Remaining Useful Life Prognostics of Bearings Based on a Novel Spatial Graph-Temporal Convolution Network

Abstract

:1. Introduction

2. Preliminaries

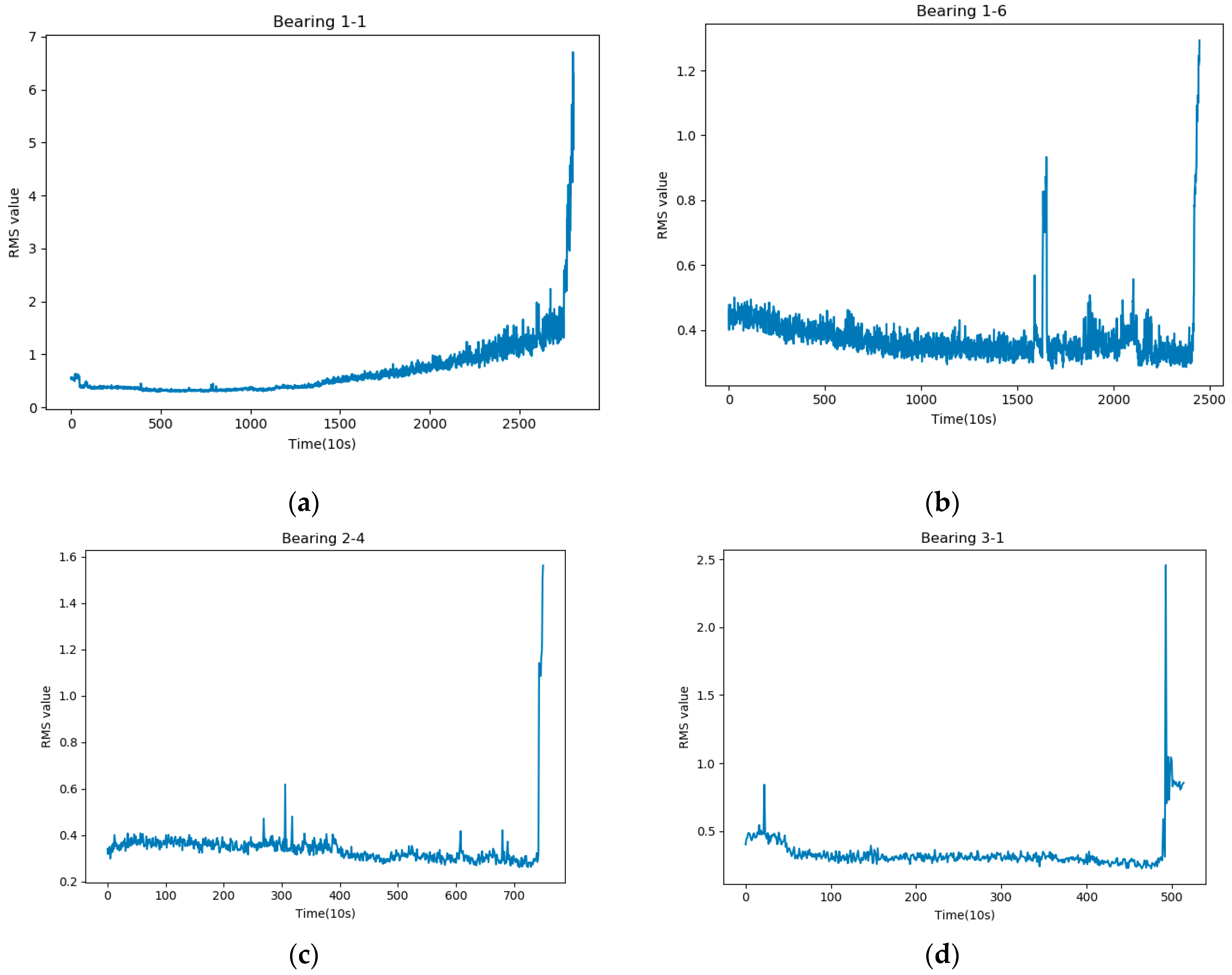

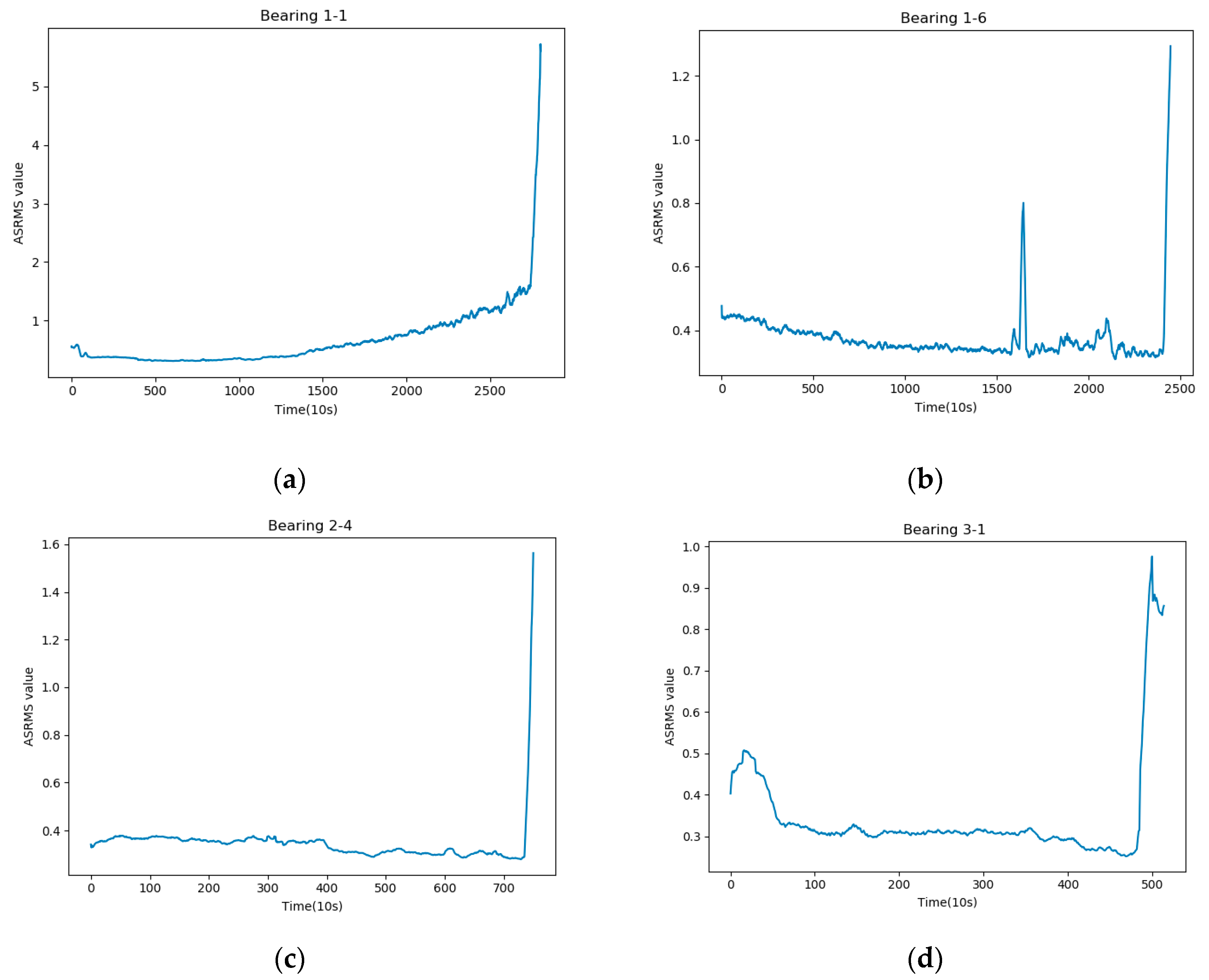

2.1. Average Sliding Root Mean Square Value

2.2. Spatial Graph-Temporal Convolution

2.2.1. Spatial Graph Convolution

2.2.2. Temporal Convolution

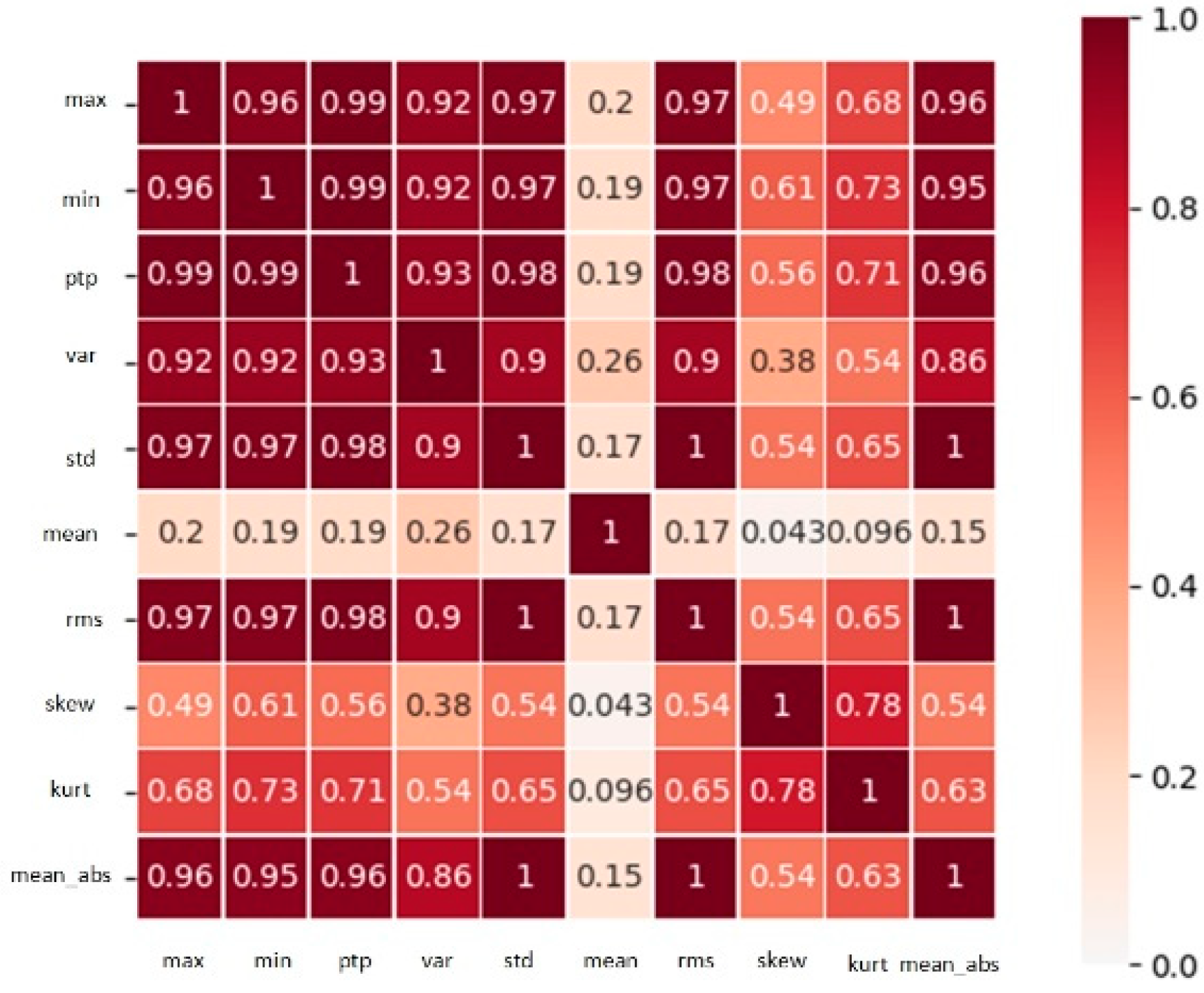

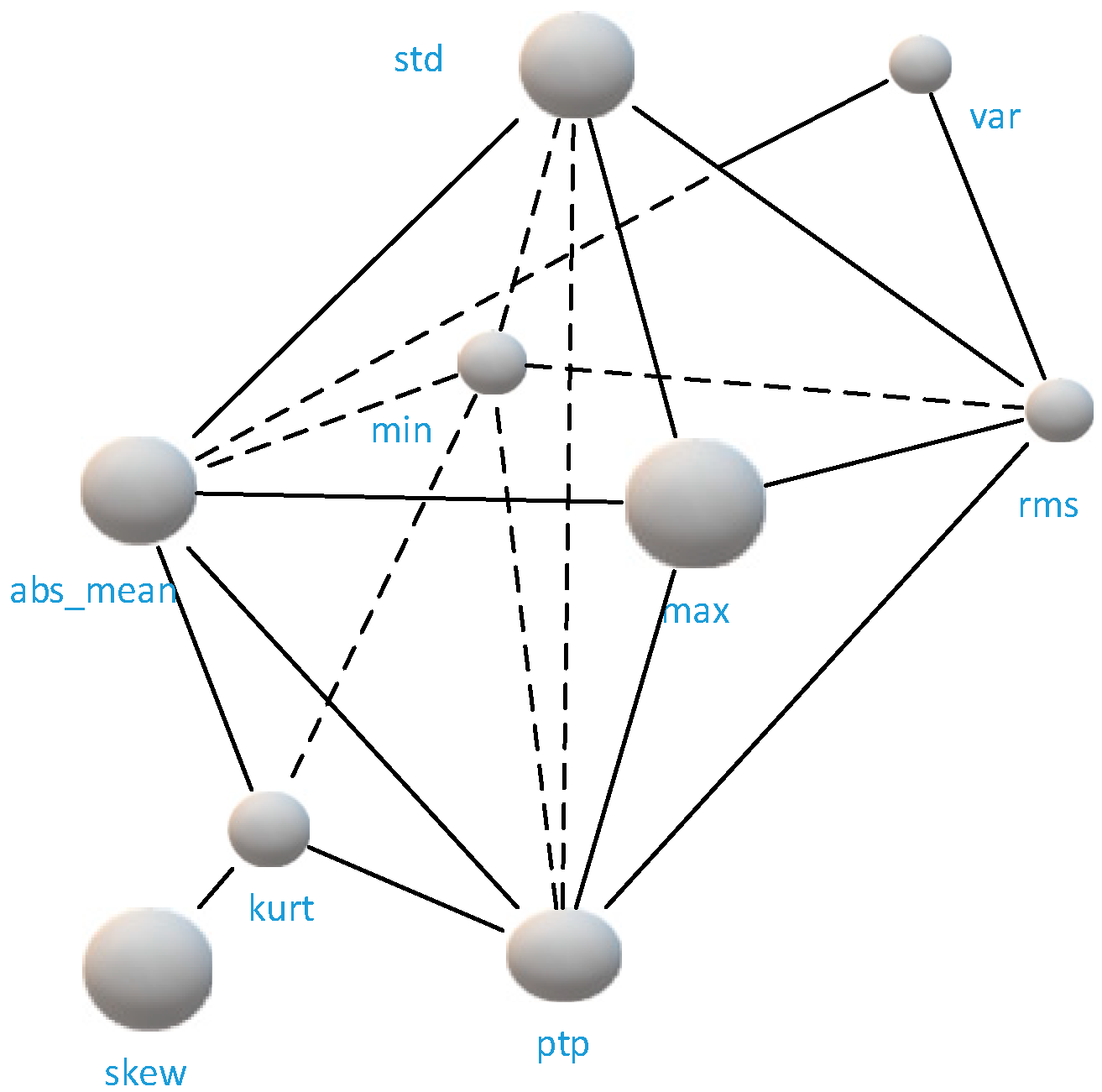

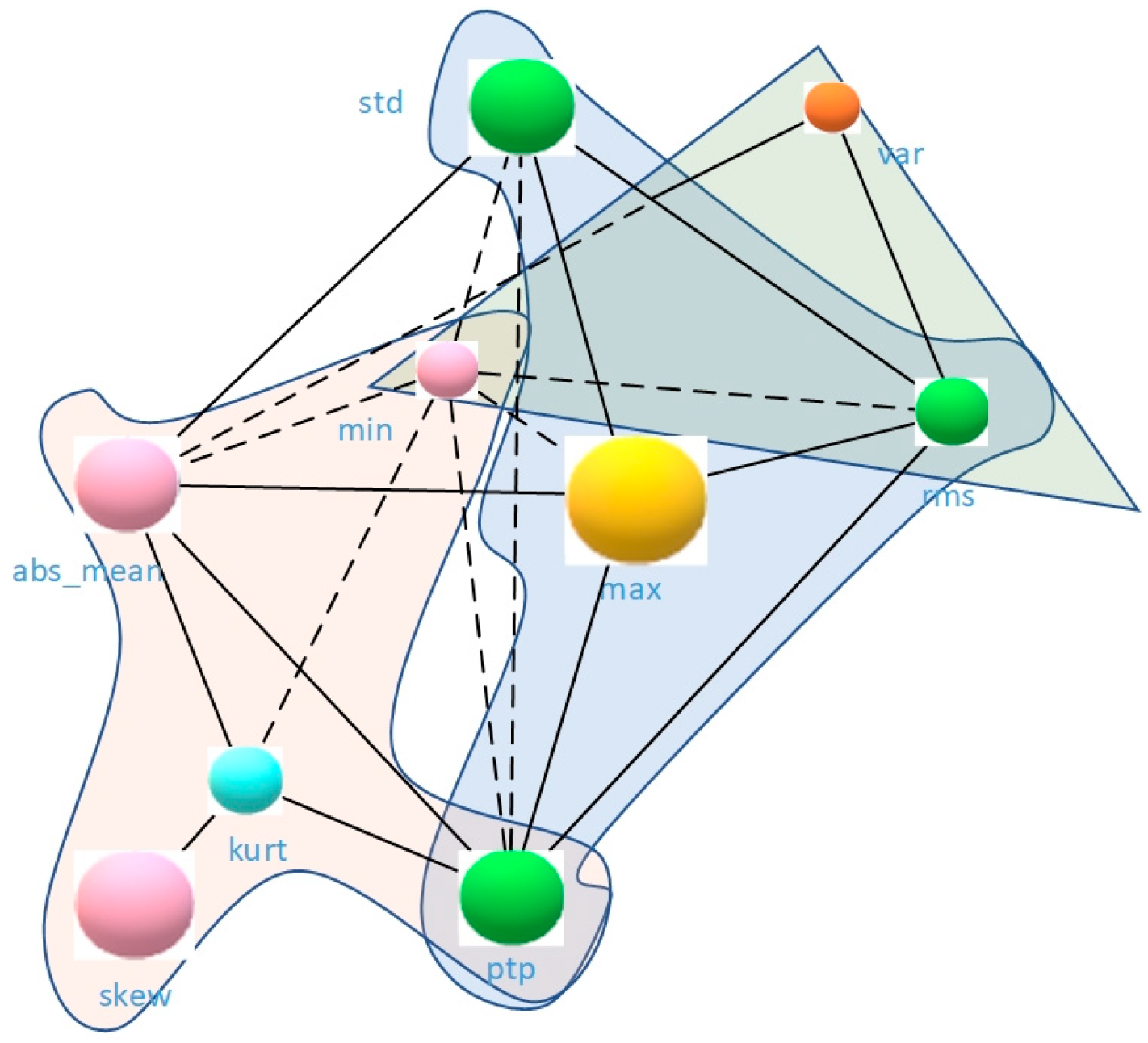

2.3. Spatial Domain Construction of Bearings

3. Proposed Method

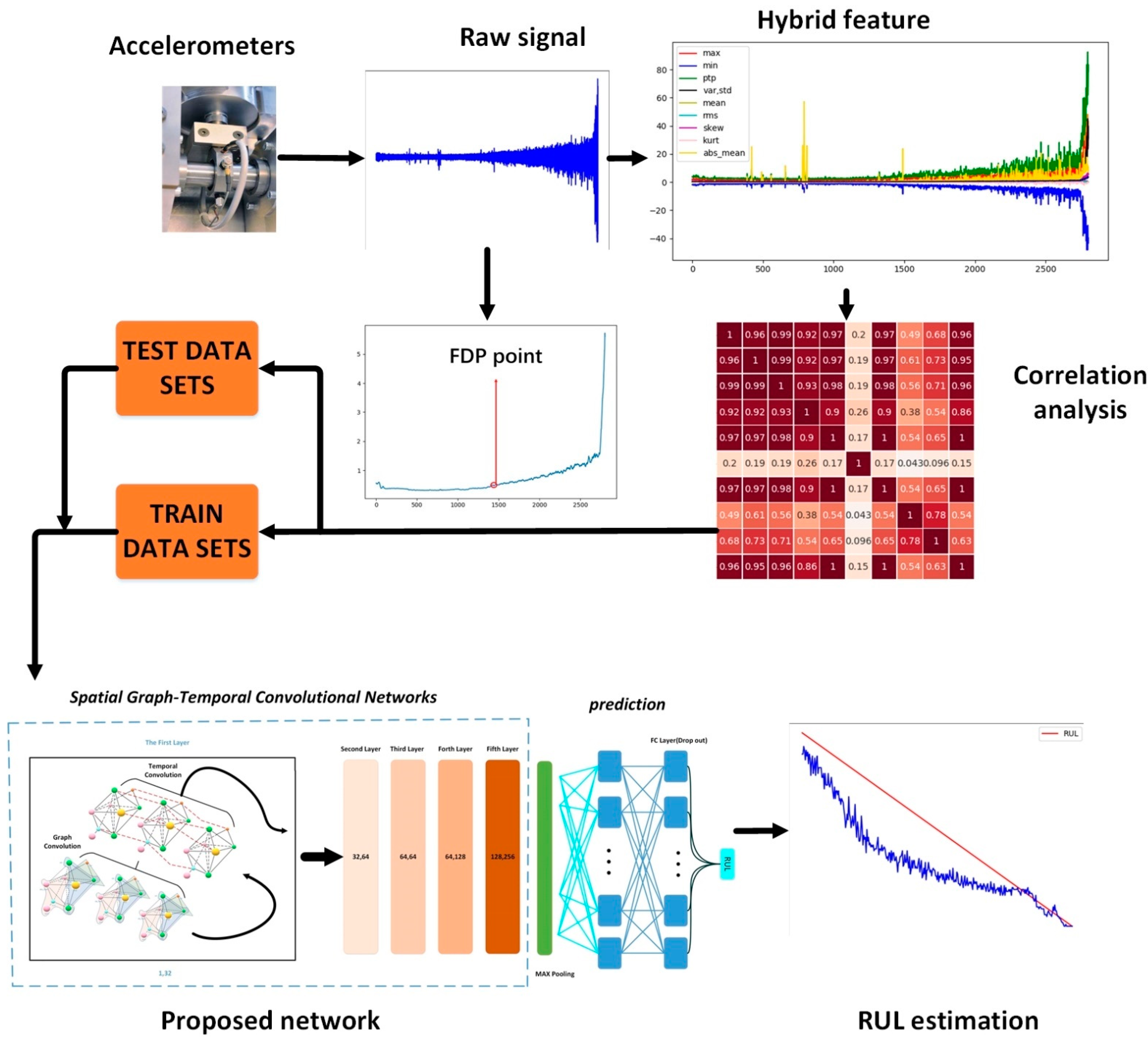

3.1. Structure of the Proposed Spatial Graph-Temporal Convolution Network

3.2. Flow Chart of the Rul Prognostics Method

3.3. Training Details and Evaluation Indexes

4. Experiments

4.1. Data Sets Description

4.2. Experimental Results

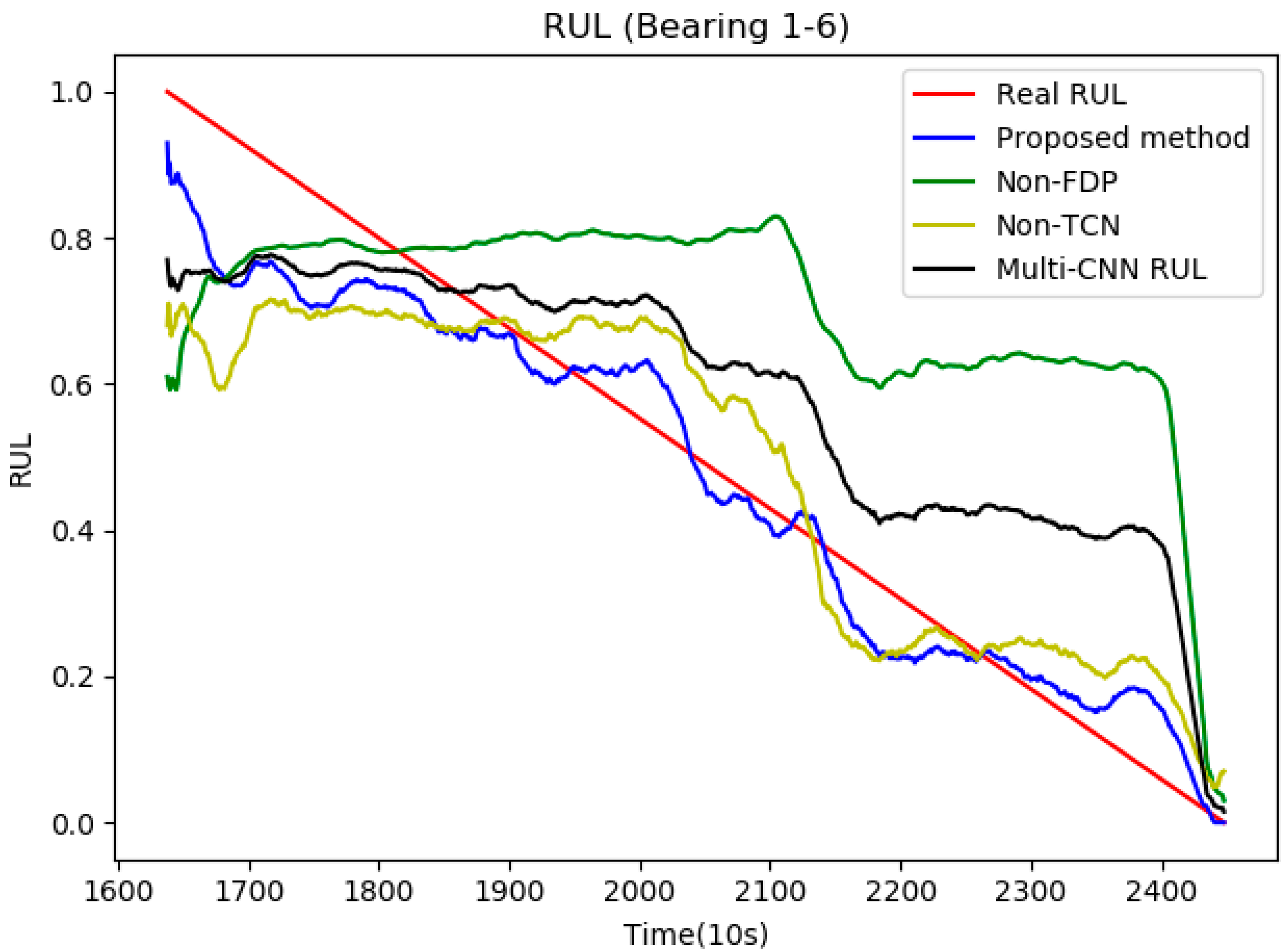

4.3. Comparison with Other Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, S.; Kang, R.; He, X.; Pecht, M.G. China’s Efforts in Prognostics and Health Management. IEEE Trans. Components Packag. Technol. 2008, 31, 509–518. [Google Scholar] [CrossRef]

- Li, R.; Verhagen, W.J.; Curran, R. A systematic methodology for Prognostic and Health Management system architecture definition. Reliab. Eng. Syst. Saf. 2020, 193, 106598. [Google Scholar] [CrossRef]

- Liu, Z.; Jia, Z.; Vong, C.-M.; Han, J.; Yan, C.; Pecht, M. A Patent Analysis of Prognostics and Health Management (PHM) Innovations for Electrical Systems. IEEE Access 2018, 6, 18088–18107. [Google Scholar] [CrossRef]

- Lee, J.; Wu, F.; Zhao, W.; Ghaffari, M.; Liao, L.; Siegel, D. Prognostics and health management design for rotary machinery systems—Reviews, methodology and applications. Mech. Syst. Signal Process. 2014, 42, 314–334. [Google Scholar] [CrossRef]

- Vogl, G.W.; Weiss, B.A.; Helu, M. A review of diagnostic and prognostic capabilities and best practices for manufacturing. J. Intell. Manuf. 2019, 30, 79–95. [Google Scholar] [CrossRef] [PubMed]

- Sui, W.; Zhang, D.; Qiu, X.; Zhang, W.; Yuan, L. Prediction of Bearing Remaining Useful Life based on Mutual Information and Support Vector Regression Model. IOP Conf. Ser. Mater. Sci. Eng. 2019, 533, 012032. [Google Scholar] [CrossRef]

- Rai, A.; Upadhyay, S.H. Intelligent bearing performance degradation assessment and remaining useful life prediction based on self-organising map and support vector regression. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 1118–1132. [Google Scholar] [CrossRef]

- Wang, Z.-Q.; Hu, C.-H.; Fan, H.-D. Real-Time Remaining Useful Life Prediction for a Nonlinear Degrading System in Service: Application to Bearing Data. IEEE/ASME Trans. Mechatron. 2018, 23, 211–222. [Google Scholar] [CrossRef]

- Ren, L.; Cui, J.; Sun, Y.; Cheng, X. Multi-bearing remaining useful life collaborative prediction: A deep learning approach. J. Manuf. Syst. 2017, 43, 248–256. [Google Scholar] [CrossRef]

- Liu, Z.; Zuo, M.J.; Qin, Y. Remaining useful life prediction of rolling element bearings based on health state assessment. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 314–330. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Lei, Y.; Li, N.; Li, N. A Hybrid Prognostics Approach for Estimating Remaining Useful Life of Rolling Element Bearings. IEEE Trans. Reliab. 2020, 69, 401–412. [Google Scholar] [CrossRef]

- Cui, L.; Wang, X.; Wang, H.; Ma, J. Research on Remaining Useful Life Prediction of Rolling Element Bearings Based on Time-Varying Kalman Filter. IEEE Trans. Instrum. Meas. 2020, 69, 2858–2867. [Google Scholar] [CrossRef]

- Zhang, C.; Lim, P.; Qin, A.K.; Tan, K.C. Multiobjective Deep Belief Networks Ensemble for Remaining Useful Life Estimation in Prognostics. IEEE Trans. Neural Netw. Learn. Syst. 2017, 28, 2306–2318. [Google Scholar] [CrossRef]

- Pecht, M.; Gu, J. Physics-of-failure-based prognostics for electronic products. Trans. Inst. Meas. Control. 2009, 31, 309–322. [Google Scholar] [CrossRef]

- Heimes, F.O. Recurrent neural networks for remaining useful life estimation. In Proceedings of the 2008 International Conference on Prognostics and Health Management, Denver, CO, USA, 6–9 October 2008; pp. 1–6. [Google Scholar]

- Heng, A.; Zhang, S.; Tan, A.C.; Mathew, J. Rotating machinery prognostics: State of the art, challenges and opportunities. Mech. Syst. Signal Process. 2009, 23, 724–739. [Google Scholar] [CrossRef]

- Cheng, S.; Pecht, M. A fusion prognostics method for remaining useful life prediction of electronic products. In Proceedings of the 2009 IEEE International Conference on Automation Science and Engineering, Bangalore, India, 22–25 August 2009; pp. 102–107. [Google Scholar]

- Yang, J.; Yin, S.; Chang, Y.; Gao, T.; Yang, C. An Efficient Method for Monitoring Degradation and Predicting the Remaining Useful Life of Mechanical Rotating Components. IEEE Trans. Instrum. Meas. 2021, 70, 1–14. [Google Scholar] [CrossRef]

- Shao, Y.; Nezu, K. Prognosis of remaining bearing life using neural networks. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2000, 214, 217–230. [Google Scholar] [CrossRef]

- Powell, M.J.D. Radial basis functions for multivariable interpolation: A review. In IMA Conference on Algorithms for the Approximation of Functions and Data; Clarendon Press: Oxford, UK, 1987. [Google Scholar]

- Bors, A.G. Introduction of the Radial Basis Function (RBF) Networks. Online Symp. Electron. Eng. 1996, 1, 1–7. [Google Scholar]

- Chen, X.; Xiao, H.; Guo, Y.; Kang, Q. A multivariate grey RBF hybrid model for residual useful life prediction of industrial equipment based on state data. Int. J. Wirel. Mob. Comput. 2016, 10, 90–96. [Google Scholar] [CrossRef]

- Liu, F.; Liu, Y.; Chen, F.; He, B. Residual life prediction for ball bearings based on joint approximate diagonalization of eigen matrices and extreme learning machine. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 231, 1699–1711. [Google Scholar] [CrossRef]

- Pan, Z.; Meng, Z.; Chen, Z.; Wenqing, G.; Ying, S. A two-stage method based on extreme learning machine for predicting the remaining useful life of rolling-element bearings. Mech. Syst. Signal Process. 2020, 144, 106899. [Google Scholar] [CrossRef]

- Guo, L.; Li, N.; Jia, F. A recurrent neural network-based health indicator for remaining useful life prediction of bearings. Neurocomputing 2017, 240, 98–109. [Google Scholar] [CrossRef]

- Hou, M.; Pi, D.; Li, B. Similarity-based deep learning approach for remaining useful life prediction. Measurement 2020, 159. [Google Scholar] [CrossRef]

- Hinton, G.E.; Salakhutdinov, R.R. Reducing the Dimensionality of Data with Neural Networks. Science 2006, 313, 504–507. [Google Scholar] [CrossRef] [Green Version]

- Hu, C.-H.; Pei, H.; Si, X.-S.; Du, D.-B.; Pang, Z.-N.; Wang, X. A Prognostic Model Based on DBN and Diffusion Process for Degrading Bearing. IEEE Trans. Ind. Electron. 2019, 67, 8767–8777. [Google Scholar] [CrossRef]

- Lawrence, S.; Giles, C.L.; Tsoi, A.C.; Back, A.D. Face recognition: A convolutional neural-network approach. IEEE Trans. Neural Netw. 1997, 8, 98–113. [Google Scholar] [CrossRef] [Green Version]

- Song, Z.; Sun, M. Learning Pooling for Convolutional Neural Network. Neurocomputing 2017, 224, 96–104. [Google Scholar] [CrossRef]

- Xiang, L.; Wei, Z.; Qian, D. Deep learning-based remaining useful life estimation of bearings using multi-scale feature extraction. Reliab. Eng. Syst. Saf. 2019, 182, 208–218. [Google Scholar] [CrossRef]

- Li, X.; Ding, Q.; Sun, J.Q. Remaining useful life estimation in prognostics using deep convolution neural networks. Reliab. Eng. Syst. Saf. 2018, 172, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Zhang, W.; Ma, H.; Luo, Z.; Li, X. Data alignments in machinery remaining useful life prediction using deep adversarial neural networks. Knowl. Based Syst. 2020, 197, 105843. [Google Scholar] [CrossRef]

- Radford, A.; Metz, L.; Chintala, S. Unsupervised Representation Learning with Deep Convolutional Generative Adversarial Networks. arXiv 2016, arXiv:1511.06434. [Google Scholar]

- Dechen, Y.; Boyang, L.; Hengchang, L.; Jianwei, Y.; Limin, J. Remaining Useful Life Prediction of Roller Bearings based on Improved 1D-CNN and Simple Recurrent Unit. Measurement 2021, 175, 109166. [Google Scholar] [CrossRef]

- Atwood, J.; Siddharth, P.; Don, T.; Ananthram, S. Sparse Diffusion-Convolutional Neural Networks. arXiv 2017, arXiv:1710.09813. [Google Scholar]

- Yang, B.; Pan, H.; Yu, J.; Han, K.; Wang, Y. Classification of Medical Images with Synergic Graph Convolutional Networks. In Proceedings of the 2019 IEEE 35th International Conference on Data Engineering Workshops (ICDEW), Macao, China, 8–12 April 2019; pp. 253–258. [Google Scholar]

- Kipf, T.N.; Welling, M. Semi-Supervised Classification with Graph Convolutional Networks. arXiv 2017, arXiv:160902907. [Google Scholar]

- Cui, Z.; Henrickson, K.; Ke, R.; Wang, Y. Traffic Graph Convolutional Recurrent Neural Network: A Deep Learning Framework for Network-Scale Traffic Learning and Forecasting. IEEE Trans. Intell. Transp. Syst. 2020, 21, 4883–4894. [Google Scholar] [CrossRef] [Green Version]

- Lea, C.; Vidal, R.; Reiter, A.; Hager, G.D. Temporal Convolutional Networks: A Unified Approach to Action Segmentation. In European Conference on Computer Vision; Springer International Publishing: Cham, Switzerland, 2016; pp. 47–54. [Google Scholar] [CrossRef] [Green Version]

- Rethage, D.; Pons, J.; Serra, X. A Wavenet for Speech Denoising. In Proceedings of the 2018 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Calgary, AB, Canada, 15–20 April 2018; pp. 5069–5073. [Google Scholar]

- Mechanical Vibration-Measurement and Evaluation of Machine Vibration-Part 1: General Guidelines. 2017. Available online: https://standards.globalspec.com/std/10157117/DIN%20ISO%2020816-1 (accessed on 15 July 2020).

- Blake, M.P.; Mitchell, W.S. Vibration and Acoustic Measurement Handbook; Spartan Books: East Lansing, MI, USA, 1973; Volume 5, pp. 44–45. [Google Scholar]

- Singh, J.; Darpe, A.K.; Singh, S.P. Bearing remaining useful life estimation using an adaptive data-driven model based on health state change point identification and K-means clustering. Meas. Sci. Technol. 2020, 31, 085601. [Google Scholar] [CrossRef]

- Henaff, M.; Bruna, J.; Lecun, Y. Deep Convolutional Networks on Graph-Structured Data. arXiv 2015, arXiv:1506.05163. [Google Scholar]

- Mei, S.; Ji, J.; Hou, J.; Li, X.; Du, Q. Learning Sensor-Specific Spatial-Spectral Features of Hyperspectral Images via Convolutional Neural Networks. IEEE Trans. Geosci. Remote Sens. 2017, 55, 4520–4533. [Google Scholar] [CrossRef]

- Girshick, R. Fast R-CNN. In Proceedings of the 2015 IEEE International Conference on Computer Vision (ICCV), Santiago, Chile, 7–13 December 2015; pp. 1440–1448. [Google Scholar]

- Liu, B.; Liu, J.; Bai, X.; Lu, H. Regularized Hierarchical Feature Learning with Non-negative Sparsity and Selectivity for Image Classification. In Proceedings of the 2014 22nd International Conference on Pattern Recognition, Stockholm, Sweden, 24–28 August 2014; pp. 4293–4298. [Google Scholar]

- Zhang, Q.; Wu, Y.N.; Zhu, S.-C. Interpretable Convolutional Neural Networks. In Proceedings of the 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; pp. 8827–8836. [Google Scholar]

- Dubois, M.K.; Bohling, G.C.; Chakrabarti, S. Comparison of four approaches to a rock facies classification problem. Comput. Geosci. 2007, 33, 599–617. [Google Scholar] [CrossRef]

- Nectoux, P.; Gouriveau, R.; Medjaher, K.; Ramasso, E.; Chebel-Morello, B.; Zerhouni, N.; Varnier, C. PRONOSTIA: An experimental platform for bearings accelerated degradation tests. In Proceedings of the IEEE International Conference on Prognostics and Health Management, Denver, CO, USA, 18–21 June 2012. [Google Scholar]

| O.C. 1 | Load(N) | Speed(rpm) | B.N. 2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 4000 | 1800 | B1-1 | B1-2 | B1-3 | B1-4 | B1-5 | B1-6 | B1-7 |

| 2 | 4200 | 1650 | B2-1 | B2-2 | B2-3 | B2-4 | B2-5 | B2-6 | B2-7 |

| 3 | 5000 | 1500 | B3-1 | B3-2 | B3-3 |

| Bearing 1-2 | Bearing 1-6 | Bearing 2-2 | Bearing 2-4 | ||||||||

| Act 1 | Pre 2 | Er 3 | Act | Pre | Er | Act | Pre | Er | Act | Pre | Er |

| 450 | 396 | 12% | 8110 | 7542 | 7% | 3430 | 3052 | 11% | 4820 | 4241 | 12% |

| 419 | 353 | 13% | 7519 | 6406 | 14.8% | 3239 | 3018 | 6.8% | 4489 | 4388 | 3.37% |

| 388 | 366 | 5% | 6928 | 6569 | 5.2% | 3058 | 2641 | 13.7% | 4308 | 4048 | 6% |

| 357 | 319 | 10.7% | 6588 | 6409 | 2.8% | 2758 | 2160 | 21% | 4108 | 3952 | 3.8% |

| 337 | 281 | 16.7% | 6017 | 5839 | 2.96% | 782 | 651 | 16.7% | 3908 | 3904 | 0.1% |

| 306 | 276 | 9.8% | 5436 | 5433 | 0.05% | 762 | 686 | 9.9% | 3727 | 3663 | 1.73% |

| 276 | 209 | 24% | 4926 | 4947 | −0.4% | 621 | 651 | −1.5% | 2455 | 2361 | 3.8% |

| 245 | 186 | 23.9 | 4335 | 4460 | −2.8% | 581 | 583 | −0.2% | 2274 | 2265 | 0.41% |

| 204 | 168 | 17.5% | 3674 | 3649 | 0.68% | 471 | 445 | 5.4% | 1913 | 1879 | 1.8% |

| 163 | 114 | 29.8% | 3183 | 3162 | 0.66% | 300 | 274 | 8.8% | 1513 | 1494 | 1.25% |

| 40 | 37 | 9.2% | 2442 | 2433 | 0.41% | 250 | 240 | 4.2% | 1142 | 1108 | 3.0% |

| 20 | 22 | 12.5% | 310 | 243 | 21.6% | 150 | 137 | 8.8% | 521 | 530 | −1.7% |

| Bearing 2-5 | Bearing 2-6 | Bearing 3-2 | Bearing 3-3 | ||||||||

| Act | Pre | Er | Act | Pre | Er | Act | Pre | Er | Act | Pre | Er |

| 3120 | 2776 | 11% | 1000 | 900 | 10% | 1340 | 1159 | 13.5% | 1340 | 1179 | 12% |

| 2909 | 2620 | 9% | 868 | 730 | 15% | 1239 | 1112 | 10.3% | 1229 | 1159 | 5.7% |

| 2588 | 2464 | 3.27% | 737 | 730 | 1% | 1128 | 1092 | 3.22% | 1138 | 1105 | 2.898% |

| 2307 | 2308 | −0.06% | 636 | 570 | 10.4% | 1047 | 1045 | 0.249% | 1057 | 1065 | −0.7% |

| 2066 | 1716 | 16.1% | 595 | 610 | −4.12% | 906 | 991 | −9.36% | 916 | 958 | −4.5% |

| 1755 | 1747 | 0.48% | 444 | 500 | −12.5% | 795 | 958 | −20.4% | 795 | 897.8 | −12.8% |

| 1474 | 1497 | −1.55% | 333 | 360 | −8.001% | 685 | 904 | −32% | 695 | 824 | −18.5% |

| 1213 | 1216 | −0.24% | 292 | 280 | 4.414% | 231 | 268 | −15.6% | 634 | 797 | −25.6% |

| 1033 | 967 | 6.3% | 242 | 240 | 0.998% | 221 | 201 | 9.3% | 574 | 770 | −34.2% |

| 632 | 748 | −18.5% | 161 | 150 | 7.19% | 201 | 167 | 16.9% | 80 | 87 | −8.1% |

| 421 | 411 | 2.25% | 101 | 85 | 15.85% | 171 | 147 | 13.9% | 50 | 67 | −33% |

| 30 | 15 | 48.2% | 60 | 60 | 0% | 60 | 34 | 44.58% | 10 | 1 | 90% |

| Bearing Names. | SG-TCN | Non-FDP | Non-TCN | Multi-CNN | ||||

|---|---|---|---|---|---|---|---|---|

| MAE | RMSE | MAE | RMSE | MAE | RMSE | MAE | RMSE | |

| Bearing 1-1 | 16.4 | 21.7 | 51.3 | 60.45 | 21.9 | 26.4 | 31.7 | 35.7 |

| Bearing 1-2 | 9.3 | 11.2 | 35.4 | 38.9 | 11.6 | 16.0 | 25.3 | 28.6 |

| Bearing 1-3 | 6.1 | 8.8 | 23.8 | 31.7 | 15.5 | 18.7 | 20.6 | 24.5 |

| Bearing 1-4 | 17.3 | 19.6 | 48.6 | 55.4 | 25.5 | 30.5 | 50.9 | 60.1 |

| Bearing 1-5 | 14.1 | 17.8 | 43.5 | 50.8 | 18.9 | 24.6 | 29.4 | 34.6 |

| Bearing 1-6 | 7.3 | 9.3 | 38.6 | 45.4 | 11.1 | 14.1 | 26.1 | 30.6 |

| Bearing 1-7 | 6.6 | 8.9 | 20.4 | 24.7 | 10.6 | 14.2 | 16.2 | 19.3 |

| Bearing 2-1 | 15.4 | 17.5 | 48.6 | 55.4 | 23.7 | 26.9 | 31.6 | 39.5 |

| Bearing 2-2 | 16.4 | 19.6 | 64.5 | 90.5 | 20.5 | 25.4 | 32.2 | 50.8 |

| Bearing 2-3 | 22.4 | 26.4 | 64.8 | 70.2 | 28.7 | 32.4 | 44.3 | 49.4 |

| Bearing 2-4 | 5.6 | 6.8 | 30.5 | 33.4 | 10.1 | 13.4 | 18.4 | 21.5 |

| Bearing 2-5 | 8.3 | 10.5 | 31.9 | 36.7 | 13.7 | 16.1 | 15.2 | 19.2 |

| Bearing 2-6 | 15.5 | 18.3 | 46.7 | 49.3 | 21.4 | 24.1 | 31.6 | 36.9 |

| Bearing 2-7 | 19.6 | 25.3 | 54.8 | 58.9 | 23.7 | 27.3 | 34.0 | 40.7 |

| Bearing 3-1 | 15.4 | 19.6 | 49.3 | 56.1 | 26.1 | 29.4 | 32.4 | 36.2 |

| Bearing 3-2 | 19.4 | 21.7 | 60.5 | 68.4 | 22.1 | 29.4 | 37.9 | 40.6 |

| Bearing 3-3 | 23.3 | 28.6 | 70.1 | 75.8 | 27.9 | 43.6 | 45.8 | 78.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Liu, X.; Yang, Y. Remaining Useful Life Prognostics of Bearings Based on a Novel Spatial Graph-Temporal Convolution Network. Sensors 2021, 21, 4217. https://doi.org/10.3390/s21124217

Li P, Liu X, Yang Y. Remaining Useful Life Prognostics of Bearings Based on a Novel Spatial Graph-Temporal Convolution Network. Sensors. 2021; 21(12):4217. https://doi.org/10.3390/s21124217

Chicago/Turabian StyleLi, Peihong, Xiaozhi Liu, and Yinghua Yang. 2021. "Remaining Useful Life Prognostics of Bearings Based on a Novel Spatial Graph-Temporal Convolution Network" Sensors 21, no. 12: 4217. https://doi.org/10.3390/s21124217

APA StyleLi, P., Liu, X., & Yang, Y. (2021). Remaining Useful Life Prognostics of Bearings Based on a Novel Spatial Graph-Temporal Convolution Network. Sensors, 21(12), 4217. https://doi.org/10.3390/s21124217