Comparison of Metal-Based PZT and PMN–PT Energy Harvesters Fabricated by Aerosol Deposition Method

Abstract

:1. Introduction

2. Materials and Methods

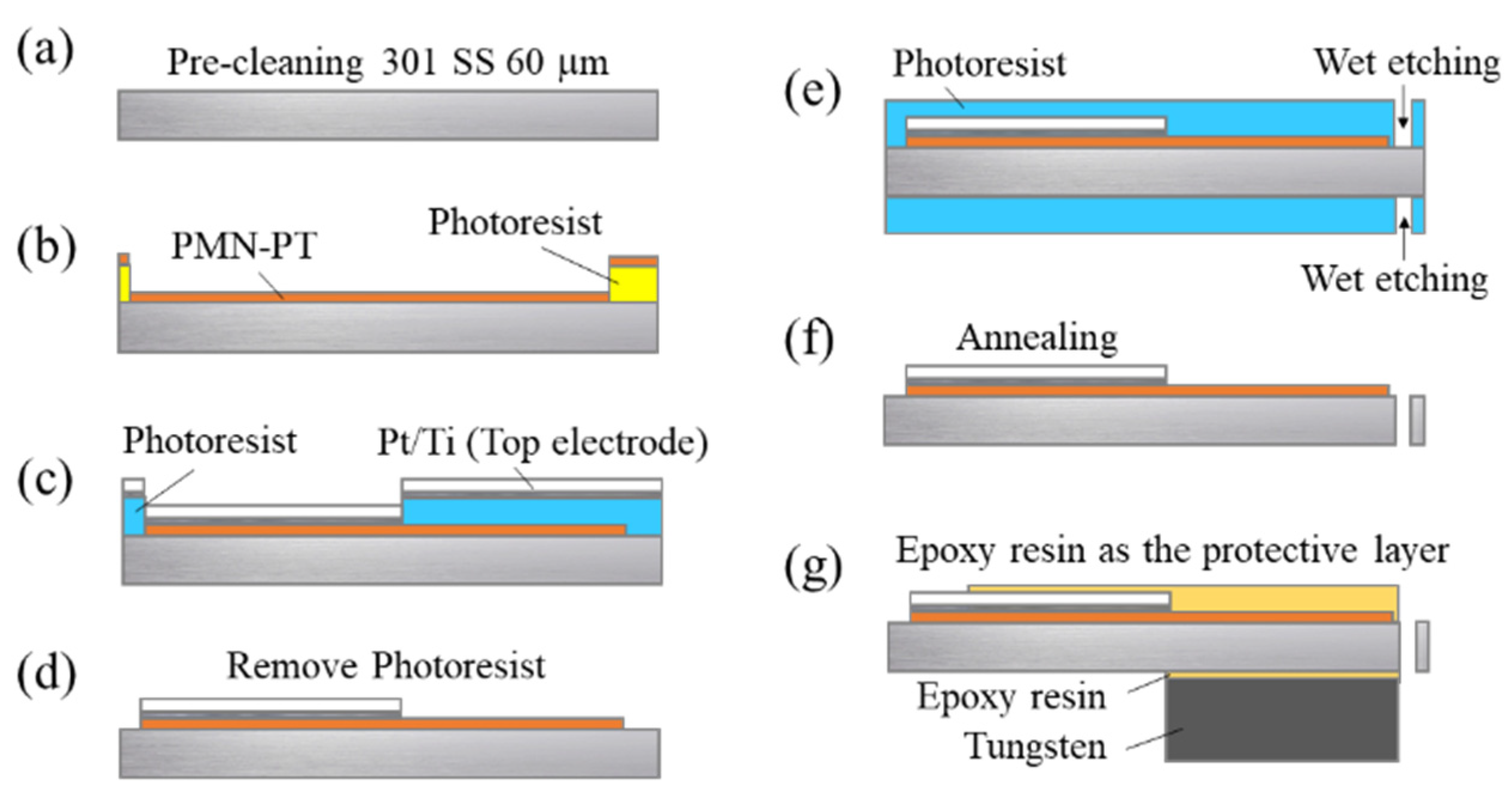

2.1. Fabrication Process

2.2. Experimental Setup

3. Results and Discussion

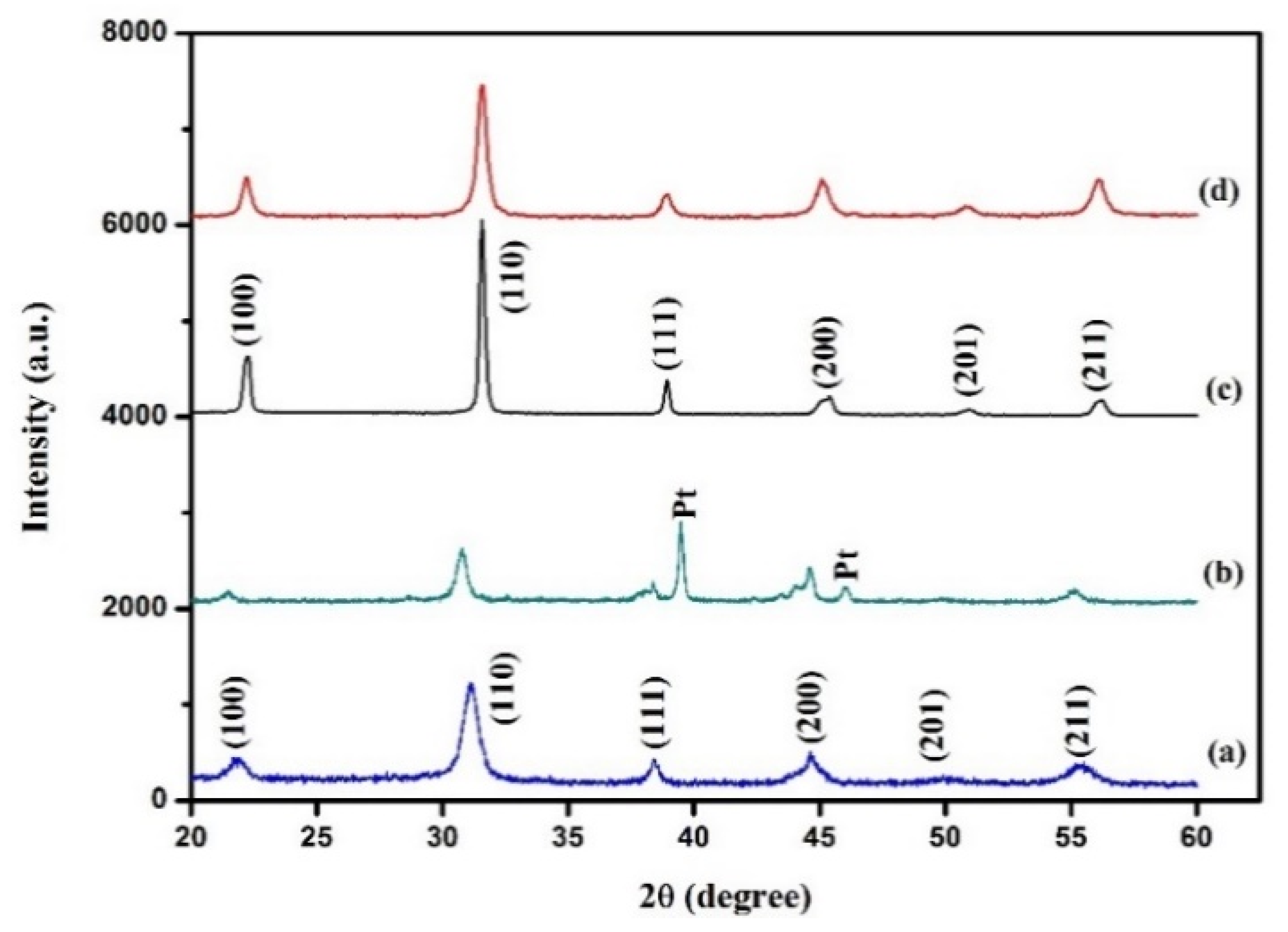

3.1. Powder Indentification

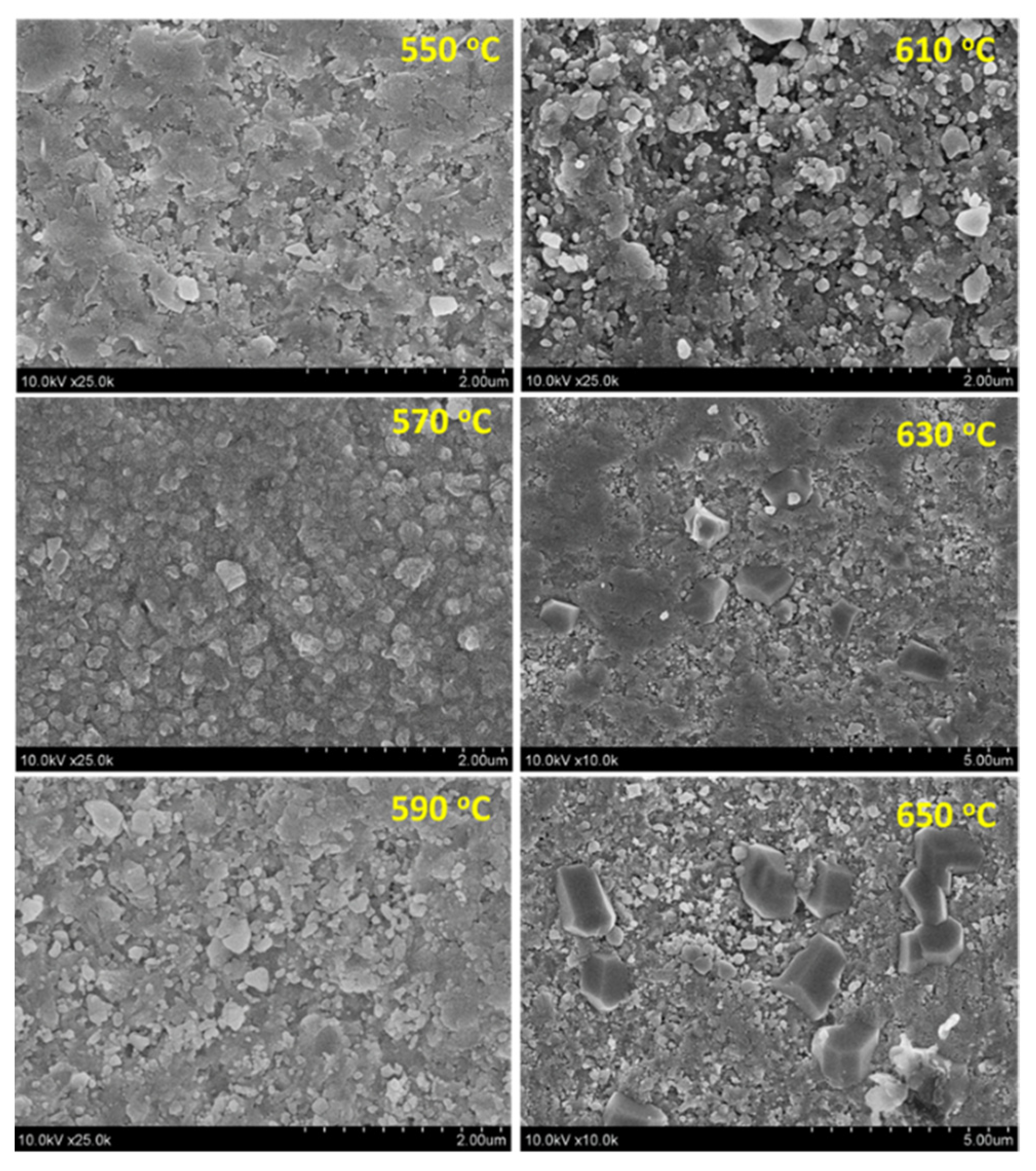

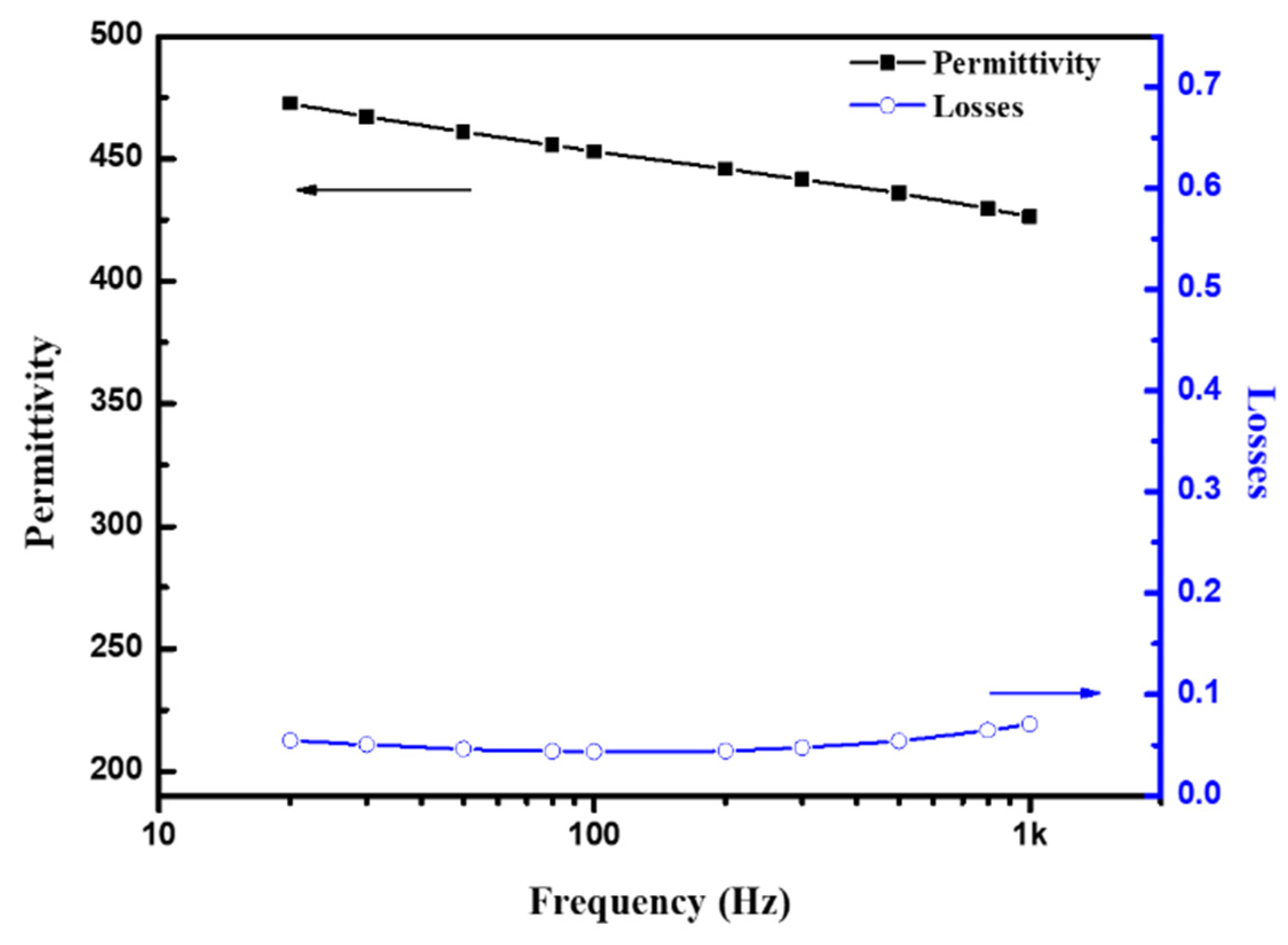

3.2. Film Characterization

3.3. Young’s Modulus and Hardness

3.4. Output Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, W.; Ling, Z.; Yu, W.; Shi, J. A review of MEMS scale piezoelectric energy harvester. Appl. Sci. 2018, 8, 645. [Google Scholar] [CrossRef] [Green Version]

- Roundy, S.; Wright, P.K.; Rabaey, J. A study of low level vibrations as a power source for wireless sensor nodes. Comput. Commun. 2003, 26, 1131. [Google Scholar] [CrossRef]

- Roundy, S.; Leland, E.S.; Baker, J.; Carleton, E.; Reilly, E.; Lai, E.; Sundararajan, V. Improving power output for vibration-based energy scavengers. IEEE Pervasive Comput. 2005, 4, 28. [Google Scholar] [CrossRef]

- Elvin, N.; Erturk, A. Advances in Energy Harvesting Methods; Springer: New York, NY, USA, 2013. [Google Scholar]

- Marin, A.; Bressers, S.; Priya, S. Multiple cell configuration electromagnetic vibration energy harvester. J. Phys. D Appl. Phys. 2011, 44, 295501. [Google Scholar] [CrossRef]

- Beeby, S.P.; Torah, R.; Tudor, M.; Glynne-Jones, P.; O’donnell, T.; Saha, C.; Roy, S. A micro electromagnetic generator for vibration energy harvesting. J. Micromech. Microeng. 2007, 17, 1257. [Google Scholar] [CrossRef]

- Chalasani, S.; Conrad, J.M. A survey of energy harvesting sources for embedded systems. In Proceedings of the IEEE SoutheastCon, Huntsville, AL, USA, 3–6 April 2008; pp. 442–447. [Google Scholar]

- Beeby, S.P.; O’Donnell, T. Electromagnetic energy harvesting. In Energy Harvesting Technologies; Priya, S., Inman, D.J., Eds.; Springer: Boston, MA, USA, 2009; pp. 129–161. [Google Scholar]

- Anton, S.R.; Sodano, H.A. A review of power harvesting using piezoelectric materials (2003–2006). Smart Mater. Struct. 2007, 16, R1. [Google Scholar] [CrossRef]

- Janphuang, P.; Lockhart, R.; Uffer, N.; Briand, D.; de Rooij, N.F. Vibrational piezoelectric energy harvesters based on thinned bulk PZT sheets fabricated at the wafer level. Sens. Actuators A 2014, 210, 1–9. [Google Scholar] [CrossRef]

- Van Minh, L.; Sano, T.; Fujii, T.; Kuwano, H. Comparison of PZN-PT, PMN-PT single crystals and PZT ceramic for vibration energy harvesting. J. Phys. Conf. Ser. 2016, 773, 012003. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Xie, M.; Roscow, J.; Bao, Y.; Zhou, K.; Zhang, D.; Bowen, C.R. Enhanced pyroelectric and piezoelectric properties of PZT with aligned porosity for energy harvesting applications. J. Mater. Chem. A 2017, 5, 6569. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, L.; Wen, Z.; Zhao, X.; Yuan, C.; Luo, G.; Mo, J. High Voltage Output MEMS Vibration Energy Harvester in d31 Mode With PZT Thin Film. J. Microelectromech. Syst. 2014, 23, 855. [Google Scholar] [CrossRef]

- Kuo, C.-L.; Lin, S.-C.; Wu, W.-J. Fabrication and performance evaluation of a metal-based bimorph piezoelectric MEMS generator for vibration energy harvesting. Smart Mater. Struct. 2016, 25, 105016. [Google Scholar] [CrossRef]

- Kang, M.-G.; Jung, W.-S.; Kang, C.-Y.; Yoon, S.-J. Recent Progress on PZT based piezoelectric energy harvesting technologies. Actuators 2016, 5, 5. [Google Scholar] [CrossRef]

- Lin, S.-C.; Wu, W.-J. Fabrication of PZT MEMS energy harvester based on silicon and stainless-steel substrates utilizing an aerosol deposition method. J. Micromech. Microeng. 2013, 23, 125028. [Google Scholar] [CrossRef]

- Song, H.-C.; Kang, C.-Y.; Yoon, S.-J.; Jeong, D.-Y. Engineered domain configuration and piezoelectric energy harvesting in 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 single crystals. Met. Mater. Int. 2012, 18, 499. [Google Scholar] [CrossRef]

- Hwang, G.T.; Byun, M.; Jeong, C.K.; Lee, K.J. Flexible Piezoelectric Thin-Film Energy Harvesters and Nanosensors for Biomedical Applications. Adv. Healthcare Mater. 2015, 4, 646. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zu, J. Comparison of PZN-PT, PMN-PT single crystals and PZT ceramic for vibration energy harvesting. Energy Convers. Manag. 2016, 122, 321. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Hao, X.; An, S. High energy-storage performance of 0.9 Pb (Mg1/3Nb2/3) O3-0.1 PbTiO3 relaxor ferroelectric thin films prepared by RF magnetron sputtering. Mater. Res. Bull. 2015, 65, 73. [Google Scholar] [CrossRef]

- Baek, S.H.; Park, J.; Kim, D.M.; Aksyuk, V.A.; Das, R.R.; Bu, S.D.; Eom, C.B. Giant piezoelectricity on Si for hyperactive MEMS. Science 2011, 334, 958. [Google Scholar] [CrossRef] [Green Version]

- Gabor, U.; Spreitzer, M.; Uršič, H.; Tchernychova, E.; Samardžija, Z.; Wu, W.J.; Suvorov, D. Structural peculiarities of 0.67 Pb (Mg1/3Nb2/3) O3–0.33 PbTiO3 thin films grown directly on SrTiO3 substrates. J. Eur. Ceram. Soc. 2018, 38, 4453. [Google Scholar] [CrossRef]

- Gabor, U.; Vengust, D.; Samardžija, Z.; Matavž, A.; Bobnar, V.; Suvorov, D.; Spreitzer, M. Stabilization of the perovskite phase in PMN-PT epitaxial thin films via increased interface roughness. Appl. Surf. Sci. 2020, 513, 145787. [Google Scholar] [CrossRef]

- Akedo, J.; Nakano, S.; Park, J.; Baba, S.; Ashida, K. The aerosol deposition method. Synth. Engl. Ed. 2008, 1, 121. [Google Scholar] [CrossRef] [Green Version]

- Akedo, J. Room temperature impact consolidation (RTIC) of fine ceramic powder by aerosol deposition method and applications to microdevices. J. Therm. Spray Technol. 2008, 17, 181. [Google Scholar] [CrossRef]

- Muralt, P. PZT thin films for microsensors and actuators: Where do we stand? IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2000, 47, 903. [Google Scholar] [CrossRef]

- Akedo, J.; Lebedev, M. Effects of annealing and poling conditions on piezoelectric properties of Pb (Zr0.52, Ti0.48) O3 thick films formed by aerosol deposition method. J. Cryst. Growth 2002, 235, 415. [Google Scholar] [CrossRef]

- Akedo, J. Aerosol techniques for manufacturing piezoelectric materials. In Advanced Piezoelectric Materials; Elsevier: Amsterdam, The Netherlands, 2010; p. 493. [Google Scholar]

- Elfrink, R.; Kamel, T.; Goedbloed, M.; Matova, S.; Hohlfeld, D.; van Andel, Y.; van Schaijk, R. Vibration energy harvesting with aluminum nitride-based piezoelectric devices. J. Micromech. Microeng. 2009, 19, 094005. [Google Scholar] [CrossRef] [Green Version]

- Xu, R.; Kim, S. Figures of merits of piezoelectric materials in energy harvesters. In Proceedings of the 12th International Workshop on Micro and Nanotechnology for Power Generation and Energy Conversion Applications, Atlanta, GA, USA, 2–5 December 2012; pp. 464–467. [Google Scholar]

- Akedo, J.; Lebedev, M. Powder preparation in aerosol deposition method for lead zirconate titanate thick films. Jpn. J. Appl. Phys. 2002, 41, 6980. [Google Scholar] [CrossRef]

- Maria, J.-P.; Hackenberger, W.; Trolier-McKinstry, S. Phase development and electrical property analysis of pulsed laser deposited Pb(Mg1/3Nb2/3)O3–PbTiO3 (70/30) epitaxial thin films. J. Appl. Phys. 1998, 84, 5147. [Google Scholar] [CrossRef]

- Shih, W.Y.; Luo, H.; Li, H.; Martorano, C.; Shih, W.-H. Sheet geometry enhanced giant piezoelectric coefficients. Appl. Phys. Lett. 2006, 89, 242913. [Google Scholar] [CrossRef] [Green Version]

- Lin, S.-C. High performance piezoelectric MEMS generators based on stainless steel substrate. In Deparment of Engineering Science and Ocean Engingeering; National Taiwan University: Taipei, Taiwan, 2014. [Google Scholar]

- Özenbaş, M.; Yıldırım, A. Pb (Zr0.52Ti0.48) O3 films on stainless steel by chemical solution deposition. Key Eng. Mater. 2004, 264, 1217. [Google Scholar] [CrossRef]

- Shekhani, H.N.; Gurdal, E.A.; Ural, S.O.; Uchino, K. Analysis of High Power Behavior in Piezoelectric Ceramics from a Mechanical Energy Density Perspective. arXiv 2016, arXiv:1605.06685. [Google Scholar]

- Tsui, T.; Pharr, G. Substrate effects on nanoindentation mechanical property measurement of soft films on hard substrates. J. Mater. Res. 1999, 14, 292. [Google Scholar] [CrossRef]

- Shu, Y.; Yin, P.; Liang, B.; Wang, S.; Gao, L.; Wang, H.; Guo, L. Layer by layer assembly of heparin/layered double hydroxide completely renewable ultrathin films with enhanced strength and blood compatibility. J. Mater. Chem. 2012, 22, 21667. [Google Scholar] [CrossRef]

- Bahr, D.; Robach, J.; Wright, J.; Francis, L.; Gerberich, W. Mechanical deformation of PZT thin films for MEMS applications. Mater. Sci. Eng. A 1999, 259, 126. [Google Scholar] [CrossRef]

- Akedo, J.; Lebedev, M. Piezoelectric properties and poling effect of Pb(Zr,Ti)3 thick films prepared for microactuators by aerosol deposition. Appl. Phys. Lett. 2000, 77, 1710. [Google Scholar] [CrossRef]

- Zhong, X.; Lu, L.; Lai, M. Growth of highly orientated 0.65Pb(Mg1/3Nb2/3)O3–0.35PbTiO3 films by pulsed laser deposition. Surf. Coat. Technol. 2005, 198, 400. [Google Scholar] [CrossRef]

- Shu, Y.; Lien, I. Analysis of power output for piezoelectric energy harvesting systems. Smart Mater. Struct. 2006, 15, 1499. [Google Scholar] [CrossRef]

- Kanno, I.; Kotera, H.; Wasa, K. Measurement of transverse piezoelectric properties of PZT thin films. Sens. Actuators A 2003, 107, 68. [Google Scholar] [CrossRef]

- Morimoto, K.; Kanno, I.; Wasa, K.; Kotera, H. High-efficiency piezoelectric energy harvesters of c-axis-oriented epitaxial PZT films transferred onto stainless steel cantilevers. Sens. Actuators A 2010, 163, 428. [Google Scholar] [CrossRef]

- Suwa, E.; Tsujiura, Y.; Kurokawa, F.; Hida, H.; Kanno, I. Fabrication of high-efficiency piezoelectric energy harvesters of epitaxial Pb (Zr, Ti) O3 thin films by laser lift-off. Energy Harvest. Syst. 2016, 3, 61. [Google Scholar] [CrossRef]

- Berksoy-Yavuz, A.; Savacı, U.; Turan, S.; Alkoy, S.; Mensur-Alkoy, E. Structural features and energy harvester device applications of textured 0.675 PMN–0.325 PT piezoceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 9650. [Google Scholar] [CrossRef]

- Gibus, D.; Gasnier, P.; Morel, A.; Formosa, F.; Charleux, L.; Boisseau, S.; Badel, A. Strongly coupled piezoelectric cantilevers for broadband vibration energy harvesting. Appl. Energy 2020, 277, 115518. [Google Scholar] [CrossRef]

| Material | Permittivity | Piezoelectric Constant, d31 (pC/N) | Coupling Coefficient, kp |

|---|---|---|---|

| Poly-PMN–PT | 3621 | −250 | 0.69 |

| Poly-PZT | 1300 | −130 | 0.6 |

| Material/Film Type | Pb (%) | Mg (%) | Nb (%) | Ti (%) | Cr (%) | Fe (%) |

|---|---|---|---|---|---|---|

| Stainless steel | - | - | - | - | 21 | 71 |

| Ceramic | 47 | 8 | 25 | 20 | ||

| As-deposited film | 45 | 9 | 26 | 19 | - | - |

| 600 °C annealed film | 46 | 14 | 22 | 18 | - | - |

| 650 °C annealed film | 39 | 6 | 28 | 18 | 2 | 8 |

| Second-phase grain on 650 °C annealed film | 55 | 0 | 7 | 2 | 29 | 5 |

| Material | Young’s Modulus (GPa) | Hardness (GPa) |

|---|---|---|

| PZT film [39,40] | 80 | 5–8 |

| PMN–PT single crystal [41] | 126.81 | 5.59 |

| Poly-PMN–PT sheet [33] | 70 ± 15 | - |

| Poly-PZT (thick film) (this study) | 90.75 | 5.9 |

| Poly-PMN–PT (thick film) (this study) | 86.47 | 5.59 |

| Parameter | PZT | PMN–PT |

|---|---|---|

| Thickness (μm) | 10 | 10 |

| Resonant frequency (Hz) | 101.6 | 98 |

| Quality factor | 72.8 | 147.4 |

| Damping ratio | 0.007 | 0.003 |

| Capacitance (nF) | 9.8 | 20.5 |

| Permittivity, εr | 309 | 426 |

| Piezoelectric coefficient, d31 () | −17.8 | −26.9 |

| Coupling coefficient, | 0.10 | 0.11 |

| Dielectric loss (%) | 1.5 | 3 |

| Normalized FOM | 1 | 1.5 |

| Output power (μW) | 71.8 | 90.4 |

| Output voltage with load (VP–P) | 9.3 | 7.7 |

| Optimum impedance (kΩ) | 150 | 82 |

| Study | Piezoelectric Material | Substrate Material | Dimension (mm3) | Acceleration (g) | Frequency (Hz) | Avg. Output Power (μW) | Energy Density (μW cm−3 Hz−1) |

|---|---|---|---|---|---|---|---|

| Morimoto [44] | PZT | Steel | 4.9 | 0.5 | 126 | 5.3 | 34.5 |

| Tsujiura [45] | PZT | Steel | 17.1 | 0.1 | 143 | 1.8 | 73.6 |

| Yang [19] | PZT | Aluminum | 486 | 0.3 | 151 | 150 | 22.7 |

| Ayse [46] | PZT | Brass | - | 0.2 | 34 | 1.1 | - |

| Gibus [47] | PZT | Steel | 4500 | 0.02 | 32.1 | 0.6 | 10.2 |

| This work | PZT | Steel | 25.4 | 0.5 | 101.6 | 71.8 | 145.7 |

| Yang [19] | PMN–PT* | Aluminum | 486 | 0.3 | 159 | 250 | 35.9 |

| Ayse [46] | PMN–PT* | Brass | - | 0.2 | 35 | 1.2 | - |

| Gibus [47] | PMN–PT* | Steel | 3750 | 0.02 | 29.1 | 0.4 | 12.3 |

| This work | PMN–PT | Steel | 25.4 | 0.5 | 98.0 | 90.4 | 111.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.-T.; Lin, S.-C.; Trstenjak, U.; Spreitzer, M.; Wu, W.-J. Comparison of Metal-Based PZT and PMN–PT Energy Harvesters Fabricated by Aerosol Deposition Method. Sensors 2021, 21, 4747. https://doi.org/10.3390/s21144747

Chen C-T, Lin S-C, Trstenjak U, Spreitzer M, Wu W-J. Comparison of Metal-Based PZT and PMN–PT Energy Harvesters Fabricated by Aerosol Deposition Method. Sensors. 2021; 21(14):4747. https://doi.org/10.3390/s21144747

Chicago/Turabian StyleChen, Chao-Ting, Shun-Chiu Lin, Urška Trstenjak, Matjaž Spreitzer, and Wen-Jong Wu. 2021. "Comparison of Metal-Based PZT and PMN–PT Energy Harvesters Fabricated by Aerosol Deposition Method" Sensors 21, no. 14: 4747. https://doi.org/10.3390/s21144747

APA StyleChen, C.-T., Lin, S.-C., Trstenjak, U., Spreitzer, M., & Wu, W.-J. (2021). Comparison of Metal-Based PZT and PMN–PT Energy Harvesters Fabricated by Aerosol Deposition Method. Sensors, 21(14), 4747. https://doi.org/10.3390/s21144747