Error Fusion of Hybrid Neural Networks for Mechanical Condition Dynamic Prediction

Abstract

:1. Introduction

2. Methodology

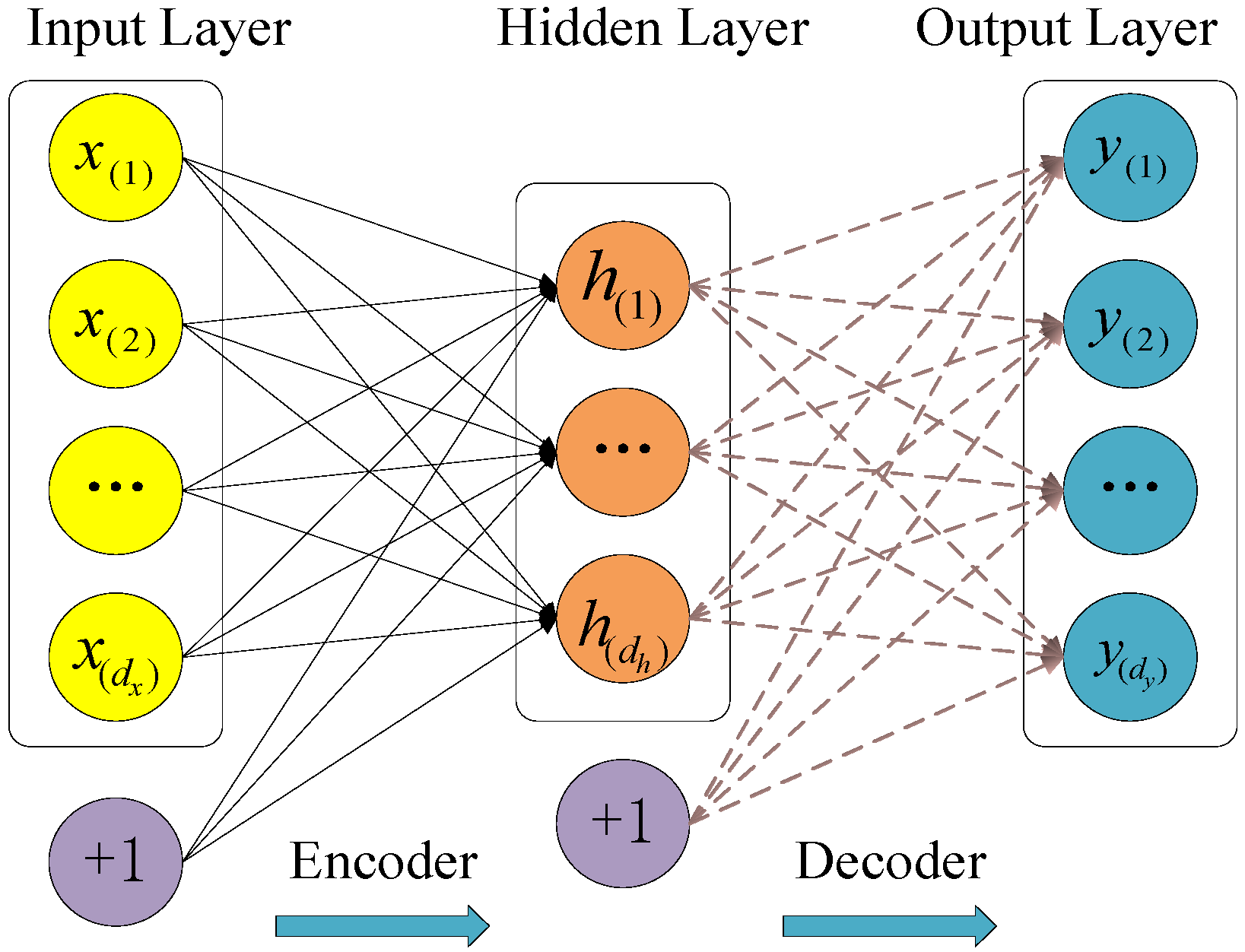

2.1. Sparse Auto-Encoders

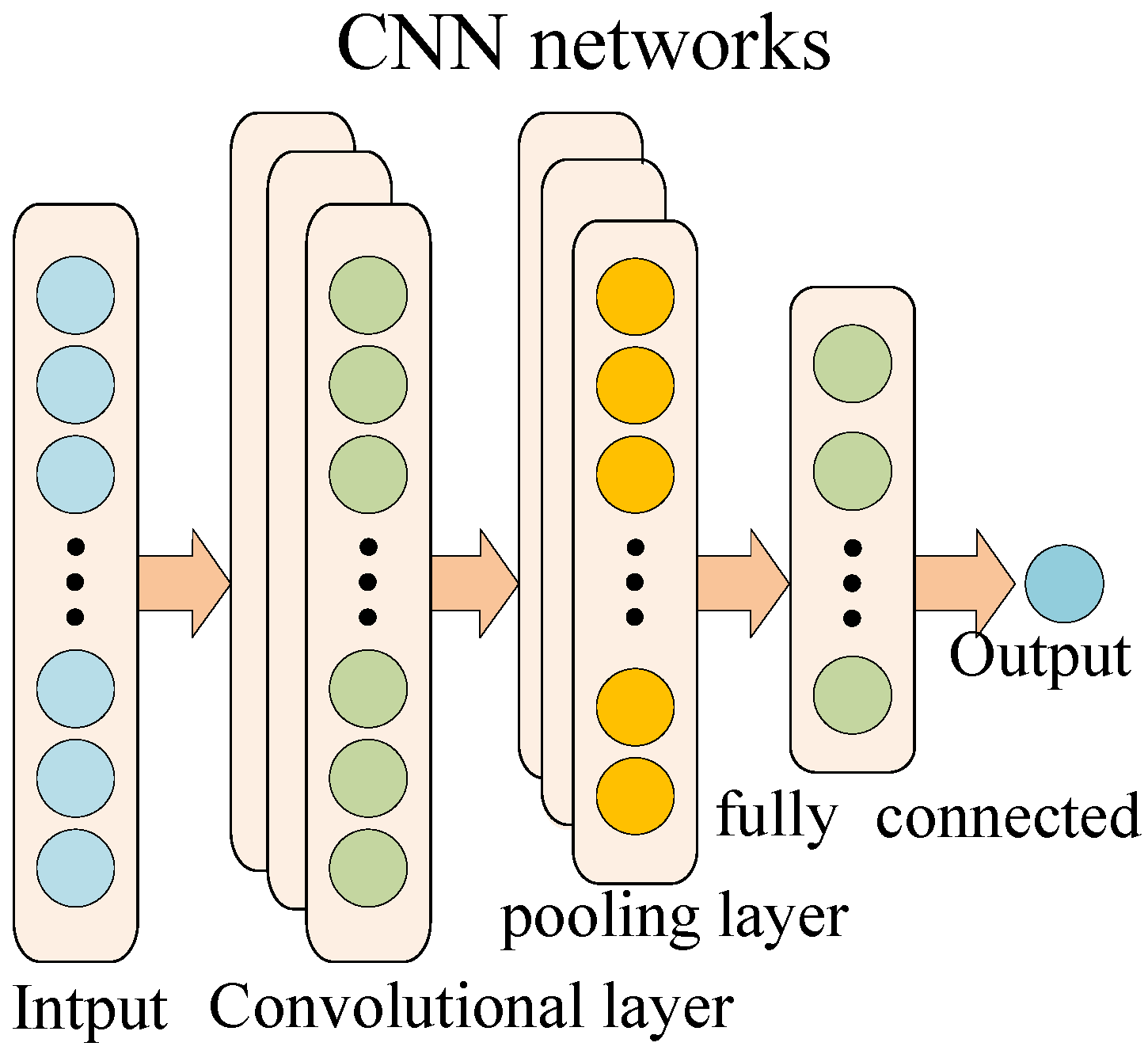

2.2. Convolutional Neural Networks Method

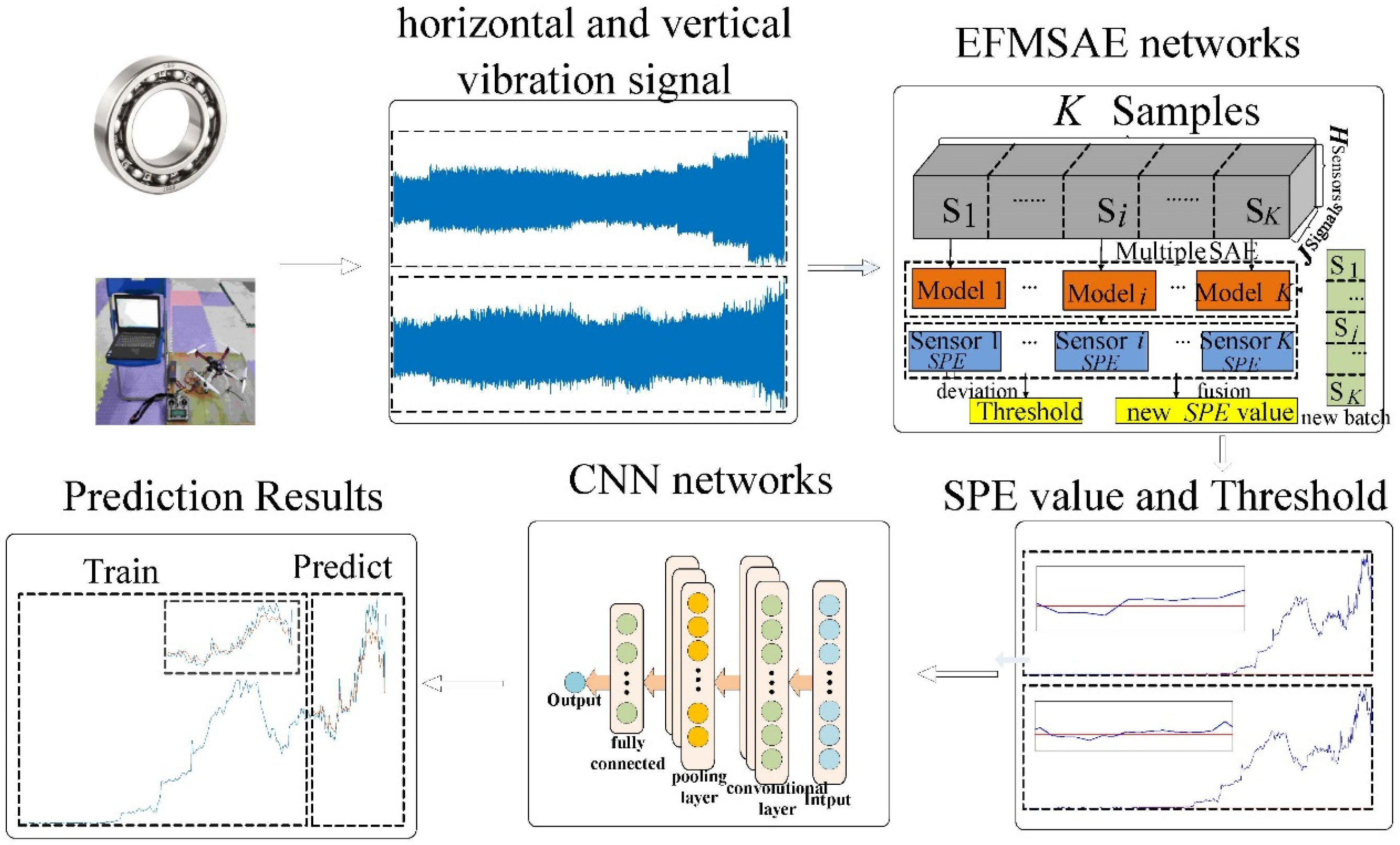

2.3. Error Fusion of Hybrid Neural Networks

2.4. Overview of the Proposed Algorithm

- Step 1. Collect the full life cycle data set based on different sensors released by Xi’an Jiaotong University and UAV propellers.

- Step 2. Extract multi-feature sequence representation of unlabeled data by multiple SAEs.

- Step 3. On the basis of conventional data batch processing, the threshold line is estimated according to the conventional data batch, and the SPE value is calculated according to the test data.

- Step 4. Combine the SPE value of the multi-channel sensor to obtain the trend curve of the system.

- Step 5. CNN is used to forecast the trend of time series with multi-feature fusion, and analyze the level of anomaly of its parts. End.

3. Experiments

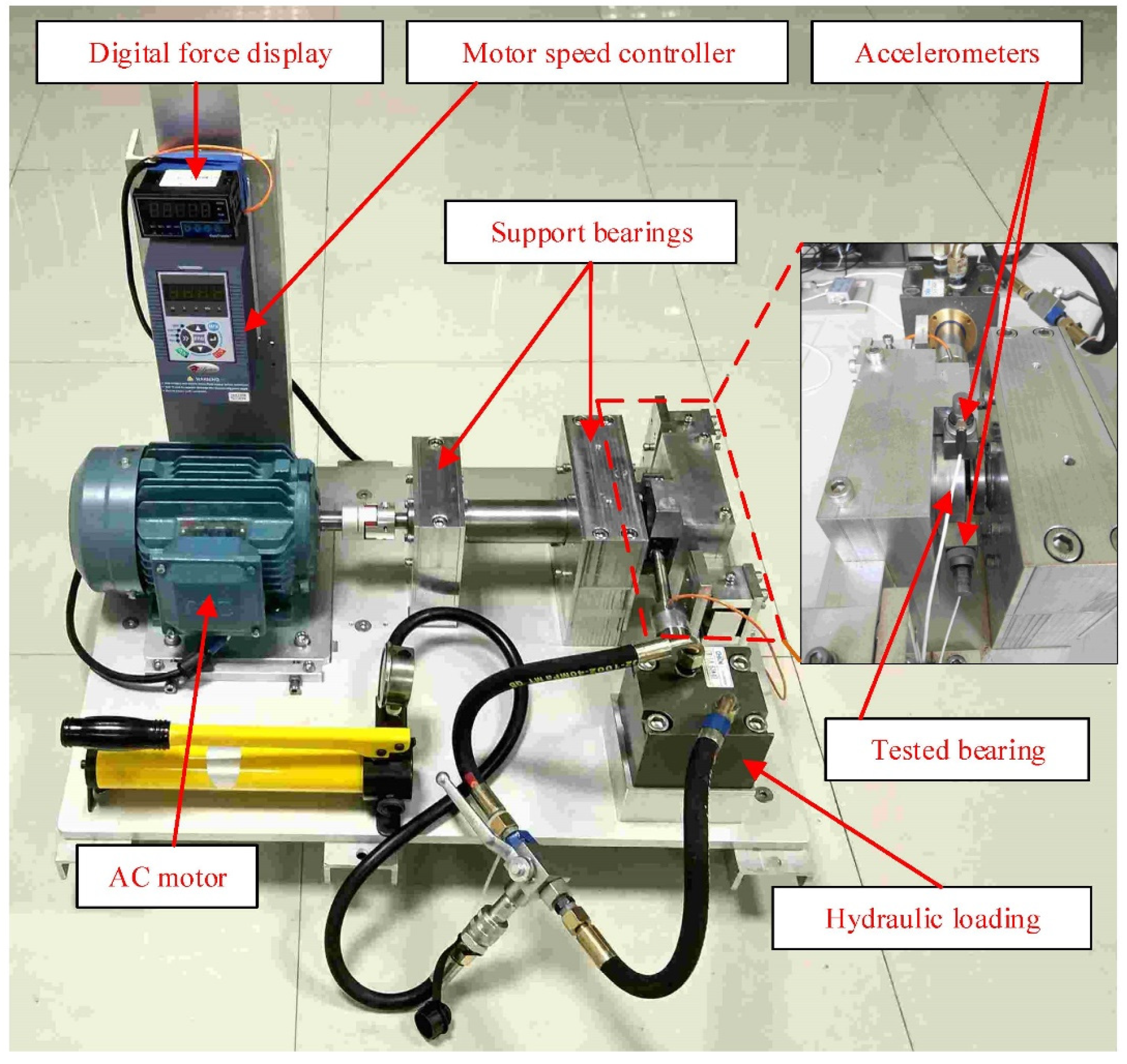

3.1. The Toolbar and Its Menus

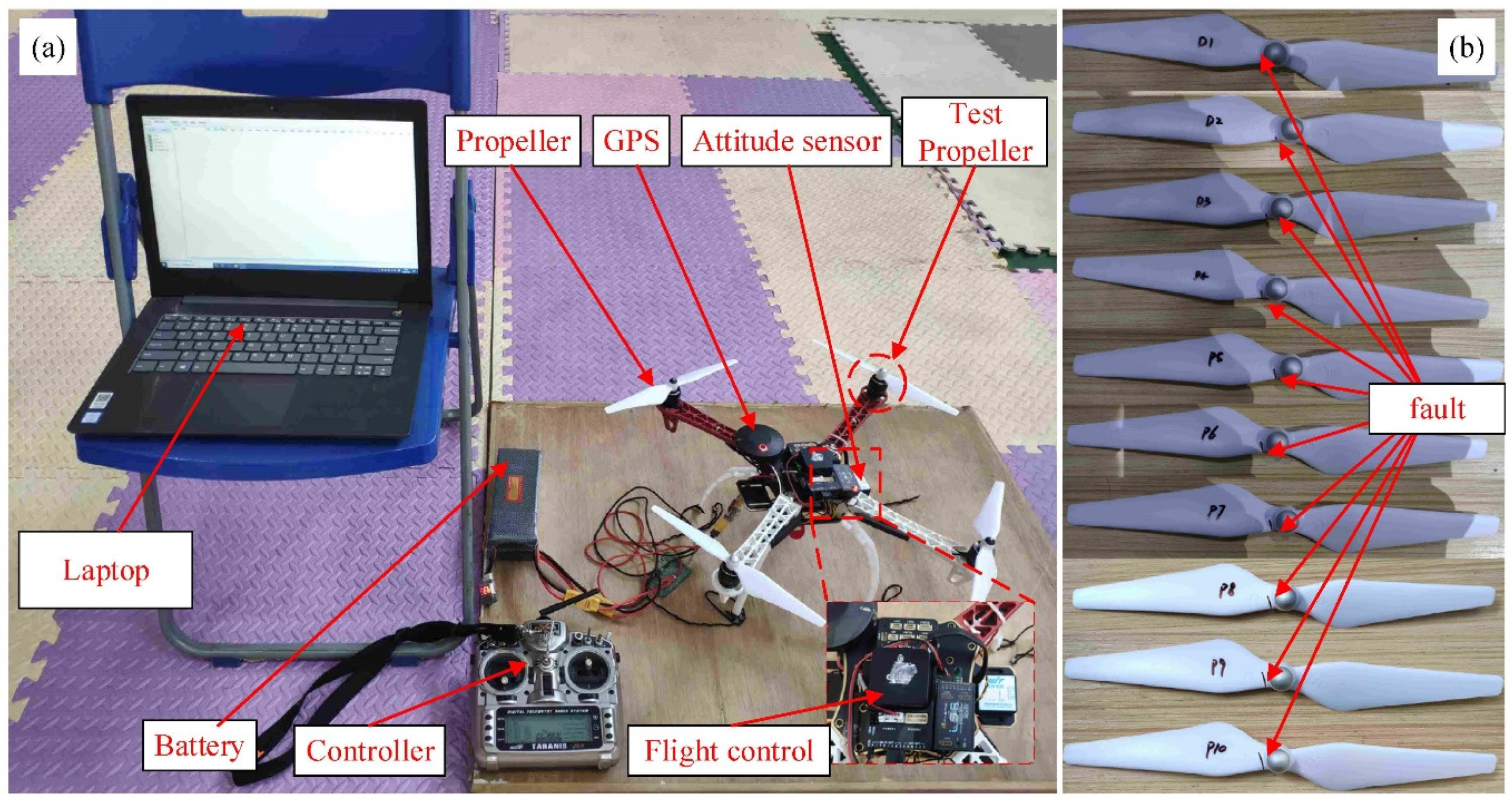

3.2. Experiments in Unmanned Aerial Vehicle

4. Validation of the Proposed Algorithm

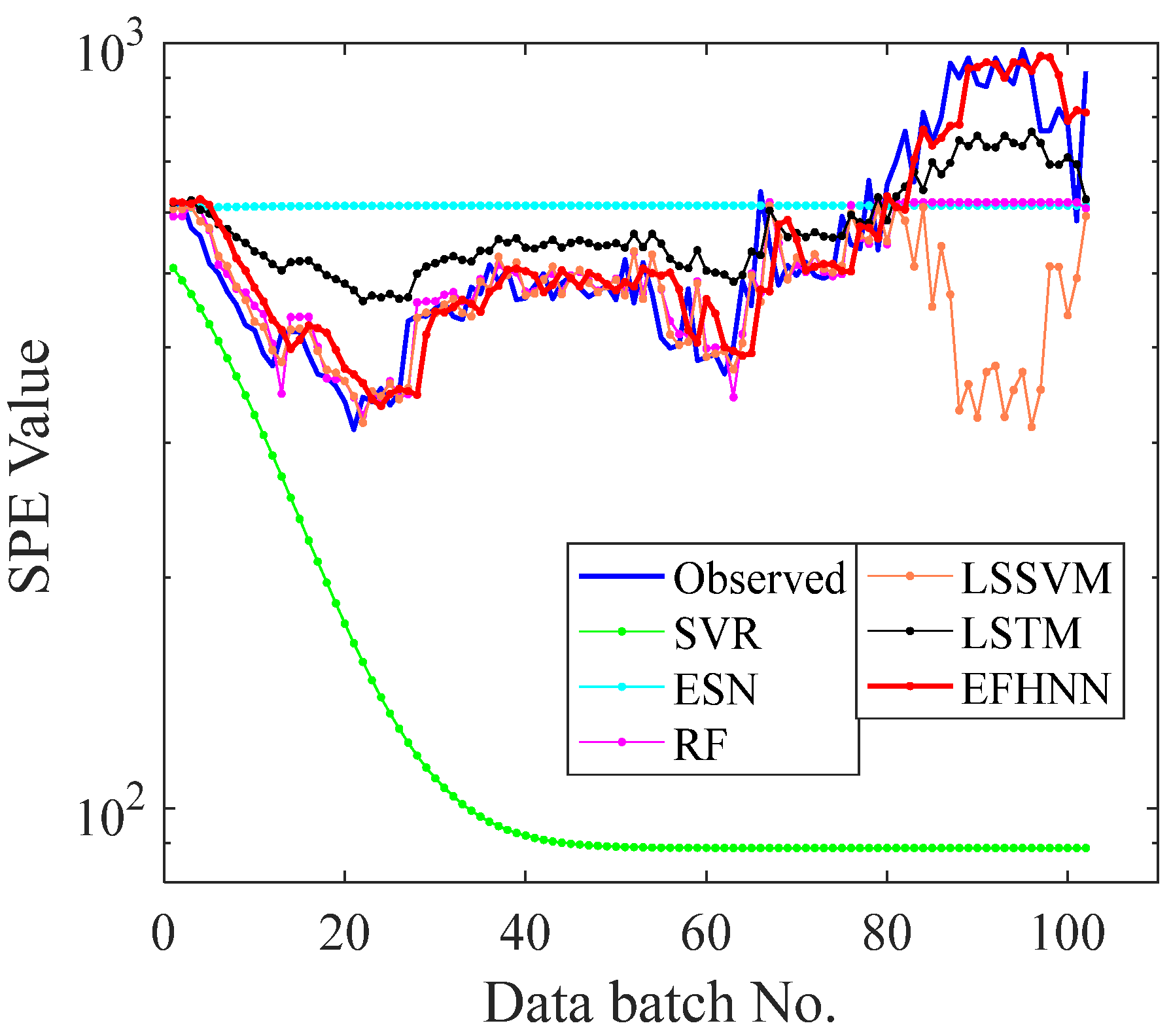

4.1. Validations Using Rolling Bearing Data

4.1.1. Data Preprocess and Parameter Set

4.1.2. Analysis and Discussion on Experimental Results of Bearing Operation

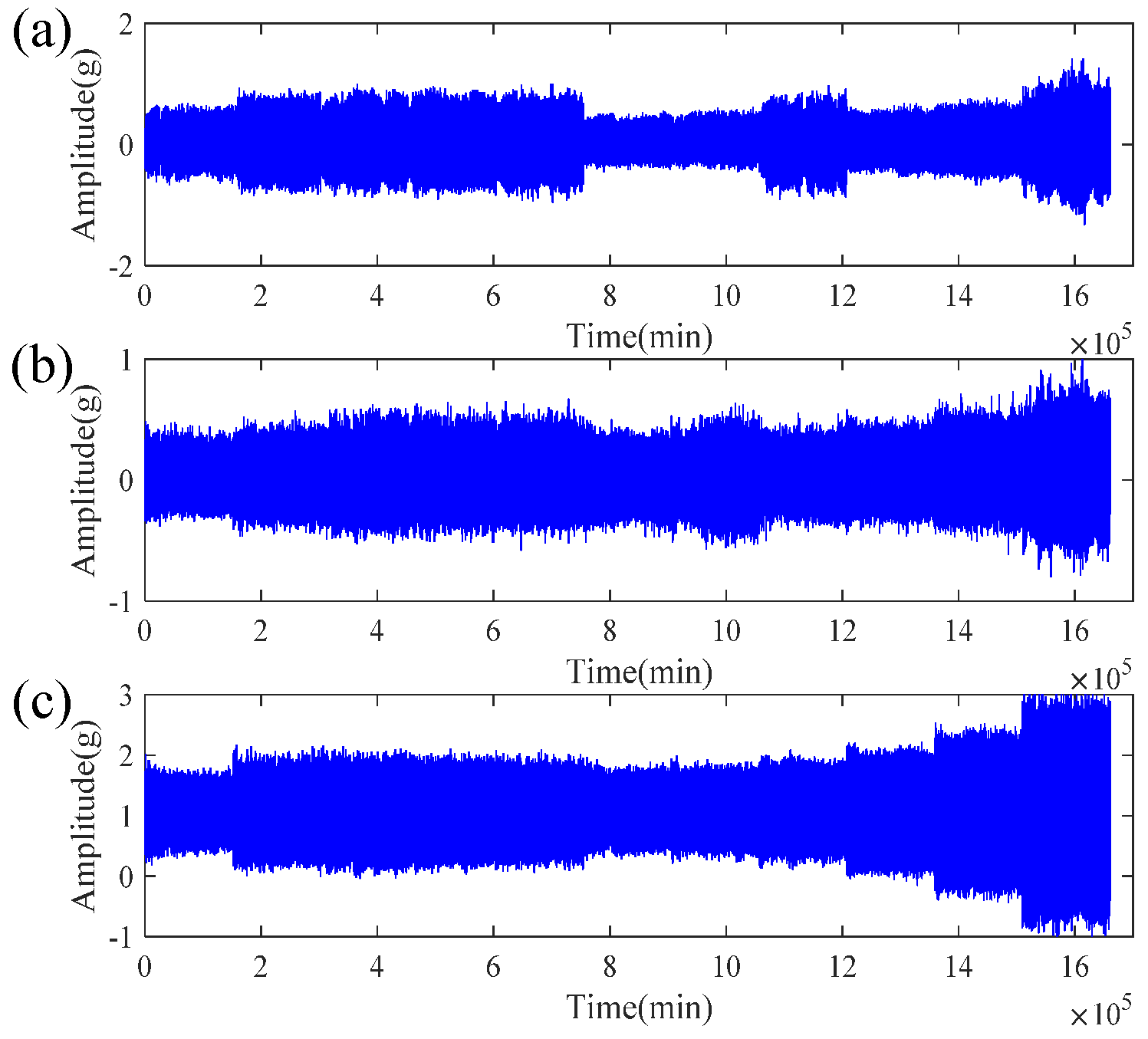

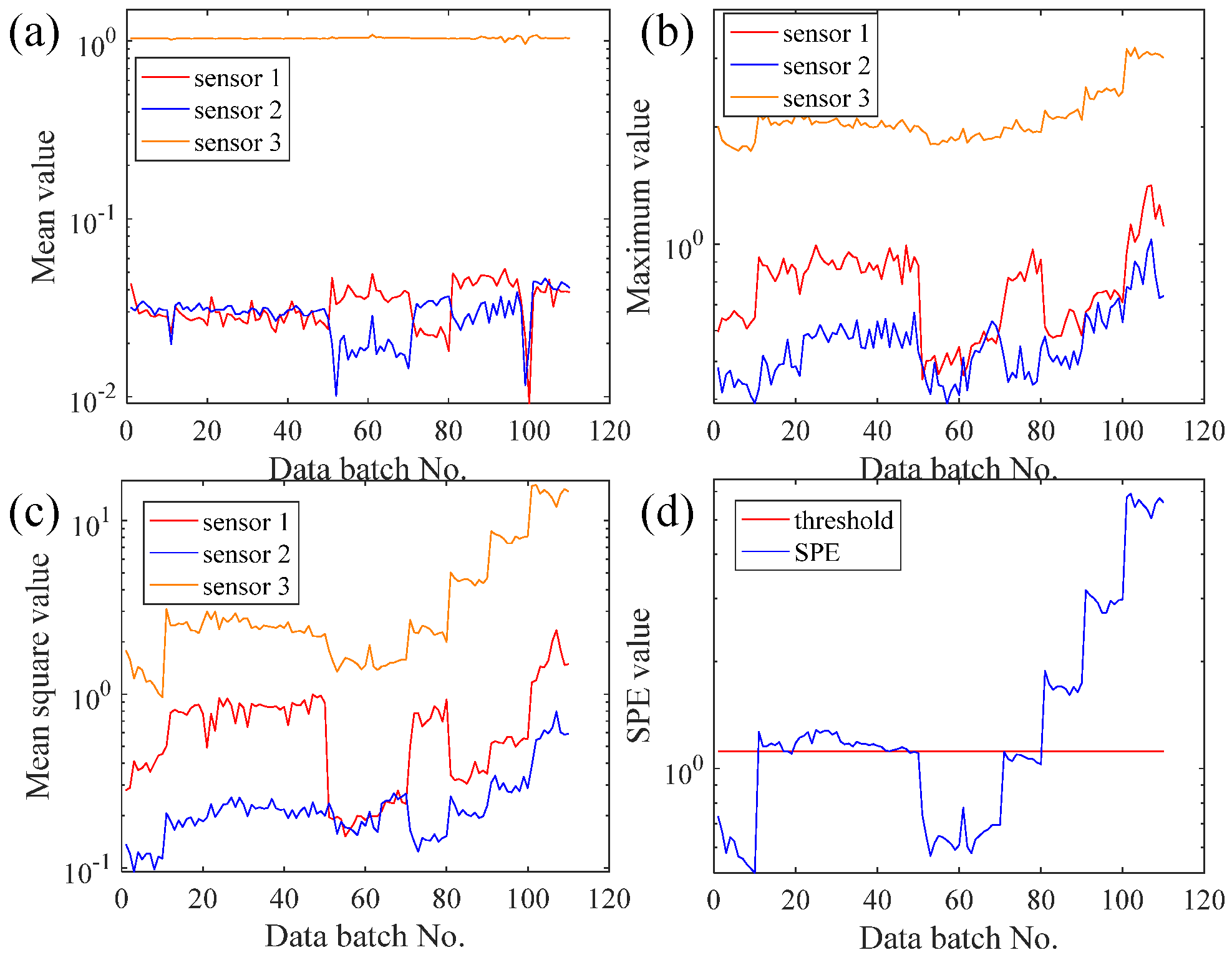

4.2. Validations Using Unmanned Aerial Vehicle Data

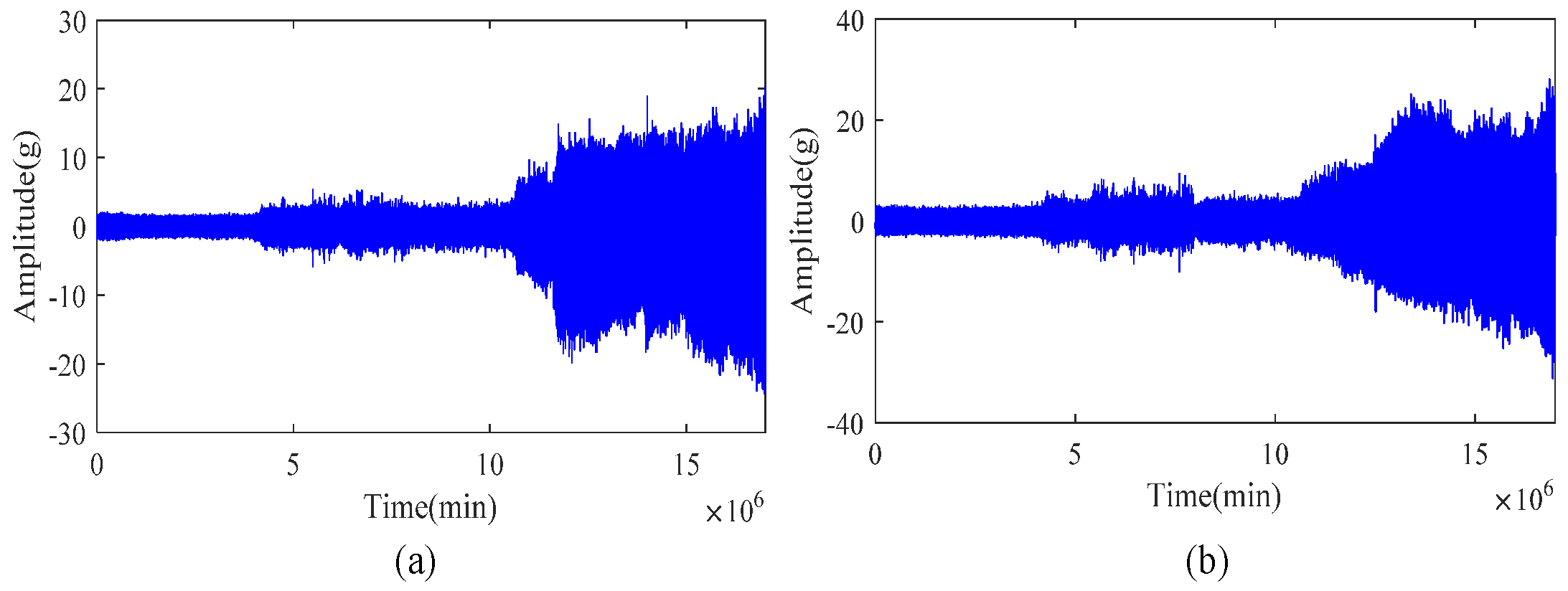

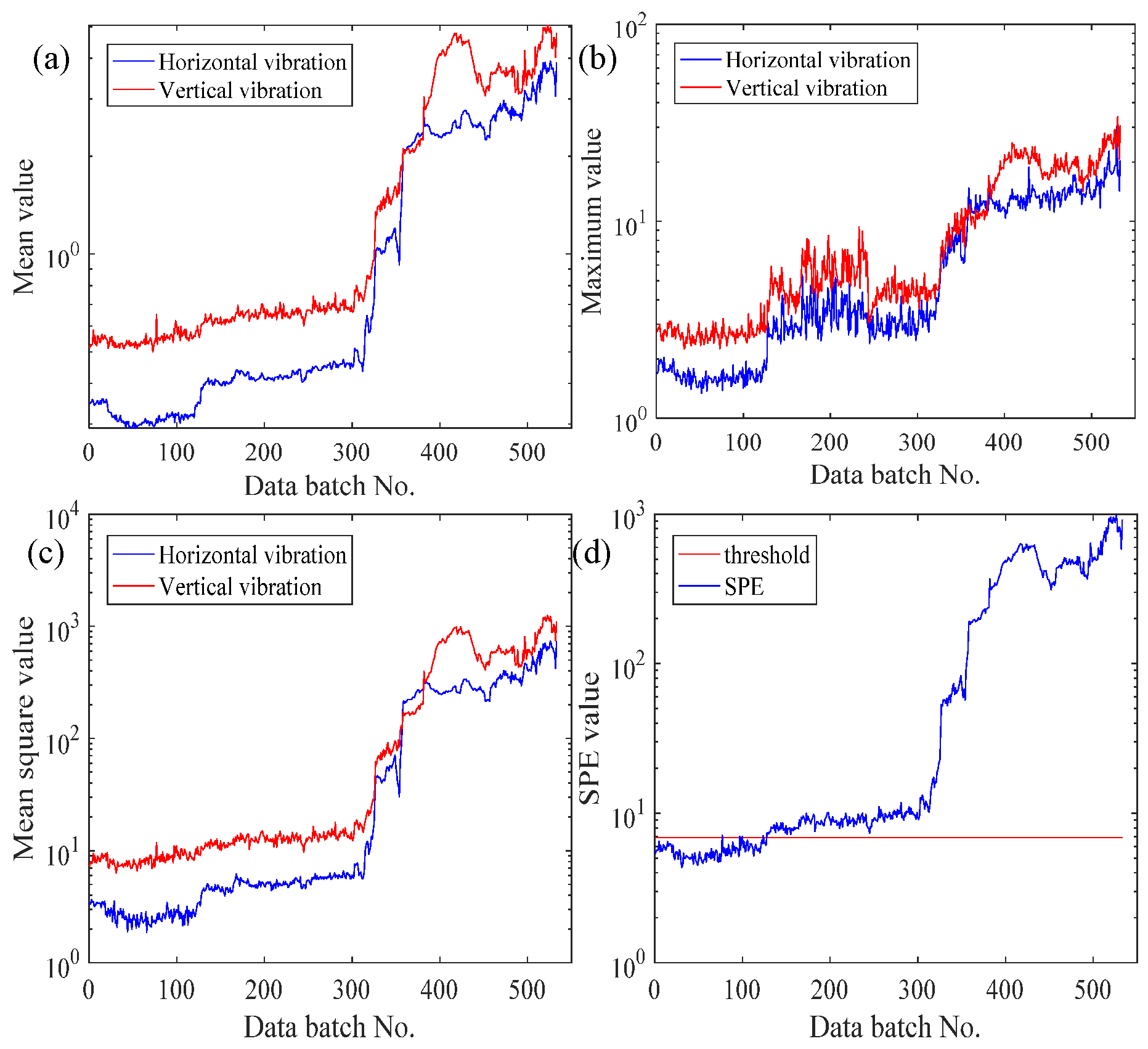

4.2.1. Data Preprocess and Parameter Set

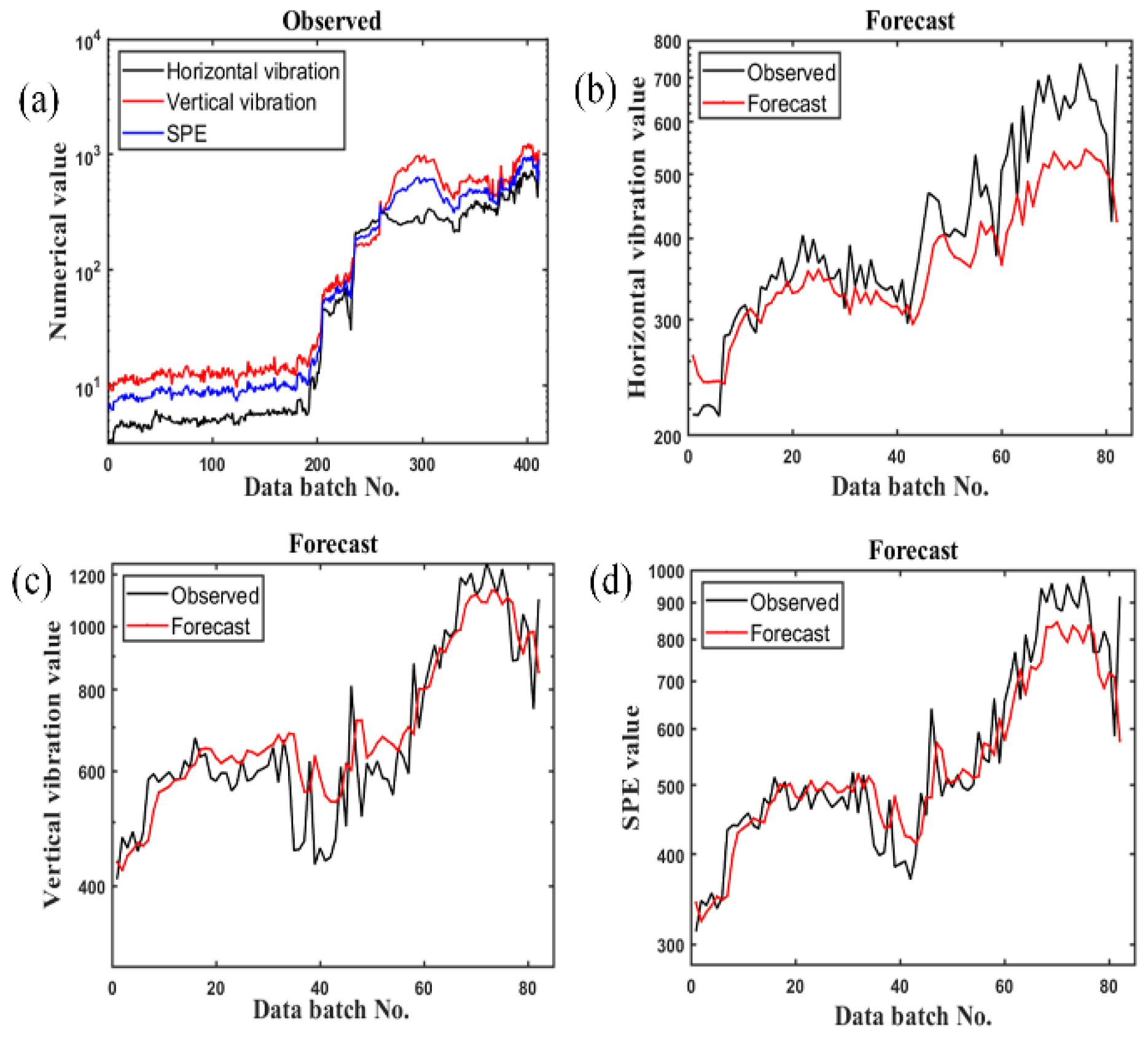

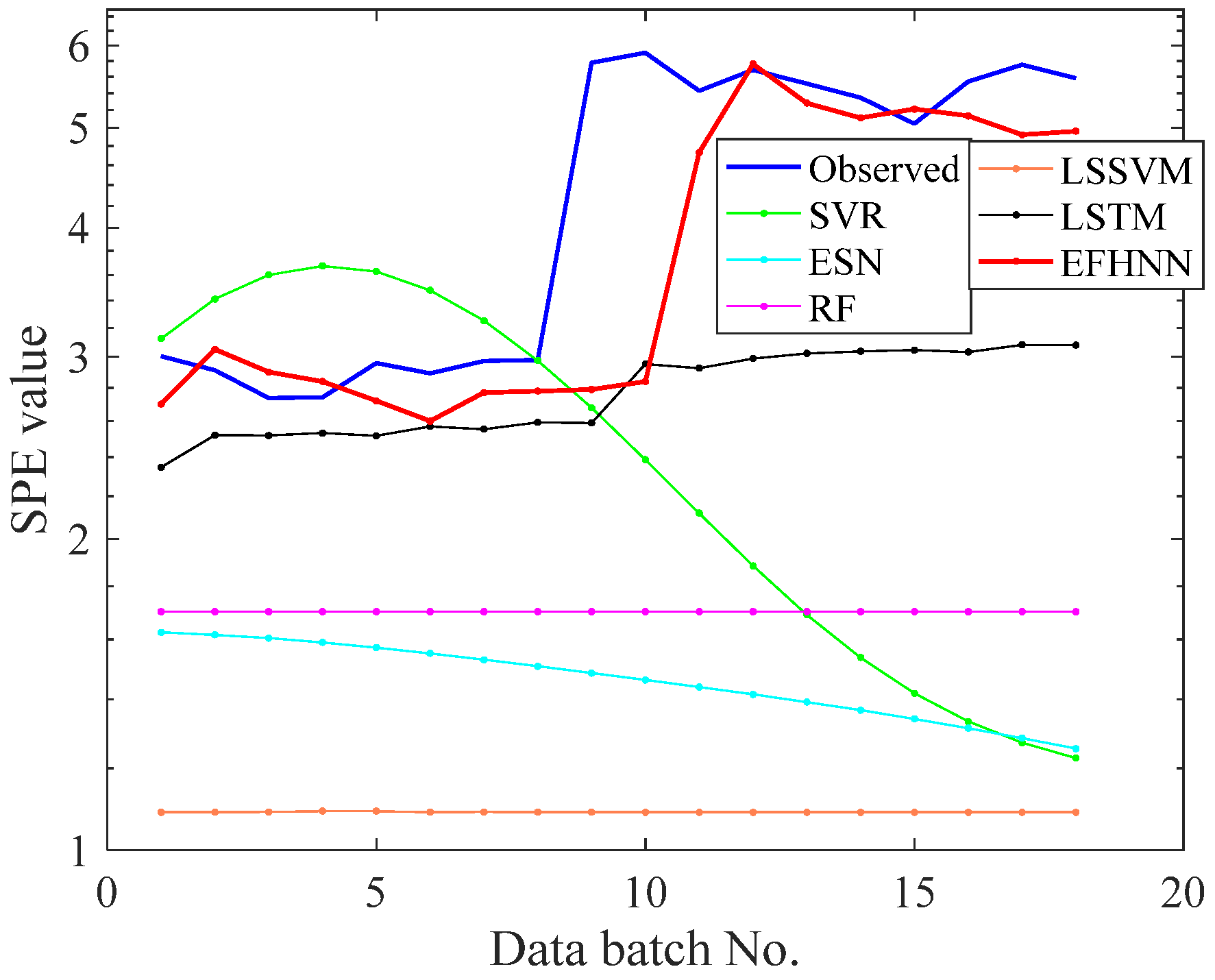

4.2.2. Analysis and Discussion on Experimental Results of Unmanned Aerial Vehicle

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, L.X.; Jin, W.J.; Pavel, R. Enhanced Restricted Boltzmann Machine with Prognosability Regularization for Prognostics and Health Assessment. IEEE Trans. Ind. Electron. 2016, 63, 7076–7083. [Google Scholar] [CrossRef]

- Peeters, C.; Guillaume, P.; Helsen, J. Vibration-based bearing fault detection for operations and maintenance cost reduction in wind energy. Renew. Energy 2018, 116, 74–87. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.Q.; Chen, Z.H.; Mao, K.Z.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Deutsch, J.; He, D. Using Deep Learning-Based Approach to Predict Remaining Useful Life of Rotating Components. IEEE Trans. Syst. Man Cybern. Syst. 2018, 48, 11–20. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, J.; Mo, R.; Zhang, X. In-process tool condition forecasting based on a deep learning method. Robot. Comput. Integr. Manuf. 2020, 64, 101924. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, D.Z.; Yan, R.Q.; Mao, K.Z.; Shen, F.; Wang, J.J. Machine Health Monitoring Using Local Feature-Based Gated Recurrent Unit Networks. IEEE Trans. Ind. Electron. 2018, 65, 1539–1548. [Google Scholar] [CrossRef]

- Shao, S.Y.; McAleer, S.; Yan, R.Q.; Baldi, P. Highly Accurate Machine Fault Diagnosis Using Deep Transfer Learning. IEEE Trans. Ind. Inform. 2019, 15, 2446–2455. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, G.; Zhu, Z.; Li, S. A novel deep learning method based on attention mechanism for bearing remaining useful life prediction. Appl. Soft Comput. 2020, 86, 105919. [Google Scholar] [CrossRef]

- Chang, W.-Y.; Wu, S.-J.; Hsu, J.-W. Investigated iterative convergences of neural network for prediction turning tool wear. Int. J. Adv. Manuf. Technol. 2020, 106, 2939–2948. [Google Scholar] [CrossRef]

- Fang, W.; Guo, Y.; Liao, W.; Ramani, K.; Huang, S. Big data driven jobs remaining time prediction in discrete manufacturing system: A deep learning-based approach. Int. J. Prod. Res. 2020, 58, 2751–2766. [Google Scholar] [CrossRef]

- Ren, L.; Cui, J.; Sun, Y.; Cheng, X. Multi-bearing remaining useful life collaborative prediction: A deep learning approach. J. Manuf. Syst. 2017, 43, 248–256. [Google Scholar] [CrossRef]

- Sun, C.; Ma, M.; Zhao, Z.; Tian, S.; Yan, R.; Chen, X. Deep transfer learning based on sparse autoencoder for remaining useful life prediction of tool in manufacturing. IEEE Trans. Ind. Inform. 2018, 15, 2416–2425. [Google Scholar] [CrossRef]

- Huang, M.; Liu, Z.; Tao, Y. Mechanical fault diagnosis and prediction in IoT based on multi-source sensing data fusion. Simul. Model. Pract. Theory 2020, 102, 101981. [Google Scholar] [CrossRef]

- Zachary, C.; David, C.; Charles, E.; Randall, W. Learning to Diagnose with LSTM Recurrent Neural Networks. In Proceedings of the International Conference on Learning Representations, ICLR 2016, San Juan, Puerto Rico, 2–4 May 2016. [Google Scholar]

- Wu, J.; Hu, K.; Cheng, Y.; Zhu, H.; Shao, X.; Wang, Y. Data-driven remaining useful life prediction via multiple sensor signals and deep long short-term memory neural network. ISA Trans. 2020, 97, 241–250. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.T.; Yuan, M.; Dong, S.P.; Lin, L.; Liu, Y.Q. Remaining useful life estimation of engineered systems using vanilla LSTM neural networks. Neurocomputing 2018, 275, 167–179. [Google Scholar] [CrossRef]

- Cai, W.; Zhang, W.; Hu, X.; Liu, Y. A hybrid information model based on long short-term memory network for tool condition monitoring. J. Intell. Manuf. 2020, 31, 1497–1510. [Google Scholar] [CrossRef]

- Wang, B.; Lei, Y.; Li, N.; Yan, T. Deep separable convolutional network for remaining useful life prediction of machinery. Mech. Syst. Signal Process. 2019, 134, 106330. [Google Scholar] [CrossRef]

- Huang, Z.; Zhu, J.; Lei, J.; Li, X.; Tian, F. Tool wear predicting based on multi-domain feature fusion by deep convolutional neural network in milling operations. J. Intell. Manuf. 2019, 31, 953–966. [Google Scholar] [CrossRef]

- Wang, J.; Yan, J.; Li, C.; Gao, R.X.; Zhao, R. Deep heterogeneous GRU model for predictive analytics in smart manufacturing: Application to tool wear prediction. Comput. Ind. 2019, 111, 1–14. [Google Scholar] [CrossRef]

- Duan, J.; Duan, J.; Zhou, H.; Zhang, X.; Li, T.; Shi, T. Multi-frequency-bands deep CNN model for tool wear prediction. Meas. Sci. Technol. 2020, 32, 065009. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Ding, Q. Deep learning-based remaining useful life estimation of bearings using multi-scale feature extraction. Reliab. Eng. Syst. Saf. 2019, 182, 208–218. [Google Scholar] [CrossRef]

- Wang, B.; Lei, Y.; Yan, T.; Li, N.; Guo, L. Recurrent convolutional neural network: A new framework for remaining useful life prediction of machinery. Neurocomputing 2020, 379, 117–129. [Google Scholar] [CrossRef]

- Fu, J.; Chu, J.; Guo, P.; Chen, Z. Condition monitoring of wind turbine gearbox bearing based on deep learning model. IEEE Access 2019, 7, 57078–57087. [Google Scholar] [CrossRef]

- Guo, J.; Lao, Z.; Hou, M.; Li, C.; Zhang, S. Mechanical fault time series prediction by using EFMSAE-LSTM neural network. Measurement 2020, 173, 108566. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, Z.; Long, J.; Li, C.; Bai, Y. Dynamic condition monitoring for 3D printers by using error fusion of multiple sparse auto-encoders. Comput. Ind. 2019, 105, 164–176. [Google Scholar] [CrossRef]

- Shin, H.C.; Orton, M.R.; Collins, D.J.; Doran, S.J.; Leach, M.O. Stacked Autoencoders for Unsupervised Feature Learning and Multiple Organ Detection in a Pilot Study Using 4D Patient Data. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 1930–1943. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.F.; Huang, B.; Wang, Y.L.; Yang, C.H.; Gui, W.H. Deep Learning-Based Feature Representation and Its Application for Soft Sensor Modeling with Variable-Wise Weighted SAE. IEEE Trans. Ind. Inform. 2018, 14, 3235–3243. [Google Scholar] [CrossRef]

- Hoseinzade, E.; Haratizadeh, S. CNNpred: CNN-based stock market prediction using a diverse set of variables. Expert Syst. Appl. 2019, 129, 273–285. [Google Scholar] [CrossRef]

- Rosas-Romero, R.; Guevara, E.; Peng, K.; Nguyen, D.K.; Lesage, F.; Pouliot, P.; Lima-Saad, W.E. Prediction of epileptic seizures with convolutional neural networks and functional near-infrared spectroscopy signals. Comput. Biol. Med. 2019, 111, 103355. [Google Scholar] [CrossRef]

- Qian, Y.; Yan, R.; Gao, R.X. A multi-time scale approach to remaining useful life prediction in rolling bearing. Mech. Syst. Signal Process. 2017, 83, 549–567. [Google Scholar] [CrossRef] [Green Version]

- Lei, Y.; Han, T.; Wang, B.; Li, N.; Yan, T.; Yang, J. Interpretation of XJTU-SY rolling bearing accelerated life tested dataset. Chin. J. Mech. Eng. 2019, 55, 1–6. [Google Scholar]

| Operating Condition | Radial Force (kN) | Rotating Speed (rpm) | Bearing Dataset |

|---|---|---|---|

| 1 | 11 | 2250 | Bearing2_3 Bearing2_5 |

| 2 | 10 | 2400 | Bearing3_4 |

| Curve | MSE | RMSE | MAE | MAPE |

|---|---|---|---|---|

| H-mean square value | 9.80 × 103 | 98.50 | 70.05 | 13.79 |

| V-mean square value | 9.73 × 103 | 98.61 | 72.81 | 10.52 |

| SPE value | 7.00 × 103 | 82.42 | 59.35 | 9.71 |

| Bearing Type | Method | RMSE | MAE | MAPE |

|---|---|---|---|---|

| Bearing 2_3 | SVR | 449.10 | 389.23 | 68.58 |

| ESN | 182.60 | 161.54 | 32.74 | |

| RF | 115.53 | 72.23 | 10.89 | |

| LSSVM | 197.66 | 105.22 | 14.48 | |

| LSTM [32] | 105.67 | 90.94 | 17.87 | |

| EFHNN | 66.83 | 49.23 | 9.17 | |

| Bearing 2_5 | SVR | 1505.93 | 1255.15 | 68.11 |

| ESN | 1045.14 | 894.17 | 54.91 | |

| RF | 950.96 | 716.35 | 35.22 | |

| LSSVM | 1296.33 | 974.10 | 47.27 | |

| LSTM [32] | 673.44 | 503.12 | 25.03 | |

| EFHNN | 299.86 | 212.78 | 12.92 | |

| Bearing 3_4 | SVR | 268.87 | 117.70 | 40.11 |

| ESN | 268.93 | 117.51 | 36.21 | |

| RF | 268.36 | 116.91 | 32.65 | |

| LSSVM | 268.87 | 117.27 | 32.87 | |

| LSTM [32] | 268.02 | 116.63 | 31.83 | |

| EFHNN | 72.10 | 24.73 | 15.72 |

| Method | RMSE | MAE | MAPE |

|---|---|---|---|

| SVR | 2.67 | 2.06 | 41.77 |

| ESN | 3.04 | 2.64 | 58.07 |

| RF | 2.80 | 2.43 | 53.27 |

| LSSVM | 3.34 | 3.02 | 68.89 |

| LSTM [32] | 2.26 | 1.92 | 41.54 |

| EFHNN | 1.07 | 0.61 | 12.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liu, Y.; Zhang, S.; Long, T.; Liang, J. Error Fusion of Hybrid Neural Networks for Mechanical Condition Dynamic Prediction. Sensors 2021, 21, 4043. https://doi.org/10.3390/s21124043

Zhang W, Liu Y, Zhang S, Long T, Liang J. Error Fusion of Hybrid Neural Networks for Mechanical Condition Dynamic Prediction. Sensors. 2021; 21(12):4043. https://doi.org/10.3390/s21124043

Chicago/Turabian StyleZhang, Wentao, Yucheng Liu, Shaohui Zhang, Tuzhi Long, and Jinglun Liang. 2021. "Error Fusion of Hybrid Neural Networks for Mechanical Condition Dynamic Prediction" Sensors 21, no. 12: 4043. https://doi.org/10.3390/s21124043

APA StyleZhang, W., Liu, Y., Zhang, S., Long, T., & Liang, J. (2021). Error Fusion of Hybrid Neural Networks for Mechanical Condition Dynamic Prediction. Sensors, 21(12), 4043. https://doi.org/10.3390/s21124043