1. Introduction

Piezoresistive single crystal silicon (Si) based sensors are widely used to measure pressure in numerous applications, including aerospace, oil and gas, and industrial [

1,

2,

3,

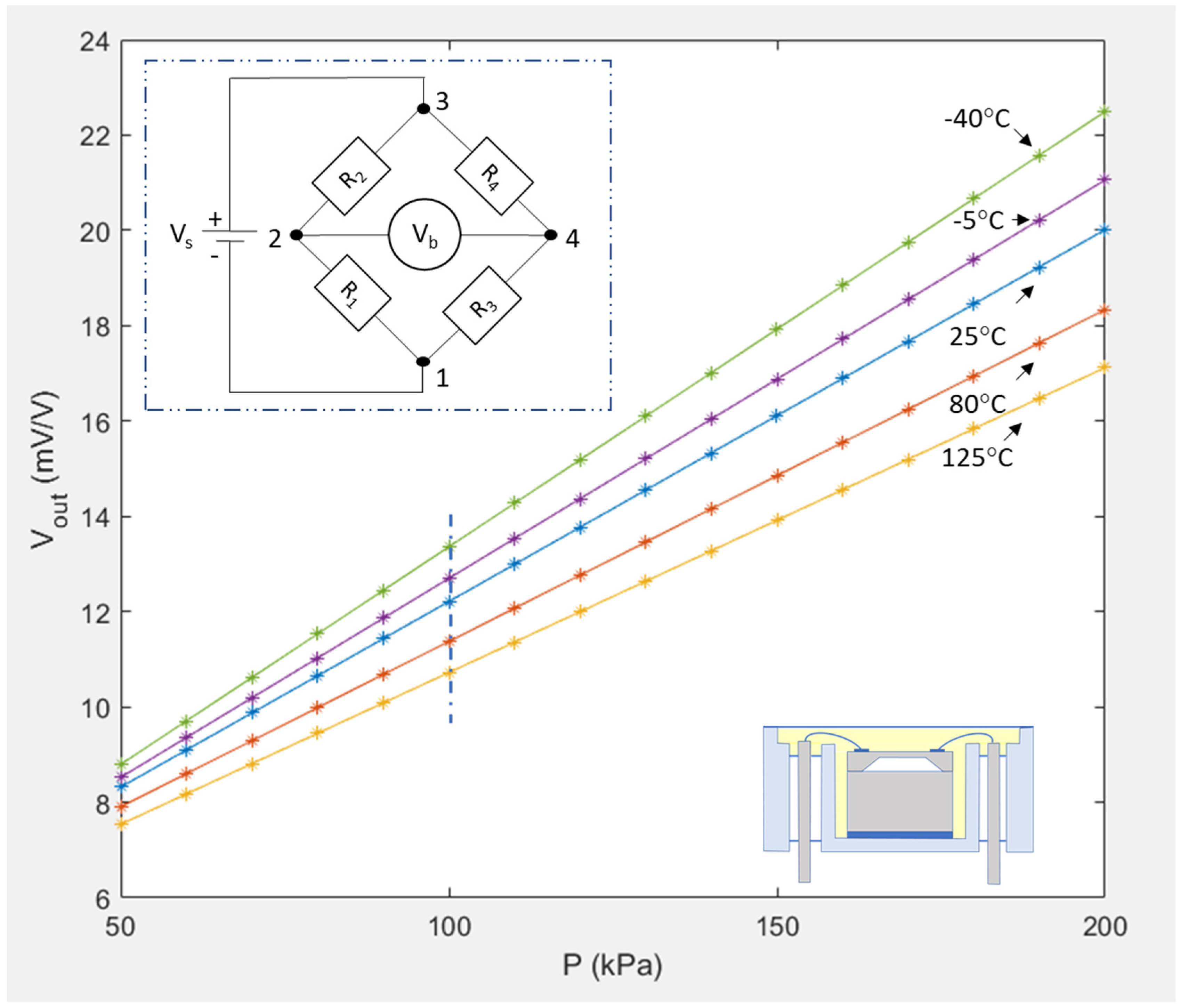

4]. Their transduction mechanism is based upon the external pressure causing the deflection of a thinned section of Si that forms a diaphragm. This deflection is sensed through the use of piezoresistors embedded in the Si surface which act as strain gauges connected in a Wheatstone bridge configuration, thereby transforming the applied pressure into a voltage output. This mechanism has been widely studied over the last 50 years, where the mechanical properties of single crystal Si [

5,

6,

7] and its piezoresistive properties at different doping concentrations [

8,

9,

10,

11,

12] have been well established. Enhanced models, which account for both the anisotropy of Si and thermal effects on the piezoresistivity, have also been recently published [

13,

14,

15,

16,

17,

18,

19]. This provides an excellent basis for initial sensor design, but cannot be solely relied upon to accurately predict the output of a complete pressure sensor. This is because the isolated sensing element (SE), which the theoretical models describe, cannot function as a practical pressure sensor if it is not mechanically supported and protected, and its electrical output made accessible to electronic instrumentation, i.e., it is packaged. Therefore, various packaging elements are required to transform the SE into a functioning sensor, but these may themselves affect the diaphragm deflection and/or the measured voltage output of the SE. While considering the SE alone was acceptable in the past, researchers and designers are recognizing the need to account for the effects of packaging elements as significant performance drivers for complete piezoresistive pressure sensors [

20,

21], particularly where devices are required to operate with higher precision and stability over longer operational lifetimes and within more demanding operating environments.

Pressure sensors can have various mechanical elements supporting and protecting the SE, such as adhesives [

22], frits [

23], glob tops [

24], isolation fluids [

25], and metal membrane caps [

26]. Electrical elements connecting the piezoresistors to signal conditioning electronics can include the bond pad metallisations on the SE surface [

27] along with, for example, wire bonds [

28], solders [

29,

30], or more complex flip chip connections [

31]. The role of each of these elements on the performance of a SE is not fully understood and their impacts will vary with the particular overall sensor design. Developing a universal transduction model capable of predicting the effect of such a wide range of packaging elements on the SE output would therefore be challenging; however, if the most significant contributors of a particular design can be identified then this will facilitate further improvements. With this in mind, the primary aim of this study is to propose a novel methodology, independent of sensor design, for assessing the relative effects of packaging elements on the performance of a chosen device. This would enable the quantification of the individual contributions and highlight the areas for focus in any future design optimisation.

Piezoresistive pressure sensors have been reported to exhibit thermal dependency similar to that reported by Liu et al. [

19]. Thermal dependence can have its source either in the Si itself or in the elements used to package the SE. The stiffness of Si has both first and second order temperature coefficients [

32], while there is also a thermal component to its piezoresistive coefficient, as reported by Kanda [

12]. Si also has a temperature coefficient of resistance that is a function of doping levels. During device manufacturing, and throughout its operational lifetime, temperature-dependent package-related stresses will inevitably be transferred to the SE, due to different thermal expansion coefficients and other temperature dependent behaviour of the package. The SEs are usually designed so that any symmetrical stresses affecting the piezoresistors within the Wheatstone bridge are theoretically cancelled out. However, due to manufacturing tolerances and the assembly sequences, packaging will rarely impose perfectly balanced stresses that remain constant with time. The combined effects of most of these dependencies can be eliminated if the temperature of the SE is known and a mathematical fitting function [

21,

31] is applied to the raw voltage output to correct for any thermal contributions to the pressure signal. When the effects of these stresses cannot be compensated away, their effects will be falsely misinterpreted as pressure inputs that the sensor is designed to measure and will therefore negatively impact the performance of the sensor.

As will be described later, when thermally cycled, the stresses imposed on the SE by the packaging elements may lead to device hysteresis, i.e., the output voltage for the same applied pressure will vary depending on the thermal history [

33]. However, to accurately quantify any hysteresis requires the sensor output to be recorded at identical pressure and temperature values during both the increasing and decreasing phases of the temperature cycle. In practice, due to limitations of the measurement system as well as in the pressure and temperature controllers, the applied pressure and temperature always vary slightly from the desired set values. An interpolation of the raw data to a fitted value at exactly the required point is consequently necessary to account for these variations and to ensure the calculated hysteresis is due to packaging effects and not due to errors in the test and measurement system. Therefore, a secondary aim of this paper is to establish the benefit and necessity of fitting the data as a means of accurate identification of the presence of sensor hysteresis and its quantification.

There have been a number of published studies on thermal hysteresis of piezoresistive pressure sensors [

21,

31,

34,

35]. All investigated fully packaged sensors, and to the authors’ knowledge, none have investigated the relative contributions of the packaging elements involved in a particular design to the overall hysteresis. Waber et al. [

31] characterised a flip-chipped absolute pressure sensor cleverly decoupled from its substrate using flexible copper springs. The hysteresis of the sensor was studied over a −30 to 70 °C temperature range at 100 kPa by applying a fitting function to the sensor’s raw output. The hysteresis was reduced from 140 to 20 Pa by reducing the width of the metallisation on the active face and increasing the depth of the reference cavity. Unfortunately, neither details of the number of pressure and temperature cycles used to obtain the fitting function, nor its mathematical description, were presented. Sandvand et al. [

21] used a linear regression applied to the third thermal cycle to measure the hysteresis effect due to a 0.8 μm-thick Aluminium (Al) metallisation layer deposited directly on top of the piezoresistors in an absolute SE designed for pressures up to 100 kPa. These SEs were glass frit bonded to a Si stress isolation layer, which itself was glass frit bonded to a TO-8 header. The study reported that the units underwent ten –55 to 125 °C thermal cycles followed by a stabilisation bake for 24 hours at 150 °C. The sensors having the extra Al metallisation on top of the piezoresistors exhibited an additional error of approximately 250 Pa (0.25% of full scale) compared with those without the extra Al. The thermal hysteresis figures in these papers were determined over different temperature ranges and the sensors did not undergo the same thermal preconditioning. It is, therefore, unfortunately not possible to directly compare their results and draw any further conclusions on the effects of the packaging on thermal hysteresis.

In summary, two specific aims were addressed in this study. First, a packaging and testing methodology was derived in order to identify the relative contributions of packaging elements to thermal hysteresis over several temperature cycling ranges. Without being subjected to any thermal pre-treatment, the same SEs were packaged in consecutive configurations, so that differences due to variability from SE to SE could be eliminated. As a hypothesis, it is postulated that packaging effects are cumulative in nature and that one could predict the overall hysteresis by knowing the effect of each group of packaging elements. If this is correct, then the methodology of decomposing the entire package into “sub-packages” could be generalized to other packaging configurations incorporating different sets of packaging elements. The second aim of this work was to establish the requirement for fitting the sensor’s output voltage as a means of eliminating any test and measurement inaccuracies to reveal and quantify hysteresis as a function of the thermal cycling regime. This included an investigation of the effect of increasing orders of polynomial fitting function, leading to the use of the same optimal polynomial order to compare hysteresis values between the different packaging levels.

4. Packaging Element Effects on Sensor Hysteresis

In this study, it was decided that the SEs would not be subject to any thermal preconditioning prior to testing and that all fitting functions, although unique to every sensor, would be of the same mathematical form and polynomial order. This would therefore enable a direct comparison between hysteresis errors of differently packaged pressure sensors. Hysteresis can be evaluated at different pressures, but to simplify the study, all hysteresis effects were calculated only at 100 kPa for the five SEs at each successive packaging level from L1-F to L2. These were tested and data-processed for the limited (5 to 65 °C), intermediate (−20 to 80 °C), and extended (−40 to 125 °C) thermal ranges (LR, IR, and ER respectively). The packaging effects on hysteresis are presented for SE #9, but all of the other four repackaged SEs displayed similar trends.

4.1. Temperature Cycle Range Effect on Hysteresis

Figure 6 shows the fitting error loops for SE #9 when packaged in the L1-F configuration. The blue, green, and red loops represent the LR, IR, and ER respectively. Each loop starts with a filled dot representing the start of the first cycle, and the top right arrow shows the thermal cycling direction. For the LR (blue loop), the test was stopped before the end of the fourth cycle, and therefore hysteresis could only be calculated for the first three cycles.

The first cycles of the IR and ER loops (green and red) looked quite different from their subsequent three cycles. This is due to the fact that, for this packaging configuration only, more intermediate temperature points with respect to the original design of experiment were included in the testing. These were added, as the scale of hysteresis effects was not fully understood at that initial stage of testing. It was, furthermore, chosen to only make measurements at the extreme temperature points and at 25 °C throughout the remaining three cycles to shorten the test time. The hysteresis values were calculated as 7.4, 19.8, and 49.5 μV/V for the LR, IR, and ER respectively, and two observations were made. Firstly, as expected, hysteresis increased with increasing temperature range (a factor of 7 increase between the LR and ER). Secondly, for all temperature ranges, the fitting error loops largely stabilised and became repeatable after just one full temperature cycle.

Figure 7 shows the fitting error loops for the same SE when repackaged in the L1 configuration. The hysteresis values were calculated as being 27.9, 26.7, and 51.9 μV/V for the three cycle ranges. Unlike the L1-F package, the LR and IR loops exhibited a “ratcheting” effect wherein the loop moved downwards with each cycle, although this behaviour was not displayed during the extended temperature range cycles. As the tests were performed consecutively and the ratcheting effect was not present in the L1-F package, the ratcheting behaviour was attributed to the additional presence of the adhesive and housing elements in the L1 package. Of these two packaging elements, it is thought likely that the ratcheting is primarily due to the inelastic nature of the adhesive (a two-part epoxy) rather than the housing (stainless steel). It was also noticeable for both the LR and IR that the ratcheting appeared to be stabilising, i.e., the change in offset with each cycle was reducing. This can be seen by analysing the difference in the consecutive error values at the maximum temperatures of the loops (i.e., the blue and green circles at the 65 and 80 °C points, respectively). In contrast, the loop for the extended temperature range stabilised after only one cycle. In this case, it was observed that the first two points (i.e., at 25 and 80 °C) of the extended loop were significantly outside of the following stabilised loops, which led to the first cycle dominating the hysteresis of the unit.

Figure 8 shows error loops for the L2 packaged SE #9, for which the hysteresis values calculated for the three cycle ranges were 9.54, 15.2, and 55.9 μV/V. There was an initial phase of ratcheting of the loop for the LR cycle, which was attributed to the additional presence of the isolation membrane and the fluid fill, rather than the adhesive. Indeed, the adhesive was added in the L1 packaging stage and had already stabilised after the previous ER cycling. As the isolation membrane was welded onto the housing, the ratcheting was assumed to stem from the welded joint between the membrane and housing and not the fluid fill. By observing the decrease in the distance between consecutive points at 65 °C, it can be seen that it only took two cycles for these hysteresis loops to stabilise. As for the L1 package results, it was observed that the first points of the first cycle were significantly outside of the stabilised loops. It could only be concluded that a non-permanent physical phenomenon was occurring during that stage of the first cycle, which disappeared later in the cycling.

4.2. Evaluation of Packaging Stages on Consecutively Tested SEs

Figure 9 shows the sequence of hysteresis values for SE #9 as it was consecutively packaged from L1-F to L2. Each bar represents the hysteresis value over the extended temperature range (i.e., the red loops of

Figure 6,

Figure 7 and

Figure 8). Comparing packaging configurations to one another was deemed appropriate only for the cases where the loop exhibited a stabilised behaviour, which only occurred for the ER. The LR and IR were therefore not compared, as the ratcheting effect dominated the hysteresis value and one would be comparing the stabilisation of the packaging rather than actual hysteresis behaviour. Assuming the superposition principal holds true, it is possible to calculate the amount of hysteresis contributed by the individual groups of packaging elements. From a hysteresis value of 55.9 μV/V for the L2 package, 7.2% was attributed to the isolation membrane and the fluid fill, 4.3% was attributed to the adhesive and housing, and the remaining 88.5% was attributed to the bond pads and wire bonds. This result is of paramount importance, as it shows that further investigation of the L1-F packaging elements should be prioritised if hysteresis is to be significantly improved.

4.3. Thermal Stabilisation Due to Packaging Elements

It was found that, when calculated for each individual cycle, hysteresis often decreased with repeated thermal cycling.

Figure 10 shows the hysteresis value per cycle for SE #9 in the L2 configuration when consecutively cycled. It can be seen that, for the LR cycles, hysteresis reduced from 7.8 μV/V over the first cycle to 3.8 μV/V over the last; i.e., a total decrease of 51.3%. During the IR cycles, the unit exhibited a stable hysteresis of 14 μV/V, whereas for the ER cycles, hysteresis decreased from 58.7 μV/V over the first cycle to 45.4 μV/V over the last. This represented an overall reduction of 22.6%, most of which occurred between the first and second cycle.

5. Discussion

To the authors’ knowledge, this study is the first to consecutively package the same SEs to increasing levels in order to determine the relative contribution of the packaging elements to thermal hysteresis. Fitting is of paramount importance in the assessment of thermal hysteresis, as it enables the hysteresis to be confidently attributed to the packaging and not to uncertainties within the test set up. This good practice is not systematically applied, with some authors touching upon this matter [

21,

31] and others not [

41]. To the authors’ knowledge, this study is also the first to do a systematic evaluation of increasing fitting orders on revealing thermal hysteresis, and to use the same fitting order on consecutively packaged sensors to compare the relative contributions of packaging elements. However, quantitative comparisons were judged to be acceptable only for instances in which the sensor exhibited stabilised, ratcheting-free thermal hysteresis loops.

5.1. Temperature and Humidity Effects on Hysteresis

Increased hysteresis for the wider temperature range cycles was expected, due to the increase in any package-related stress due to coefficient of thermal expansion (CTE) mismatches, which are then transmitted to the piezoresistors, thus changing the voltage output of the sensor. It is possible that the packaging materials are therefore subjected to viscoplastic and/or creep deformation, leading to history-dependant behaviour that is therefore very difficult to fit, as demonstrated by the pronounced hysteresis values. The ratcheting seen for the L1 package is thought to be due to the adhesive continuing to cure throughout both the LR and IR cycling, as the adhesive was initially cured at room temperature only. The ratcheting stopped after cycling the unit once over the ER, which suggests that one cycle at the extended range is more effective in stabilising the adhesive than multiple thermal cycles over narrower ranges. However, this could only be confirmed if the L1 configuration were to be cycled again in the LR and IR to observe whether the ratcheting effect had permanently disappeared. This test was unfortunately not undertaken prior to packaging the SEs into the L2 configuration. However, analysing the L2 package behaviour suggests that the repeatable loops seen for both the LR (after only the second cycle) and the IR, indicate that the adhesive had indeed stabilised after the ER in the L1 configuration. A suitable preconditioning step for the adhesive packaging element might therefore be to cycle it two or three times over the −40 to 125 °C range.

It should be noted that the L1 packages were exposed and therefore potentially sensitive to changes in humidity in the pressurising medium, as reported in the literature [

42,

43,

44]. The testing apparatus applied relatively dry pressurised air, which could affect the level of moisture that may have accumulated within the adhesive during the rest time before the LR testing commenced. Therefore, the ratcheting effect cannot be conclusively attributed to temperature alone. It could be that the initial ratcheting effect is due to humidity being slowly desorbed from the adhesive when subjected to the dry air. As the initial humidity level of the adhesive was not controlled during this test, it would be necessary for future experiments to precondition the units such that testing of all exposed packages (L1-F and L1) would commence after stabilisation at the same humidity level.

5.2. Thermal Cycling Effects on Hysteresis

During the first cycle, the initial data points, as the temperature increased from 25 °C towards the maximum of the cycle, did not follow a similar line to the points recorded at the same temperatures in later cycles. This could be indicative of a relaxation phenomenon within the packaging elements, which would be expected to depend on the resting time between tests. Plastic deformation during the first cycle was ruled out, as the loops resumed a “stable” path after the second cycle onwards. It would be interesting to establish whether the deviation of the initial starting points is directly dependent on the resting time between tests and/or on the resting storage temperature. Similar tests could therefore be repeated after a period of resting time (e.g., three months) where the first cycle of the new test is compared to the last cycle of the previous test. This could indicate the presence of a non-permanent deformation behaviour (e.g., viscoelastic) of the packaging elements during storage. As a non-negligible part of the hysteresis is due to these initial data points, it could be argued that the calculation of the hysteresis accounting for all data points is too conservative. This could be conceded only if one was sure that all subsequent hysteresis loops, following a resting time period, were also stable.

The data indicates that the hysteresis observed in this study mainly stems from the elements present in the L1-F configuration, which are the Al–Si bond pads, the Al–Si wire bonds, and the borosilicate glass. As the borosilicate glass is CTE-matched to Si and is in contact with the underside of the SE away from the piezoresistors, this is not thought to contribute significantly to the hysteresis. However, due to the pronounced CTE mismatch (20.7 × 10−6 /°C) between the Al–Si and Si and the location of the bond pads on the active face of the SE and in close proximity to the piezoresistors, it is thought that the bond pads and/or the attached wire bonds are the main contributors to hysteresis.

The hysteresis could stem from the wire bonds exerting temperature-dependant stresses. Due to the CTE mismatch (8.5 × 10−6 /°C) between the housing and the Si, the effective distance between the bond pad and the feedthrough pin could change with temperature, leading to changes in the stresses transmitted from the wire bonds to the bond pad metallisations, and hence to the piezoresistors. This could be the case, especially for the L1-F configuration where the SEs were only supported by the wire bonds. It could be argued that an indirect way of assessing the effect of the wire bonds pulling on the L0 package would be to deliberately introduce changes in bond wire stresses.

Hysteresis could also stem from the bond pads experiencing stresses that are beyond their elastic limit [

45,

46,

47]. Due to the manufacturing sequence of the L0 package, it is believed that returning to room temperature after both sintering the Al–Si and bonding to glass at elevated temperatures led to inelastic stress at least at the base of the bond pads where they are in contact with the Si. It therefore seems likely that the bond pads during the thermal cycling test are experiencing a combination of creep and plastic behaviour that could stem from dislocation alignment within the Al–Si bond pads as suggested by Khatibi et al. [

48]. This behaviour would lead to the appearance of the hysteresis loops, the size of which would depend on the temperature points and the time spent at each point. Performing a cross section of the bond pad/Si interface may reveal any microstructural changes with electron microscopy, but was not possible in these experiments, as a destructive test such as this would impede the consecutive nature of the packaging methodology. However the existence of creep could be validated by conducting material analysis of the in-situ properties of the pad metallization, using, for example, nanoindentation at different temperatures and over time scales comparable to those applied during the thermal cycles. It would also be important to correlate any creep within the Al–Si to creep experiments for the SE in an L1-F packaging configuration. This would necessitate finite element modelling of at least the L1-F configuration, which should be capable of predicting creep in the Al–Si under different thermal conditions and the corresponding stresses transferred to the piezoresistors.

It could be argued that, because the temperature points in the IR and ER cycles for the L1-F package were not the same ones as for the L1 and L2 packages, the validity of the hysteresis values could be compromised. These results are worth analysing, as the finer granularity during the first cycle shows a rounded fitting error loop. Having more intermediate points, with each having a 1 h-dwell time, meant that the SEs experienced more time at both hotter and colder temperatures than for the L1 and L2 tests. This could mean that the hysteresis value is dependent on the time spent at each temperature, which would indicate that hysteresis is related to time dependent phenomena, such as creep, occurring predominantly within the bond pads and wires in the L1-F package.

5.3. Superposition Principal

The application of the superposition principal, as demonstrated by the bar graph in

Figure 9, was thought to only be valid for cases where all packages reached a stabilised hysteresis loop, which was only observed for the ER cycles. It could be argued that if the L1-F package were to be inclined, certain wire bonds would support the weight of the SE more than others, leading to an asymmetric stress distribution. This effect would be prevented by adding the adhesive in the L1 package. It could therefore mean that the L1-F package is adding additional stresses that would not be present in the L1 and L2 packages, thereby invalidating the superposition principal; i.e., 88.5% of the 55.9 μV/V due to bond pad and wire bond effects may in reality reduce in magnitude, thereby increasing the contribution of the adhesive to a much higher percentage than 4.3%. This would be the case if the fitting function were to be unable to compensate for these orientation/inclination effects. It is for this reason that every packaged SE is fitted using a unique function with individualised fitting coefficients and always tested in the same orientation within the manifold. It would therefore be recommended to repeat the L1-F test cycles in different orientations and analyse the resulting hysteresis to see if the fitting function is able to accommodate these effects.

To prove the validity of the superposition principal, it would be interesting to rework the L2 packaged SEs back into L1 packages by removing the isolation membrane and releasing the fluid fill. If the hysteresis were found to return to that presented in

Figure 7, it would further support the validity of the superposition principal. However, it is anticipated that the initial points may be slightly misaligned with the remaining loops, due to relaxation of package-related stresses.

6. Conclusions

To summarise the findings from this study, a novel packaging and testing methodology capable of revealing the cumulative effect of different groups of packaging elements on the hysteresis of a 50 to 200 kPa Si MEMS pressure sensor was demonstrated over three thermal cycling ranges. Five SEs were packaged consecutively at levels L1-F to L2 without being subjected to any previous thermal preconditioning. It was noted that the application of a mathematical fitting function is necessary in order to reveal the hysteresis behaviour and to compensate for testing set point uncertainties within the pressure and temperature sources. In this study, it was found that a “least squares” fitted third order polynomial function using the pressure, P, and diode voltage, Vd, to allow extrapolation of the fitted output voltage, Vfout, was sufficient to reveal any fitting error, e, when compared to the sensor’s voltage output, Vout. This error could then be used to identify any hysteresis, which was attributed directly to the effect of the packaging elements.

The effect on hysteresis of the individual packaging elements could not be entirely segregated for each packaging level. However, using a set of carefully selected assumptions regarding the combination of packaging elements, it was possible to pinpoint the effect of the adhesive contributing towards ratcheting and the bond pads and wire bonds as dominant contributors to the observed hysteresis. Assuming the validity of the superposition principle, 88.5% of the stabilised hysteresis of the complete L2 package at the extended temperature cycle range stemmed from the packaging elements of the initial L1-F configuration (i.e., the borosilicate glass, bond pad metallisation, and wire bonds). This was mainly thought to be driven by the high CTE mismatch between the SE and bond pad metallisation and the changing forces exerted by the wire bonds. Just 4.3% of the hysteresis was attributed to the additional packaging elements of the L1 configuration (i.e., the adhesive and the housing) and 7.2% to the packaging elements in the L2 configuration (i.e., fluid fill and isolation membrane). A reduction of thermal hysteresis was also witnessed due to repeated thermal cycling across all configurations and ranges.