Design and Validation of a Device Attached to a Conventional Bicycle to Measure the Three-Dimensional Forces Applied to a Pedal

Abstract

1. Introduction

2. Materials and Methods

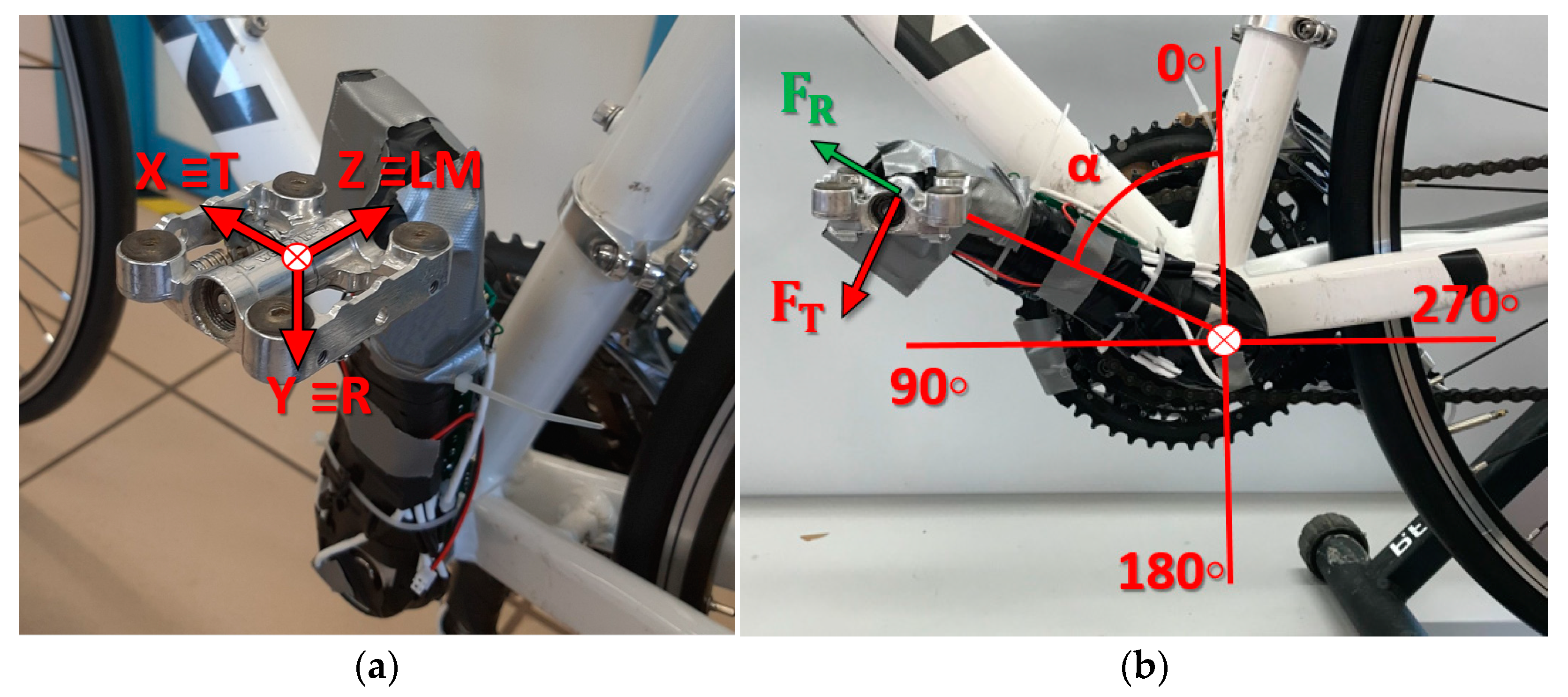

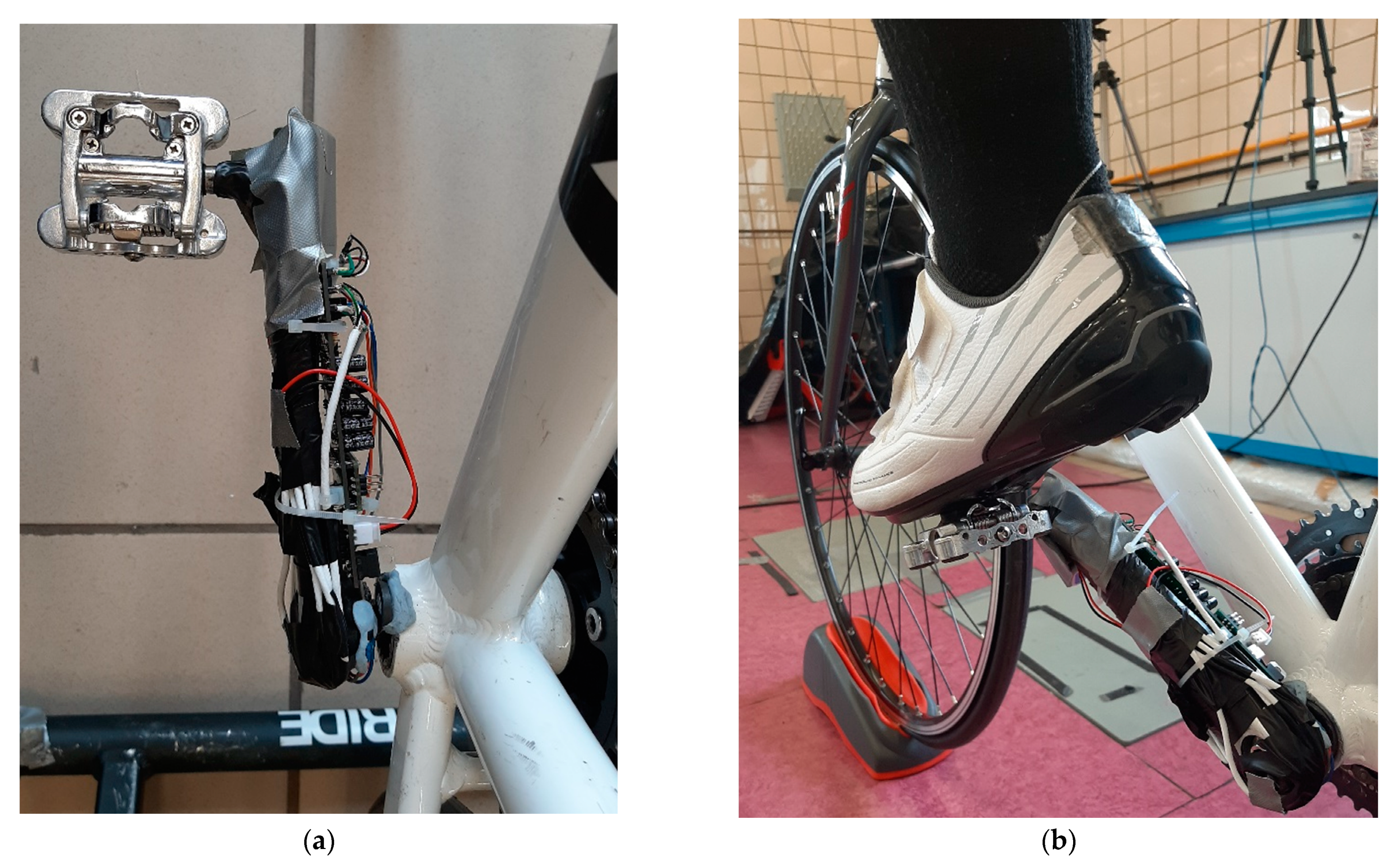

2.1. Measurement Equipment

2.2. Experimental Force Determination

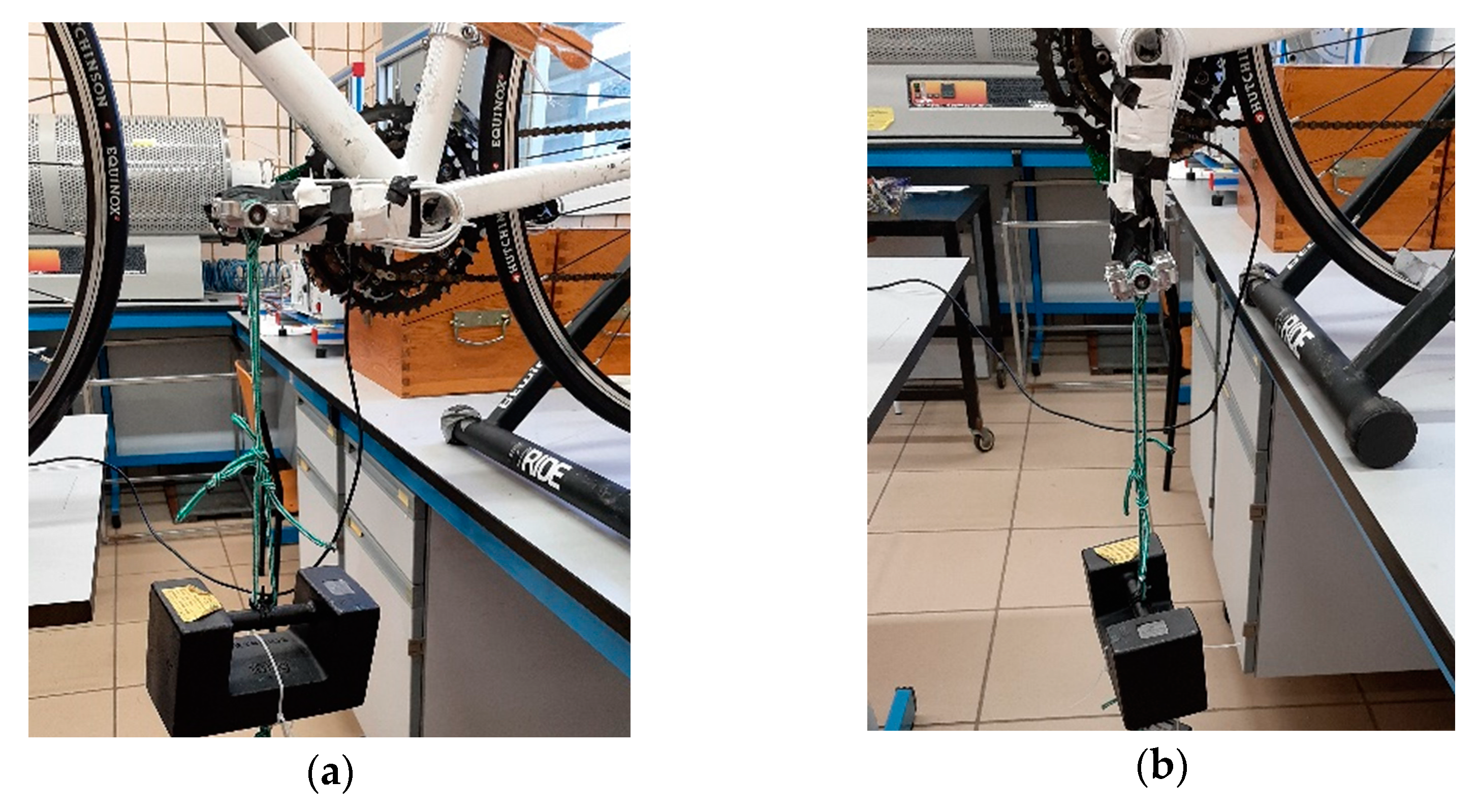

2.3. Calibration Results Assessment

2.4. Test Conditions

2.5. Effectiveness Index Analysis

3. Results

3.1. Device Calibration

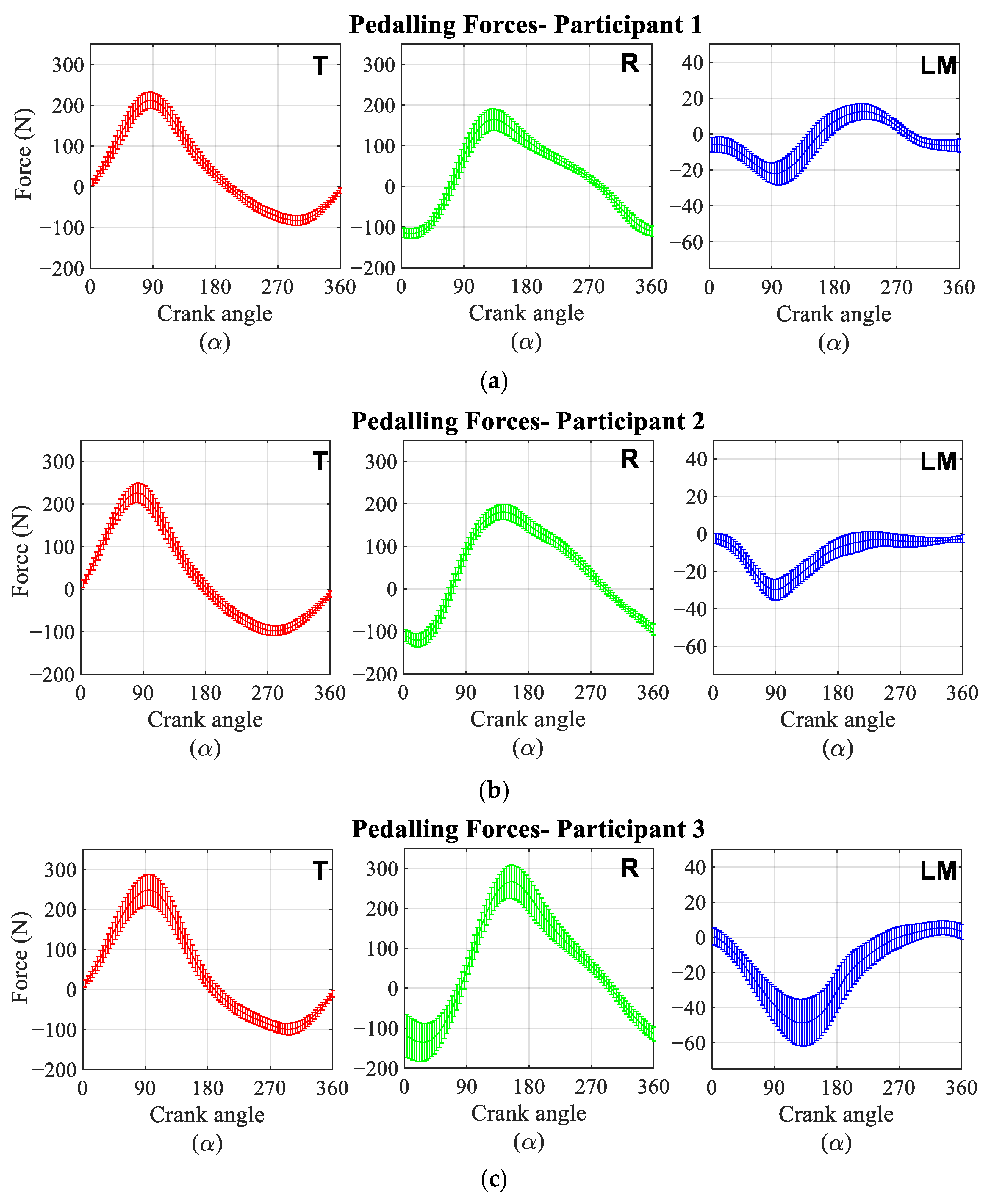

3.2. Device Results in Pedalling Conditions

4. Discussion

4.1. Device Calibration

4.2. Results of the Device during Pedalling

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Korff, T.; Romer, L.M.; Mayhew, I.; Martin, J.C. Effect of pedaling technique on mechanical effectiveness and efficiency in cyclists. Med. Sci. Sports Exerc. 2007, 36, 991–995. [Google Scholar] [CrossRef]

- Bini, R.R.; Hume, P.A.; Crofta, J.L. Effects of saddle height on pedal force effectiveness. Procedia Eng. 2011, 13, 51–55. [Google Scholar] [CrossRef][Green Version]

- McLeod, W.D.; Blackburn, T.A. Biomechanics of knee rehabilitation with cycling. Am. J. Sports Med. 1980, 8, 175–180. [Google Scholar] [CrossRef]

- Harman, E.; Knuttgen, H.G.; Frykman, P. Automated data collection and processing for a cycle ergometer. J. Appl. Phys. 1987, 62, 831–836. [Google Scholar] [CrossRef]

- Newmiller, J.; Hull, M.L.; Zajac, F.E. A mechanically decoupled two force component bicycle pedal dynamometers. J. Biomech. 1988, 21, 375–386. [Google Scholar] [CrossRef]

- Álvarez, G.; Vinyolas, J. A new bicycle pedal design for on-road measurements of cycling forces. J. Appl. Biomech. 1996, 12, 130–142. [Google Scholar] [CrossRef]

- Ericson, M.O.; Nisell, R. Efficiency of pedal forces during ergometer cycling. Int. J. Sports Med. 1988, 9, 118–122. [Google Scholar] [CrossRef] [PubMed]

- Reiser, R.F.; Peterson, M.L.; Broker, J.P. Instrumented bicycle pedals for dynamic measurement of propulsive cycling loads. Sports Eng. 2003, 6, 41–48. [Google Scholar] [CrossRef]

- Stapelfeldt, B.; Mornieux, G.; Oberheim, R.; Belli, A.; Gollhofer, A. Development and evaluation of a new bicycle instrument for measurements of pedal forces and power output in cycling. Int. J. Sports Med. 2007, 28, 326–332. [Google Scholar] [CrossRef] [PubMed]

- Candotti, C.T.; Ribeiro, J.; Soares, D.P.; de Oliveira, A.R.; Loss, J.F.; Guimaraes, A.C.S. Effective force and economy of triathletes and cyclists. Sports Biomech. 2007, 6, 31–43. [Google Scholar] [CrossRef] [PubMed]

- Dorel, S.; Drouet, J.M.; Hug, F.; Lepretre, P.M.; Champoux, Y. New instrumented pedals to quantify 2D forces at the shoe-pedal interface in ecological conditions: Preliminary study in elite track cyclists. Comput. Methods Biomech. Biomed. Eng. 2008, 11, 89–90. [Google Scholar] [CrossRef]

- Davis, R.R.; Hull, M.L. Measurement of pedal loading in bicycling: I. Instrumentation. J. Biomech. 1981, 12, 843–856. [Google Scholar]

- Davis, R.R.; Hull, M.L. Measurement of pedal loading in bicycling: II. Analysis and results. J. Biomech. 1981, 12, 857–872. [Google Scholar] [CrossRef]

- Nabinger, E.; Iturrioz, I.; Zaro, M.A. Development of a triaxial force platform for the measurement of force at a bicycle pedal. In Proceedings of the International Symposium on Biomechanics in Sports, Cáceres, Spain, 1–5 July 2002. [Google Scholar]

- Mournieux, C.; Stapelfeldt, B.; Collhofer, A.; Belli, A. Effects of pedal type and pull-up action during cycling. Int. J. Sports Med. 2008, 29, 817–822. [Google Scholar] [CrossRef]

- Alexander, N.; Strutzenberger, G.; Jenny, H.; Augustin, H.; Schwameder, H. Static and dynamic evaluation of a pedal system for measuring three-dimensional forces in cycling. Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2015, 4, 220–230. [Google Scholar] [CrossRef]

- Lee, J.H.; Choi, J.S.; Kang, D.W.; Seo, J.W.; Kim, J.Y.; Kim, D.H.; Yang, S.T.; Tack, G.R. Development of a system for measuring the three-axis pedal force in cycling and its applications. Int. J. Sport Health Sci. 2015, 2, 235–238. [Google Scholar]

- Dieltiens, S.; D’Hondt, J.; Juwet, M. Development of a low-cost measurement system to determine 3-dimensional pedal loads during in-situ cycling. Trans. Probl. 2019, 4, 151–160. [Google Scholar] [CrossRef]

- Pigatto, A.V.; Moura, K.O.A.; Favieiro, G.W.; Balbinot, A. A new crank arm based load cell, with built-in conditioning circuit and strain gages, to measure the components of the force applied by a cyclist. In Proceedings of the 2016 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016; pp. 1983–1986. [Google Scholar]

- Bini, R.R.; Carpes, F.P. Biomechanics of Cycling, 1st ed.; Springer: Cham, Switzerland, 2014; pp. 13–21. [Google Scholar]

- Balbinot, A.; Milani, C.; da Nascimiento, J.S.B. A new crank arm-based load cell for the 3D analysis of the force applied by a cyclist. Sensors 2004, 14, 22921–22939. [Google Scholar] [CrossRef] [PubMed]

- Dieltiens, S.; D’Hondt, J.; Juwet, M.; Shariatmadar, K.; Versteyhe, M. Design and Calibration of an Instrumented Seat Post to Measure Sitting Loads While Cycling. Sensors 2020, 20, 1384. [Google Scholar]

- Holmes, J.C.; Pruitt, A.L.; Whalen, N.J. Lower extremity overuse in bicycling. Clin. Sports Med. 1994, 13, 187–205. [Google Scholar] [CrossRef]

- Boyd, T.; Hull, M.L.; Wooten, D. An improved accuracy six-load component pedal dynamometer for cycling. J. Biomech. 1996, 8, 1105–1110. [Google Scholar]

- Sanderson, D.J.; Henning, E.M.; Black, A. The influence of cadence and power output on force application and in-shoe pressure distribution during cycling by competitive and recreational cyclists. J. Sports Sci. 2000, 18, 191–199. [Google Scholar] [CrossRef] [PubMed]

- Sanderson, D.J.; Black, A. The effect of prolonged cycling on pedal forces. J. Sports Sci. 2002, 21, 173–181. [Google Scholar] [CrossRef] [PubMed]

- Ruby, P.; Hull, M.L.; Hawkins, D. Three-dimensional knee joint loading during cycling. J. Biomech. 1992, 1, 41–53. [Google Scholar] [CrossRef]

- Ruby, P.; Hull, M.L. Response of intersegmental knee loads to foot/pedal platform degrees of freedom in cycling. J. Biomech. 1993, 26, 1327–1340. [Google Scholar] [CrossRef]

| Wheastone Bridge | Gauge | Load Application Direction | ||

|---|---|---|---|---|

| T | R | LM | ||

| 1 | G1 | 20.142 | −1.145 | −5.230 |

| 1 | G2 | −21.371 | 1.098 | −5.182 |

| 2 | G3 | 2.779 | 20.764 | −5.526 |

| 2 | G4 | 3.131 | −19.987 | −5.202 |

| 3 | G5 | 1.005 | −76.543 | 67.202 |

| 3 | G6 | 0.961 | 76.674 | −65.305 |

| Load (N) | M1 (49.05) | M2 (73.57) | M3 (98.16) | M4 (127.53) | M5 (147.15) | M6 (196.2) | M7 (294.3) |

|---|---|---|---|---|---|---|---|

| m11 | 1.520 | 1.542 | 1.526 | 1.499 | 1.499 | 1.558 | 1.558 |

| m12 | 0.386 | 0.402 | 0.425 | 0.361 | 0.375 | 0.407 | 0.407 |

| m13 | 0.381 | 0.403 | 0.376 | 0.349 | 0.357 | 0.379 | 0.379 |

| m21 | −0.033 | −0.059 | −0.065 | −0.085 | −0.095 | −0.118 | −0.118 |

| m22 | −1.651 | −1.644 | −1.588 | −1.625 | −1.651 | −1.654 | −1.654 |

| m23 | −0.131 | −0.143 | −0.082 | −0.169 | −0.155 | −0.153 | −0.153 |

| m31 | 0.013 | 0.015 | 0.019 | 0.016 | 0.015 | 0.008 | 0.008 |

| m32 | −0.999 | −0.973 | −0.956 | −0.958 | −0.960 | −0.967 | −0.967 |

| m33 | −1.157 | −1.152 | −1.129 | −1.156 | −1.147 | −1.156 | −1.156 |

| Components | Mmean |

|---|---|

| m11 | 1.529 |

| m12 | 0.386 |

| m13 | 0.365 |

| m21 | −0.087 |

| m22 | −1.652 |

| m23 | −0.159 |

| m31 | 0.013 |

| m32 | −0.971 |

| m33 | −1.155 |

| Error | Value (%) |

|---|---|

| NRMSEMT | 2.188 |

| NRMSEMR | 3.398 |

| NRMSEMLM | 1.132 |

| NRMSEMGLOBAL | 2.243 |

| Test Direction | NRMSEMT (%) | NRMSEMR (%) | NRMSEMLM (%) | NRMSEMGLOBAL (%) |

|---|---|---|---|---|

| Tangential | 0.118 | 2.782 | 0.783 | 1.229 |

| Radial | 1.117 | 0.250 | 1.278 | 0.884 |

| Lateral-medial | 0.331 | 2.849 | 1.418 | 1.529 |

| Crank Angle (°) | NRMSEMT (%) | NRMSEMR (%) | NRMSEMLM (%) |

|---|---|---|---|

| 0 | 1.126 | 0.254 | 1.278 |

| 45 | 2.097 | 2.556 | 1.340 |

| 90 | 0.116 | 2.781 | 0.785 |

| 135 | 1.010 | 0.846 | 0.604 |

| 180 | 0.848 | 0.337 | 0.377 |

| 225 | 1.668 | 2.634 | 0.950 |

| 270 | 1.439 | 4.205 | 0.561 |

| 315 | 3.276 | 0.744 | 0.910 |

| Participant | EIE Max 1 | EIE Min 2 | Error EIE Max (%) | Error EIE Min (%) | ||

|---|---|---|---|---|---|---|

| 2D | 3D | 2D | 3D | |||

| 1 | 0.993 | 0.991 | −0.992 | −0.989 | 0.202 | 0.303 |

| 2 | 0.994 | 0.987 | −0.994 | −0.993 | 0.689 | 0.111 |

| 3 | 0.979 | 0.969 | −0.988 | −0.986 | 1.063 | 0.193 |

| 4 | 0.985 | 0.982 | −0.983 | −0.980 | 0.346 | 0.286 |

| 5 | 0.996 | 0.995 | −0.990 | −0.988 | 0.131 | 0.223 |

| 6 | 0.992 | 0.991 | −0.986 | −0.983 | 0.101 | 0.305 |

| Mean | 0.974 | 0.969 | −0.970 | −0.968 | 0.495 | 0.165 |

| Participant | EI | Error (%) | |

|---|---|---|---|

| 2D | 3D | ||

| 1 | 0.293 | 0.292 | 0.319 |

| 2 | 0.210 | 0.209 | 0.303 |

| 3 | 0.245 | 0.243 | 0.707 |

| 4 | 0.212 | 0.211 | 0.374 |

| 5 | 0.425 | 0.424 | 0.203 |

| 6 | 0.429 | 0.429 | 0.067 |

| Mean | 0.290 | 0.290 | 0.235 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Sosa, E.; Chaves, V.; Alvarado, I.; Mayo, J.; Ojeda, J. Design and Validation of a Device Attached to a Conventional Bicycle to Measure the Three-Dimensional Forces Applied to a Pedal. Sensors 2021, 21, 4590. https://doi.org/10.3390/s21134590

Martín-Sosa E, Chaves V, Alvarado I, Mayo J, Ojeda J. Design and Validation of a Device Attached to a Conventional Bicycle to Measure the Three-Dimensional Forces Applied to a Pedal. Sensors. 2021; 21(13):4590. https://doi.org/10.3390/s21134590

Chicago/Turabian StyleMartín-Sosa, Ezequiel, Víctor Chaves, Ignacio Alvarado, Juana Mayo, and Joaquín Ojeda. 2021. "Design and Validation of a Device Attached to a Conventional Bicycle to Measure the Three-Dimensional Forces Applied to a Pedal" Sensors 21, no. 13: 4590. https://doi.org/10.3390/s21134590

APA StyleMartín-Sosa, E., Chaves, V., Alvarado, I., Mayo, J., & Ojeda, J. (2021). Design and Validation of a Device Attached to a Conventional Bicycle to Measure the Three-Dimensional Forces Applied to a Pedal. Sensors, 21(13), 4590. https://doi.org/10.3390/s21134590