Evaluation of the Uniformity of Protective Coatings on Concrete Structure Surfaces Based on Cluster Analysis

Abstract

:1. Introduction

2. Materials and Methods

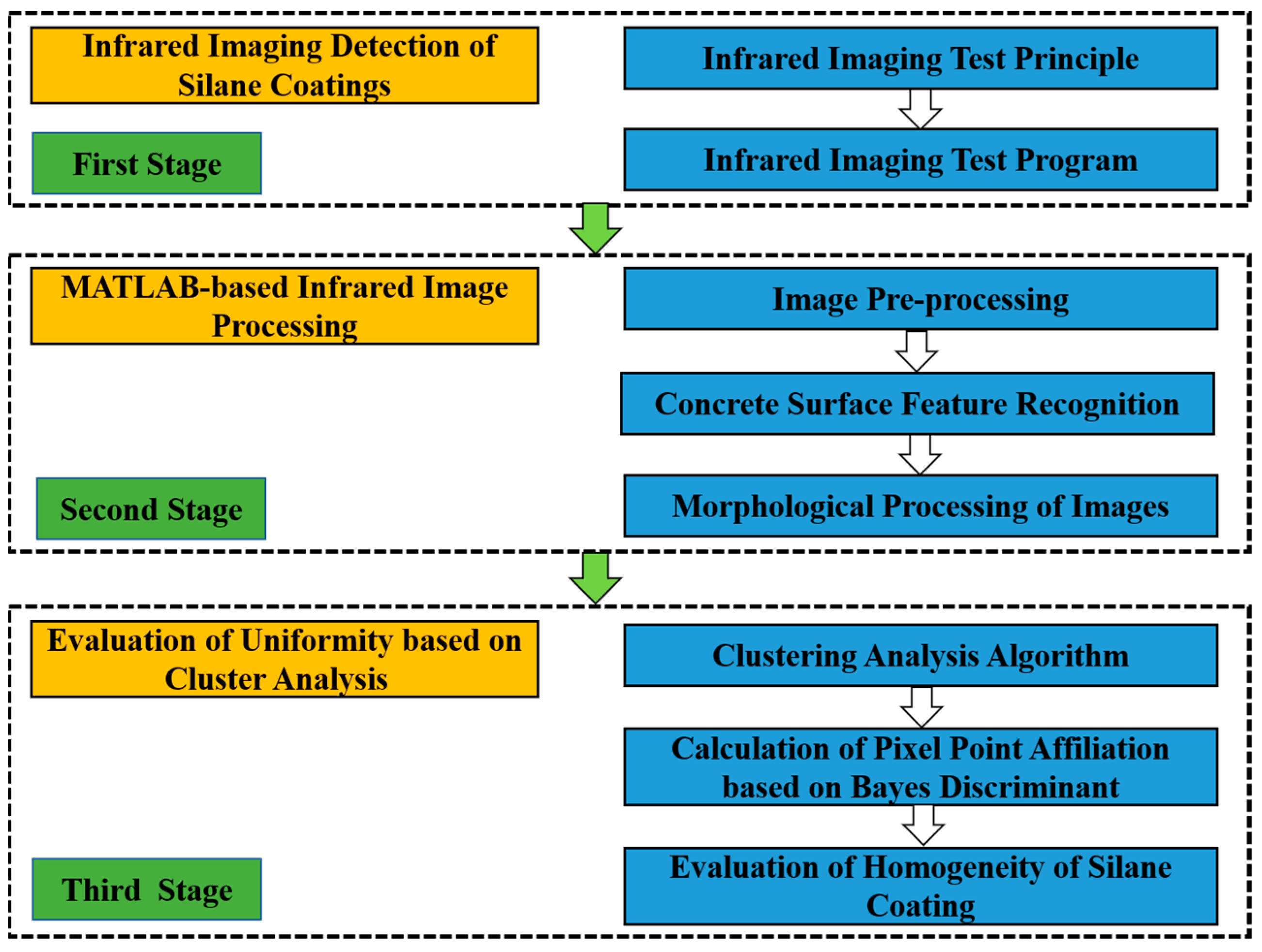

2.1. Infrared Imaging Detection of Silane Coatings

2.1.1. Infrared Imaging Test Principle

2.1.2. Infrared Imaging Test Program

2.2. MATLAB-Based Infrared Image Processing

2.2.1. Image Pre-Processing

2.2.2. Concrete Surface Feature Recognition

2.2.3. Morphological Processing of Images

2.3. Evaluation of Uniformity Based on Cluster Analysis

2.3.1. Clustering Analysis Algorithm

2.3.2. Calculation of Pixel Point Affiliation Based on Bayes Discriminant

2.3.3. Evaluation of Homogeneity of Silane Coating

3. Results

3.1. Infrared Imaging Test Results

3.2. Infrared Image Processing Results

3.3. Cluster Analysis Results of Pixel Point Temperature Index

3.4. Pixel Point Affiliation Calculation Results

3.5. Coating Uniformity Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zaki, A.; Chai, H.K.; Aggelis, D.G.; Alver, N. Non-destructive evaluation for corrosion monitoring in concrete: A review and capability of acoustic emission technique. Sensors 2015, 15, 19069–19101. [Google Scholar] [CrossRef]

- Hou, B.; Li, X.; Ma, X.; Du, C.; Zhang, D.; Zheng, M.; Ma, F. The cost of corrosion in China. NPJ Mater. Degrad. 2017, 1, 41. [Google Scholar] [CrossRef]

- Geng, Y.; Li, S.; Hou, D.; Chen, X.; Jin, Z. Effect of SiO2 sol/silane emulsion in reducing water and chloride ion penetration in concrete. Coatings 2020, 10, 682. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Zhang, W.; Chen, X.; Hou, D.; Zhao, T.; Li, X. Preparation and mechanism of graphene oxide/isobutyltriethoxy silane composite emulsion and its effects on waterproof performance of concrete. Constr. Build. Mater. 2019, 208, 343–349. [Google Scholar] [CrossRef]

- Baltazar, L.; Santana, J.; Lopes, B. Surface skin protection of concrete with silicate-based impregnations: Influence of the substrate roughness and moisture. Constr. Build. Mater. 2014, 70, 191–200. [Google Scholar] [CrossRef]

- Park, S.; Kim, Y.Y.; Lee, B.J. Evaluation of concrete durability performance with sodium silicate impregnants. Adv. Mater. Sci. Eng. 2014, 2014, 945297. [Google Scholar] [CrossRef] [Green Version]

- Velayutham, T.S.; Majid, W.H.A.; Ahmad, A.B. Synthesis and characterization of polyurethane coatings derived from polyols synthesized with glycerol, phthalic anhydride and oleic acid. Prog. Org. Coat. 2009, 66, 367–371. [Google Scholar] [CrossRef]

- Petcherdchoo, A. Sensitivity of service life extension and CO2 emission due to repairs by silane treatment applied on concrete structures under time-dependent chloride attack. Adv. Mater. Sci. Eng. 2018, 27, 93481. [Google Scholar] [CrossRef] [Green Version]

- Scarfato, P.; DiMaio, L.; Fariello, M.L. Preparation and evaluation of polymer/clay nanocomposite surface treatments for concrete durability enhancement. Cem. Concr. Compos. 2012, 34, 297–305. [Google Scholar] [CrossRef]

- Zanella, C.; Lekka, M.; Rossi, S.; Deflorian, F. Study of the influence of sonication during the electrod eposition of nickel matrix nanocomposite coatings on the protective properties. Corros. Rev. 2011, 29, 253–260. [Google Scholar] [CrossRef]

- Wu, L.; Hu, C.; Liu, W.V. The Sustainability of Concrete in Sewer Tunnel-A Narrative Review of Acid Corrosion in the City of Edmonton, Canada. Sustainability 2018, 10, 5172. [Google Scholar] [CrossRef] [Green Version]

- Garrido, I.; Laguela, S.; Arias, P. Infrared thermography’s application to infrastructure inspections. Infrastructures 2018, 3, 353. [Google Scholar] [CrossRef] [Green Version]

- Vadivambal, R.; Jayas, D.S. Applications of thermal imaging in agriculture and food industry—A review. Food Bioprocess Technol. 2011, 4, 186–199. [Google Scholar] [CrossRef]

- Qu, Z.; Jiang, P.; Zhang, W. Development and application of infrared thermography non-destructive testing techniques. Sensors 2020, 20, 385114. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Sfarra, S.; Genest, M. A comparative study of enhanced infrared image processing for foreign object detection in lightweight composite honeycomb structures. Int. J. Thermophys. 2018, 39, 140. [Google Scholar] [CrossRef]

- Kiseleva, Y.V.; Gektin, Y.M.; Zaytsev, A.A. Data intercalibration technique for infrared channels of the Elektro-L/MSU-GS imager with the AIRS infrared sounder data. Izv. Atmos. Ocean. Phys. 2016, 52, 1181–1190. [Google Scholar] [CrossRef]

- Bulychev, O.A.; Shleenkov, S.A.; Gusev, O.A. Revealing surface microcracks in metal articles by excitation of high-frequency eddy currents with subsequent infrared-camera imaging. Russ. J. Nondestruct. Test. 2016, 52, 457–462. [Google Scholar] [CrossRef]

- Xu, H.; Shui, Z.; Chen, B.; Chen, W.; Ding, S. Defects Detection in Concrete Structure with Infrared Thermal Imaging and Numerical Simulation. Adv. Mater. Res. 2012, 345, 378–379. [Google Scholar] [CrossRef]

- Ying, X.; Sohn, H. Nondestructive debonding detection of fiber reinforced plastics strengthened structure based on infrared thermal imaging with laser thermal excitation. Proc. SPIE 2020, 11379, 1137914. [Google Scholar] [CrossRef]

- Ptacek, L.; Strauss, A.; Hinterstoisser, B.; Zitek, A. Curing Assessment of Concrete with Hyperspectral Imaging. Materials 2021, 14, 384814. [Google Scholar] [CrossRef]

- Lu, Y.; Golrokh, A.J.; Islam, M.D.A. Concrete Pavement Service Condition Assessment Using Infrared Thermography. Adv. Mater. Sci. Eng. 2017, 2017, 3829340. [Google Scholar] [CrossRef] [Green Version]

- Jang, K.; Kim, N.; An, Y. Deep learning-based autonomous concrete crack evaluation through hybrid image scanning. Struct. Health Monit. Int. J. 2019, 18, 1722–1737. [Google Scholar] [CrossRef]

- Hardie, R.C.; Hayat, M.M.; Armstrong, E. Scene-based nonuniformity correction with video sequences and registration. Appl. Opt. 2000, 39, 1241–1250. [Google Scholar] [CrossRef] [PubMed]

- Catarius, A.M.; Seal, M.D. Static scene statistical algorithm for nonuniformity correction in focal-plane arrays. Opt. Eng. 2015, 54, 104–111. [Google Scholar] [CrossRef]

- Rong, S.H.; Zhou, H.X.; Qin, H.L. Guided filter and adaptive learning rate based non-uniformity correction algorithm for infrared focal plane array. Infrared Phys. Technol. 2016, 76, 691–697. [Google Scholar]

- Moallem, P.; Masoumzadeh, M.; Habibi, M. A novel adaptive Gaussian restoration filter for reducing periodic noises in digital image. Signal Image Video Process. 2015, 9, 1–13. [Google Scholar] [CrossRef]

- Forbus, K.D. Qualitative process theory. Artif. Intell. 1984, 24, 85–168. [Google Scholar] [CrossRef] [Green Version]

- Sulaiman, S.N.; Isa, A.M. Adaptive fuzzy-K-means clustering algorithm for image segmentation. IEEE Trans. Consum. Electron. 2010, 56, 2661–2668. [Google Scholar] [CrossRef]

- Diday, E.; Simon, J.C. Clustering analysis. Digit. Pattern Recognit. 1980, 10, 47–94. [Google Scholar]

- Steinley, D. Local optima in k-means clustering: What you don’t know may hurt you. Psychol. Methods 2003, 8, 294–304. [Google Scholar] [CrossRef]

- MacQueen, J.B. Some methods for classification and analysis of multivariate observations. In Proceedings of the 5th Berkeley Symposium on Mathematical Statistics and Probability; University of California Press: Berkeley, CA, USA, 21 June 1967; Volume 1, pp. 281–297. [Google Scholar]

- Evans, S.; Lloyd, J.; Stoddard, G.; Nekeber, J.; Samone, M. Risk factors for adverse drug events. Ann. Pharmacother. 2005, 39, 1161–1168. [Google Scholar] [CrossRef]

- David, W.B.; Elizabeth, B.; Miller, D.J.; Cullen, L.B.; Lawrence, W.; Nan, L.; Laura, A.P.; Stephen, D.S.; Bobbie, J.S.; Martha, V.V.; et al. Patient Risk Factors for Adverse Drug Events in Hospitalized Işık M., Data with Partitioned Clustering Methods Mining Practices. Master’s Thesis, Institute of Science, Istanbul, Turkey, 2006; 76p. [Google Scholar]

- Menesatti, P.; Biocca, M.; D’Andrea, S.; Pincu, M. Thermography to analyze distribution of agricultural sprayers. Qirt Journal. 2008, 5, 81–96. [Google Scholar] [CrossRef]

- Shoa, P.; Hemmat, A.; Amirfattahi, R.; Gheysari, M. Automatic extraction of canopy and artificial reference temperatures for determination of crop water stress indices by using thermal imaging technique and a fuzzy-based image-processing algorithm. Quant. Infrared Thermogr. J. 2020, 1–12. [Google Scholar] [CrossRef]

- Yousefi, B.; Castanedo, C.I.; Bedard, E.; Beaudoin, G.; Maldague, X.P.V. Mineral identification in LWIR hyperspectral imagery applying sparse-based clustering. Quant. Infrared Thermogr. J. 2019, 16, 147–162. [Google Scholar] [CrossRef]

- Li, S.; Jin, W.; Li, L.; Liu, M.; Yang, J. Fusion algorithm based on grayscale-gradient estimation for infrared images with multiple integration times. Infrared Phys. Technol. 2020, 105, 103179. [Google Scholar] [CrossRef]

- Khaw, H.Y.; Soon, F.C.; Chuah, J.H.; Chow, C. High-density impulse noise detection and removal using deep convolutional neural network with particle swarm optimisation. IET Image Process. 2019, 13, 365–374. [Google Scholar] [CrossRef]

- Suzuki, K.; Oho, E. Feature evaluation of complex hysteresis smoothing and its practical applications to noisy sem images. Scanning 2013, 35, 292–301. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Tang, C.; Zhu, X.; Li, X.; Wang, L. An efficient method for salt-and-pepper noise removal based on shearlet transform and noise detection. Aeu-Int. J. Electron. Commun. 2015, 69, 93–102. [Google Scholar] [CrossRef]

- Haffner, O.; Kucera, E.; Drahos, P.; Ciganek, J. Using Entropy for Welds Segmentation and Evaluation. Entropy 2019, 21, 116812. [Google Scholar] [CrossRef] [Green Version]

- Ahn, S.; Park, J.; Luo, L.; Chong, J. Adaptive Object-Region-Based Image Pre-Processing for a Noise Removal Algorithm. Ksii Trans. Internet Inf. Syst. 2013, 7, 3166–3179. [Google Scholar]

- Del Valdes, C.M.; Inamura, M.; Valera, J.D.R.; Lu, Y. Multidimensional filtering approaches for pre-processing thermal images. Multidimens. Syst. Signal Process. 2006, 17, 299–325. [Google Scholar] [CrossRef]

- Xu, J.; Ye, L.; Luo, W. Color edge detection using multiscale quaternion convolution. Int. J. Imaging Syst. Technol. 2010, 20, 354–358. [Google Scholar] [CrossRef]

- Xu, C.; Han, W.; Wang, D.; Huang, D. Salient region detection with multi-feature fusion and edge constraint. IEICE Trans. Inf. Syst. 2020, 103, 4. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, C.; Zeng, X.; Yuan, X. The study of binarization algorithm about digital rubbings image based on threshold segmentation and morphology. J. Comput. Methods Sci. Eng. 2020, 20, 399–409. [Google Scholar] [CrossRef]

- Said, K.A.M.; Jambek, A.B. A study on image processing using mathematical morphological. In Proceedings of the 3rd International Conference on Electronic Design (ICED), Phuket, Thailand, 11–12 August 2016; Volume 1, pp. 507–512. [Google Scholar]

- Zhang, H.; Yu, H.; Li, Y.; Hu, B. Improved K-means Algorithm Based on the Clustering Reliability Analysis. ACSR-Adv. Comput. Sci. Res. 2015, 13, 2516–2523. [Google Scholar]

- Lakshmi, R.; Baskar, S. DIC-DOC-K-means: Dissimilarity-based initial centroid selection for DOCument clustering using K-means for improving the effectiveness of text document clustering. J. Inf. Sci. 2019, 45, 818–832. [Google Scholar] [CrossRef]

- Kwedlo, W. A clustering method combining differential evolution with the K-means algorithm. Pattern Recognit. Lett. 2011, 32, 1613–1621. [Google Scholar] [CrossRef]

- Subedi, S.; McNicholas, P.D. Variational Bayes approximations for clustering via mixtures of normal inverse Gaussian distributions. Adv. Data Anal. Classif. 2014, 8, 167–193. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Wang, S.; Chen, L. Multiple Bayesian discriminant functions for high-dimensional massive data classification. Data Min. Knowl. Discov. 2017, 31, 1–37. [Google Scholar] [CrossRef]

- Davidson, I.; Ravi, S.S. Using instance-level constraints in agglomerative hierarchical clustering: Theoretical and empirical results. Data Min. Knowl. Discov. 2009, 18, 257–282. [Google Scholar] [CrossRef]

- Naeem, A.; Rehman, M.; Anjum, M.; Asif, M. Development of an efficient hierarchical clustering analysis using an agglomerative clustering algorithm. Curr. Sci. 2019, 117, 1045–1053. [Google Scholar] [CrossRef]

| Uniformity Grade | Very Even | More Uniform | Uneven | Very Uneven |

|---|---|---|---|---|

| Unevenness U | ≤0.1 | 0.1 < U ≤ 0.25 | 0.25 < U ≤ 0.4 | >0.4 |

| Sample Pixel Dots | y1/°C | y2/°C | y3/°C | y4/°C |

|---|---|---|---|---|

| 1 | 34.01 | 35.22 | 35.27 | 35.29 |

| 2 | 30.76 | 32.11 | 32.44 | 32.64 |

| 3 | 28.47 | 29.85 | 30.41 | 30.85 |

| 4 | 26.72 | 28.14 | 28.87 | 29.48 |

| 5 | 25.46 | 26.93 | 27.80 | 28.51 |

| 6 | 24.60 | 26.08 | 27.05 | 27.81 |

| 7 | 23.75 | 25.26 | 26.29 | 27.15 |

| 8 | 23.01 | 24.53 | 25.65 | 26.57 |

| 9 | 22.87 | 24.36 | 25.55 | 26.45 |

| 10 | 22.43 | 23.99 | 25.25 | 26.16 |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ |

| 17,098 | 27.97 | 28.35 | 29.11 | 29.56 |

| Indicators | Final Clustering Center | ||||

|---|---|---|---|---|---|

| I | II | III | IV | V | |

| y1/°C | 29.64 | 26.58 | 24.93 | 23.92 | 22.70 |

| y2/°C | 31.11 | 28.15 | 26.56 | 25.54 | 24.33 |

| y3/°C | 32.27 | 29.41 | 27.92 | 26.93 | 25.75 |

| y4/°C | 33.11 | 30.35 | 28.93 | 27.97 | 26.82 |

| Sample Pixel Dots | y1/°C | y2/°C | y3/°C | y4/°C | Clustering Results |

|---|---|---|---|---|---|

| 1 | 34.01 | 35.22 | 35.27 | 35.29 | I |

| 2 | 30.76 | 32.11 | 32.44 | 32.64 | I |

| 3 | 28.47 | 29.85 | 30.41 | 30.85 | II |

| 4 | 26.72 | 28.14 | 28.87 | 29.48 | II |

| 5 | 25.46 | 26.93 | 27.80 | 28.51 | III |

| 6 | 24.60 | 26.08 | 27.05 | 27.81 | IV |

| 7 | 23.75 | 25.26 | 26.29 | 27.15 | IV |

| 8 | 23.01 | 24.53 | 25.65 | 26.57 | V |

| 9 | 22.87 | 24.36 | 25.55 | 26.45 | V |

| 10 | 22.43 | 23.99 | 25.25 | 26.16 | V |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ |

| 17,098 | 27.97 | 28.35 | 29.11 | 29.56 | II |

| Sample Pixel Dots | Pre-Painting Results | Results after Spraying | Affiliation |

|---|---|---|---|

| 1 | I | II | 1 |

| 2 | I | I | 1 |

| 3 | II | I | 0.99985 |

| 4 | II | IV | 0.99830 |

| 5 | III | V | 0.87697 |

| 6 | IV | V | 0.80302 |

| 7 | IV | V | 0.62214 |

| 8 | V | V | 0.96985 |

| 9 | V | V | 0.98881 |

| 10 | V | V | 0.99867 |

| ⋮ | ⋮ | ⋮ | ⋮ |

| 17,098 | II | II | 0.99431 |

| Experimental Group | N1 | N2 | N3 |

|---|---|---|---|

| Unevenness U | 0.122 | 0.298 | 0.415 |

| Homogeneity evaluation grade | More uniform | Uneven | Very uneven |

| Actual painting situation | More uniform | Uneven | Very uneven |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Zhang, W.; Tang, Y.; Jian, Y.; Gong, C.; Qiu, F. Evaluation of the Uniformity of Protective Coatings on Concrete Structure Surfaces Based on Cluster Analysis. Sensors 2021, 21, 5652. https://doi.org/10.3390/s21165652

Liu D, Zhang W, Tang Y, Jian Y, Gong C, Qiu F. Evaluation of the Uniformity of Protective Coatings on Concrete Structure Surfaces Based on Cluster Analysis. Sensors. 2021; 21(16):5652. https://doi.org/10.3390/s21165652

Chicago/Turabian StyleLiu, Dunwen, Wanmao Zhang, Yu Tang, Yinghua Jian, Chun Gong, and Fengkai Qiu. 2021. "Evaluation of the Uniformity of Protective Coatings on Concrete Structure Surfaces Based on Cluster Analysis" Sensors 21, no. 16: 5652. https://doi.org/10.3390/s21165652

APA StyleLiu, D., Zhang, W., Tang, Y., Jian, Y., Gong, C., & Qiu, F. (2021). Evaluation of the Uniformity of Protective Coatings on Concrete Structure Surfaces Based on Cluster Analysis. Sensors, 21(16), 5652. https://doi.org/10.3390/s21165652