Ideal Oscillation of a Hydrogenated Deformable Rotor in a Gigahertz Rotation–Translation Nanoconverter at Low Temperatures

Abstract

:1. Introduction

2. Results and Discussion

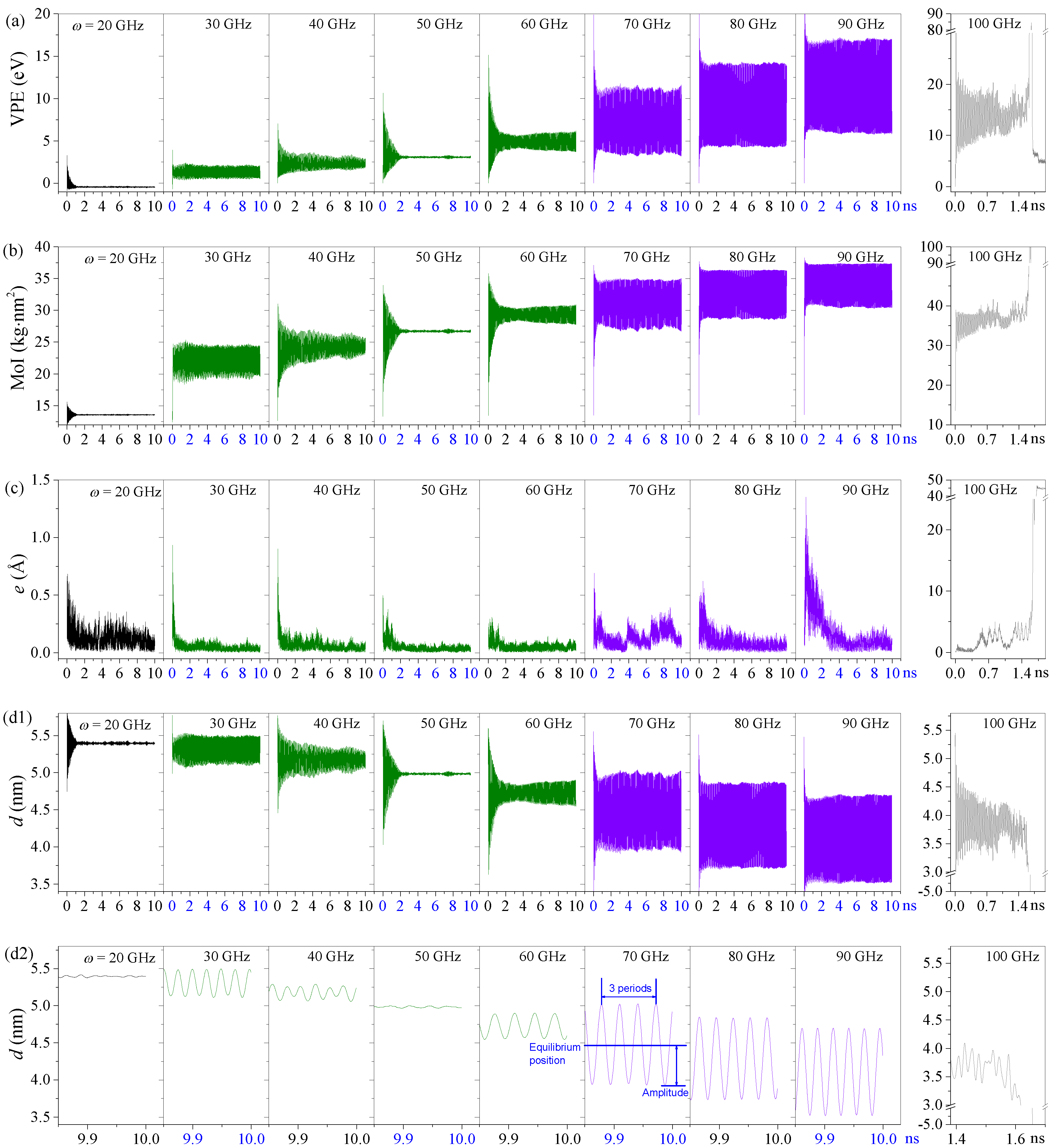

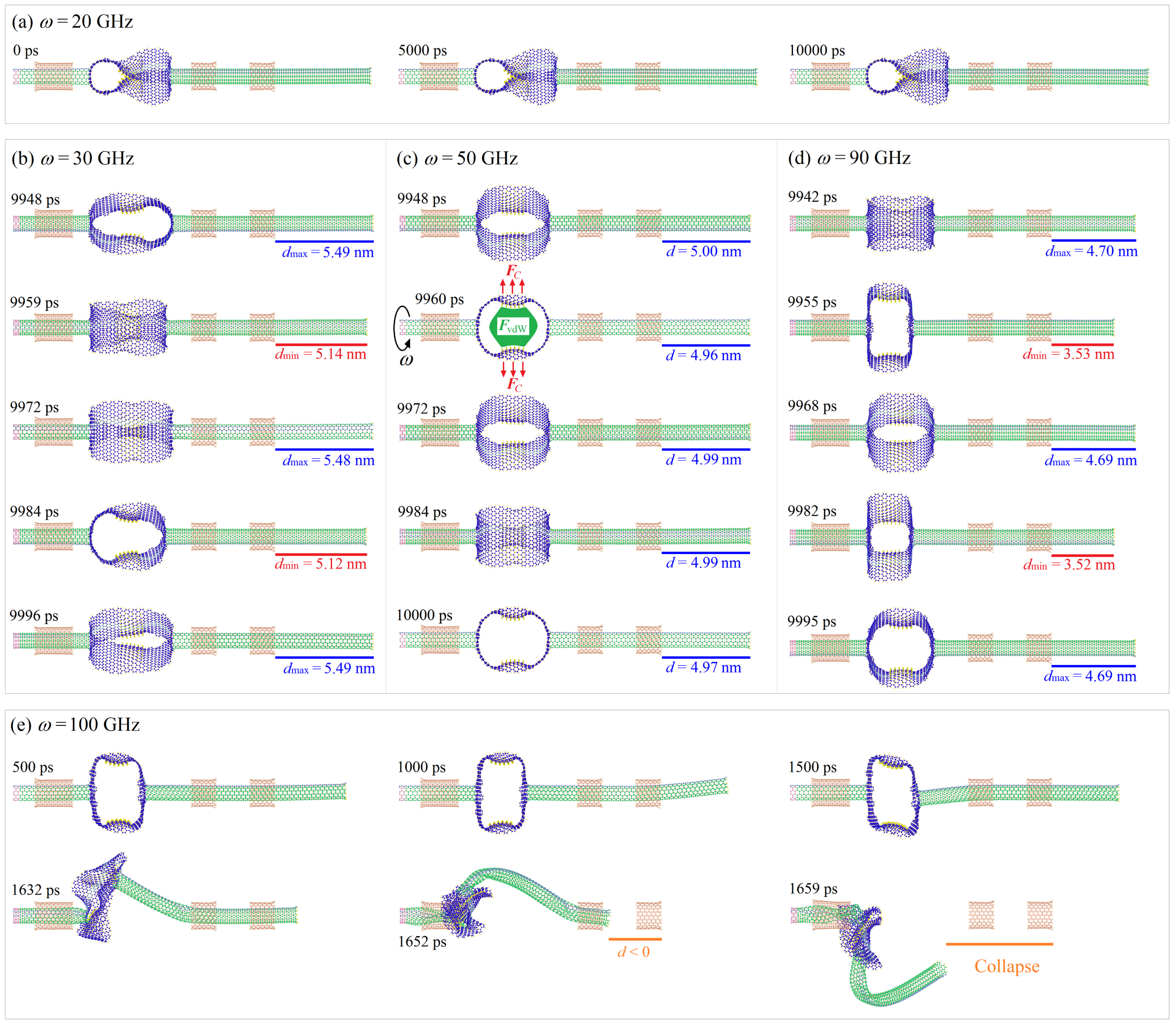

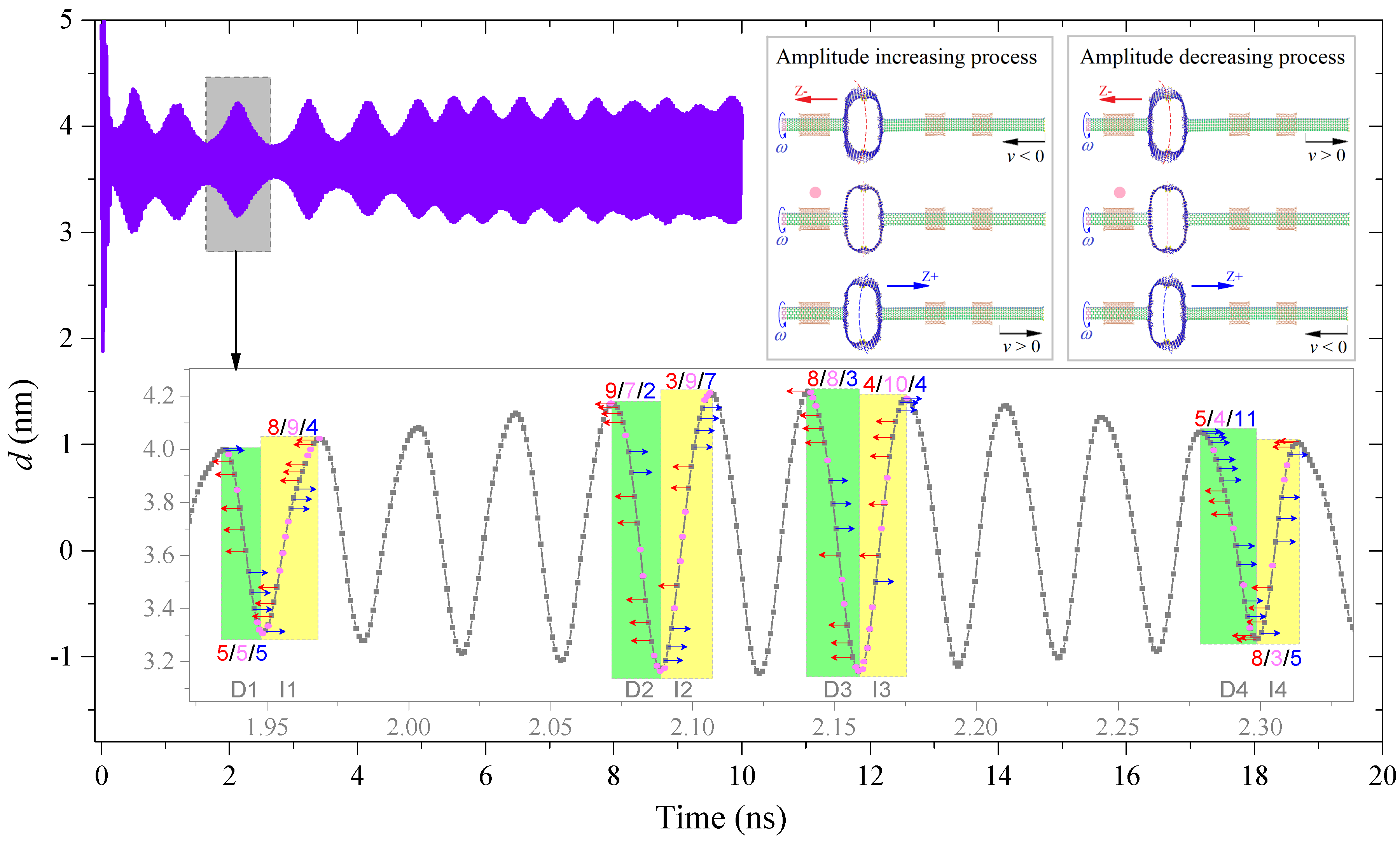

2.1. Dynamic Behaviors for the Z2H6 System at an Extremely Low Temperature, e.g., 8 K

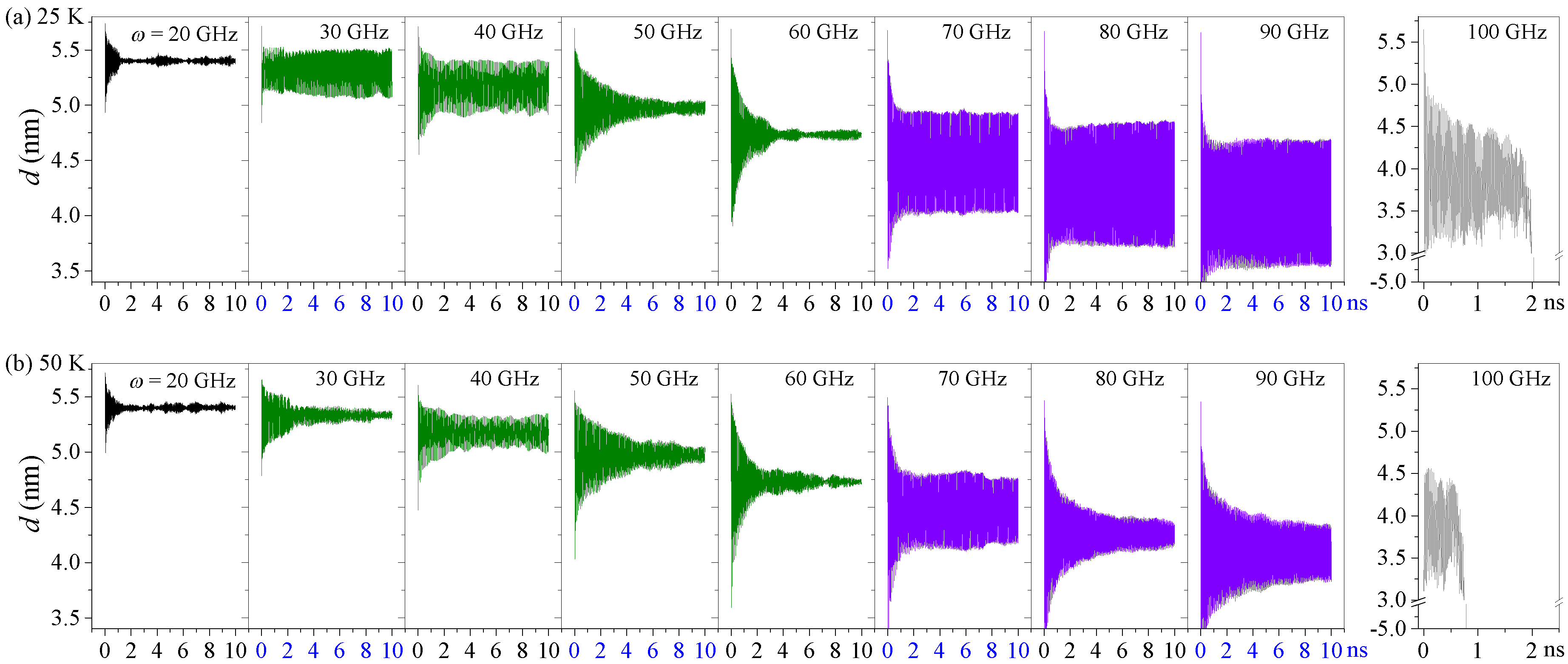

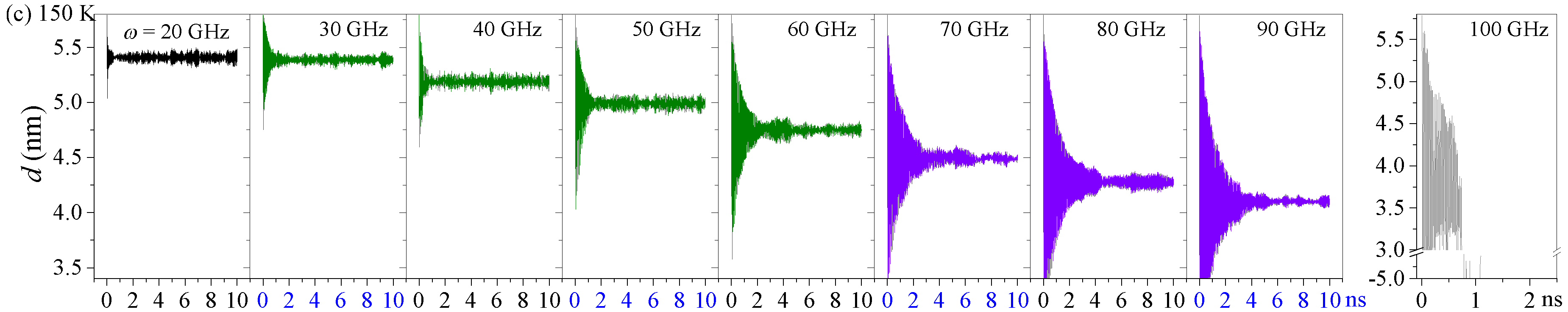

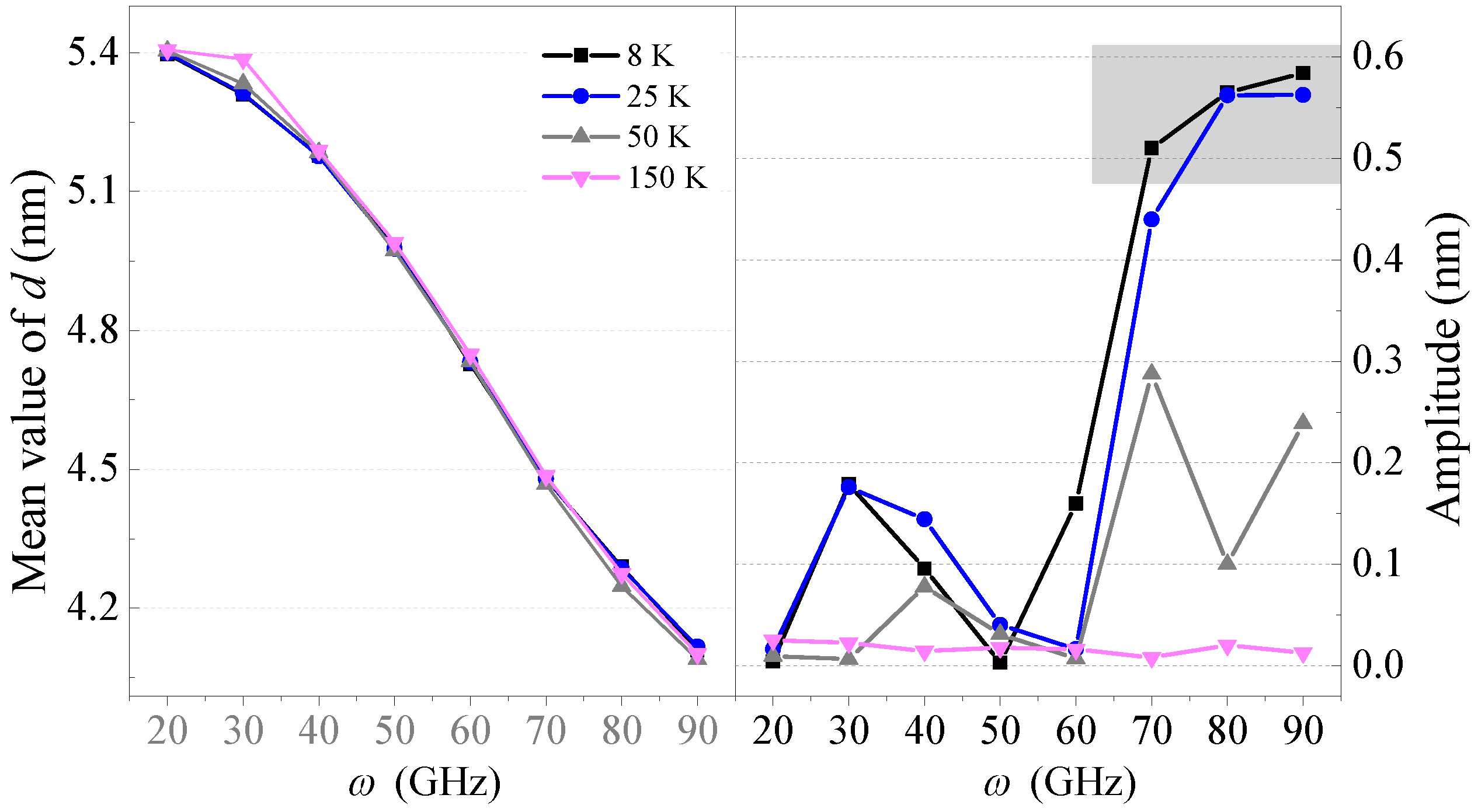

2.2. Axial Translational Motion in the Z2H6 System at 25 K, 50 K, and 150 K

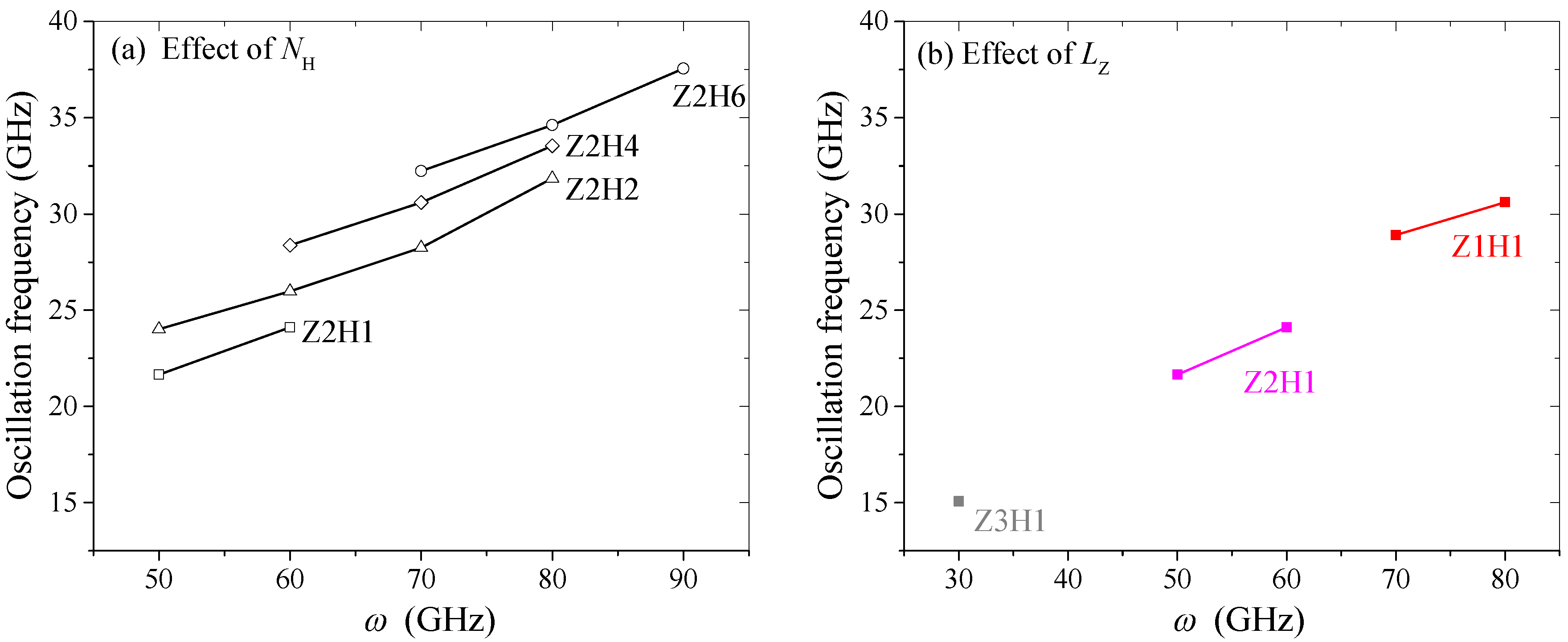

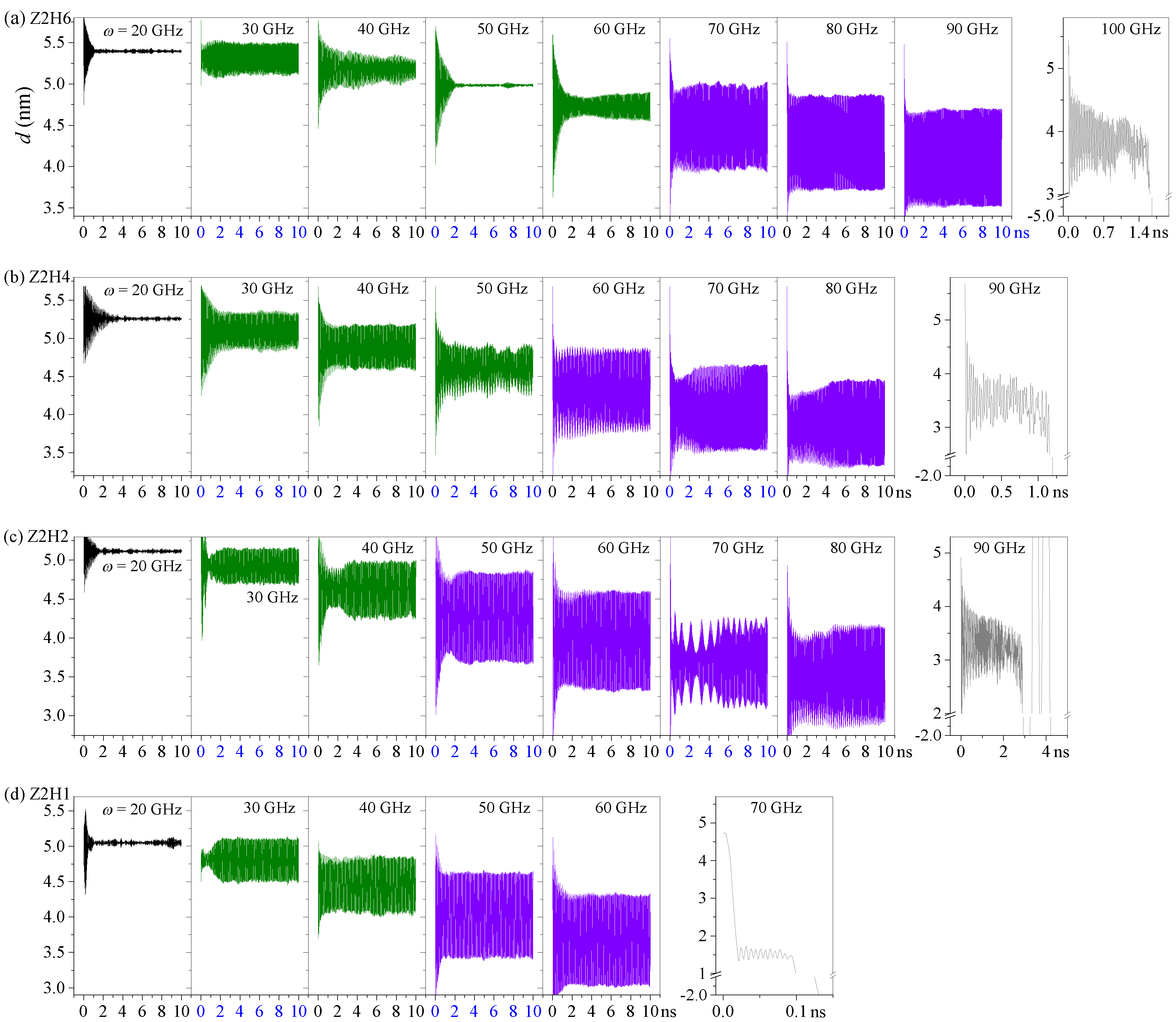

2.3. Effect of the Hydrogenation Scheme (NH) on the Axial Oscillation of the R-Rotor at 8 K

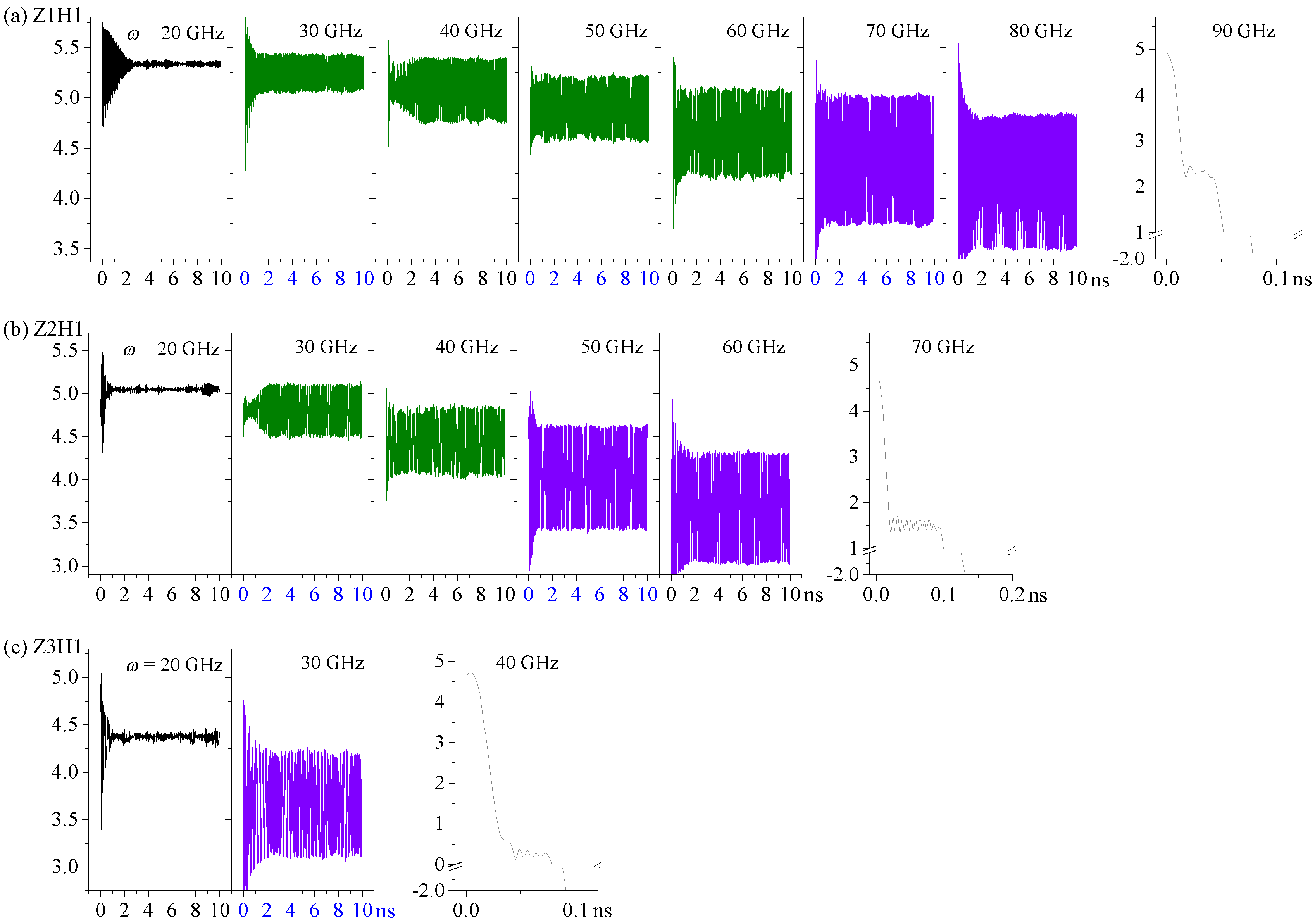

2.4. Effect of the Length of the HDP with NH = 1 on Its Oscillation at 8 K

3. Materials and Methods

3.1. Model

3.2. Methodology

3.2.1. Features of the HDP

3.2.2. Flowchart of the Molecular Dynamics Simulation

3.2.3. Fast Fourier Transmission

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Qian, D.; Wagner, G.J.; Liu, W.K.; Yu, M.F.; Ruoff, R.S. Mechanics of carbon nanotubes. Appl. Mech. Rev. 2002, 55, 495–533. [Google Scholar] [CrossRef]

- Lee, C.G.; Wei, X.D.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Cumings, J.; Zettl, A. Low-friction nanoscale linear bearing realized from multiwall carbon nanotubes. Science 2000, 289, 602–604. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.F.; Ning, Z.Y.; Zhang, Y.Y.; Zheng, Q.S.; Chen, Q.; Xie, H.H.; Zhang, Q.; Qian, W.Z.; Wei, F. Superlubricity in centimetres-long double-walled carbon nanotubes under ambient conditions. Nat. Nanotechnol. 2013, 8, 912–916. [Google Scholar] [CrossRef]

- Cook, E.H.; Buehler, M.J.; Spakovszky, Z.S. Mechanism of friction in rotating carbon nanotube bearings. J. Mech. Phys. Solids 2013, 61, 652–673. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Somada, H.; Hirahara, K.; Akita, S.; Nakayama, Y. A molecular linear motor consisting of carbon nanotubes. Nano Lett. 2009, 9, 62–65. [Google Scholar] [CrossRef]

- Tu, Z.C.; Hu, X. Molecular motor constructed from a double-walled carbon nanotube driven by axially varying voltage. Phys. Rev. B 2005, 72, 033404. [Google Scholar] [CrossRef] [Green Version]

- Cai, K.; Cai, H.F.; Ren, L.; Shi, J.; Qin, Q.H. Over-speeding rotational transmission of a carbon nanotube-based bearing. J. Phys. Chem. C 2016, 120, 5797–5803. [Google Scholar] [CrossRef]

- Zheng, Q.S.; Jiang, Q. Multiwalled carbon nanotubes as gigahertz oscillators. Phys. Rev. Lett. 2002, 88, 045503. [Google Scholar] [CrossRef] [PubMed]

- Sazonova, V.; Yaish, Y.; Ustunel, H.; Roundy, D.; Arias, T.A.; McEuen, P.L. A tunable carbon nanotube electromechanical oscillator. Nature 2004, 431, 284–287. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, J.W.; Kim, K.-S.; Hwang, H.J.; Kwon, O.K. Molecular dynamics study of effects of intertube gap on frequency-controlled carbon-nanotube oscillators. Phys. Lett. A 2010, 374, 3658–3665. [Google Scholar] [CrossRef]

- Joseph, S.; Aluru, N.R. Pumping of confined water in carbon nanotubes by rotation-translation coupling. Phys. Rev. Lett. 2008, 101, 064502. [Google Scholar] [CrossRef] [Green Version]

- Barreiro, A.; Rurali, R.; Hernandez, E.R.; Moser, J.; Pichler, T.; Forro, L.; Bachtold, A. Subnanometer motion of cargoes driven by thermal gradients along carbon nanotubes. Science 2008, 320, 775–778. [Google Scholar] [CrossRef] [Green Version]

- Cai, K.; Li, Y.; Qin, Q.H.; Yin, H. Gradientless temperature-driven rotating motor from a double-walled carbon nanotube. Nanotechnology 2014, 25, 505701. [Google Scholar] [CrossRef]

- Fennimore, A.M.; Yuzvinsky, T.D.; Han, W.Q.; Fuhrer, M.S.; Cumings, J.; Zettl, A. Rotational actuators based on carbon nanotubes. Nature 2003, 424, 408–410. [Google Scholar] [CrossRef]

- Kang, J.W.; Hwang, H.J. Nanoscale carbon nanotube motor schematics and simulations for micro-electro-mechanical machines. Nanotechnology 2004, 15, 1633–1638. [Google Scholar] [CrossRef]

- Prokop, A.; Vacek, J.; Michl, J. Friction in carborane-based molecular rotors driven by gas flow or electric field: Classical molecular dynamics. ACS Nano 2012, 6, 1901–1914. [Google Scholar] [CrossRef]

- Yu, M.F.; Yakobson, B.I.; Ruoff, R.S. Controlled sliding and pullout of nested shells in individual multiwalled carbon nanotubes. J. Phys. Chem. B 2000, 104, 8764–8767. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ansari, R.; Mahmoudinezhad, E.; Motevalli, B. Different motion patterns of triple-walled carbon nanotubeoscillators. J. Vib. Control 2014, 20, 773–785. [Google Scholar] [CrossRef]

- Motevalli, B.; Liu, J.Z. Tuning the oscillation of nested carbon nanotubes by insertion of an additional inner tube. J. Appl. Phys. 2013, 114, 56–58. [Google Scholar] [CrossRef]

- Neild, A.; Ng, T.W.; Zheng, Q. Controlled driven oscillations of double-walled carbon nanotubes. Europhys. Lett. 2009, 87, 16002. [Google Scholar] [CrossRef]

- Kang, J.W.; Song, K.O.; Hwang, H.J.; Jiang, Q. Nanotube oscillator based on a short single-walled carbon nanotube bundle. Nanotechnology 2006, 17, 2250–2258. [Google Scholar] [CrossRef]

- Rivera, J.L.; McCabe, C.; Cummings, P.T. Oscillatory behavior of double-walled nanotubes under extension: A simple nanoscale damped spring. Nano Lett. 2003, 3, 1001–1005. [Google Scholar] [CrossRef]

- Legoas, S.B.; Coluci, V.R.; Braga, S.F.; Coura, P.Z.; Dantas, S.O.; Galvão, D.S. Molecular-dynamics simulations of carbon nanotubes as gigahertz oscillators. Phys. Rev. Lett. 2003, 90, 055504. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.L.; Guo, Y.F.; Gao, H.J.; Zheng, Q.S.; Zhong, W.Y. Energy dissipation in gigahertz oscillators from multiwalled carbon nanotubes. Phys. Rev. Lett. 2003, 91, 125501. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, C.C.; Chen, G.H.; Jiang, Q. Energy dissipation mechanisms in carbon nanotube oscillators. Phys. Rev. Lett. 2003, 91, 175504. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Li, T. Ultrafast nano-oscillators based on interlayer-bridged carbon nanoscrolls. Nanoscale Res. Lett. 2011, 6, 470. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.P.; Zheng, Q.S.; Chen, G.H. Thermally driven large-amplitude fluctuations in carbon-nanotube-based devices: Molecular dynamics simulations. Phys. Rev. B 2007, 75, 195445. [Google Scholar] [CrossRef]

- Cai, K.; Yin, H.; Qin, Q.H.; Li, Y. Self-excited oscillation of rotating double-walled carbon nanotubes. Nano Lett. 2014, 14, 2558–2562. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Wang, Z.Z.; Chen, Z. Concurrence of oscillatory and rotation of the rotors in a thermal nanotube motor. Comp. Mater. Sci. 2016, 120, 94–98. [Google Scholar] [CrossRef]

- Cai, K.; Zhang, X.N.; Shi, J.; Qin, Q.H. Rotation-excited perfect oscillation of a tri-walled nanotube-based oscillator at ultralow temperature. Nanotechnology 2017, 28, 155701. [Google Scholar] [CrossRef]

- Song, B.; Cai, K.; Shi, J.; Xie, Y.M.; Qin, Q. Coupling effect of van der Waals, centrifugal, and frictional forces on a GHz rotation-translation nano-convertor. Phys. Chem. Chem. Phys. 2019, 21, 359–368. [Google Scholar] [CrossRef] [PubMed]

- Cai, K.; Yu, J.Z.; Shi, J.; Qin, Q.H. A method for measuring rotation of a thermal carbon nanomotor using centrifugal effect. Sci. Rep. 2016, 6, 27338. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, B.; Shi, J.; Hu, C.W.; Wang, J.; Cai, K.; Zhang, C. Recoverability of a gigahertz rotation-translation nanoconvertor with hydrogenated deformable rotor at room temperature. Nanotechnology 2019, 30, 465301. [Google Scholar] [CrossRef] [PubMed]

- Pei, Q.X.; Zhang, Y.W.; Shenoy, V.B. A molecular dynamics study of the mechanical properties of hydrogen functionalized graphene. Carbon 2010, 48, 898–904. [Google Scholar] [CrossRef]

- Zhu, S.; Li, T. Hydrogenation-assisted graphene origami and its application in programmable molecular mass uptake, storage, and release. ACS Nano 2014, 8, 2864–2872. [Google Scholar] [CrossRef]

- Reddy, C.D.; Zhang, Y.W. Structure manipulation of graphene by hydrogenation. Carbon 2014, 69, 86–91. [Google Scholar] [CrossRef]

- Cai, K.; Yu, J.Z.; Wan, J.; Yin, H.; Shi, J.; Qin, Q.H. Configuration jumps of rotor in a nanomotor from carbon nanostructures. Carbon 2016, 101, 168–176. [Google Scholar] [CrossRef]

- Cai, K.; Zhang, X.N.; Shi, J.; Qin, Q.H. Temperature effects on a motion transmission device made from carbon nanotubes: A molecular dynamics study. RSC Adv. 2015, 5, 66438–66450. [Google Scholar] [CrossRef]

- Cai, K.; Liu, L.N.; Shi, J.; Qin, Q.H. Winding a nanotube from black phosphorus nanoribbon onto a CNT at low temperature: A molecular dynamics study. Mater. Des. 2017, 121, 406–413. [Google Scholar] [CrossRef]

- Cai, K.; Yu, J.Z.; Shi, J.; Qin, Q.H. Spectrum of temperature-dependent rotational frequency of the rotor in a thermally diven rotary nanomotor. J. Phys. Chem. C 2017, 121, 16985–16995. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef] [Green Version]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamic. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Jones, J.E. On the determination of molecular fields. II. From the equation of state of a gas. Proc. R. Soc. Lond. 1924, 106, 463–477. [Google Scholar]

- Mohlenkamp, M.J. A fast transform for spherical harmonics. J. Fourier Anal. Appl. 1999, 5, 159–184. [Google Scholar] [CrossRef]

- Luo, Y.J.; Bao, J.W. A material-field series-expansion method for topology optimization of continuum structures. Comput. Struct. 2019, 225, 106122. [Google Scholar] [CrossRef]

| Model | LZ/Å | NH | Number of Atoms on HDP | |

|---|---|---|---|---|

| HDP | Z1H1 | 26.99 | 1 | 960C + 96H (boundary) + 16H (NH) |

| Z2H1 | 35.51 | 1 | 1128C + 112H (boundary) + 16H (NH) | |

| Z2H2 | 35.51 | 2 | 1128C + 112H (boundary) + 34H (NH) | |

| Z2H4 | 35.51 | 4 | 1128C + 112H (boundary) + 68H (NH) | |

| Z2H6 | 35.51 | 6 | 1128C + 112H (boundary) + 102H (NH) | |

| Z3H1 | 48.29 | 1 | 1380C + 136H (boundary) + 16H (NH) | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, B.; Shi, J.; Wang, J.; Shen, J.; Cai, K. Ideal Oscillation of a Hydrogenated Deformable Rotor in a Gigahertz Rotation–Translation Nanoconverter at Low Temperatures. Sensors 2020, 20, 1969. https://doi.org/10.3390/s20071969

Song B, Shi J, Wang J, Shen J, Cai K. Ideal Oscillation of a Hydrogenated Deformable Rotor in a Gigahertz Rotation–Translation Nanoconverter at Low Temperatures. Sensors. 2020; 20(7):1969. https://doi.org/10.3390/s20071969

Chicago/Turabian StyleSong, Bo, Jiao Shi, Jinbao Wang, Jianhu Shen, and Kun Cai. 2020. "Ideal Oscillation of a Hydrogenated Deformable Rotor in a Gigahertz Rotation–Translation Nanoconverter at Low Temperatures" Sensors 20, no. 7: 1969. https://doi.org/10.3390/s20071969

APA StyleSong, B., Shi, J., Wang, J., Shen, J., & Cai, K. (2020). Ideal Oscillation of a Hydrogenated Deformable Rotor in a Gigahertz Rotation–Translation Nanoconverter at Low Temperatures. Sensors, 20(7), 1969. https://doi.org/10.3390/s20071969