Laser Patterning a Graphene Layer on a Ceramic Substrate for Sensor Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Design

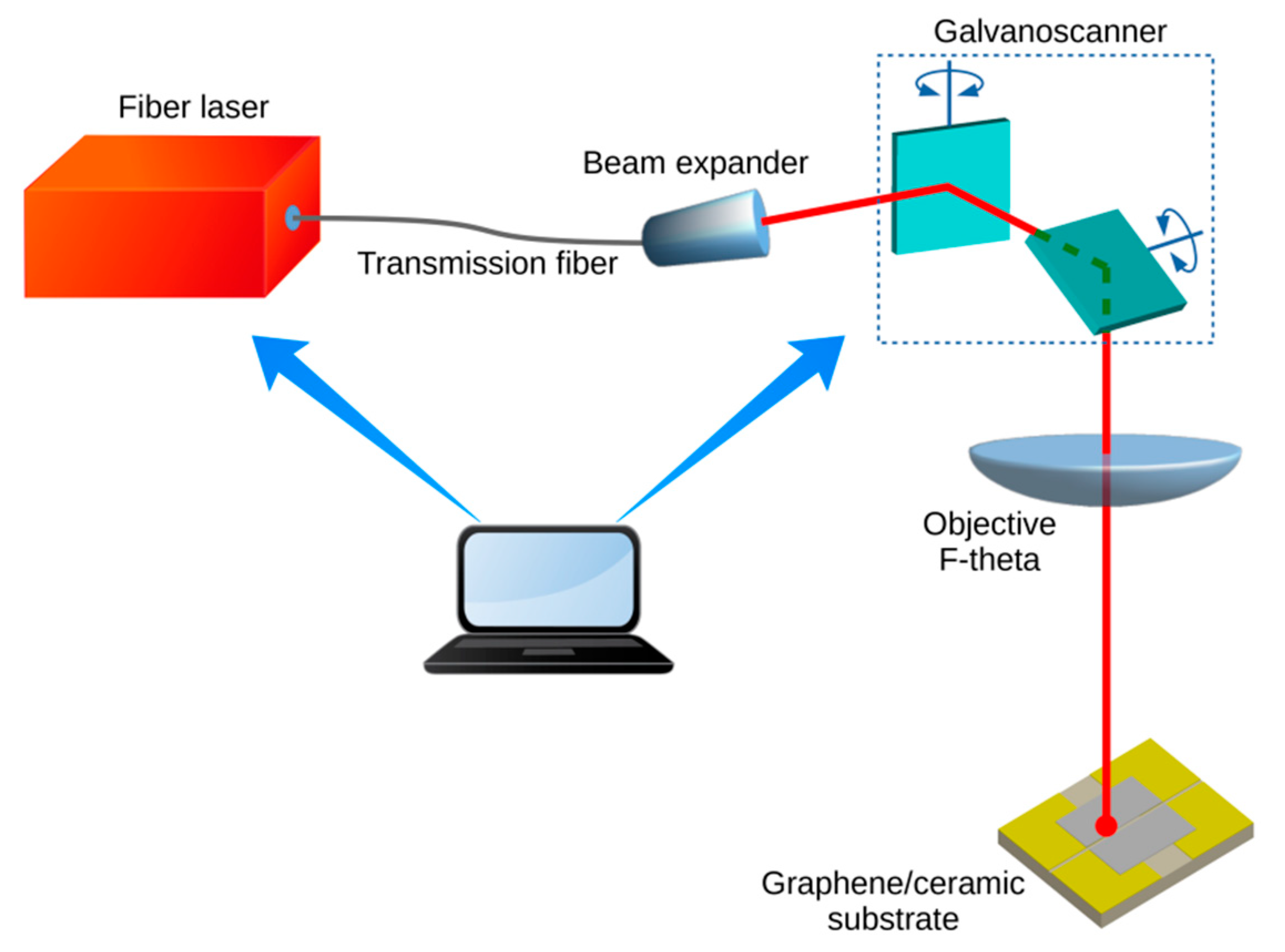

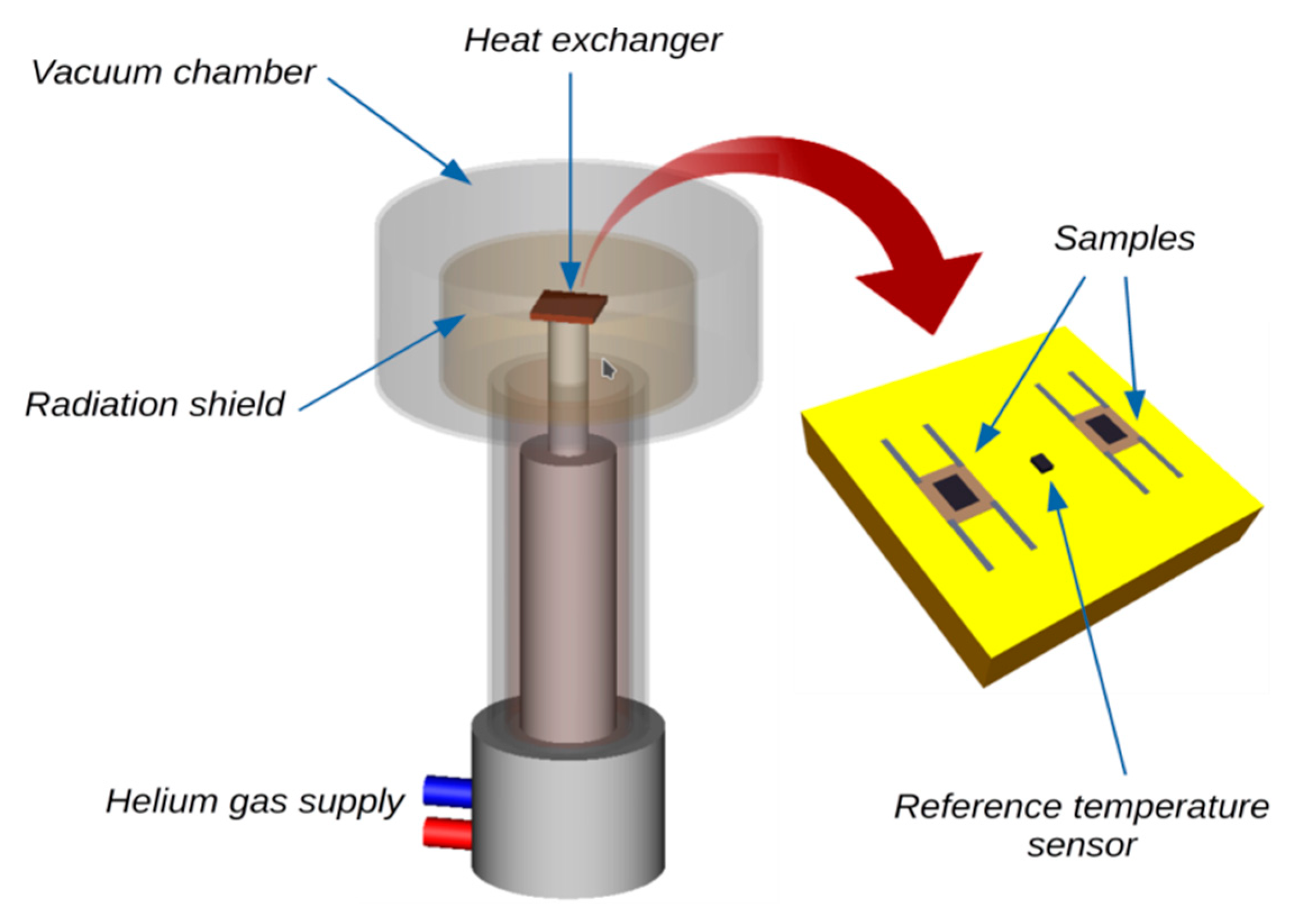

2.2. Instrumentation and Measurement Procedure

3. Results and Discussion

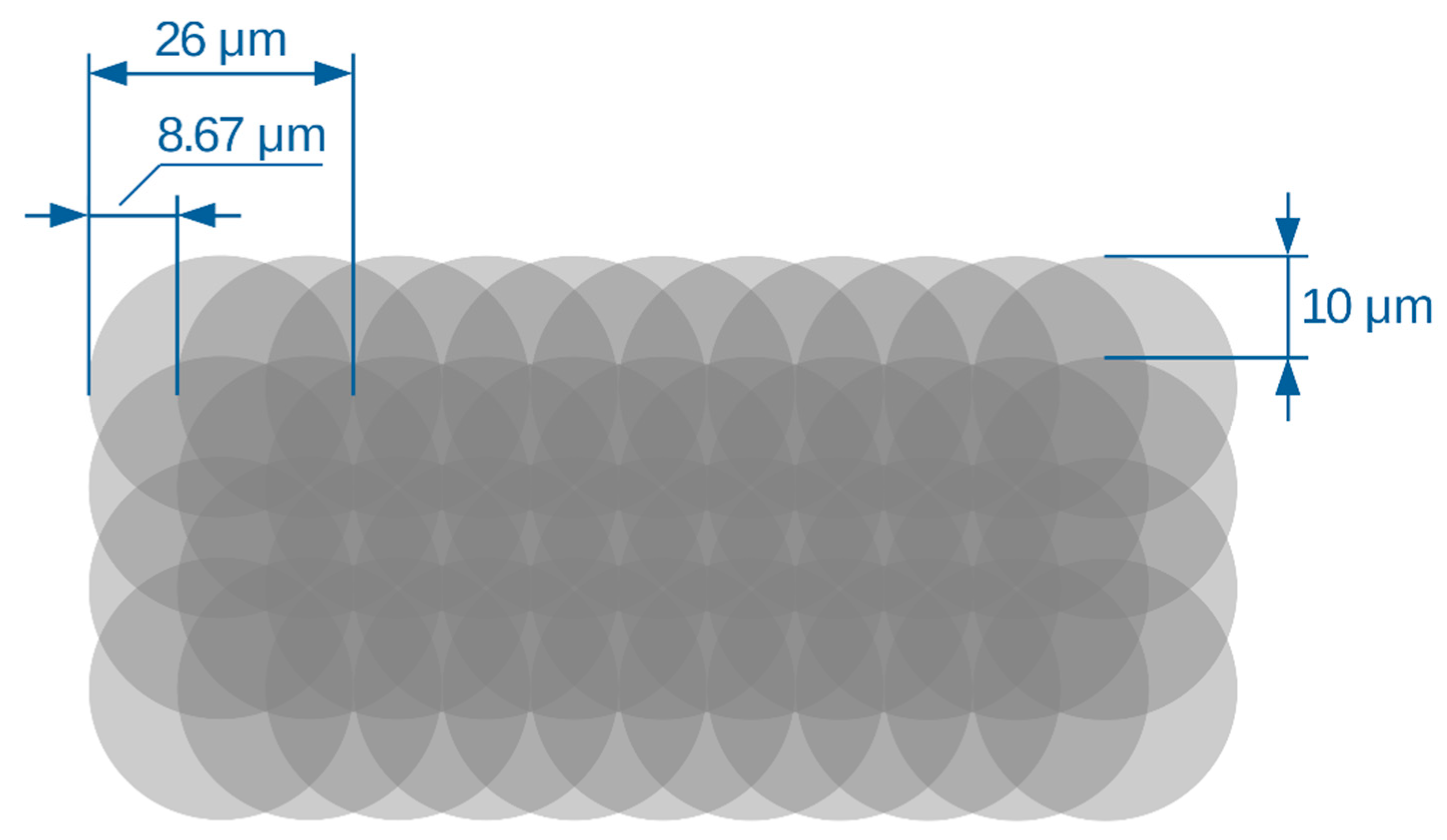

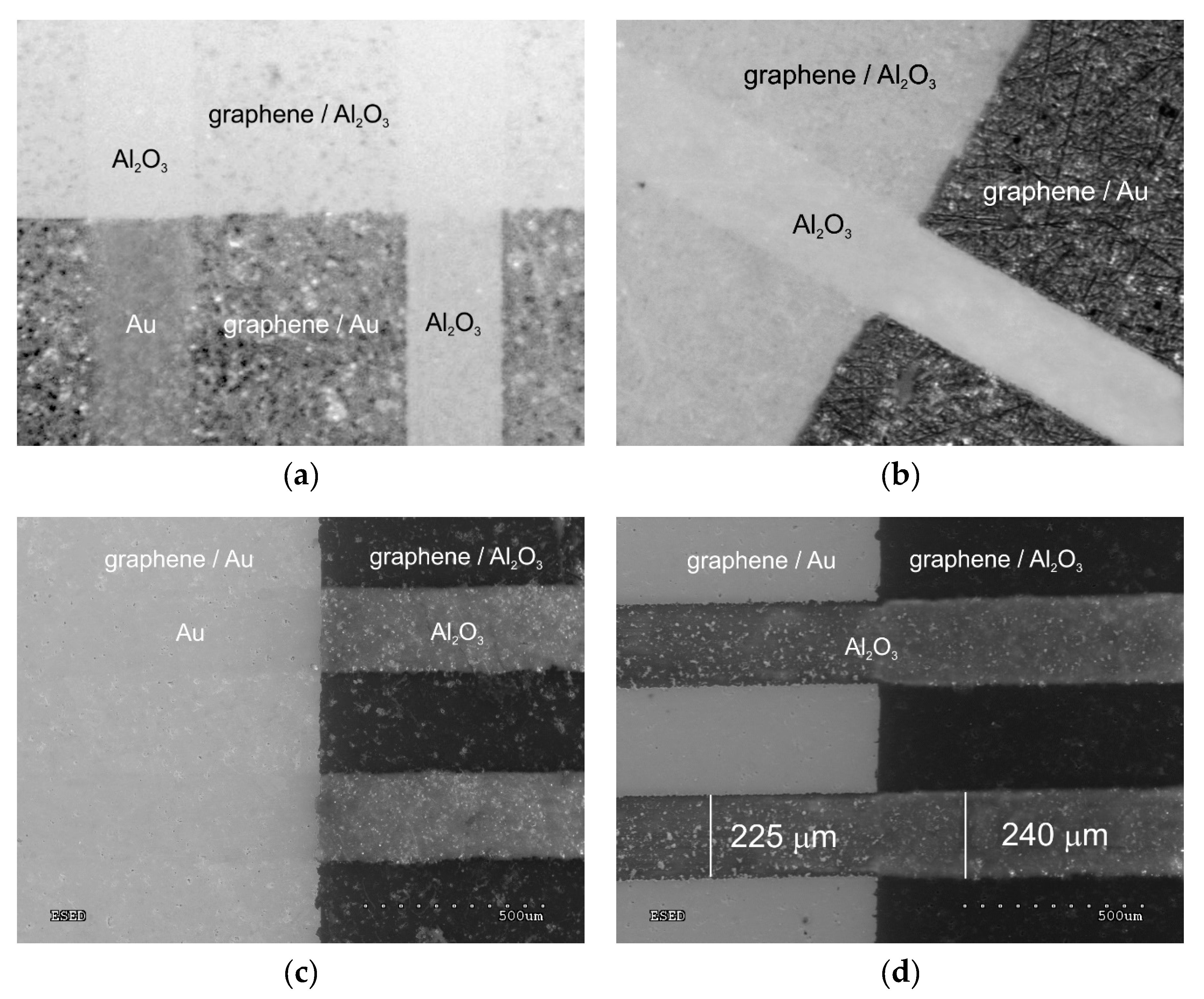

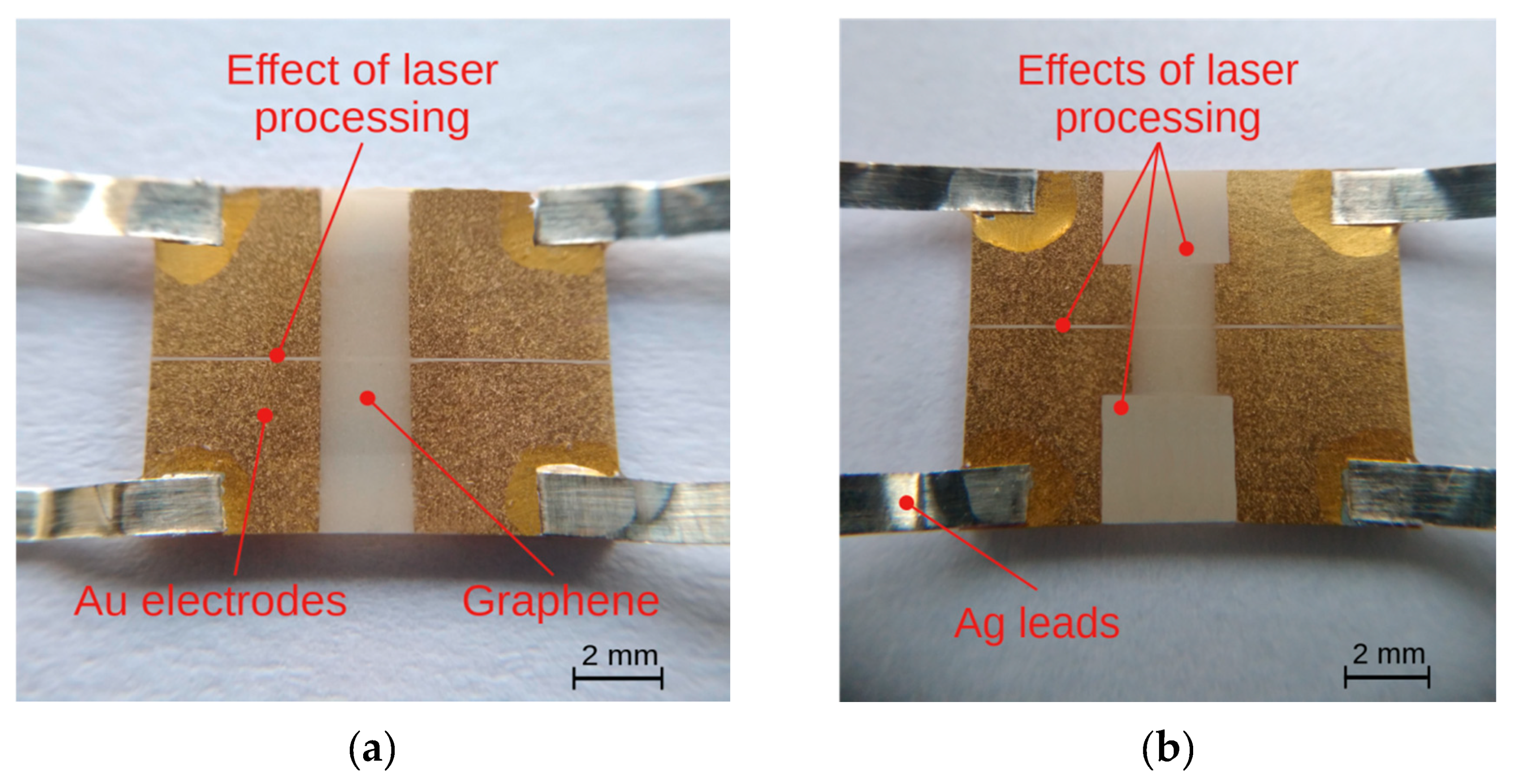

3.1. Laser Patterning of the Graphene Layer

3.2. Raman Spectroscopy Results

3.3. Temperature Dependence of Resistance

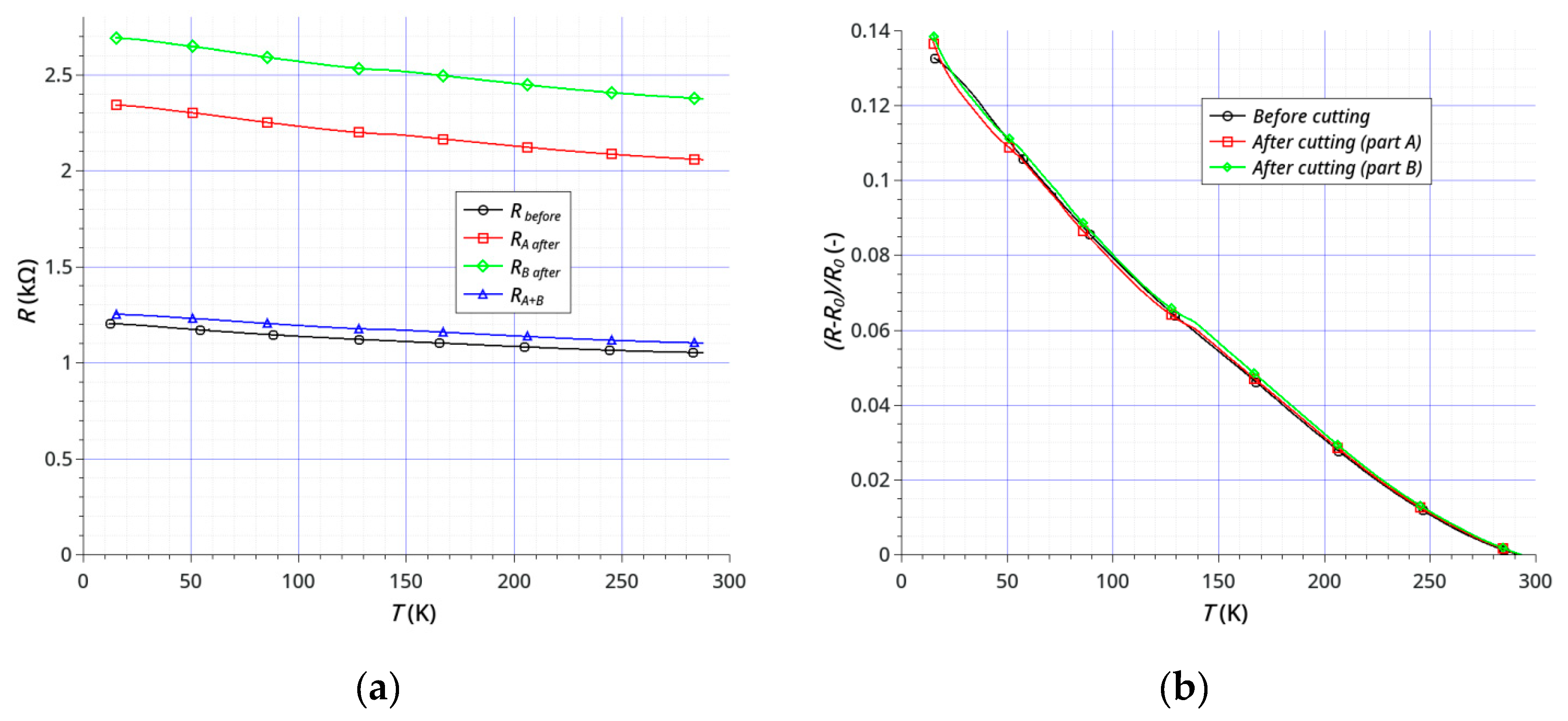

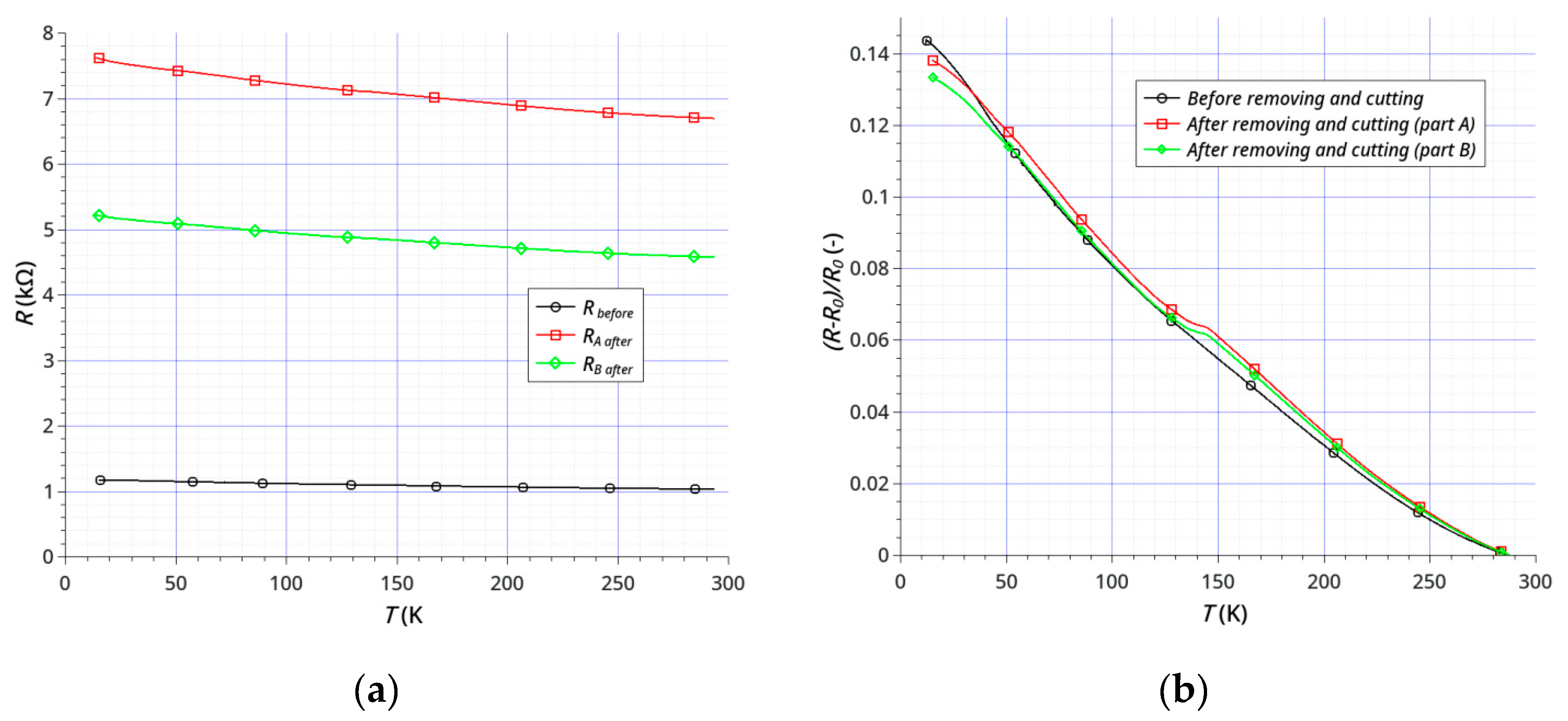

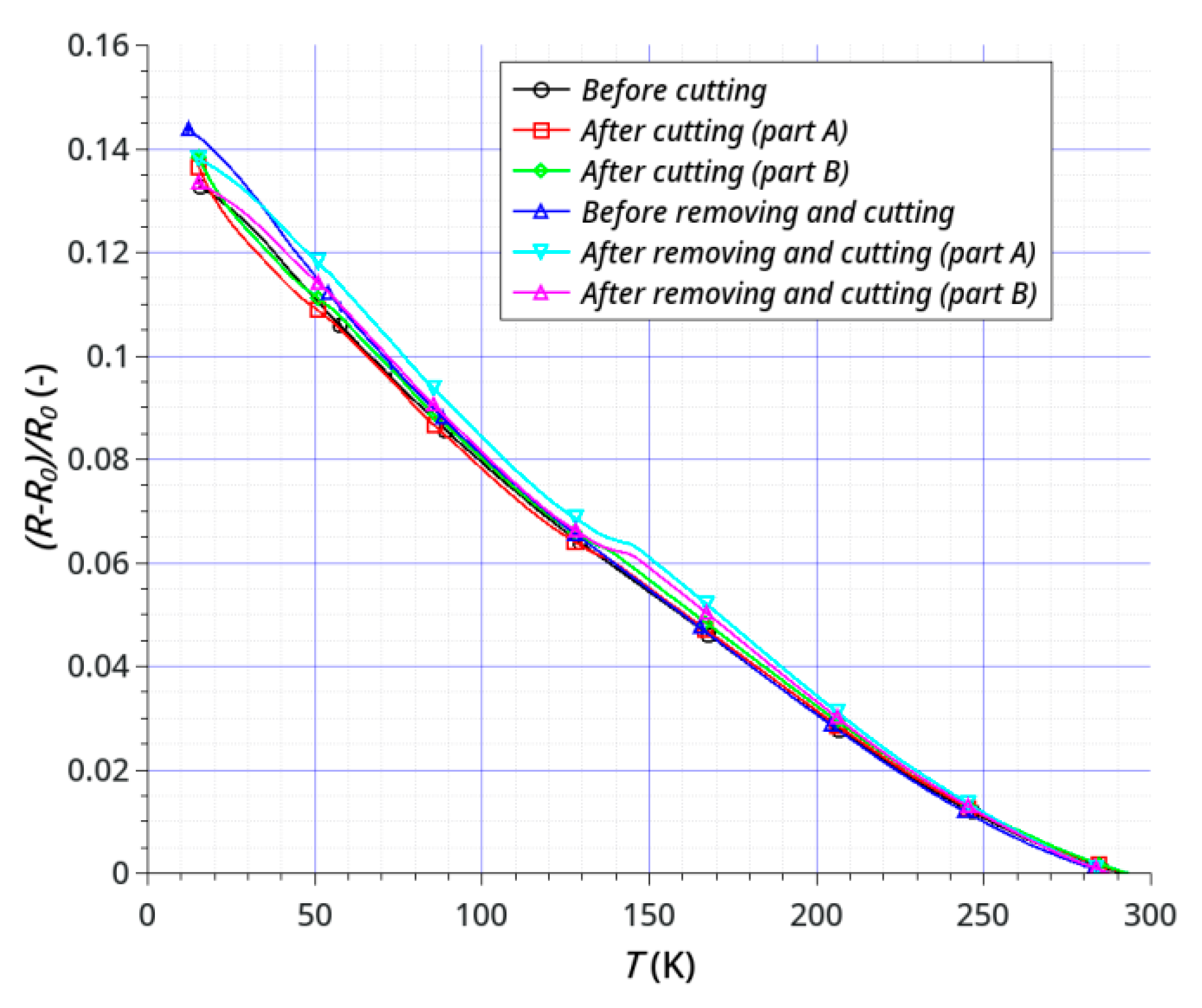

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Seo, J.-T.; Han, J.; Lim, T.; Lee, K.-H.; Hwang, J.; Yang, H.; Ju, S. Fully transparent quantum dot light-emitting diode integrated with graphene anode and cathode. ACS Nano 2014, 8, 12476–12482. [Google Scholar] [CrossRef]

- Yan, C.; Wang, J.; Lee, P.S. Stretchable graphene thermistor with tunable thermal index. ACS Nano 2015, 9, 2130–2137. [Google Scholar] [CrossRef]

- Lawal, A.T. Synthesis and utilisation of graphene for fabrication of electrochemical sensors. Talanta 2015, 131, 424–443. [Google Scholar] [CrossRef]

- Liao, C.; Zhang, M.; Niu, L.; Zheng, Z.; Yan, F. Organic electrochemical transistors with graphene-modified gate electrodes for highly sensitive and selective dopamine sensors. J. Mater. Chem. B 2014, 2, 191–200. [Google Scholar] [CrossRef]

- El-Kady, M.F.; Shao, Y.; Kaner, R.B. Graphene for batteries, supercapacitors and beyond. Nat. Rev. Mater. 2016, 1, 16033. [Google Scholar] [CrossRef]

- Liang, J.; Chen, Y.; Xu, Y.; Liu, Z.; Zhang, L.; Zhao, X.; Zhang, X.; Tian, J.; Huang, Y.; Ma, Y.; et al. Toward all-carbon electronics: Fabrication of graphene-based flexible electronic circuits and memory cards using maskless laser direct writing. ACS Appl. Mater. Interfaces 2010, 2, 3310–3317. [Google Scholar] [CrossRef]

- Yang, P.-K.; Chang, W.-Y.; Teng, P.-Y.; Jeng, S.-F.; Lin, S.-J.; Chiu, P.-W.; He, J.-H. Fully transparent resistive memory employing graphene electrodes for eliminating undesired surface effects. Proc. IEEE 2013, 101, 1732–1739. [Google Scholar] [CrossRef]

- Bae, S.-H.; Lee, Y.; Sharma, B.K.; Lee, H.-J.; Kim, J.-H.; Ahn, J.-H. Graphene-based transparent strain sensor. Carbon 2013, 51, 236–242. [Google Scholar] [CrossRef]

- Avouris, P. Graphene: Electronic and photonic properties and devices. Nano Lett. 2010, 10, 4285–4294. [Google Scholar] [CrossRef]

- Huang, X.; Yin, Z.; Wu, S.; Qi, X.; He, Q.; Zhang, Q.; Yan, Q.; Boey, F.; Zhang, H. Graphene-based materials: Synthesis, characterization, properties, and applications. Small 2011, 7, 1876–1902. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [Green Version]

- Frank, I.W.; Tanenbaum, D.M.; van der Zande, A.M.; McEuen, P.L. Mechanical properties of suspended graphene sheets. J. Vac. Sci. Technol. B 2007, 25, 2558–2561. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.; Li, W.; Qian, X.; Qi, J.; Qi, L.; Li, J. Patterning of grapheme. Nanoscale 2012, 4, 4883–4899. [Google Scholar] [CrossRef]

- Shukla, S.; Kang, S.-Y.; Saxena, S. Synthesis and patterning of graphene: Strategies and prospects (Review). Appl. Phys. Rev. 2019, 6, 021311. [Google Scholar] [CrossRef]

- Bhuyan, M.S.A.; Uddin, M.N.; Islam, M.M.; Bipasha, F.A.; Hossain, S.S. Synthesis of graphene. Int. Nano Lett. 2016, 6, 65–83. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Colombo, L.; Ruoff, R.S. Synthesis of graphene films on copper foils by chemical vapor deposition. Adv. Mater. 2016, 28, 6247–6252. [Google Scholar] [CrossRef]

- Shi, R.; Xu, H.; Chen, B.; Zhang, Z.; Peng, L.-M. Scalable fabrication of graphene devices through photolithography. Appl. Phys. Lett. 2013, 102, 113102. [Google Scholar] [CrossRef]

- Shin, J.-W.; Han, J.-H.; Cho, H.; Moon, J.; Kwon, B.-H.; Cho, S.; Yoon, T.; Kim, T.-S.; Suemitsu, M.; Lee, J.-I.; et al. Display process compatible accurate graphene patterning for OLED applications. 2D Mater. 2018, 5, 014003. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Parvez, K.; Feng, X.; Müllen, K. Photolithographic fabrication of high-performance all-solid-state graphene-based planar micro-supercapacitors with different interdigital fingers. J. Mater. Chem. A 2014, 2, 8288–8293. [Google Scholar] [CrossRef] [Green Version]

- Ahlberg, P.; Hinnemo, M.; Song, M.; Gao, X.; Olsson, J.; Zhang, S.-L.; Zhang, Z.-B. A two-in-one process for reliable graphene transistors processed with photo-lithography. Appl. Phys. Lett. 2015, 107, 203104. [Google Scholar] [CrossRef] [Green Version]

- Kotakoski, J.; Brand, C.; Lilach, Y.; Cheshnovsky, O.; Mangler, C.; Arndt, M.; Meyer, J.C. Toward two-dimensional all-carbon heterostructures via ion beam patterning of single-layer grapheme. Nano Lett. 2015, 15, 5944–5949. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Celis, A.; Nair, M.N.; Taleb-Ibrahimi, A.; Conrad, E.H.; Berger, C.; De Heer, W.A.; Tejeda, A. Graphene nanoribbons: Fabrication, properties and devices. J. Phys. D 2016, 49, 143001. [Google Scholar] [CrossRef]

- Abbas, A.N.; Liu, G.; Liu, B.; Zhang, L.; Liu, H.; Ohlberg, D.; Wu, W.; Zhou, C. Patterning, characterization, and chemical sensing applications of graphene nanoribbon arrays down to 5 nm using helium ion beam lithography. ACS Nano 2014, 8, 1538–1546. [Google Scholar] [CrossRef] [PubMed]

- Iberi, V.; Vlassiouk, I.; Zhang, X.-G.; Matola, B.; Linn, A.; Joy, D.C.; Rondinone, A.J. Maskless lithography and in situ visualization of conductivity of graphene using helium ion microscopy. Sci. Rep. 2015, 5, 11952. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- López-Suárez, M.; Torres, F.; Mestres, N.; Rurali, R.; Abadal, G. Fabrication of highly regular suspended graphene nanoribbons through a one-step electron beam lithography process. Microelectron. Eng. 2014, 129, 81–85. [Google Scholar] [CrossRef]

- Qi, Z.J.; Rodr íguez-Manzo, J.A.; Botello-M éndez, A.R.; Hong, S.J.; Stach, E.A.; Park, Y.W.; Charlier, J.-C.; Drndić, M.; Johnson, A.T.C. Correlating atomic structure and transport in suspended graphene nanoribbons. Nano Lett. 2014, 14, 4238–4244. [Google Scholar] [CrossRef]

- Lan, Y.-W.; Chang, W.-H.; Xiao, B.-T.; Liang, B.-W.; Chen, J.-H.; Jiang, P.-H.; Li, L.-J.; Su, Y.-W.; Zhong, Y.-L.; Chen, C.-D. Polymer-free patterning of graphene at sub-10-nm scale by low-energy repetitive electron beam. Small 2014, 10, 4778–4784. [Google Scholar] [CrossRef]

- Kalhor, N.; Boden, S.A.; Mizuta, H. Sub-10 nm patterning by focused He-ion beam milling for fabrication of downscaled graphene nano devices. Microelectron. Eng. 2014, 114, 70–77. [Google Scholar] [CrossRef]

- Zhang, K.; Fu, Q.; Pan, N.; Yu, X.; Liu, J.; Luo, Y.; Wang, X.; Yang, J.; Hou, J. Direct writing of electronic devices on graphene oxide by catalytic scanning probe lithography. Nat. Commun. 2012, 3, 1194. [Google Scholar] [CrossRef]

- Stempień, Z.; Khalid, M.; Kozicki, M.; Kozanecki, M.; Varela, H.; Filipczak, P.; Pawlak, R.; Korzeniewska, E.; Sąsiadek, E. In-situ deposition of reduced graphene oxide layers on textile surfaces by the reactive inkjet printing technique and their use in supercapacitor applications. Synth. Met. 2019, 256, 116144. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.; Singh, D.P.; Joanni, E.; Yadav, R.M.; Moshkalev, S.A. Laser-assisted synthesis, reduction and micro-patterning of graphene: Recent progress and applications (Review). Coord. Chem. Rev. 2017, 342, 34–79. [Google Scholar] [CrossRef]

- El-Kady, M.F.; Kaner, R.B. Direct laser writing of graphene electronics (Review). ACS Nano 2014, 8, 8725–8729. [Google Scholar] [CrossRef] [PubMed]

- Park, J.B.; Xiong, W.; Gao, Y.; Qian, M.; Xie, Z.Q.; Mitchell, M.; Zhou, Y.S.; Han, G.H.; Jiang, L.; Lu, Y.F. Fast growth of graphene patterns by laser direct writing. Appl. Phys. Lett. 2011, 98, 123109. [Google Scholar] [CrossRef]

- Jiang, J.; Lin, Z.; Ye, X.; Zhong, M.; Huang, T.; Zhu, H. Graphene synthesis by laser-assisted chemical vapor deposition on Ni plate and the effect of process parameters on uniform graphene growth. Thin Solid Films 2014, 556, 206–210. [Google Scholar] [CrossRef]

- Xiong, W.; Zhou, Y.S.; Hou, W.J.; Jiang, L.J.; Gao, Y.; Fan, L.S.; Jiang, L.; Silvain, J.F.; Lu, Y.F. Direct writing of graphene patterns on insulating substrates under ambient conditions. Sci. Rep. 2014, 4, 4892. [Google Scholar] [CrossRef]

- Wei, D.; Mitchell, J.I.; Tansarawiput, C.; Nam, W.; Qi, M.; Ye, P.D.; Xu, X. Laser direct synthesis of graphene on quartz. Carbon 2013, 53, 374–379. [Google Scholar] [CrossRef]

- Wei, D.; Xu, X. Laser direct growth of graphene on silicon substrate. Appl. Phys. Lett. 2012, 100, 023110. [Google Scholar] [CrossRef] [Green Version]

- Yannopoulos, S.N.; Siokou, A.; Nasikas, N.K.; Dracopoulos, V.; Ravani, F.; Papatheodorou, G.N. CO2—Laser-induced growth of epitaxial graphene on 6H-SiC(0001). Adv. Funct. Mater. 2012, 22, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Kaplas, T.; Svirko, Y. Self-assembled graphene on dielectric micro- and nanostructures. Carbon 2014, 70, 273–278. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Han, D.; Tian, Y.; Shao, R.; Wei, S. Mask-free and programmable patterning of graphene by ultrafast laser direct writing. Chem. Phys. 2014, 430, 13–17. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, L.; Wei, S.; He, Y.; Xia, H.; Chen, Q.; Sun, H.-B.; Xiao, F.-S. Direct imprinting of microcircuits on graphene oxides film by femtosecond laser reduction. Nano Today 2010, 5, 15–20. [Google Scholar] [CrossRef]

- Bobrinetskiy, I.I.; Emelianov, A.V.; Smagulova, S.A.; Komarov, I.A.; Otero, N.; Romero, P.M. Laser direct 3D patterning and reduction of graphene oxide film on polymer substrate. Mater. Lett. 2017, 187, 20–23. [Google Scholar] [CrossRef]

- Trusovas, R.; Ratautas, K.; Račiukaitis, G.; Barkauskas, J.; Stankevičiene, I.; Niaura, G.; Mažeikiene, R. Reduction of graphite oxide to graphene with laser irradiation. Carbon 2013, 52, 574–582. [Google Scholar] [CrossRef]

- Yung, K.C.; Liem, H.; Choy, H.S.; Chen, Z.C.; Cheng, K.H.; Cai, Z.X. Laser direct patterning of a reduced-graphene oxide transparent circuit on a graphene oxide thin film. J. Appl. Phys. 2013, 113, 244903. [Google Scholar] [CrossRef]

- Sokolov, D.A.; Rouleau, C.M.; Geohegan, D.B.; Orlando, T.M. Excimer laser reduction and patterning of graphite oxide. Carbon 2013, 53, 81–89. [Google Scholar] [CrossRef]

- Gao, W.; Singh, N.; Song, L.; Liu, Z.; Reddy, A.L.M.; Ci, L.; Vajtai, R.; Zhang, Q.; Wei, B.; Ajayan, P.M. Direct laser writing of micro-supercapacitors on hydrated graphite oxide films. Nat. Nanotechnol. 2011, 6, 496–500. [Google Scholar] [CrossRef]

- Arul, R.; Oosterbeek, R.N.; Robertson, J.; Xu, G.; Jin, J.; Simpson, M.C. The mechanism of direct laser writing of graphene features into graphene oxide films involves photoreduction and thermally assisted structural rearrangement. Carbon 2016, 99, 423–431. [Google Scholar] [CrossRef]

- Guo, L.; Jiang, H.-B.; Shao, R.-Q.; Zhang, Y.-L.; Xie, S.-Y.; Wang, J.-N.; Li, X.-B.; Jiang, F.; Chen, Q.-D.; Zhang, T.; et al. Two-beam-laser interference mediated reduction, patterning and nanostructuring of graphene oxide for the production of a flexible humidity sensing device. Carbon 2012, 50, 1667–1673. [Google Scholar] [CrossRef]

- Gupta, S.; Narayan, J. Non-equilibrium processing of ferromagnetic heavily reduced graphene oxide. Carbon 2019, 153, 663–673. [Google Scholar] [CrossRef]

- Gupta, S.; Narayan, J. Reduced graphene oxide/amorphous carbon P-N junctions: Nanosecond laser patterning. ACS Appl. Mater. Interfaces 2019, 11, 24318–24330. [Google Scholar] [CrossRef] [PubMed]

- Sahin, R.; Simsek, E.; Akturk, S. Nanoscale patterning of graphene through femtosecond laser ablation. Appl. Phys. Lett. 2014, 104, 053118. [Google Scholar] [CrossRef] [Green Version]

- Kalita, G.; Qi, L.; Namba, Y.; Wakita, K.; Umeno, M. Femtosecond laser induced micropatterning of graphene film. Mater. Lett. 2011, 65, 1569–1572. [Google Scholar] [CrossRef]

- Dong, T.; Sparkes, M.; Durkan, C.; O’Neill, W. Evaluating femtosecond laser ablation of graphene on SiO2/Si substrate. J. Laser Appl. 2016, 28, 022202. [Google Scholar] [CrossRef] [Green Version]

- Lorenzoni, M.; Brandi, F.; Dante, S.; Giugni, A.; Torre, B. Simple and effective graphene laser processing for neuron patterning application. Sci. Rep. 2013, 3, 1954. [Google Scholar] [CrossRef] [Green Version]

- Bobrinetskiy, I.I.; Emelianov, A.V.; Otero, N.; Romero, P.M. Patterned graphene ablation and two-photon functionalization by picosecond laser pulses in ambient conditions. Appl. Phys. Lett. 2015, 107, 043104. [Google Scholar] [CrossRef]

- Chang, T.-L.; Chen, Z.-C.; Chen, W.-Y.; Han, H.-C.; Tseng, S.-F. Patterning of multilayer graphene on glass substrate by using ultraviolet picosecond laser pulses. Microelectron. Eng. 2016, 158, 1–5. [Google Scholar] [CrossRef]

- Tseng, S.-F.; Haiso, W.-T.; Cheng, P.-Y.; Chung, C.-K.; Lin, Y.-S.; Chien, S.-C.; Huang, W.-Y. Graphene-based chips fabricated by ultraviolet laser patterning for an electrochemical impedance spectroscopy. Sens. Actuators B Chem. 2016, 226, 342–348. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Y.; Wen, Y.; Huang, L.; Xue, Y.; Geng, D.; Wu, B.; Luo, B.; Yu, G.; Liu, Y. Two-stage metal-catalyst-free growth of high-quality polycrystalline graphene films on silicon nitride substrates. Adv. Mater. 2013, 25, 992–997. [Google Scholar] [CrossRef]

- Liu, X.; Lin, T.; Zhou, M.; Bi, H.; Cui, H.; Wan, D.; Huang, F.; Lin, J. A novel method for direct growth of a few-layer graphene on Al2O3 film. Carbon 2014, 71, 20–26. [Google Scholar] [CrossRef]

- Sun, J.; Gao, T.; Song, X.; Zhao, Y.; Lin, Y.; Wang, H.; Ma, D.; Chen, Y.; Xiang, W.; Wang, J.; et al. Direct growth of high-quality graphene on high-k dielectric SrTiO3 substrates. J. Am. Chem. Soc. 2014, 136, 6574–6577. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Shang, P.; Zhong, J.; Lin, S.; Chi, Y. A multilayer-graphene nanosheet film deposited on a ceramic substrate without a catalyst for constructing an electrochemiluminescence imaging platform. Nanoscale 2019, 11, 12132–12138. [Google Scholar] [CrossRef] [PubMed]

- Kolodziejczyk, L.; Kula, P.; Szymanski, W.; Atraszkiewicz, R.; Dybowski, K.; Pietrasik, R. Frictional behavior of polycrystalline graphene grown on liquid metallic matrix. Tribol. Int. 2016, 93, 628–639. [Google Scholar] [CrossRef]

- Pawlak, R.; Lebioda, M.; Rymaszewski, J.; Szymanski, W.; Kolodziejczyk, L.; Kula, P. A fully transparent flexible sensor for cryogenic temperatures based on high strength metallurgical graphene. Sensors 2017, 17, 51. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Huang, D.; Lv, R.; Bai, Y.; Huang, Z.-H.; Guc, J.; Kang, F. Three-dimensional reduced graphene oxide powder for efficient microwave absorption in the Sband (2–4 GHz). RSC Adv. 2017, 7, 25773–25779. [Google Scholar] [CrossRef] [Green Version]

- Yin, F.; Wu, S.; Wang, Y.; Wu, L.; Yuan, P.; Wang, X. Self-assembly of mildly reduced graphene oxide monolayer for enhanced Raman scattering. J. Solid State Chem. 2016, 237, 57–63. [Google Scholar] [CrossRef]

- Yasin, G.; Arif, M.; Shakeel, M.; Dun, Y.; Zuo, Y.; Khan, W.Q.; Tang, Y.; Khan, A.; Nadeem, M. Exploring the nickel–graphene nanocomposite coatings for superior corrosion resistance: Manipulating the effect of deposition current density on its morphology, mechanical properties, and erosion-corrosion performance. Adv. Eng. Mater. 2018, 20, 1701166. [Google Scholar] [CrossRef]

- Das, A.; Chakraborty, B.; Sood, A.K. Raman spectroscopy of graphene on different substrates and influence of defects. Bull. Mater. Sci. 2008, 31, 579–584. [Google Scholar] [CrossRef]

- Mortazavia, S.; Mollabashia, M.; Ismat Shah, S. Micropatterning of CVD single layer graphene using KrF laser irradiation. Appl. Surf. Sci. 2018, 428, 94–97. [Google Scholar] [CrossRef]

- Pérez-Mas, A.M.; Álvarez, P.; Campos, N.; Gómez, D.; Menéndez, R. Graphene patterning by nanosecond laser ablation: The effect of the substrate interaction with graphene. J. Phys. D Appl. Phys. 2016, 49, 305301. [Google Scholar] [CrossRef] [Green Version]

- Vasquez, A.; Samolis, P.; Zeng, J.; Sander, M.Y. Micro-structuring, ablation, and defect generation in graphene with femtosecond pulses. OSA Continuum 2019, 2, 2925–2934. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lebioda, M.; Pawlak, R.; Szymański, W.; Kaczorowski, W.; Jeziorna, A. Laser Patterning a Graphene Layer on a Ceramic Substrate for Sensor Applications. Sensors 2020, 20, 2134. https://doi.org/10.3390/s20072134

Lebioda M, Pawlak R, Szymański W, Kaczorowski W, Jeziorna A. Laser Patterning a Graphene Layer on a Ceramic Substrate for Sensor Applications. Sensors. 2020; 20(7):2134. https://doi.org/10.3390/s20072134

Chicago/Turabian StyleLebioda, Marcin, Ryszard Pawlak, Witold Szymański, Witold Kaczorowski, and Agata Jeziorna. 2020. "Laser Patterning a Graphene Layer on a Ceramic Substrate for Sensor Applications" Sensors 20, no. 7: 2134. https://doi.org/10.3390/s20072134

APA StyleLebioda, M., Pawlak, R., Szymański, W., Kaczorowski, W., & Jeziorna, A. (2020). Laser Patterning a Graphene Layer on a Ceramic Substrate for Sensor Applications. Sensors, 20(7), 2134. https://doi.org/10.3390/s20072134