Laser Micromachining of Lithium Niobate-Based Resonant Sensors towards Medical Devices Applications

Abstract

:1. Introduction

2. Methodology and Experimental Setup

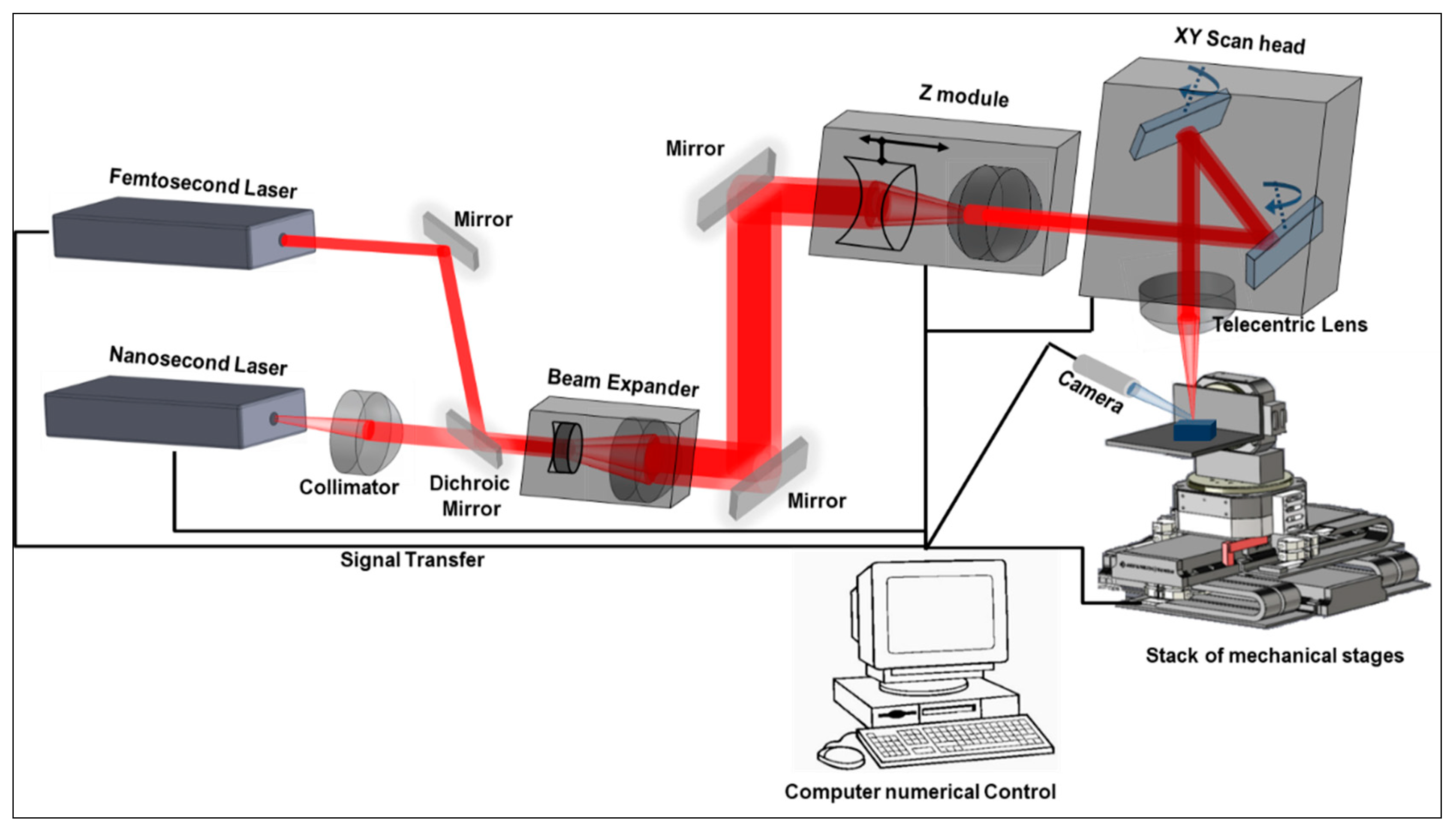

2.1. Laser Platform Setup

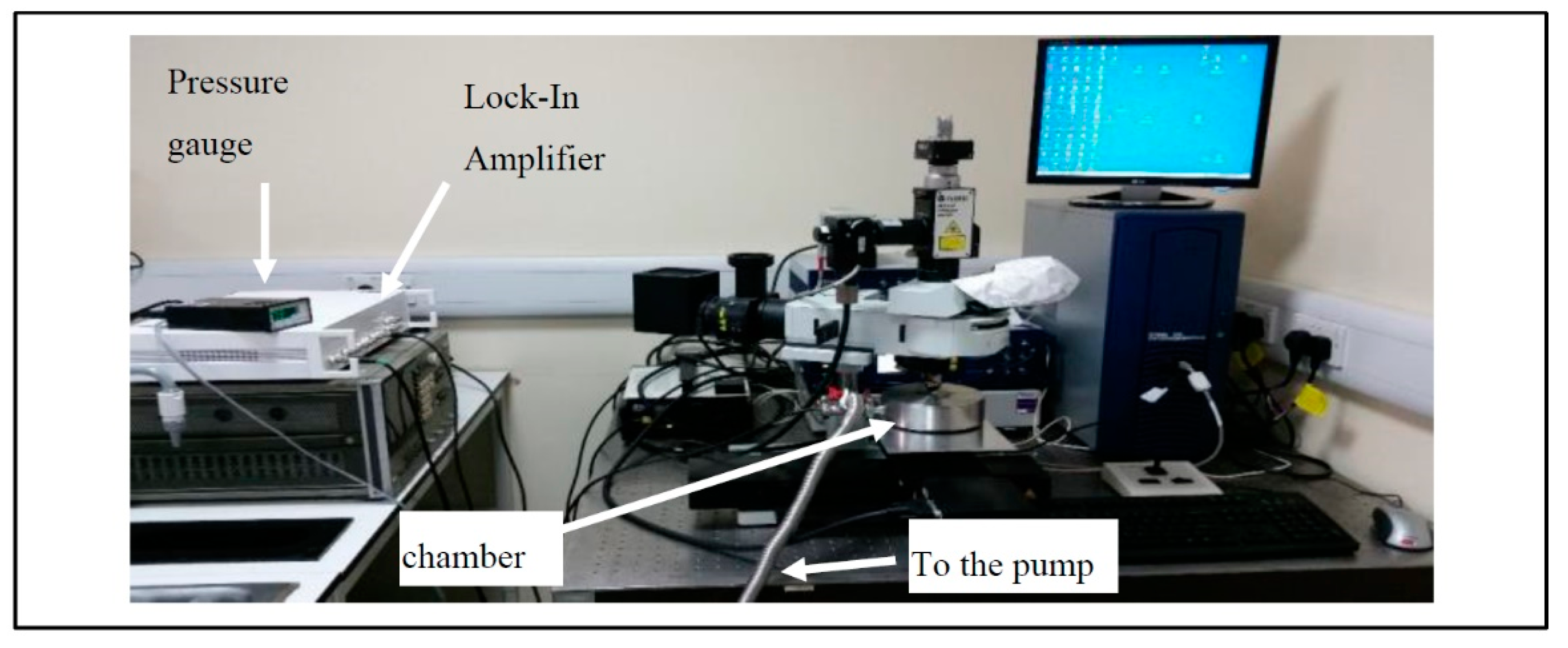

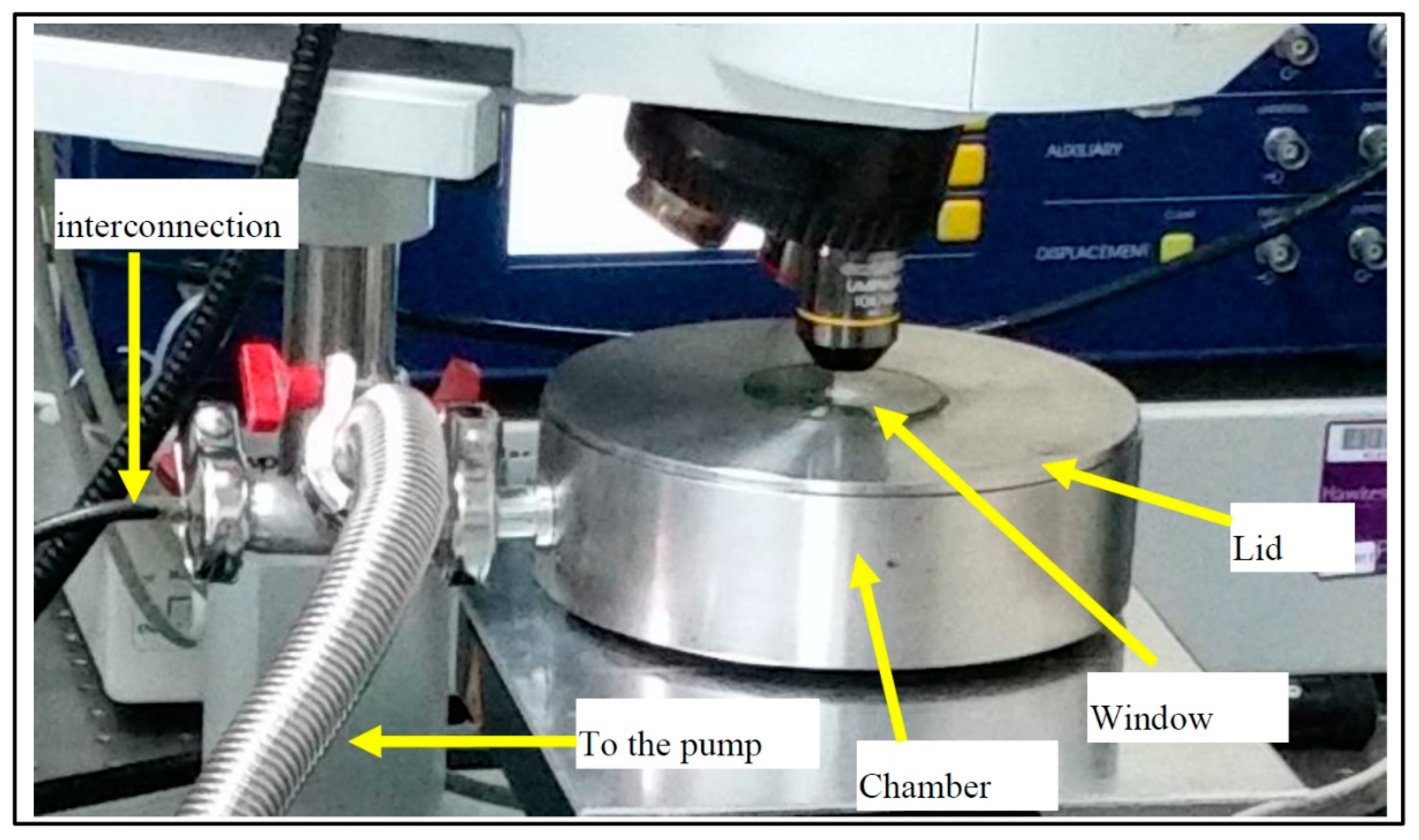

2.2. Vibrometer and Chamber Setup

2.3. Microscope

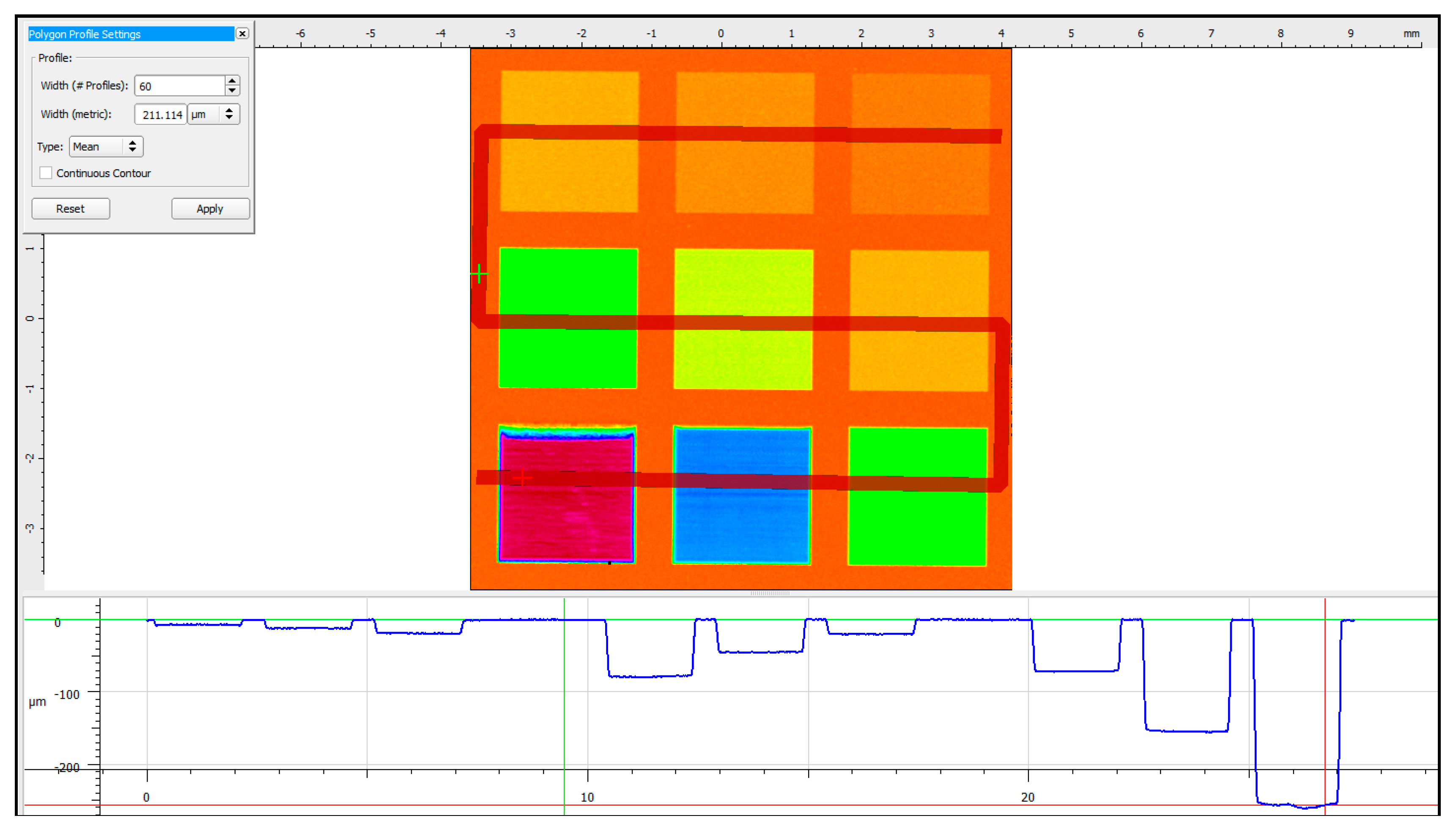

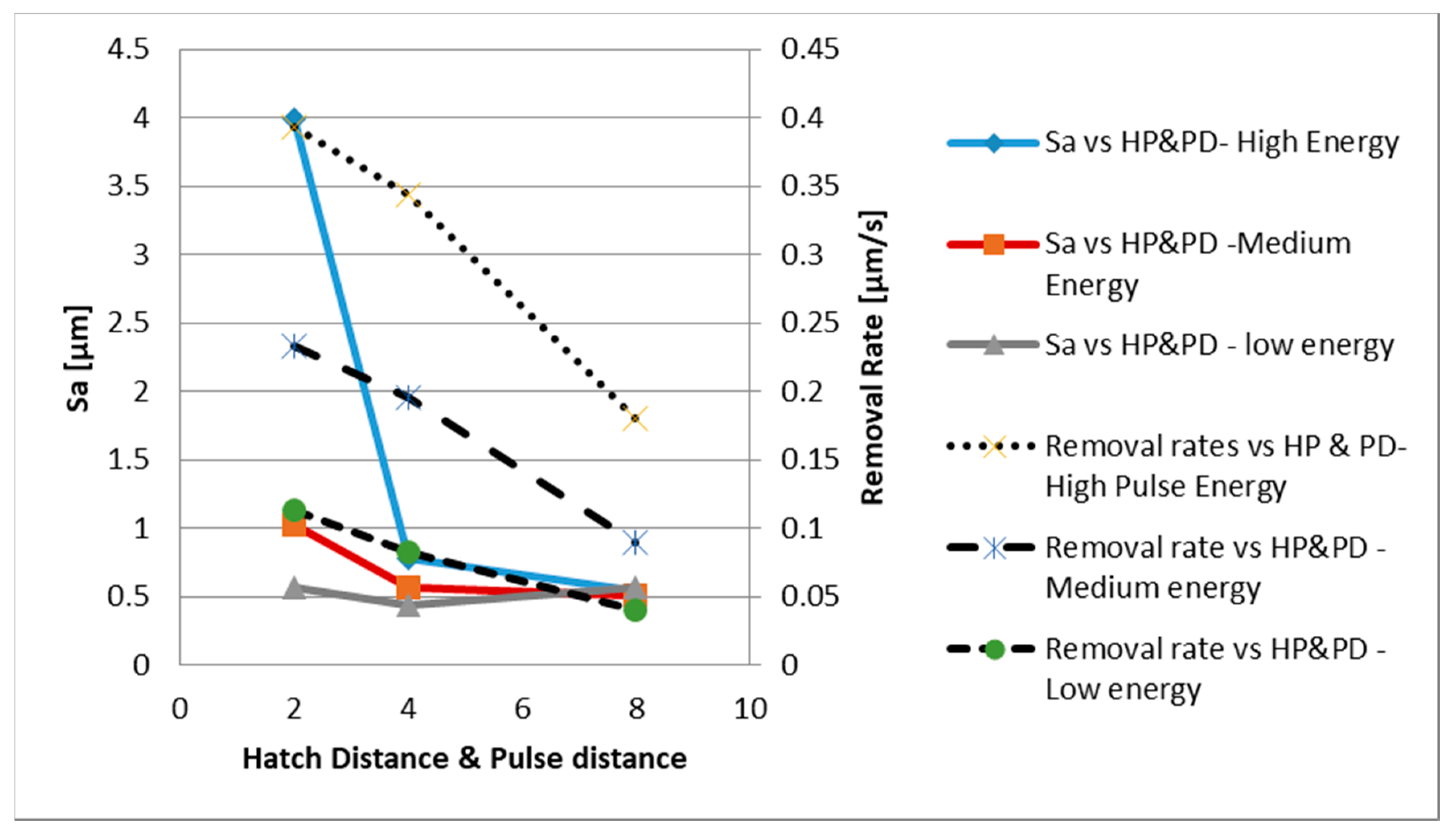

3. Optimisation of Laser Parameters

- -

- The highest removal rates (0.39 µm/s) were obtained with the smallest hatch pitch and pulse distance (2 µm) and the highest pulse energy (7.8 µJ).

- -

- The effect of the hatch pitch and pulse distance on the resulting Sa was very much dependent on the used laser energy; in particular, the hatch pitch and pulse distance had a high impact on Sa at the highest pulse energy, while they had a negligible effect at the lowest energy setting.

- -

- The lowest Sa (Sa = 0.431 µm) was obtained with a hatch pitch and pulse distance of 4 µm and the lowest pulse energy (3 µJ).

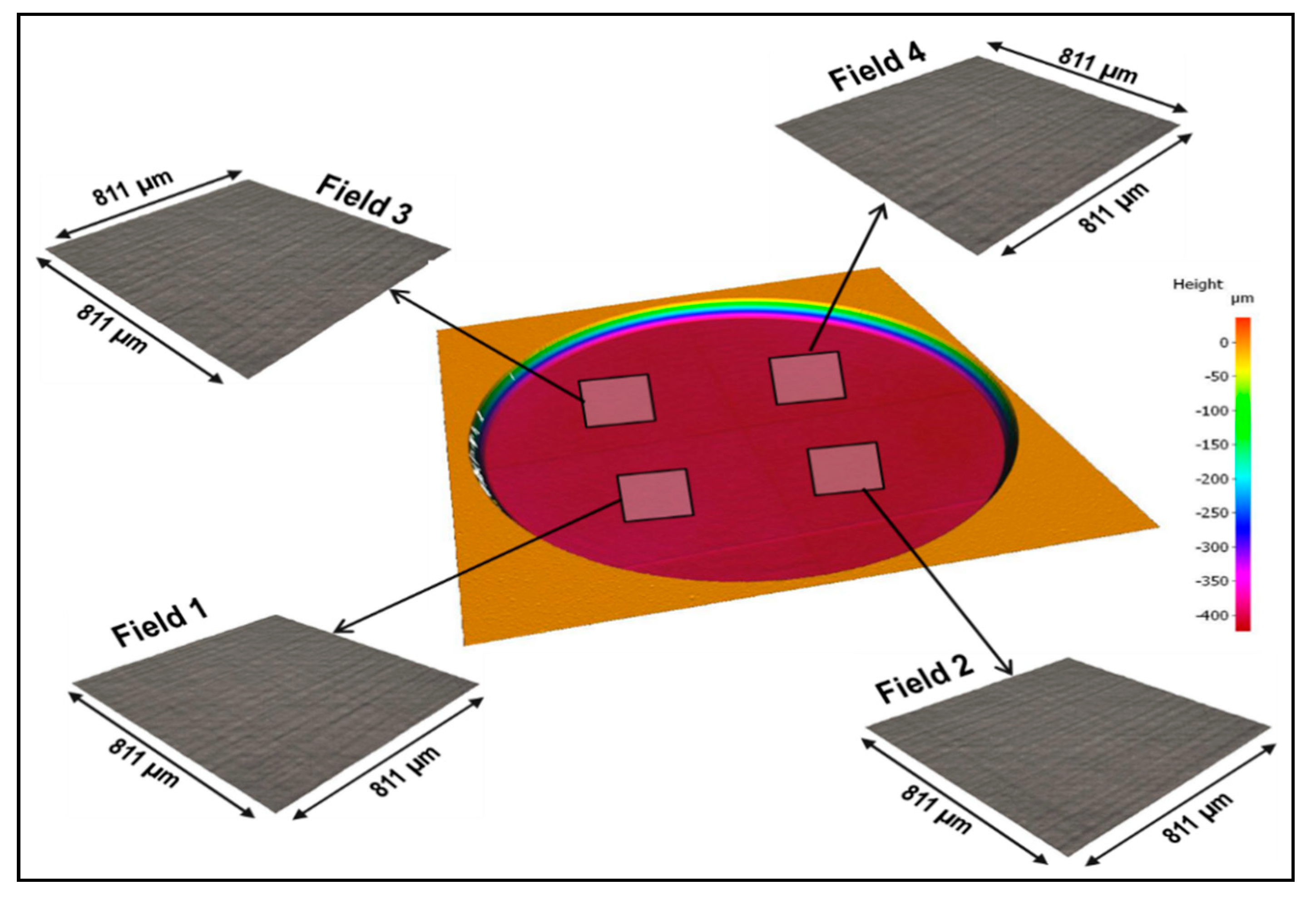

4. Micromachining Results

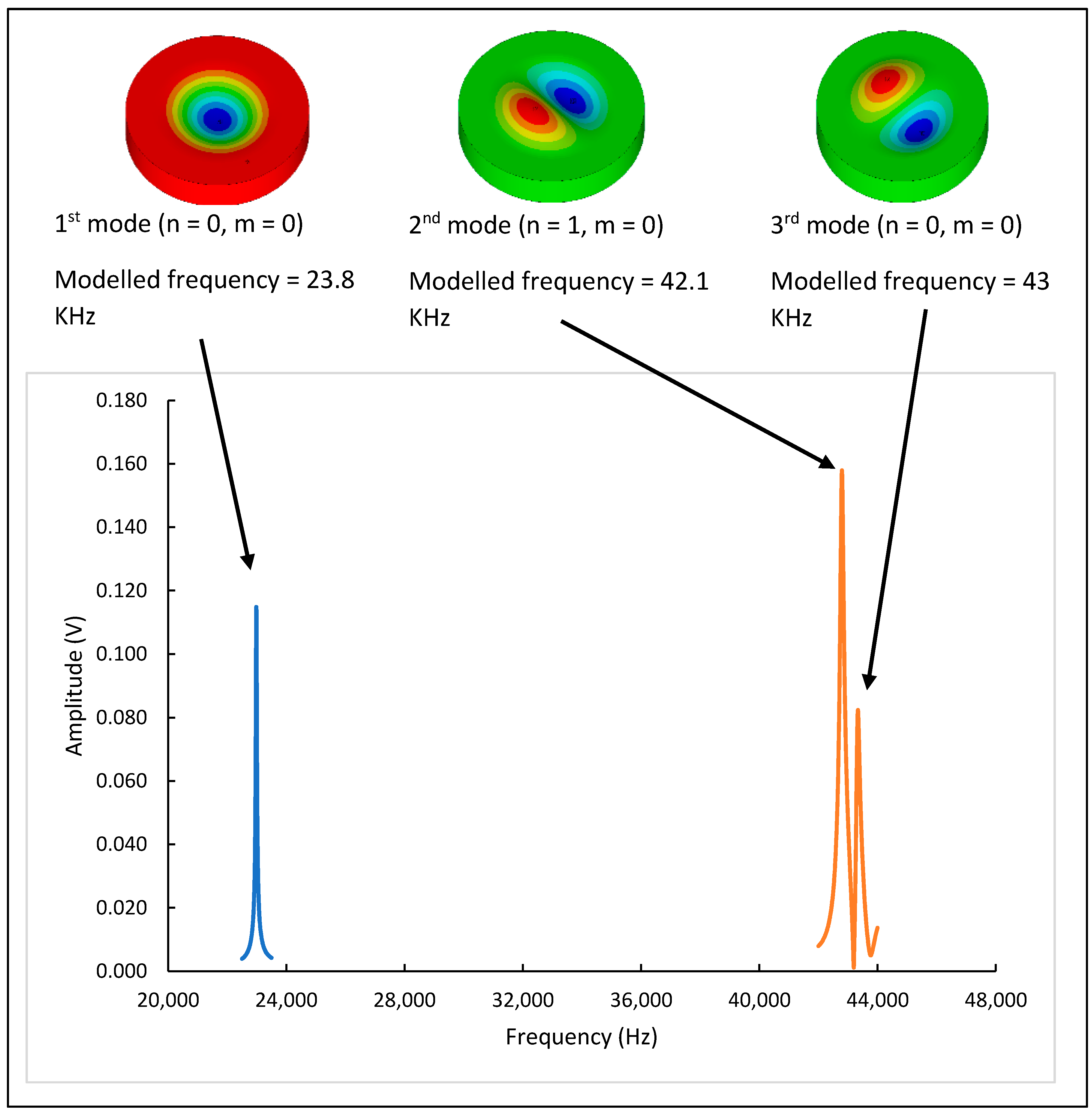

5. Sensor Performance

5.1. Finite Element Analysis (FEA) of the Sensor by ANSYS

5.2. Vibrometer Measurement

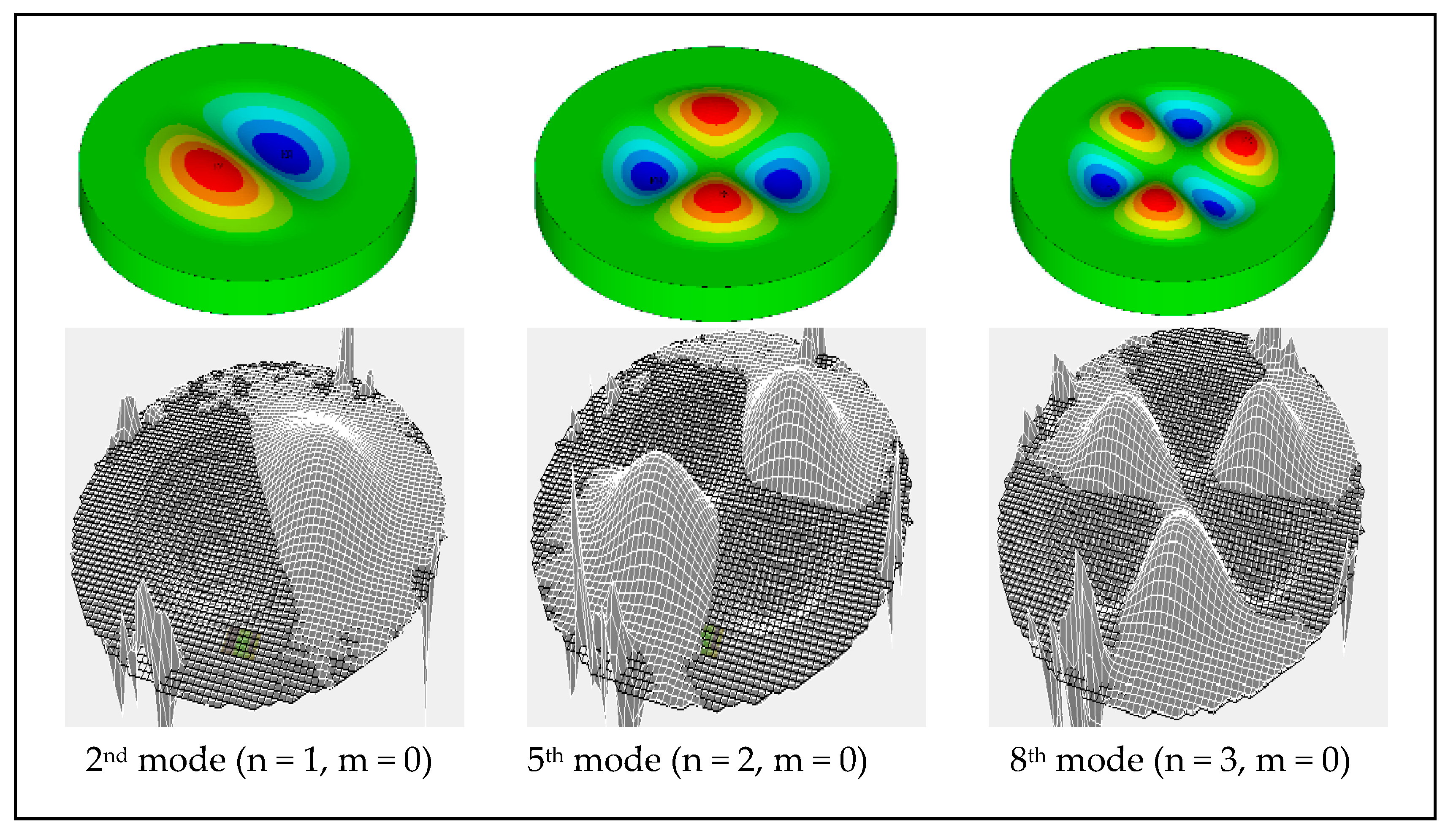

5.3. Mode Mapping

5.4. Experimental Verification

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gattass, R.R.; Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photonics 2008, 2, 219. [Google Scholar] [CrossRef]

- Wong, K.-K. Properties of Lithium Niobate; The Institute of Electrical Engineers: London, UK, 2002. [Google Scholar]

- Presti, D.A.; Guarepi, V.; Videla, F.; Fasciszewski, A.; Torchia, G.A. Intensity modulator fabricated in LiNbO3 by femtosecond laser writing. Opt. Lasers Eng. 2018, 111, 222–226. [Google Scholar] [CrossRef]

- Al-Shibaany, Z.Y.A.; Hedley, J.; Huo, D.; Hu, Z. Micromachining lithium niobate for rapid prototyping of resonant biosensors. IOP Conf. Ser. Mater. Sci. Eng. 2014, 65, 012030. [Google Scholar] [CrossRef] [Green Version]

- Al-Shibaany, Z.Y.A.; Choong, Z.J.; Huo, D.; Hedley, J.; Hu, Z. CNC machining of lithium niobate for rapid prototyping of sensors. In Proceedings of the 2015 IEEE Sensors, Busan, South Korea, 1–4 November 2015. [Google Scholar]

- Zhang, D.; Crean, G.M.; Flaherty, T.; Shallow, A. Development of interdigitated acoustic wave transducers for biosensor applications. Analyst 1993, 118, 429–432. [Google Scholar] [CrossRef]

- Naznin, S.; Sher, M.S.M. Design of a lithium niobate-on-insulator-based optical microring resonator for biosensing applications. Opt. Eng. 2016, 55, 087108. [Google Scholar] [CrossRef]

- Jiang, L.J.; Maruo, S.; Osellame, R.; Xiong, W.; Campbell, J.H.; Lu, Y.F. Femtosecond laser direct writing in transparent materials based on nonlinear absorption. MRS Bull. 2016, 41, 975–983. [Google Scholar] [CrossRef]

- Zhang, Y.-L.; Chen, Q.D.; Xia, H.; Sun, H.B. Designable 3D nanofabrication by femtosecond laser direct writing. Nano Today 2010, 5, 435–448. [Google Scholar] [CrossRef]

- Hohmann, J.K.; Renner, M.; Waller, E.H.; von Freymann, G. Three-dimensional μ-printing: An enabling technology. Adv. Opt. Mater. 2015, 3, 1488–1507. [Google Scholar] [CrossRef]

- Maruo, S.; Inoue, H. Optically driven micropump produced by three-dimensional two-photon microfabrication. Appl. Phys. Lett. 2006, 89, 144101. [Google Scholar] [CrossRef]

- Maruo, S.; Takaura, A.; Saito, Y. Optically driven micropump with a twin spiral microrotor. Opt. Express 2009, 17, 18525–18532. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Niu, L.G.; Wu, S.Z.; Xu, J.; Midorikawa, K.; Sugioka, K. Ship-in-a-bottle femtosecond laser integration of optofluidic microlens arrays with center-pass units enabling coupling-free parallel cell counting with a 100% success rate. Lab A Chip 2015, 15, 1515–1523. [Google Scholar] [CrossRef] [PubMed]

- Aerotech, I. Aerotech. PRO165LM Series Stage User’s Manual P/N: EDS142 (Revision 1.06.00), 2010; Aerotech Worldwide: Pittsburgh, PA, USA, 2010. [Google Scholar]

- Penchev, P.; Dimov, S.; Bhaduri, D.; Soo, S.L.; Crickboom, B. Generic software tool for counteracting the dynamics effects of optical beam delivery systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 48–64. [Google Scholar] [CrossRef]

- Polytec Inc. 2019. Available online: https://www.polytec.com/uk/vibrometry/products/$single-point-vibrometers/ (accessed on 12 January 2020).

- Shaat, M. Calibration of mass sensors for surface roughness of their micro-resonators. Sens. Actuators A Phys. 2019, 296, 302–315. [Google Scholar] [CrossRef]

- Ansys Inc. 2019. Available online: http://www.ansys.com/ (accessed on 11 March 2019).

- Wu, X.; Chen, W.; Reza, A. Optimal design of piezoelectric micromachined modal gyroscope (PMMG) with modes matched: Modal analysis. Microsyst. Technol. 2015, 21, 101–108. [Google Scholar] [CrossRef]

- Auld, B.A. Acoustic Fields and Waves in Solids; John Wiley & Sons: New York, NY, USA, 1990. [Google Scholar]

- Damie, R. Elastic constants of lithium niobate. J. Phys. D Appl. Phys. 1992, 25, 1091. [Google Scholar] [CrossRef]

- Weis, R.; Gaylord, T. Lithium niobate: Summary of physical properties and crystal structure. Appl. Phys. A Mater. Sci. Process. 1985, 37, 191–203. [Google Scholar] [CrossRef]

| Laser Parameter | Units | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| Pulse energy | µJ | 7.8 (maximum energy) | 5 (medium energy) | 3 (just above ablation threshold) |

| Pulse distance and hatch distance | µm | 2 | 4 | 8 |

| Laser Parameter | Units | Value |

|---|---|---|

| Power | W | 3.9 |

| Frequency | kHz | 500 |

| Pulse energy | µJ | 7.8 |

| Scanning speed | m/s | 2 |

| Pulse duration | fs | 310 |

| Beam diameter | µm | 30 |

| Laser beam polarisation | - | Circular |

| Hatch style | - | Random |

| Hatch pitch | µm | 4 |

| Layer thickness | µm | 7.5 |

| Machining rate | mm3/s | 0.05 |

| Surface Roughness Parameters | Field 1 | Field 2 | Field 3 | Field 4 |

|---|---|---|---|---|

| Sa [µm] | 0.526 | 0.536 | 0.545 | 0.533 |

| Sq [µm] | 0.656 | 0.672 | 0.681 | 0.670 |

| Sz [µm] | 5.429 | 5.421 | 5.288 | 5.618 |

| S10z [µm] | 5.003 | 5.037 | 4.849 | 5.016 |

| Sp [µm] | 2.886 | 2.985 | 2.627 | 2.98 |

| Sv [µm] | 2.543 | 2.436 | 2.661 | 2.638 |

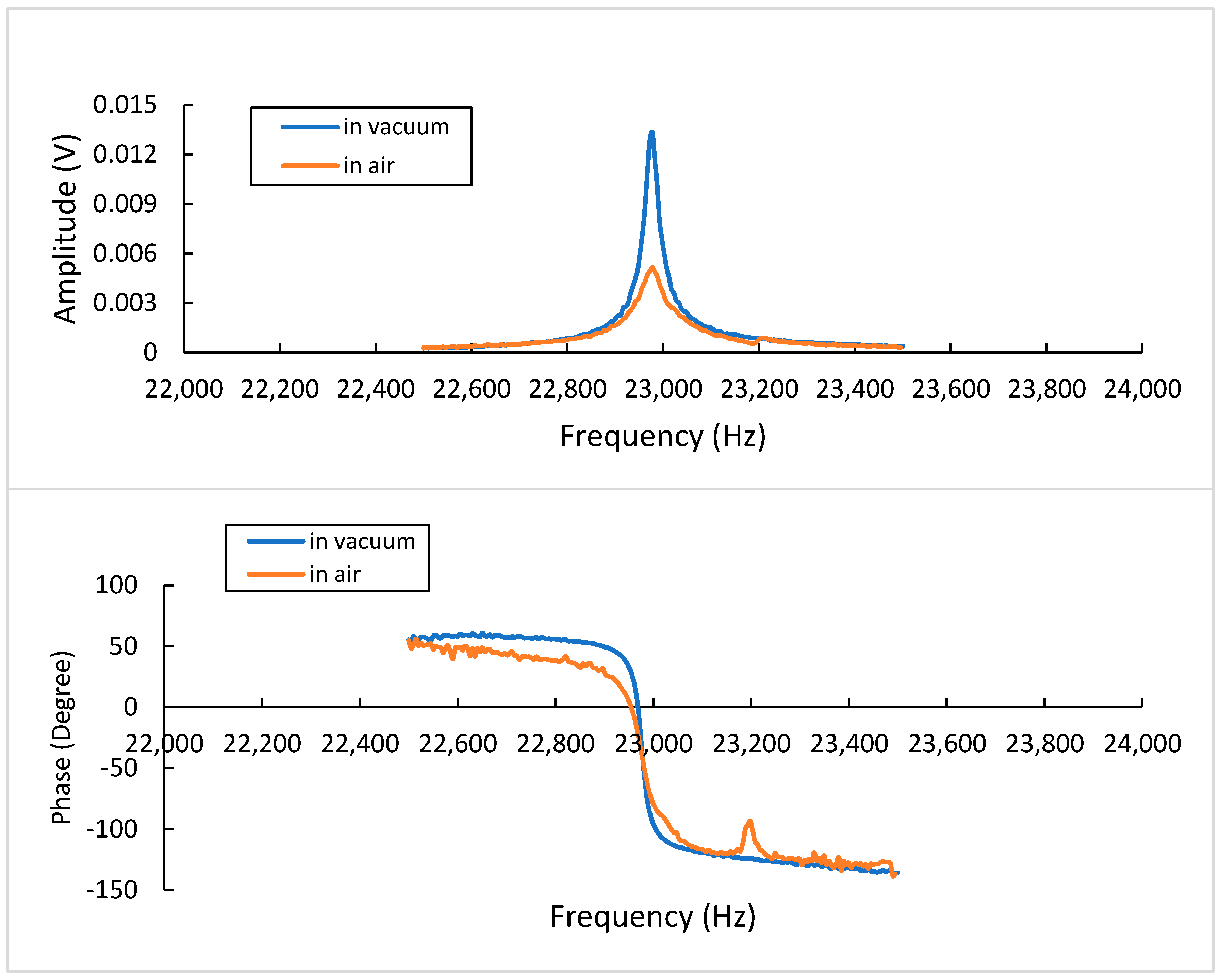

| Mode Number | Modelled Frequency (KHz) | Vibrometer Frequency (KHz) Vacuum | Electrical Measurement (KHz) Vacuum | Q-Factor in Vacuum | Q-Factor in Air |

|---|---|---|---|---|---|

| 1 | 23.8 | 22.98 | 21.40 | 646 | 49 |

| 2 | 42.1 | 42.70 | 42.79 | 366 | 222 |

| 3 | 43.0 | 43.10 | 43.32 | 366 | 222 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Shibaany, Z.Y.A.; Penchev, P.; Hedley, J.; Dimov, S. Laser Micromachining of Lithium Niobate-Based Resonant Sensors towards Medical Devices Applications. Sensors 2020, 20, 2206. https://doi.org/10.3390/s20082206

Al-Shibaany ZYA, Penchev P, Hedley J, Dimov S. Laser Micromachining of Lithium Niobate-Based Resonant Sensors towards Medical Devices Applications. Sensors. 2020; 20(8):2206. https://doi.org/10.3390/s20082206

Chicago/Turabian StyleAl-Shibaany, Zeyad Yousif Abdoon, Pavel Penchev, John Hedley, and Stefan Dimov. 2020. "Laser Micromachining of Lithium Niobate-Based Resonant Sensors towards Medical Devices Applications" Sensors 20, no. 8: 2206. https://doi.org/10.3390/s20082206

APA StyleAl-Shibaany, Z. Y. A., Penchev, P., Hedley, J., & Dimov, S. (2020). Laser Micromachining of Lithium Niobate-Based Resonant Sensors towards Medical Devices Applications. Sensors, 20(8), 2206. https://doi.org/10.3390/s20082206