Appraisal of Low-Cost Pushbroom Hyper-Spectral Sensor Systems for Material Classification in Reflectance

Abstract

1. Introduction

2. Methods

2.1. Sensor Design

2.2. Sensor Considerations

2.3. Noise Considerations

2.4. Calibration

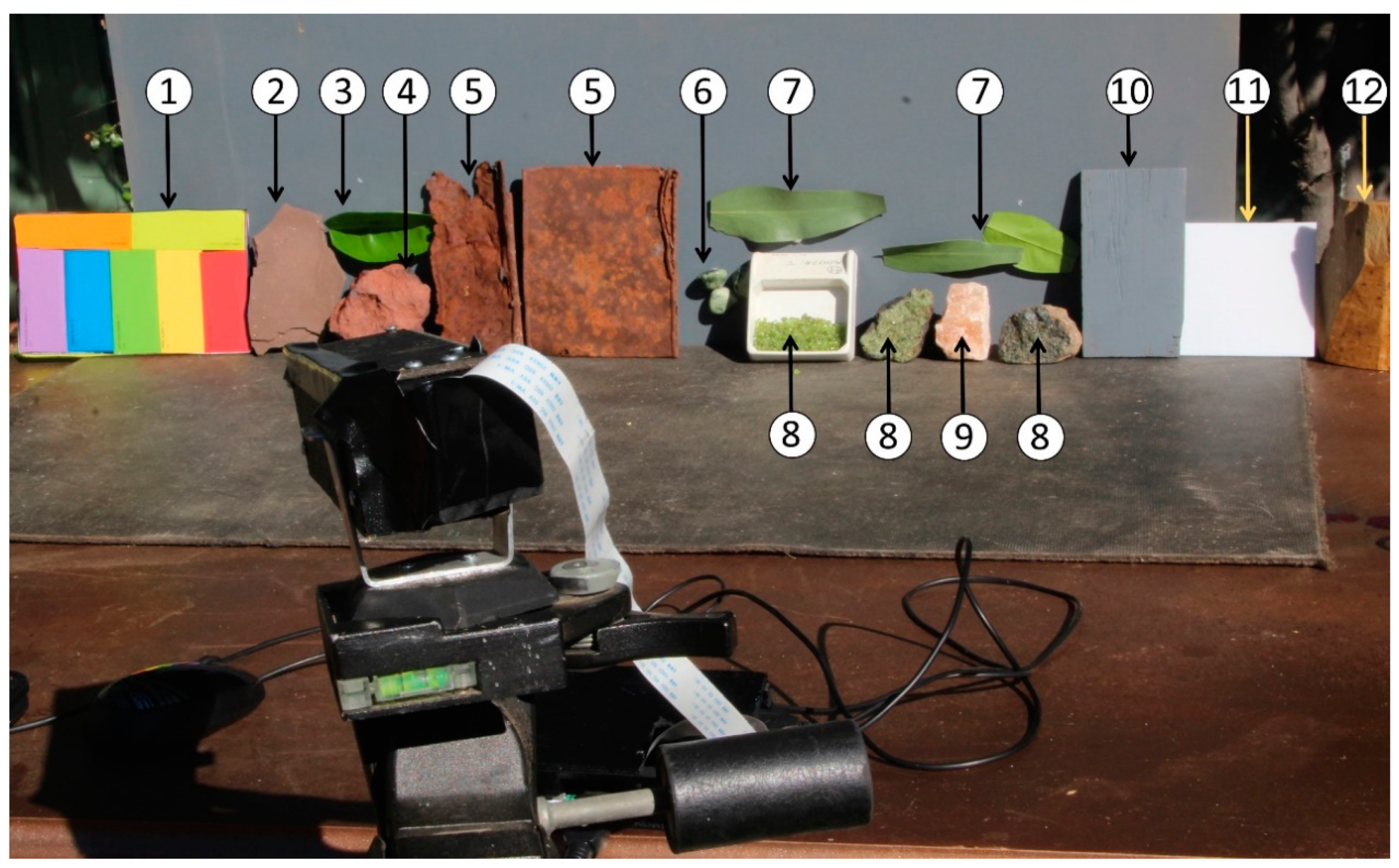

2.5. Sample Capture

- (1)

- (2)

- (3)

- (4)

- (5)

- (6)

- (7)

- (8)

- (9)

- gypsum, also relevant to extraterrestrial mineralogy [51].

- (10)

- grey; and

- (11)

- white specular reflectors. The spectra from these reflectors were analyzed using a laboratory grade Spectral Evolution SR-3500 spectroradiometer to confirm that they exhibited consistent, flat spectra.

- (12)

- A goethite-rich sample (12), hereafter referred to as Goethite, completed the analyzed samples.

2.6. Sample Processing

2.7. Comparison and Discrimination Methods

3. Results

3.1. Dark Frame Output and Spectral Comparisons

3.2. Material Detection Analysis

4. Discussion

4.1. Overview and Major Findings

4.2. Other Sensor Considerations

4.3. General Considerations and Future Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

Experiment Setup

| Material | Mk 1 R2 | Mk 2 R2 |

|---|---|---|

| Goethite | 0.80 | 0.91 |

| Rust 1 | 0.80 | 0.91 |

| Rust 2 | 0.98 | 0.91 |

| Mudstone | 0.91 | 0.95 |

| Hematite | 0.72 | 0.69 |

| Gypsum | 0.91 | 0.52 |

| Hot Pop Red | >0.99 | 0.88 |

| High Alert Yellow | 0.85 | 0.27 |

References

- James, J. Spectrograph Design Fundamentals; Cambridge University Press (CUP): Cambridge, UK, 2007. [Google Scholar]

- Jensen, J.R. Introductory Digital Image Processing: A Remote Sensing Perspective, 4th ed.; Prentice-Hall Inc.: Upper Saddle River, NJ, USA, 2015; ISBN 0132058405. [Google Scholar]

- Borengasser, M.; Hungate, W.S.; Watkins, R. Hyperspectral Remote Sensing; CRC Press: Boca Ratan, FL, USA, 2008; pp. 7–20. [Google Scholar]

- Gómez, A.H.; He, Y.; Pereira, A.G. Non-destructive measurement of acidity, soluble solids and firmness of Satsuma mandarin using Vis/NIR-spectroscopy techniques. J. Food Eng. 2006, 77, 313–319. [Google Scholar] [CrossRef]

- Middleton, C.; Underwood, C.; Woolliams, E.; Bridges, C.; Fox, N. CHAFF: CubeSat Hyperspectral Application for Farming. In Proceedings of the 12th IAA Symposium on Small Satellites for Earth Observation, Berlin, Germany, 6–10 May 2019. [Google Scholar]

- Lekki, J.; Ruberg, S.; Binding, C.; Anderson, R.; Vander Woude, A. Airborne hyperspectral and satellite imaging of harmful algal blooms in the Great Lakes Region: Successes in sensing algal blooms. J. Great Lakes Res. 2019, 45, 405–412. [Google Scholar] [CrossRef]

- Kohout, T.; Näsilä, A.; Tikka, T.; Granvik, M.; Kestilä, A.; Penttilä, A.; Kuhno, J.; Muinonen, K.; Viherkanto, K.; Kallio, E. Feasibility of asteroid exploration using CubeSats—ASPECT case study. Adv. Space Res. 2018, 62, 2239–2244. [Google Scholar] [CrossRef]

- Brown, A. Spectral curve fitting for automatic hyperspectral data analysis. IEEE Trans. Geosci. Remote Sens. 2006, 44, 1601–1608. [Google Scholar] [CrossRef]

- Slawson, R.W.; Ninkov, Z.; Horch, E.P. Hyperspectral Imaging: Wide-Area Spectrophotometry Using a Liquid-Crystal Tunable Filter. Publ. Astron. Soc. Pac. 1999, 111, 621–626. [Google Scholar] [CrossRef]

- Zucco, M.; Pisani, M.; Caricato, V.; Egidi, A. A hyperspectral imager based on a Fabry-Perot interferometer with dielectric mirrors. Opt. Express 2014, 22, 1824–1834. [Google Scholar] [CrossRef]

- Sigernes, F.; Syrjasuo, M.; Storvold, R.; Fortuna, J.; Grøtte, M.E.; Johansen, T.A. Do it yourself hyperspectral imager for handheld to airborne operations. Opt. Express 2018, 26, 6021–6035. [Google Scholar] [CrossRef]

- Salazar-Vazquez, J.; Mendez-Vazquez, A. A plug-and-play Hyperspectral Imaging Sensor using low-cost equipment. HardwareX 2020, 7, e00087. [Google Scholar] [CrossRef]

- Widiatmoko, E.; Budiman, M.; Abdullah, M. A simple spectrometer using common materials and a digital camera. Phys. Educ. 2011, 46, 332–338. [Google Scholar] [CrossRef]

- Wilkes, T.C.; McGonigle, A.J.S.; Willmott, J.R.; Pering, T.D.; Cook, J. Low-cost 3D printed 1 nm resolution smartphone sensor-based spectrometer: Instrument design and application in ultraviolet spectroscopy. Opt. Lett. 2017, 42, 4323–4326. [Google Scholar] [CrossRef]

- Bell, J.F.; Squyres, S.W.; Herkenhoff, K.E.; Maki, J.N.; Arneson, H.M.; Brown, D.; Collins, S.A.; Dingizian, A.; Elliot, S.T.; Hagerott, E.C.; et al. Mars Exploration Rover Athena Panoramic Camera (Pancam) investigation. J. Geophys. Res. Space Phys. 2003, 108, 1–30. [Google Scholar] [CrossRef]

- Bell, J.F., III; Glotch, T.D.; Hamilton, V.E.; McConnochie, T.; McCord, T.; McEwan, A.; Christensen, P.R.; Arvidson, R.E. Visible to near-IR multispectral orbital observations of Mars. In The Martian Surface: Composition, Mineralogy and Physical Properties; Bell, J.F., III, Ed.; Cambridge University Press: New York, NY, USA, 2008; pp. 169–198. ISBN 978-0-521-86698-9. [Google Scholar]

- Farrand, W.H.; Bell, J.F., III; Johnson, J.R.; Bishop, J.L.; Morris, R.V. Multispectral imaging from Mars Pathfinder. In The Martian Surface: Composition, Mineralogy and Physical Properties; Bell, J.F., III, Ed.; Cambridge University Press: New York, NY, USA, 2008; pp. 265–280. ISBN 978-0-521-86698-9. [Google Scholar]

- Boreman, G.D. Classification of imaging spectrometers for remote sensing applications. Opt. Eng. 2005, 44, 013602. [Google Scholar] [CrossRef]

- Burns, R.G. Mineralogical Applications of Crystal Field Theory; Cambridge University Press (CUP): New York, NY, USA, 1993; pp. 460–470. [Google Scholar]

- Schade, U.; Wäsch, R.; Moroz, L. Near-infrared reflectance spectroscopy of Ca-rich clinopyroxenes and prospects for remote spectral characterization of planetary surfaces. Icarus 2004, 168, 80–92. [Google Scholar] [CrossRef]

- Klingelhöfer, G.; Van Morris, R.; Bernhardt, B.; Schröder, C.; Rodionov, D.S.; De Souza, P.A.; Yen, A.S.; Gellert, R.; Evlanov, E.N.; Zubkov, B.V.; et al. Jarosite and Hematite at Meridiani Planum from Opportunity’s Mössbauer Spectrometer. Science 2004, 306, 1740–1745. [Google Scholar] [CrossRef]

- Soffen, G.A. The Viking Project. J. Geophys. Res. Space Phys. 1977, 82, 3959–3970. [Google Scholar] [CrossRef]

- Kerekes, J.P.; Schott, J.R. Hyperspectral imaging systems. In Hyperspec, Data Exploitation: Theory and Applications; Chang, C.-I., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 12, pp. 19–45. [Google Scholar]

- Valle, B.; Simonneau, T.; Boulord, R.; Sourd, F.; Frisson, T.; Ryckewaert, M.; Hamard, P.; Brichet, N.; Dauzat, M.; Christophe, A. PYM: A new, affordable, image-based method using a Raspberry Pi to phenotype plant leaf area in a wide diversity of environments. Plant Methods 2017, 13, 98. [Google Scholar] [CrossRef]

- Rajak, A.; Munir, M.M.; Abidin, M.S. Khairurrijal A Simple Spectrometer Using Various LEDs and a Photodiode Sensor for Photocatalytic Performance Evaluation. Appl. Mech. Mater. 2015, 771, 17–20. [Google Scholar] [CrossRef]

- Lopez-Ruiz, N.; Granados-Ortega, F.; Carvajal, M.A.; Martinez-Olmos, A. Portable multispectral imaging system based on Raspberry Pi. Sens. Rev. 2017, 37, 322–329. [Google Scholar] [CrossRef]

- Shailesh, K.R.; Kurian, C.P.; Kini, S.G. Auto-calibration of emission spectra of light sources captured using camera spectrometer. In Proceedings of the 2015 International Conference on Smart Sensors and Systems (IC-SSS), Bangalore, India, 21–23 December 2015; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2017; pp. 1–5. [Google Scholar]

- Anderson, A.C.; Haldemann, A.F.C.; Dohm, J.; Huntsberger, T. A Dress Rehearsal for the 2003 Mars Exploration Rovers; Mars Analog Research; American Astronomical Society: Long Beach CA, USA, 2006; Volume 11, pp. 117–128. [Google Scholar]

- Cubesat Design Specification. Available online: https://static1.squarespace.com/static/5418c831e4b0fa4ecac1bacd/t/5f24997b6deea10cc52bb016/1596234122437/CDS+REV14+2020-07-31+DRAFT.pdf (accessed on 17 May 2021).

- Wang, L.; Jin, J.; Song, Z.; Wang, J.; Zhang, L.; Rehman, T.U.; Ma, D.; Carpenter, N.R.; Tuinstra, M.R. LeafSpec: An accurate and portable hyperspectral corn leaf imager. Comput. Electron. Agric. 2020, 169, 1–11. [Google Scholar] [CrossRef]

- ZWO. 2018. Available online: https://astronomy-imaging-camera.com (accessed on 20 March 2020).

- Pagnutti, M.; Ryan, R.E.; Cazenavette, G.; Gold, M.; Harlan, R.; Leggett, E.; Pagnutti, J. Laying the foundation to use Raspberry Pi 3 V2 camera module imagery for scientific and engineering purposes. J. Electron. Imaging 2017, 26, 013014. [Google Scholar] [CrossRef]

- Hubel, P.M.; Liu, J.; Guttosch, R.J. Spatial frequency response of color image sensors: Bayer color filters and Foveon X3. In Proceedings of the Electronic Imaging 2004, San Jose, CA, USA, 18 January 2004; pp. 402–407. [Google Scholar]

- Lapray, P.-J.; Wang, X.; Thomas, J.-B.; Gouton, P. Multispectral Filter Arrays: Recent Advances and Practical Implementation. Sensors 2014, 14, 21626–21659. [Google Scholar] [CrossRef]

- He, X.; Liu, Y.; Ganesan, K.; Ahnood, A.; Beckett, P.; Eftekhari, F.; Smith, D.; Uddin, H.; Skafidas, E.; Nirmalathas, A.; et al. A single sensor based multispectral imaging camera using a narrow spectral band color mosaic integrated on the monochrome CMOS image sensor. APL Photonics 2020, 5, 046104. [Google Scholar] [CrossRef]

- Fowler, B.A.; El Gamal, A.; Yang, D.X.D.; Tian, H. Method for estimating quantum efficiency for CMOS image sensors. Photonics West ’98 Electron. Imaging 1998, 3301, 178–185. [Google Scholar] [CrossRef]

- Janesick, J.R. Scientific Charge-Coupled Devices; SPIE Press: Bellingham, WA, USA, 2001; pp. 22–121. [Google Scholar]

- Irie, K.; McKinnon, A.E.; Unsworth, K.; Woodhead, I.M. A model for measurement of noise in CCD digital-video cameras. Meas. Sci. Technol. 2008, 19, 1–10. [Google Scholar] [CrossRef]

- Selva, D.; Krejci, D. A survey and assessment of the capabilities of Cubesats for Earth observation. Acta Astronaut. 2012, 74, 50–68. [Google Scholar] [CrossRef]

- Reibel, Y.; Jung, M.; Bouhifd, M.; Cunin, B.; Draman, C. CCD or CMOS camera noise characterisation. Eur. Phys. J. Appl. Phys. 2002, 21, 75–80. [Google Scholar] [CrossRef]

- Bowman, R.; Vodenicharski, B.; Collins, J.; Stirling, J. Flat-Field and Colour Correction for the Raspberry Pi Camera Module. J. Open Hardw. 2020, 4, 1–19. [Google Scholar] [CrossRef]

- Gach, J.; Darson, D.; Guillaumé, C.; Goillandeau, M.; Cavadore, C.; Balard, P.; Boissin, O.; Boulesteix, J. A New Digital CCD Readout Technique for Ultra–Low-Noise CCDs. Publ. Astron. Soc. Pac. 2003, 115, 1068–1071. [Google Scholar] [CrossRef]

- Dominec, F. Design and Construction of a Digital CCD Spectrometer. Research Thesis, Czech Technical University, Prague, Czech Republic, 2010. [Google Scholar]

- Bougot-Robin, K.; Paget, J.; Atkins, S.C.; Edel, J.B. Optimization and Design of an Absorbance Spectrometer Controlled Using a Raspberry Pi To Improve Analytical Skills. J. Chem. Educ. 2016, 93, 1232–1240. [Google Scholar] [CrossRef]

- Mccord, T.B.; Clark, R.N. The Mercury soil: Presence of Fe2+. J. Geophys. Res. Space Phys. 1979, 84, 7664–7668. [Google Scholar] [CrossRef]

- Bareth, G.; Aasen, H.; Bendig, J.; Gnyp, M.L.; Bolten, A.; Jung, A.; Michels, R.; Soukkamäki, J. Leichte und UAV-getragene hyperspektrale, bildgebende Kameras zur Beobachtung von landwirtschaftlichen Pflanzenbeständen: Spektraler Vergleich mit einem tragbaren Feldspektrometer. Photogramm. Fernerkund. Geoinf. 2015, 2015, 69–79. [Google Scholar] [CrossRef]

- Bishop, J.L.; Perry, K.A.; Dyar, M.D.; Bristow, T.F.; Blake, D.F.; Brown, A.J.; Peel, S.E. Coordinated spectral and XRD analyses of magnesite-nontronite-forsterite mixtures and implications for carbonates on Mars. J. Geophys. Res. Planets 2013, 118, 635–650. [Google Scholar] [CrossRef]

- Brown, A.J.; Viviano, C.E.; Goudge, T.A. Olivine-Carbonate Mineralogy of the Jezero Crater Region. J. Geophys. Res. Planets 2020, 125, 1–30. [Google Scholar] [CrossRef]

- Bishop, J.L.; Lane, M.D.; Dyar, M.D.; Brown, A.J. Reflectance and emission spectroscopy study of four groups of phyllosilicates: Smectites, kaolinite-serpentines, chlorites and micas. Clay Miner. 2008, 43, 35–54. [Google Scholar] [CrossRef]

- Brown, A.J.; Hook, S.J.; Baldridge, A.M.; Crowley, J.K.; Bridges, N.T.; Thomson, B.J.; Marion, G.M.; Filho, C.R.S.; Bishop, J.L. Hydrothermal formation of Clay-Carbonate alteration assemblages in the Nili Fossae region of Mars. Earth Planet. Sci. Lett. 2010, 297, 174–182. [Google Scholar] [CrossRef]

- Fishbaugh, K.E.; Poulet, F.; Chevrier, V.; Langevin, Y.; Bibring, J.-P. On the origin of gypsum in the Mars north polar region. J. Geophys. Res. Space Phys. 2007, 112. [Google Scholar] [CrossRef]

- Abramoff, M.D.; Magalhaes, P.J.; Ram, S.J. Image Processing with Image. J. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Fridman, A.; Høye, G.; Løke, T. Resampling in hyperspectral cameras as an alternative to correcting keystone in hardware, with focus on benefits for optical design and data quality. Opt. Eng. 2014, 53, 053107. [Google Scholar] [CrossRef][Green Version]

- Henriksen, M.B. Hyperspectral Imager Calibration and Image Correction. Master’s Thesis, Norwegian University of Science and Technology, Høgskoleringen, Norway, 2019. [Google Scholar]

- Wertz, J.D.F.; Everett, D.F.; Puschell, J.J. Space Mission Engineering: The New SMAD; Microcosm Press: Hawthorne, CA, USA, 2011; pp. 803–821. [Google Scholar]

- Horgan, B.H.; Cloutis, E.A.; Mann, P.; Bell, J.F. Near-infrared spectra of ferrous mineral mixtures and methods for their identification in planetary surface spectra. Icarus 2014, 234, 132–154. [Google Scholar] [CrossRef]

- Sivakumar, V.; Neelakantan, R.; Santosh, M. Lunar surface mineralogy using hyperspectral data: Implications for primordial crust in the Earth–Moon system. Geosci. Front. 2017, 8, 457–465. [Google Scholar] [CrossRef]

- Carlson, T.N.; Ripley, D.A. On the relation between NDVI, fractional vegetation cover, and leaf area index. Remote. Sens. Environ. 1997, 62, 241–252. [Google Scholar] [CrossRef]

- Lillesand, T.; Kiefer, R.W.; Chipman, J. Remote Sensing and Image Interpretation, 6th ed.; John Wiley and Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Barlow, N.G. Mars: An Introduction to its Interior, Surface and Atmosphere; Cambridge University Press (CUP): Cambridge, UK, 2008; pp. 163–185. [Google Scholar]

- Williford, K.H.; Farley, K.A.; Stack, K.M.; Allwood, A.C.; Beaty, D.; Beegle, L.W.; Bhartia, R.; Brown, A.J.; Juarez, M.D.L.T.; Hamran, S.-E.; et al. The NASA Mars 2020 Rover Mission and the Search for Extraterrestrial Life. In From Habitability to Life on Mars; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 275–308. [Google Scholar]

- Dong, T.; Liu, J.; Shang, J.; Qian, B.; Ma, B.; Kovacs, J.M.; Walters, D.; Jiao, X.; Geng, X.; Shi, Y. Assessment of red-edge vegetation indices for crop leaf area index estimation. Remote. Sens. Environ. 2019, 222, 133–143. [Google Scholar] [CrossRef]

- Farley, K.A.; Williford, K.H.; Stack, K.M.; Bhartia, R.; Chen, A.; De La Torre, M.; Hand, K.; Goreva, Y.; Herd, C.D.K.; Hueso, R.; et al. Mars 2020 Mission Overview. Space Sci. Rev. 2020, 216, 1–41. [Google Scholar] [CrossRef]

- Kinch, K.M.; Madsen, M.B.; Bell, J.F.; Maki, J.N.; Bailey, Z.J.; Hayes, A.G.; Jensen, O.B.; Merusi, M.; Bernt, M.H.; Sørensen, A.N.; et al. Radiometric Calibration Targets for the Mastcam-Z Camera on the Mars 2020 Rover Mission. Space Sci. Rev. 2020, 216, 1–51. [Google Scholar] [CrossRef]

| Index | Requirement |

|---|---|

| 1 | The budget for the sensor shall not exceed AUD $1000. |

| 2 | The sensor shall be sensitive to at least the 600–800 nm VIS/NIR spectral range. |

| 3 | One sensor design shall include a Bayer filter. |

| 4 | One sensor design shall not include a Bayer filter. |

| 5 | The sensor and supporting electronics shall consume at most 15 W. |

| 6 | The sensor shall occupy a volume not exceeding 2 U (100 × 100 × 200 mm). |

| 7 | The sensor and supporting electronics shall weigh less than 1 kg. |

| 8 | The sensor design shall not require specialist assembly. |

| 9 | The sensor shall operate on an open-source, single-board computer. |

| Property | Value | ||

| Sf at Earth Surface (600–800 nm) | 295 Wm−2 | ||

| Mineral Reflectance | Hematite | ||

| Reflectance at 600 nm (%) | 5 | ||

| Reflectance at 700 nm (%) | 7 | ||

| Reflectance at 800 nm (%) | 7 | ||

| Sensor Qe | Monochrome | Rpi Mk1 | Rpi Mk2 |

| Sensor Qe at 600 nm (%) | 78 | 50 | 78 |

| Sensor Qe at 700 nm (%) | 65 | 50 | 50 |

| Sensor Qe at 800 nm (%) | 40 | 40 | 45 |

| Grating at 600 nm (%) | 50 | ||

| Grating at 700 nm (%) | 40 | ||

| Grating at 800 nm (%) | 32 | ||

| Raspberry Pi Mk 1 Camera | |||

| DN (Minimum) | DN (Average) | DN (Maximum) | DN (Std Deviation) |

| 0 | 0.86 | 2.8 | 0.56 |

| Hematite (DN, average 600–650 nm) | Hematite (DN, average 650–700 nm) | Hematite (DN, average 700–750 nm) | Hematite (DN, average 750–800 nm) |

| 35 | 27 | 19 | 17 |

| Raspberry Pi Mk 2 Camera | |||

| DN (minimum) | DN (Average) | DN (Maximum) | DN (Std Deviation) |

| 0 | 0.28 | 1.8 | 1.38 |

| Hematite (DN, average 600–650 nm) | Hematite (DN, average 650–700 nm) | Hematite (DN, average 700–750 nm) | Hematite (DN, average 750–800 nm) |

| 40 | 27 | 19 | 14 |

| ZWO Mini Camera | |||

| DN (minimum) | DN (Average) | DN (Maximum) | DN (Std Deviation) |

| 0 | 0.73 | 1.8 | 0.24 |

| Hematite (DN, average 600–650 nm) | Hematite (DN, average 650–700 nm) | Hematite (DN, average 700–750 nm) | Hematite (DN, average 750–800 nm) |

| 46 | 41 | 34 | 26 |

| Material | Mk 1 R2 | Mk 2 R2 | ZWO R2 |

|---|---|---|---|

| Eucalyptus Leaf | >0.99 | 0.99 | >0.99 |

| Lemon Leaf | 0.99 | 0.99 | 0.99 |

| Olivine 1 | 0.99 | >0.99 | >0.99 |

| Olivine 2 | 0.98 | >0.99 | >0.99 |

| Olivine 3 | 0.98 | >0.99 | 0.99 |

| Rust 1 | 0.98 | >0.99 | 0.98 |

| Rust 2 | >0.99 | >0.99 | 0.98 |

| Mudstone | 0.99 | >0.99 | 0.99 |

| Hematite | 0.99 | >0.99 | 0.99 |

| Gypsum | 0.98 | >0.99 | >0.99 |

| Goethite | 0.99 | 1 | >0.99 |

| Serpentine | 0.99 | >0.99 | >0.99 |

| Hot Pop Red | >0.99 | 0.99 | >0.99 |

| High Alert Yellow | 0.99 | 0.99 | >0.99 |

| Majestic Purple | 0.98 | 0.96 | 0.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hobbs, S.; Lambert, A.; Ryan, M.J.; Paull, D.J.; Haythorpe, J. Appraisal of Low-Cost Pushbroom Hyper-Spectral Sensor Systems for Material Classification in Reflectance. Sensors 2021, 21, 4398. https://doi.org/10.3390/s21134398

Hobbs S, Lambert A, Ryan MJ, Paull DJ, Haythorpe J. Appraisal of Low-Cost Pushbroom Hyper-Spectral Sensor Systems for Material Classification in Reflectance. Sensors. 2021; 21(13):4398. https://doi.org/10.3390/s21134398

Chicago/Turabian StyleHobbs, Steven, Andrew Lambert, Michael J. Ryan, David J. Paull, and John Haythorpe. 2021. "Appraisal of Low-Cost Pushbroom Hyper-Spectral Sensor Systems for Material Classification in Reflectance" Sensors 21, no. 13: 4398. https://doi.org/10.3390/s21134398

APA StyleHobbs, S., Lambert, A., Ryan, M. J., Paull, D. J., & Haythorpe, J. (2021). Appraisal of Low-Cost Pushbroom Hyper-Spectral Sensor Systems for Material Classification in Reflectance. Sensors, 21(13), 4398. https://doi.org/10.3390/s21134398