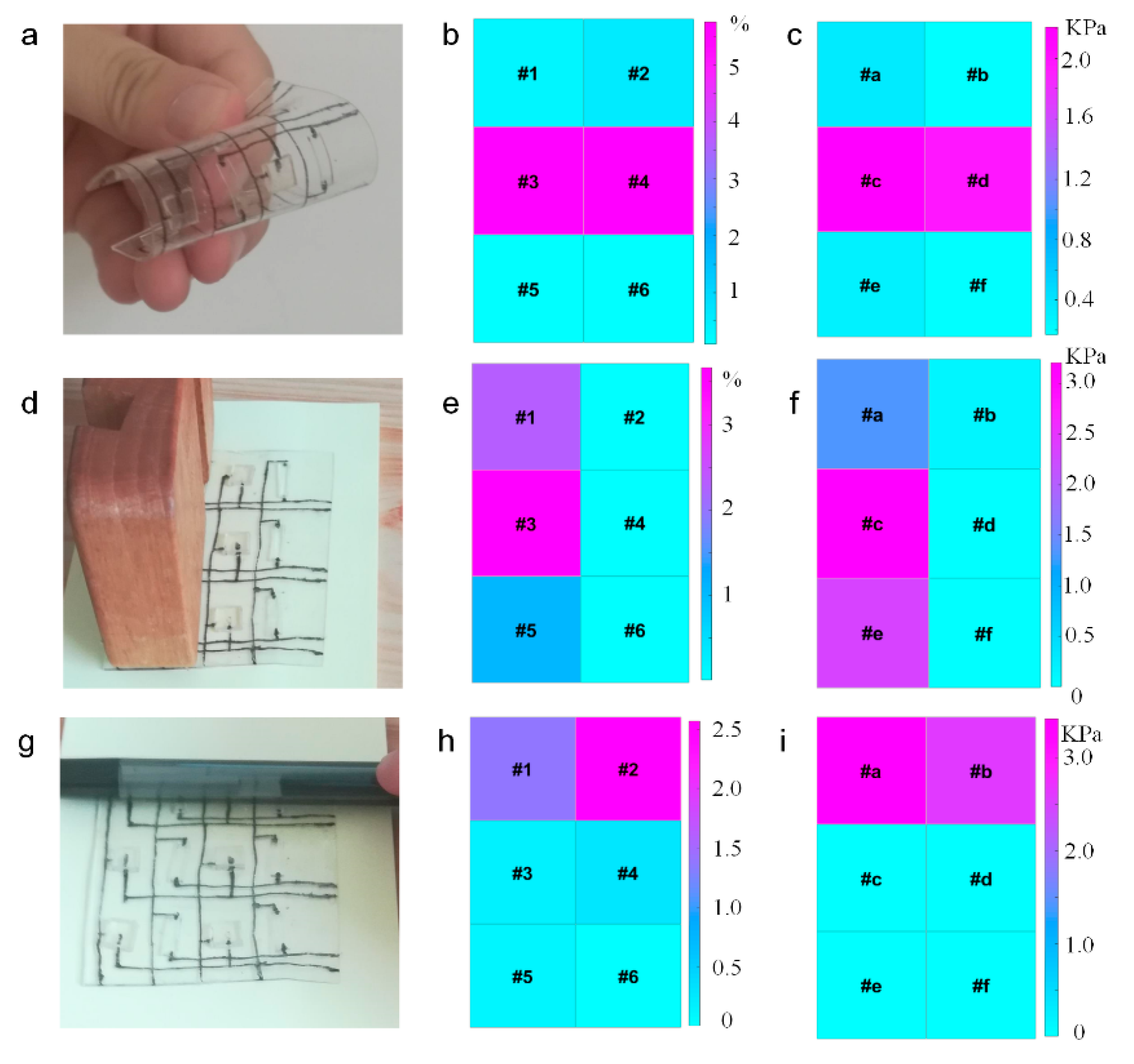

3.2. Strain and Pressure Distribution

3.3. Bending Angle Measurement

3.4. Hand Gesture Monitoring

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sigari, M.-H.; Pourshahabi, M.-R.; Soryani, M.; Fathy, M. A review on driver face monitoring systems for fatigue and distraction detection. Int. J. Adv. Sci. Technol. 2014, 64, 73–100. [Google Scholar] [CrossRef]

- Tivesten, E.; Dozza, M. Driving context and visual-manual phone tasks influence glance behavior in naturalistic driving. Transp. Res. Part F Traff. Psychol. Behav. 2014, 26, 258–272. [Google Scholar] [CrossRef] [Green Version]

- Orquin, J.L.; Loose, S.M. Attention and choice: A review on eye movements in decision making. Acta Psychol. 2013, 144, 190–206. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, S.G.; Kim, D.; Kim, S.; Yoon, J.; Lee, H.S. Human-Iris-Like aperture and sphincter muscle comprising hyperelastic composite hydrogels containing graphene oxide. Macromol. Mater. Eng. 2019, 304, 1800560. [Google Scholar] [CrossRef]

- Bu, T.; Xiao, T.; Yang, Z.; Liu, G.; Fu, X.; Nie, J.; Guo, T.; Pang, Y.; Zhao, J.; Xi, F.; et al. Stretchable Triboelectric–Photonic Smart Skin for Tactile and Gesture Sensing. Adv. Mater. 2018, 30, 1800066. [Google Scholar] [CrossRef]

- Li, W.; Hu, X.; Gravina, R.; Fortino, G. A neuro-fuzzy fatigue-tracking and classification system for wheelchair users. IEEE Access 2017, 5, 19420–19431. [Google Scholar] [CrossRef]

- Feng, Y.; Huang, X.; Liu, S.; Guo, W.; Li, Y.; Wu, H. A self-powered smart safety belt enabled by triboelectric nanogenerators for driving status monitoring. Nano Energy 2019, 62, 197–204. [Google Scholar] [CrossRef]

- Kaiser, M.S.; Chowdhury, Z.I.; Mamun, S.A.; Hussain, A.; Mahmud, M. A neuro-fuzzy control system based on feature extraction of surface electromyogram signal for solar-powered wheelchair. Cogn. Comput. 2016, 8, 946–954. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.H.; Liu, S.T.; Lin, H.D.; Tseng, W.J. Driver’s health management system using nanosecond pulse near-field sensing technology. In Proceedings of the 2014 International Conference on Computer, Communications, and Control Technology (I4CT), Langkawi, Malaysia, 2–4 September 2014. [Google Scholar]

- Jin, L.; Xian, H.; Jiang, Y.; Niu, Q.; Xu, M.; Yang, D. Research on evaluation model for secondary task driving safety based on driver eye movements. Adv. Mech. Eng. 2015, 6, 624561. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Dong, W.; Zhu, C.; Xiao, L. Electromechanical Design of self-similar inspired surface electrodes for human-machine interaction. Complexity 2018, 2018, 1–14. [Google Scholar] [CrossRef]

- Kim, J.; Lee, M.; Shim, H.J.; Ghaffari, R.; Cho, H.R.; Son, D.; Jung, Y.H.; Soh, M.; Choi, C.; Jung, S.; et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 2014, 5, 5747. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Atalay, O.; Atalay, A.; Gafford, J.; Wang, H.; Wood, R.; Walsh, C. A highly stretchable capacitive-based strain sensor based on metal deposition and laser rastering. Adv. Mater. Technol. 2017, 2, 1700081. [Google Scholar] [CrossRef]

- Li, S.; Gu, Y.; Wu, G.; Dong, K.; Jia, M.; Zhang, D.; Xiao, X. A flexible piezoresistive sensor with highly elastic weave pattern for motion detection. Smart Mater. Struct. 2019, 28, 035020. [Google Scholar] [CrossRef]

- Jeong, Y.R.; Kim, J.; Xie, Z.; Xue, Y.; Won, S.M.; Lee, G.; Jin, S.W.; Hong, S.Y.; Feng, X.; Huang, Y.; et al. A skin-attachable, stretchable integrated system based on liquid GaInSn for wireless human motion monitoring with multi-site sensing capabilities. NPG Asia Mater. 2017, 9, e443. [Google Scholar] [CrossRef] [Green Version]

- Jeong, J.W.; Yeo, W.H.; Akhtar, A.; Norton, J.J.; Kwack, Y.J.; Li, S.; Jung, S.-Y.; Su, Y.; Lee, W.; Xia, J.; et al. Materials and optimized designs for human-machine interfaces via epidermal electronics. Adv. Mater. 2013, 25, 6839–6846. [Google Scholar] [CrossRef]

- Lim, S.; Son, D.; Kim, J.; Lee, Y.B.; Song, J.K.; Choi, S.; Lee, N.J.; Kim, J.H.; Lee, M.; Hyeon, T.; et al. Transparent and stretchable interactive human machine interface based on patterned graphene heterostructures. Adv. Funct. Mater. 2015, 25, 375–383. [Google Scholar] [CrossRef]

- Sungmook, J.; Hoon, K.J.; Jaemin, K.; Suji, C.; Jongsu, L.; Inhyuk, P.; Hyeon, T.; Kim, D.H. Reverse-micelle-induced porous pressure-sensitive rubber for wearable human-machine interfaces. Adv. Mater. 2014, 26, 4825–4830. [Google Scholar]

- Han, S.; Kim, M.K.; Wang, B.; Wie, D.S.; Wang, S.; Lee, C.H. Mechanically reinforced skin-electronics with networked nanocomposite elastomer. Adv. Mater. 2016, 28, 10257–10265. [Google Scholar] [CrossRef]

- Benight, S.J.; Wang, C.; Tok, J.B.H.; Bao, Z. Stretchable and self-healing polymers and devices for electronic skin. Prog. Polym. Sci. 2013, 38, 1961–1977. [Google Scholar] [CrossRef]

- Dong, W.; Xiao, L.; Zhu, C.; Ye, D.; Wang, S.; Huang, Y.; Yin, Z. Theoretical and experimental study of 2D conformability of stretchable electronics laminated onto skin. Sci. China Technol. Sci. 2017, 60, 1415. [Google Scholar] [CrossRef]

- Al-Rahayfeh, A.; Faezipour, M. Eye Tracking and Head Movement Detection: A State-of-Art Survey. IEEE J. Transl. Eng. Health Med. 2013, 1, 2100212. [Google Scholar] [CrossRef] [PubMed]

- Ge, G.; Zhang, Y.; Shao, J.; Wang, W.; Si, W.; Huang, W.; Dong, X. Stretchable, transparent, and self-patterned hydrogel-based pressure sensor for human motions detection. Adv. Funct. Mater. 2018, 28, 1802576. [Google Scholar] [CrossRef]

- Won, S.M.; Song, E.; Zhao, J.; Li, J.; Rivnay, J.; Rogers, J.A. Recent advances in materials, devices, and systems for neural interfaces. Adv. Mater. 2018, 30, e1800534. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, Z.; Yang, J.; Xu, C.; Zhang, Q.; Peng, Z. Ionic gels and their applications in stretchable electronics. Macromol. Rapid Commun. 2018, 39, 1800246. [Google Scholar] [CrossRef]

- Sun, J.Y.; Keplinger, C.; Whitesides, G.M.; Suo, Z. Ionic skin. Adv. Mater. 2014, 26, 7608–7614. [Google Scholar] [CrossRef]

- Tang, J.; Li, J.; Vlassak, J.J.; Suo, Z. Adhesion between highly stretchable materials. Soft Matter 2016, 12, 1093–1099. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Zhao, X. Hydrogel bioelectronics. Chem. Soc. Rev. 2019, 48, 1642–1667. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Miao, L.; Su, Z.; Song, Y.; Han, M.; Chen, X.; Cheng, X.; Chen, D.; Zhang, H. Fingertip-inspired electronic skin based on triboelectric sliding sensing and porous piezoresistive pressure detection. Nano Energy 2017, 40, 65–72. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Xu, D.; Michel, S.; McKay, T.; O’Brien, B.; Gisby, T.; Anderson, I. Sensing frequency design for capacitance feedback of dielectric elastomers. Sens. Actuators A Phys. 2015, 232, 195–201. [Google Scholar] [CrossRef]

- Maiolino, P.; Galantini, F.; Mastrogiovanni, F.; Gallone, G.; Cannata, G.; Carpi, F. Soft dielectrics for capacitive sensing in robot skins: Performance of different elastomer types. Sens. Actuators A Phys. 2015, 226, 37–47. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H. Flexible, stretchable sensors for wearable health monitoring: Sensing mechanisms, materials, fabrication strategies and features. Sensors 2018, 18, 645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Li, Y.; Su, M.; Li, W.; Li, Y.; Li, H.; Qian, X.; Zhang, X.; Li, F.; Song, Y. Electronic textile by dyeing method for multiresolution physical kineses monitoring. Adv. Electron. Mater. 2017, 3, 1700253. [Google Scholar] [CrossRef]

- Rajabi, M.; Roxhed, N.; Shafagh, R.Z.; Haraldson, T.; Fischer, A.C.; Van Der Wijngaart, W.; Stemme, G.; Niklaus, F. Flexible and stretchable microneedle patches with integrated rigid stainless steel microneedles for transdermal biointerfacing. PLoS ONE 2016, 11, e0166330. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Pharr, M.; Salvatore, G.A. A Lab-on-Skin: A review of flexible and stretchable electronics for wearable health monitoring. ACS Nano 2017, 11, 9614. [Google Scholar] [CrossRef] [PubMed]

- Keplinger, C.; Sun, J.Y.; Foo, C.C.; Rothemund, P.; Whitesides, G.M.; Suo, Z. Stretchable, transparent, ionic conductors. Science 2013, 341, 984–987. [Google Scholar] [CrossRef] [Green Version]

- Calvert, P. Hydrogels for soft machines. Adv. Mater. 2009, 21, 743–756. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Huang, Z.; Xu, S. Materials and structures toward soft electronics. Adv. Mater. 2018, 30, 1801368. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Koganezawa, K.; Yamashita, H. Three DOF wrist joint—Control of joint stiffness and angle. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 1973–1979. [Google Scholar]

- Bae, G.Y.; Han, J.T.; Lee, G.; Lee, S.; Kim, S.W.; Park, S.; Kwon, J.; Jung, S.; Cho, K. Pressure/Temperature sensing bimodal electronic skin with stimulus discriminability and linear sensitivity. Adv. Mater. 2018, 30, e1803388. [Google Scholar] [CrossRef]

- Jung, M.; Kim, K.; Kim, B.; Cheong, H.; Shin, K.; Kwon, O.S.; Park, J.-J.; Jeon, S. Paper-based bimodal sensor for electronic skin applications. ACS Appl. Mater. Interfaces 2017, 9, 26974–26982. [Google Scholar] [CrossRef] [PubMed]

| Sensor Array | Sensing Ability | Stretch Ability | Fabrication | Sensitivity |

|---|---|---|---|---|

| Literature [41] | Pressure/temperature | <2% | MEMS | 0.7 kPa−1 |

| Literature [42] | Pressure/temperature | <3% | Inject print | -- |

| Literature [7] | Strain | >20% | MEMS | 0.89 V/cm2 |

| This manuscript | Strain/pressure | >15% | sol–gel process | 1.638/0.267 kPa−1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, W.; Yao, D.; Yang, L. Soft Bimodal Sensor Array Based on Conductive Hydrogel for Driving Status Monitoring. Sensors 2020, 20, 1641. https://doi.org/10.3390/s20061641

Dong W, Yao D, Yang L. Soft Bimodal Sensor Array Based on Conductive Hydrogel for Driving Status Monitoring. Sensors. 2020; 20(6):1641. https://doi.org/10.3390/s20061641

Chicago/Turabian StyleDong, Wentao, Daojin Yao, and Lin Yang. 2020. "Soft Bimodal Sensor Array Based on Conductive Hydrogel for Driving Status Monitoring" Sensors 20, no. 6: 1641. https://doi.org/10.3390/s20061641