Study of the Stability of Palletized Cargo by Dynamic Test Method Performed on Laboratory Test Bench

Abstract

1. Introduction

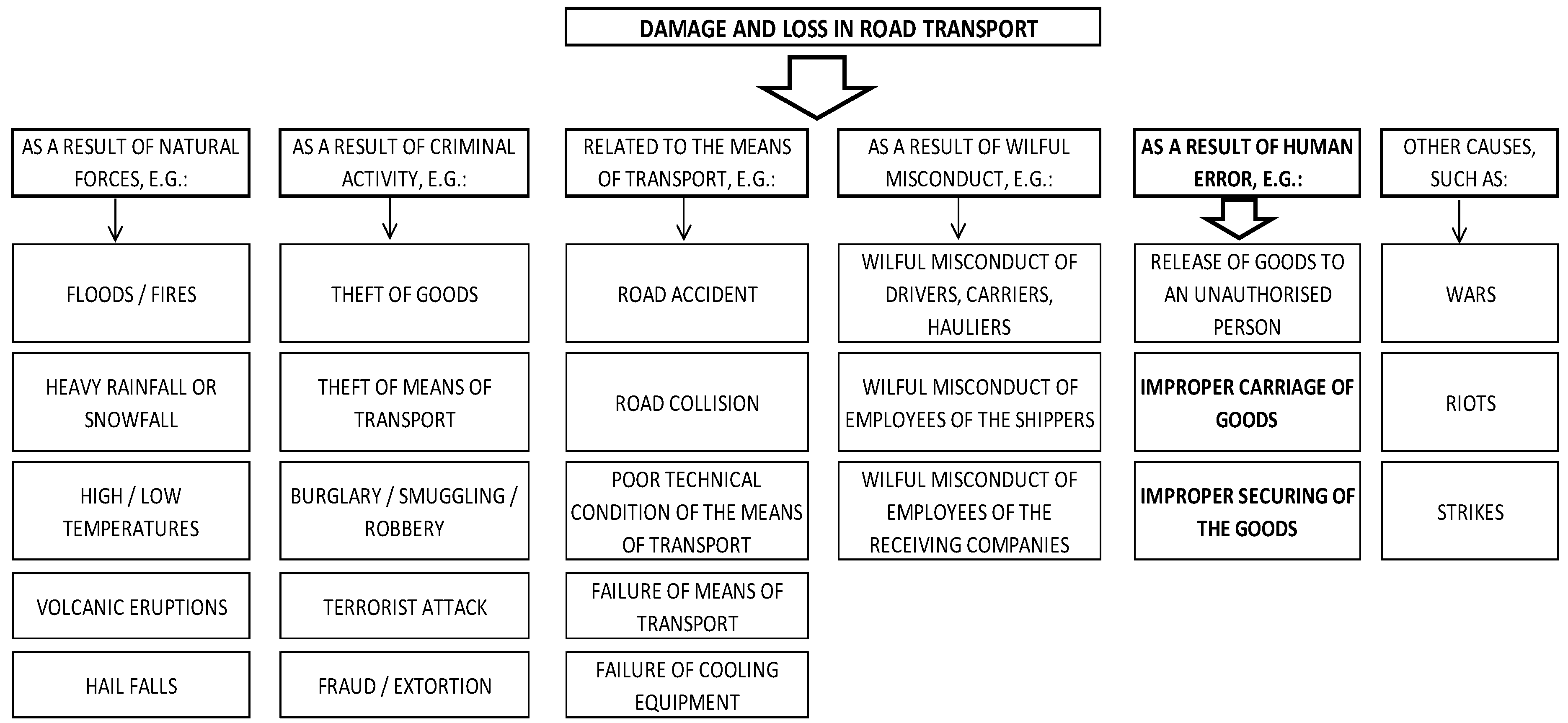

2. Literature Analysis of the Cargo Safety and Stability

3. Safety of Cargo in Transport

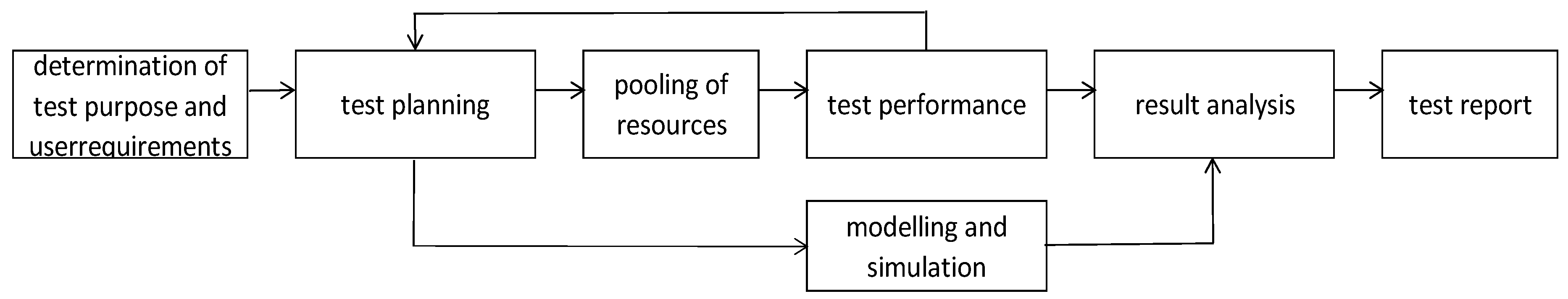

4. The Method of Testing the Stability of Palletized Cargo

4.1. Assumptions of the Method

- proof of concept for a technical solution,

- ensuring safe operation/use of the technical solution,

- ensuring appropriate ergonomic conditions,

- ensuring that all (defined) customer requirements are met,

- increasing reliability,

- ensuring compliance of project results with the order (contract),

- evaluation of the parameters of the technical solution and the effectiveness of its application,

- investment decision support,

- providing feedback to the designer,

- service quality assessment,

- validation of models used in research—this is usually a separate stage of model building (mathematical, simulation).

- comparison of different variants of design solutions.

- Characteristics of the current situation regarding cargo security in transport. It lists the factors that influence the occurrence of damage and losses. Mechanical damage is characterized. It defines what secure cargo is and what helps protect cargo from damage or destruction during transport. The obligations imposed on the shipper and the carrier by the transport contract concerning cargo security are defined.

- Formulation of the research problem. The most important factor protecting the cargo from damage or destruction is proper packaging and formation of the PUL at the shipper’s site. The choice of packaging material for the palletized cargo plays an important role here. This poses a significant difficulty for shippers and carriers, resulting in poor cargo packaging and its damage.

- A study of the stability of palletized cargo. At this stage, two cargo stability tests were performed. The tests differed in two parameters: stretch film with different characteristics/parameters to secure the cargo on the pallet and a different total number of PUL wrappings with stretch film. In each test, two cargo stability tests were performed—verification of the stability of the cargo with set accelerations of 0.4 g and 0.5 g.

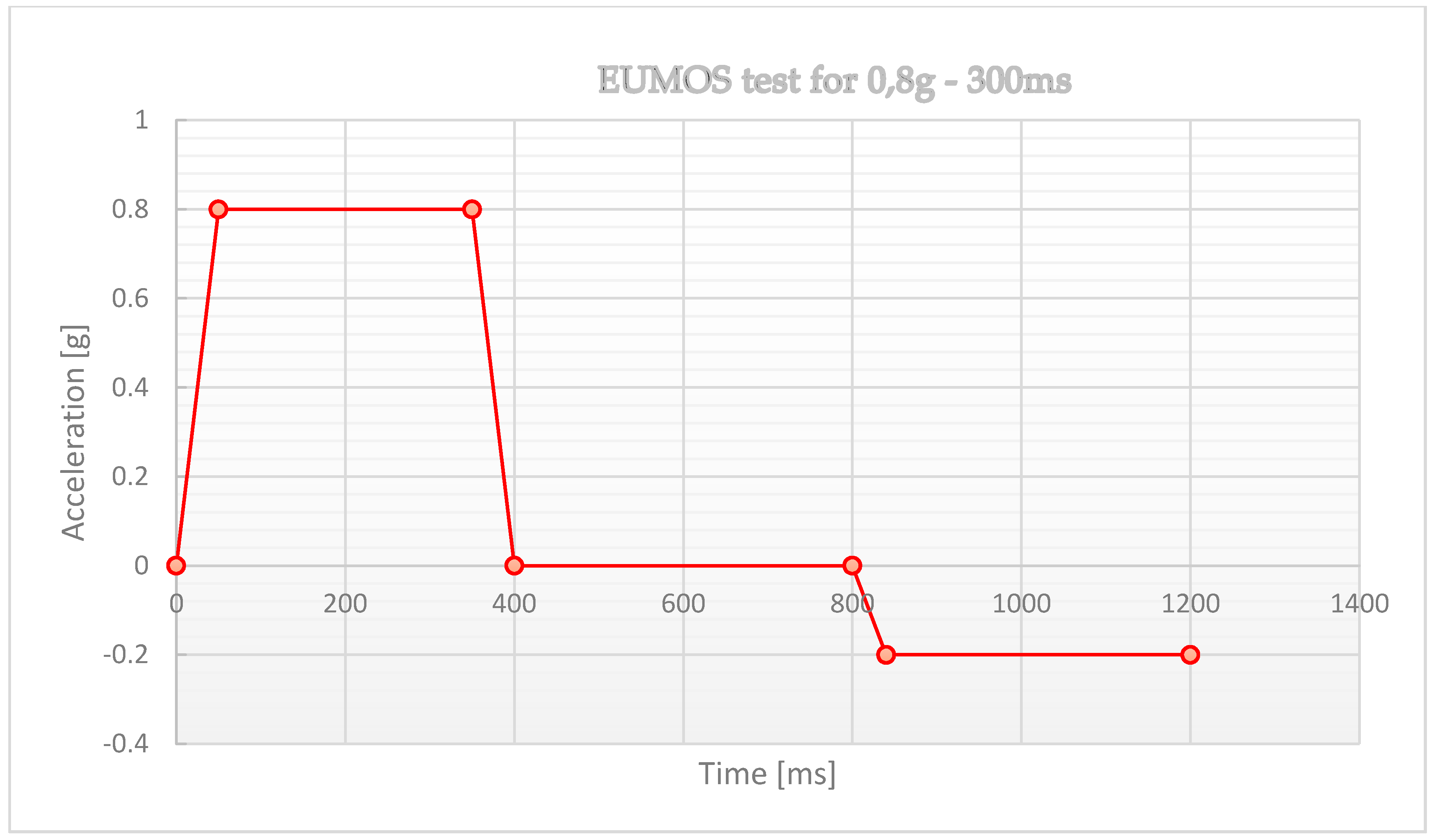

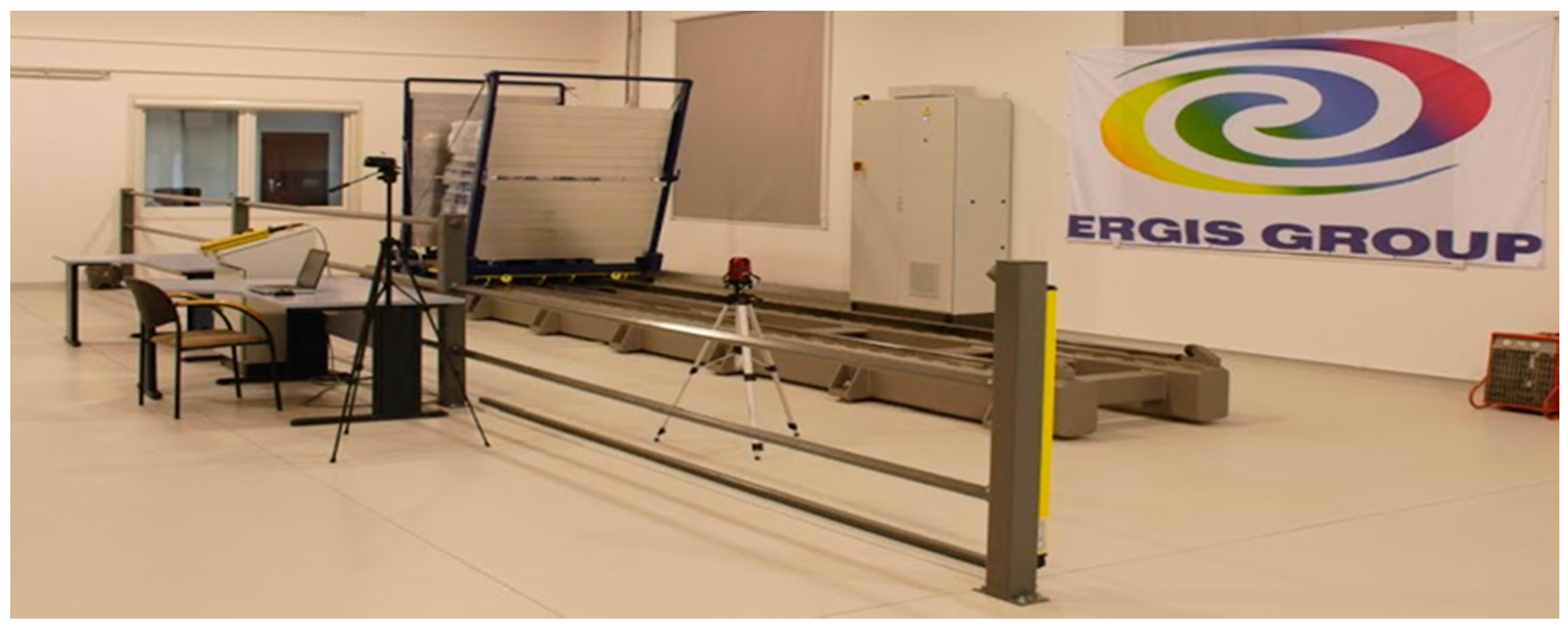

4.2. Test Stand Description

- it is accelerated by an electric motor (according to EUMOS, an acceleration with a duration of at least 300 ms and reached in less than 50 ms),

- it has an inclined front and rear wall of 14°, following the EUMOS standard,

- it has a sliding steel platform with non-slip floor and side guards (to prevent the cargo from falling; the steel basket, inclined on both sides, is designed to perform accelerations and decelerations to analyse the cargo’s behaviour during transport),

- this system has the ability to modify the acceleration value k with an accuracy of two decimal places, which allows for modification of the acceleration time,

- in addition, an optional high-speed camera is available to record the test for later analysis.

- place the unit load to be tested on the test platform,

- the platform accelerates until it reaches the programmed acceleration (this acceleration must be reached in less than 50 ms),

- once the target acceleration has been reached, it shall be maintained for at least 300 ms,

- the braking of the platform should be smooth so as not to affect the cargo under test,

- the stiffness level of the cargo is determined by the deformations whose maximum value is defined by the standard (Figure 4).

5. Experimental Research

5.1. Assumptions for Research on Selection of Film for Cargo Securing

- the tests aimed to show the impact of the choice of packaging on the environment and security in transport,

- the cargo stability test was limited to testing the effect of securing the PUL with a stretch film,

- the test was divided into the following stages/tests:

- ○

- analysis of the PUL wrapping and verification of the technical possibilities of the standard film applied,

- ○

- dynamic test—verification of the rigidity of the PUL protected with a standard film,

- ○

- the new cargo wrapping application (modification of the wrapping program appropriate for the non-standard film used and the capabilities of the wrapping machine),

- ○

- dynamic test—verification of the rigidity of the PUL with a non-standard/dedicated film,

- tests were only carried out with the long side of the pallet parallel to the direction of acceleration,

- a PUL stability at the level of at least 0.5 g was considered a success,

- description of the tested cargo (Figure 5):

- ○

- PUL—EPAL pallet with cardboard boxes filled with the manual film was the tested cargo,

- ○

- cardboard boxes placed in 3 layers, 11 cardboard boxes in each layer,

- ○

- cardboard box dimensions—21 × 33 × 52 mm,

- ○

- total cargo height—1.7 m,

- ○

- total cargo weight—655 kg.

5.2. Wrapping Tests and Verification of Rigidity of Palletized Units Secured with Standard Film

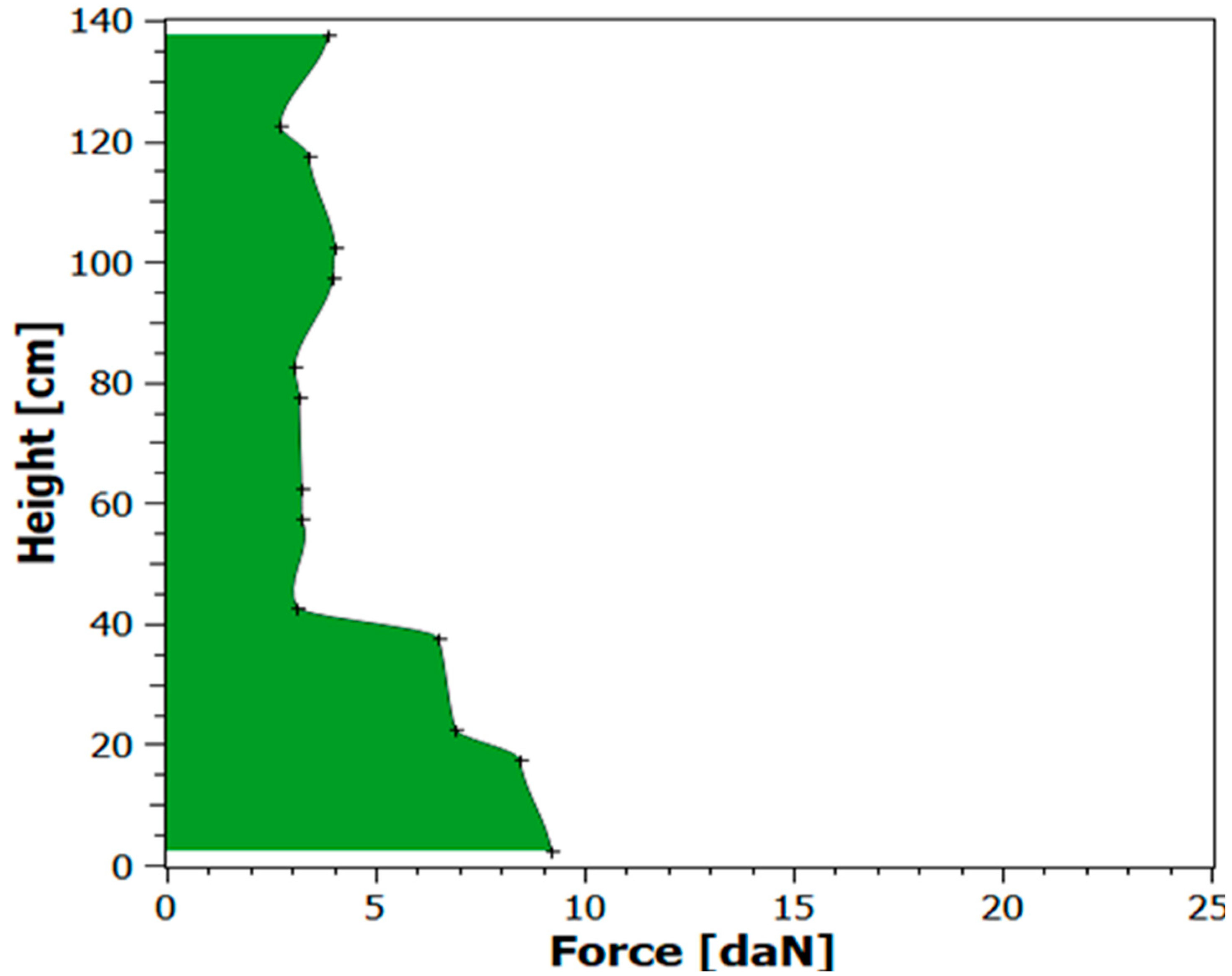

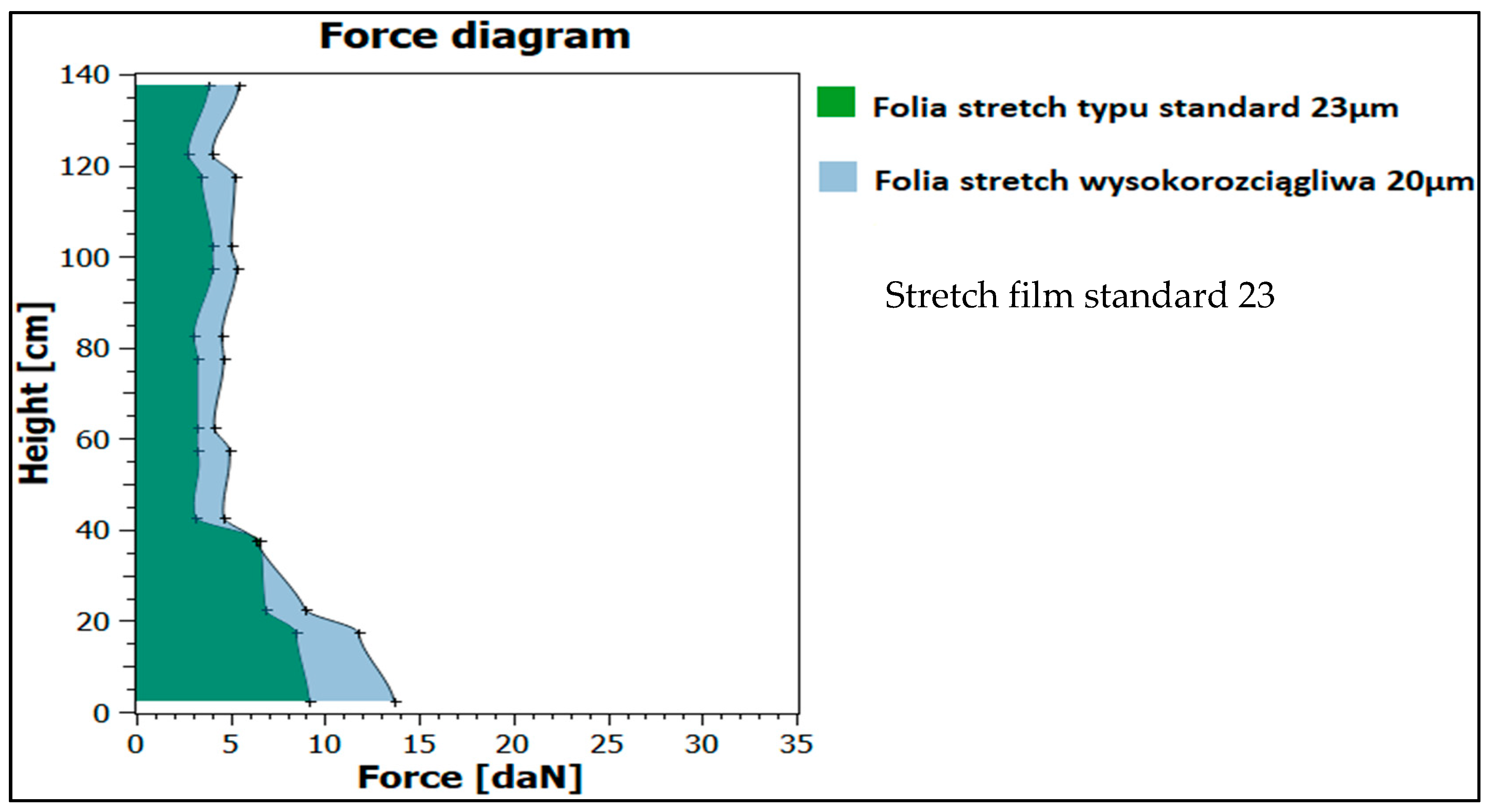

5.2.1. Analysis of Cargo Stabilization Forces for a Standard Film

- characteristics of application (cargo wrapping) with standard film (Table 3),

- applied parameters of the programme of cargo wrapping with standard film (Table 4),

- FEF-200 sensors were used as a measuring tool,

- sensors were placed on the cargo before stretch film wrapping to determine the forces exerted by the film on one edge of the cargo,

- the pressure force was measured at 14 points at various cargo heights,

- at each height of the PUL, the vector of the force acting along the long and short side was measured and the resultant force vector was determined (Figure 6),

- the collected data was wirelessly transferred to a computer,

- measured cargo stabilization forces using FEF-200 sensors (Figure 7),

- verification of the technical capabilities of the wrapping machine:

- ○

- smooth adjustment of pre-stretch up to 300%

- ○

- smooth adjustment of film tension

- ○

- ability to change the number of wraps at each stage of wrapping.

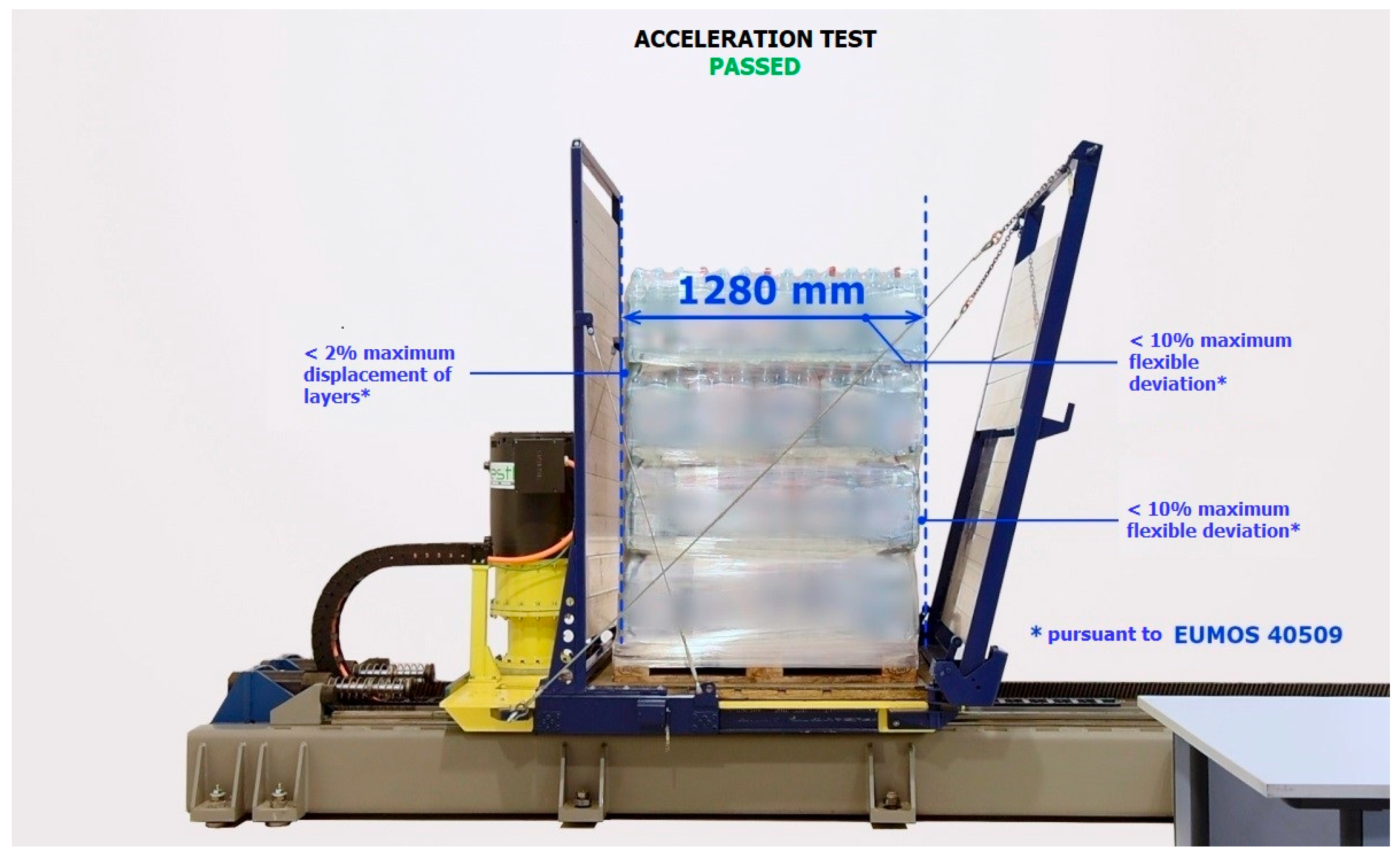

5.2.2. Verification of Cargo Stability Level for Non-Standard Film—Acceleration Test

- the pallets were loaded onto the mobile truck of the acceleration ramp (Figure 8),

- the ramp has the ability to generate horizontal acceleration in the range of 0–10 m/s² in 0.5 m/s2 increments,

- acceleration duration is not less than 300 ms,

- by changing the acceleration value, it is possible to simulate certain traffic situations (sudden acceleration or emergency braking),

- each test is recorded at an accelerated pace for slow motion playback,

- the space for free movement of the cargo during the movement of the ramp is limited (Figure 9),

- the first test—the PUL was subjected to the acceleration of 3 m/s2 (0.3 g),

- if the condition of the cargo after the test is satisfactory, the acceleration value is increased by 1 m/s2,

- the test shall be considered positive if the deformation of the cargo is not greater than that specified in EUMOS 40509, i.e.,:

- ○

- the cargo must not shift more than 5% of its height,

- ○

- the cargo must not incline by more than 10% of its height,

- ○

- the tested cargo must not be damaged during the test.

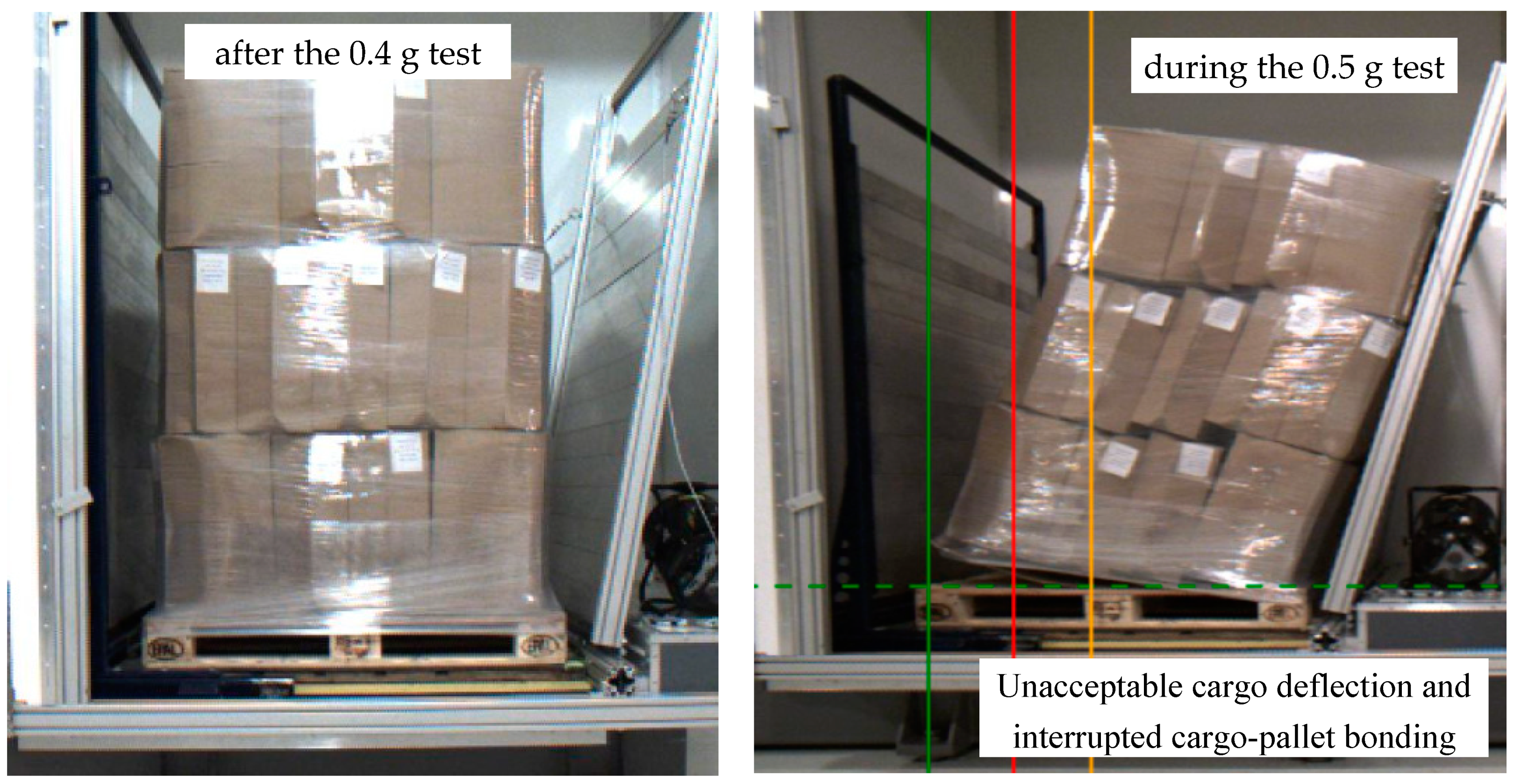

- as part of the test performed, further tests were carried out and the maximum acceleration level at which the cargo meets the safety criteria was determined—0.4 g (Figure 10),

- during tests with the set acceleration of 0.5 g, too much deflection occurred and the cargo and pallet bonding was interrupted (Figure 11),

- measured cargo displacements during the test with acceleration of 0.5 g (Table 5).

5.3. Wrapping Tests and Verification of Rigidity of Palletized Units Secured with Non-Standard Film

5.3.1. Analysis of Cargo Stabilization Forces for a Non-Standard Film

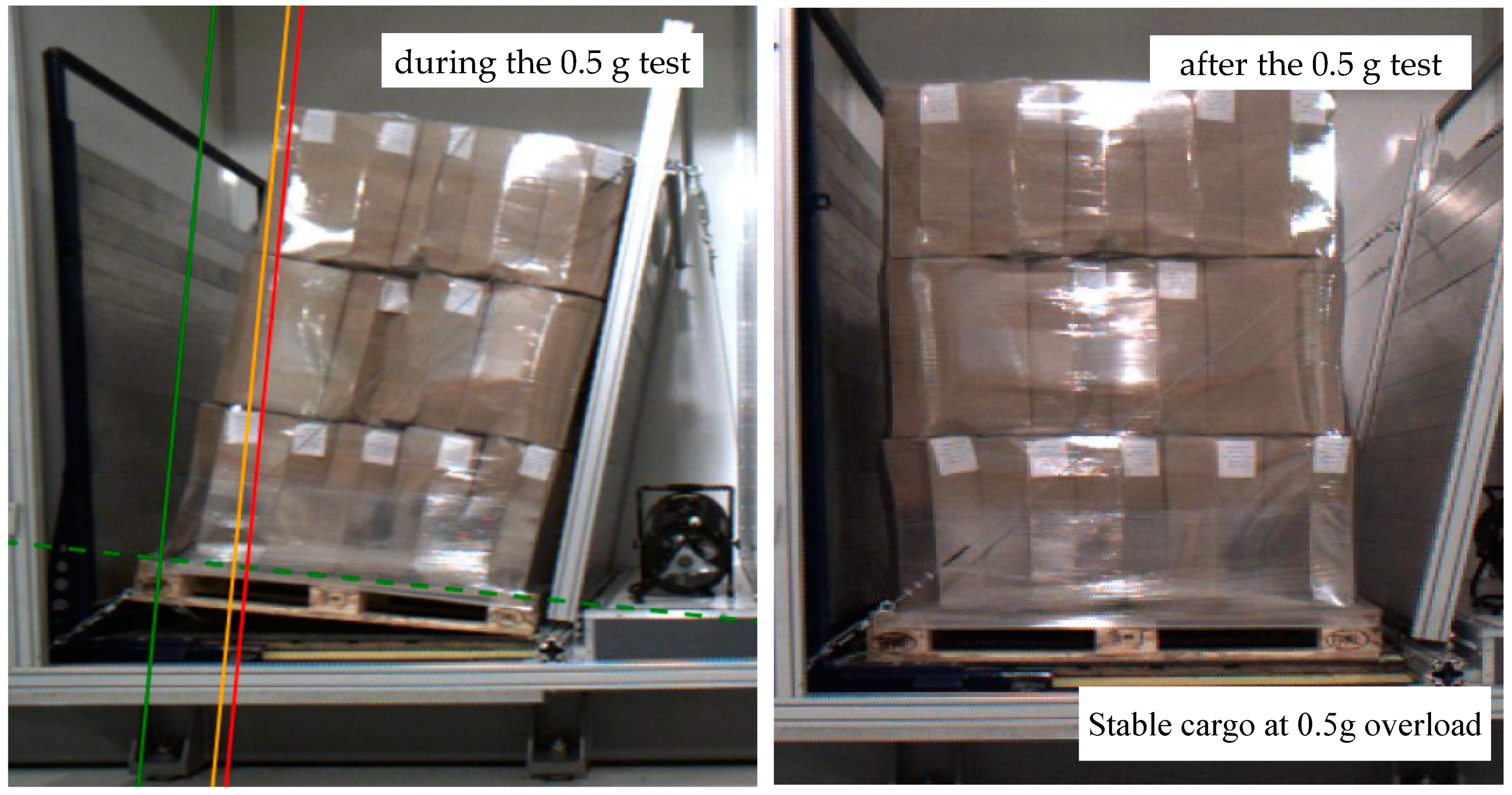

- in view of the adjustability of the wrapping machine, the use of multilayer film with a guaranteed stretch of 300% was decided,

- in addition, by analysing the deflection not accepted in the test and the interrupted bonding between the cargo and the pallet, an increase of the number of wrappings at the bottom and in the middle of the cargo was decided,

- new characteristics of application (cargo wrapping) with non-standard film were applied (Table 6),

- applied parameters of the programme of cargo wrapping with non-standard film (Table 7),

- measured cargo stabilization forces using FEF-200 sensors (Figure 11).

5.3.2. Verification of Cargo Stability for Non-Standard Film—Acceleration Test

- as part of the test performed, further tests were carried out and the maximum acceleration level at which the cargo meets the safety criteria was determined—0.4 g,

- during the test with the set acceleration of 0.5 g, the cargo was still stable and met the safety criteria (Figure 12),

- measured cargo displacements during the test with the acceleration of 0.5 g (Table 8) were made.

6. Discussion of Obtained Results and Conclusions

- test 1:

- ○

- standard film was used—17 wrappings per PUL, and film weight—448 g/PUL (packaging weight is expressed in grams per PUL),

- ○

- the applied standard film was characterized by low parameters of stretch and tension,

- ○

- trial 1 (acceleration level 0.4 g)—the cargo met the safety criteria,

- ○

- trial 2 (acceleration level 0.5 g)—the cargo did not meet the safety criterion (excessive deflection and interruption of the cargo–pallet bonding occurred),

- test 2:

- ○

- non-standard film was used—24 wraps, and film weight—225 g/PUL,

- ○

- test 1 (acceleration level 0.4 g)—the cargo met the safety criteria,

- ○

- trial 2 (acceleration level 0.5 g)—the cargo was stable, met safety criteria.

7. Directions for Further Research

- the packaged cargo and its properties before packaging,

- the film and its properties,

- packaging machines (wrapping machines) and their characteristics.

8. Conclusions

- development of procedures for stretch film application when wrapping palletized cargo, applied by shippers in supply chains,

- development of procedures for applying additional security measures to improve cargo stability,

- development of a method to optimize the use of stretch film for securing palletized cargo,

- development of a tool for stakeholders (manufacturers and shippers) to assist them in deciding on the level of cargo securing at a cost appropriate to the stability of the cargo,

- the establishment of a certification body to be appointed given the forthcoming new standard EN 17321:2020 (intermodal cargo units and commercial vehicles, transport stability of packaging, minimum requirements and tests), which will set the minimum requirements for packaging stability and various test methods for packaging stability in transport.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kłodawski, M.; Jacyna, M. Selected aspects of research on order picking productivity in aspect of congestion problems. In Proceedings of the International Conference on Industrial Logistics, ICIL 2012, Zadar, Croatia, 14–16 June 2012; pp. 204–210. [Google Scholar]

- Jacyna, M.; Izdebski, M.; Szczepański, E.; Gołda, P. The task assignment of vehicles for a production company. Symmetry 2018, 10, 551. [Google Scholar] [CrossRef]

- Kłodawski, M.; Jachimowski, R.; Jacyna-Gołda, I.; Izdebski, M. Simulation analysis of order picking efficiency with congestion situations. Int. J. Simul. Model. 2018, 17, 431–443. [Google Scholar] [CrossRef]

- Izdebski, M.; Jacyna-Gołda, I.; Jakowlewa, I. Planning International Transport Using the Heuristic Algorithm. Adv. Intell. Syst. Comput. 2019, 844, 229–241. [Google Scholar]

- Jacyna, M.; Semenov, I. Models of vehicle service system supply under information uncertainty. Eksploat. Niezawodn. 2020, 22, 694–704. [Google Scholar] [CrossRef]

- Popiela, K.; Wasiak, M. Optimization of unit load formation taking into account the mass of packaging units. Arch. Transp. 2014, 32, 73–80. [Google Scholar] [CrossRef]

- Directive 2014/47/EU of the European Parliament and of the Council of 3 April 2014 on the Technical Roadside Inspection of the Roadworthiness of Commercial Vehicles Circulating in the Union and Repealing Directive 2000/30/EC. Available online: https://eur-lex.europa.eu/eli/dir/2014/47/oj (accessed on 8 June 2021).

- Jacyna, M.; Jachimowski, R.; Szczepański, E.; Izdebski, M. Road vehicle sequencing problem in a railroad intermodal terminal-simulation research. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 1135–1148. [Google Scholar] [CrossRef]

- Jacyna, M.; Wasiak, M.; Jachimowski, R.; Jacyna-Gołda, I.; Izdebski, M. The concept of EPLOS database of the transport infrastructure. In Proceedings of the Transport Means—International Conference, Palanga, Lithuania, 2–4 October 2019; pp. 1250–1255. [Google Scholar]

- Vlkovský, M.; Neubauer, J.; Malíšek, J.; Michálek, J. Improvement of Road Safety through Appropriate Cargo Securing Using Outliers. Sustainability 2021, 13, 2688. [Google Scholar] [CrossRef]

- Singh, J.; Cernokus, E.; Saha, K.; Soma Roy, S. The Effect of Stretch Wrap Prestretch on Unitized Load Containment. Pack. Technol. Sci. 2014, 27, 944–961. [Google Scholar] [CrossRef]

- Singh, J.; Saha, K.; Sewell, T. Evaluation of stability of unit loads for tilt and shock events during distribution. J. Appl. Packag. Res. 2017, 9, 5. [Google Scholar]

- Kuskil’din, R.B.; Vasilyeva, M.A. Dynamic loads during safety braking of the container with cargo. Procedia Eng. 2017, 206, 248–253. [Google Scholar] [CrossRef]

- Cieśla, M.; Opasiak, T. Load Securing in Cargo Transport Units; Polish Academy of Science: Katowice, Poland, 2014. [Google Scholar]

- Ambroziak, T.; Tkaczyk, S. The Selection of Transportation Means for Technological Processes. Arch. Transp. 2015, 36. [Google Scholar] [CrossRef]

- Wasiak, M.; Jacyna-Gołda, I.; Markowska, K.; Kłodawski, M.; Izdebski, M. The use of a supply chain configuration model to assess the reliability of logistics processes. Eksploat. Niezawodn. 2019, 21, 367–374. [Google Scholar] [CrossRef]

- Jacyna-Gołda, I.; Izdebski, M.; Murawski, J. The assumptions to the ant algorithm in the assignment of vehicles to tasks in the production companies. In Proceedings of the Transport Means—International Conference, Juodkrantė, Lithuania, 20–22 September 2017; pp. 985–990. [Google Scholar]

- Izdebski, M.; Jacyna-Gołda, I.; Markowska, K.; Murawski, J. Heuristic algorithms applied to the problems of servicing actors in supply chains. Arch. Transp. 2017, 44, 25–34. [Google Scholar] [CrossRef]

- EUMOS 40509:2012. Test Method for Load Unit Rigidity. Available online: https://www.safeloadtesting.com/eumos-test-standards/ (accessed on 8 June 2021).

- EUMOS 40674. European Cargo Safety Cards—Minimum Requirements. Available online: https://eumos.eu/quality-standards/ (accessed on 8 June 2021).

- Tkaczyk, S.; Różyk, J. Odpowiedzialność za Uszkodzenia Ładunku Spaletyzowanego w Transporcie Drogowym-Regulacje prawne. In Bezpieczeństwo Transportu i Logistyki; Wiśniewski, T.R., Ed.; Difin: Warsaw, Poland, 2021; pp. 125–149. ISBN 978-83-66491-22-9. [Google Scholar]

- ASTM D4649-03. Standard Guide for Selection and Use of Stretch Wrap Films. West Conshohocken, PA, USA: American Society for Testing and Materials (ASTM) International. 2016. Available online: https://standards.globalspec.com/std/594170/astm-d4649 (accessed on 8 June 2021).

- Tkaczyk, S.; Szpotański, M. Metody Testowe Zachowania Ładunku w Transporcie. In Bezpieczeństwo Transportu i Logistyki; Wiśniewski, T.R., Ed.; Difin: Warsaw, Poland, 2021; pp. 105–124. ISBN 978-83-66491-22-9. [Google Scholar]

- Greco, A.; Renzini, A.; Vaccari, M.; De Camargo, F.V. Testing methods and equipment for palletized products. Mater. Sci. Eng. 2019, 659, 012087. [Google Scholar] [CrossRef]

- Finnemore, D. Stretch Wrap Film and Pallet Load Stability. Powder Bulk Eng. 2017. Available online: https://www.powderbulk.com/enews/2017/editorial/story_pdf/pbe_04_19_17rihf.pdf (accessed on 8 June 2021).

- Drozd, M.; Kędzierski, Ł.; Tkaczyk, S. Raport—Przykładowe Testy Stabilnosci; Materials of Ergis Load Stability Academy: Oława, Poland, 2020. [Google Scholar]

- Danjou, S.; Ostergaard, N. Application of computational MBD for simulation of wrap packaging performance. J. Appl. Packag. Res. 2018, 10, 25–36. Available online: https://scholarworks.rit.edu/japr/vol10/iss3/3 (accessed on 8 June 2021).

- Matyja, T. Tilt Test of a Pallet Load Unit—Simulation Studies. Sci. J. Sil. Univ. Technology. Ser. Transp. 2020, 107, 107–117. [Google Scholar] [CrossRef]

- Matyja, T. Assessment of the Pallet Unit Load Stability by Simulation Methods. Commun. Sci. Lett. Univ. Zilina 2020, 22, 19–28. [Google Scholar] [CrossRef]

- Rouillard, V.; Lamb, M.J.; Lepine, J.; Long, M.; Ainalis, D. The case for reviewing laboratory-based road transport simulations for packaging optimization. Pack. Technol. Sci. 2021, 34, 339–351. [Google Scholar] [CrossRef]

- Ratkiewicz, A.; Lewczuk, K. Rack cell configuration problem: A mathematical model and effective combined heuristic. Bull. Pol. Acad. Sci. Technol. Sci. 2021, 69, e135836. [Google Scholar] [CrossRef]

- Hifi, M.; Kacem, I.; Negre, S.; Wu, L. A Linear Programming Approach for the Three Dimensional Bin-Packing Problem. Electron. Notes Discret. Math. 2010, 36, 993–1000. [Google Scholar] [CrossRef]

- Lodi, A.; Martello, S.; Monaci, M. Two dimensional packing problems: A survey. Eur. J. Oper. Res. 2002, 141, 241–252. [Google Scholar] [CrossRef]

- Lodi, A.; Martello, S.; Vigo, D. Models and Bounds for Two-dimensional Level Packing Problems. J. Comb. Optim. 2004, 8, 363–379. [Google Scholar] [CrossRef]

- Taraska, M.; Iwańkowicz, R. Multi-objective evolutionary method for cargo arrangement in a loading space. Arch. Transp. 2017, 44, 65–73. [Google Scholar] [CrossRef]

- Kocjan, W.; Holmström, K. Computing stable loads for pallets. Eur. J. Oper. Res. 2010, 207, 980–985. [Google Scholar] [CrossRef]

- Maciukiewicz, J.M.; Whittaker, R.L.; Hogervorst, K.B.; Dickerson, C.R. Wrapping technique and wrapping height interact to modify physical exposures during manual pallet wrapping. Appl. Ergon. 2021, 93, 103378. [Google Scholar] [CrossRef]

- Jacyna-Gołda, I.; Lewczuk, K. The method of estimating dependability of supply chain elements on the base of technical and organizational redundancy of process. Eksploat. Niezawodn. Maint. Reliab. 2017, 19, 382–392. [Google Scholar] [CrossRef]

- Melo, S.; Baptista, P. Evaluating the impacts of using cargo cycles on urban logistics: Integrating traffic, environmental and operational boundaries. Eur. Transp. Res. Rev. 2017, 9, 30. [Google Scholar] [CrossRef]

- Nocera, S.; Cavallaro, F. A Two-Step Method to Evaluate the Well-To-Wheel Carbon Efficiency of Urban Consolidation Centres. Res. Transp. Econ. 2017, 65, 44–55. [Google Scholar] [CrossRef]

- Deviatkin, I.; Khan, M.; Ernst, E.; Horttanainen, M. Wooden and plastic pallets: A review of life cycle assessment (LCA) studies. Sustainability 2019, 11, 5750. [Google Scholar] [CrossRef]

- Lewczuk, K. Dependability issues in designing warehouse facilities and their functional areas. J. Konbin 2016, 38, 201–228. [Google Scholar] [CrossRef][Green Version]

- Wyns, J.; Cook, J.; Dunno, K. Post-Wrapping Behavior of High-Performance Stretch Film. J. Appl. Packag. 2018, 10, 1. [Google Scholar]

- Tkaczyk, S. The Problem of Reducing Consumption of Stretch Film Used to Secure Palletized Loads. Rocz. Ochr. Srodowiska 2020, 22, 359–375. [Google Scholar]

- Pavlovic, A.; Kostic, S.C. Design and optimization of mechanical solutions for high speed components in packaging machines Mech. Transp. Commun. 2009, 3, 44–48. [Google Scholar]

- Stankiewicz, A. Minimizing the Consumption of Stretch Film for Wrapping Cylindrical Baled Silage Using the IntelliWrap Method. Trans. ASABE 2020, 63, 967–980. [Google Scholar] [CrossRef]

- Stankiewicz, A. On the uniform distribution and optimal consumption of stretch film used for wrapping cylindrical baled silage. Grass Forage Sci. 2019, 74, 583–727. [Google Scholar] [CrossRef]

- Stankiewicz, A.; Stępniewski, A.A.; Nowak, J. On the mathematical modelling and optimization of film consumptio3n for cylindrical bale wrapping. Econtechmod. Int. Q. J. 2016, 5, 101–110. [Google Scholar]

- Bisha, J.V. Correlation of the Elastic Properties of Stretch Film on Unit Load Containment. Ph.D. Thesis, Faculty of the Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2012. [Google Scholar]

- Klein, D.; Stommel, M.; Zimmer, J. Constitutive modeling of the mechanics of polyethylene films in stretch wrapping processes. AIP Conf. Proc. 2019, 2113, 130001. [Google Scholar] [CrossRef]

- Hong, S.; Kang, D.; Kim, D.; Lee, S. Analysis of Bale Surface Pressure According to Stretch Film Layer Changes on Round Bale Wrapping. J. Biosyst. Eng. 2017, 42, 136–146. [Google Scholar]

- Best Packing. The Transportable Test Pallet. Available online: https://www.bestpackaging.com.au/ (accessed on 16 December 2019).

- ESTL. Transport Packaging Damage Reduction with ESTL. Available online: https://www.estl.be/packaging/ (accessed on 8 June 2021).

- Lantech to Demonstrate Load-Stabilizing Technology at Drinktec 2017. Lantech.com. Available online: https://www.lantech.com/blog/news/news-lantech-to-demonstrate-load-stabilizing-technology-at-drinktec-2017/ (accessed on 8 June 2021).

- Safeload Testing Technologies. Available online: https://www.safeloadtesting.com/package-testing/ (accessed on 8 June 2021).

- Lindum Packing LCD. A Fresh Take on Transit Packaging. Available online: www.lindumpackaging.com (accessed on 8 June 2021).

- Atlantic Packing. The Most Technical Resource in Sustainable Packaging. Programs for Efficiency & Circularity in Packaging. Available online: https://www.atlanticpkg.com/ (accessed on 8 June 2021).

- ELSA (Ergis Load Stability Academy—Centrum Badania Stabilności Ładunków). Available online: https://ergis.eu/en/content/customers/nano-ergis-films/elsa (accessed on 8 June 2021).

- EUMOS. The European Safe Logistics Association. Available online: https://eumos.eu/ (accessed on 8 June 2021).

- ISTA. Available online: https://ista.org/lab_certification.php (accessed on 8 June 2021).

- International Guidelines on Safe Load Securing for Road Transport IRU I-0323. IRU_CIT-2014 Version 01. Available online: https://www.wko.at/branchen/transport-verkehr/IRU-Ladungssicherungs-Leitfaden-2014.pdf (accessed on 8 June 2021).

- KSIST FPREN 17321:2021. Intermodal Loading Units and Commercial Vehicles—Transport Stability of Packages—Minimum Requirements and Tests. Available online: https://standards.iteh.ai/catalog/standards/cen/093d9fa8-f424-4e19-9a0e-61a1e40c4827/fpren-17321 (accessed on 8 June 2021).

- EN 12195-1:2010. Load Restraining on Road Vehicles. Safety. Calculation of Securing Forces. Available online: https://standards.iteh.ai/catalog/standards/cen/72067d57-b90c-4ca5-8bd0-f876e25e6a6e/en-12195-1-2010 (accessed on 30 April 2014).

- EN 12642:2016. Securing of Cargo on Road Vehicles. Body Structure of Commercial Vehicles. Minimum Requirements. Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000030324374 (accessed on 30 November 2016).

- Jacyna, M. The role of the cargo consolidation center in urban logistics system. Int. J. Sustain. Dev. Plann. 2013, 8, 100–113. [Google Scholar] [CrossRef]

- Jacyna, M.; Szczepański, E. Holistic approach to the ecological cargo distribution in urban areas with the use of multi-modal transport. WIT Trans. Built Environ. 2013, 130, 53–65. [Google Scholar]

- Izdebski, M.; Jacyna-Gołda, I.; Gołębiowski, P.; Plandor, J. The optmization tool supporting supply chain management in the multi-criteria approach|Optymalizacyjne narzedzie wspomagajace zarzadzanie łancuchem dostaw w ujeciu wieloryterianym. Arch. Civ. Eng. 2020, 66, 505–524. [Google Scholar] [CrossRef]

| Transport Stability Level (TSL) | Horizontal Acceleration α |

|---|---|

| TSL 1 | α ≥ 1.0 g |

| TSL 2 | 0.8 g ≤ α < 1.0 g |

| TSL 3 | 0.5 g ≤ α < 0.8 g |

| TSL 4 | 0.18 1 g ≤ α < 0.5 g |

| Research and Tests in the Course of R&D Work | Utility (Operational) Research and Tests |

|---|---|

| - tests in a controlled environment, - involvement of qualified users (scientists, designers) - collection of key data - limited number of variables (tested parameters) - focus on the technical parameters (properties) of the tested solution | - tests in a real environment, often different from that envisaged by the designer - users with different background - emphasis on the realism of research, - number of tested variables (parameters) unlimited (theoretically) - focus on the parameters (properties) of the solution |

| Material | Stretch Film Standard Type 23 µm |

|---|---|

| total number of wrappings [wraps/PUL] | 17 |

| unit weight of packaging [g/PUL] | 448 |

| Characteristics | Marking | Value |

|---|---|---|

| number of initial bottom rotating wraps | owpd | 3 |

| number of initial lower rotating wraps | owpn | 1 |

| number of top rotating wraps | owg | 2 |

| number of bottom rotating wraps before binding | owdw | 0 |

| number of tied rotating wraps | oww | 0 |

| starting position of the trolley | pws | 0 |

| position of the trolley to slow down during binding | pwk | 75 |

| stretchability of the film at the start | rfs | 100 |

| stretchability of the film when wrapping upwards | rfwg | 100 |

| stretchability of the film at top wrapping | rfg | 100 |

| stretchability of the film when wrapping downwards | rfwd | 100 |

| stretchability of the film at bottom wrapping | rfd | 100 |

| stretchability of the film at binding | rfw | 100 |

| stretchability of the film at final wrap | rfk | 100 |

| tensioning force of the film at the start | nns | 25 |

| tensioning force of the film when wrapping upwards | nnng | 25 |

| tensioning force of the film at top wrapping | nng | 25 |

| tensioning force of the film when wrapping downwards | nnwd | 25 |

| tensioning force of the film at bottom wrapping | nnd | 25 |

| tensioning force of the film at binding | nnw | 25 |

| tensioning force of the film at the final wrap | nnoz | 25 |

| turntable speed | vs | 10 |

| upward trolley speed | vwg | 50 |

| downward trolley speed | vwd | 50 |

| Maximum Displacements According to EUMOS Standard 40509: | Measurement |

|---|---|

| maximum cargo displacement—8.5 cm (5% of the cargo height) | top—2.6 cm bottom—0.8 cm |

| maximum cargo deflection—17.0 cm (10% of the cargo height) | 31.4 cm—unacceptable |

| Material | Multilayer Stretch Film 20 µm |

|---|---|

| total number of wrappings [wraps/PUL] | 24 |

| unit weight of packaging [g/PUL] | 225 |

| Characteristics | Marking | Value |

|---|---|---|

| number of initial bottom rotating wraps | owpd | 5 |

| number of initial lower rotating wraps | owpn | 1 |

| number of top rotating wraps | owg | 2 |

| number of bottom rotating wraps before binding | owdw | 2 |

| number of tied rotating wraps | oww | 0 |

| starting position of the trolley | pws | 0 |

| position of the trolley to slow down during binding | pwk | 75 |

| stretchability of the film at the start | rfs | 300 |

| stretchability of the film when wrapping upwards | rfwg | 300 |

| stretchability of the film at top wrapping | rfg | 300 |

| stretchability of the film when wrapping downwards | rfwd | 300 |

| stretchability of the film at bottom wrapping | rfd | 300 |

| stretchability of the film at binding | rfw | 300 |

| stretchability of the film at final wrap | rfk | 300 |

| tensioning force of the film at the start | nns | 50 |

| tensioning force of the film when wrapping upwards | nnng | 50 |

| tensioning force of the film at top wrapping | nng | 50 |

| tensioning force of the film when wrapping downwards | nnwd | 50 |

| tensioning force of the film at bottom wrapping | nnd | 50 |

| tensioning force of the film at binding | nnw | 50 |

| tensioning force of the film at the final wrap | nnoz | 50 |

| turntable speed | vs | 10 |

| upward trolley speed | vwg | 40 |

| downward trolley speed | vwd | 40 |

| Maximum Displacements According to EUMOS Standard 40509 | Measurement |

| maximum load displacement—8.5 cm (5% of the cargo height) | top—2.2 cm; bottom—1.6 cm |

| maximum cargo deflection—17.0 cm (10% of the cargo height) | 14.3 cm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tkaczyk, S.; Drozd, M.; Kędzierski, Ł.; Santarek, K. Study of the Stability of Palletized Cargo by Dynamic Test Method Performed on Laboratory Test Bench. Sensors 2021, 21, 5129. https://doi.org/10.3390/s21155129

Tkaczyk S, Drozd M, Kędzierski Ł, Santarek K. Study of the Stability of Palletized Cargo by Dynamic Test Method Performed on Laboratory Test Bench. Sensors. 2021; 21(15):5129. https://doi.org/10.3390/s21155129

Chicago/Turabian StyleTkaczyk, Sławomir, Mikołaj Drozd, Łukasz Kędzierski, and Krzysztof Santarek. 2021. "Study of the Stability of Palletized Cargo by Dynamic Test Method Performed on Laboratory Test Bench" Sensors 21, no. 15: 5129. https://doi.org/10.3390/s21155129

APA StyleTkaczyk, S., Drozd, M., Kędzierski, Ł., & Santarek, K. (2021). Study of the Stability of Palletized Cargo by Dynamic Test Method Performed on Laboratory Test Bench. Sensors, 21(15), 5129. https://doi.org/10.3390/s21155129