Acoustic Emission Analysis of Corroded Reinforced Concrete Columns under Compressive Loading

Abstract

:1. Introduction

2. Experimental Procedures

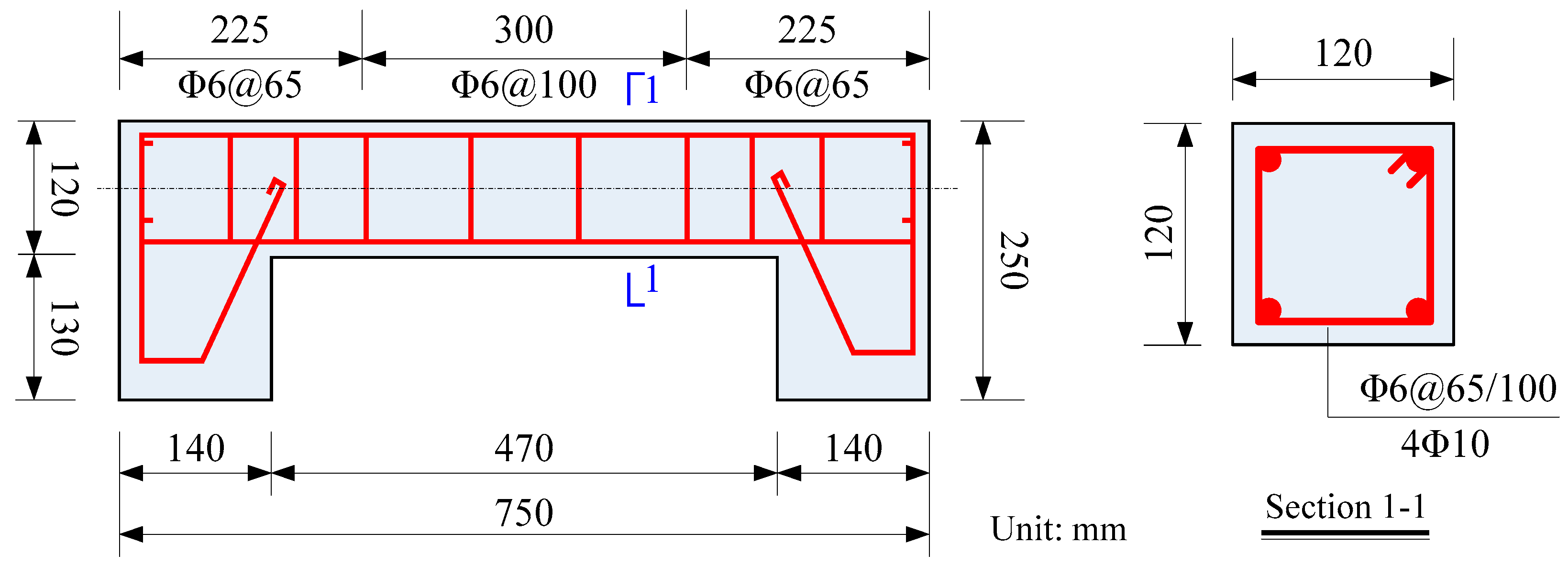

2.1. Material and Specimen Preparation

2.2. Corrosion of Specimens

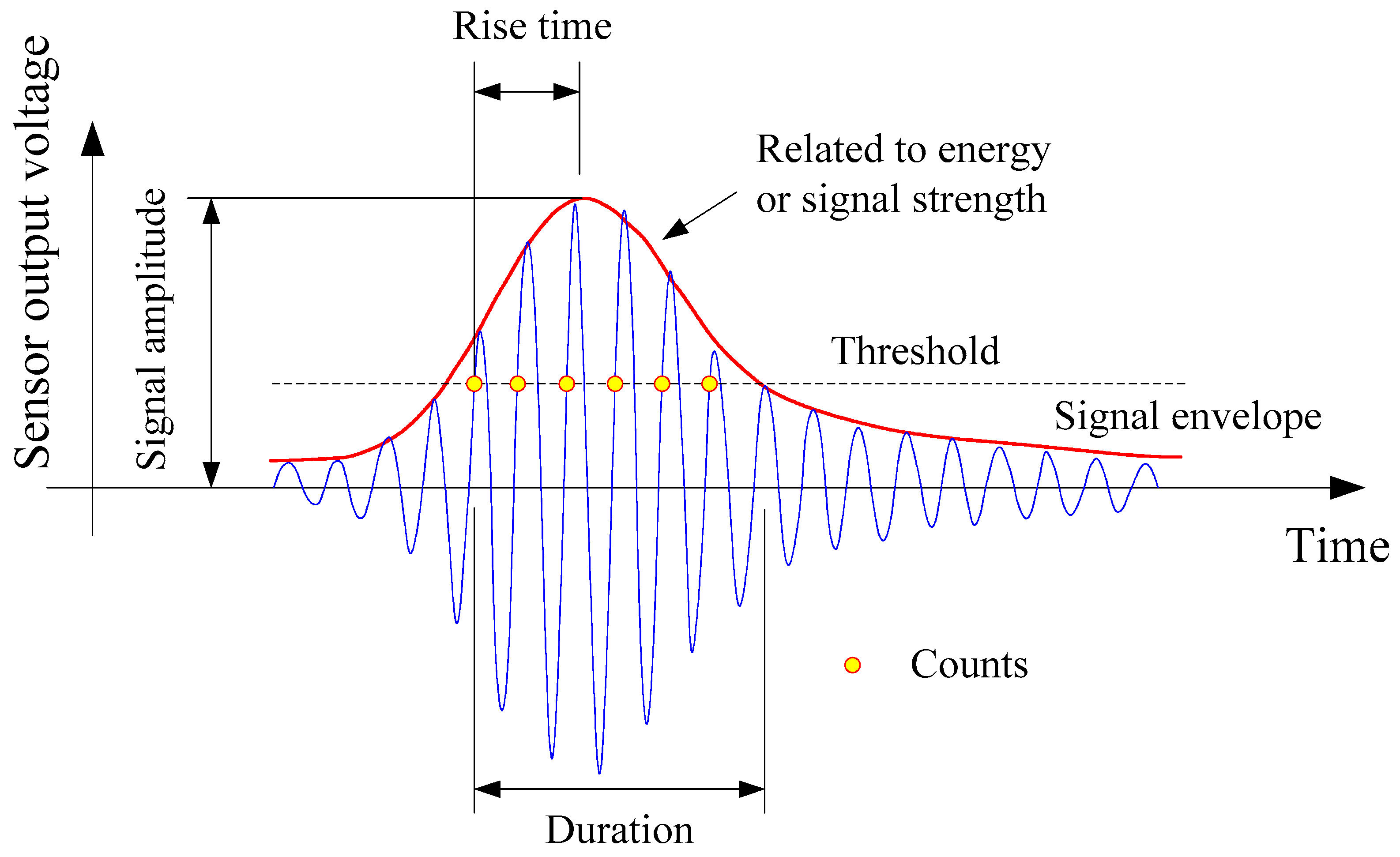

2.3. Monitoring System during Loading

3. Results and Discussion

3.1. Corrosion-Induced Crack Behavior

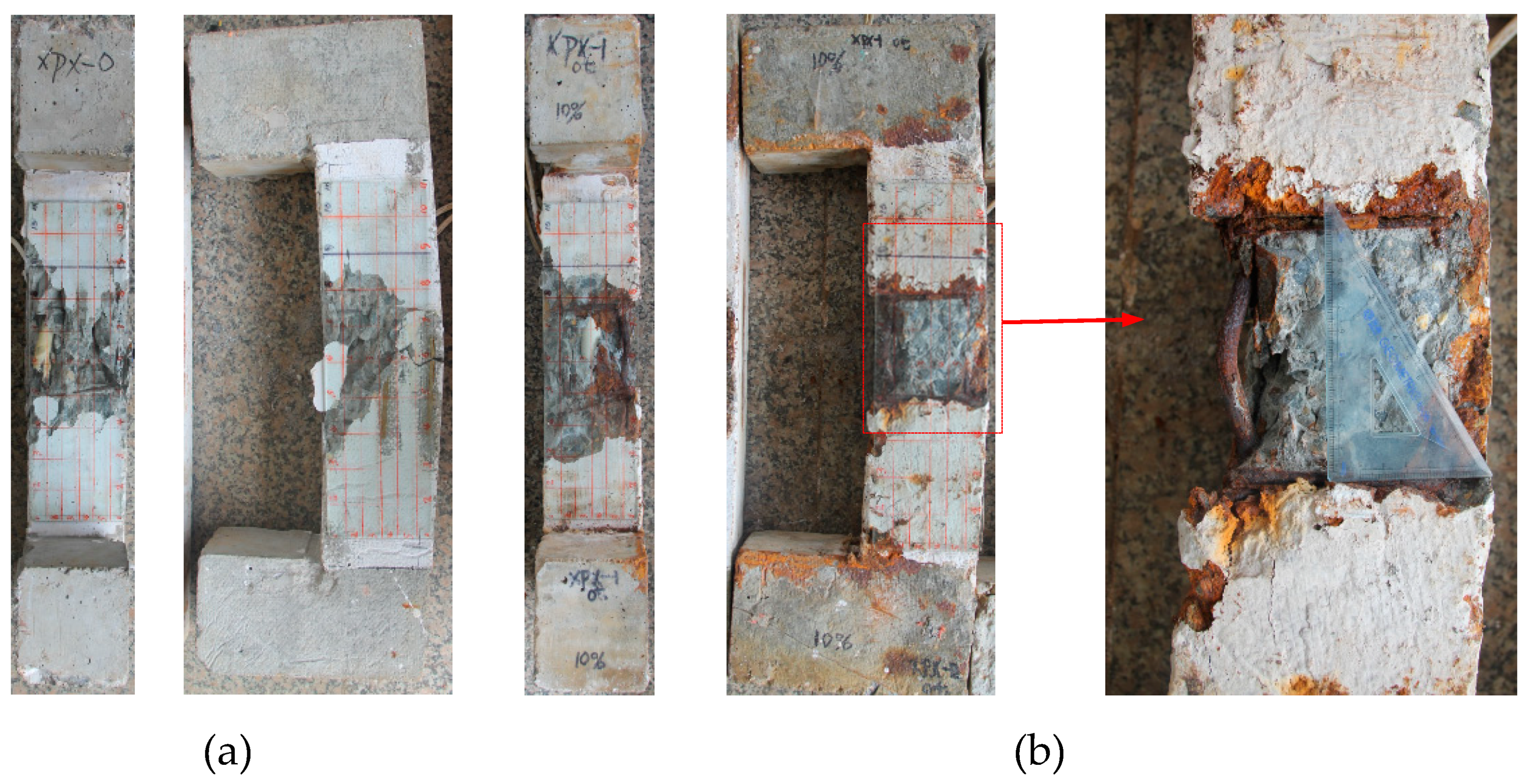

3.2. Corrosion of Reinforcements

3.3. Structural Performance of Specimens

3.3.1. General Behaviors

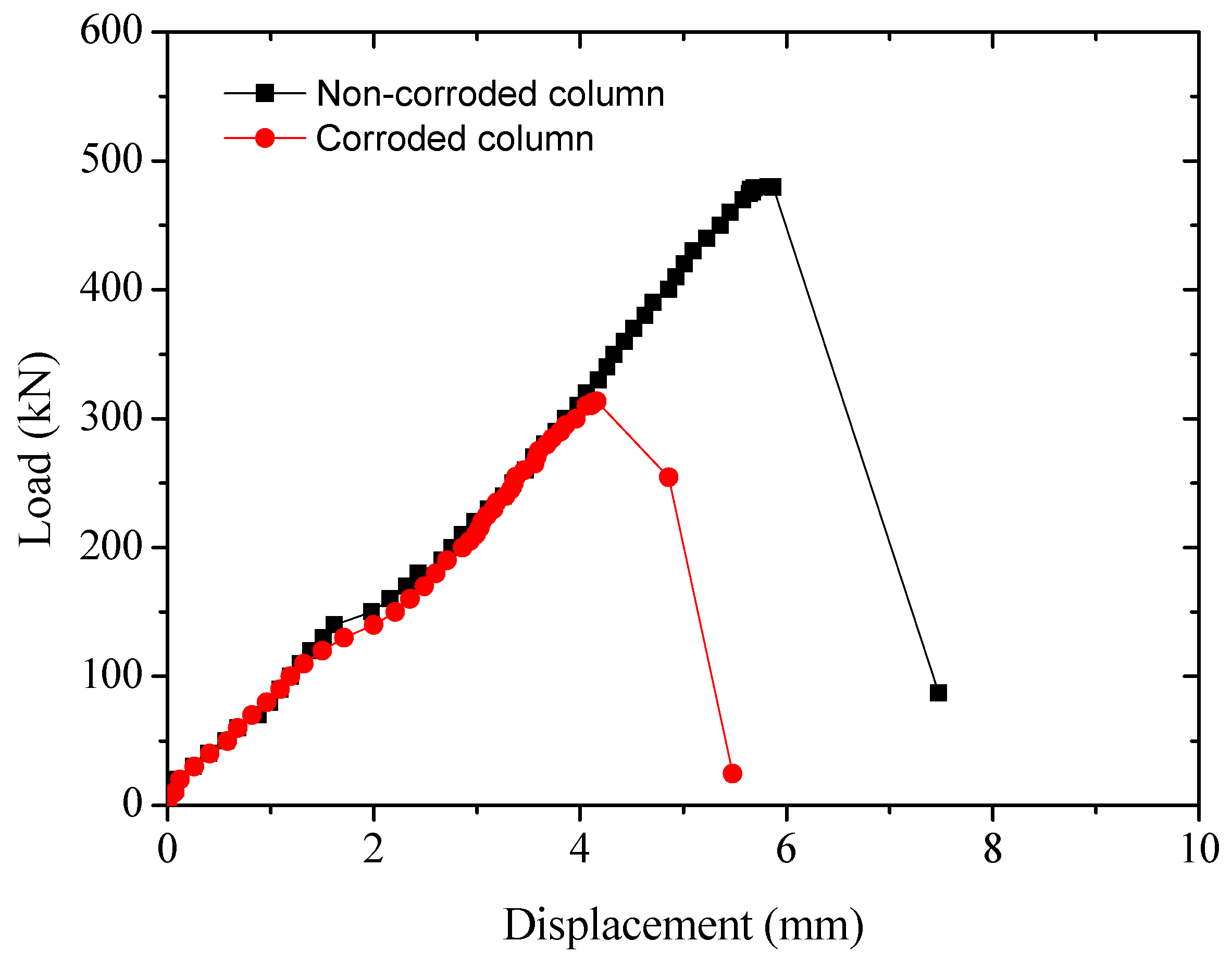

3.3.2. Load-Vertical Displacement Response

3.3.3. Load-Mid-Span Flexural Deflection Response

3.3.4. Load-Strain Response

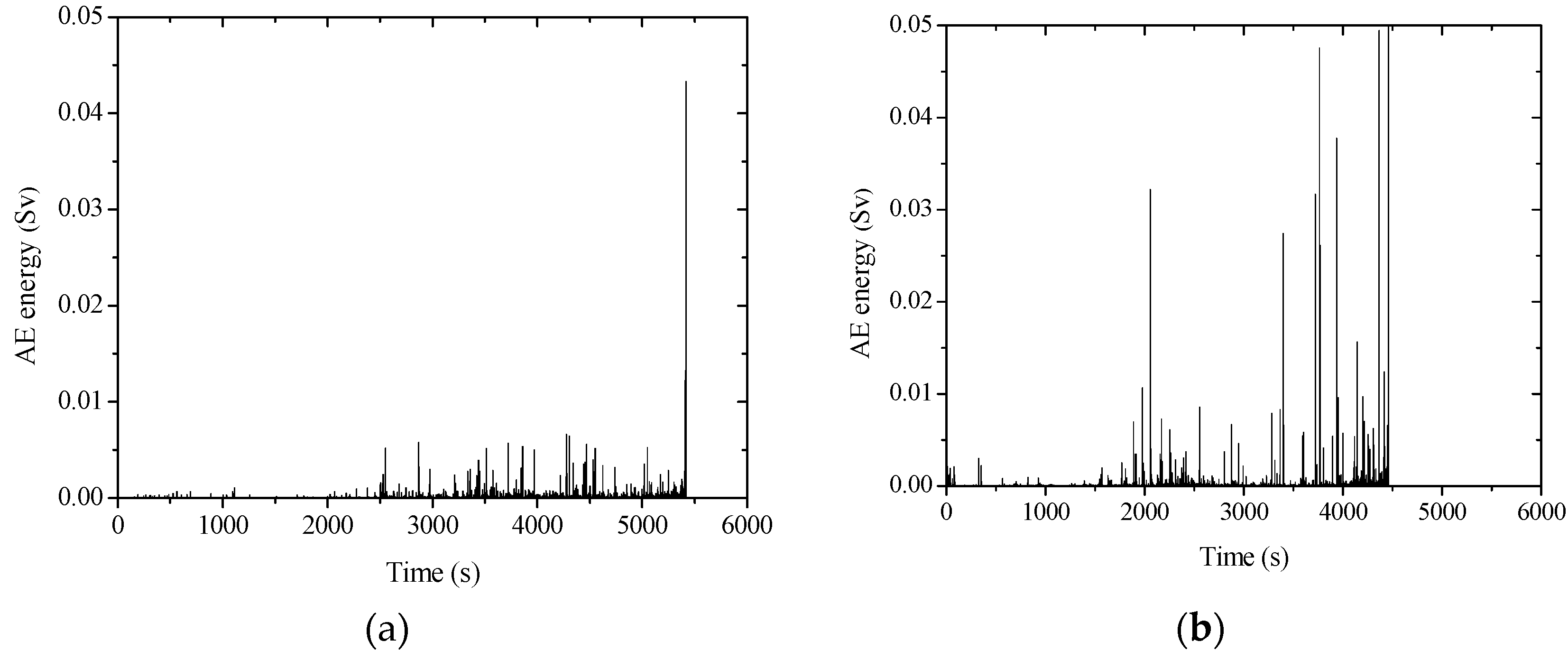

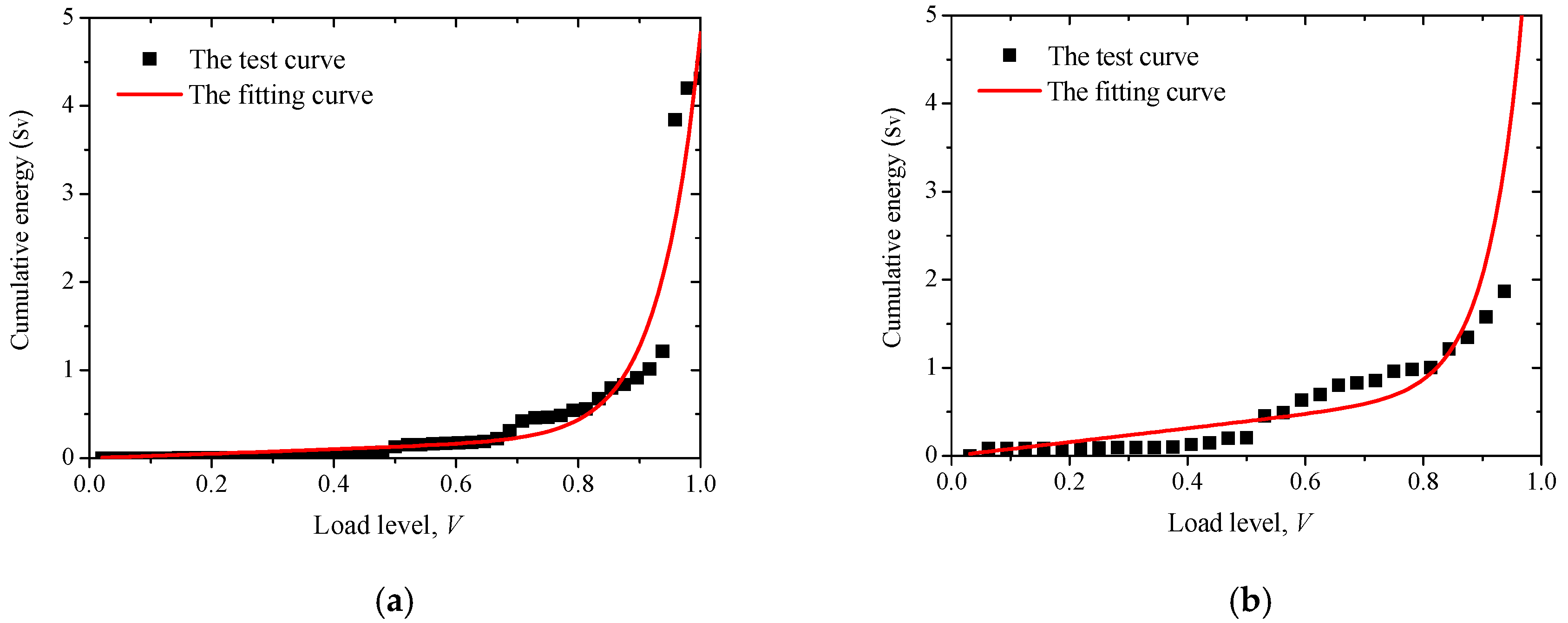

3.4. Time-Dependent Development of AE Signal Energy

3.5. Time-Dependent Development of AE Hits

3.6. AE Cumulative Total Hit Number and Cumulative Total Energy

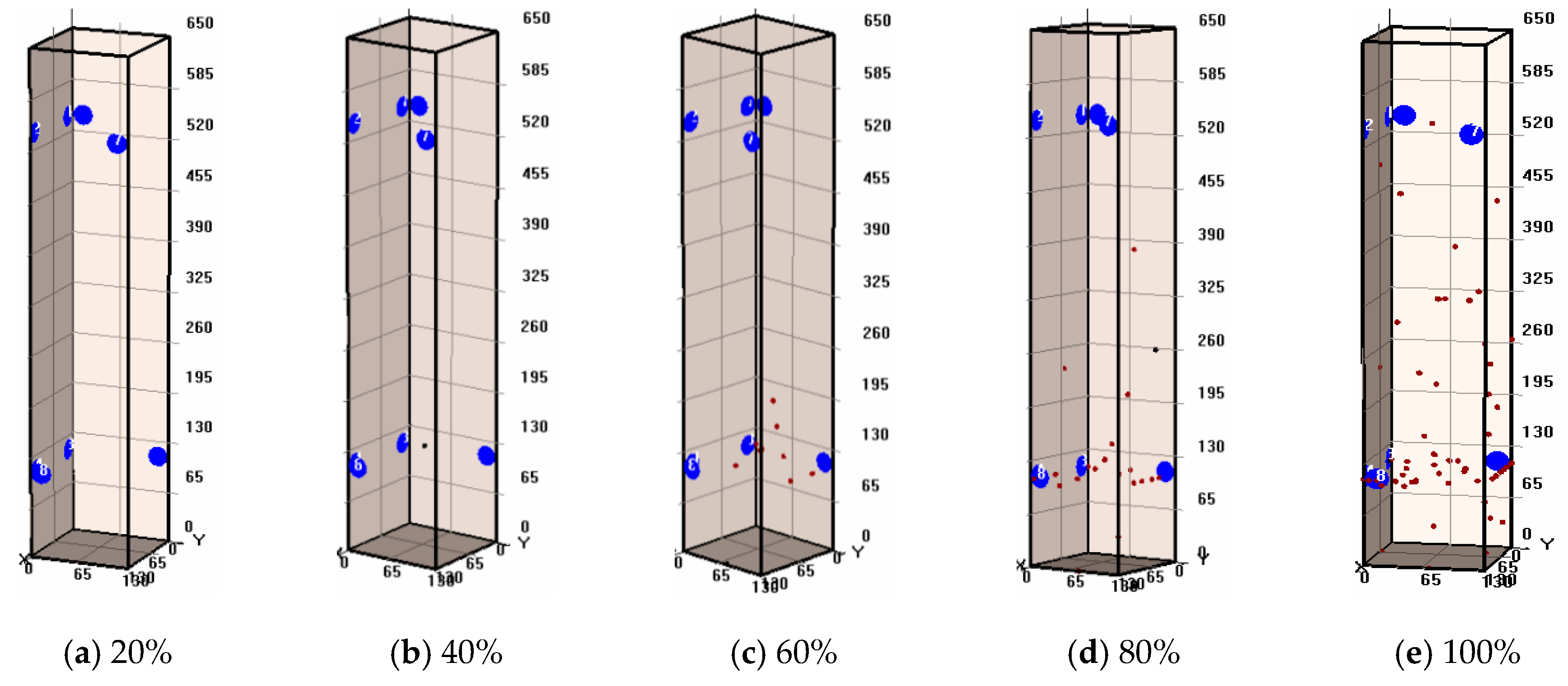

3.7. AE Events Location

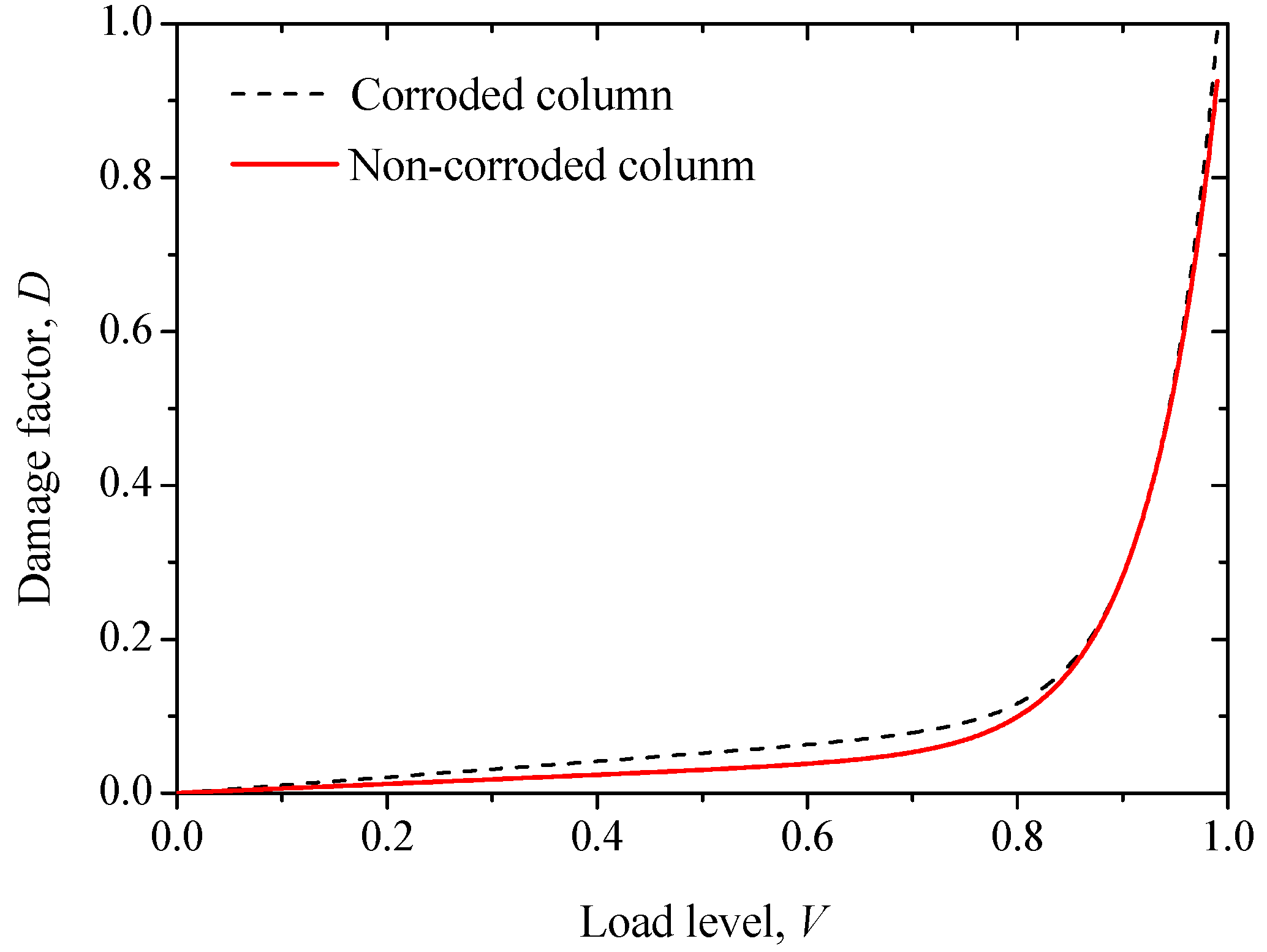

4. Damage Evolution Model

5. Conclusions

- (1)

- The AE characteristics of RC columns are in strong agreement with the macroscopic mechanical behaviors observed during the loading and failure process. The reinforcement corrosion considerably affects the mechanical performance of columns, causing the concrete cover to spall during compressive loading.

- (2)

- The presence of corroded rebar makes the AE signals highly active at the initial stage of loading, in comparison to the non-corroded counterpart. Also, a continuous AE hit pattern with a higher number of cumulative hits was observed for the corroded RC column, while the hit event is almost absent at the early loading period for the non-corroded case.

- (3)

- The spatial distribution and evolution of AE events indicate that the reinforcement corrosion considerably affects the initiation, propagation, and cracking evolution in RC columns.

- (4)

- The concrete damage evolution equation presented by AE parameters can quantitatively describe the effects of corrosion damage on the mechanical performance of concrete.

Author Contributions

Funding

Conflicts of Interest

References

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Redaelli, E.; Polder, R.B. Corrosion of Steel in Concrete: Prevention, Diagnosis, Repair; John Wiley & Sons: Weinheim, Germany, 2013. [Google Scholar]

- Broomfield, J.P. Corrosion of Steel in Concrete: Understanding, Investigation and Repair; CRC Press: Oxon, UK, 2003. [Google Scholar]

- Ye, H.; Fu, C.; Tian, Y.; Jin, N. Chloride-Induced Steel Corrosion in Concrete Under Service Loads; Springer: Singapore, 2020. [Google Scholar]

- Fu, C.; Jin, N.; Ye, H.; Jin, X.; Dai, W. Corrosion Characteristics of a 4-Year Naturally Corroded Reinforced Concrete Beam with Load-Induced Transverse Cracks. Corros. Sci. 2017, 117, 11–23. [Google Scholar] [CrossRef]

- Vidal, T.; Castel, A.; François, R. Corrosion Process and Structural Performance of a 17 Year Old Reinforced Concrete Beam Stored in Chloride Environment. Cem. Concr. Res. 2007, 37, 1551–1561. [Google Scholar] [CrossRef]

- Jiang, H.; Jin, N.; Ye, H.; Tian, Y.; Jin, X.; Zeng, Q.; Yan, D.; Xu, X. Fractal Characterization of Non-Uniform Corrosion of Steel Bars in Concrete Beams after Accelerated Depassivation and Seven-Year Natural Corrosion. Materials 2019, 12, 3919. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Sulaimani, G.J.; Kaleemullah, M.; Basunbul, I.A. Influence of Corrosion and Cracking on Bond Behavior and Strength of Reinforced Concrete Members. Struct. J. 1990, 87, 220–231. [Google Scholar]

- Zhu, W.; François, R. Corrosion of the Reinforcement and Its Influence on the Residual Structural Performance of a 26-Year-Old Corroded RC Beam. Constr. Build. Mater. 2014, 51, 461–472. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, Y.; Feng, P.; Ye, H.; Ozbolt, J.; Jiang, C.; Yang, J.-Q. State-of-the-Art Review on the Bond Properties of Corroded Reinforcing Steel Bar. Constr. Build. Mater. 2019, 213, 216–233. [Google Scholar] [CrossRef]

- Huang, L.; Ye, H.; Jin, X.; Jin, N.; Xu, Z. Corrosion-Induced Shear Performance Degradation of Reinforced Concrete Beams. Constr. Build. Mater. 2020, 248, 118668. [Google Scholar] [CrossRef]

- Fu, C.; Ye, H.; Jin, N.; Huang, Y. Chloride Penetration in Reinforced Concrete Beams under Combined Sustained Loading and Drying–Wetting Cycles. J. Mater. Civ. Eng. 2020, 32, 4020025. [Google Scholar] [CrossRef]

- Ye, H.; Fu, C.; Jin, N.; Jin, X. Influence of Flexural Loading on Chloride Ingress in Concrete Subjected to Cyclic Drying-Wetting Condition. Comput. Concr. 2015, 15, 183–198. [Google Scholar] [CrossRef]

- Tapan, M.; Aboutaha, R.S. Effect of Steel Corrosion and Loss of Concrete Cover on Strength of Deteriorated RC Columns. Constr. Build. Mater. 2011, 25, 2596–2603. [Google Scholar] [CrossRef]

- Wang, X.-H.; Liang, F.-Y. Performance of RC Columns with Partial Length Corrosion. Nucl. Eng. Des. 2008, 238, 3194–3202. [Google Scholar] [CrossRef]

- Zandi Hanjari, K.; Kettil, P.; Lundgren, K. Analysis of Mechanical Behavior of Corroded Reinforced Concrete Structures. ACI Struct. J. 2011, 108, 532–541. [Google Scholar]

- Li, Q.; Huang, L.; Ye, H.; Fu, C.; Jin, X. Mechanical Degradation of Reinforced Concrete Columns Corroded under Sustained Loads. Int. J. Civ. Eng. 2020, 1–19. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Z.G.; Wu, D. Temporal and Spatial Evolution of Acoustic Emission in the Damage Process of Reinforced Concrete Column. Appl. Mech. Mater. 2014, 638, 275–278. [Google Scholar] [CrossRef]

- Helal, J.; Sofi, M.; Mendis, P. Non-Destructive Testing of Concrete: A Review of Methods. Electron. J. Struct. Eng. 2015, 14, 97–105. [Google Scholar]

- Grosse, C.U.; Ohtsu, M. Acoustic Emission Testing; Springer Science & Business Media: Berlin, Germany, 2008. [Google Scholar]

- Rossing, T. Springer Handbook of Acoustics; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Tsangouri, E.; Aggelis, D.G. A Review of Acoustic Emission as Indicator of Reinforcement Effectiveness in Concrete and Cementitious Composites. Constr. Build. Mater. 2019, 224, 198–205. [Google Scholar] [CrossRef]

- Rüsch, H. Physical Problems in the Testing of Concrete. Zement-Kalk-Gips 1959, 12, 1–9. [Google Scholar]

- Wells, D. An Acoustic Apparatus to Record Emissions from Concrete under Strain. Nucl. Eng. Des. 1970, 12, 80–88. [Google Scholar] [CrossRef]

- Manterola, J.; Aguirre, M.; Zurbitu, J.; Renart, J.; Turon, A.; Urresti, I. Using Acoustic Emissions (AE) to Monitor Mode I Crack Growth in Bonded Joints. Eng. Fract. Mech. 2020, 224, 106778. [Google Scholar] [CrossRef]

- Hu, S.; Lu, J.; Xiao, F. Evaluation of Concrete Fracture Procedure Based on Acoustic Emission Parameters. Constr. Build. Mater. 2013, 47, 1249–1256. [Google Scholar] [CrossRef]

- Li, D.; Ou, J.; Lan, C.; Li, H. Monitoring and Failure Analysis of Corroded Bridge Cables under Fatigue Loading Using Acoustic Emission Sensors. Sensors 2012, 12, 3901–3915. [Google Scholar] [CrossRef] [PubMed]

- Di, B.; Wang, J.; Li, H.; Zheng, J.; Zheng, Y.; Song, G. Investigation of Bonding Behavior of FRP and Steel Bars in Self-Compacting Concrete Structures Using Acoustic Emission Method. Sensors 2019, 19, 159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ohtsu, M. Acoustic Emission Characteristics in Concrete and Diagnostic Applications. J. Acoust. Emiss. 1987, 6, 99–108. [Google Scholar]

- Ohtsu, M. The History and Development of Acoustic Emission in Concrete Engineering. Mag. Concr. Res. 1996, 48, 321–330. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Experimental Study on AE Characteristics of Three-Point-Bending Concrete Beams. Cem. Concr. Res. 2004, 34, 391–397. [Google Scholar] [CrossRef]

- Goszczyńska, B. Analysis of the Process of Crack Initiation and Evolution in Concrete with Acoustic Emission Testing. Arch. Civ. Mech. Eng. 2014, 14, 134–143. [Google Scholar] [CrossRef]

- Ohno, K.; Uji, K.; Ueno, A.; Ohtsu, M. Fracture Process Zone in Notched Concrete Beam under Three-Point Bending by Acoustic Emission. Constr. Build. Mater. 2014, 67, 139–145. [Google Scholar] [CrossRef]

- Abdelrahman, M.; ElBatanouny, M.K.; Ziehl, P.H. Acoustic Emission Based Damage Assessment Method for Prestressed Concrete Structures: Modified Index of Damage. Eng. Struct. 2014, 60, 258–264. [Google Scholar] [CrossRef]

- Nguyen-Tat, T.; Ranaivomanana, N.; Balayssac, J.-P. Characterization of Damage in Concrete Beams under Bending with Acoustic Emission Technique (AET). Constr. Build. Mater. 2018, 187, 487–500. [Google Scholar] [CrossRef]

- Fu, C.; Ye, H.; Jin, X.; Yan, D.; Jin, N.; Peng, Z. Chloride Penetration into Concrete Damaged by Uniaxial Tensile Fatigue Loading. Constr. Build. Mater. 2016, 125, 714–723. [Google Scholar] [CrossRef]

- Ye, H.; Fu, C.; Jin, N.; Jin, X. Performance of Reinforced Concrete Beams Corroded under Sustained Service Loads: A Comparative Study of Two Accelerated Corrosion Techniques. Constr. Build. Mater. 2018, 162, 286–297. [Google Scholar] [CrossRef]

- Malumbela, G.; Alexander, M.; Moyo, P. Steel Corrosion on RC Structures under Sustained Service Loads—A Critical Review. Eng. Struct. 2009, 31, 2518–2525. [Google Scholar] [CrossRef]

- Ma, G.; Li, H. Acoustic Emission Monitoring and Damage Assessment of FRP-Strengthened Reinforced Concrete Columns under Cyclic Loading. Constr. Build. Mater. 2017, 144, 86–98. [Google Scholar] [CrossRef]

- Abouhussien, A.A.; Hassan, A.A.A.; AbdelAleem, B.H. Acoustic Emission Analysis of Self-Consolidating Rubberized Concrete Beam-Column Connections under Cyclic Loading. ACI Struct. J. 2019, 116, 41–51. [Google Scholar] [CrossRef]

- Kawasaki, Y.; Wasada, S.; Okamoto, T.; Izuno, K. Evaluation for RC Specimen Damaged from Rebar Corrosion by Acoustic Emission Technique. Constr. Build. Mater. 2014, 67, 157–164. [Google Scholar] [CrossRef]

- Patil, S.; Karkare, B.; Goyal, S. Acoustic Emission Vis-à-Vis Electrochemical Techniques for Corrosion Monitoring of Reinforced Concrete Element. Constr. Build. Mater. 2014, 68, 326–332. [Google Scholar] [CrossRef]

- Kawasaki, Y.; Wakuda, T.; Kobarai, T.; Ohtsu, M. Corrosion Mechanisms in Reinforced Concrete by Acoustic Emission. Constr. Build. Mater. 2013, 48, 1240–1247. [Google Scholar] [CrossRef]

- El Maaddawy, T.A.; Soudki, K.A. Effectiveness of Impressed Current Technique to Simulate Corrosion of Steel Reinforcement in Concrete. J. Mater. Civ. Eng. 2003, 15, 41–47. [Google Scholar] [CrossRef]

- Beattie, A.G. Acoustic Emission, Principles and Instrumentation. J. Acoust. Emiss. 1983, 2, 96–128. [Google Scholar]

- Zhu, W.; François, R.; Coronelli, D.; Cleland, D. Effect of Corrosion of Reinforcement on the Mechanical Behaviour of Highly Corroded RC Beams. Eng. Struct. 2013, 56, 544–554. [Google Scholar] [CrossRef]

| Water-to-Binder Ratio | Water (kg/m3) | Cement (kg/m3) | GGBS (kg/m3) | Sand (kg/m3) | Coarse Aggregate (kg/m3) |

|---|---|---|---|---|---|

| 0.53 | 203.0 | 191.5 | 191.5 | 766 | 1149 |

| Targeted Corrosion Rate (%) | Mloss (g) | icorr (A/cm2) | As,0 (cm2) | Icorr (A) | t (h) |

|---|---|---|---|---|---|

| 10 | 195.2 | 0.0002 | 1238.42 | 0.2477 | 754.48 |

| Targeted Corrosion Rate | Actual Corrosion Rate | ||

|---|---|---|---|

| 10 | Longitudinal Steel Bars | Stirrups | Average* |

| 3.90 | 12.60 | 8.25 | |

| Specimen | Non-Corroded Column | Corroded Column |

|---|---|---|

| Cumulative AE energy (Sv) | 3.35 | 8.10 |

| Load-bearing capacity (kN) | 480 | 314 |

| Specimen | a | b | c | Correlation Coefficient |

|---|---|---|---|---|

| non-corroded column | 0.25 | 1.62 × 10−6 | 14.80 | 0.93 |

| corroded column | 0.78 | 0.27 × 10−6 | 17.12 | 0.91 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Jin, X.; Wu, D.; Ye, H. Acoustic Emission Analysis of Corroded Reinforced Concrete Columns under Compressive Loading. Sensors 2020, 20, 2412. https://doi.org/10.3390/s20082412

Li Q, Jin X, Wu D, Ye H. Acoustic Emission Analysis of Corroded Reinforced Concrete Columns under Compressive Loading. Sensors. 2020; 20(8):2412. https://doi.org/10.3390/s20082412

Chicago/Turabian StyleLi, Qiang, Xianyu Jin, Dan Wu, and Hailong Ye. 2020. "Acoustic Emission Analysis of Corroded Reinforced Concrete Columns under Compressive Loading" Sensors 20, no. 8: 2412. https://doi.org/10.3390/s20082412

APA StyleLi, Q., Jin, X., Wu, D., & Ye, H. (2020). Acoustic Emission Analysis of Corroded Reinforced Concrete Columns under Compressive Loading. Sensors, 20(8), 2412. https://doi.org/10.3390/s20082412