Bridge Resistance Compensation for Noise Reduction in a Self-Balanced PHMR Sensor

Abstract

:1. Introduction

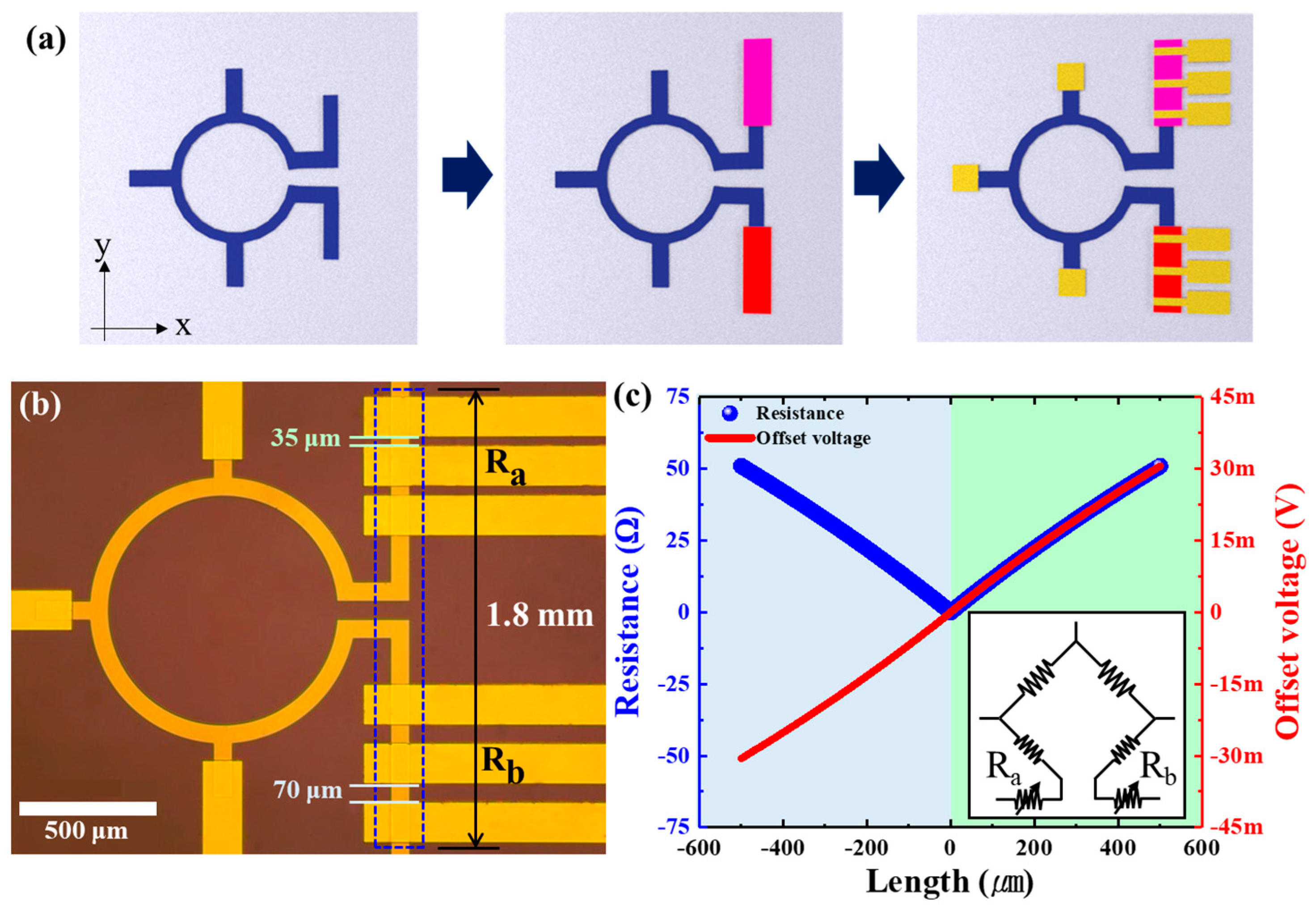

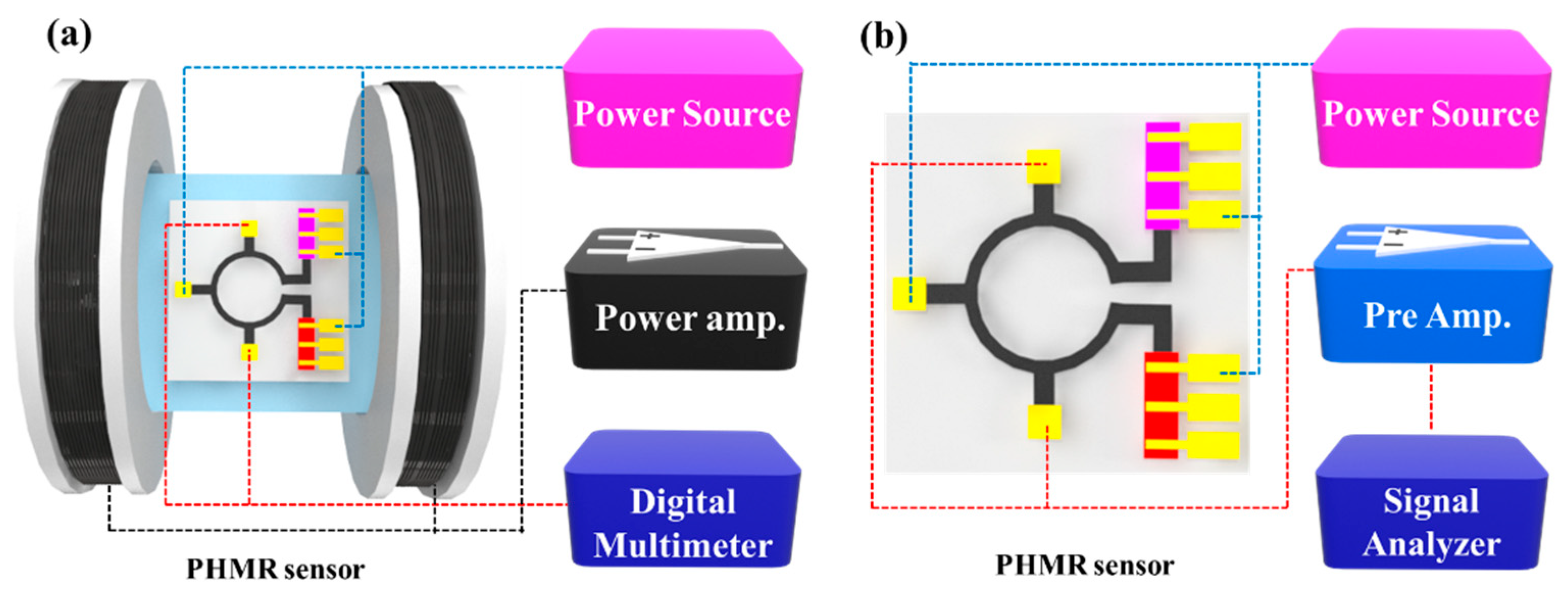

2. Materials and Methods

PHMR Sensor Fabrication and Experimental Details

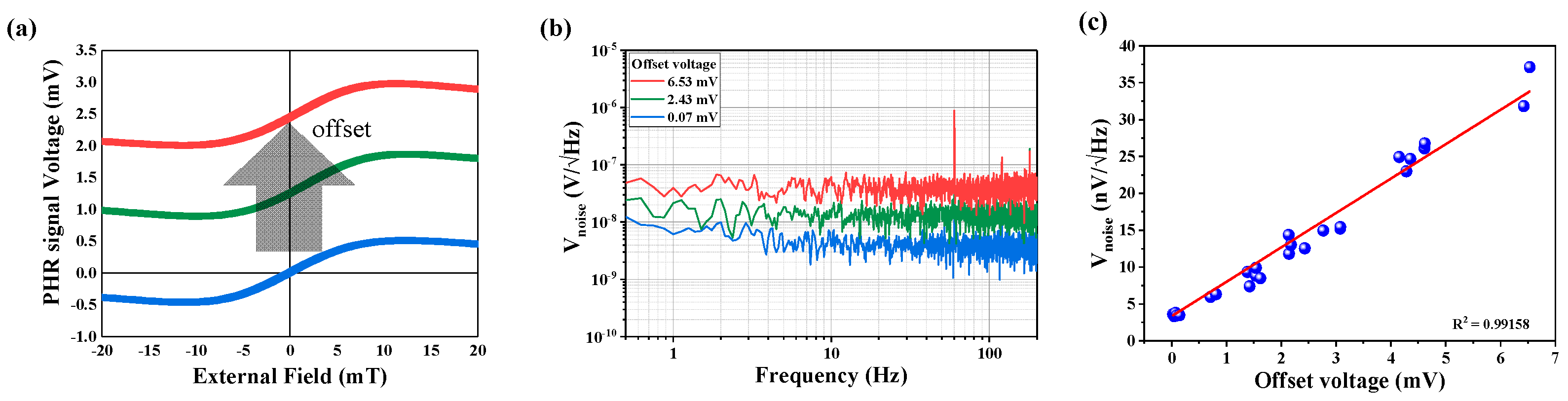

3. Results

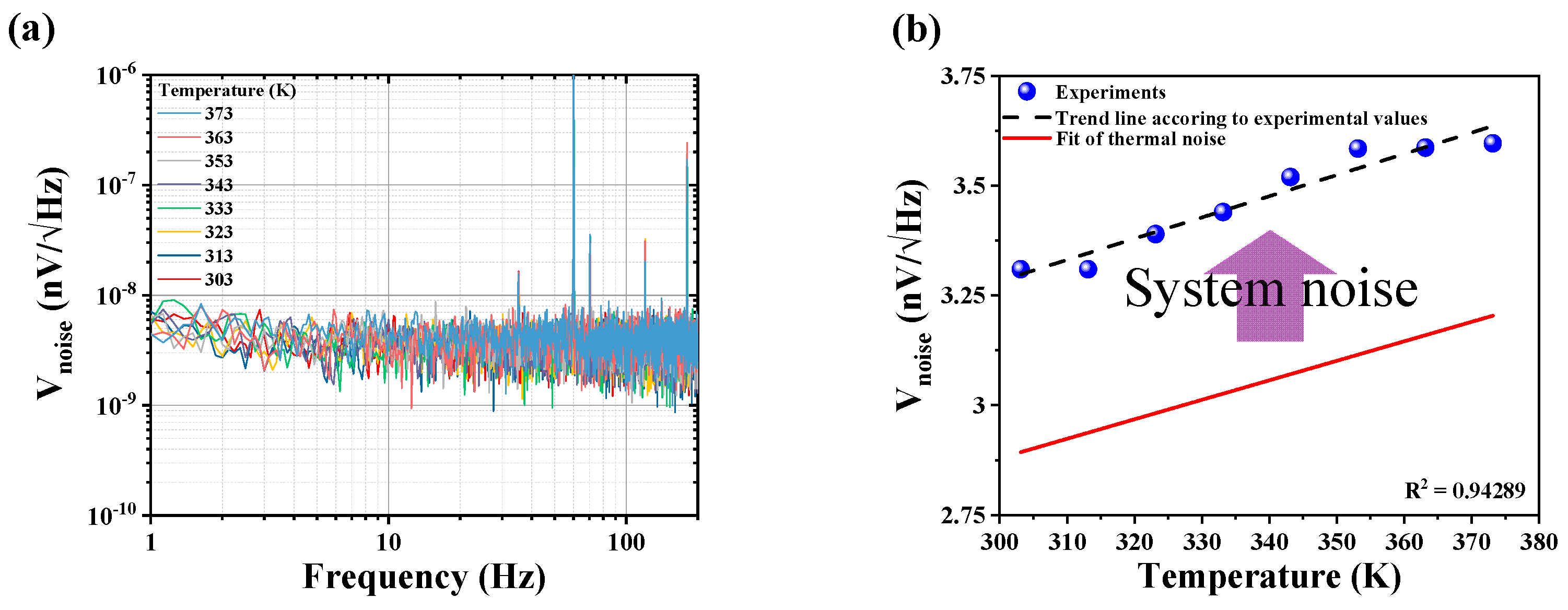

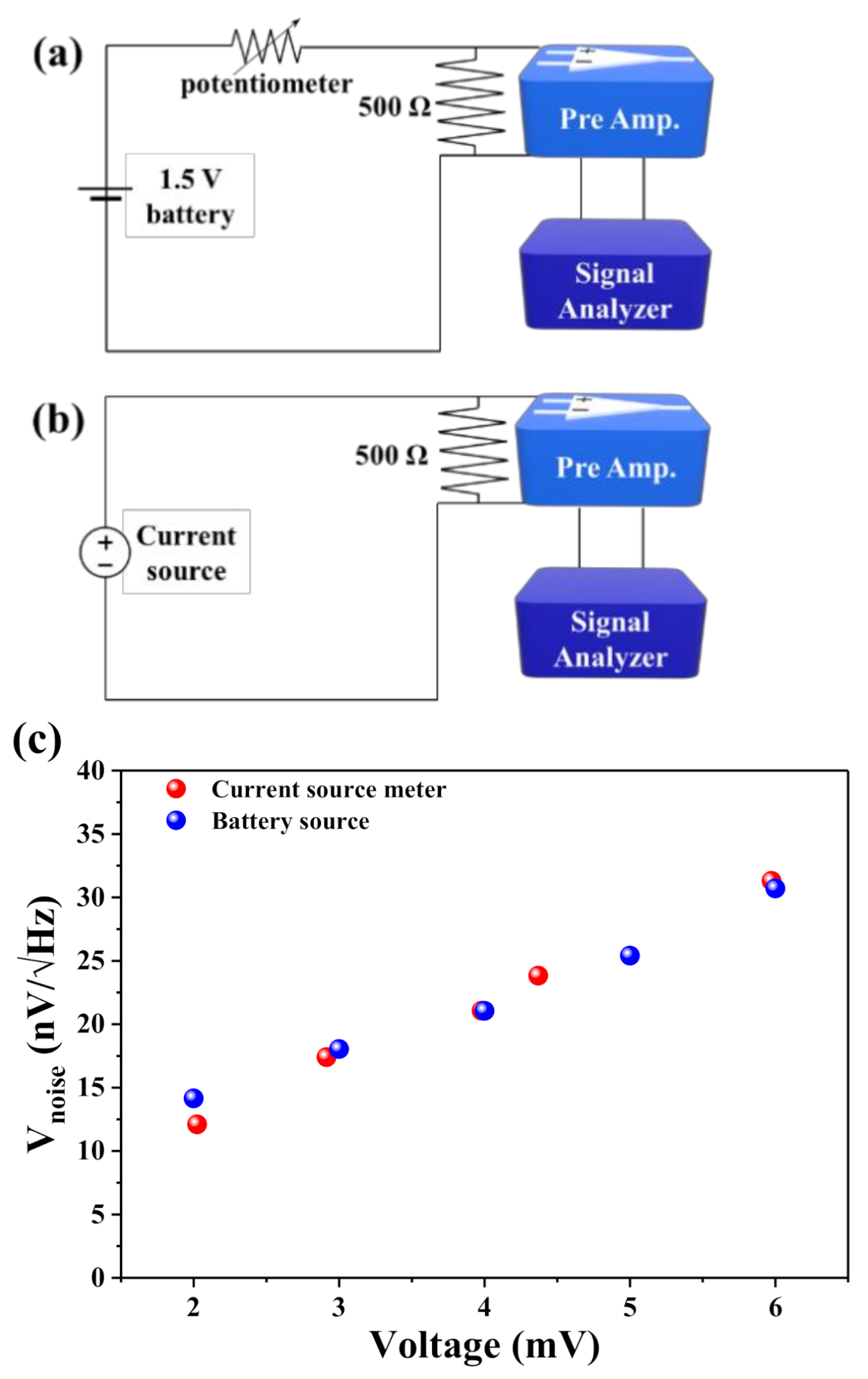

3.1. Noise Classification

3.2. Decomposition of Noise Components

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Guerrero-Ibáñez, J.; Zeadally, S.; Contreras-Castillo, J. Sensor Technologies for Intelligent Transportation Systems. Sensors 2018, 18, 1212. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trigona, C.; Andò, B.; Sinatra, V.; Vacirca, C.; Rossino, E.; Palermo, L.; Kurukunda, S.; Baglio, S. Implementation and characterization of a smart parking system based on 3-axis magnetic sensors. In Proceedings of the 2016 IEEE International Instrumentation and Measurement Technology Conference, Taipei, Taiwan, 23–26 May 2016. [Google Scholar]

- Sifuentes, E.; Casas, O.; Pallas-Areny, R. Wireless Magnetic Sensor Node for Vehicle Detection with Optical Wake-Up. IEEE Sens. J. 2011, 11, 1669–1676. [Google Scholar] [CrossRef]

- Ilyas, M.; Cho, K.; Baeg, S.H.; Park, S. Drift Reduction in Pedestrian Navigation System by Exploiting Motion Constraints and Magnetic Field. Sensors 2016, 16, 1455. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhai, J.; Dong, S.; Xing, Z.; Li, J.; Viehland, D. Geomagnetic sensor based on giant magnetoelectric effect. Appl. Phys. Lett. 2007, 91, 123513. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-S.; Seo, W.; Baek, K.-R. Indoor Positioning System Using Magnetic Field Map Navigation and an Encoder System. Sensors 2017, 17, 651. [Google Scholar] [CrossRef]

- Baillet, S.; Mosher, J.C.; Leahy, R.M. Electromagnetic brain mapping. IEEE Signal Process. Mag. 2001, 18, 14–30. [Google Scholar] [CrossRef]

- Jin, Z.; Mohd Noor Sam, M.A.I.; Oogane, M.; Ando, Y. Serial MTJ-Based TMR Sensors in Bridge Configuration for Detection of Fractured Steel Bar in Magnetic Flux Leakage Testing. Sensors 2021, 21, 668. [Google Scholar] [CrossRef]

- Bermúdez, G.S.C.; Fuchs, H.; Bischoff, L.; Fassbender, J.; Makarov, D. Electronic-skin compasses for geomagnetic field-driven artificial magnetoreception and interactive electronics. Nat. Electron. 2018, 1, 589–595. [Google Scholar] [CrossRef]

- Luong, V.-S.; Jeng, J.-T.; Lai, B.-L.; Hsu, J.-H.; Chang, C.-R.; Lu, C.-C. Design of 3-D Magnetic Field Sensor with Single Bridge of Spin-Valve Giant Magnetoresistance Films. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Choi, S.-M.; Jeong, J.-C.; Kim, J.; Lim, E.-G.; Kim, C.-B.; Park, S.-J.; Song, D.-Y.; Krause, H.-J.; Hong, H.; Kweon, I.S. A novel three-dimensional magnetic particle imaging system based on the frequency mixing for the point-of-care diagnostics. Sci. Rep. 2020, 10, 1–16. [Google Scholar] [CrossRef]

- Xianyu, Y.; Wang, Q.; Chen, Y. Magnetic particles-enabled biosensors for point-of-care testing. TrAC Trends Anal. Chem. 2018, 106, 213–224. [Google Scholar] [CrossRef]

- Choi, J.; Gani, A.W.; Bechstein, D.J.; Lee, J.R.; Utz, P.J.; Wang, S.X. Portable, one-step, and rapid GMR biosensor platform with smartphone interface. Biosens. Bioelectron. 2016, 85, 1–7. [Google Scholar] [CrossRef]

- Wu, K.; Klein, T.; Krishna, V.D.; Su, D.; Perez, A.M.; Wang, J.-P. Portable GMR Handheld Platform for the Detection of Influenza A Virus. ACS Sens. 2017, 2, 1594–1601. [Google Scholar] [CrossRef]

- Fang, X.; Misra, S.; Xue, G.; Yang, D. Smart grid—The new and improved power grid: A survey. IEEE Commun. Surv. Tutor. 2011, 14, 944–980. [Google Scholar] [CrossRef]

- Tuballa, M.L.; Abundo, M.L. A review of the development of Smart Grid technologies. Renew. Sustain. Energy Rev. 2016, 59, 710–725. [Google Scholar] [CrossRef]

- Bolognani, S.; Zampieri, S. On the Existence and Linear Approximation of the Power Flow Solution in Power Distribution Networks. IEEE Trans. Power Syst. 2015, 31, 163–172. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Torati, S.R.; Talantsev, A.; Jeon, C.; Lee, S.; Kim, C. Performance validation of a planar hall resistance biosensor through beta-amyloid biomarker. Sensors 2020, 20, 434. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Wang, X.; Li, M.; Gao, Y.; Hu, Z.; Nan, T.; Liang, X.; Chen, X.; Yang, J.; Cash, S.; et al. Highly Sensitive Flexible Magnetic Sensor Based on Anisotropic Magnetoresistance Effect. Adv. Mater. 2016, 28, 9370–9377. [Google Scholar] [CrossRef]

- Bauer, M.J.; Thomas, A.; Isenberg, B.; Varela, J.; Faria, A.; Arnold, D.P.; Andrew, J.S. Ultra-Low-Power Current Sensor Utilizing Magnetoelectric Nanowires. IEEE Sens. J. 2020, 20, 5139–5145. [Google Scholar] [CrossRef]

- Damsgaard, C.D.; de Freitas, S.C.; Freitas, P.P.; Hansen, M.F. Exchange-biased planar Hall effect sensor optimized for biosensor applications. J. Appl. Phys. 2008, 103, 7. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, J.; Ramirez, D.; Ravelo, S.I.; Lopes, A.; Cardoso, S.; Ferreira, R.; De Freitas, S.C. Electrical Characterization of a Magnetic Tunnel Junction Current Sensor for Industrial Applications. IEEE Trans. Magn. 2012, 48, 2823–2826. [Google Scholar] [CrossRef]

- Zheng, C.; Zhu, K.; de Freitas, S.C.; Chang, J.-Y.; Davies, J.E.; Eames, P.; Freitas, P.P.; Kazakova, O.; Kim, C.; Leung, C.-W.; et al. Magnetoresistive Sensor Development Roadmap (Non-Recording Applications). IEEE Trans. Magn. 2019, 55, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Quynh, L.K.; Tu, B.D.; Anh, C.V.; Duc, N.H.; Phung, A.T.; Dung, T.T.; Giang, D.H. Design Optimization of an Anisotropic Magnetoresistance Sensor for Detection of Magnetic Nanoparticles. J. Electron. Mater. 2019, 48, 997–1004. [Google Scholar] [CrossRef]

- Shen, H.-M.; Hu, L.; Fu, X. Integrated Giant Magnetoresistance Technology for Approachable weak Biomagnetic Signal Detections. Sensors 2018, 18, 148. [Google Scholar] [CrossRef] [Green Version]

- Jung, J.W.; Sakuraba, Y.; Sasaki, T.T.; Miura, Y.; Hono, K. Enhancement of magnetoresistance by inserting thin NiAl layers at the interfaces in Co2FeGa0.5Ge0.5/Ag/Co2FeGa0.5Ge0.5 current-perpendicular-to-plane pseudo spin valves. Appl. Phys. Lett. 2016, 108, 102408. [Google Scholar] [CrossRef]

- Du, Q.; Peng, J.; Qiu, W.; Ding, Q.; Pan, M.; Hu, J.; Sun, K.; Chen, D.; Pan, L.; Che, Y.; et al. High Efficiency Magnetic Flux Modulation Structure for Magnetoresistance Sensor. IEEE Electro. Device Lett. 2019, 40, 1824–1827. [Google Scholar] [CrossRef]

- Luong, V.S.; Nguyen, A.T.; Hoang, Q.K. Resolution enhancement in measuring low-frequency magnetic field of tunnel magnetoresistance sensors with AC-bias polarity technique. Measurement 2018, 127, 512–517. [Google Scholar] [CrossRef]

- Grosz, A.; Mor, V.; Amrusi, S.; Faivinov, I.; Paperno, E.; Klein, L.; Mor, V. A High-Resolution Planar Hall Effect Magnetometer for Ultra-Low Frequencies. IEEE Sens. J. 2016, 16, 3224–3230. [Google Scholar] [CrossRef]

- Guedes, A.; Almeida, J.M.; Cardoso, S.; Ferreira, R.; Freitas, P.P. Improving magnetic field detection limits of spin valve sensors using magnetic flux guide concentrators. IEEE Trans. Magn. 2007, 43, 2376–2378. [Google Scholar] [CrossRef]

- Zhang, X.; Bi, Y.; Chen, G.; Liu, J.; Li, J.; Feng, K.; Lv, C.; Wang, W. Influence of size parameters and magnetic field intensity upon the amplification characteristics of magnetic flux concentrators. AIP Adv. 2018, 8, 125222. [Google Scholar] [CrossRef] [Green Version]

- Mateos, I.; Ramos-Castro, J.; Lobo, A. Low-frequency noise characterization of a magnetic field monitoring system using an anisotropic magnetoresistance. Sens. Actuators A Phys. 2015, 235, 57–63. [Google Scholar] [CrossRef] [Green Version]

- Chu, Z.; Yu, Z.; PourhosseiniAsl, M.; Tu, C.; Dong, S. Enhanced low-frequency magnetic field sensitivity in magnetoelectric composite with amplitude modulation method. Appl. Phys. Lett. 2019, 114, 132901. [Google Scholar] [CrossRef]

- Yaul, F.M.; Chandrakasan, A.P. A Noise-Efficient 36 nV/√Hz Chopper Amplifier Using an Inverter-Based 0.2-V Supply Input Stage. IEEE J. Solid-State Circuits 2017, 52, 3032–3042. [Google Scholar] [CrossRef]

- Mușuroi, C.; Oproiu, M.; Volmer, M.; Firastrau, I. High Sensitivity Differential Giant Magnetoresistance (GMR) Based Sensor for Non-Contacting DC/AC Current Measurement. Sensors 2020, 20, 323. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Hong, S.; Park, W.; Kim, W.; Lee, J.; Shin, K.; Kim, C.-G.; Lee, D. High Accuracy Open-Type Current Sensor with a Differential Planar Hall Resistive Sensor. Sensors 2018, 18, 2231. [Google Scholar] [CrossRef] [Green Version]

- Henriksen, A.D.; Rizzi, G.; Hansen, M.F. Experimental comparison of ring and diamond shaped planar Hall effect bridge magnetic field sensors. J. Appl. Phys. 2015, 118, 103901. [Google Scholar] [CrossRef] [Green Version]

- Henriksen, A.D.; Dalslet, B.T.; Skieller, D.H.; Lee, K.H.; Okkels, F.; Hansen, M.F. Planar Hall effect bridge magnetic field sensors. Appl. Phys. Lett. 2010, 97, 13507. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, Y.; Zhang, M.; Luo, Z.; Wu, Y. Ultrathin All-in-One Spin Hall Magnetic Sensor with Built-In AC Excitation Enabled by Spin Current. Adv. Mater. Technol. 2018, 3, 1800073. [Google Scholar] [CrossRef]

- Alnasser, E. A Novel Low Output Offset Voltage Charge Amplifier for Piezoelectric Sensors. IEEE Sens. J. 2020, 20, 5360–5367. [Google Scholar] [CrossRef]

- Park, B.-K.; Boric-Lubecke, O.; Lubecke, V.M. Arctangent Demodulation with DC Offset Compensation in Quadrature Doppler Radar Receiver Systems. IEEE Trans. Microw. Theory Tech. 2007, 55, 1073–1079. [Google Scholar] [CrossRef]

- Hwang, S.-H.; Liu, L.; Li, H.; Kim, J.-M. DC Offset Error Compensation for Synchronous Reference Frame PLL in Single-Phase Grid-Connected Converters. IEEE Trans. Power Electron. 2012, 27, 3467–3471. [Google Scholar] [CrossRef]

- Kumar, T.B.; Ma, K.; Yeo, K.S. Temperature-compensated dB-linear digitally controlled variable gain amplifier with DC offset cancellation. IEEE Trans. Microw. Theory Tech. 2013, 61, 2648–2661. [Google Scholar] [CrossRef]

- Kim, D.; Kim, C.; Park, B.; Park, C. Thickness dependence of planar Hall resistance and field sensitivity in NiO(30 nm)/NiFe(t) bilayers. J. Magn. Magn. Mater. 2000, 215, 585–588. [Google Scholar] [CrossRef]

- Thanh, N.; Chun, M.; Schmalhorst, J.; Reiss, G.; Kim, K.; Kim, C. Magnetizing angle dependence of planar Hall resistance in spin-valve structure. J. Magn. Magn. Mater. 2006, 304, e84–e87. [Google Scholar] [CrossRef]

- Kim, J.M.; Lee, Y.H.; Kim, K.; Kwon, H.; Park, Y.K.; Sasada, I. Compact readout electronics for 62-channel DROS magnetocardiogram system. IEEE Trans. Appl. Supercond. 2005, 15, 644–647. [Google Scholar] [CrossRef]

| Intrinsic Noise | Extrinsic Noise | Intermixing Noise | |

|---|---|---|---|

| Thermal | Preamp. | Environ. | Coefficient * |

| Auto-Zeroing | Chopping | Resistance Compensator | |

|---|---|---|---|

| Advantage |

|

|

|

| Disadvantage |

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Jeon, C.; Jeon, T.; Das, P.T.; Lee, Y.; Lim, B.; Kim, C. Bridge Resistance Compensation for Noise Reduction in a Self-Balanced PHMR Sensor. Sensors 2021, 21, 3585. https://doi.org/10.3390/s21113585

Lee J, Jeon C, Jeon T, Das PT, Lee Y, Lim B, Kim C. Bridge Resistance Compensation for Noise Reduction in a Self-Balanced PHMR Sensor. Sensors. 2021; 21(11):3585. https://doi.org/10.3390/s21113585

Chicago/Turabian StyleLee, Jaehoon, Changyeop Jeon, Taehyeong Jeon, Proloy Taran Das, Yongho Lee, Byeonghwa Lim, and CheolGi Kim. 2021. "Bridge Resistance Compensation for Noise Reduction in a Self-Balanced PHMR Sensor" Sensors 21, no. 11: 3585. https://doi.org/10.3390/s21113585

APA StyleLee, J., Jeon, C., Jeon, T., Das, P. T., Lee, Y., Lim, B., & Kim, C. (2021). Bridge Resistance Compensation for Noise Reduction in a Self-Balanced PHMR Sensor. Sensors, 21(11), 3585. https://doi.org/10.3390/s21113585