Sensing Using Light: A Key Area of Sensors

Abstract

:1. Introduction

2. Photonics? Light?

Photonics is understood as the comprehensive or inclusive field of knowledge that includes the devices, technologies, techniques, methods, and scientific knowledge applied to the generation, propagation, control, amplification, detection, storage, processing, etc. of Light signals and derived uses.

3. Photonic Sensors

3.1. Sensors

Photonic Sensors

Photonic sensors (PS) are the devices/systems designed to carry out the faithful reproduction of the measurand in the domain using photonic technologies in its key sensor parts [38].

- (a)

- the modulating technique used to encode the measurand on LX. The PS can be of intensity, phase or interferometric, polarimetric and spectrometric when Mx is encoded on the intensity, phase, polarization, or spectrum, respectively, of the Lx signal;

- (b)

- interaction of Light-Object-Measurand. The PS can be intrinsic when the interaction is indirect (Light always remains inside a waveguide) or extrinsic when the Light interacts directly with the object (Light is not inside a waveguide during the interaction);

- (c)

- way or mode to obtain the LM. The PS can be active or passive when producing the Light requires the pumping or excitation of the object or the waveguides of the transducer (if any) to generate the Lx, respectively;

- (d)

- the measurand’s domain. The PS can be Physical, Chemical, Biological, Mechanical, Biomedical, etc., when the Mx on/in the object is in physical, chemical, biological, mechanical, or biomedical domains, respectively;

- (e)

- the spatial distribution of the measurand in the object. The PS can be punctual, integral, quasi-distributed, or distributed when the detected measurand is in a point, or is the result of the integral of the measurand along of a given line or an area, or is distributed in separate points along a line, or is fully distributed along a line or surface, given a spatial resolution, respectively;

- (f)

- the requirement to dope or not the object to obtain the Lx. The PS can be Labeled or Non-Labeled, respectively;

- (g)

- the technology used to build-up the transducer. The photonic sensor can be an Optical Fiber sensor, Integrated Optic sensor, Hybrid sensor, Volume Optical sensor, or Image sensor when fiber optic, integrated optic, hybrid, volume optic, or image-based technologies are used, respectively (Figure 6).

- The transducer is made by using fiber technology. It measures the strain on N points along a length of fiber placed inside an aircraft wing. The measurand is encoded in the spectrum of an interrogation light signal that is always inside the fiber using Fiber Bragg gratings (FBGs); to interrogate the transducer, pumping energy is not needed. The output of OU gives only a faithful reproduction of the measurand in the electric domain. With this data, an appropriate definition of the PS could be a Bragg grating Optical Fiber sensor for Quasi-distributed strain monitoring in an aircraft wing. Or, Quasi-distributed Optical Fiber Bragg Grating sensor for strain monitoring in an aircraft wing. It is not necessary to mention that it is passive, neither that it is intrinsic, nor that is spectrometric, because it is deduced from the FBG technology used.

- By using the excitation with a pulsed light pump source of a surface of an X composite material; without any contact with the object, their emitted infrared radiation is acquired after the pump pulse, properly treated (in the OU), and the sub-surface in-homogeneities (defects) are detected. An adequate definition of this PS could be an Active Thermographic Non-contact photonic sensor for sub-surface defects detection in X composites. Here, non-contact can be removed, and extrinsic is not necessary to be mentioned because of the thermographic technology used.

- By using the appropriate laser illumination of a hand finger and Doppler Effect, in an adequate OU, the speed of the blood inside the finger vessels (and hence the blood perfusion map) is determined. When the perfusion is below a level, an actuation signal is offered by the OU. A possible definition of the PS could be a Non-Contact Doppler-based Smart Photonic Sensor for monitoring spatial distribution of blood perfusion in hand fingers. Here, the terms based and spatial can be removed.

4. Ten Significant Cases of Photonic Sensors

4.1. Photonic Sensors Based on Optical Fiber Technology

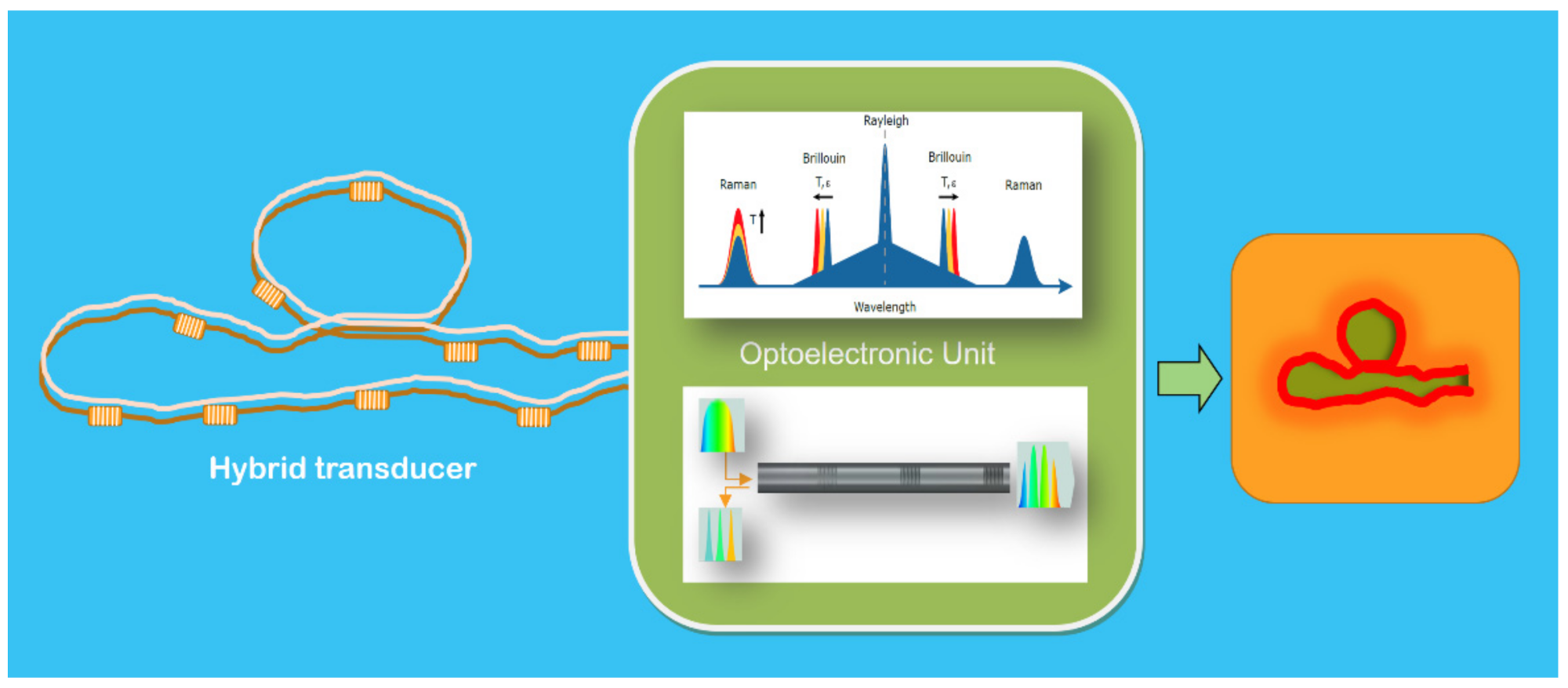

4.1.1. Ultrahigh Temperature Hybrid Fiber Sensor

4.1.2. Quasidistributed OFS for Structural Integrity Monitoring of Wind Turbine Blades

4.1.3. Integral Speckle Fiber Optic Sensor for Patient Monitoring on Bed

4.2. Photonic Sensors on Integrated Optics Technology

4.3. Non-Contact Photonic Sensors

4.3.1. Smart Photonic Sensors Based on Infrared Thermography for NDT Applications

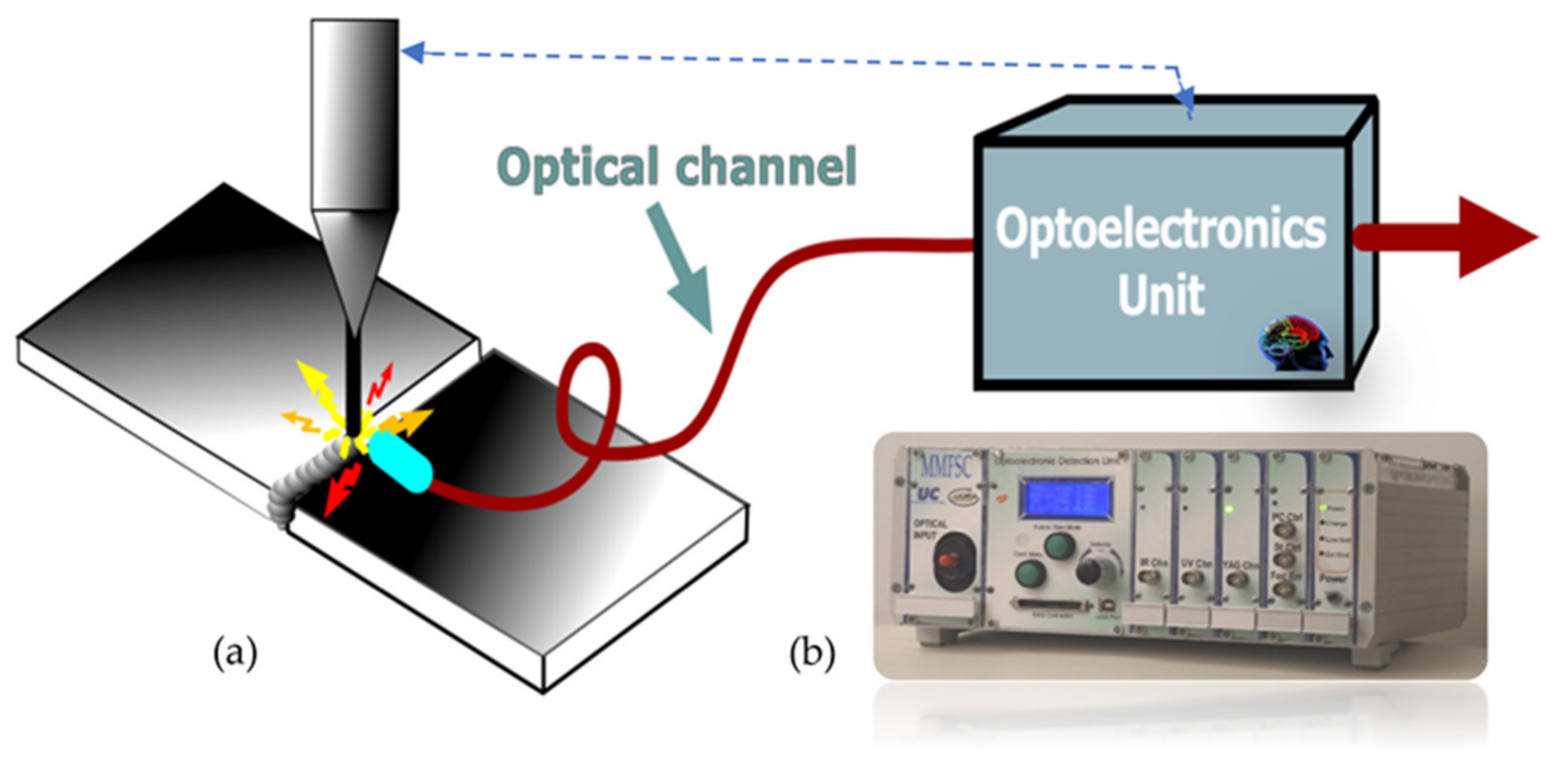

4.3.2. Plasma Spectrometric Photonic Sensor for Welding Monitoring

4.3.3. Laser Spectrometric Photonic Sensors for Material’s Elements Composition

4.3.4. Hybrid SPS for Physiological Reserve Diagnosis of Older People

4.3.5. Smart Image Photonic Sensors for Intraoperative Cancer Detection

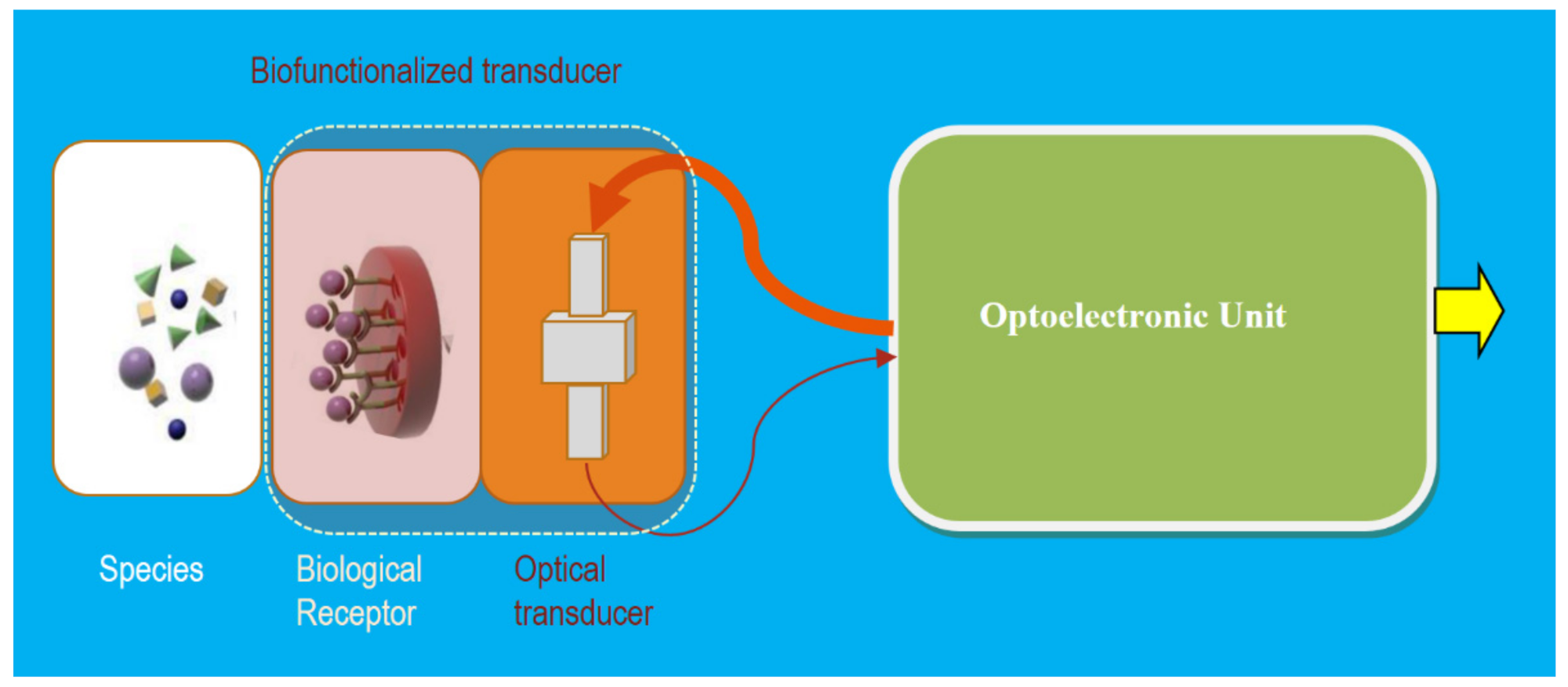

4.3.6. Toward BioPSs for Early Detection of Alzheimer through the Eye

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- López-Higuera, J.M.; Winzer, P.; Sun, T.; Jin, W.; Piqué, A.; Molpeceres, C. Introduction to the JSTQE Special Issue on Photonics for Industry 4.0. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–4. [Google Scholar] [CrossRef]

- Photonics: Key Enabling Technology. Available online: https://cordis.europa.eu/programme/id/H2020_ICT-30-2017/es (accessed on 20 June 2021).

- Photonic Sensors Market—Growth, Trends, COVID-19 Impact, and Forecasts (2021–2026). Mordor Intelligence. 2021. Available online: https://www.mordorintelligence.com/industry-reports/photonic-sensor-market (accessed on 20 June 2021).

- Liang, Y.; Sun, H.; Cheng, L.; Jin, L.; Guan, B.-O. High spatiotemporal resolution optoacoustic sensing with photothermally induced acoustic vibrations in optical fibres. Nat. Commun. 2021, 12, 4139. [Google Scholar] [CrossRef]

- Dominguez, I.; Del Villar, I.; Fuentes, O.; Corres, J.M.; Matias, I.R. Interdigital concept in Photonic Sensors based on an array of lossy mode resonances. Sci. Rep. 2021, 11, 13228. [Google Scholar] [CrossRef]

- Roldán-Varona, P.; Pérez-Herrera, R.A.; Rodríguez-Cobo, L.; Reyes-González, L.; López-Amo, M.; López-Higuera, J.M. Liquid level sensor based on dynamic Fabry-Perot interferometers in processed capillary fiber. Sci. Rep. 2021, 11, 3039. [Google Scholar] [CrossRef]

- Pallarés-Aldeiturriaga, D.; Roldán-Varona, P.; Rodríguez-Cobo, L.; López-Higuera, J.M. Optical Fiber Sensors by Direct Laser Processing: A Review. Sensors 2020, 20, 6971. [Google Scholar] [CrossRef]

- Liu, T.; Pagliano, F.; van Veldhoven, R.; Pogoretskiy, V.; Jiao, Y.; Fiore, A. Integrated nano-optomechanical displacement sensor with ultrawide optical bandwidth. Nat. Commun. 2020, 11, 2407. [Google Scholar] [CrossRef] [PubMed]

- Roldán-Varona, P.; Pallarés-Aldeiturriaga, D.; Rodríguez-Cobo, L.; López-Higuera, J. All-in-fiber multiscan Mach-Zehnder interferometer assisted by core FBG for simultaneous multi-parameter sensing. Opt. Laser Technol. 2020, 132, 106459. [Google Scholar] [CrossRef]

- Lai, Y.-H.; Lu, Y.-K.; Suh, M.-G.; Yuan, Z.; Vahala, K. Observation of the exceptional-point-enhanced Sagnac effect. Nature 2019, 576, 65–69. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Viera-Artiles, J.; Valdiande, J.J.; Ospina, J.; Costales, M.; López-Higuera, J.M. An inertial sensor-based system designed to measure and prevent undesired camera rotation during endoscopic sinus surgery. Int. Forum Allergy Rhinol. 2020, 10, 689–691. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, R.; Wang, Z.L. Light-induced pyroelectric effect as an effective approach for ultrafast ultraviolet nanosensing. Nat. Commun. 2015, 6, 8401. [Google Scholar] [CrossRef] [PubMed]

- Lobo, D.; Anuarbe, P.; López-Higuera, J.M.; Viera-Artiles, J.; Castillo, N.; Megía, R. Estimation of surgeons’ ergonomic dynamics with a structured light system during endoscopic surgery. Int. Forum Allergy Rhinol. 2019, 9, 857–864. [Google Scholar] [CrossRef]

- Thadson, K.; Visitsattapongse, S.; Pechprasarn, S. Deep learning-based single-shot phase retrieval algorithm for surface plasmon resonance microscope based refractive index sensing application. Sci. Rep. 2021, 11, 16289. [Google Scholar] [CrossRef] [PubMed]

- Cuevas, A.R.; Fontana, M.; Rodriguez-Cobo, L.; Lomer, M.; Lopez-Higuera, J.M. Machine Learning for Turning Optical Fiber Specklegram Sensor into a Spatially-Resolved Sensing System. Proof of Concept. J. Light. Technol. 2018, 36, 3733–3738. [Google Scholar] [CrossRef] [Green Version]

- Roldán-Varona, P.; Rodríguez-Cobo, L.; Lopez-Higuera, J.-M. López-Higuera; Reflection-based lab-in-fiber sensor integrated in a surgical needle for biomedical applications. Opt. Lett. 2020, 45, 5242. [Google Scholar] [CrossRef] [PubMed]

- Bykov, D.S.; Schmidt, O.A.; Russell, P.S.J. Flying particle sensors in hollow-core photonic crystal fibre. Nat. Photonics 2015, 9, 461–465. [Google Scholar] [CrossRef]

- Gutiérrez-Gutiérrez, J.A.; Pardo, A.; Real, E.; López-Higuera, J.M.; Conde, O.M. Custom scanning hyperspectral imaging system for biomedical applications: Modeling, benchmarking, and specifications. Sensors 2019, 19, 1692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.; Bu, J.; Li, W.; Lv, J.; Wang, X.; Hu, K.; Yu, Y. Fiber optic Fabry–Perot sensor that can amplify ultrasonic wave for an enhanced partial discharge detection. Sci. Rep. 2021, 11, 8661. [Google Scholar] [CrossRef] [PubMed]

- Pallares-Aldeiturriaga, D.; Rodriguez-Cobo, L.; Quintela, A.; Lopez-Higuera, J.M. Curvature sensor based on In-fiber Mach-Zehnder Interferometer inscribed with femtosecond laser. J. Light. Technol. 2017, 35, 4624–4628. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Perez-Morelo, D.J.; Aksyuk, V. Overcoming thermo-optical dynamics in broadband nanophotonic sensing. Microsyst. Nanoeng. 2021, 7, 1–11. [Google Scholar] [CrossRef]

- Yang, F.; Gyger, F.; Thévenaz, L. Intense Brillouin amplification in gas using hollow-core waveguides. Nat. Photonics 2020, 14, 700–708. [Google Scholar] [CrossRef]

- Real, E.; Icardo, J.M.; Fernández-Barreras, G.; Revuelta, J.M.; Díez, M.C.; Pontón, A.; Gutiérrez, J.F.; Higuera, J.M.L.; Conde, O.M. Identification of Human Pathological Mitral Chordae Tendineae Using Polarization-sensitive Optical Coherence Tomography. Sensors 2019, 19, 543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Belyaev, V.K.; Rodionova, V.V.; Fedyanin, A.A. Magnetic field sensor based on magnetoplasmonic crystal. Sci. Rep. 2020, 10, 7133. [Google Scholar] [CrossRef] [PubMed]

- Minardo, A.; Bernini, R.; Ruiz-Lombera, R.; Mirapeix, J.; Lopez-Higuera, J.M.; Zeni, L. Proposal of Brillouin optical frequencydomain reflectometry (BOFDR). Opt. Express 2016, 24, 29994–30001. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Lombera, R.; Urricelqui, J.; Sagues, M.; Mirapeix, J.; Lopez-Higuera, J.M.; Loayssa, A. Overcoming Nonlocal Effects and Brillouin Threshold Limitations in Brillouin Optical Time-Domain Sensors. IEEE Photonics J. 2015, 7, 1–9. [Google Scholar] [CrossRef]

- Zhao, P.; Zhao, Y.; Wang, P. Mode-phase-difference photothermal spectroscopy for gas detection with an anti-resonant hollow-core optical fiber. Nat. Commun. 2020, 11, 847. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kamil, Y.M.; Al-Rekabi, S.H.; Yaacob, M.H.; Syahir, A.; Chee, H.Y.; Mahdi, M.A.; Abu Bakar, M.H. Detection of dengue using PAMAM dendrimer integrated tapered optical fiber sensor. Sci. Rep. 2019, 9, 13483. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raele, M.P.; De Pretto, L.R.; De Rossi, W.; Vieira, N.D.; Samad, R.E. Ricardo Elgul Samad, Focus Tracking System for Femtosecond Laser Machining using Low Coherence Interferometry. Sci. Rep. 2019, 9, 4167. [Google Scholar] [CrossRef]

- Cheng, Y.-C.; Chang, Y.-J.; Chuang, Y.-C.; Huang, B.-Z.; Chen, C.-C. A plasmonic refractive index sensor with an ultrabroad dynamic sensing range. Sci. Rep. 2019, 9, 5134. [Google Scholar] [CrossRef] [Green Version]

- Flores, R.; Janeiro, R.; Viegas, J. Optical fibre Fabry-Pérot interferometer based on inline microcavities for salinity and temperature sensing. Sci. Rep. 2019, 9, 9556. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, S.; Biswas, P.; Palit, P.; Zhou, W.; Sun, Y. Optofluidic vapor sensing with free-space coupled 2D photonic crystal slabs. Sci. Rep. 2019, 9, 4209. [Google Scholar] [CrossRef] [Green Version]

- Yu, W.; Jiang, W.C.; Lin, Q.; Lu, T. Cavity optomechanical spring sensing of single molecules. Nat. Commun. 2016, 7, 12311. [Google Scholar] [CrossRef]

- Caucheteur, C.; Guo, T.; Liu, F.; Guan, B.-O.; Albert, J. Ultrasensitive plasmonic sensing in air using optical fibre spectral combs. Nat. Commun. 2016, 7, 13371. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez-Cobo, L.; Lomer, M.; Cobo, A.; Lopez-Higuera, J.M. Optical fiber strain sensor with extended dynamic range based on specklegrams. Sens. Actuators A Phys. 2013, 203, 341–345. [Google Scholar] [CrossRef]

- Pardini, L.; Elhassan, A.; Ferretti, M.; Foresta, A.; Legnaioli, S.; Lorenzetti, G.; Nebbia, E.; Catalli, F.; Harith, M.A.; Pace, D.D.; et al. X-Ray Fluorescence and Laser-Induced Breakdown Spectroscopy analysis of Roman silver denarii. Spectrochim. Acta Part B At. Spectrosc. 2012, 74–75, 156–161. [Google Scholar] [CrossRef]

- Ullan, A.; Quintela, M.A.; Rodriguez-Cobo, L.; Perez-Herrera, R.A.; Lopez-Amo, M.; López-Higuera, J.M.; Quintela, A. Quasi distributed hybrid Brillouin fiber laser sensor system. Meas. Sci. Technol. 2012, 23, 085202. [Google Scholar] [CrossRef]

- López-Higuera, J.M. Introduction to Optical Fiber Sensor Technology. In The Handbook of Optical Fiber Sensing Technology; John Wiley & Sons Inc.: New York, NY, USA, 2002; ISBN 0-47182-053-9. [Google Scholar]

- López-Higuera, J.M.; Light Based Sensors, International School of Light Sciences and Technologies. Invited Lecture, ISLIST at UIMP, Santander, Spain, 25–29 June 2018. Available online: https://www.youtube.com/watch?v=ogoVA3QO75k (accessed on 20 June 2021).

- López-Higuera, J.M. Sensing using Light: An integral vision of a key Photonics area. In Proceedings of the Invited Keynote Symposium on Fibre Optic and Photonic Sensors for Industrial and Healthcare Applications: New Challenges and Opportunities, The Wordsworth Hotel, Grasmere, Cumbria, UK, 15–18 October 2018. [Google Scholar]

- Lopez-Higuera, J.M.; Cobo, L.R.; Incera, A.Q.; Cobo, A. Fiber Optic Sensors in Structural Health Monitoring. J. Lightwave Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- López-Higuera, J.M. Smart Sensors using light technologies: A comprehensive vision. In Proceedings of the 5th Ed. Smart Materials and Surfaces—SMS Conference, Lisbon, Portugal, 23–25 October 2019. [Google Scholar]

- López-Higuera, J.M. Smart Photonic sensors for materials and structures assessment. In Proceedings of the Advanced Materials online Congress, The International Association of Advanced Materials, Ulrika, Sweden, 26 February 2021. [Google Scholar]

- Crossley, S.D. The commercialitation of fibre optic sensors. In Handbook of Optical Fiber Sensing Technology; López-Higuera, J.M., Ed.; Wiley&Sons: New York, NY, USA, 2002; pp. 23–30. [Google Scholar]

- Santos, J.L.; Farahi, F. Optical Sensors; CRC Press: Boca Raton, FL, USA, 2015; ISBN 978-1-4398-6685-6. [Google Scholar]

- Barrias, A.; Casas, J.R.; Villalba, S. A Review of Distributed Optical Fiber Sensors for Civil Engineering Applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Inaudi, D. Photonic Sensing Technology in Civil Engineering and Applications. In Handbook of Optical Fiber Sensing Technology; López-Higuera, J.M., Ed.; Wiley&Sons: New York, NY, USA, 2002; pp. 517–542. [Google Scholar]

- Fujiwara, E.; Dos Santos, M.F.; Suzuki, C.K. Optical fiber specklegram sensor analysis by speckle pattern division. Appl. Opt. 2017, 56, 1585–1590. [Google Scholar] [CrossRef] [PubMed]

- Ran, Z.; He, X.; Rao, Y.; Sun, D.; Qin, X.; Zeng, D.; Chu, W.; Li, X.; Wei, Y. Fiber-Optic Microstructure Sensors: A Review. Photonic Sens. 2021, 11, 227–261. [Google Scholar] [CrossRef]

- Bado, M.; Casas, J. A Review of Recent Distributed Optical Fiber Sensors Applications for Civil Engineering Structural Health Monitoring. Sensors 2021, 21, 1818. [Google Scholar] [CrossRef]

- Bao, X.; Wang, Y. Recent Advancements in Rayleigh Scattering-Based Distributed Fiber Sensors. Adv. Devices Instrum. 2021, 2021, 8696571. [Google Scholar] [CrossRef]

- Laarossi, I.; Roldán-Varona, P.; Quintela-Incera, M.A.; Rodríguez-Cobo, L.; López-Higuera, J.M. Ultrahigh temperature and strain hybrid integrated sensor system based on Raman and femtosecond FBG inscription in a multimode gold-coated fiber. Opt. Express 2019, 27, 37122–37130. [Google Scholar] [CrossRef]

- Laarossi, I.; Quintela-Incera, M.Á.; López-Higuera, J.M. Comparative Experimental Study of a High-Temperature Raman-Based Distributed Optical Fiber Sensor with Different Special Fibers. Sensors 2019, 19, 574. [Google Scholar] [CrossRef] [Green Version]

- Laarossi, I.; Ruiz-Lombera, R.; Quintela, M.A.; Mirapeix, J.; Lima, D.; Solana, D.; Lopez-Higuera, J.-M. Ultrahigh Temperature Raman-Based Distributed Optical Fiber Sensor with Gold-Coated Fiber. IEEE J. Sel. Top. Quantum Electron. 2016, 23, 296–301. [Google Scholar] [CrossRef] [Green Version]

- Wu, T.; Liu, G.; Fu, S.; Xing, F. Recent Progress of Fiber-Optic Sensors for the Structural Health Monitoring of Civil Infrastructure. Sensors 2020, 20, 4517. [Google Scholar] [CrossRef]

- Rodriguez-Cobo, L.; Quintela, A.; Aramburu, J.; Lopez-Higuera, J.M. OFS Quasi-Distributed Transducer for Wind Blade Monitoring. In Proceedings of the OSA Congress: Light, Energy and Environment 2016, Leipzig, Germany, 14–17 November 2016. [Google Scholar] [CrossRef]

- Aramburu Arriaga, J.; López Higuera, J.M.; Quintela Incera, A.; Rodríguez Cobo, L.; Zabalaandikoetxea Puente, A. Sistema Transductor Basado en Redes de Difracción en Fibra Óptica. Aeroblade. SA Patent Application No. ES2419579B1, 25 August 2014. [Google Scholar]

- Spillman, W.B., Jr.; Mayer, M.; Bennett, J.; Gong, J.; Meissner, K.E.; Davis, B.; Claus, R.O.; Muelenaer, A.A., Jr.; Xu, X. A ‘smart’ bed for non-intrusive monitoring of patient physiological factors. Meas. Sci. Technol. 2004, 15, 1614–1620. [Google Scholar] [CrossRef]

- Podbreznik, P.; Đonlagić, D.; Lešnik, D.; Cigale, B.; Zazula, D. Cost-efficient speckle interferometry with plastic optical fiber for unobtrusive monitoring of human vital signs. J. Biomed. Opt. 2013, 18, 107001. [Google Scholar] [CrossRef] [PubMed]

- Lomer, M.; Rodriguez-Cobo, L.; Revilla, P.; Herrero, G.; Madruga, F.; Lopez-Higuera, J.M. Speckle POF sensor for detecting vital signs of patients. In 23rd International Conference on Optical Fibre Sensors; SPIE: Bellingham, WA, USA, 2014; Volume 9157. [Google Scholar]

- Rodriguez-Cobo, L.; Lomer, M.; López-Higuera, J.-M.; Rodriquez-Cobo, L. Fiber Specklegram Multiplexed Sensor. J. Light. Technol. 2014, 33, 2591–2597. [Google Scholar] [CrossRef]

- Cuevas, A.R.; Peña, E.R.; Rodríguez-Cobo, L.; Lomer, M.; Lopez-Higuera, J.M. Low-cost fiber specklegram sensor for noncontact continuous patient monitoring. J. Biomed. Opt. 2017, 22, 037001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- López-Higuera, J.M.; Barboza, M.L.; Cobo, L.R.; Cuevas, A.R. Dispositivo de Detección de Actividad/Inactividad Fisiológica Basado en Fibra Óptica. Patent of University of Cantabria Application No. P201600626, 22 July 2016. [Google Scholar]

- Lechuga, L. Nano/micro-Biosensors using Light Sceinces and Technologies. In Proceedings of the ISLIST, Santander, Spain, 17–21 June 2019. [Google Scholar]

- Sang, S.; Wang, Y.; Feng, Q.; Wei, Y.; Ji, J.; Zhang, W. Progress of new label-free techniques for biosensors: A review. Crit. Rev. Biotechnol. 2016, 36, 465–481. [Google Scholar] [CrossRef] [PubMed]

- Lafleur, J.P.; Jönsson, A.; Senkbeil, S.; Kutter, J.P. Recent advances in lab-on-a-chip for biosensing applications. Biosens. Bioelectron. 2016, 76, 213–233. [Google Scholar] [CrossRef] [PubMed]

- Estevez, M.-C.; Otte, M.A.; Sepulveda, B.; Lechuga, L. Trends and challenges of refractometric nanoplasmonic biosensors: A review. Anal. Chim. Acta 2014, 806, 55–73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- González-Guerrero, A.B.; Maldonado, J.; Herranz, S.; Lechuga, L.M. Trends in photonic lab-on-chip interferometric biosensors for point-of-care diagnostics. Anal. Methods 2016, 8, 8380–8394. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Sanchez, M.M.; Yin, Y.; Herzer, R.; Ma, L.; Schmidt, O.G. Silicon-Based Integrated Label-Free Optofluidic Biosensors: Latest Advances and Roadmap. Adv. Mater. Technol. 2020, 5, 1901138. [Google Scholar] [CrossRef]

- Kurt, H.; Pishva, P.; Pehlivan, Z.S.; Arsoy, E.G.; Saleem, Q.; Bayazıt, M.K.; Yüce, M. Nanoplasmonic biosensors: Theory, structure, design, and review of recent applications. Anal. Chim. Acta 2021, 338842. [Google Scholar] [CrossRef]

- Ruiz-Vega, G.; Soler, M.; Lechuga, L.M. Nanophotonic biosensors for point-of-care COVID-19 diagnostics and coronavirus surveillance. J. Phys. Photonics 2021, 3, 011002. [Google Scholar] [CrossRef]

- González, D.A.; Madruga, F.J.; Quintela, M.Á.; López-Higuera, J.M. Quality control of radiant heaters. SPIE/Photonics Appl. Ind. Res. 2005, 5948, 594823. [Google Scholar] [CrossRef] [Green Version]

- González, D.; Madruga, F.; Quintela, M.; Lopez-Higuera, J. Defect assessment on radiant heaters using infrared thermography. NDT E Int. 2005, 38, 428–432. [Google Scholar] [CrossRef]

- Rodríguez-Martín, M.; Fueyo, J.; Gonzalez-Aguilera, D.; Madruga, F.; García-Martín, R.; Muñóz, Á.; Pisonero, J. Predective Models for the Characterization of Internal Defects in Additive Materials from Active Thermography Squences Supported by Machine Learnig Methods. Sensors 2020, 20, 3982. [Google Scholar] [CrossRef] [PubMed]

- Madruga, F.J.; Sfarra, S.; Perilli, S.; Pivarčiová, E.; López-Higuera, J.M. Measuring the Water Content in Wood Using Step-Heating Thermography and Speckle Patterns-Preliminary Results. Sensors 2020, 20, 316. [Google Scholar] [CrossRef] [Green Version]

- Blunck, D.L. Applications of Infrared Thermography for Studying Flows with Participating Media. Exp. Therm. Fluid Sci. 2021, 130, 110502. [Google Scholar] [CrossRef]

- Wu, C.; Ushio, M.; Tanaka, M. Analysis of the TIG welding arc behavior. Comput. Mater. Sci. 1997, 7, 308–314. [Google Scholar]

- Mirapeix, J.; Cobo, A.; Fernandez, S.; Cardoso, R.; Lopez-Higuera, J.M. Spectroscopic analysis of the plasma continuum radiation for online arc-welding defect detection. J. Phys. D Appl. Phys. 2008, 41, 135202. [Google Scholar] [CrossRef]

- Serrano, J.M.; Lombera, R.R.; Valdiande, J.J.; López-Higuera, J.M. Colorimetric analysis for online arc-welding diagnostics by means of plasma optical spectroscopy. IEEE Sens. J. 2014, 16, 637–640. [Google Scholar] [CrossRef] [Green Version]

- García-Allende, P.; Mirapeix, J.; Conde, O.M.; Cobo, A.; Lopez-Higuera, J.M. Spectral processing technique based on feature selection and artificial neural networks for arc-welding quality monitoring. NDT E Int. 2009, 42, 56–63. [Google Scholar] [CrossRef]

- Mirapeix, J.; Garcia-Allende, P.B.; Cobo, A.; Conde, O.M.; López-Higuer, J.M. Real-time arc welding defect detection and classification with Principal Component Analysis and Artificial Neural Networks. NDT E Int. 2007, 40, 315–323. [Google Scholar] [CrossRef]

- Garcia-Allende, P.B.; Mirapeix, J.; Conde, O.M.; Cobo, A.; Lopez-Higuera, J.M. Arc-Welding Spectroscopic Monitoring based on Feature Selection and Neural Networks. Sensors 2008, 8, 6496–6506. [Google Scholar] [CrossRef] [Green Version]

- Mirapeix, J.; Cobo, A.; González, D.A.; López-Higuera, J.M. Plasma spectroscopy analysis technique based on optimization algorithms and spectral synthesis for arc-welding quality assurance. Opt. Express 2007, 15, 1884–1897. [Google Scholar] [CrossRef]

- Mirapeix, J.; Cobo, A.; Jáuregui, C.; López-Higuera, J.M. Fast algorithm for spectral processing with application to online welding quality assurance. Meas. Sci. Technol. 2006, 17, 2623–2629. [Google Scholar] [CrossRef]

- Cobo, A.; Mirapeix, J.; Linares, F.; Piney, J.A.; Solana, D.; López-Higuera, J.M. Sensor System for Quality Assurance of the Tube-To-Tubesheet Welding Process in Nuclear Steam Generators. IEEE Sens. J. 2007, 7, 1219–1224. [Google Scholar] [CrossRef]

- Mirapeix, J.; Vila, E.; Valdiande, J.J.; Riquelme, A.; Garcia, M.; Cobo, A. Real-time detection of the aluminium contribution during laserwelding of Usibor1500 tailor-welded blanks. J. Mater. Process. Technol. 2016, 235, 106–113. [Google Scholar] [CrossRef] [Green Version]

- Mirapeix, J.; Cobo, A.; Fuentes, J.; Dávila, M.; Etayo, J.M.; Lopez-Higuera, J.-M. Use of the plasma spectrum rms signal for arc-welding diagnostics. Sensors 2009, 9, 5263–5276. [Google Scholar] [CrossRef] [Green Version]

- Cobo, A.; Bardin, F.; Mirapeix, J.; Hand, D.P.; Jones, J.D.C.; López-Higuera, J.M. Optoelectronic device for non-invasive focal point measurement and control of the laser welding process. Meas. Sci. Technol. 2005, 16, 1–6. [Google Scholar] [CrossRef]

- Kearton, B.; Mattley, Y. Laser-induced breakdown spectroscopy: Sparking new applications. Nat. Photonics 2008, 2, 537–540. [Google Scholar] [CrossRef]

- Anabitarte, F.; Cobo, A.; López-Higuera, J.M. Laser-Induced Breakdown Spectroscopy: Fundamentals, applications and challenges. ISRN Spectrosc. 2012, 2012, 285240. [Google Scholar] [CrossRef] [Green Version]

- García-Escárzaga, A.; Clarke, L.J.; Gutiérrez-Zugasti, I.; González-Morales, M.R.; Martínez-Minchero, M.; Lopez-Higuera, J.M.; Cobo, A. Mg/Ca profiles within archaeological mollusc (Patella vulgata) shells: Laser-Induced Breakdown Spectroscopy compared to Inductively Coupled Plasma-Optical Emission Spectrometry. Spectrochim. Acta Part B At. Spectrosc. 2018, 148, 8–15. [Google Scholar] [CrossRef]

- García-Escárzaga, A.; Martínez-Minchero, M.; Cobo, A.; Gutiérrez-Zugasti, I.; Arrizabalaga, A.; Roberts, P. Using Mg/Ca Ratios from the Limpet Patella depressa Pennant, Measured by Laser-Induced Breakdown Spectroscopy (LIBS) to Reconstruct Paleoclimate. Appl. Sci. 2021, 11, 2959. [Google Scholar] [CrossRef]

- Martínez-Minchero, M.; Ulloa, L.; Cobo, A.; Bringas, E.; San-Román, M.-F.; López-Higuera, J.M. Laser-induced breakdown spectroscopy analysis of copper and nickel in chelating resins for metal recovery in wastewater. Spectrochim. Acta Part B At. Spectrosc. 2021, 180, 106170. [Google Scholar] [CrossRef]

- Chow, R.B.; Lee, A.; Kane, B.G.; Jacoby, J.L.; Barraco, R.D.; Dusza, S.W.; Meyers, M.C.; Greenberg, M.R. Effectiveness of the “Timed Up and Go” (TUG) and the Chair test as screening tools for geriatric fall risk assessment in the ED. Am. J. Emerg. Med. 2018, 37, 457–460. [Google Scholar] [CrossRef]

- Nishimura, T.; Arima, K.; Okabe, T.; Mizukami, S.; Tomita, Y. Usefulness of chair stand time as a surrogate of gait speed in diagnosing sarcopenia. Geriatr. Gerontol. Int. 2017, 17, 659–661. [Google Scholar] [CrossRef]

- Yee, X.S.; Ng, Y.S.; Allen, J.C.; Latib, A.; Tay, E.L.; Bakar, H.M.; Ho, C.Y.; Koh, W.C.; Kwek, H.H.; Tay, L. Performance on sit-to-stand tests in relation to measures of functional fitness and sarcopenia diagnosis in community-dwelling older adults. Eur. Rev. Aging Phys. Act. 2021, 18, 1. [Google Scholar] [CrossRef]

- Video on the TeDFES-Marcha System. Available online: https://youtu.be/rrWrF9b82AY (accessed on 28 September 2021).

- Anabitarte-García, F.; Reyes-Gonzalez, L.; Rodriguez-Cobo, L.; Fernandez-Viadero, C.; Somonte-Segares, S.; Díez-Del-Valle, S.; Mandaluniz, E.; García-García, R.; López-Higuera, J.M. Early diagnosis of frailty; technological and non-intrusive devices for clinical detection. Ageing Res. Rev. 2021, 70, 101399. [Google Scholar] [CrossRef]

- Martín, G.D.-S.; Reyes-González, L.; Sainz-Ruiz, S.; Rodríguez-Cobo, L.; López-Higuera, J. Automatic Ankle Angle Detection by Integrated RGB and Depth Camera System. Sensors 2021, 21, 1909. [Google Scholar] [CrossRef] [PubMed]

- Pogue, B.W.; Krishnaswamy, V.; Paulsen, K.D.; Allende, P.B.; Conde, O.M.; Lopez-Higuera, J.M. Apparatus and Method for Surgical Instrument with Integral Automated Tissue Classifier. International Patent Application No. WO 2010/080611 A3, 2 September 2010. [Google Scholar]

- Karabeber, H.; Huang, R.; Iacono, P.; Samii, J.M.; Pitter, K.; Holland, E.C.; Kircher, M.F. Guiding brain tumor resection using surface-enhanced Raman scattering nanoparticles and a hand-held Raman scanner. ACS Nano 2014, 8, 9755–9766. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, C.; Wang, Y.; Song, W.; Lu, L. Delineating the tumor margin with intraoperative surface-enhanced Raman spectroscopy. Anal. Bioanal. Chem. 2019, 411, 3993–4006. [Google Scholar] [CrossRef]

- Strobbia, P.; Cupil-Garcia, V.; Crawford, B.M.; Fales, A.M.; Pfefer, T.J.; Liu, Y.; Maiwald, M.; Sumpf, B.; Vo-Dinh, T. Accurate in vivo tumor detection using plasmonic-enhanced shifted-excitation Raman difference spectroscopy (SERDS). Theranostics 2021, 11, 4090–4102. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Bi, X.; Gu, Y.; Wang, F.; Ye, J. Surface-enhanced Raman scattering nanotags for bioimaging. J. Appl. Phys. 2021, 129, 191101. [Google Scholar] [CrossRef]

- Parnell, M.; Guo, L.; Abdi, M.; Cordeiro, M.F. Ocular manifestations of Alzheimer’s disease in animal models. Int. J. Alzheimer’s Dis. 2012, 2012, 786494. [Google Scholar] [CrossRef] [Green Version]

- Kerbage, C.; Sadowsky, C.H.; Tariot, P.N.; Agronin, M.; Alva, G.; Turner, F.D.; Nilan, D.; Cameron, A.; Cagle, G.D.; Hartung, P.D. Detection of Amyloid Î2 Signature in the Lens and Its Correlation in the Brain to Aid in the Diagnosis of Alzheimer’s Disease. Am. J. Alzheimers Dis. Other Demen. 2014, 30, 738–745. [Google Scholar] [CrossRef]

- Sadowsky, C.H.; Kerbage, C.; Tariot, P.N.; Agronin, M.; Alva, G.; Doraiswamy, P.M.; Turner, F.D.; Nilan, D.; Cameron, A.; Cagle, G.D.; et al. Diagnosis of Alzheimer’s Disease through the Eye and its Correlation with Cognitive Tests and Brain Imaging. JSM Alzheimer’s Dis. Relat. Dement. 2014, 1, 1008. [Google Scholar]

- Chibhabha, F.; Yaqi, Y.; Li, F. Retinal involvement in Alzheimer’s disease (AD): Evidence and current progress on the non-invasive diagnosis and monitoring of AD-related pathology using the eye. Rev. Neurosci. 2020, 31, 883–904. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Shi, C.; Shen, M.; Lu, F. Advances in retina imaging as potential biomarkers for early diagnosis of Alzheimer’s disease. Transl. Neurodegener. 2021, 10, 6. [Google Scholar] [CrossRef]

- Fereshetian, S.; Agranat, J.S.; Siegel, N.; Ness, S.; Stein, T.D.; Subramanian, M.L. Protein and Imaging Biomarkers in the Eye for Early Detection of Alzheimer’s Disease. J. Alzheimer’s Dis. Rep. 2021, 5, 375–387. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Higuera, J.M. Sensing Using Light: A Key Area of Sensors. Sensors 2021, 21, 6562. https://doi.org/10.3390/s21196562

López-Higuera JM. Sensing Using Light: A Key Area of Sensors. Sensors. 2021; 21(19):6562. https://doi.org/10.3390/s21196562

Chicago/Turabian StyleLópez-Higuera, José Miguel. 2021. "Sensing Using Light: A Key Area of Sensors" Sensors 21, no. 19: 6562. https://doi.org/10.3390/s21196562

APA StyleLópez-Higuera, J. M. (2021). Sensing Using Light: A Key Area of Sensors. Sensors, 21(19), 6562. https://doi.org/10.3390/s21196562