Site Investigations of the Lacustrine Clay in Taihu Lake, China, Using Self-Boring Pressuremeter Test

Abstract

:1. Introduction

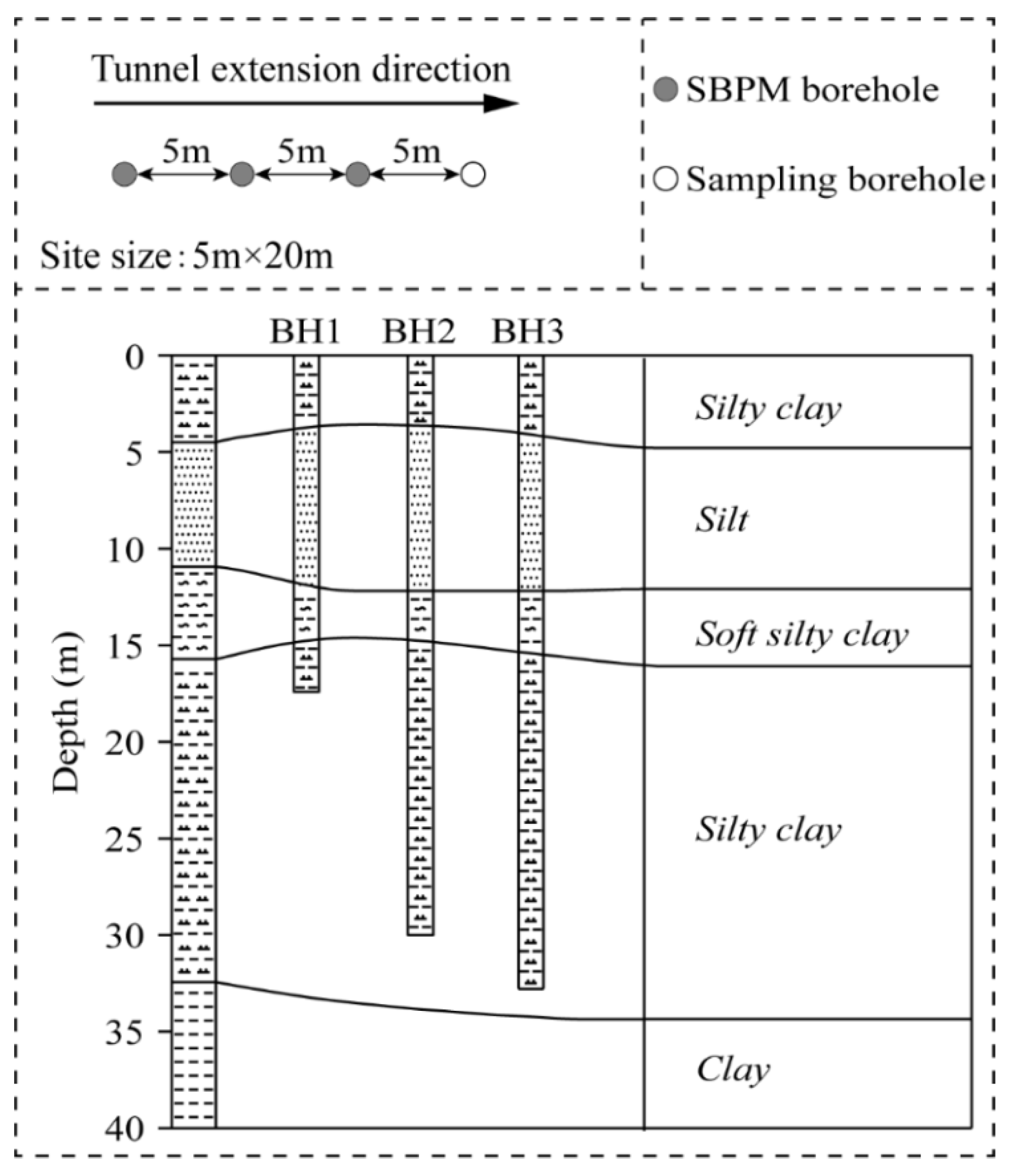

2. SBPM Test Apparatus and Test Site

3. Methods to Analyze the Test Results

3.1. Shear Modulus

3.2. Undrained Shear Strength

4. SBPM Test Results

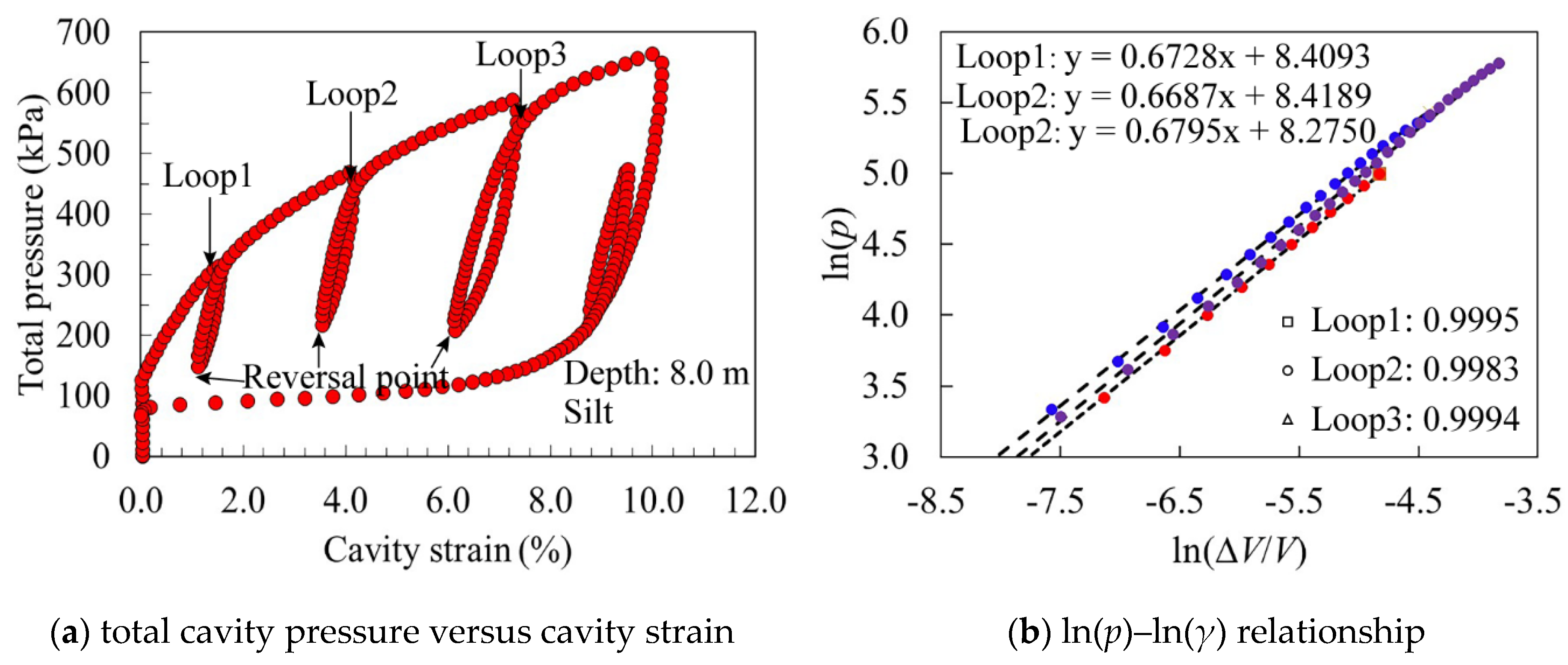

4.1. Stress–Strain Response of Soils

4.2. Undrained Shear Strength

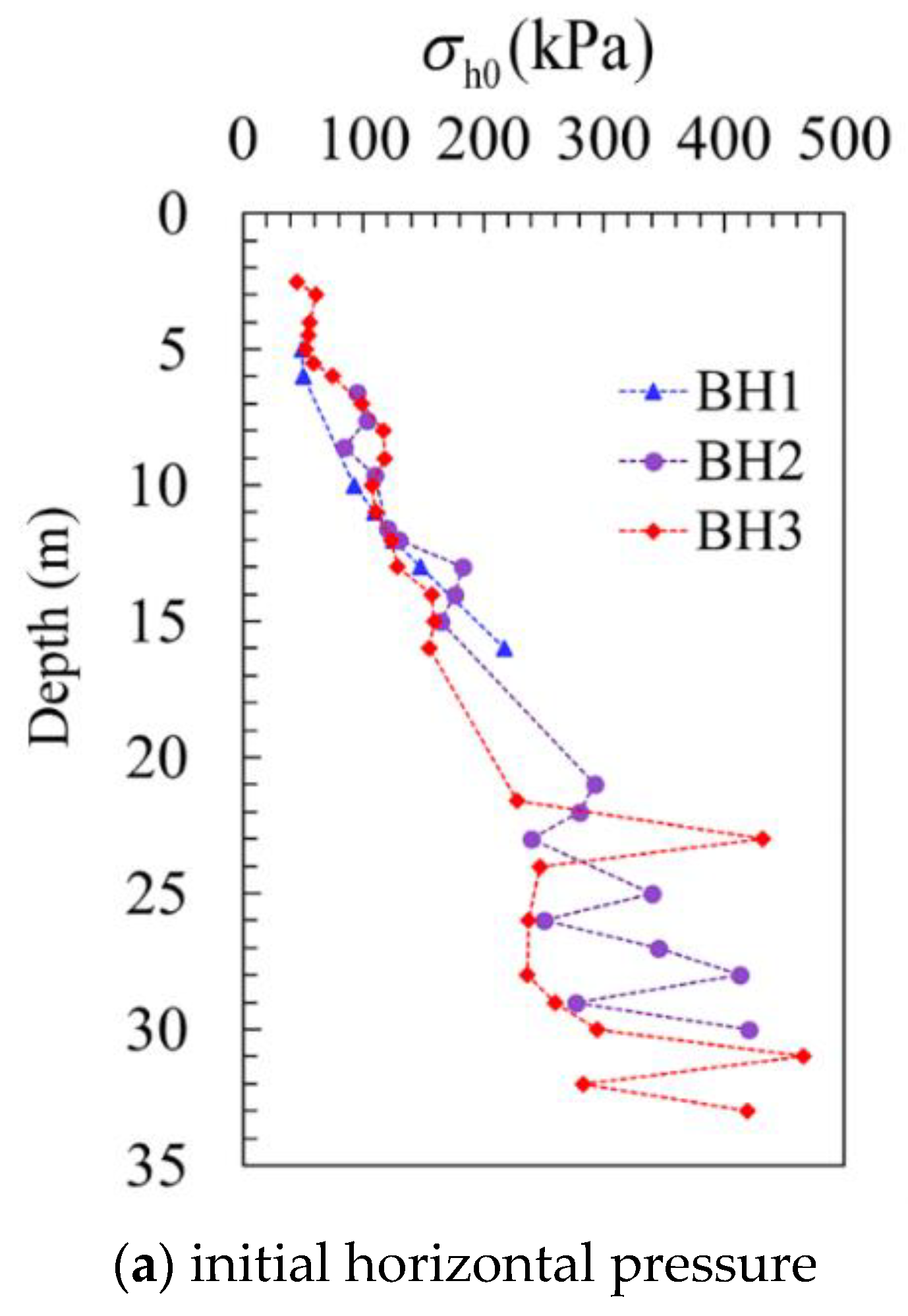

4.3. In Situ Horizontal Stress

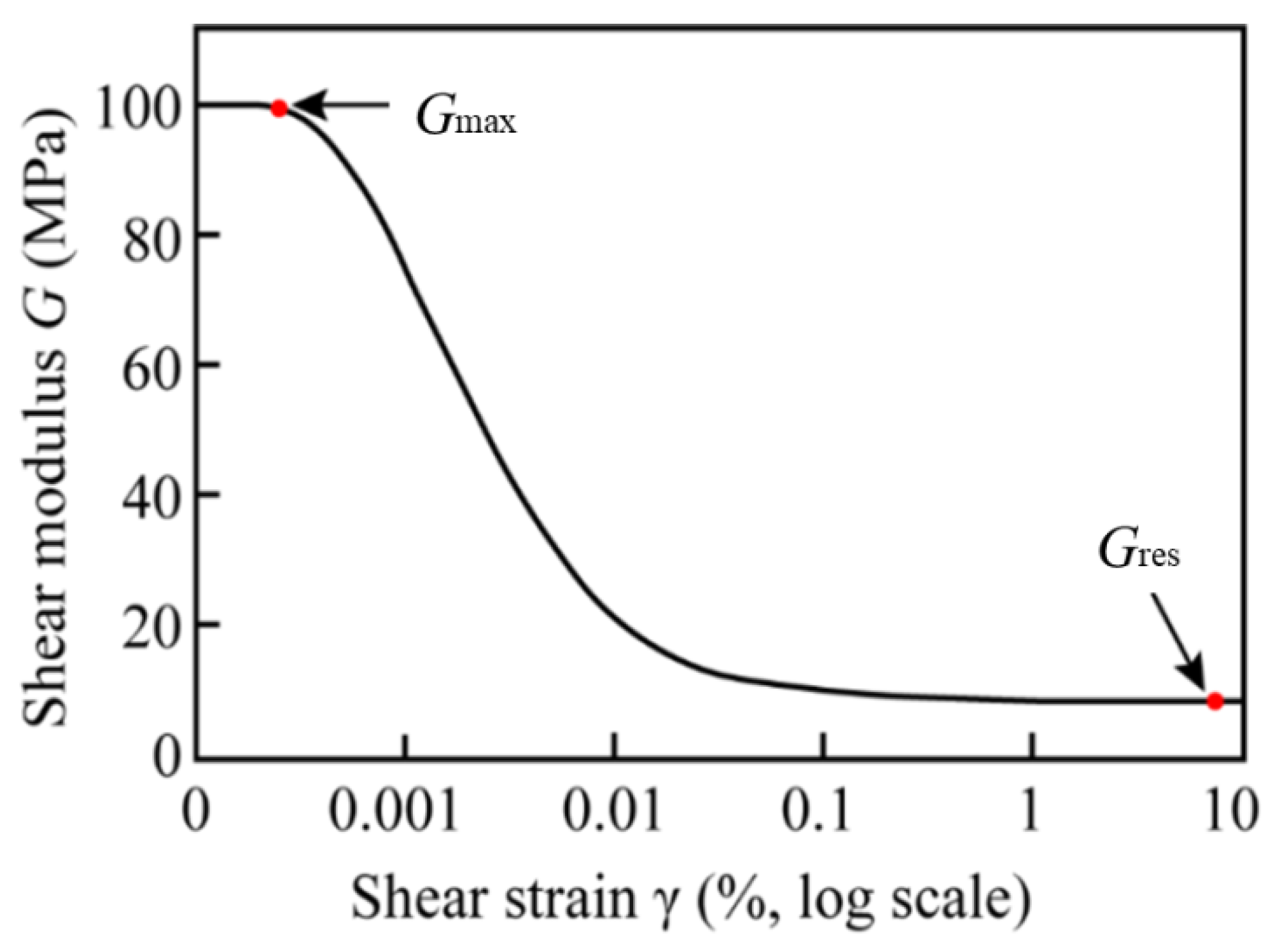

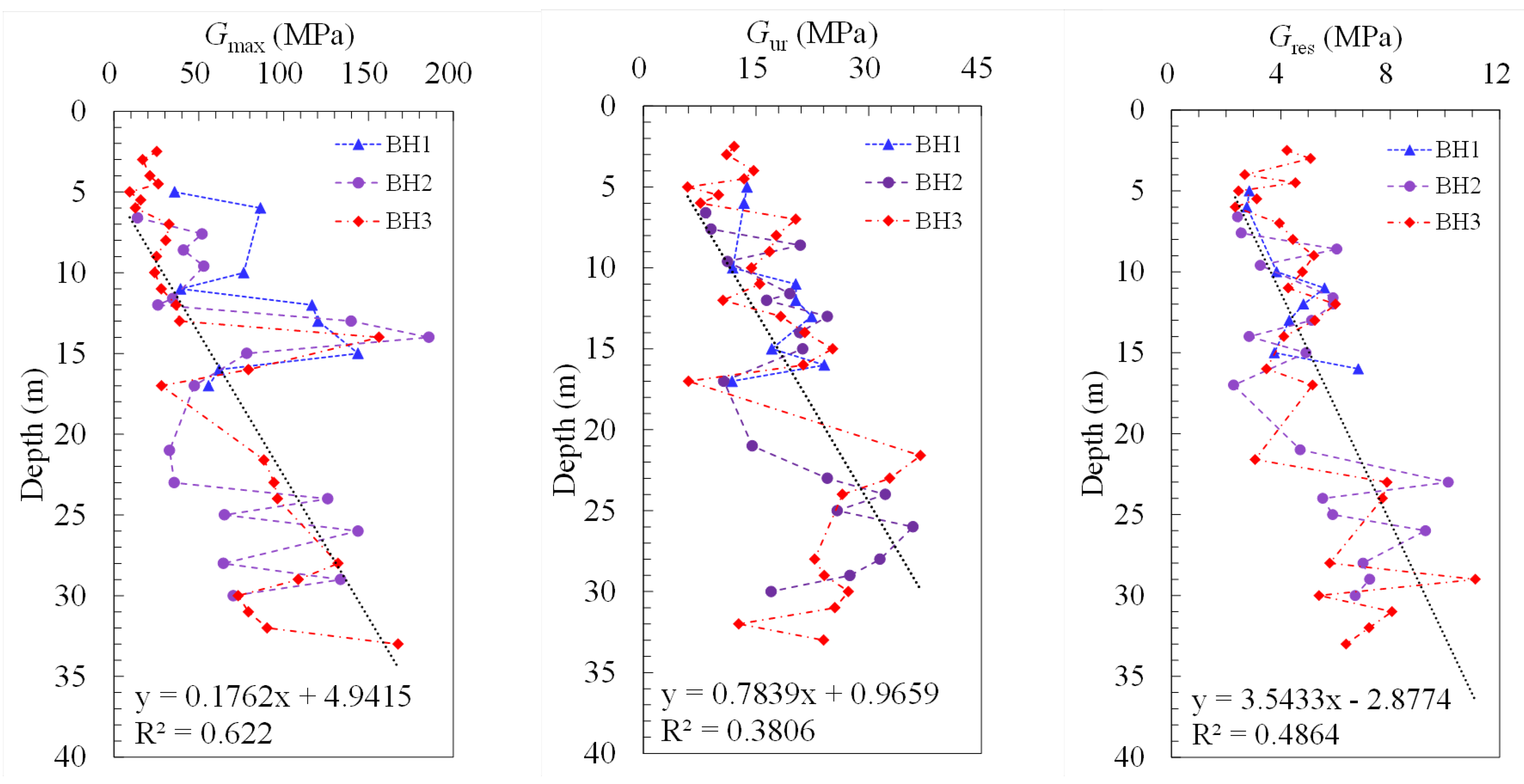

4.4. Shear Modulus

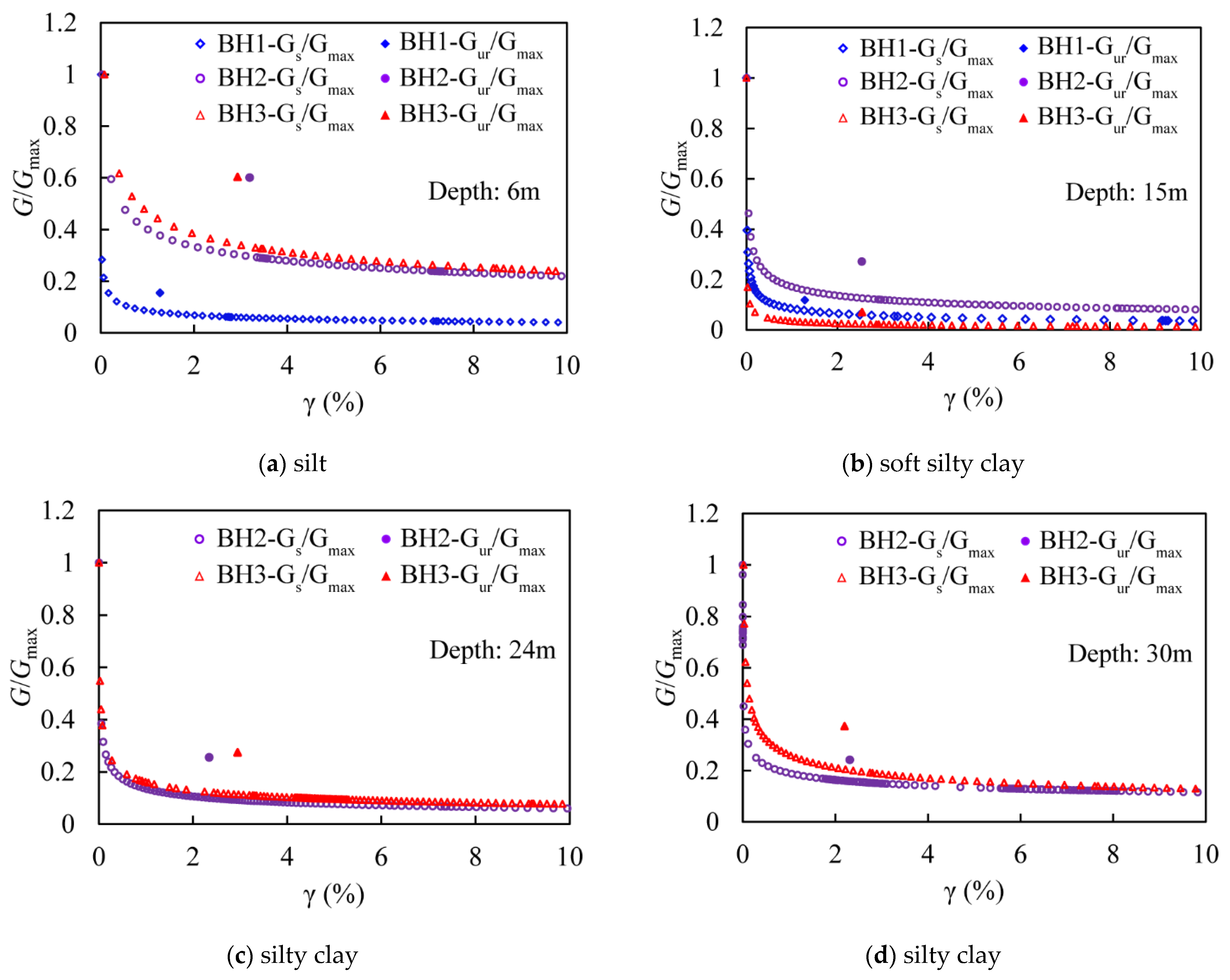

4.4.1. Degradation Characteristics of the Shear Modulus

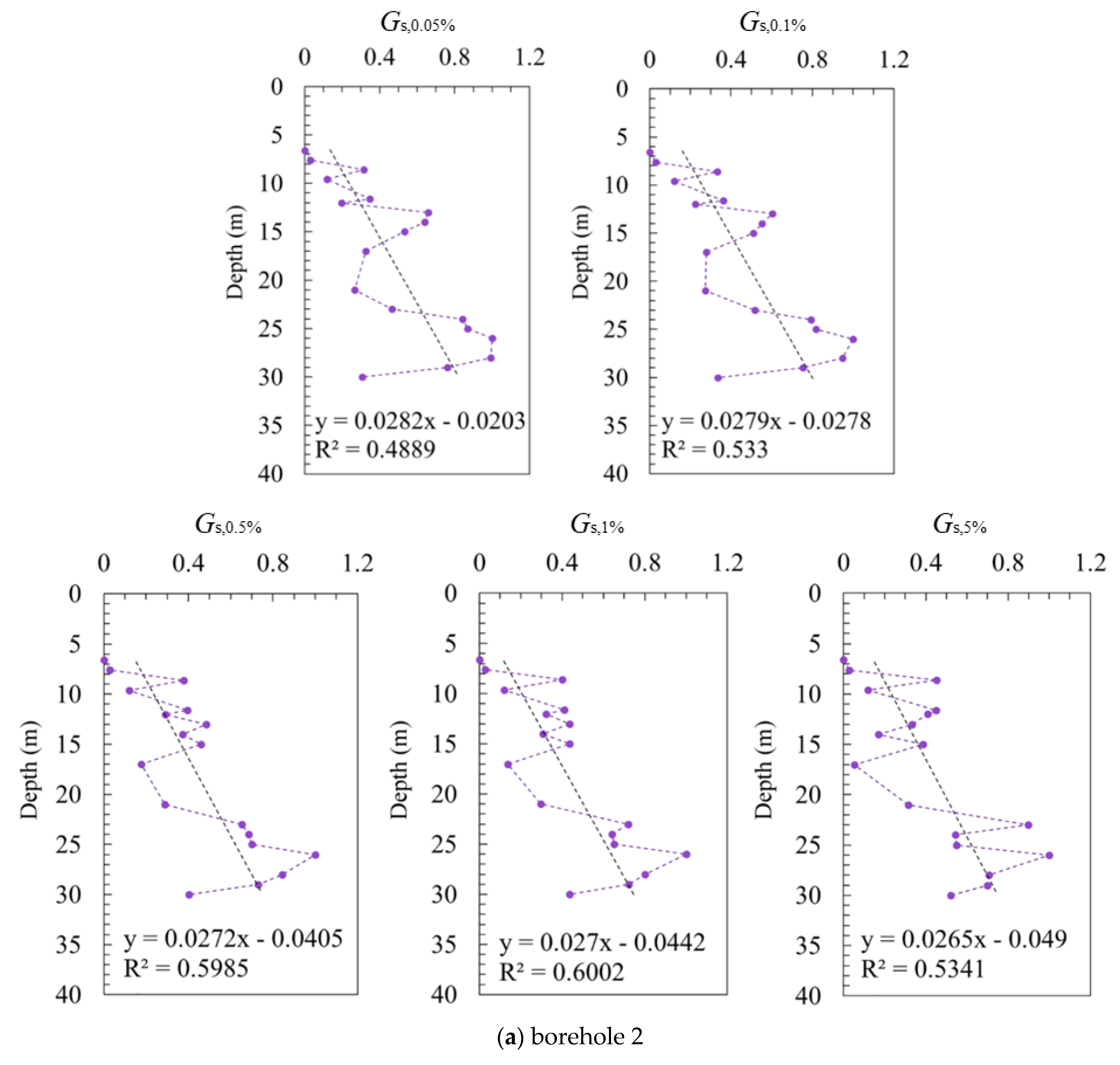

4.4.2. Strain Influence on Distribution of Secant Shear Moduli

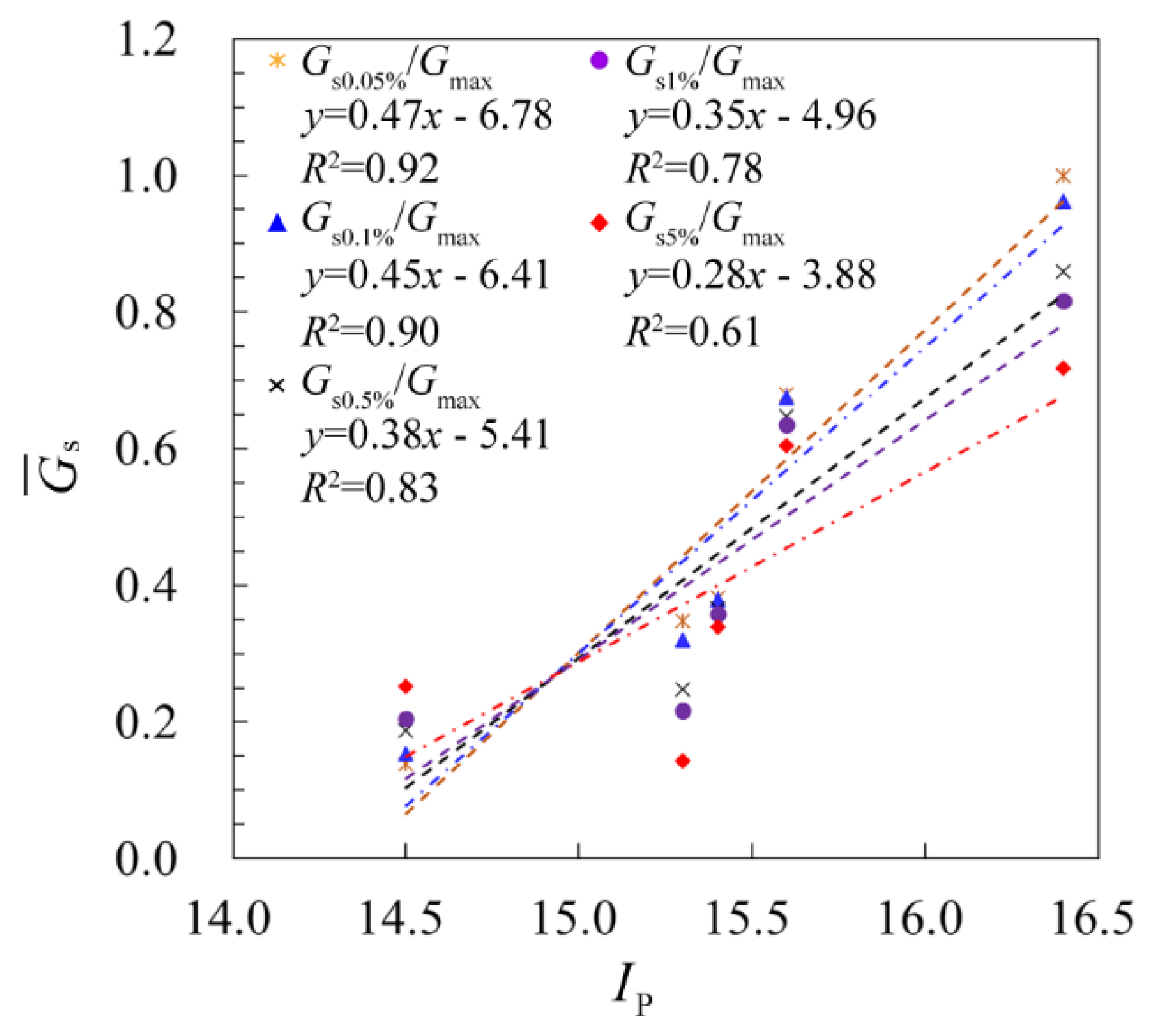

4.4.3. Relationship between Secant Shear Moduli and Plastic Index

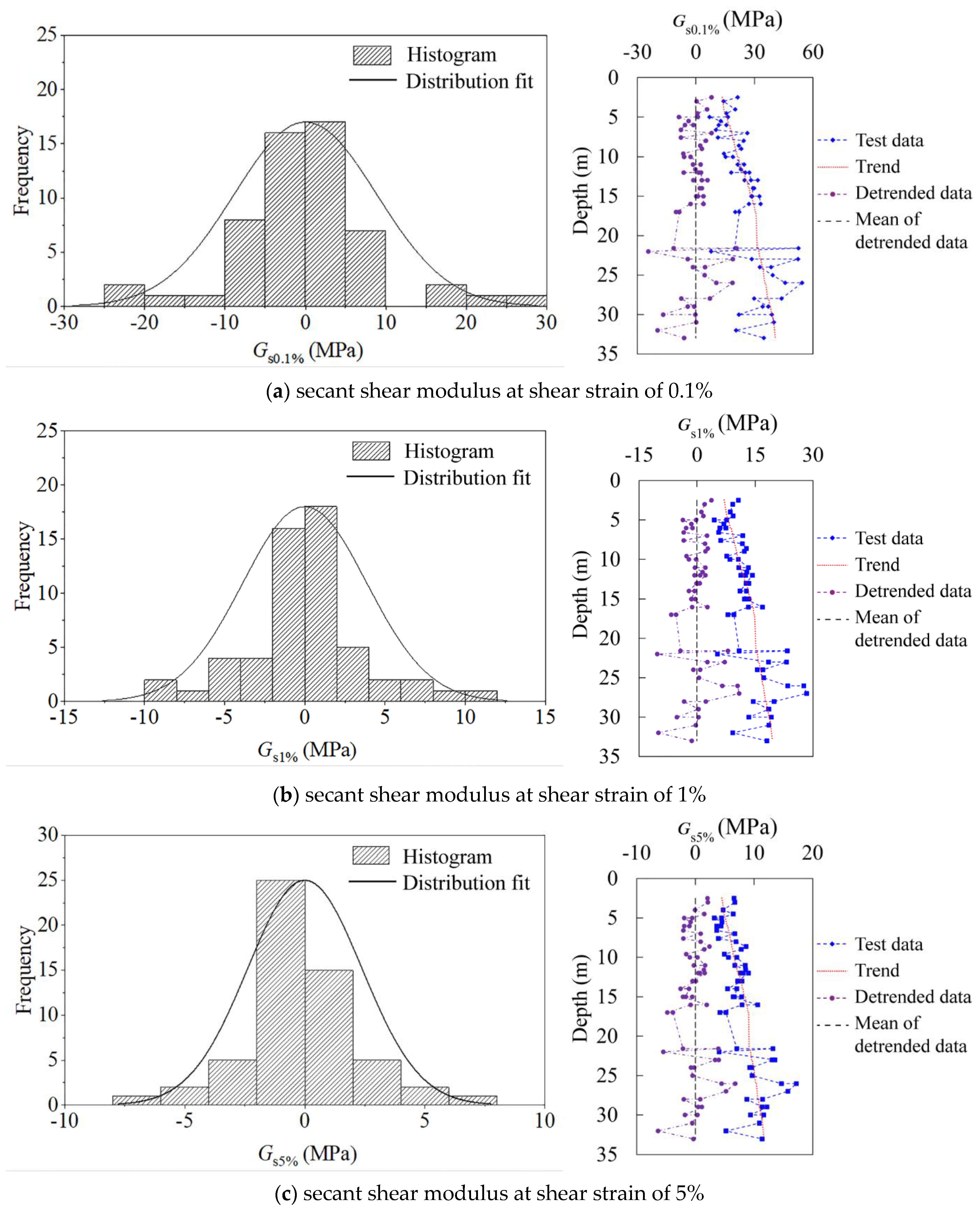

4.5. Statistics Analysis of Secant Shear Modulus and Undrained Shear Strength

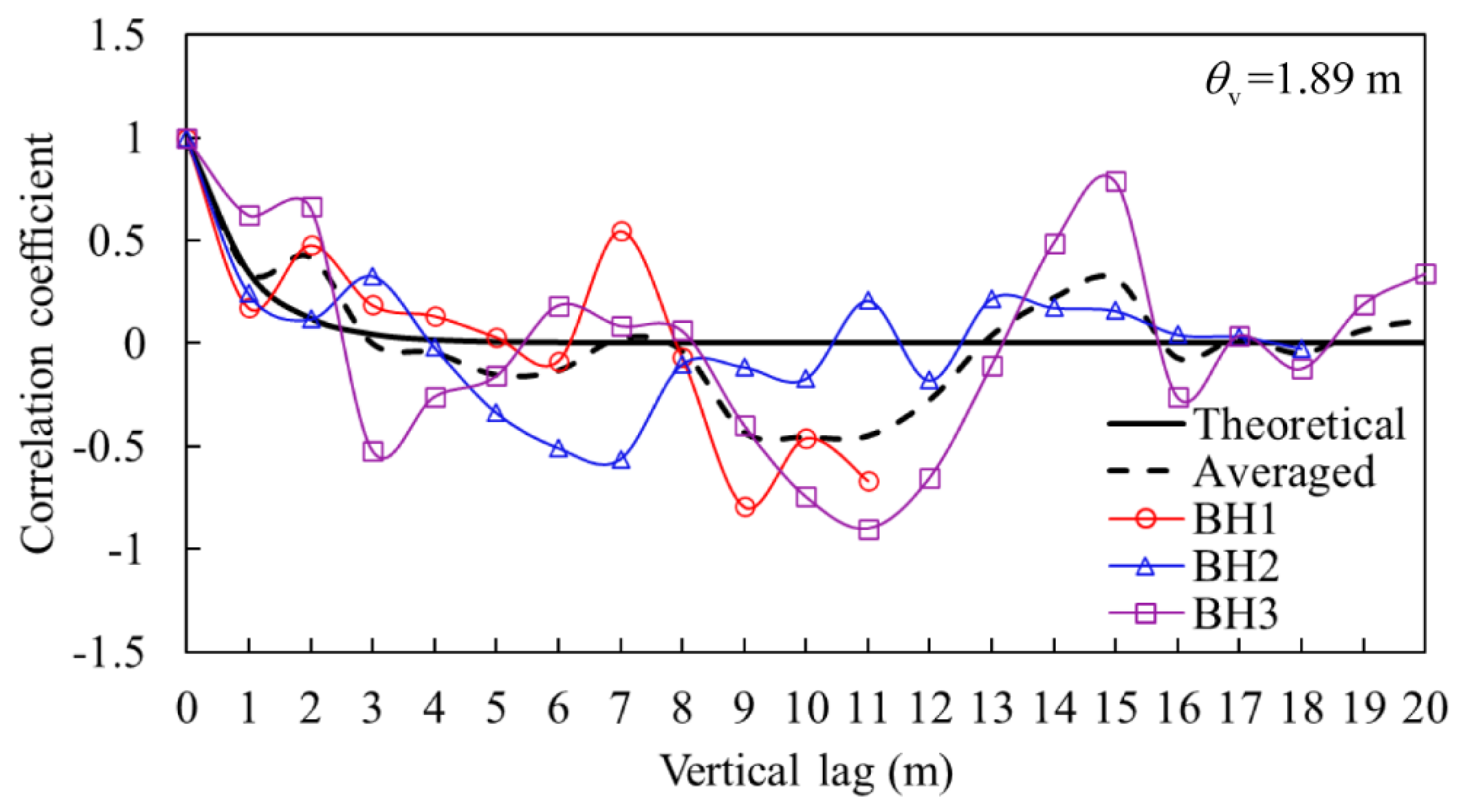

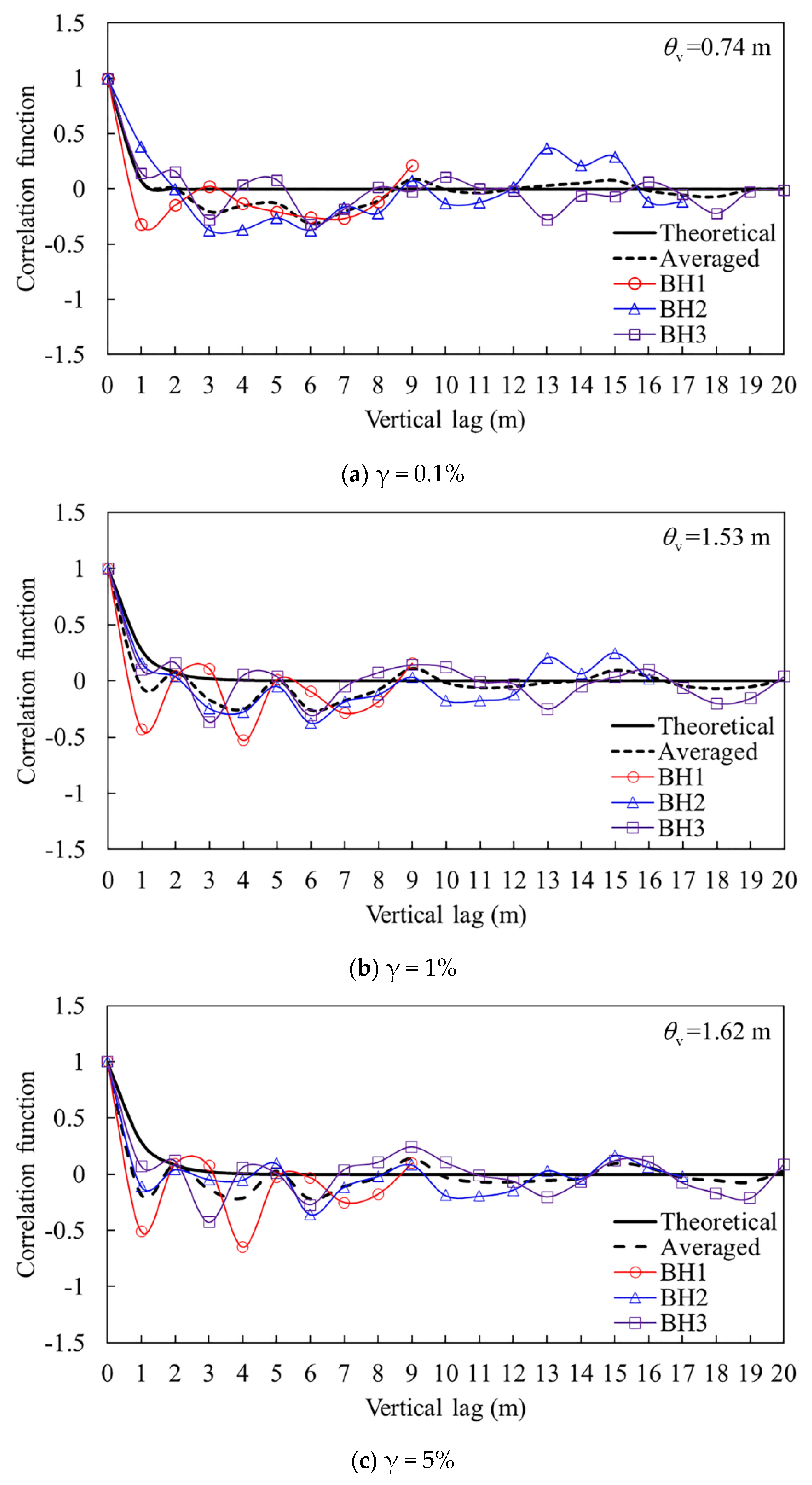

4.6. Scale of Fluctuation of the secant Shear Modulus and Undrained Shear Strength

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benoit, J.; Clough, G.W. Self-boring pressuremeter tests in soft clay. J. Geotech. Eng. 1986, 112, 60–78. [Google Scholar] [CrossRef]

- Fahey, M.; Carter, J.P. A finite element study of the pressuremeter test in sand using a nonlinear elastic plastic model. Can. Geotech. J. 1993, 30, 348–362. [Google Scholar] [CrossRef]

- Baquelin, F.; Jezequel, J.F.; Shields, D.H. The Pressuremeter and Foundation Engineering; Trans Tech Publications: Clausthal-Zellerfeld, Germany, 1978. [Google Scholar]

- Lv, J.; Zhou, T.; Du, Q.; Wu, H. Experimental investigation on properties of gypsum-quicklime-soil grout material in the reparation of earthen site cracks. Constr. Build. Mater. 2017, 157, 253–262. [Google Scholar] [CrossRef]

- Worth, C.P.; Hughes, J.M.O. An instrument for the in–situ measurement of the properties of soft clays. Proc. 8th Int. Conf. Soil Mech. Found. Eng. 1973, 12, 487–494. [Google Scholar]

- Clarke, B.G. In Situ Testing of Clay Using Cambridge Self-Boring Pressuremeter. Ph.D. Thesis, Cambridge University, Cambridge, UK, 1981. [Google Scholar]

- Mair, R.J.; Wood, D.M. Pressuremeter Testing: Methods and Interpretation; Construction Industry Research and Information Association: London, UK; Butterworths: New York, NY, USA, 1987. [Google Scholar]

- Palmer, A.C. Undrained plane strain expansion of a cylindrical cavity in clay: A simple interpretation of the pressuremeter test. Géotechnique 1972, 22, 451–457. [Google Scholar] [CrossRef] [Green Version]

- Ladanyi, B. In-situ determination of undrained stress–strain behaviour of sensitive clays with the pressuremeter. Can. Geotech. J. 1972, 9, 313–319. [Google Scholar] [CrossRef]

- Baguelin, F.; Jézéquel, J.-F.; Lemée, E.; Le Méhauté, A. Expansion of cylindrical probes in cohesive soils. J. Soil Mech. Found. Div. ASCE 1972, 98, 1129–1142. [Google Scholar] [CrossRef]

- Houlsby, G.T.; Withers, N.J. Analysis of the cone pressuremeter test in clay. Géotechnique 1988, 38, 575–587. [Google Scholar] [CrossRef]

- Jefferies, M.G. Determination of horizontal geostatic stress in clay with the self–bored pressuremeter. Can. Geotech. J. 1988, 25, 559–573. [Google Scholar] [CrossRef]

- Bellotti, R.; Ghionna, V.; Jamiolkowski, M.; Robertson, P.K.; Peterson, R.W. Interpretation of moduli from self-boring pressuremeter tests in sand. Géotechnique 1989, 39, 269–292. [Google Scholar] [CrossRef]

- Ferreira, R.S.; Robertson, P.K. Interpretation of undrained self-boring test results incorporating unloading. Can. Geotech. J. 1992, 29, 918–928. [Google Scholar] [CrossRef]

- Ferreira, R.S.; Robertson, P.K. Large-strain undrained pressuremeter interpretation based on loading and unloading data. Can. Geotech. J. 1994, 31, 71–78. [Google Scholar] [CrossRef]

- Schnaid, F.; Ortigao, J.A.; Mántaras, F.M.; Cunha, R.P.; Macgregor, I. Analysis of self-boring pressuremeter (SBPM) and Marchetti dilatometer (DMT) tests in granite saprolites. Can. Geotech. J. 2000, 37, 796–810. [Google Scholar] [CrossRef]

- Silvestri, V. Assessment of self-boring pressuremeter tests in sensitive clay. Can. Geotech. J. 2003, 40, 362–387. [Google Scholar] [CrossRef]

- Kayabasi, A. Prediction of pressuremeter modulus and limit pressure of clayey soils by simple and non-linear multiple regression techniques: A case study from Mersin, Turkey. Environ. Earth Sci. 2012, 66, 2171–2183. [Google Scholar] [CrossRef]

- Whittle, R.W.; Liu, L. A method for describing the stress and strain dependency of stiffness in sand. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013. [Google Scholar]

- Mehdi, A.M.; Ehsan, K. Interpretation of in situ horizontal stress from self-boring pressuremeter tests in sands via cavity pressure less than limit pressure: A numerical study. Environ. Earth Sci. 2017, 76, 333. [Google Scholar]

- Christian, J.T.; Baecher, G.B. Probabilistic foundation settlement on spatially random soil. J. Geotech. Geoenviron. 2003, 129, 866. [Google Scholar] [CrossRef]

- Santoso, A.M.; Phoon, K.K.; Quek, S.T. Effects of soil spatial variability on rainfall-induced landslides. Comput. Struct. 2011, 89, 893–900. [Google Scholar] [CrossRef]

- Li, Y.; Hicks, M.A.; Nuttall, J.D. Comparative analyses of slope reliability in 3D. Eng. Geol. 2015, 196, 12–23. [Google Scholar] [CrossRef]

- Firouzianbandpey, S.; Griffiths, D.V.; Ibsen, L.B.; Andersen, L.V. Spatial correlation length of normalized cone data in sand: Case study in the north of Denmark. Can. Geotech. J. 2014, 51, 844–857. [Google Scholar] [CrossRef]

- De Gast, T.; Vardon, P.J.; Hicks, M.A. Estimating spatial correlations under man-made structures on soft soils. Geo-Risk 2017, 382–389. [Google Scholar]

- Bolton, M.D.; Whittle, R.W. A non-linear elastic/perfectly plastic analysis for plane strain undrained expansion tests. Géotechnique 1999, 49, 133–141. [Google Scholar] [CrossRef] [Green Version]

- Gibson, R.E.; Anderson, W.F. In situ measurement of soil properties with the pressuremeter. Civ. Eng. Public Work. Rev. 1961, 56, 615–618. [Google Scholar]

- Ching, J.; Phoon, K.K. Multivariate distribution for undrained shear strengths under various test procedures. Can. Geotech. J. 2013, 50, 907–923. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Cao, Z. Probabilistic slope stability analysis by risk aggregation. Eng. Geol. 2014, 176, 57–65. [Google Scholar] [CrossRef]

- Li, D.Q.; Zheng, D.; Cao, Z.J.; Tang, X.S.; Phoon, K.-K. Response surface methods for slope reliability analysis: Review and comparison. Eng. Geol. 2016, 203, 3–14. [Google Scholar] [CrossRef]

- Liu, L.-L.; Deng, Z.-P.; Zhang, S.-h.; Cheng, Y.-M. Simplified framework for system reliability analysis of slopes in spatially variable soils. Eng. Geol. 2018, 239, 330–343. [Google Scholar] [CrossRef]

- Kulhawy, F.H.; Roth, M.J.S.; Grigoriu, M.D. Some statistical evaluations of geotechnical properties. In Proceedings of the ICASP6, 6th International Conference on Applied Statistics Probability in Civil Engineering, Mexico City, Mexico, 17–21 June 1991. [Google Scholar]

- Griffiths, D.V.; Fenton, G.A. Probabilistic slope stability analysis by finite elements. J. Geotech. Geoenvironmental. Eng. 2004, 130, 507–518. [Google Scholar] [CrossRef] [Green Version]

- Griffiths, D.V.; Huang, J.; Fenton, G.A. Influence of spatial variability on slope reliability using 2-d random fields. J. Geotech. Geoenviron. 2009, 135, 1367–1378. [Google Scholar] [CrossRef] [Green Version]

- Griffiths, D.V.; Yu, X. Another look at the stability of slopes with linearly increasing undrained strength. Géotechnique 2015, 65, 824–830. [Google Scholar] [CrossRef]

- Shui-Hua, J.; Jinsong, H. Modeling of non-stationary random field of undrained shear strength of soil for slope reliability analysis. Soils Found. 2018, 58, 185–198. [Google Scholar]

- Jaksa, M.B. The Influence of Spatial Variability on the Geotechnical Design Properties of a Stiff Over-Consolidated Clay. Ph.D. Thesis, University of Adelaide, Adelaide, Australia, 1995. [Google Scholar]

- Vanmarcke, E.H. Probabilistic modeling of soil profiles. ASCE J. Geotech. Eng. 1977, 103, 1227–1246. [Google Scholar]

| Sample No. | Depth (m) | Specific Gravity | Water Contents (%) | Void Ratio | Density (g/cm3) | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index |

|---|---|---|---|---|---|---|---|---|

| TH-SC1 | 3.0–3.5 | 2.72 | 27.3 | 0.835 | 1.92 | 35.1 | 20.6 | 14.5 |

| TH-S | 8.0–8.5 | 2.70 | 31.1 | 0.774 | 1.96 | 33.2 | 22.7 | 6.9 |

| TH-SSC | 13.0–13.5 | 2.74 | 36.4 | 1.099 | 1.91 | 38.4 | 19.0 | 15.4 |

| TH-SC2 | 18.0–18.5 | 2.74 | 23.2 | 0.677 | 2.00 | 35.0 | 19.6 | 15.3 |

| TH-SC2 | 21.0–21.5 | 2.72 | 22.0 | 0.746 | 2.02 | 32.9 | 16.5 | 16.4 |

| TH-SC2 | 30.0–30.5 | 2.72 | 29.5 | 0.996 | 1.88 | 31.2 | 15.6 | 15.6 |

| TH-C | 41.0–41.5 | 2.74 | 26.6 | 0.709 | 1.94 | 36.9 | 21.4 | 15.5 |

| Depth (m) | Statistics Parameters | Gs0.05% (MPa) | Gs0.1% (MPa) | Gs0.5% (MPa) | Gs1% (MPa) | Gs5% (MPa) | Cu (kPa) |

|---|---|---|---|---|---|---|---|

| ≤17 | Mean | 26.17 | 21.03 | 12.77 | 10.33 | 6.36 | 264.91 |

| Standard deviation | 9.38 | 6.92 | 3.57 | 2.77 | 1.71 | 91.23 | |

| COV (%) | 35.83 | 32.91 | 27.95 | 26.81 | 26.82 | 34.44 | |

| >17 | Mean | 45.89 | 36.90 | 22.33 | 18.02 | 11.00 | 280.30 |

| Standard deviation | 17.80 | 13.62 | 7.39 | 5.72 | 3.28 | 79.94 | |

| COV (%) | 38.79 | 36.92 | 33.09 | 31.76 | 29.83 | 28.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Liu, K.; Wang, Y.; Jiang, Q. Site Investigations of the Lacustrine Clay in Taihu Lake, China, Using Self-Boring Pressuremeter Test. Sensors 2021, 21, 6026. https://doi.org/10.3390/s21186026

Wang B, Liu K, Wang Y, Jiang Q. Site Investigations of the Lacustrine Clay in Taihu Lake, China, Using Self-Boring Pressuremeter Test. Sensors. 2021; 21(18):6026. https://doi.org/10.3390/s21186026

Chicago/Turabian StyleWang, Bin, Kang Liu, Yong Wang, and Quan Jiang. 2021. "Site Investigations of the Lacustrine Clay in Taihu Lake, China, Using Self-Boring Pressuremeter Test" Sensors 21, no. 18: 6026. https://doi.org/10.3390/s21186026