Early-Stage Gas Identification Using Convolutional Long Short-Term Neural Network with Sensor Array Time Series Data

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Sensor Array Fabrication

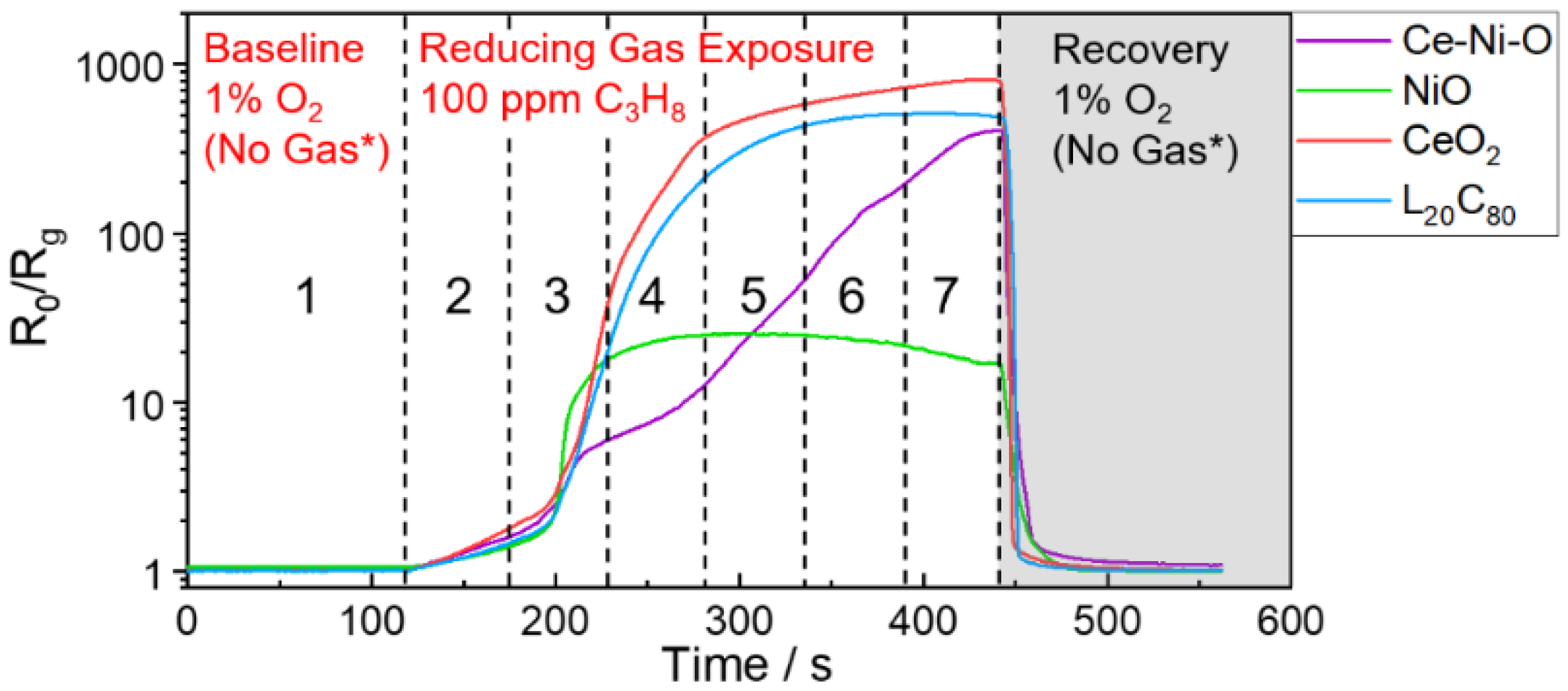

2.2. Sensor Array Measurements

3. Sensor Array Dataset

4. Gas Identification Framework

4.1. Background/Overview of CLSTM Neural Network

4.2. Data Labeling, Time Series Reformatting, and Problem Setup

4.3. CLSTM Neural Network Architecture Configuration

4.4. Baseline Models

5. Implementation, Results and Discussions

5.1. Performance Investigation of CLSTM Neural Network Model—Comparison with Baseline Models and Examination of Sample Length Effect

5.2. External Validation of CLSTM Neural Network Model

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Parisi, J.; Sun, X.; Lei, Y. Solid-state gas sensors for high temperature applications—A review. J. Mater. Chem. A 2014, 2, 9919–9943. [Google Scholar] [CrossRef]

- Moos, R. A brief overview on automotive exhaust gas sensors based on electroceramics. Int. J. Appl. Ceram. Technol. 2005, 2, 401–413. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, L.; Li, W.; Li, W.; Liu, X. A high-temperature mixed potential CO gas sensor for in situ combustion control. J. Mater. Chem. A 2020, 8, 20101–20110. [Google Scholar] [CrossRef]

- Fomekong, R.L.; Kelm, K.; Saruhan, B. High-Temperature hydrogen sensing performance of Ni-Doped TiO2 prepared by co-precipitation method. Sensors 2020, 20, 5992. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Lin, H.-J.; Gao, H.; Lu, X.; Nam, C.-Y.; Gao, P.-X. Perovskite-sensitized β-Ga2O3 nanorod arrays for highly selective and sensitive NO2 detection at high temperature. J. Mater. Chem. A 2020, 8, 10845–10854. [Google Scholar] [CrossRef]

- Albert, K.J.; Lewis, N.S.; Schauer, C.L.; Sotzing, G.A.; Stitzel, S.E.; Vaid, T.; Walt, D.R. Cross-Reactive chemical sensor arrays. Chem. Rev. 2000, 100, 2595–2626. [Google Scholar] [CrossRef] [PubMed]

- Jeong, S.Y.; Kim, J.S.; Lee, J.H. Rational design of semiconductor-based chemiresistors and their libraries for next-generation artificial olfaction. Adv. Mater. 2020, 32, 2002075. [Google Scholar] [CrossRef]

- Abdelhalim, A.; Winkler, M.; Loghin, F.; Zeiser, C.; Lugli, P.; Abdellah, A. Highly sensitive and selective carbon nanotube-based gas sensor arrays functionalized with different metallic nanoparticles. Sens. Actuators B Chem. 2015, 220, 1288–1296. [Google Scholar] [CrossRef]

- Compagnone, D.; Fusella, G.; Del Carlo, M.; Pittia, P.; Martinelli, E.; Tortora, L.; Paolesse, R.; Di Natale, C. Gold nanoparticles-peptide based gas sensor arrays for the detection of foodaromas. Biosens. Bioelectron. 2013, 42, 618–625. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, J.; Jiang, C.; Liu, A.; Xia, B. Quantitative detection of formaldehyde and ammonia gas via metal oxide-modified graphene-based sensor array combining with neural network model. Sensors Actuators B Chem. 2017, 240, 55–65. [Google Scholar] [CrossRef]

- Liu, S.F.; Moh, L.C.H.; Swager, T.M. Single-Walled carbon nanotube–metalloporphyrin chemiresistive gas sensor arrays for volatile organic compounds. Chem. Mater. 2015, 27, 3560–3563. [Google Scholar] [CrossRef] [Green Version]

- Zhong, X.; Huo, D.; Fa, H.; Luo, X.; Wang, Y.; Zhao, Y.; Hou, C. Rapid and ultrasensitive detection of biogenic amines with colorimetric sensor array. Sens. Actuators B Chem. 2018, 274, 464–471. [Google Scholar] [CrossRef]

- Queralto, N.; Berliner, A.N.; Goldsmith, B.; Martino, R.; Rhodes, P.; Lim, S.H. Detecting cancer by breath volatile organic compound analysis: A review of array-based sensors. J. Breath Res. 2014, 8, 027112. [Google Scholar] [CrossRef]

- Shan, B.; Broza, Y.Y.; Li, W.; Wang, Y.; Wu, S.; Liu, Z.; Wang, J.; Gui, S.; Wang, L.; Zhang, Z.; et al. Multiplexed nanomaterial-based sensor array for detection of COVID-19 in exhaled breath. ACS Nano 2020, 14, 12125–12132. [Google Scholar] [CrossRef] [PubMed]

- Schroeder, V.; Evans, E.D.; Wu, Y.-C.M.; Voll, C.-C.A.; McDonald, B.R.; Savagatrup, S.; Swager, T.M. Chemiresistive sensor array and machine learning classification of food. ACS Sens. 2019, 4, 2101–2108. [Google Scholar] [CrossRef]

- Pierce, K.M.; Hope, J.L.; Johnson, K.J.; Wright, B.W.; Synovec, R.E. Classification of gasoline data obtained by gas chromatography using a piecewise alignment algorithm combined with feature selection and principal component analysis. J. Chromatogr. A 2005, 1096, 101–110. [Google Scholar] [CrossRef]

- Murugan, S.; Sankaralingam, M.N. Potential of gas sensor array based principal component analysis hybrid for Escherichia coli detection. Int. J. Model. Simul. 2010, 30, 445–451. [Google Scholar] [CrossRef]

- Lu, Y.; Partridge, C.; Meyyappan, M.; Li, J. A carbon nanotube sensor array for sensitive gas discrimination using principal component analysis. J. Electroanal. Chem. 2006, 593, 105–110. [Google Scholar] [CrossRef]

- Khan, A.H.; Thomson, B.; Debnath, R.; Motayed, A.; Rao, M.V. Nanowire-Based sensor array for detection of cross-sensitive gases using PCA and machine learning algorithms. IEEE Sens. J. 2020, 20, 6020–6028. [Google Scholar] [CrossRef]

- Fan, S.; Li, Z.; Xia, K.; Hao, D. Quantitative and qualitative analysis of multicomponent gas using sensor array. Sensors 2019, 19, 3917. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Xue, Y.; Sun, Q.; Zhang, T.; Chen, Y.; Yu, W.; Xiong, Y.; Wei, X.; Yu, G.; Wan, H.; et al. A miniaturized electronic nose with artificial neural network for anti-interference detection of mixed indoor hazardous gases. Sens. Actuators B Chem. 2021, 326, 128822. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, Y.; Chen, K.; Li, H.; Jian, J. Concentration estimator of mixed voc gases using sensor array with neural networks and decision tree learning. IEEE Sens. J. 2017, 17, 1884–1892. [Google Scholar] [CrossRef]

- Ha, D.; Ahmed, U.; Pyun, H.; Lee, C.-J.; Baek, K.H.; Han, C. Multi-mode operation of principal component analysis with k-nearest neighbor algorithm to monitor compressors for liquefied natural gas mixed refrigerant processes. Comput. Chem. Eng. 2017, 106, 96–105. [Google Scholar] [CrossRef]

- Vergara, A.; Fonollosa, J.; Mahiques, J.; Trincavelli, M.; Rulkov, N.; Huerta, R. On the performance of gas sensor arrays in open sampling systems using Inhibitory Support Vector Machines. Sens. Actuators B Chem. 2013, 185, 462–477. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Welling, C.M.; Vasquez, M.M.; Grego, S.; Chakrabarty, K. Sensor-Array optimization based on time-series data analytics for sanitation-related malodor detection. IEEE Trans. Biomed. Circuits Syst. 2020, 14, 705–714. [Google Scholar] [CrossRef] [PubMed]

- Chu, J.; Li, W.; Yang, X.; Wu, Y.; Wang, D.; Yang, A.; Yuan, H.; Wang, X.; Li, Y.; Rong, M. Identification of gas mixtures via sensor array combining with neural networks. Sens. Actuators B Chem. 2021, 329, 129090. [Google Scholar] [CrossRef]

- Peng, P.; Zhao, X.; Pan, X.; Ye, W. Gas classification using deep convolutional neural networks. Sensors 2018, 18, 157. [Google Scholar] [CrossRef] [Green Version]

- Xing, C.; Ma, L.; Yang, X. Stacked denoise autoencoder based feature extraction and classification for hyperspectral images. J. Sens. 2016, 2016, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Tang, J. Efficient characterization of dynamic response variation using multi-fidelity data fusion through composite neural network. Eng. Struct. 2021, 232, 111878. [Google Scholar] [CrossRef]

- Cao, P.; Zhang, S.; Tang, J. Preprocessing-Free gear fault diagnosis using small datasets with deep convolutional neural network-based transfer learning. IEEE Access 2018, 6, 26241–26253. [Google Scholar] [CrossRef]

- Khan, A.H.; Motayed, A.; Rao, M.V. Identification and quantification of gases and their mixtures using GaN sensor array and artificial neural network. Meas. Sci. Technol. 2021, 32, 055111. [Google Scholar] [CrossRef]

- Nanto, H.; Tsubakino, S.; Ikeda, M.; Endo, F. Identification of aromas from wine using quartz-resonator gas sensors in conjuction with neural-network analysis. Sens. Actuators B Chem. 1995, 25, 794–796. [Google Scholar] [CrossRef]

- Gulbag, A.; Temurtas, F.; Tasaltin, C.; Ozturk, Z.Z. A study on radial basis function neural network size reduction for quantitative identification of individual gas concentrations in their gas mixtures. Sens. Actuators B Chem. 2007, 124, 383–392. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, Z.; Kong, D.; Han, H.; Zhao, Y. EA-LSTM: Evolutionary attention-based LSTM for time series prediction. Knowl. Based Syst. 2019, 181, 104785. [Google Scholar] [CrossRef] [Green Version]

- Graves, A.; Jaitly, N.; Mohamed, A.-r. Hybrid Speech Recognition with Deep Bidirectional LSTM; University of Toronto Department of Computer Science: Toronto, ON, Canada, 2013; pp. 273–278. [Google Scholar]

- Bogaerts, T.; Masegosa, A.D.; Angarita-Zapata, J.S.; Onieva, E.; Hellinckx, P. A graph CNN-LSTM neural network for short and long-term traffic forecasting based on trajectory data. Transp. Res. Part C Emerg. Technol. 2020, 112, 62–77. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, Y.; Gao, H.; Zhang, L.; Gao, P.; Li, B.; Lei, Y. La0.67Sr0.33MnO3 nanofibers for in situ, real-time, and stable high temperature oxygen sensing. RSC Adv. 2012, 2, 3872–3877. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, Y.; Zhang, L.; Gao, P.-X.; Lei, Y. CeO2 nanofibers for in situ O2 and CO sensing in harsh environments. RSC Adv. 2012, 2, 5193–5198. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, X.; Zhou, Z.; Lei, Y. Electrospun Ce–Ni–O composite nanofibers for highly selective propane detection at high temperature based on its rapid reaction kinetics. J. Mater. Chem. A 2014, 2, 14038–14047. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, X.; Li, B.; Lei, Y. Tunable p–n transition behaviour of a p-La0.67Sr0.33MnO3/n-CeO2nanofibers heterojunction for the development of selective high temperature propane sensors. J. Mater. Chem. A 2014, 2, 11651–11659. [Google Scholar] [CrossRef]

- Ordóñez, F.J.; Roggen, D. Deep Convolutional and LSTM Recurrent Neural Networks for Multimodal Wearable Activity Recognition. Sensors 2016, 16, 115. [Google Scholar] [CrossRef] [Green Version]

- Zhao, R.; Yan, R.; Wang, J.; Mao, K. Learning to Monitor Machine Health with Convolutional Bi-Directional LSTM Networks. Sensors 2017, 17, 273. [Google Scholar] [CrossRef]

- Zhu, G.; Zhang, L.; Shen, P.; Song, J. Multimodal Gesture Recognition Using 3-D Convolution and Convolutional LSTM. IEEE Access 2017, 5, 4517–4524. [Google Scholar] [CrossRef]

- Bilgera, C.; Yamamoto, A.; Sawano, M.; Matsukura, H.; Ishida, H. Application of Convolutional Long Short-Term Memory Neural Networks to Signals Collected from a Sensor Network for Autonomous Gas Source Localization in Outdoor Environments. Sensors 2018, 18, 4484. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Lei, Y. Pt-CeO2 nanofibers based high-frequency impedancemetric gas sensor for selective CO and C3H8 detection in high-temperature harsh environment. Sensors Actuators B Chem. 2013, 188, 1141–1147. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, K.; Lei, Y. Using Bayesian Inference Framework towards Identifying Gas Species and Concentration from High Temperature Resistive Sensor Array Data. J. Sensors 2015, 2015, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Dehghani, A.; Sarbishei, O.; Glatard, T.; Shihab, E. A Quantitative Comparison of Overlapping and Non-Overlapping Sliding Windows for Human Activity Recognition Using Inertial Sensors. Sensors 2019, 19, 5026. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Steinwart, I.; Christmann, A. Support Vector Machines; Information Science and Statistics, 1st ed.; Springer: New York, NY, USA, 2008; ISBN 978-0-387-77241-7. [Google Scholar]

- Hofmann, T.; Schölkopf, B.; Smola, A.J. Kernel methods in machine learning. Ann. Stat. 2008, 36, 1171–1220. [Google Scholar] [CrossRef] [Green Version]

- Vang-Mata, R. Multilayer Perceptrons: Theory and Applications; Nova Science Publishers: Hauppauge, NY, USA, 2020; ISBN1 9781536173642. ISBN2 1536173649. [Google Scholar]

- Gulli, A. Deep Learning with Keras: Implementing Deep Learning Models and Neural Networks with the Power of Python; Packt Publishing: Birmingham, UK, 2017; ISBN 9781787128422. [Google Scholar]

- Raschka, S. Model evaluation, model selection, and algorithm selection in machine learning. arXiv 2018, arXiv:1811.12808. [Google Scholar]

- Sammut, C.; Webb, G.I. Encyclopedia of Machine Learning; Springer: New York, NY, USA, 2011; ISBN 9780387307688. [Google Scholar]

- Singh, R.; Mangat, N.S. Stratified Sampling BT—Elements of Survey Sampling; Springer: Dordrecht, Netherlands, 1996; ISBN 978-94-017-1404-4. [Google Scholar]

| CO (ppm) | CH4 (ppm) | C3H8 (ppm) | No Gas | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 50 | 80 | 100 | 50 | 80 | 100 | 50 | 80 | 100 | |

| Class 1 | Class 2 | Class 3 | Class 4 | ||||||

| 381 samples | 381 samples | 381 samples | 378 samples | ||||||

| Layer ID | Layer Type | Size | Output Shape | Parameters |

|---|---|---|---|---|

| #1 | Input | |||

| #2 | Convolutional (ReLU) | |||

| #3 | Convolutional (ReLU) | |||

| #4 | Max pooling | |||

| #5 | Fully connected (Flatten) | No | ||

| #6 | LSTM | |||

| #7 | Fully connected (ReLU) | |||

| #8 | Output (Softmax) |

| Models | Data Points Per Sample | Accuracy | Standard Deviation |

|---|---|---|---|

| CLSTM | 100 | 95.79% | 1.98% |

| MLP | 100 | 87.82% | 4.48% |

| SVM | 100 | 77.75% | 3.23% |

| CLSTM | 40 | 96.76% | 2.67% |

| MLP | 40 | 91.22% | 2.74% |

| SVM | 40 | 79.02% | 3.02% |

| Gas | Accuracy | # of Misclassifications (442 Samples in Total) |

|---|---|---|

| 100 ppm CO | 97.06% | 13 |

| 100 ppm C3H8 | 97.28% | 12 |

| 100 ppm CH4 | 97.96% | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, K.; Liu, Y. Early-Stage Gas Identification Using Convolutional Long Short-Term Neural Network with Sensor Array Time Series Data. Sensors 2021, 21, 4826. https://doi.org/10.3390/s21144826

Zhou K, Liu Y. Early-Stage Gas Identification Using Convolutional Long Short-Term Neural Network with Sensor Array Time Series Data. Sensors. 2021; 21(14):4826. https://doi.org/10.3390/s21144826

Chicago/Turabian StyleZhou, Kai, and Yixin Liu. 2021. "Early-Stage Gas Identification Using Convolutional Long Short-Term Neural Network with Sensor Array Time Series Data" Sensors 21, no. 14: 4826. https://doi.org/10.3390/s21144826

APA StyleZhou, K., & Liu, Y. (2021). Early-Stage Gas Identification Using Convolutional Long Short-Term Neural Network with Sensor Array Time Series Data. Sensors, 21(14), 4826. https://doi.org/10.3390/s21144826