1. Introduction

Human gait analysis, namely the kinematic data, has manifold applications, as follows. First, it has the potential to be applied as an automatic assessment tool for motor disorders to foster better treatment decisions. Second, to design personalized gait therapies. Third, to recognize walking risk situations, and to support the clinical motor diagnosis [

1,

2].

Current challenges include the development of wearable motion labs with unobtrusive, low-cost, and effective wearable sensor systems for all-day and any-place gait monitoring without interfering with the user’s movement [

1,

3]. Research contributions related to the ambulatory human kinematic gait analysis may involve inertial sensor-based systems with inertial measurement units (IMUs) [

1]. Low-cost IMUs-based sensor system showed excellent performance for joint angle gait analysis with lower errors than the low-cost vision-based gait capture systems [

4].

There is growing interest in developing low-cost, wearable IMU-based systems for kinematic gait analysis, including orientation estimation [

5,

6,

7,

8] and gait event analysis [

5], and their integrating into third-party systems [

6,

9]. Nonetheless, the systems proposed in the research community have to deal with challenges, as follows: (i) automatic, user-independent calibration to avoid the use of time-consuming calibration methods [

5,

8], (ii) time-effective computational tools, eventually combined with biomechanical models, for the real-time orientation estimation [

10], (iii) technical matters to deal with sensor’s misalignments [

11,

12], and (iv) to assess the reliability of the inertial sensor system for gait analysis in daily and non-structured conditions for inferring its real-world application validity.

Related studies that developed wearable IMU-based systems for kinematic gait analysis, including segment orientation and/or joint angle estimation [

5,

6,

11,

13], face a limited validation analysis concerning daily walking conditions. The study [

6] presents a 7 IMU-based system, either for integration into lower limb exoskeletons or human gait kinematic analysis, using Kalman filtering and the factored quaternion algorithm for orientation estimation. The validation of the wearable inertial measurement system included flexion/extension isolated motions of lower limb joints and 30 walking steps. The performance analysis of the wearable IMU-based system proposed in [

5] was limited to four strides. This system integrates six IMUs (three-dimensional (3D)-gyroscopes and two-dimensional-accelerometers) placed on the shank, thigh, and foot segments, aiming lower limb orientation estimation through mathematical integration of the angular velocity measured. Kardos et al. [

13] proposed a seven IMU sensor array system designed for kinematic gait sensing, namely joint angle estimation based on fusion methods (complementary and Kalman’s filters). However, this study did not disclose results concerning the system’s effectiveness for gait analysis. Tadano et al. [

11] presented a wearable sensor system consisting of seven sensors (3D accelerometer and gyroscope) for lower limb orientation estimation using quaternion. Experiments were conducted indoors on a straight flat floor with five healthy volunteers. Additionally, Kyrarini et al. [

4] asked the participants to walk in a straight line for 2.5 m to compare the performance of vision-based and commercial IMU-based systems for joint angle gait analysis.

On the other hand, commercial IMU-based solutions such as MVN BIOMECH (Xsens, Netherlands), RIABLO (CoReHab, Italy), G-walk (BTS Bioengineering Corp., Quincy, Massachusetts, USA) (i) are high-cost systems, (ii) usually require non-wearable processing units to run the software interfaces, (iii) do not offer a fully wearable integration into a further sensor and actuation systems, and (iv) do not directly and efficiently provide the real-time kinematic data to third-party devices or algorithms (for instance, techniques for human motion intention recognition and motor diagnosis).

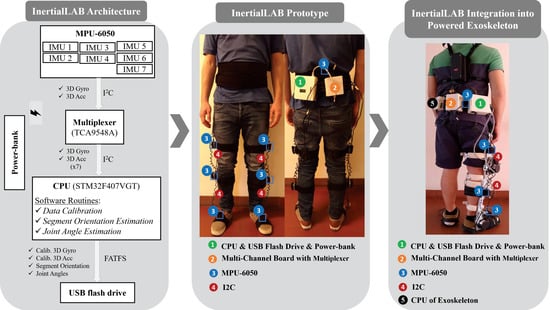

This study holds three main goals. First, we developed a wearable inertial sensor system, the InertialLAB, for the real-time tracking of 3D-angular velocity and 3D-acceleration up to 6 lower limbs and trunk segment, and joint angle measures in the sagittal plane up to 6 joints. The kinematic data monitored by InertialLAB aimed at a holistic gait analysis application every day and anywhere, such as the gait event analysis reported in [

14] and human locomotion intention decoding [

15]. It can be used for healthy and pathological gait assessment, either for preventive healthcare or for the evaluation of rehabilitation processes and assisted gait conditions by a wearable exoskeleton [

16].

InertialLAB was designed to be cost-, time-effective, and easily calibrated. It includes an automatic and user-independent calibration with a minimum-to-null effort for the user and assessor. InertialLAB has an advantage over existing solutions by avoiding the commonly applied manual, time-consuming, and subject-specific calibration. Moreover, InertialLAB encompasses up to seven small, lightweight IMUs placed on the back, thigh, shank, and foot segments, as suggested by [

9,

17] for gait analysis applications. The developed software interfaces running up to 200 Hz for real-time (i) monitoring and providing kinematic data to third-party systems, (ii) segment orientation determination using inertial data fusion-based methods, the complementary filter and Kalman filter, and (iii) joint angle estimation using a trigonometry-based method dependent on the segments’ orientation and segment-joint relations in the calibration. InertialLAB attempts to pursuit the limitations found in similar commercial systems. It is a low-cost gait data capture system that includes a modular and open-architecture to enable both stand-alone use and direct integration into third-party systems, such as robotic assistive devices [

16]. Consequently, compared to similar commercial systems, InertialLAB can timely provide real-time kinematic data to third-party wearable devices or algorithms. This main innovative feature of InertialLAB is determinant for yielding personalized therapies concerning the user’s actual kinematic state. Additionally, the fairly simple software interfaces of InertialLAB make it a low computational load system to enable their execution into wearable processing units, advancing commercial systems that require non-wearable processing units. Thus, InertialLAB offers a fully wearable solution for more practical daily use.

The second goal covers a benchmarking analysis of InertialLAB against the MVN BIOMECH [

18], a well-established commercial wearable system for human kinematic gait analysis [

1,

12]. This benchmarking analysis involved heterogenous gait cycles from healthy subjects walking varying gait speed and terrain (flat, ramp, and stairs) and including turns. This validation innovates the actual literature works [

4,

5,

6,

11,

13], as follows: (i) by extending the joint angle analyzes with the 3D-angular velocity and 3D-acceleration analyses and (ii) including heterogenous gait patterns from more subjects and more non-structured real-world scenarios (flat surfaces, stairs, and ramps). The validation enables us to better assess the reliability, repeatability, and practical evidence of InertialLAB, as a low-cost wearable inertial sensor system for daily kinematic gait analysis. When compared to related studies [

4,

5,

6,

11,

13], this work extends the InertialLAB’s validation by performing a usability assessment using the system usability scale [

19].

Lastly, we explored the hypothesis that a machine learning-based regression model would improve the InertialLAB’s accuracy for joint angle estimation with minimal drift bias. This approach potentially eliminates the need for high-complex biomechanical models for reliable joint angle estimation. For this purpose, we compared the accuracy of different machine learning-based regression models, namely neural network (NN), decision tree, and support vector machine (SVM), to identify a well-fitted model for improving the accuracy of InertialLAB for joint angle estimations.

3. Experimental Evaluation

For the benchmarking analysis, we involved the lower-body configuration of the gold standard commercial wearable inertial system, the MVN BIOMECH [

18], for three-fold reasons. First, it is a well-established wearable inertial system able to track all kinematic data monitored by the InertialLAB [

1,

12]. Second, the motion IMUs of Xsens demonstrated higher accuracy when compared to other commercially available IMU-based systems, such as APDM Opal and Inertial Labs OSv3, in a benchmarking analysis with Optotrak motion tracking system [

30]. These findings reinforce the reliability of MVN BIOMECH as a ground truth IMU-based sensor system. Third, the MVN BIOMECH is a wearable solution able to track the human gait in ambulatory scenarios like those explored in this work. We did not consider the use of camera-based motion systems since they do not provide benchmarked measures for the angular velocity and acceleration and do not allow an ambulatory gait analysis in non-structured and outdoor environments. Additionally, the literature’s results report that MVN BIOMECH is a valid tool for quantifying kinematics during functional movements when compared to camera-based motion systems. The orientation information provided by an IMU had shown to be accurate [

8,

30]. The lower-limb joint angles provided by MVN BIOMECH software in the sagittal plane were scored with an excellent validity and fair-to-excellent reliability for healthy participants performing overground walking [

31,

32] and for climbing stairs [

32].

We centered the benchmarking analysis to the kinematic data monitored by InertialLAB to evaluate its operability for gait analysis. However, the MVN BIOMECH includes further gait analysis functions, and it can perform a full 3D tracking of the body motion using wearable IMUs (MTw Awinda) and native biomechanical tools.

3.1. Participants

We included 11 able-bodied subjects (7 males and 4 females). The participants’ mean age was 24.53 ± 2.09 years old, with a height of 1.71 ± 0.10 m and a body mass of 65.29 ± 9.02 kg. All participants provided written informed consent to participate in this study. The study was conducted according to the rules of ethical conduct of the Life and Health Sciences defined by the University of Minho Ethics Committee, addressing the principles of the Declaration of Helsinki and the Oviedo Convention.

3.2. Protocol and Data Collection

The participants wore their sport-shoes and 7 IMUs in the configuration depicted in

Figure 3b. To ensure the repeatability of the sensor’s alignment in the leg, the assessor identified and marked the lateral side in the middle of the thigh and shank segments [

33]. For the trunk and foot segments, the assessor identified the lower back position (near to the center of mass) aligned with the spinal cord and the instep position aligned with the navicular bone, respectively. The sensors of InertialLAB and MVN BIOMECH were placed on these positions by the assessor, who used the double holder straps of InertialLAB to ensure that its sensors are aligned and fixed over the IMUs of MVN BIOMECH, as shown in

Figure 3b. We used a hardware-based sync method (TTL sync) to synchronize both systems.

The MVN BIOMECH performance may be affected by base station distance. Consequently, before starting the experiments, the assessor strategically studied the best position of the base station to ensure adequate wireless communication from the IMUs of MVN BIOMECH to the base station during all data acquisition period. The base station position in the real-world scenario was established where the MVN Analyse software, already validated by the Xsens, rated a good wireless communication signal.

Each trial started by calibrating the MVN BIOMECH in N-pose considering anthropometric user data (height and foot length). The experiments only proceeded after the successful finalization of the calibration procedures in the intended walking environment. Subsequently, we asked the participant to stay in the stand-up steady-state in N-pose for 10 s to calibrate InertialLAB, and then, he/she could start the gait trial. The data were collected and stored for a posteriori analysis at 100 Hz, the maximum sample rate allowed by MVN BIOMECH.

The participants were asked to randomly perform 9 trials at three self-selected gait speeds (slow, normal, and fast) on a10 m-flat surface. Additionally, the subjects randomly conducted 10 gait trials on two real-world terrains (

Figure 3c), at a self-selected gait speed. In the first terrain, they walked 2 m forward in level-ground; ascended a staircase; walked forward in level-ground for 2 m and stopped; turned around and descended the staircase back to the starting position. The indoor staircase had 8 steps with 17 cm of height, 31 cm of depth, and 110 cm width. On the second circuit, the participants walked 2 m forward in level-ground; ascended a ramp; walked forward in for 2 m and stopped; turned around and descended the ramp back to the starting position. The outdoor ramp was 10 m with a 10° inclination.

Furthermore, we asked the participants to conduct trials with turns (

Figure 3d) to assess the increment of the InertialLAB’s drift error in this performed daily-activity. Each participant performed 9 trials as follows: walked forward for 5 m, changed the walking direction with a 180° turn, and walked forward to back to the starting position.

Additionally, we studied the InertialLAB’s usability collecting the end-users’ perception and satisfaction upon the InertialLAB’s use in daily locomotion conditions. At the end of the experiment, each participant was asked to fulfill the System Usability Scale (SUS) questionnaire available as a paper-and-pencil tool. No time constraints were established, such that the subjects had enough time to complete the questionnaire. The participants were queried regarding the InertialLAB’s usability through a 10-item questionnaire proposed in [

19] that uses the 5-point Likert scale. The SUS is a well-known usability questionnaire since it is a reliable, stand-alone evaluation valid to be applied to any product [

34]. Consequently, it was involved in InertialLAB’s usability assessment. All questionnaires were collected for posterior analysis.

3.3. Data Analysis

We used the Matlab

® (2017b, The Mathworks, Natick, MA, USA) for the benchmarking analysis of 3D angular velocity, 3D acceleration, and joint angles as follows, without considering the acceleration and deacceleration zone. First, we computed the NRMSE and metrics for assessing the waveform similarity, such as the correlation coefficient (

) and cross-approximate entropy (XApEn [

35]). These analyses were conducted separately for every sensor unit and trial varying gait speed and terrain to evaluate the operability of IntertialLAB considering the sensor’s location, gait speed, and the terrain.

Second, we assessed the drift error in the joint angle estimations to investigate the effectiveness of the proposed trigonometry-based method upon to inertial data-based fusion methods comparatively to the biomechanical model-based approach of the MVN BIOMECH. As such, we computed the ratio among the InertialLAB’ drift error and the MVN BIOMECH’s drift error. For both sensor systems, we computed the drift error as the slope of the linear trend of the joint angle signals (by assuming that the drift error follows a linear trend throughout the gait trial [

5]). For trials including turns, we determined the percentage of the increment of drift with the 180° turn by comparing the drift error before and after the turning. Third, we conducted a statistical analysis to investigate the hypothesis that NRMSE comes from a distribution with mean zero using the one-sample

t-test with a significance level of 5%.

Lastly, we performed InertialLAB’s usability assessment. The mean SUS score and InertialLAB’s usability grade were determined considering the eleven answered questionnaires. The SUS score was computed according to the questionnaire guidelines [

19], as follows: (i) for odd items (1, 3, 5, 7, and 9), we subtracted one from the user response to get the score contributions; (ii) for even-numbered items (2, 4, 6, 8, and 10), the contribution is 5 minus the user response; (iii) we added up the score contributions for each user and multiply by 2.5 to obtain the SUS score (range from 0 to 100); (iv) SUS scores obtained from eleven questionnaires were averaged to determine the overall value of SUS score for InertialLAB. Additionally, we analyzed the distribution of the users’ reports to each item of the questionnaire through a histogram in an attempt to verify the need for additional usability improvement.

5. Discussion

5.1. System Design and Usability and Reliability Analysis

This study introduced a cost-effective, low-power consumption, and easily calibrated wearable inertial sensor system. It was designed for monitoring 3D angular velocity and 3D acceleration up to 6 lower limb segments and trunk and joint angle in the sagittal plane up to 6 joints. The main contributions of InertialLAB design are as follows. First, the use of an automatic, user-independent, on-body calibration routine in the first 10 s of the data monitoring avoids higher time-consuming calibration methods with several manual maneuvers per IMU, as proposed in [

5,

6]. Moreover, the approached calibration routine is generic to any user and demands minimum-to-null physical and cognitive effort for the user and assessor, which favors its daily application.

Second, the InertialLAB design centered on a multiplatform insight, considering both stand-alone and system-cooperative functioning. The software followed a modular and open-architecture to be easy, time-effectively, and directly integrated into third-party systems, advancing the commercial IMU-based systems, for monitoring kinematic data up to 200 Hz with minimal latency. Additionally, the hardware design of the power supply and storage unit of InertialLAB also showed a modular character by enabling their easy replacement as needed. Third, the power supply unit of InertialLAB showed to be advantageous than the one used in MVN BIOMECH regarding the durability and usability (power unit of 20 × 20 × 100 mm vs. two power units of 60 × 50 × 150 mm). Furthermore, it includes software interfaces operating up to 200 Hz with a low computational load to enable its execution into a wearable CPU (80 × 100 × 25 mm) when compared to MVN BIOMECH (higher-dimensionality CPU such as a personal computer) and the one (200 × 137 × 55 mm) used in [

6]. This allows a more practical application of InertialLAB for the ambulatory gait analysis. The findings also indicate that the selected wearable CCU is able to timely execute the software routines of InertialLAB (the mean computation time of 2.4 ± 0.47 ms is lower than the timing requirements of 5 ms) that were implemented for real-time data acquisition and processing towards kinematic gait data analysis. There is still room to include further computational methods into InertialLAB.

Additionally, this work goes forward to related studies, which addressed the inertial system validations [

4,

5,

6,

11,

13], by performing a usability assessment. The users report that InertialLAB presents good usability after their experience when interacting with this sensor system in daily conditions. Its good usability is an important quality attribute for suggesting the use of InertialLAB in daily kinematic gait analysis.

Standard methods to ensure the system reliability and reduced the probability to failure were followed: (i) use charged power-bank at the beginning of each experimental procedure; (ii) employment of robust USB cables to reduce the probability to failure; (iii) development of overall hardware into a custom-designed printed circuit board; (iv) use of robust straps to ensure proper and lasted IMUs attachment to the human body, avoiding displacements; (v) reduce system vibration by fixing all hardware modules in custom-designed 3D printed boxes through M2 screws; (vi) release USB flash drive memory at the end of each experimental procedure for a remote database. Additionally, we ensure consistency in the calibration procedure since the user should remain in stand-up steady-state while the green LED is on (corresponds to 10-s calibration routine), and the subject can only start walking as the calibration is completed, i.e., when the blue LED is turned on. Software issues were solved during the systematic technical validation testes that were performed prior to data collection with end-users. However, the InertialLAB reliability may be compromised by occasional failures, such as USB cable disconnection stop IMU data collection, data storage error due to USB flash driver disconnection from CPU, and data storage overflow. Additionally, the quality of data acquisition depends on an IMU body placement, which should be laterally placed over bone zones.

5.2. Kinematic Gait Analysis

The implications of the sensor technology and kinematic gait analysis of InertialLAB are discussed below by considering the benchmarking analysis against the MVN BIOMECH. Variations in gait speed may affect the performance of the gyroscope and accelerometer embedded in the InertialLAB by increasing the magnitude-based errors. This may be explained by the increment of the IMUs’ attachment instability as speed increases. There is evidence the waveform similarity of angular velocity signals improves as the gait speed increases. The fluctuations in the gyroscope performance may result from its dependency on the temperature [

9] since the experiments occurred indoor and outdoor at different times. The MPU-6050 was selected due to its low latency performance and its widespread use for developing low-power and low-cost motion tracking devices [

19]. However, the MPU-6050 is susceptible to temperature changes and requires careful calibration in order to make it useable. Despite caution during calibration, the findings may suggest the need for technological improvements in MPU-6050 when compared to IMU of MVN BIOMECH.

Furthermore, the performance of the IMUs embedded in the InertialLAB was better in climbing stairs than in flat terrain and ramp. Two reasons may explain this. First, it may result from a shorter walked distance in the staircase comparing to other terrains. Second, climbing stairs may deal with a slight impact interaction with the ground, resulting in lower secondary motions of the IMUs than in other terrains. To the best knowledge of the authors, there is no study in the state-of-the-art exploring the reliability of the gyroscope and accelerometer in a wearable inertial sensor system for gait analysis in terrains commonly encountered in daily routine. The sensors’ comparative analysis in these conditions is itself a contribution to the state-of-the-art.

The proposed joint angle estimation method is fairly simple. It is important to stress that a central requirement in our system was to achieve a low computational load (95% of the samples were computed within 3.1 ms) in wearable CPU towards ambulatory human motion analysis and for interfacing with wearable assistive devices. Comparing to concurrent wearable systems, InertialLAB does not involve manual measurements [

11] nor kinematic constraints assuming the symmetry of the limbs [

8]. The fusion method, followed by a trigonometry-based approach, estimated the joint angles with a high waveform similarity (as shown in

Table 3) and time-series regularity (as illustrated in

Figure 4 and

Figure 5) when compared with MVN BIOMECH. The waveform similarity was more evident for climbing stairs, which is in line with previous reports. The studies [

31,

32] reported an excellent waveform similarity (>0.9) for the three joints measured by MVN BIOMECH system for walking [

31,

32], jumping activity [

31] and climbing stairs [

32]. Tadano et al. [

11] have shown high correlations (

> 0.78) for three joints in a 5-m flat surface. The InertialLAB presented a comparable performance in a 10 m-flat surface (mean

= 0.905 for three joints). According to [

11] and [

31], the high correlation in joint angle time-series (

> 0.898 for the three terrains) can be interpreted as high reliability and excellent validity of the InertialLAB, respectively.

Nonetheless, there is significant evidence (

p < 0.05) for the discrepancy on the joint angles in the form of offset, such as the drift error, as reported in

Figure 4 and

Figure 5. The offset-based errors in the InertialLAB’s joint angle estimations tend to increase with the gait speed and were more expressive for descending ramp likely due to the occurrence of higher oscillatory artifacts in the suspended ramp or higher environment influences in this outdoor scenario. Previous works also reported offset-based errors for the lower limb joint angles estimation when using the quaternion algorithm upon the Kalman filter [

5,

6,

11]. Liu et al. [

5] reported a maximum RMSE of 16.6° along with trials with 3 strides; Beravs et al. [

6] reported a mean error lower than 5° when one subject walked 30 steps; and, Tadano et al. [

11] found a mean RMSE ranging from 7.88° to 10.14° from a gait analysis on 5 subjects along 5 m. These works limited the validation of IMUs-based kinematic analysis to short distance gait trials with few participants. It may limit the analysis of the repeatability of the literature fusion methods, mainly when their performance tends to decrease over time. On the other hand, it could be argued that the errors reported in the InertialLAB’s validation reflect a number of heterogenous gait patterns from non-structured scenarios, approaching the repeatability performance of the system with different issues faced in daily walking.

Our results report that the drift error was more pronounced in the ankle joint, as reported in [

6,

11,

31]. Particularly, the findings of

Figure 6 report that the kinematic analysis of the IMU placed on the foot is the least similar to the equivalent sensor of the MVN BIOMECH. Often the most distal segments move the most during gait; therefore, they are more susceptible to fluctuations and signal distortions. It was also observed a low-effectiveness in magnitude and waveform regularity of the IMU located on foot likely due to the secondary motions introduced at heel-strike and toe-off timings [

11]. Additionally, the fairly computational proposed approach for joint angle estimation is twice as sensible to the turns than MVN BIOMECH, which also showed to be sensitive [

30].

With this study, particularly by analyzing the results of

Figure 7, we verified that the NN regression models successfully attenuated the bias (decreased from 4.54° to approximately 0°) and increased the agreement between the joint angle series of InertialLAB and MVN BIOMECH. These findings suggest that the NN regression models can successfully be applied to minimize the bias in joint angle signals and to yield signals with an excellent validity (R

2 = 0.92 for hip, R

2 = 0.94 for knee, and R

2 = 0.87 for ankle) [

31]. Ankle-based regression models provided less accurate angular predictions, which is in line with the literature reports high incoherencies in ankle joints [

6,

11,

31]. There is evidence that the ankle is the lower limb joint less effectively modeled. Furthermore, the outcomes demonstrated that NN ability to improve joint angle estimation benefits from the inclusion of the joint angular velocity as an additional input to the joint angle estimated by fusion methods. The joint angular velocity likely contributed to NN robustness to predict joint angles under walking speed variations. When compared to MVN BIOMECH, there is still room to improve NN regressor capabilities on bias reduction at the limits of the joint’s range of motions in multi-terrain walking.

The proposed speed-independent regression model yielded similar results to the ones reported in [

36] when using a phase-locked regression model that exploits the cyclical nature of human gait. However, this literature approach depends on the effectiveness of gait cycle segmentation issued by an extra computational tool [

36]. On the other hand, NN regression models are a generic approach tuned to be user-independent and generalized to speed variations aiming for a versatile application of InertialLAB in biomechanical analysis. This study innovatively demonstrates the promising use of machine learning regression models for improving the accuracy of wearable inertial sensor systems for daily kinematic gait tracking.

The hardware modular design and the software open architecture of InertialLAB enable its direct integration, with low computational load, into third-party wearable devices or computational models for timely providing real-time kinematic gait data to these systems as needed. This key feature was attained, aiming the need for a personalized clinical insight considering the user’s actual kinematic condition. The relevance of this direct integration has also been reported in literature works for a prosthesis [

9] and an exoskeleton [

6]. However, the validity of these sensor systems for daily kinematic gait analysis was not inspected. In light of its low computational complexity, good validity, and usability, InertialLAB shows the reliability for providing real-time kinematic data to third-party systems into daily assistive conditions.

5.3. Limitations and Future Directions

The application of the InertialLAB for kinematic gait analysis may face limitations, as follows. First, the differences in the real joint kinematics and the assumptions considered in the calibration may introduce a fixed bias. Second, the effectiveness of the proposed calibration is affected by incorrect postures during the stand-up steady-state. Third, the existence of sensor misalignments regarding the human joint axis, mainly in long-term recording sessions. Fourth, the wired sensors’ connection may extend the installation of the sensors on the users’ body and may not be the most practical solution for daily human gait analysis. However, likely due to the cables’ flexibility, the participants did not report constraints while using the InertialLAB at different daily locomotion modes in indoor and outdoor environments. Contrariwise, they assessed the InertialLAB with good usability.

Furthermore, the tackled benchmarking analysis may be limited by the absence of magnetometers in the InertialLAB and likely by the increased misalignments of InertialLAB’s IMUs comparing to MVN BIOMECH’s IMUs as speed increases given the positioning of InertialLAB over MVN BIOMECH. The comparison should also consider the specific development of InertialLAB for gait analysis, whereas the MVN BIOMECH approaches a full 3D motion tracking, involving more complex components than the ones in InertialLAB. This study used the validated MVN BIOMECH as a ground truth wearable IMU-based sensor system for kinematic gait analysis, without re-evaluating its validity. However, there may be minor inaccuracy in the performed benchmarking analysis due to the distance of the IMUs of MVN BIOMECH to the base station and the environment influence on calibration. Moreover, MVN BIOMECH is sensitive to the effect of the magnetic field environment. The concurrent validity of the MVN BIOMECH with camera-based motion systems reported some magnitude-based errors [

31,

32]. However, these results should not be considered a failure on the part of the MVN BIOMECH solely. Other commercial IMU-based sensor systems, such as RIABLO (CoReHab, Trento, Italy), G-walk (BTS Bioengineering Corp., Quincy, MA, USA), Shimmer Sensing (Dublin, Ireland), and APDM Wearable Technologies (Portland, OR, USA), could be used to further validate the effectiveness of the proposed system.

Additionally, this study investigates the hypothesis that a machine learning-based regression model may accurately improve the joint angle estimation of InertialLAB with minimal drift bias by comparing different regression models (NN, decision tree, and SVM). The regression model comparison was limited to the prediction accuracy without considering the computational efficiency.

More research is needed to improve aesthetic and functional issues in InertialLAB to integrate a wireless solution upgrading the usability. Future work includes the sensor’s misalignments mitigation and misalignment compensation between IMUs and the human joint axis. The monitoring of 3D joint angles may enable InertialLAB’s use in further applications.