Identifying and Characterizing Conveyor Belt Longitudinal Rip by 3D Point Cloud Processing

Abstract

:1. Introduction

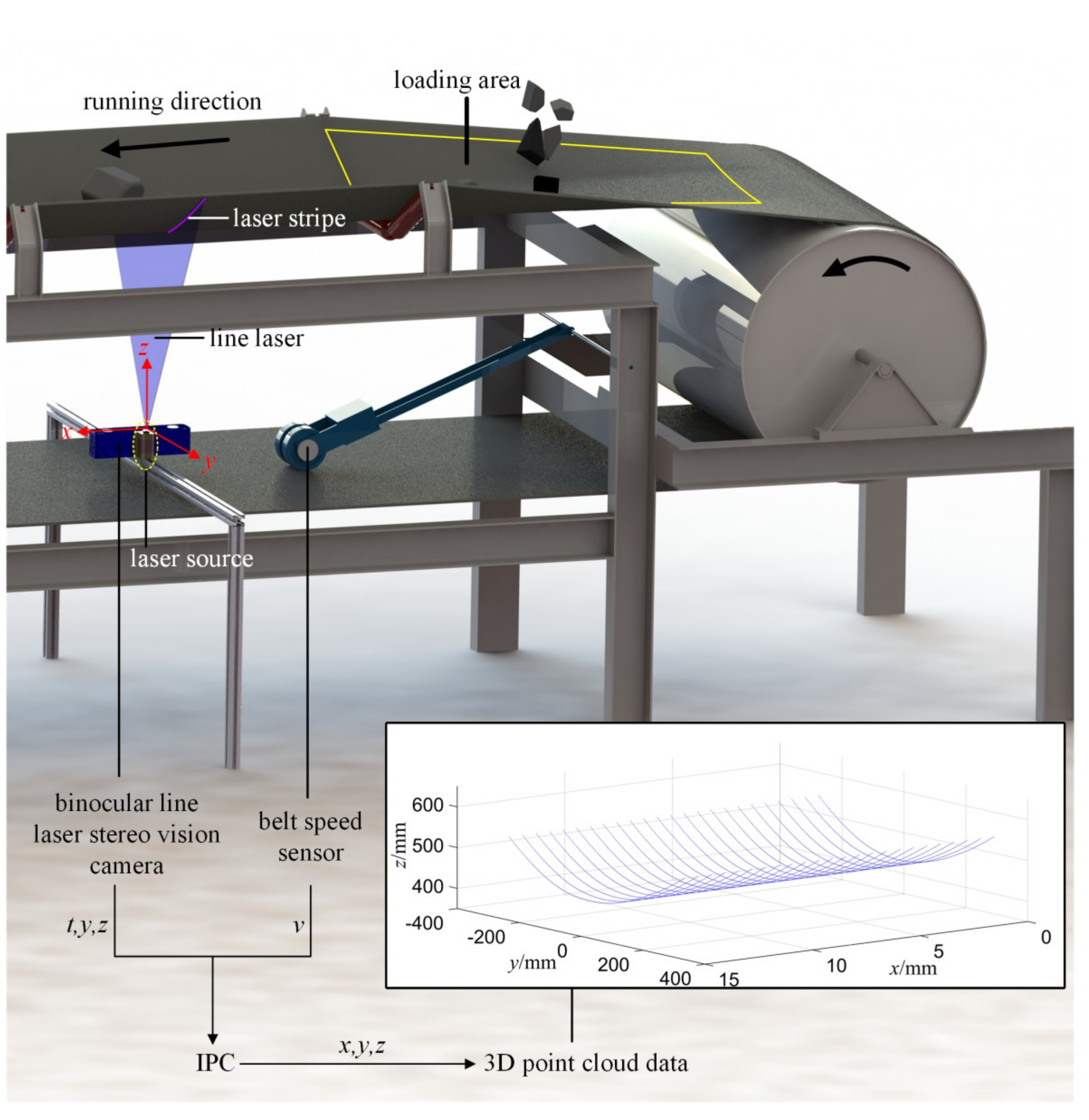

2. System Setup and Algorithm Flow in This Work

3. Phase I: Identification of the Longitudinal Rip

3.1. Suspected Points Extraction

- (1)

- Belt covered with materials.

- (2)

- Belt covered without materials.

3.2. Clustering Process

- (1)

- If there is a cluster Cj that makes ρ(Psus_i,Cj_last) ≤ Tb, where Tb is the clustering threshold, then Psus_i will be added into Cj. Hence, in Figure 5a, Psus_3 and Psus_4 are added to clusters C1 and C2, respectively. It is worth noting that if there are more than two clusters meeting the condition that ρ(Psus_i,Cj_last) ≤ Tb, then Psus_i will be added into the one with the smallest Euclidean distance.

- (2)

- If there is no cluster Cj that makes ρ(Psus_i,Cj_last) ≤ Tb, then a new cluster will be created and Psus_i will be added to it. Thus, we can see that in Figure 5a, new clusters C3 and C4 are created and Psus_1 and Psus_2 added into them, respectively.

3.3. Cluster Elimination

3.4. Empirical Discrimination

4. Phase II: Characterization of the Rip

4.1. Determination of Rip Direction

- (1)

- Firstly, P is normalized by the center to get , i.e.,

- (2)

- (3)

- The principal vectors are the columns of U, i.e., u1, u2 and u3. The first principal vector e1st is the eigenvector with the largest eigenvalue in Σ2. Namely, if = max{, , }, then e1st = ui. Similarly, the second principal vector e2nd is the eigenvector with the second largest eigenvalue in Σ2.

4.2. Maximum Width of the Rip

5. Experiment Validation

5.1. Experiment System Building

5.2. Experimental Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Symbol | Notes |

|---|---|

| b/mm | The thickness of the belt |

| Cj | The j-th cluster |

| Cj_first | The firstly suspected point added in cluster Cj |

| Cj_last | The latest suspected point added in cluster Cj |

| C j_last_x/mm | The x-coordinate value of point Cj_last |

| e1st | The first principal vector of P |

| e2nd | The second principal vector of P |

| f | Framerate, the number of stripes of input data per second |

| P | The 3D point cloud matrix of the rip edge points |

| Psus_i | The i-th suspected point extracted on the present stripe |

| sa | The empirical coefficient to determine Taz |

| sc | The coefficient to determine Tc |

| Sx/mm, Sy/mm, Sz/mm | The coefficient to determine Tb |

| Tay/mm | The extraction threshold of space in y direction |

| Taz | The extraction threshold of change rate in z direction |

| Tb/mm | The clustering threshold |

| Tc/mm | The distance threshold |

| Td/mm | The empirical discrimination threshold |

| ti/s | The timestamp to get points on the i-th laser stripe |

| v/(mm/s) | The real-time belt speed |

| vmax/(mm/s) | The maximum belt speed |

| Wmax/mm | The maximum width of the rip |

| xj/mm | The coordinate value in the belt running direction of the j-th point on the laser stripe from left to right |

| xp/mm | The x-coordinate value of all points on present stripe |

| yj/mm | The coordinate value in the width direction of the j-th point on the laser stripe from left to right |

| ymax/mm | The largest y coordinate value among all points on each laser stripe |

| ymin/mm | The smallest y coordinate value among all points on each laser stripe |

| zj/mm | The coordinate value in the height direction of the j-th point on the laser stripe from left to right |

References

- He, D.J.; Pang, Y.S.; Lodewijks, G. Green operations of belt conveyors by means of speed control. Appl. Energy 2017, 188, 330–341. [Google Scholar] [CrossRef]

- Santos, A.A.; Rocha, F.A.S.; Reis, A.J.d.R.; Guimarães, F.G. Automatic System for Visual Detection of Dirt Buildup on Conveyor Belts Using Convolutional Neural Networks. Sensors 2020, 20, 5762. [Google Scholar] [CrossRef]

- Andrejiova, M.; Grincova, A.; Marasova, D.; Fedorko, G.; Molnar, V. Using logistic regression in tracing the significance of rubber–textile conveyor belt damage. Wear 2014, 318, 145–152. [Google Scholar] [CrossRef]

- Xin, J.B.; Meng, C.; Schulte, F.; Peng, J.Z.; Liu, Y.H.; Negenborn, R.R. A Time-Space Network Model for Collision-Free Routing of Planar Motions in a Multirobot Station. IEEE Trans. Ind. Inform. 2020, 16, 6413–6422. [Google Scholar] [CrossRef]

- Bortnowski, P.; Gladysiewicz, L.; Krol, R.; Ozdoba, M. Tests of Belt Linear Speed for Identification of Frictional Contact Phenomena. Sensors 2020, 20, 5816. [Google Scholar] [CrossRef]

- Andrejiova, M.; Grincova, A.; Marasova, D. Monitoring dynamic loading of conveyer belts by measuring local peak impact forces. Measurement 2020, 158, 107690. [Google Scholar] [CrossRef]

- Li, W.; Wang, Z.W.; Zhu, Z.C.; Zhou, G.B.; Chen, G.A. Design of Online Monitoring and Fault Diagnosis System for Belt Conveyors Based on Wavelet Packet Decomposition and Support Vector Machine. Adv. Mech. Eng. 2013, 5, 797183. [Google Scholar] [CrossRef]

- Homišin, J.; Grega, R.; Kaššay, P.; Fedorko, G.; Molnár, V. Removal of systematic failure of belt conveyor drive by reducing vibrations. Eng. Fail. Anal. 2019, 99, 192–202. [Google Scholar] [CrossRef]

- Tanuska, P.; Spendla, L.; Kebisek, M.; Duris, R.; Stremy, M. Smart Anomaly Detection and Prediction for Assembly Process Maintenance in Compliance with Industry 4.0. Sensors 2021, 21, 2376. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.X. Real-time fault monitoring technology for coal mine conveying belt. Ind. Mine Autom. 2015, 41, 45–48. [Google Scholar]

- Huang, M.; Wei, R.Z. Real time monitoring techniques and fault diagnosis of mining steel cord belt conveyors. J. China Coal Soc. 2005, 30, 245–250. [Google Scholar]

- Zakharov, A.; Geike, B.; Grigmyev, A.; Zakharova, A. Analysis of Devices to Detect Longitudinal Tear on Conveyor Belts. In Proceedings of the Vth International Innovative Mining Symposium. E3S Web of Conferences. E D P SCIENCES: 17 AVE DU HOGGAR PARC D ACTIVITES COUTABOEUF BP 112, F-91944 CEDEX A, FRANCE. Voth, S., Cehlar, M., Janocko, J., Straka, M., Nuray, D., Szurgacz, D., Petrova, M., Tan, Y., Abay, A., Eds.; 2020; Available online: https://www.e3s-conferences.org/articles/e3sconf/abs/2020/34/e3sconf_iims2020_03006/e3sconf_iims2020_03006.html (accessed on 2 October 2021).

- Błazej, R.; Jurdziak, L.; Kirjanów, A.; Kozłowski, T. A device for measuring conveyor belt thickness and for evaluating the changes in belt transverse and longitudinal profile. Diagnostyka 2017, 18, 97–102. [Google Scholar]

- Nicolay, T.; Treib, A.; Blum, A. RF identification in the use of belt rip detection. In Proceedings of the SENSORS, 2004 IEEE, Vienna, Austria, 24–27 October 2004; Volume 331, pp. 333–336. [Google Scholar]

- Park, C.R.; Lee, S.J.; Eom, K.H. The Design of RFID Conveyor Belt Gate Systems Using an Antenna Control Unit. Sensors 2011, 11, 9033–9044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tong, M.M.; Wang, B.; Jiang, C.L.; Tong, Z.Y.; Tang, S.F. New Detection Method for Longitudinal Tear of Conveyor Belt in Coal Mine. Coal Mine Mach. 2013, 34, 191–193. [Google Scholar]

- Błażej, R.; Jurdziak, L.; Kozłowski, T.; Kirjanów, A. The use of magnetic sensors in monitoring the condition of the core in steel cord conveyor belts—Tests of the measuring probe and the design of the DiagBelt system. Measurement 2018, 123, 48–53. [Google Scholar] [CrossRef]

- Li, J.; Miao, C.Y. The conveyor belt longitudinal tear on-line detection based on improved SSR algorithm. Optik 2016, 127, 8002–8010. [Google Scholar] [CrossRef]

- Qiao, T.Z.; Chen, L.L.; Pang, Y.S.; Yan, G.W.; Miao, C.Y. Integrative binocular vision detection method based on infrared and visible light fusion for conveyor belts longitudinal tear. Measurement 2017, 110, 192–201. [Google Scholar] [CrossRef]

- Guo, L.X.; Fang, S.L.; Xu, M.Z.; Can, Z.; Qi, J.H. Laser-based on-line machine vision detection for longitudinal rip of conveyor belt. Optik 2018, 168, 360–369. [Google Scholar]

- Muszynski, Z.; Milczarek, W. Application of Terrestrial Laser Scanning to Study the Geometry of Slender Objects. In World Multidisciplinary Earth Sciences Symposium; IOP Conference Series-Earth and Environmental Science; Iop Publishing Ltd: Bristol, UK, 2017; Volume 95. [Google Scholar]

- Zeng, F.; Wu, Q.; Chu, X.M.; Yue, Z.S. Measurement of bulk material flow based on laser scanning technology for the energy efficiency improvement of belt conveyors. Measurement 2015, 75, 230–243. [Google Scholar] [CrossRef]

- Trybała, P.; Blachowski, J.; Błażej, R.; Zimroz, R. Damage Detection Based on 3D Point Cloud Data Processing from Laser Scanning of Conveyor Belt Surface. Remote Sens. 2020, 13, 55. [Google Scholar] [CrossRef]

- Fernández-Lozano, J.; Gutiérrez-Alonso, G.; Fernández-Morán, M.Á. Using airborne LiDAR sensing technology and aerial orthoimages to unravel roman water supply systems and gold works in NW Spain (Eria valley, Leon). J. Archaeol. Sci. 2015, 53, 356–373. [Google Scholar] [CrossRef]

- Kajzar, V.; Kukutsch, R.; Heroldov, N. verifying the possibilities of using a 3d laser scanner in the mining underground. Acta Geodyn. Geomater. 2015, 12, 51–58. [Google Scholar] [CrossRef] [Green Version]

- Rosell, J.R.; Sanz, R. A review of methods and applications of the geometric characterization of tree crops in agricultural activities. Comput. Electron. Agric. 2012, 81, 124–141. [Google Scholar] [CrossRef] [Green Version]

- Yang, B.S.; Wei, Z.; Li, Q.Q.; Li, J. Semiautomated Building Facade Footprint Extraction from Mobile LiDAR Point Clouds. IEEE Geosci. Remote Sens. Lett. 2013, 10, 766–770. [Google Scholar] [CrossRef]

- Zare, A.; Ozdemir, A.; Iwen, M.A.; Aviyente, S. Extension of PCA to Higher Order Data Structures: An Introduction to Tensors, Tensor Decompositions, and Tensor PCA. Proc. IEEE 2018, 106, 1341–1358. [Google Scholar] [CrossRef] [Green Version]

- Huang, T.S.; Narendra, P.M. Image restoration by singular value decomposition. Appl. Opt. 1975, 14, 2213–2216. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Cheng, G.; Chen, X.H.; Pang, Y.S. Planetary Gears Feature Extraction and Fault Diagnosis Method Based on VMD and CNN. Sensors 2018, 18, 1523. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Molnár, V.; Fedorko, G.; Andrejiová, M.; Grinčová, A.; Tomašková, M. Analysis of influence of conveyor belt overhang and cranking on pipe conveyor operational characteristics. Measurement 2015, 63, 168–175. [Google Scholar] [CrossRef]

- Yang, Y.L.; Miao, C.Y.; Li, X.G.; Mei, X.Z. On-line conveyor belts inspection based on machine vision. Optik 2014, 125, 5803–5807. [Google Scholar] [CrossRef]

- Hou, C.C.; Qiao, T.Z.; Zhang, H.T.; Pang, Y.S.; Xiong, X.Y. Multispectral visual detection method for conveyor belt longitudinal tear. Measurement 2019, 143, 246–257. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Cheng, G.; Pang, Y.; Jin, Z.; Kang, B. Identifying and Characterizing Conveyor Belt Longitudinal Rip by 3D Point Cloud Processing. Sensors 2021, 21, 6650. https://doi.org/10.3390/s21196650

Xu S, Cheng G, Pang Y, Jin Z, Kang B. Identifying and Characterizing Conveyor Belt Longitudinal Rip by 3D Point Cloud Processing. Sensors. 2021; 21(19):6650. https://doi.org/10.3390/s21196650

Chicago/Turabian StyleXu, Shichang, Gang Cheng, Yusong Pang, Zujin Jin, and Bin Kang. 2021. "Identifying and Characterizing Conveyor Belt Longitudinal Rip by 3D Point Cloud Processing" Sensors 21, no. 19: 6650. https://doi.org/10.3390/s21196650