3D-Printed Liquid Cell Resonator with Piezoelectric Actuation for In-Line Density-Viscosity Measurements

Abstract

1. Introduction

2. Materials and Methods

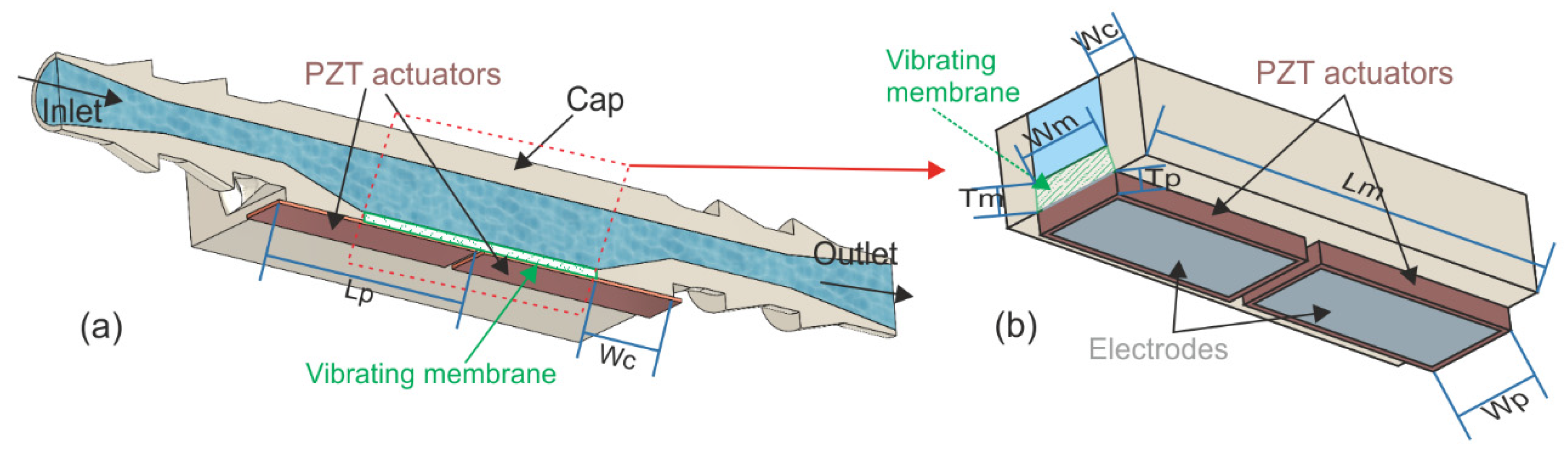

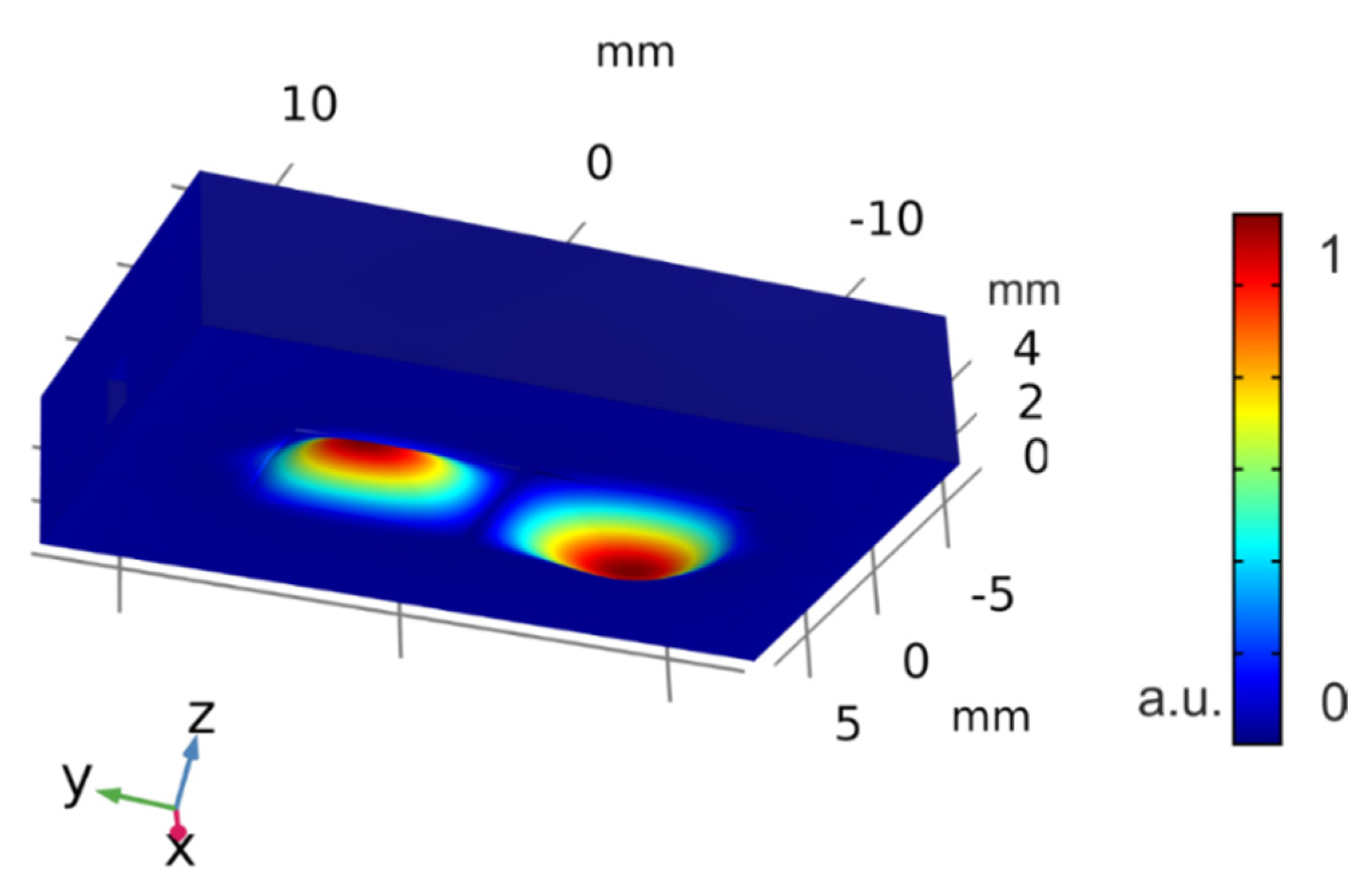

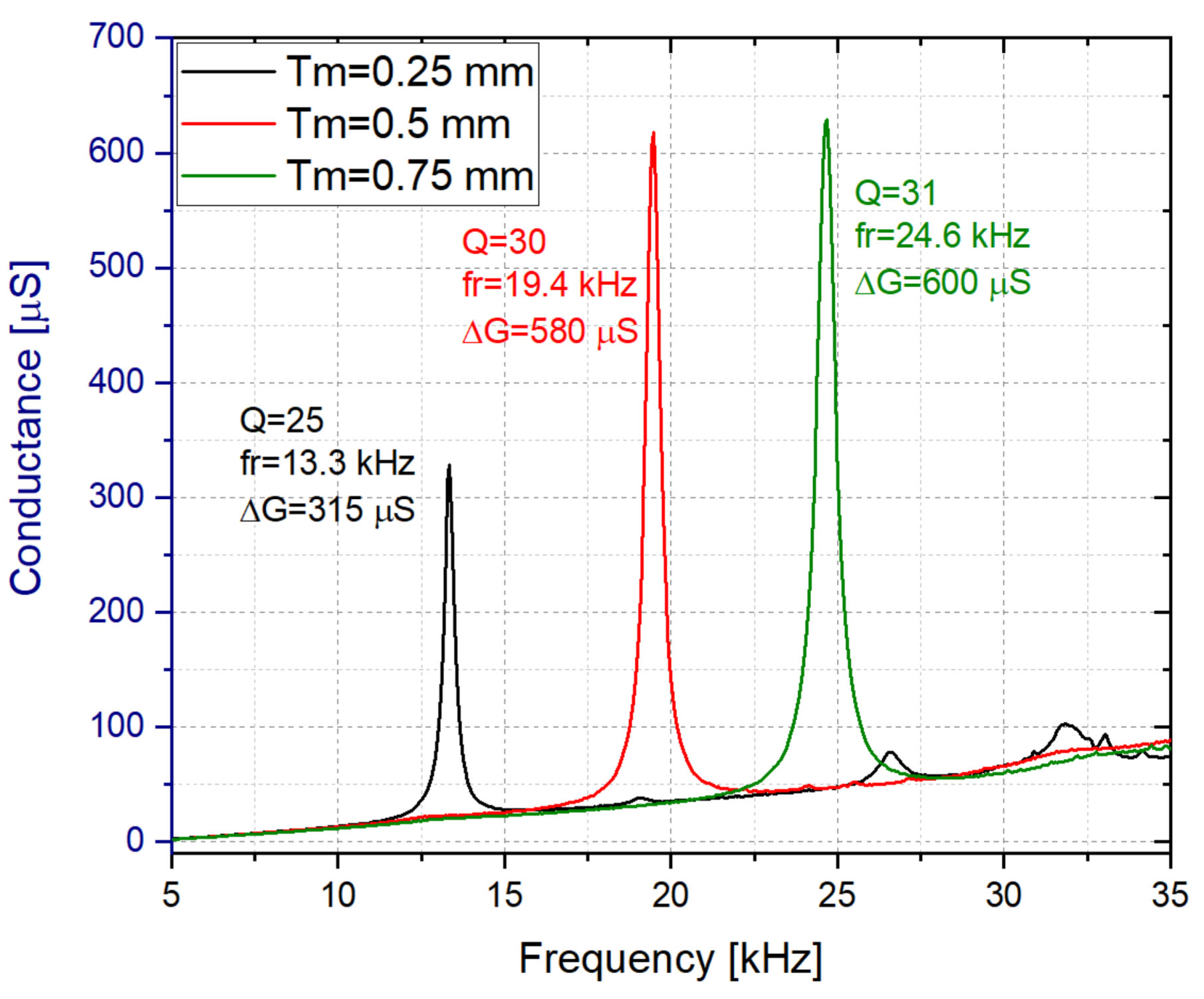

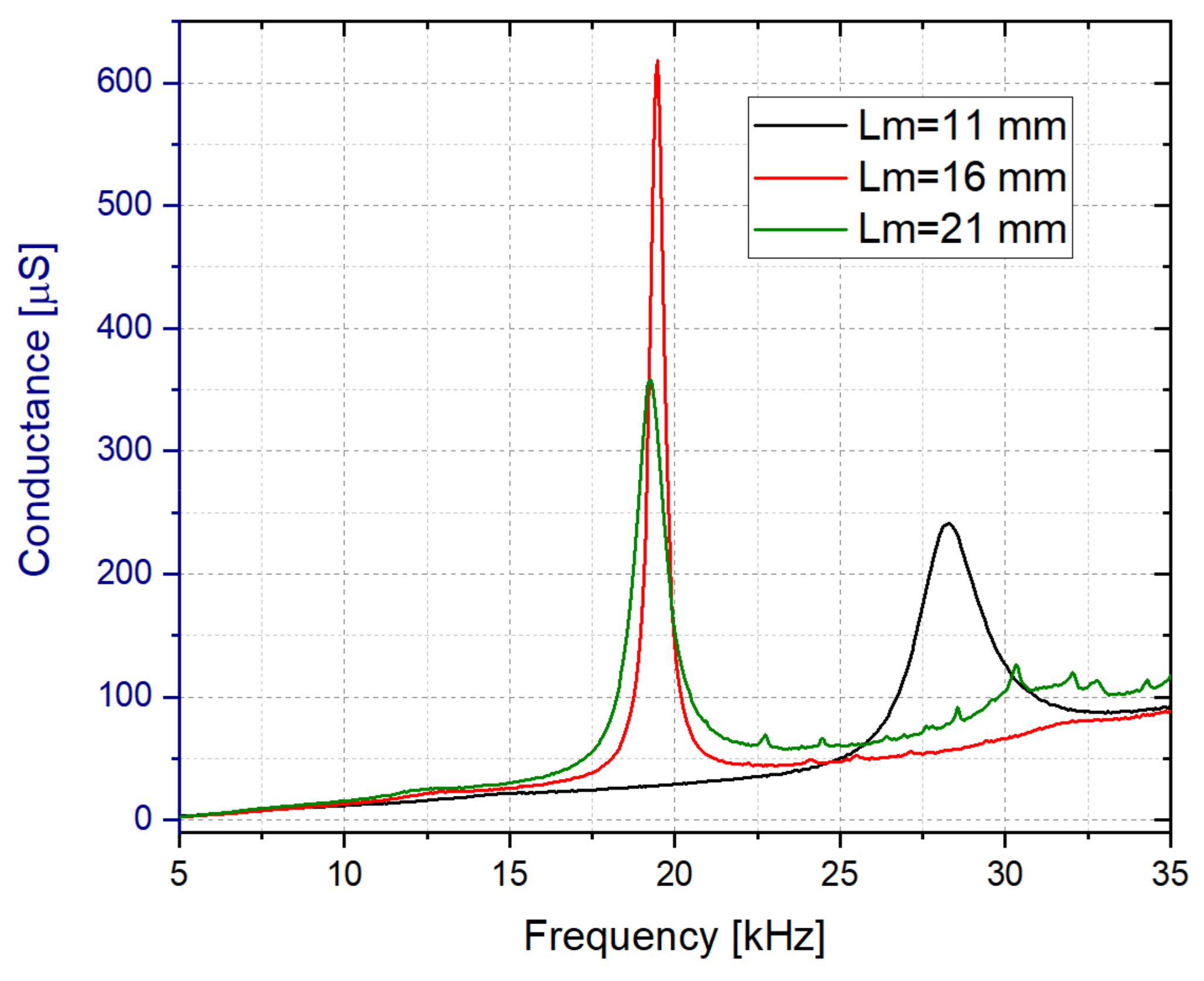

2.1. Design and Optimization

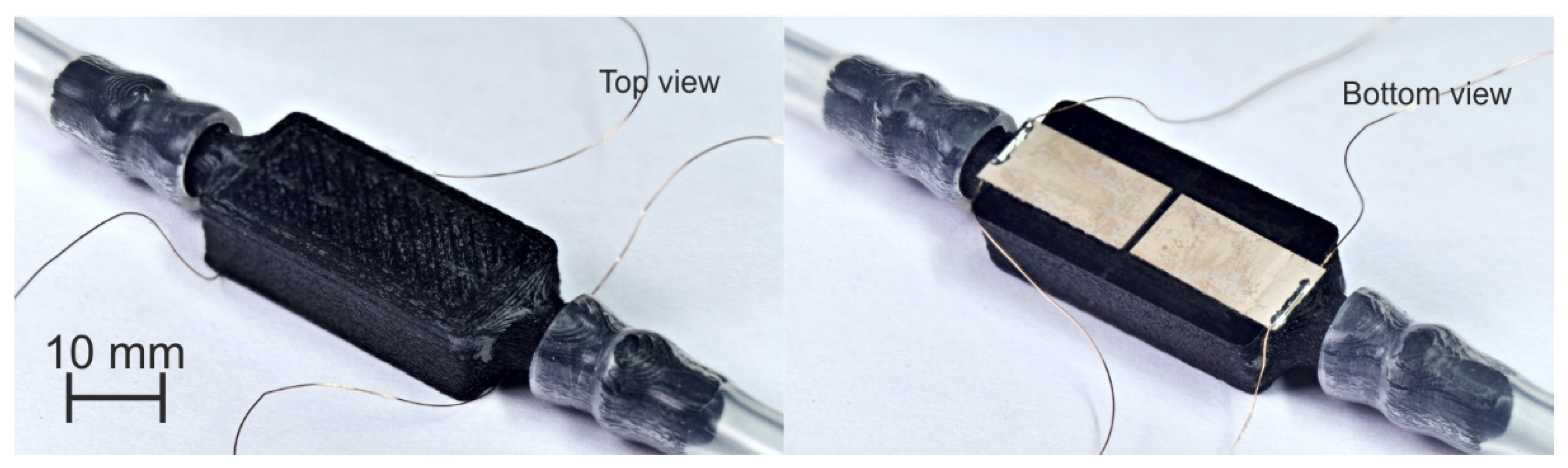

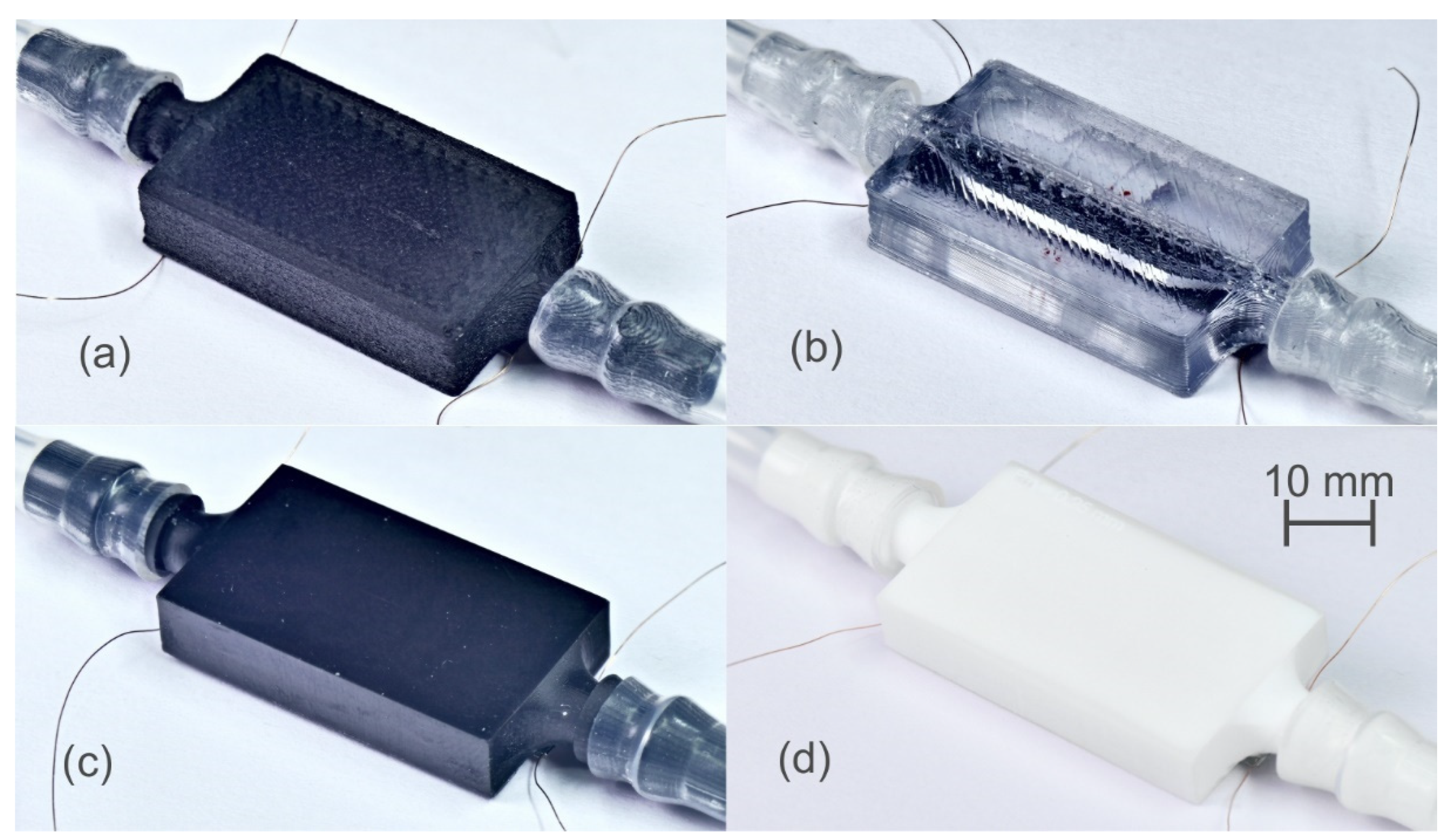

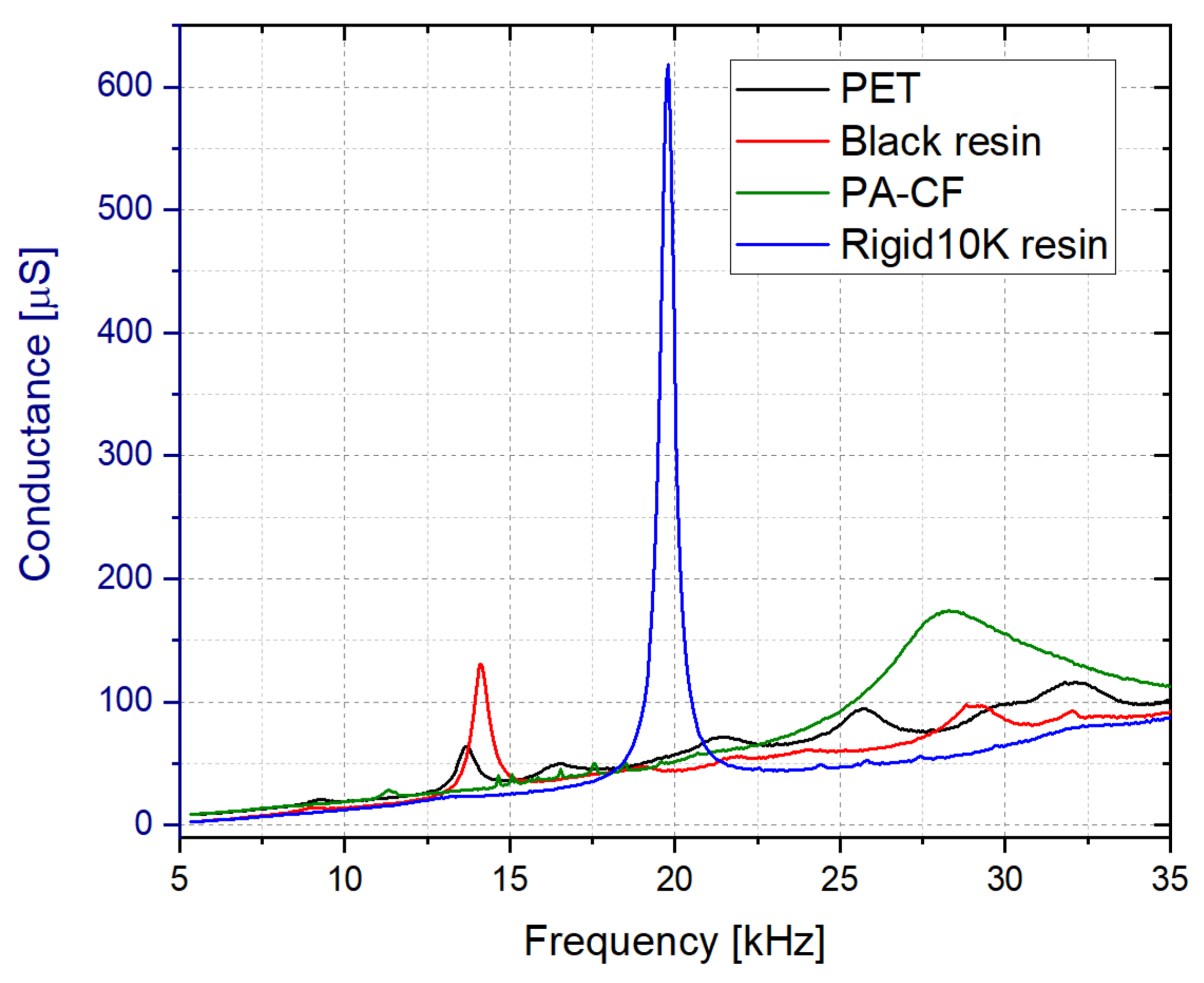

2.2. Fabrication

| Material | Printer | E [GPa] | Temperature [°C] | Printer Resolution | UV Curing |

|---|---|---|---|---|---|

| PA-CF [54] | FDM [50] | 8.38 | 250 | Z: 120 | - |

| PET [55] | FDM [50] | 1.93 | 240 | Z: 120 | - |

| Black resin [56] | SLA printer 1 [51] | 1.75 | RT | XY: 30 Z: 20 | 10 min |

| Rigid 10K resin [57] | SLA printer 2 [52] | 10 | RT | XY: 25 Z: 50 | 1 h, 70 °C |

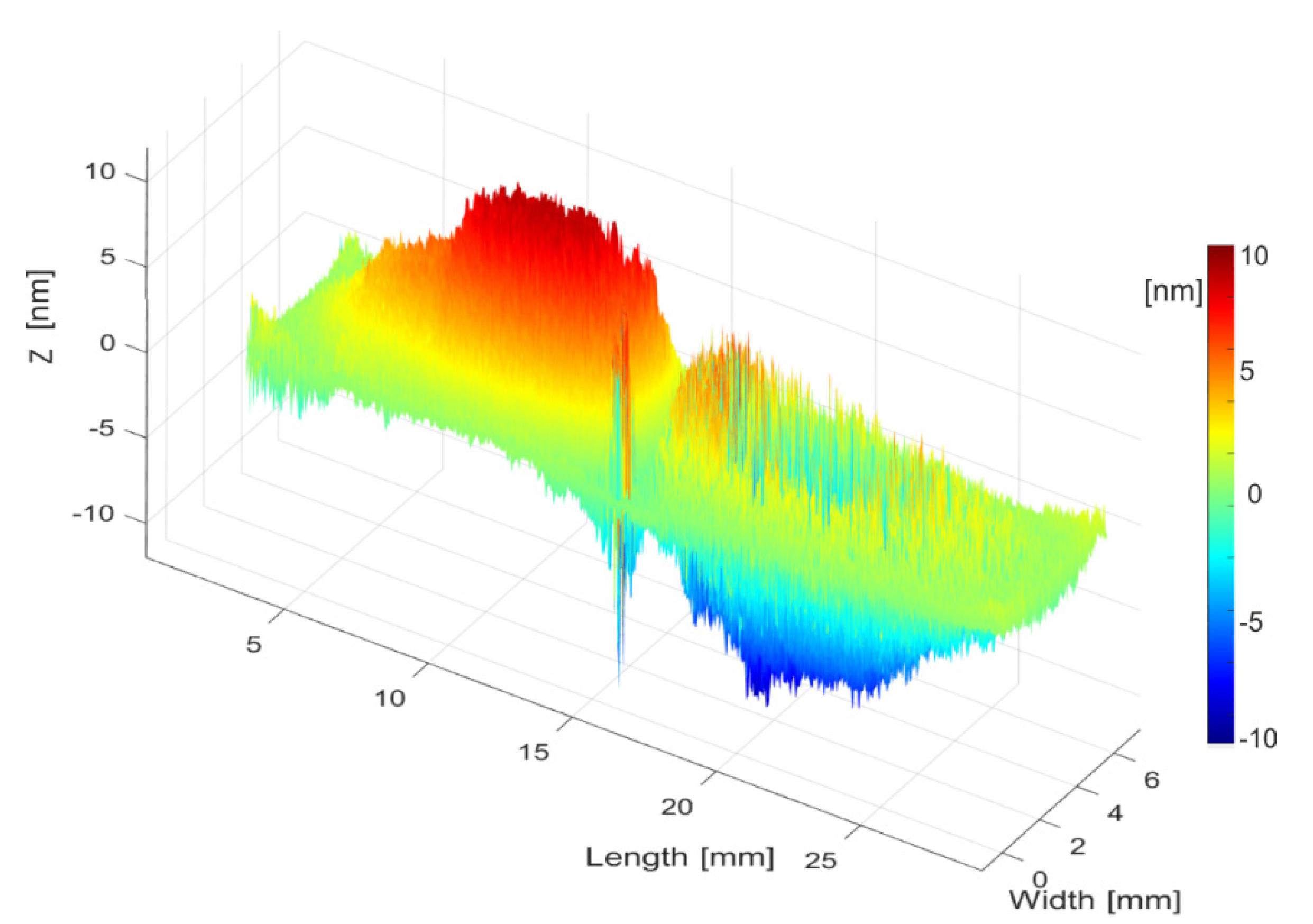

2.3. Characterization

3. Application and Results

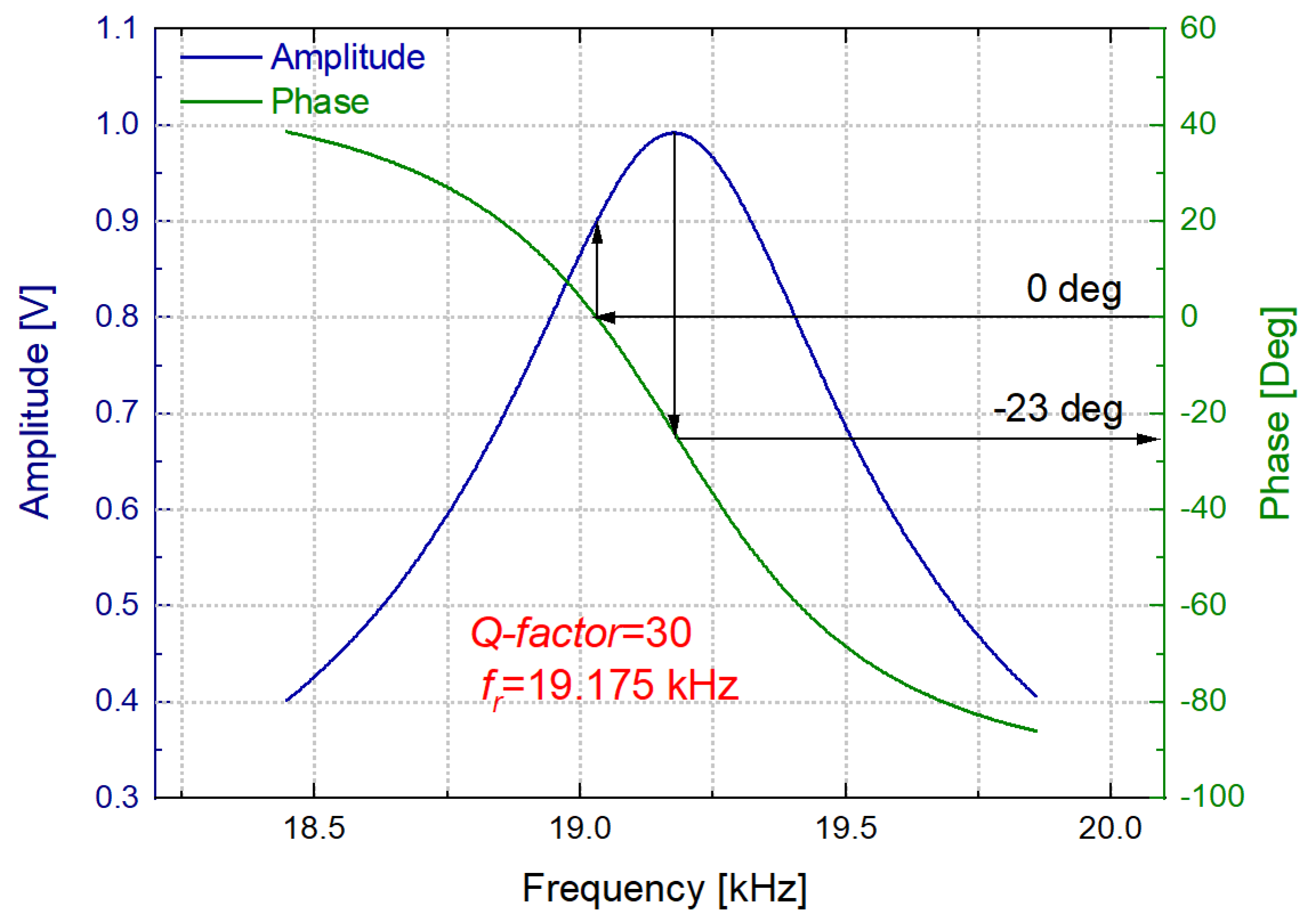

3.1. Phase-Locked Loop Based Oscillator Circuit

3.2. Calibration Procedure

3.2.1. Preparation of the Model Solutions of Grape Must

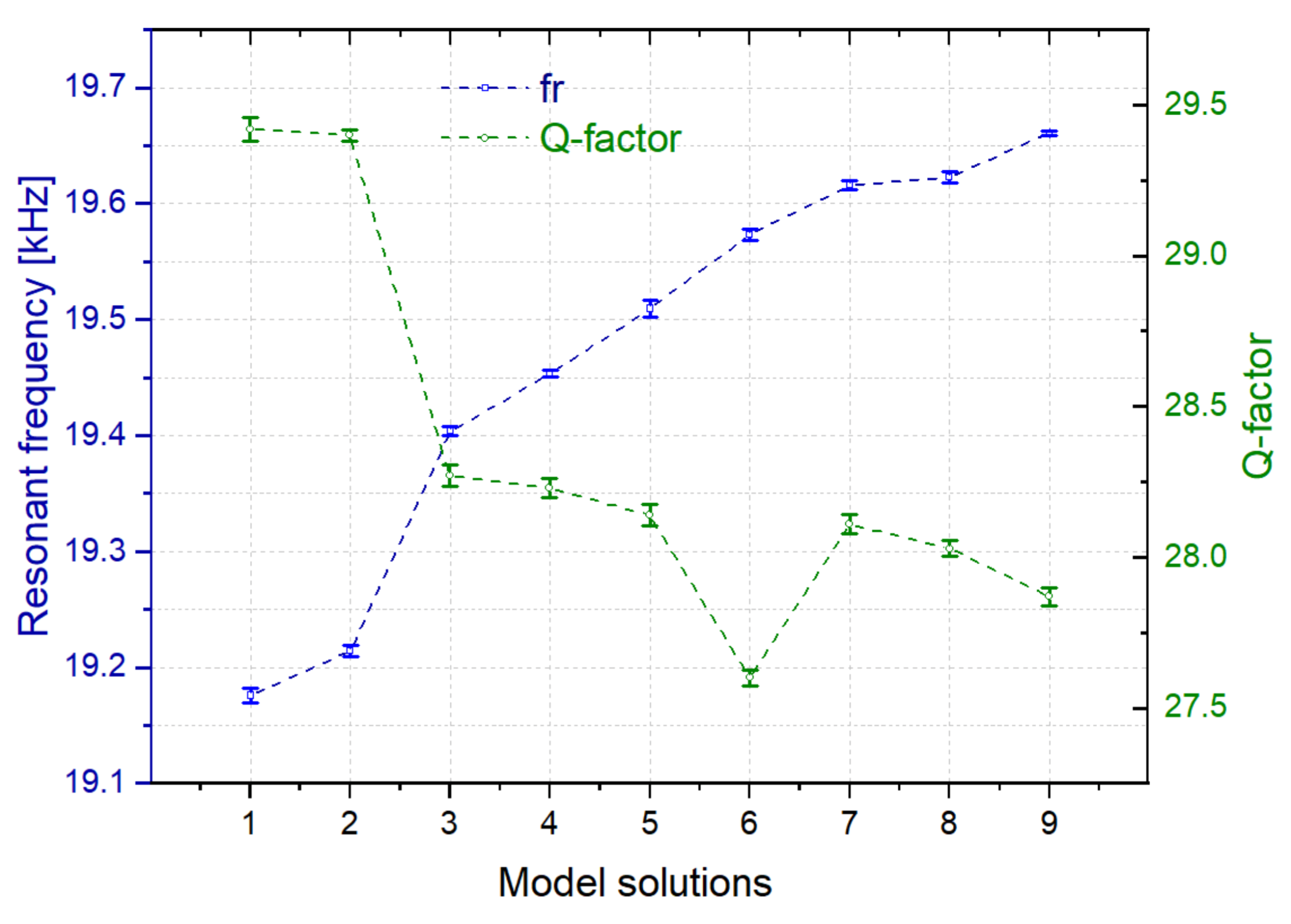

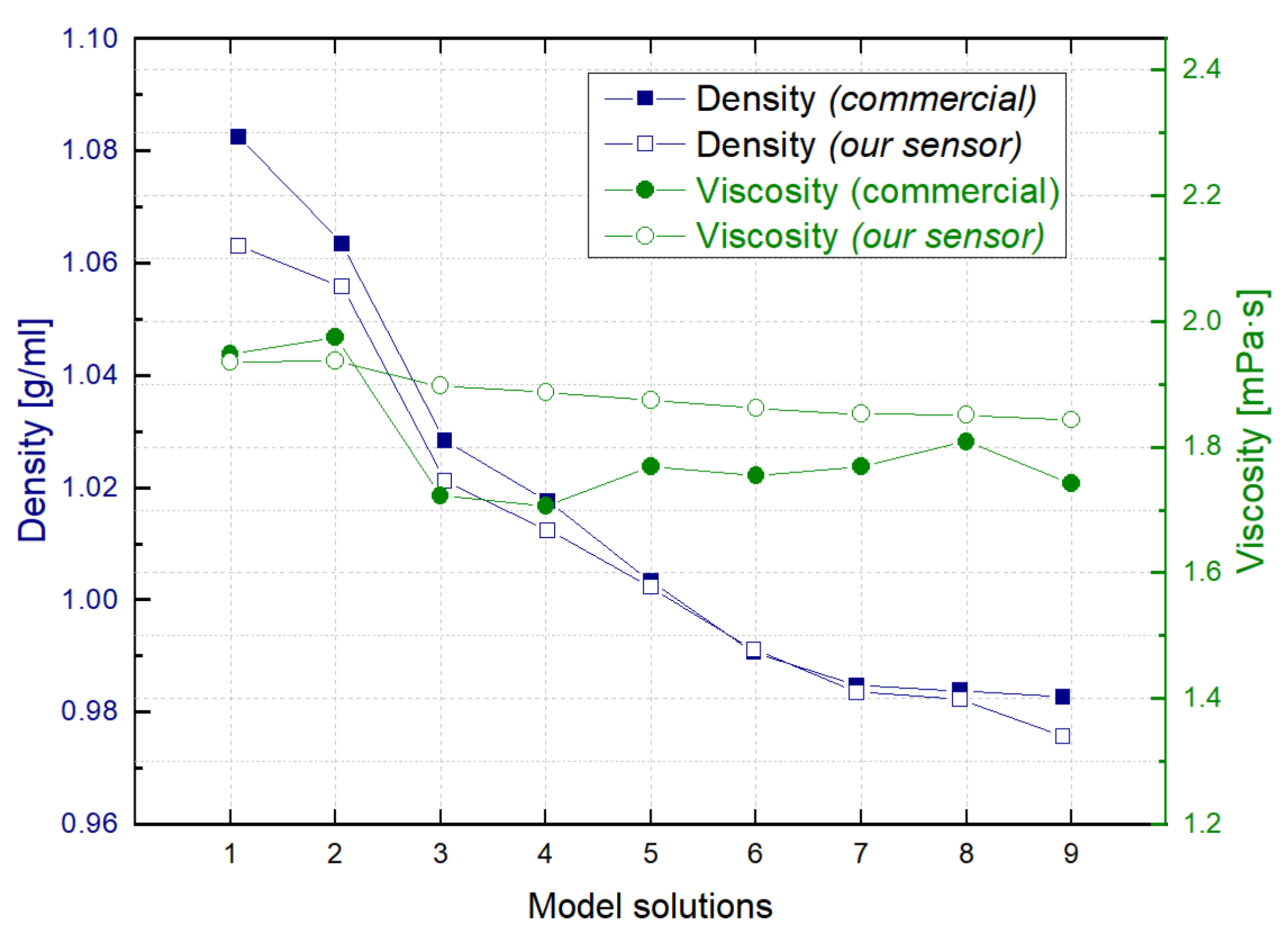

3.2.2. Calibration Process

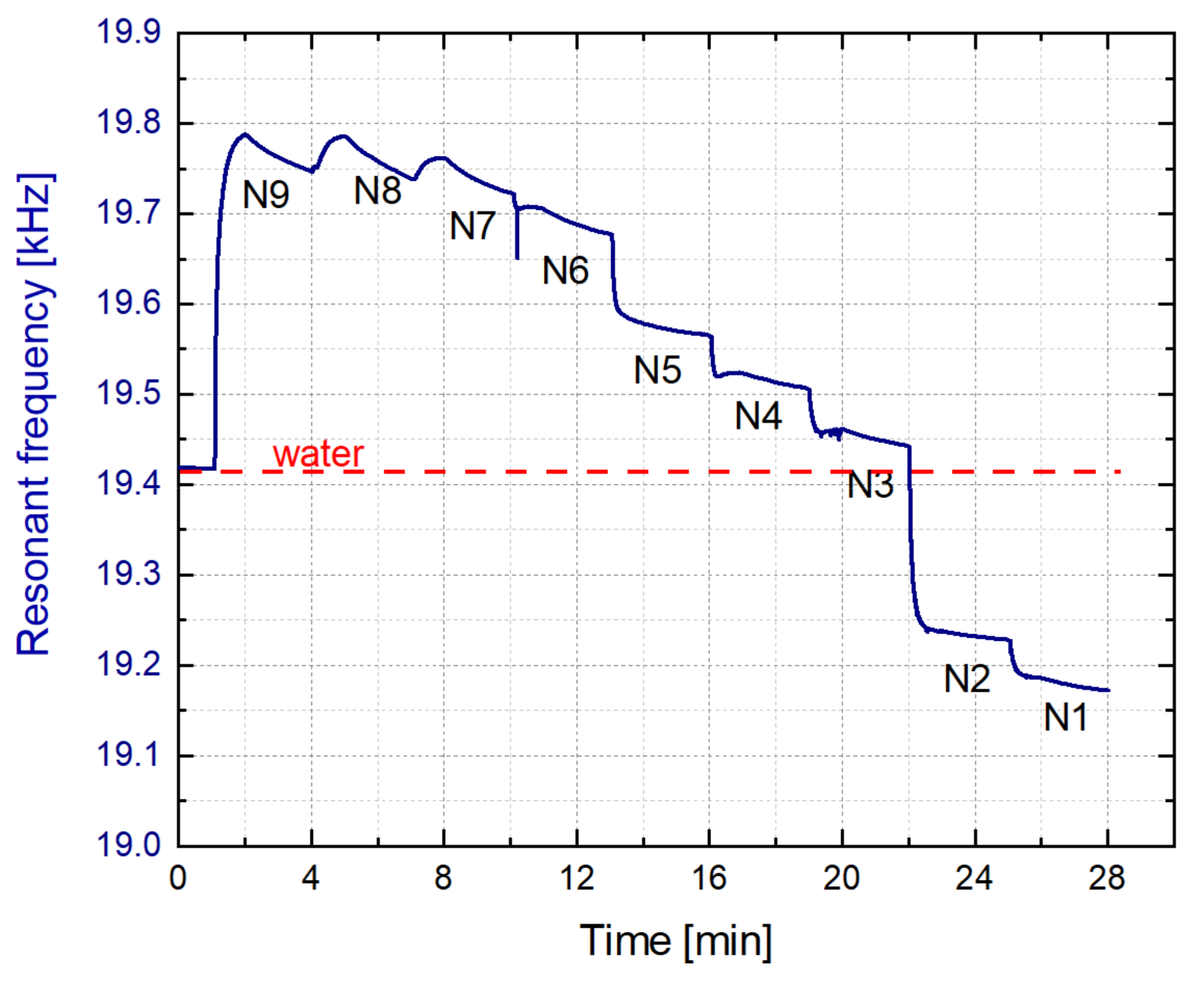

3.3. Real-Time and In-Line Monitoring of Density and Viscosity

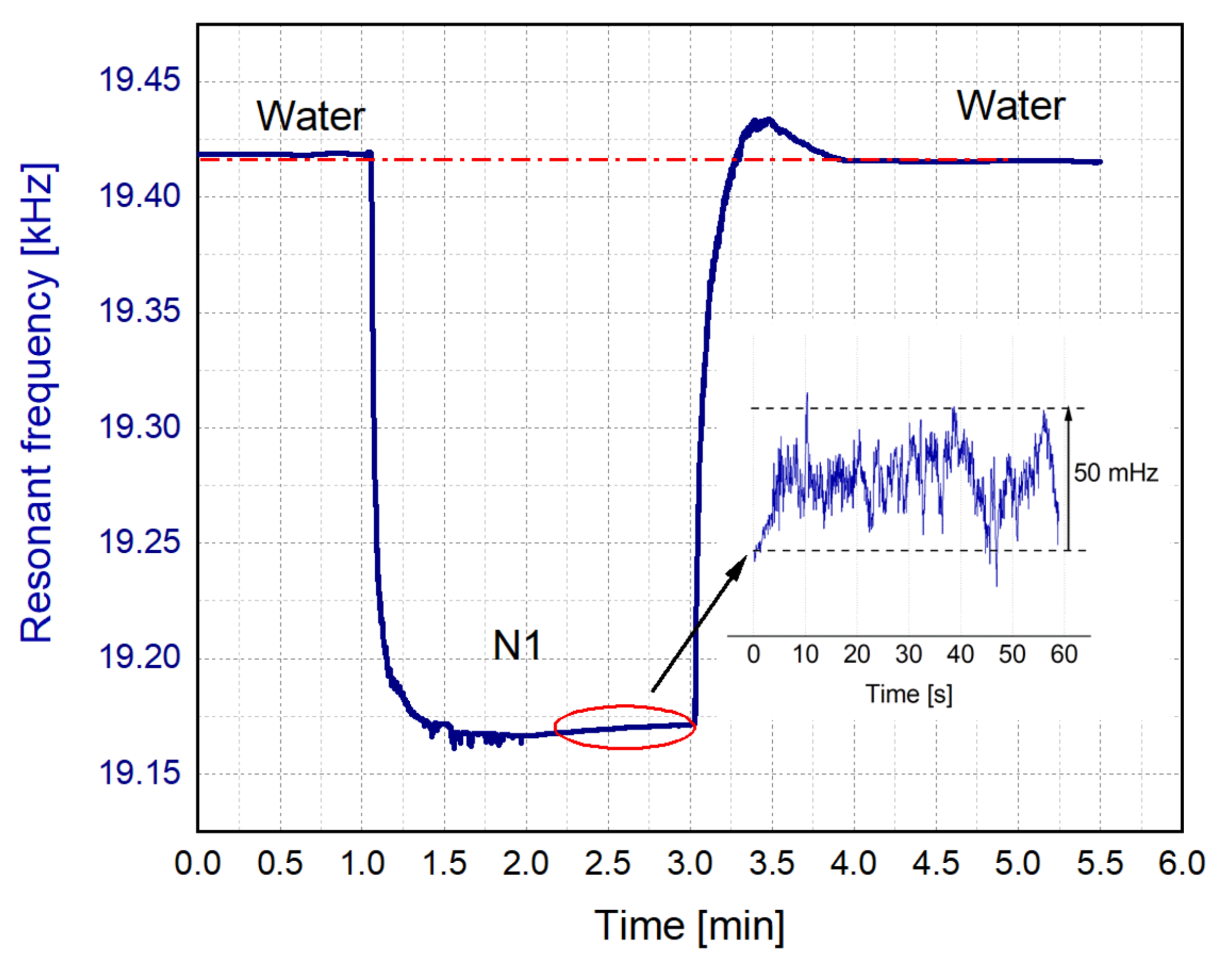

3.3.1. Real-Time Monitoring

3.3.2. In-Line Monitoring

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khosravani, M.R.; Reinicke, T. 3D-Printed Sensors: Current Progress and Future Challenges. Sens. Actuators A Phys. 2020, 305, 111916. [Google Scholar] [CrossRef]

- Liu, C.; Huang, N.; Xu, F.; Tong, J.; Chen, Z.; Gui, X.; Fu, Y.; Lao, C. 3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin. Polymers 2018, 10, 629. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, Y.; Liu, W.; Chen, D.; Wu, C.; Xie, J. An Aerosol Sensor for PM1 Concentration Detection Based on 3D Printed Virtual Impactor and SAW Sensor. Sens. Actuators A Phys. 2019, 288, 67–74. [Google Scholar] [CrossRef]

- Agarwala, S.; Goh, G.L.; Yap, Y.L.; Goh, G.D.; Yu, H.; Yeong, W.Y.; Tran, T. Development of Bendable Strain Sensor with Embedded Microchannels Using 3D Printing. Sens. Actuators A Phys. 2017, 263, 593–599. [Google Scholar] [CrossRef]

- Su, W.; Cook, B.S.; Fang, Y.; Tentzeris, M.M. Fully Inkjet-Printed Microfluidics: A Solution to Low-Cost Rapid Three-Dimensional Microfluidics Fabrication with Numerous Electrical and Sensing Applications. Sci. Rep. 2016, 6, 35111. [Google Scholar] [CrossRef] [PubMed]

- Wickberg, A.; Mueller, J.B.; Mange, Y.J.; Fischer, J.; Nann, T.; Wegener, M. Three-Dimensional Micro-Printing of Temperature Sensors Based on up-Conversion Luminescence. Appl. Phys. Lett. 2015, 106, 133103. [Google Scholar] [CrossRef]

- Courbat, J.; Kim, Y.B.; Briand, D.; de Rooij, N.F. Inkjet Printing on Paper for the Realization of Humidity and Temperature Sensors. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, TRANSDUCERS’11, Beijing, China, 5–9 June 2011; pp. 1356–1359. [Google Scholar] [CrossRef]

- Dhinesh, S.K.; Senthil Kumar, K.L. A Review on 3D Printed Sensors. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Sathyamangalam, India, 10–11 September 2019; Institute of Physics Publishing: Bristol, England, 2020; Volume 764. [Google Scholar]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D Printing of Strain Sensors within Highly Stretchable Elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef]

- SaariMatt; XiaBin; CoxBryan, S.K.; RicherEdmond, L.C. Fabrication and Analysis of a Composite 3D Printed Capacitive Force Sensor. 3d Print. Addit. Manuf. 2016, 3, 137–141. [Google Scholar] [CrossRef]

- Shemelya, C.; Cedillos, F.; Aguilera, E.; Espalin, D.; Muse, D.; Wicker, R.; Macdonald, E. Encapsulated Copper Wire and Copper Mesh Capacitive Sensing for 3-D Printing Applications. IEEE Sens. J. 2015, 15, 1280–1286. [Google Scholar] [CrossRef]

- MacDonald, E.; Salas, R.; Espalin, D.; Perez, M.; Aguilera, E.; Muse, D.; Wicker, R.B. 3D Printing for the Rapid Prototyping of Structural Electronics. IEEE Access 2014, 2, 234–242. [Google Scholar] [CrossRef]

- Wolfer, T.; Bollgruen, P.; Mager, D.; Overmeyer, L.; Korvink, J.G. Printing and Preparation of Integrated Optical Waveguides for Optronic Sensor Networks. Mechatronics 2016, 34, 119–127. [Google Scholar] [CrossRef]

- Han, T.; Kundu, S.; Nag, A.; Xu, Y. 3D Printed Sensors for Biomedical Applications: A Review. Sensors 2019, 19, 1706. [Google Scholar] [CrossRef]

- Mandon, C.A.; Blum, L.J.; Marquette, C.A. Adding Biomolecular Recognition Capability to 3D Printed Objects. Anal. Chem. 2016, 88, 10767–10772. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Park, H.S.; Mcalpine, M.C. 3D Printed Deformable Sensors. Sci. Adv. 2020, 6, 25. [Google Scholar] [CrossRef] [PubMed]

- Kadimisetty, K.; Mosa, I.M.; Malla, S.; Satterwhite-Warden, J.E.; Kuhns, T.M.; Faria, R.C.; Lee, N.H.; Rusling, J.F. 3D-Printed Supercapacitor-Powered Electrochemiluminescent Protein Immunoarray. Biosens. Bioelectron. 2016, 77, 188–193. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.-Y.; Yang, C.; Hsu, W.; Lin, L. 3D-Printed Microelectronics for Integrated Circuitry and Passive Wireless Sensors. Microsyst. Nanoeng. 2015, 1, 1–9. [Google Scholar] [CrossRef]

- Ni, Y.; Ji, R.; Long, K.; Bu, T.; Chen, K.; Zhuang, S. A Review of 3D-Printed Sensors. Appl. Spectrosc. Rev. 2017, 52, 623–652. [Google Scholar] [CrossRef]

- Haque, R.I.; Ogam, E.; Loussert, C.; Benaben, P.; Boddaert, X. Fabrication of Capacitive Acoustic Resonators Combining 3D Printing and 2D Inkjet Printing Techniques. Sensors 2015, 15, 26018–26038. [Google Scholar] [CrossRef] [PubMed]

- Salim, A.; Ghosh, S.; Lim, S. Low-Cost and Lightweight 3D-Printed Split-Ring Resonator for Chemical Sensing Applications. Sensors 2018, 18, 3049. [Google Scholar] [CrossRef] [PubMed]

- Cui, H.; Hensleigh, R.; Yao, D.; Maurya, D.; Kumar, P.; Kang, M.G.; Priya, S.; Zheng, X. (Rayne) Three-Dimensional Printing of Piezoelectric Materials with Designed Anisotropy and Directional Response. Nat. Mater. 2019, 18, 234–241. [Google Scholar] [CrossRef] [PubMed]

- Cholleti, E.R. A Review on 3D Printing of Piezoelectric Materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Telangana, India, 13–14 July 2018; Institute of Physics Publishing: Bristol, UK, 2018; Volume 455. [Google Scholar]

- Kirkpatrick, M.B.; Tarbutton, J.A.; Le, T.; Lee, C. Characterization of 3D Printed Piezoelectric Sensors: Determiniation of D33 Piezoelectric Coefficient for 3D Printed Polyvinylidene Fluoride Sensors. In Proceedings of the 2016 IEEE Sensors, Orlando, FL, USA, 30 October–3 November 2016; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2017. [Google Scholar]

- Woodward, D.I.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A.; Leigh, S.J. Additively-Manufactured Piezoelectric Devices. Phys. Status Solidi A Appl. Mater. Sci. 2015, 212, 2107–2113. [Google Scholar] [CrossRef]

- Chen, Z.; Song, X.; Lei, L.; Chen, X.; Fei, C.; Chiu, C.T.; Qian, X.; Ma, T.; Yang, Y.; Shung, K.; et al. 3D Printing of Piezoelectric Element for Energy Focusing and Ultrasonic Sensing. Nano Energy 2016, 27, 78–86. [Google Scholar] [CrossRef]

- Tressler, J.F.; Alkoy, S.; Newnham, R.E. Piezoelectric Sensors and Sensor Materials. J. Electroceramics 1998, 2, 257–272. [Google Scholar] [CrossRef]

- Advantages and Disadvantages of Piezoelectric Sensor and Its Application. Available online: http://pisuko.com/?list_30/113.html (accessed on 14 November 2021).

- Toledo, J.; Ruiz-díez, V.; Pfusterschmied, G.; Schmid, U.; Sánchez-rojas, J.L. Flow-through Sensor Based on Piezoelectric MEMS Resonator for the in-Line Monitoring of Wine Fermentation. Sens. Actuators B Chem. 2017, 254, 291–298. [Google Scholar] [CrossRef]

- Ruiz-Díez, V.; Toledo, J.; Hernando-García, J.; Pfusterschmied, G.; Schmid, U.; Sánchez-Rojas, J.L. Fluid-Structure Interaction Modelling of the Roof Tile-Shaped Modes in Piezoelectric Plate Microresonators. In Proceedings of the Smart Sensors, Actuators, and MEMS VIII, Barcelona, Spain, 5 June 2017; Volume 10246. [Google Scholar]

- Cerimovic, S.; Beigelbeck, R.; Antlinger, H.; Schalko, J.; Jakoby, B.; Keplinger, F. Sensing Viscosity and Density of Glycerol-Water Mixtures Utilizing a Suspended Plate MEMS Resonator. Microsyst. Technol. 2012, 18, 1045–1056. [Google Scholar] [CrossRef][Green Version]

- Jakoby, B.; Beigelbeck, R.; Keplinger, F.; Lucklum, F.; Niedermayer, A.; Reichel, E.K.; Riesch, C.; Voglhuber-Brunnmaier, T.; Weiss, B. Miniaturized Sensors for the Viscosity and Density of Liquids--Performance and Issues. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2010, 57, 111–120. [Google Scholar] [CrossRef]

- Riesch, C.; Keplinger, F.; Reichel, E.K.; Jakoby, B. Characterizing Resonating Cantilevers for Liquid Property Sensing. Proc. IEEE Sens. 2006, 1070–1073. [Google Scholar] [CrossRef]

- Heinisch, M.; Voglhuber-Brunnmaier, T.; Reichel, E.K.; Dufour, I.; Jakoby, B. Reduced Order Models for Resonant Viscosity and Mass Density Sensors. Sens. Actuators A Phys. 2014, 220, 76–84. [Google Scholar] [CrossRef]

- PZT Actuators. Available online: https://www.piceramic.com/en/products/piezoceramic-components/plates-and-blocks/ (accessed on 17 October 2021).

- Toledo, J.; Ruiz-Díez, V.; Bertke, M.; Suryo Wasisto, H.; Peiner, E.; Sánchez-Rojas, J. Piezoelectric MEMS Resonators for Cigarette Particle Detection. Micromachines 2019, 10, 145. [Google Scholar] [CrossRef] [PubMed]

- Cakmak, O.; Ermek, E.; Kilinc, N.; Yaralioglu, G.G.; Urey, H. Precision Density and Viscosity Measurement Using Two Cantilevers with Different Widths. Sens. Actuators A Phys. 2015, 232, 141–147. [Google Scholar] [CrossRef]

- Youssry, M.; Belmiloud, N.; Caillard, B.; Ayela, C.; Pellet, C.; Dufour, I. A Straightforward Determination of Fluid Viscosity and Density Using Microcantilevers: From Experimental Data to Analytical Expressions. Sens. Actuators A Phys. 2011, 172, 40–46. [Google Scholar] [CrossRef]

- Toledo, J.; Manzaneque, T.; Ruiz-Díez, V.; Kucera, M.; Pfusterschmied, G.; Wistrela, E.; Schmid, U.; Sánchez-Rojas, J.L. Piezoelectric Resonators and Oscillator Circuit Based on Higher-Order out-of-Plane Modes for Density-Viscosity Measurements of Liquids. J. Micromech. Microeng. 2016, 26, 8. [Google Scholar] [CrossRef]

- Manzaneque, T.; Ruiz-díez, V.; Hernando-García, J.; Wistrela, E.; Kucera, M.; Schmid, U.; Sánchez-rojas, J.L. Piezoelectric MEMS Resonator-Based Oscillator for Density and Viscosity Sensing. Sens. Actuators A. Phys. 2014, 220, 305–315. [Google Scholar] [CrossRef]

- Kucera, M.; Wistrela, E.; Pfusterschmied, G.; Ruiz-Díez, V.; Sánchez-Rojas, J.L.; Schalko, J.; Bittner, A.; Schmid, U. Characterisation of Multi Roof Tile-Shaped out-of-Plane Vibrational Modes in Aluminium-Nitride-Actuated Self-Sensing Micro-Resonators in Liquid Media. Appl. Phys. Lett. 2015. [Google Scholar] [CrossRef]

- Ruiz-Díez, V.; Manzaneque, T.; Hernando-García, J.; Ababneh, A.; Kucera, M.; Schmid, U.; Seidel, H.; Sánchez-Rojas, J.L. Design and Characterization of AlN-Based in-Plane Microplate Resonators. J. Micromech. Microeng. 2013. [Google Scholar] [CrossRef]

- Sanchez-Rojas, J.L.; Hernando, J.; Donoso, A.; Bellido, J.C.; Manzaneque, T.; Ababneh, A.; Seidel, H.; Schmid, U. Modal Optimization and Filtering in Piezoelectric Microplate Resonators. J. Micromech. Microeng. 2010. [Google Scholar] [CrossRef]

- COMSOL Software. Available online: https://www.comsol.com/ (accessed on 17 October 2021).

- Huynh, T.C.; Lee, K.S.; Kim, J.T. Local Dynamic Characteristics of PZT Impedance Interface on Tendon Anchorage under Prestress Force Variation. Smart Struct. Syst. 2015, 15, 375–393. [Google Scholar] [CrossRef]

- Ricci, A.; Giuri, E. FSI Analysis of Microcantilevers Vibrating in Fluid Environment. In Proceedings of the Comsol Conference, Milan, Italy, 15 October 2009. [Google Scholar]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Erokhin, K.S.; Gordeev, E.G.; Ananikov, V.P. Revealing Interactions of Layered Polymeric Materials at Solid-Liquid Interface for Building Solvent Compatibility Charts for 3D Printing Applications. Sci. Rep. 2019, 9, 20177. [Google Scholar] [CrossRef] [PubMed]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- FDM Printer. Available online: https://ultimaker.com/ (accessed on 17 October 2021).

- B9 Resin 3D Printer. Available online: https://www.b9c.com/ (accessed on 17 October 2021).

- Formlabs Resin 3D Printer. Available online: https://formlabs.com/ (accessed on 17 October 2021).

- Rigid 10K Resin Datasheet. Available online: https://formlabs-media.formlabs.com/datasheets/2001479-TDS-ENUS-0.pdf (accessed on 25 October 2021).

- PA-CF Filament. Available online: https://www.ultrafusefff.com/wp-content/uploads/2019/01/Ultrafuse_PAHT_CF15_TDS_EN_v3.5.pdf (accessed on 17 October 2021).

- PET Filament. Available online: https://www.ultrafusefff.com/wp-content/uploads/2016/06/Ultrafuse_PET_TDS_EN_v3.2.pdf (accessed on 17 October 2021).

- Black Resin. Available online: https://shop.b9c.com/b9r-2-black (accessed on 17 October 2021).

- Resin Rigid 10k. Available online: https://formlabs.com/es/store/materials/rigid-10k-resin/ (accessed on 17 October 2021).

- Loctite 435. Available online: http://tds.henkel.com/tds5/Studio/ShowPDF/243%20NEW-EN?pid=435&format=MTR&subformat=REAC&language=EN&plant=WERCS (accessed on 28 October 2021).

- Correia, D.M.; Nunes-Pereira, J.; Alikin, D.; Kholkin, A.L.; Carabineiro, S.A.C.; Rebouta, L.; Rodrigues, M.S.; Vaz, F.; Costa, C.M.; Lanceros-Méndez, S. Surface Wettability Modification of Poly(Vinylidene Fluoride) and Copolymer Films and Membranes by Plasma Treatment. Polymer 2019, 169, 138–147. [Google Scholar] [CrossRef]

- Slepickova Kasalkova, N.; Slepicka, P.; Kolska, Z.; Svorcik, V. Wettability and Other Surface Properties of Modified Polymers. In Wetting and Wettability; InTech: London, UK, 2015. [Google Scholar]

- Leissa, A.W. Vibration of Plates; Scientific and Technical Information Division, National Aeronautics and Space Administration: Washington, DC, USA, 1969. [Google Scholar]

- Optonor MEMSMap 510. Available online: https://optonor.com/memsmap-510/ (accessed on 18 October 2021).

- Ferrari, V.; Marioli, D.; Taroni, A. Improving the Accuracy and Operating Range of Quartz Microbalance Sensors by a Purposely Designed Oscillator Circuit. IEEE Trans. Instrum. Meas. 2001, 50, 1119–1122. [Google Scholar] [CrossRef]

- Toledo, J.; Manzaneque, T.; Ruiz-Díez, V.; Jiménez-Márquez, F.; Kucera, M.; Pfusterschmied, G.; Wistrela, E.; Schmid, U.; Sánchez-Rojas, J.L. Comparison of In-Plane and out-of-Plane Piezoelectric Microresonators for Real-Time Monitoring of Engine Oil Contamination with Diesel. Microsyst. Technol. 2016, 22, 1781–1790. [Google Scholar] [CrossRef]

- HF2LI Lock-in Amplifier Zurich Instruments. Available online: https://www.zhinst.com/products/hf2li (accessed on 17 November 2021).

- Jiménez-Márquez, F.; Vázquez, J.; Úbeda, J.; Sánchez-Rojas, J.L. Low-Cost and Portable Refractive Optoelectronic Device for Measuring Wine Fermentation Kinetics. Sens. Actuators B Chem. 2013, 178, 316–323. [Google Scholar] [CrossRef]

- Rubiola, E. Phase Noise and Frequency Stability in Oscillators. Phase Noise Freq. Stab. Oscil. 2008, 9780521886772, 1–203. [Google Scholar] [CrossRef]

- Walls, F.L.; Allan, D.W. Measurements of Frequency Stability. Proc. IEEE 1986, 74, 162–168. [Google Scholar] [CrossRef]

- Castille, C.; Dufour, I.; Lucat, C. Longitudinal Vibration Mode of Piezoelectric Thick-Film Cantilever-Based Sensors in Liquid Media. Appl. Phys. Lett. 2010, 96, 1–4. [Google Scholar] [CrossRef]

- Maali, A.; Hurth, C.; Boisgard, R.; Jai, C.; Cohen-Bouhacina, T.; Aimé, J.P. Hydrodynamics of Oscillating Atomic Force Microscopy Cantilevers in Viscous Fluids. J. Appl. Phys. 2005, 97, 1–6. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E.M. Fluid Mechanics; Elsevier: Amsterdam, The Netherlands, 1987; Volume 6, ISBN 0080339336. [Google Scholar]

- Riesch, C.; Reichel, E.K.; Keplinger, F.; Jakoby, B. Characterizing Vibrating Cantilevers for Liquid Viscosity and Density Sensing. J. Sens. 2008, 2008, 1–9. [Google Scholar] [CrossRef]

- Dufour, I.; Lemaire, E.; Caillard, B.; Debéda, H.; Lucat, C.; Heinrich, S.M.; Josse, F.; Brand, O. Effect of Hydrodynamic Force on Microcantilever Vibrations: Applications to Liquid-Phase Chemical Sensing. Sens. Actuators B Chem. 2014, 192, 664–672. [Google Scholar] [CrossRef]

- Gilson Peristaltic Pump Minipuls 3. Available online: https://es.gilson.com/minipuls-3-peristaltic-pumps.html (accessed on 14 November 2021).

- Silicone Tube. Available online: https://es.vwr.com/store/product/11601432/tubo-de-bomba-tygon-lmt-55 (accessed on 14 November 2021).

- Muramatsu, H.; Tamiya, E.; Karube, I. Computation of Equivalent Circuit Parameters of Quartz Crystals in Contact with Liquids and Study of Liquid Properties. Anal. Chem. 2002, 60, 2142–2146. [Google Scholar] [CrossRef]

- Matsiev, L.F. Application of Flexural Mechanical Resonators to High Throughput Liquid Characterization. In Proceedings of the 2000 IEEE Ultrason. Symposium. Proceedings. An International Symposium (Cat. No.00CH37121), San Juan, PR, USA, 22–25 October 2000. [Google Scholar] [CrossRef]

- Waszczuk, K.; Piasecki, T.; Nitsch, K.; Gotszalk, T. Application of Piezoelectric Tuning Forks in Liquid Viscosity and Density Measurements. Sens. Actuators B Chem. 2011, 160, 517–523. [Google Scholar] [CrossRef]

- Sell, J.K.; Niedermayer, A.O.; Babik, S.; Jakoby, B. Real-Time Monitoring of a High Pressure Reactor Using a Gas Density Sensor. Undefined 2010, 162, 215–219. [Google Scholar] [CrossRef]

- Liu, Y.; Difoggio, R.; Sanderlin, K.; Perez, L.; Zhao, J. Measurement of Density and Viscosity of Dodecane and Decane with a Piezoelectric Tuning Fork over 298–448 K and 0.1–137.9 MPa. Sens. Actuators A Phys. 2011, 167, 347–353. [Google Scholar] [CrossRef]

- Sell, J.K.; Niedermayer, A.O.; Jakoby, B. Reactance-Locked Loop for Driving Resonant Sensors. In Proceedings of the 2012 IEEE I2MTC-International Instrumentation and Measurement Technology Conference, Graz, Austria, 13–16 May 2012; pp. 1113–1116. [Google Scholar] [CrossRef]

- Toledo, J.; Ruiz-Díez, V.; Pfusterschmied, G.; Schmid, U.; Sánchez-Rojas, J.L. Calibration Procedure for Piezoelectric MEMS Resonators to Determine Simultaneously Density and Viscosity of Liquids. Microsyst. Technol. 2017, 24, 1423–1431. [Google Scholar] [CrossRef]

- Toledo, J.; Manzaneque, T.; Hernando-García, J.; Vázquez, J.; Ababneh, A.; Seidel, H.; Lapuerta, M.; Sánchez-Rojas, J.L. Application of Quartz Tuning Forks and Extensional Microresonators for Viscosity and Density Measurements in Oil/Fuel Mixtures. Microsyst. Technol. 2014, 20, 945–953. [Google Scholar] [CrossRef]

- Precision Hydrometers. Available online: https://www.ludwig-schneider.de/fileadmin//media/downloads/en/09_Hydrometer.pdf (accessed on 20 October 2021).

| PZT Actuator | Vibrating Membrane | |

|---|---|---|

| Length | Lp = Lm/2 + Wc = 13 | Lm = 16 |

| Width | Wp = 5 | Wm = 5 |

| Thickness | Tp = 0.1 | Tm = 0.5 |

| PZT Actuator | Liquid Cell (Rigid 10K Resin) | |

|---|---|---|

| Young Modulus [GPa] | 62 | 10 |

| Density [kg/m3] | 7800 | 1670 |

| Solution | Fructose | Glucose | Glycerol | Ethanol | Density | Viscosity |

|---|---|---|---|---|---|---|

| [g/L] | [g/L] | [g/L] | [% v/v] | [g/mL] | [mPa·s] | |

| N1 | 110 | 100 | 0 | 0 | 1.082 | 1.948 |

| N2 | 90 | 80 | 0 | 1 | 1.063 | 1.974 |

| N3 | 70 | 30 | 5 | 6 | 1.028 | 1.722 |

| N4 | 60 | 20 | 5 | 8 | 1.017 | 1.706 |

| N5 | 40 | 10 | 6 | 9 | 1.003 | 1.769 |

| N6 | 20 | 2 | 7 | 12 | 0.990 | 1.754 |

| N7 | 8 | 2 | 7 | 13 | 0.984 | 1.769 |

| N8 | 5 | 2 | 7 | 13 | 0.983 | 1.808 |

| N9 | 2 | 1 | 9 | 14 | 0.982 | 1.741 |

| Liquids | Density Range | Density Resolution | Viscosity Range | Viscosity Resolution | Reference |

|---|---|---|---|---|---|

| [g/mL] | [g/mL] | [mPa·s] | [mPa·s] | ||

| Aqueous solutions | 0.98–1.08 | 10 × 10−6 | 1.8–2 | 3 × 10−3 | This work |

| Real fermentation of grape must | 0.98–1.1 | 1 × 10−3 | 1.6–2.4 | 20 × 10−3 | [29] |

| Solvents | 0.71–0.88 | 0.11 | 2.71–44 | 0.43–14 | [83] |

| Lubricant-diesel Mixtures | 0.84–0.85 | 8 × 10−6–4 × 10−5 | 60–90 | 0.12–0.022 | [64] |

| Viscosity standards | 0.83–0.87 | 1.5 × 10−7–6.4 × 10−4 | 4–500 | 1.3 × 10−4–6.4 | [39] |

| Glycerol solutions | 0.995–1.15 | 0.18 × 10−3 | 0.935–4 | 1 × 10−3 | [37] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toledo, J.; Ruiz-Díez, V.; Velasco, J.; Hernando-García, J.; Sánchez-Rojas, J.L. 3D-Printed Liquid Cell Resonator with Piezoelectric Actuation for In-Line Density-Viscosity Measurements. Sensors 2021, 21, 7654. https://doi.org/10.3390/s21227654

Toledo J, Ruiz-Díez V, Velasco J, Hernando-García J, Sánchez-Rojas JL. 3D-Printed Liquid Cell Resonator with Piezoelectric Actuation for In-Line Density-Viscosity Measurements. Sensors. 2021; 21(22):7654. https://doi.org/10.3390/s21227654

Chicago/Turabian StyleToledo, Javier, Víctor Ruiz-Díez, Jaime Velasco, Jorge Hernando-García, and José Luis Sánchez-Rojas. 2021. "3D-Printed Liquid Cell Resonator with Piezoelectric Actuation for In-Line Density-Viscosity Measurements" Sensors 21, no. 22: 7654. https://doi.org/10.3390/s21227654

APA StyleToledo, J., Ruiz-Díez, V., Velasco, J., Hernando-García, J., & Sánchez-Rojas, J. L. (2021). 3D-Printed Liquid Cell Resonator with Piezoelectric Actuation for In-Line Density-Viscosity Measurements. Sensors, 21(22), 7654. https://doi.org/10.3390/s21227654