Pre-Pressure Optimization for Ultrasonic Motors Based on Multi-Sensor Fusion

Abstract

:1. Introduction

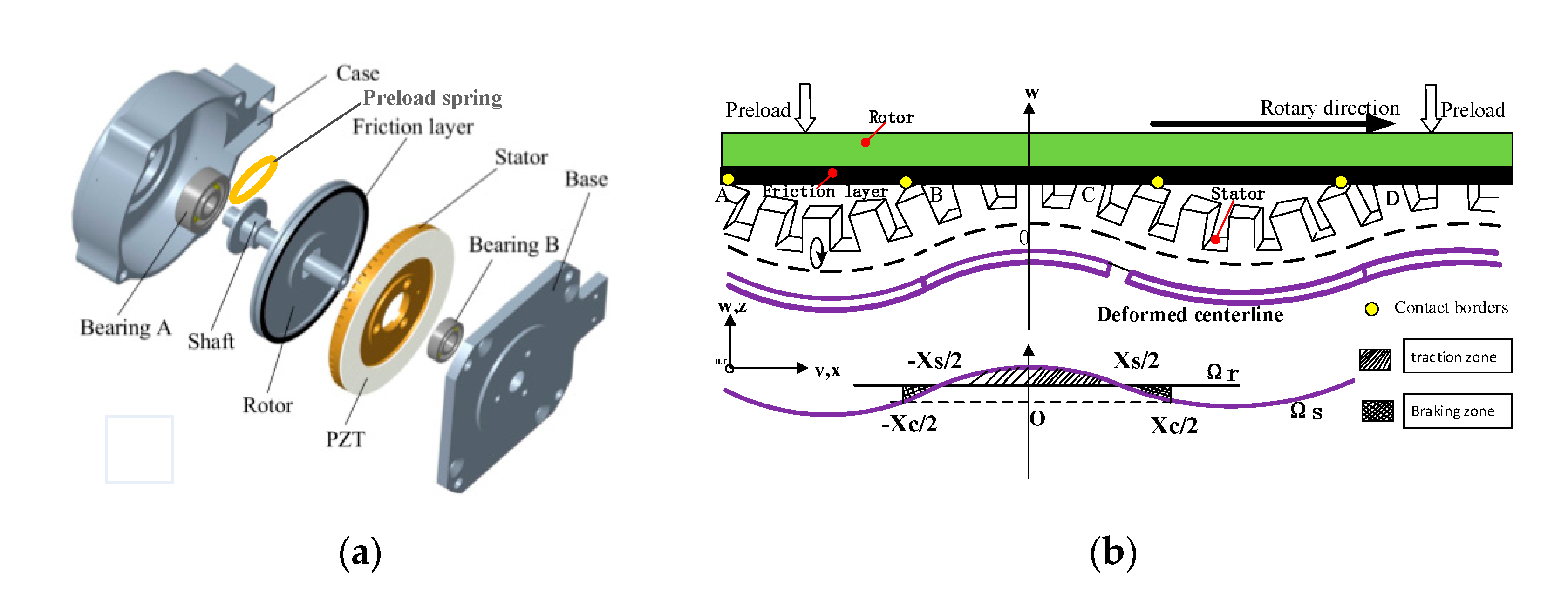

2. A Simulation Model with Power Dissipation

2.1. The Electromechanical Model

2.2. The Power Dissipation Model

3. Experimental Setup

4. Simulation and Experimental Results by Varying the Preload Force

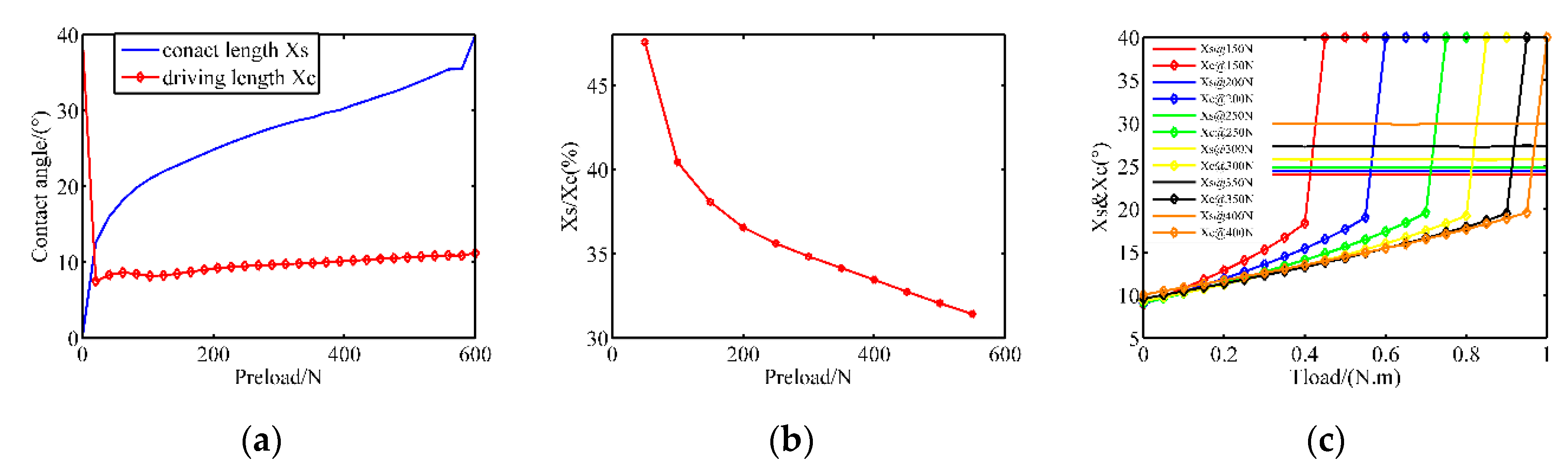

4.1. The Stator/Rotor Contact

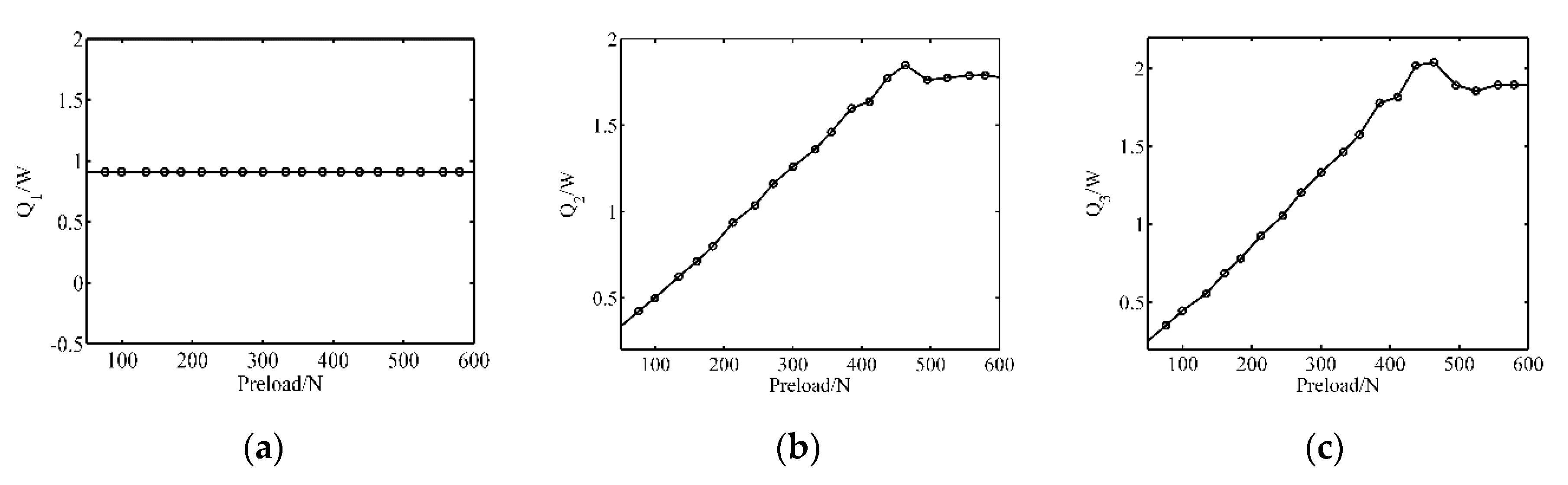

4.2. The Power Dissipation of the Motor

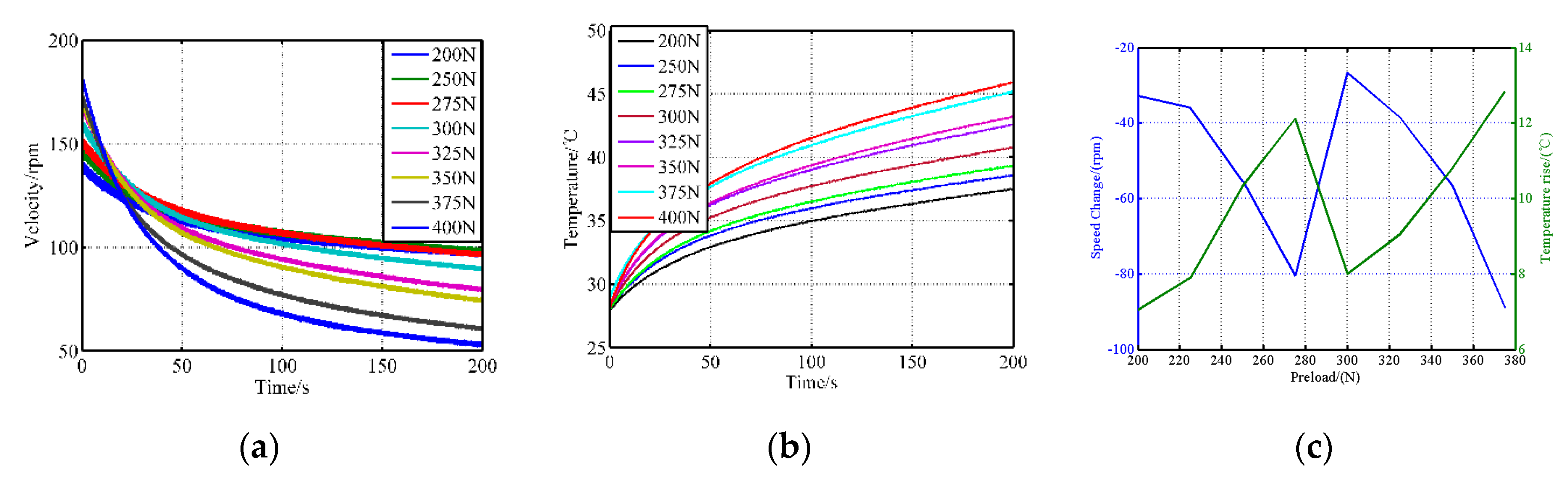

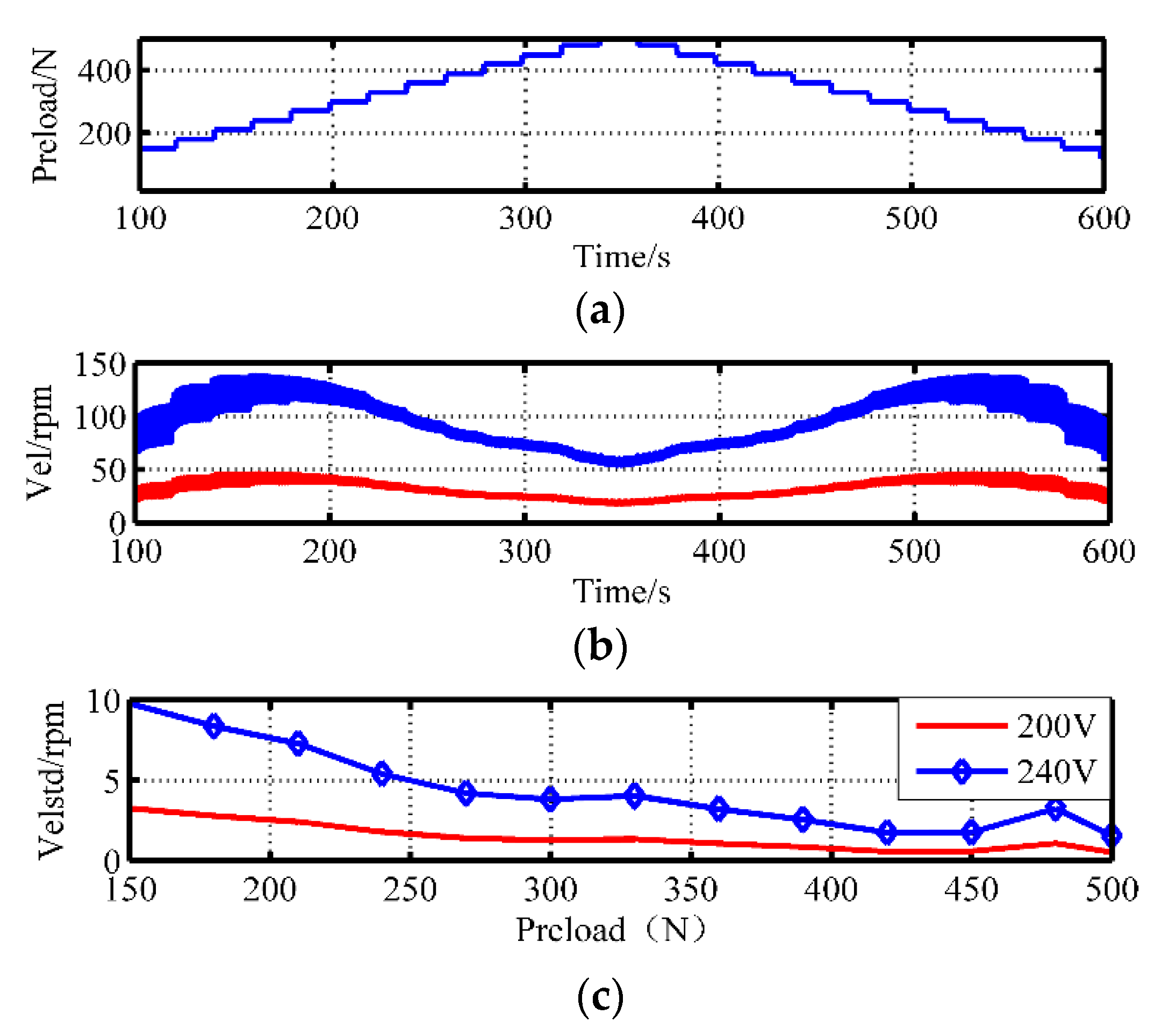

4.3. The Speed Fluctuations

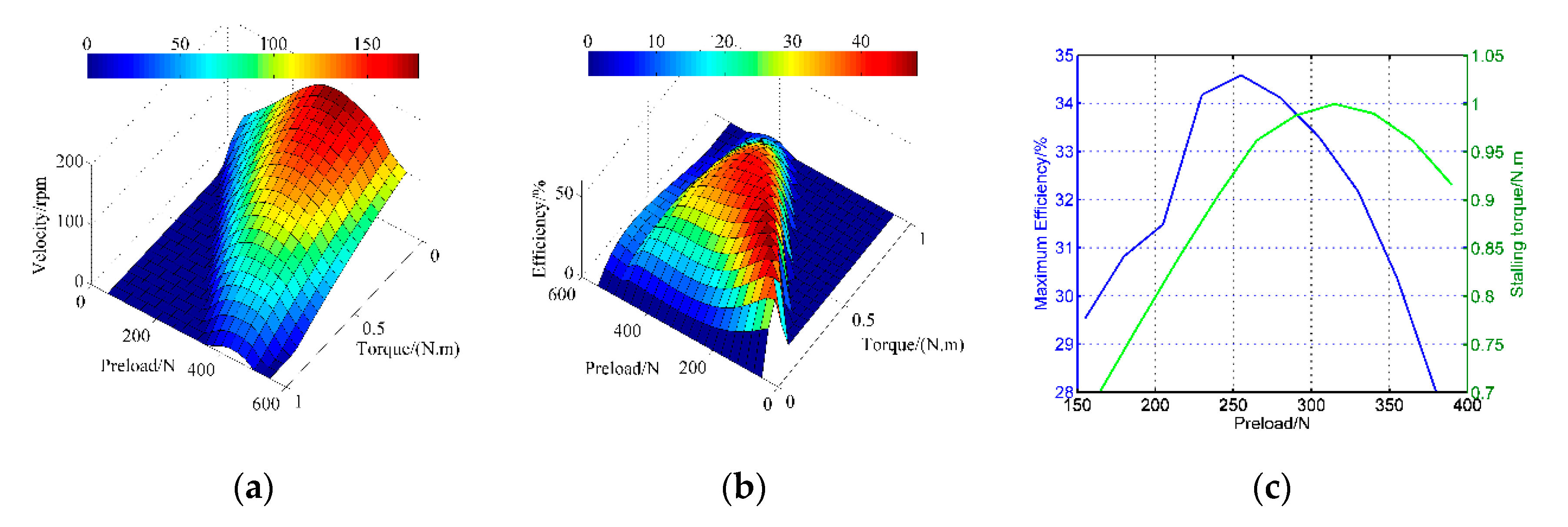

4.4. The Mechanical Characteristics

5. Discussion and Verification of the Optimal Preload Force

5.1. Optimization Criterion

- (1)

- The velocity increases first and then decreases as the pre-pressure increases, and a low pre-pressure cannot provide sufficient friction force while a higher one causes more tangential friction zones;

- (2)

- When the pre-stressing force is lower, the velocity stability deteriorates because of the weakened constraints applied on the stator and the stability improves as the preload force gradually increases;

- (3)

- With the increase of the pre-pressure, the points both from the resonant frequency and the anti-resonant frequency gradually shift to the right due to the increasing stiffness;

- (4)

- The blocking torque achieves the peak value in the moderate pre-pressure, like the mechanical efficiency, however, the apexes are different from each other.

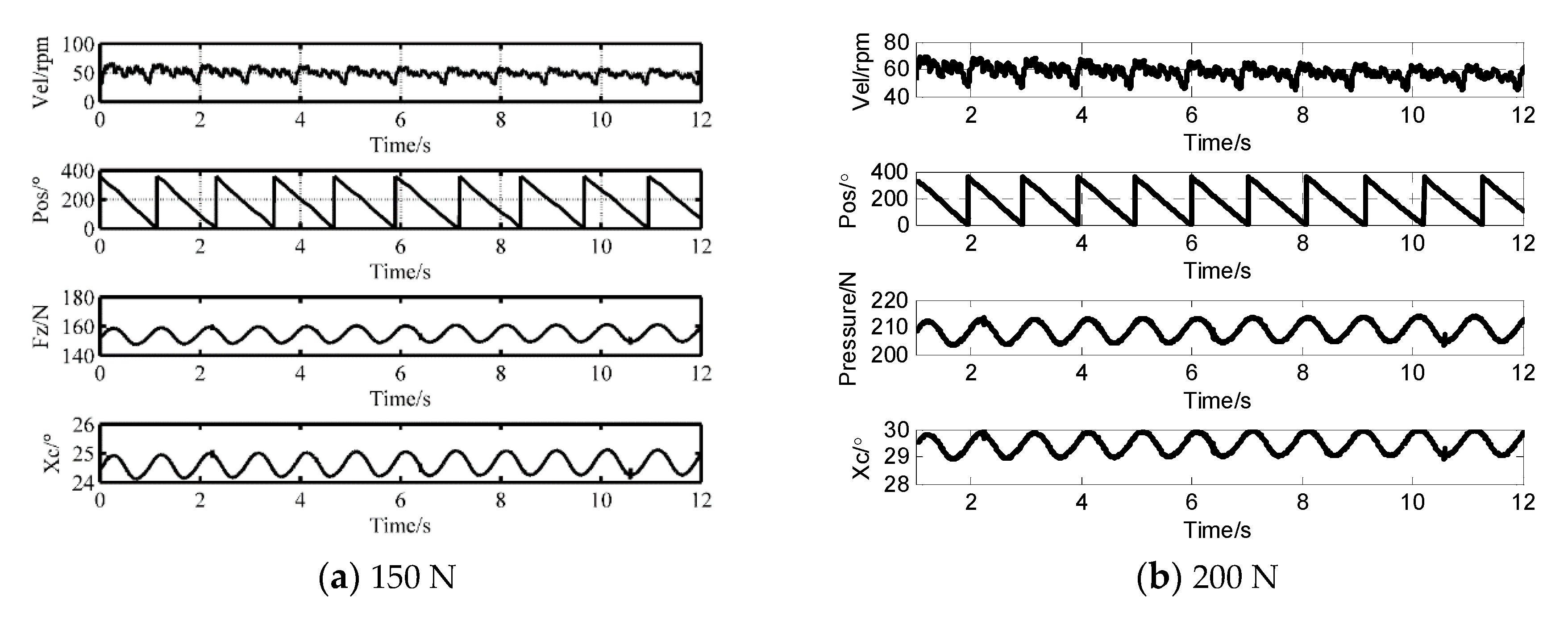

5.2. Speed Control Performances

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Description | Value (Units) | |

|---|---|---|

| N | Number of wavelengths | 9 |

| Ro | The average radius of the stator ring | 0.02625 (m) |

| λ | Traveling wavelength | 0.0187 (m) |

| mo | Modal mass of stator elastic body | 0.005 (kg) |

| ko | Modal stiffness of stator elastic body | 4.56×109 (kg.m2) |

| do | Modal damping of stator elastic body | 0.05 (N·s/m) |

| dz | Damping in the axial direction of the rotor | 1.5 × 104 (N·s/m) |

| dr | Damping in the tangential direction of the rotor | 5 × 10−4 (N·m·s) |

| kc | Force factor of piezoelectric ceramics | 0.4147 (N/V) |

| ε | Unbalance coefficient between two-phase voltage | 0.02 |

| mr | Rotor mass | 0.03 (kg) |

| Jr | Rotor inertia | 7.2 × 10−6 (kg/m2) |

| μ | Friction coefficient | 0.3 |

| Cp | Capacitance | 5.41 (nF) |

| Rm | Dynamic resistor | 149.82 (Ω) |

| Lm | Dynamic inductance | 0.102 (H) |

| Cm | Dynamic capacitance | 16.63 (pF) |

| Rd | Resumption resistor | 31.15 (KΩ) |

| Speed drop coefficient with the decreasing torque | 9.9484 (rad/(N·m·s) | |

| h | The thickness of the friction layer | 0.5 (mm) |

| S | Motor surface area | 0.02366 (m2) |

| α | Coefficient of heat transfer | 10 |

References

- Qiu, Y.Q.; Wang, H.; Demore, C.E.M.; Hughes, D.A.; Glynne-Jones, P.; Gebhardt, S.; Bolhovitins, A.; Poltarjonoks, B.; Weijer, K.; Schönecker, A.; et al. Acoustic Devices for Particle and Cell Manipulation and Sensing. Sensors 2014, 14, 14806–14838. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liang, W.; Ma, J.; Tan, K.K. Contact force control on soft membrane for an ear surgical device. IEEE Trans. Ind. Electron. 2018, 65, 9593–9603. [Google Scholar] [CrossRef]

- Shokrollahi, P.; James, M.D.; Goldenberg, A.A. Measuring the Temperature Increase of an Ultrasonic Motor in a 3-Tesla Magnetic Resonance Imaging System. Actuators 2017, 62, 20. [Google Scholar] [CrossRef] [Green Version]

- Flueckiger, M.; Bullo, M.; Chapuis, D.; Gassert, R.; Perriard, Y. FMRI compatible haptic interface actuated with traveling wave ultrasonic motor. In Proceedings of the IEEE Industry Applications Conference Fortieth IAS Annual Meeting, Kowloon, Hong Kong, China, 2–6 October 2015. [Google Scholar]

- Chapuis, D.; Gassert, R.; Burdet, E.; Bleuler, H. Hybrid ultrasonic motor and electrorheological clutch system for MR-compatible haptic rendering. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots & Systems, Beijing, China, 9–15 October 2006. [Google Scholar]

- Liu, Y.X.; Xu, D.M.; Yu, Z.Y.; Yan, J.P.; Yang, X.H.; Chen, Y.S. A Novel Rotary Piezoelectric Motor Using First Bending Hybrid Transducers. Appl. Sci. 2015, 5, 472–484. [Google Scholar] [CrossRef] [Green Version]

- Li, H.Y.; Wang, L.; Cheng, T.H. A High-Thrust Screw-Type Piezoelectric Ultrasonic Motor with Three-Wavelength Exciting Mode. Appl. Sci. 2016, 12, 442. [Google Scholar] [CrossRef] [Green Version]

- Shao, S.J.; Shi, S.J.; Chen, W.S.; Liu, J.K. Research on a Linear Piezoelectric Actuator Using T-Shape Transducer to Realize High Mechanical Output. Appl. Sci. 2016, 6, 103. [Google Scholar] [CrossRef] [Green Version]

- Oh, J.H.; Yuk, H.S.; Lim, J.N.; Lim, K.J.; Park, D.H.; Kim, H.H. An analysis of the resonance characteristics of a traveling wave types ultrasonic motor by applying a normal force and input voltage. Ferroelectrics 2009, 378, 135–143. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.K.; Lin, Y.X.; Tian, X.Q.; Yan, J.P. A novel single-mode linear piezoelectric ultrasonic motor based on asymmetric structure. Ultrasonics 2018, 89, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Hu, X.X.; Wang, B.; Guo, J.F. A novel two-degree-of-freedom spherical ultrasonic motor using three traveling-wave type annular stators. J. Cent. South Univ. 2015, 22, 1298–1306. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, G.; Nakamura, K.; Ueha, S. A robot finger joint driven by the hybrid multi-DOF piezoelectric ultrasonic motor. Sens. Actuators A Phys. 2011, 169, 206–210. [Google Scholar] [CrossRef]

- Pirrotta, S.; Sinatra, R.; Meschini, A. Evaluation of the effect of preload force on resonance frequencies for a traveling wave ultrasonic motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 746–753. [Google Scholar] [PubMed]

- Li, J.; Liu, S.; Qu, J.; Cui, Y.; Liu, Y. A contact model of traveling-wave ultrasonic motors considering preload and load torque effects. Int. J. Appl. Electromagnet Mech. 2018, 56, 151–164. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, C.S. A novel semi-analytical model of the stator of TRUM based on dynamic substructure method. In Proceedings of the USE 2005, The 26th Symposium on ULTRASONIC ELECTRONICS, Tokyo, Japan, 16–18 November 2005; pp. 17–25. [Google Scholar]

- Zhao, C.S.; Chen, C.; Zeng, J.S. A New Modeling of Traveling Wave Type Rotary Ultrasonic Motor Based on Three-Dimension Contact Mechanism. In Proceedings of the 2005 IEEE International Ultrasonic Symposium, Rotterdam, The Netherlands, 15–16 October 2005. [Google Scholar]

- Zhang, D.; Wang, S.; Xiu, J. Piezoelectric parametric effects on wave vibration and contact mechanics of traveling wave ultrasonic motor. Ultrasonics 2017, 81, 118–126. [Google Scholar] [CrossRef] [PubMed]

- Bullo, M.; Perriard, Y. Influences to the mechanical performances of the traveling wave ultrasonic motor by varying the prestressing force between stator and rotor. In Proceedings of the IEEE Symposium on Ultrasonics, Honolulu, HI, USA, 5–8 October 2003. [Google Scholar]

- Tavallaei, M.; Atashzar, S.F.; Drangova, M. Robust Motion Control of Ultrasonic Motors under Temperature Disturbance. IEEE Trans. Ind. Electron. 2016, 63, 2360–2368. [Google Scholar] [CrossRef]

- Moal, P.L.; Cusin, P. Optimization of traveling wave ultrasonic motors using a three-dimensional analysis of the contact mechanism at the stator–rotor interface. Eur. J. Mech. A. Solids 1999, 18, 1061–1084. [Google Scholar] [CrossRef]

- Yano, Y.; Iida, K.; Sakabe, T.; Yabugami, K.; Nakata, Y. Approach to speed control using temperature characteristics of ultrasonic motor. In Proceedings of the 2004 47th Midwest Symposium On Circuits And Systems, MWSCAS ’04, Hiroshima, Japan, 25–28 July 2004. [Google Scholar]

- Mashimo, T. Miniature preload mechanisms for a micro ultrasonic motor. Sens. Actuators A Phys. 2017, 257, 106–112. [Google Scholar] [CrossRef]

- Zhao, C. Ultrasonic Motors: Technologies and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Abdullah, M.; Takeshi, M. Efficiency optimization of rotary ultrasonic motors using extremum seeking control with current feedback. Sens. Actuators A Phys. 2019, 289, 26–33. [Google Scholar]

- El, G.N. Hybrid Modelling of a Traveling Wave Piezoelectric Motor. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2000. [Google Scholar]

- Ren, W.H.; Lin, Y.; Ma, C.C.; Li, X.; Zhang, J. Output performance simulation and contact analysis of traveling wave rotary ultrasonic motor based on ADINA. Comput. Struct. 2019, 216, 15–25. [Google Scholar] [CrossRef]

- Kai, J. Dynamic Modeling of Traveling Wave Motor and the Optimal Control of Vibration Mode Vector. Ph.D. Thesis, Hebei University of Technology, Tianjin, China, 2016. (In Chinese). [Google Scholar]

- Lu, X.; Hu, J.; Zhao, C. Analyses of the temperature field of traveling-wave rotary ultrasonic motors. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 2708–2719. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Qi, C.; Zheng, J.J.; Fan, D.; Fan, S. Impedance Characteristics Test of Ultrasonic Motor Based on Labview and FPGA. In Proceedings of the CSAA/IET International Conference on Aircraft Utility Systems (AUS 2018), Guiyang, China, 19–22 June 2018. [Google Scholar]

- PCB Motor Inc. PCB Motor Starter Kit User Guide. Available online: http://ww1.microchip.com/downloads/en/devicedoc/mcskuserguide75015a.pdf (accessed on 4 April 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, N.; Zheng, J.; Fan, D. Pre-Pressure Optimization for Ultrasonic Motors Based on Multi-Sensor Fusion. Sensors 2020, 20, 2096. https://doi.org/10.3390/s20072096

Chen N, Zheng J, Fan D. Pre-Pressure Optimization for Ultrasonic Motors Based on Multi-Sensor Fusion. Sensors. 2020; 20(7):2096. https://doi.org/10.3390/s20072096

Chicago/Turabian StyleChen, Ning, Jieji Zheng, and Dapeng Fan. 2020. "Pre-Pressure Optimization for Ultrasonic Motors Based on Multi-Sensor Fusion" Sensors 20, no. 7: 2096. https://doi.org/10.3390/s20072096

APA StyleChen, N., Zheng, J., & Fan, D. (2020). Pre-Pressure Optimization for Ultrasonic Motors Based on Multi-Sensor Fusion. Sensors, 20(7), 2096. https://doi.org/10.3390/s20072096