Review of Optical Humidity Sensors

Abstract

:1. Introduction

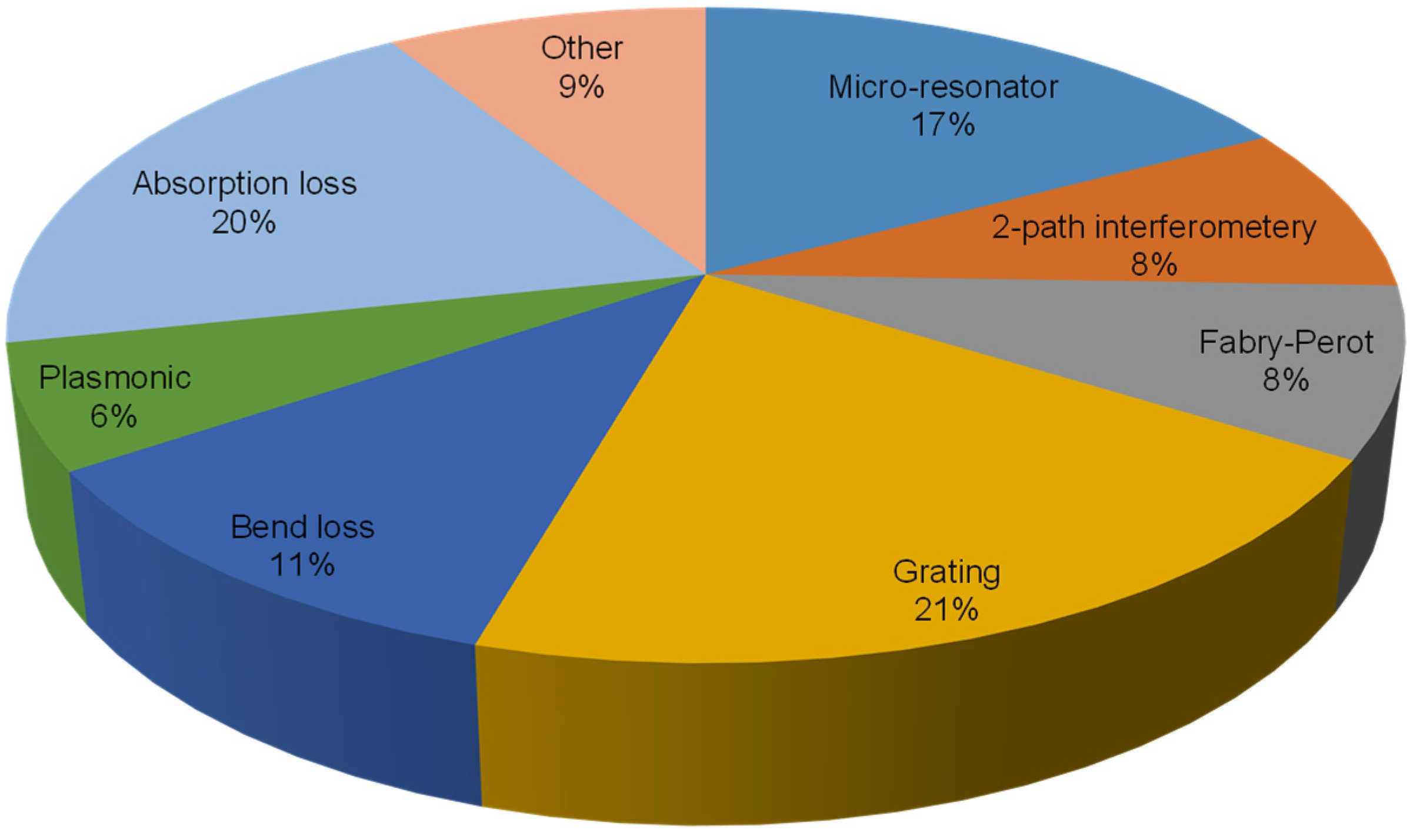

2. Basic Principles

3. Literature and the State-of-the-Art

3.1. Colorimetric Indicators

3.2. Touchless Control Systems

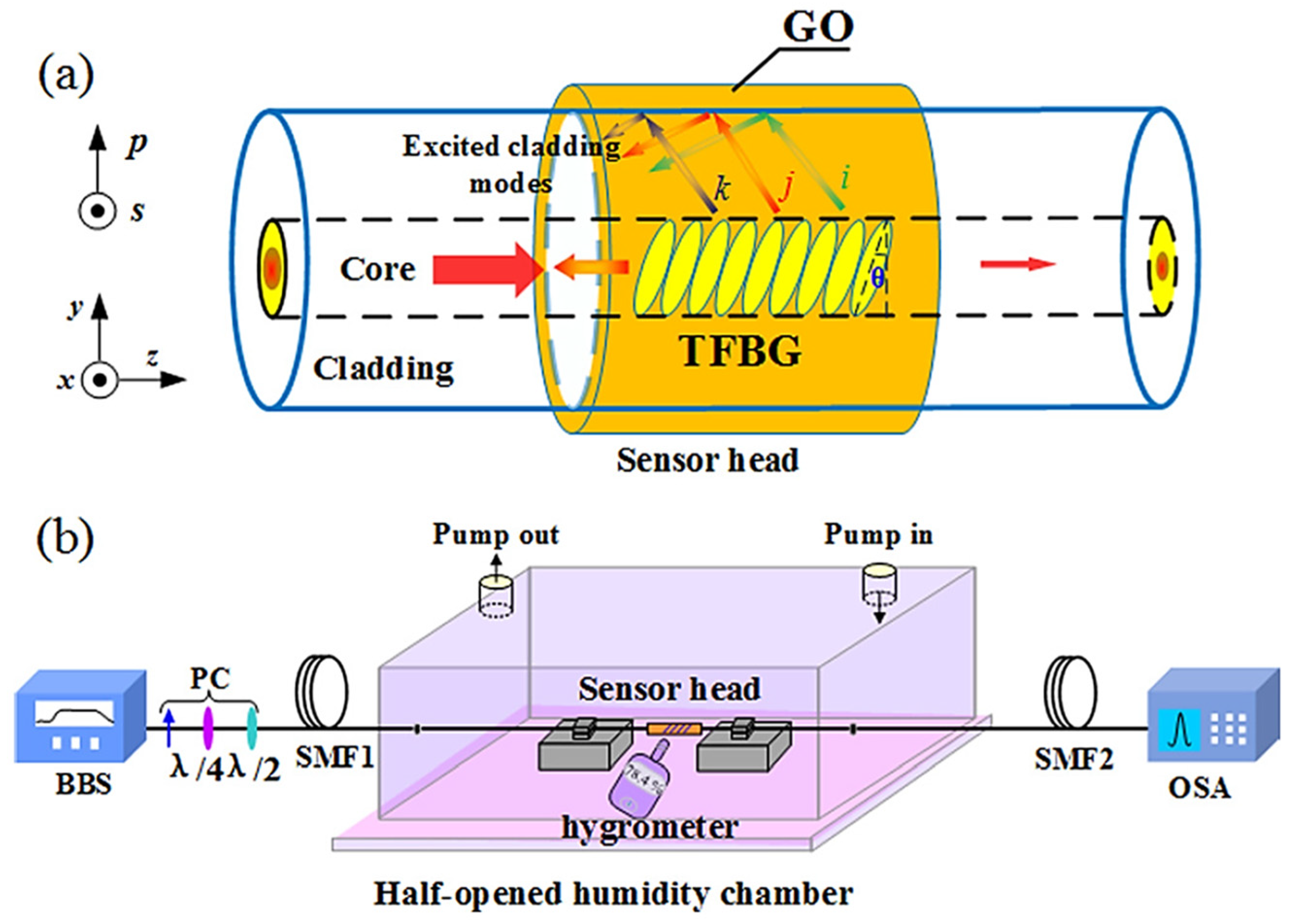

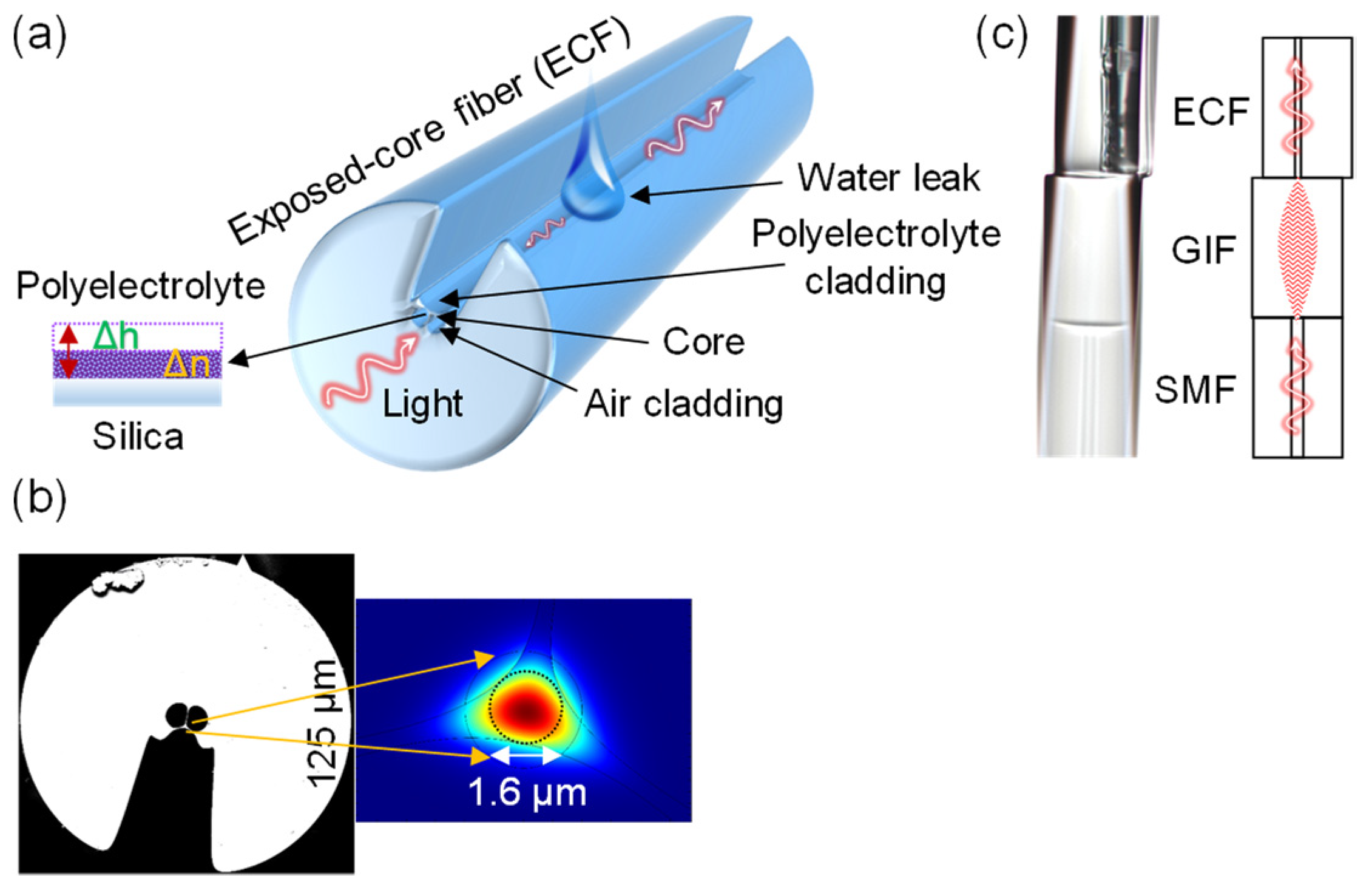

3.3. Point Sensors

3.4. Distributed Sensors

3.5. Functional Materials

4. Discussions

4.1. General Challenges

4.2. Specific Applications

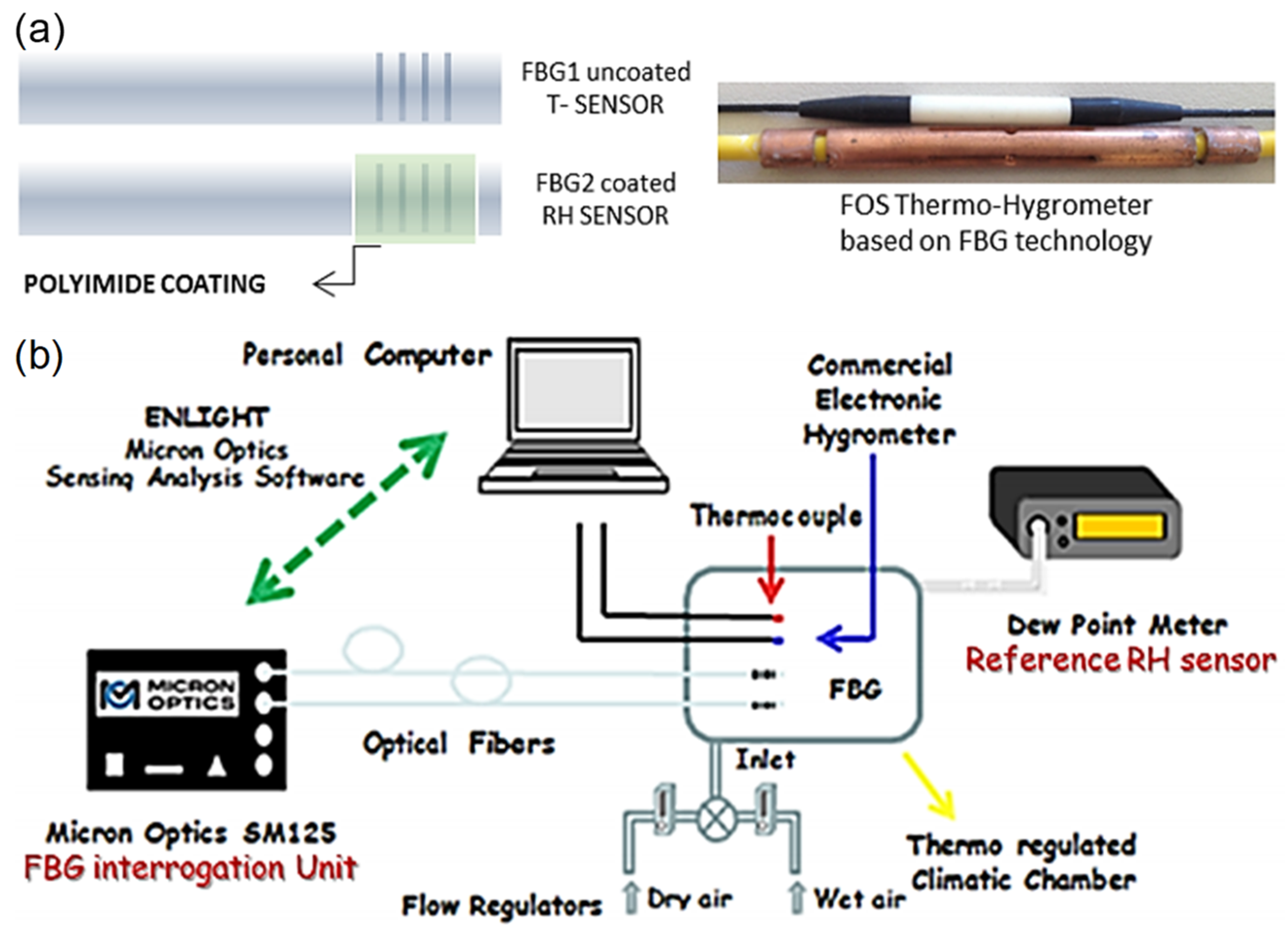

4.2.1. Respiratory Monitoring

4.2.2. Portable Wearable Healthcare Products

4.2.3. Human Health Monitoring

4.2.4. Grain Storage

4.2.5. Power Systems

4.2.6. Nuclear Power Plant

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kolpakov, S.A.; Gordon, N.T.; Mou, C.; Zhou, K. Toward a new generation of photonic humidity sensors. Sensors 2014, 14, 3986–4013. [Google Scholar] [CrossRef]

- Sikarwar, S.; Yadav, B.C. Opto-electronic humidity sensor: A review. Sens. Actuators A Phys. 2015, 233, 54–70. [Google Scholar] [CrossRef]

- Fan, L.; Bao, Y. Review of fiber optic sensors for corrosion monitoring in reinforced concrete. Cem. Concr. Compos. 2021, 120, 104029. [Google Scholar] [CrossRef]

- Rianjanu, A.; Julian, T.; Hidayat, S.N.; Yulianto, N.; Majid, N.; Syamsu, I.; Wasisto, H.S.; Triyana, K. Quartz crystal microbalance humidity sensors integrated with hydrophilic polyethyleneimine-grafted polyacrylonitrile nanofibers. Sens. Actuators B Chem. 2020, 319, 128286. [Google Scholar] [CrossRef]

- Fauzi, F.; Rianjanu, A.; Santoso, I.; Triyana, K. Gas and humidity sensing with quartz crystal microbalance (QCM) coated with graphene-based materials—A mini review. Sens. Actuators A Phys. 2021, 330, 112837. [Google Scholar] [CrossRef]

- Hammouche, H.; Achour, H.; Makhlouf, S.; Chaouchi, A.; Laghrouche, M. A comparative study of capacitive humidity sensor based on keratin film, keratin/graphene oxide, and keratin/carbon fibers. Sens. Actuators A Phys. 2021, 329, 112805. [Google Scholar] [CrossRef]

- Najeeb, M.A.; Ahmad, Z.; Shakoor, R.A. Organic Thin-Film Capacitive and Resistive Humidity Sensors: A Focus Review. Adv. Mater. Interfaces 2018, 5, 1800969. [Google Scholar] [CrossRef]

- Ascorbe, J.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Recent Developments in Fiber Optics Humidity Sensors. Sensors 2017, 17, 893. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, G.Y.; Lancaster, D.G.; Monro, T.M. Optical Microfiber Technology for Current, Temperature, Acceleration, Acoustic, Humidity and Ultraviolet Light Sensing. Sensors 2018, 18, 72. [Google Scholar] [CrossRef] [Green Version]

- Schindelholz, E.; Risteen, B.E.; Kelly, R.G. Effect of Relative Humidity on Corrosion of Steel under Sea Salt Aerosol Proxies. J. Electrochem. Soc. 2014, 161, C450–C459. [Google Scholar] [CrossRef]

- Tian, E.; Wang, J.; Zheng, Y.; Song, Y.; Jiang, L.; Zhu, D. Colorful humidity sensitive photonic crystal hydrogel. J. Mater. Chem. 2008, 18, 1116–1122. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Xie, J.; Li, C.; Li, Y.; Liang, S.; Tian, Z.; Wang, T.; Zhang, H.; Li, H.; et al. Bioinspired Water-Vapor-Responsive Organic/Inorganic Hybrid One-Dimensional Photonic Crystals with Tunable Full-Color Stop Band. Adv. Funct. Mater. 2010, 20, 3784–3790. [Google Scholar] [CrossRef]

- Hawkeye, M.M.; Brett, M.J. Optimized Colorimetric Photonic-Crystal Humidity Sensor Fabricated Using Glancing Angle Deposition. Adv. Funct. Mater. 2011, 21, 3652–3658. [Google Scholar] [CrossRef]

- Chi, H.; Liu, Y.J.; Wang, F.; He, C. Highly Sensitive and Fast Response Colorimetric Humidity Sensors Based on Graphene Oxides Film. ACS Appl. Mater. Interfaces 2015, 7, 19882–19886. [Google Scholar] [CrossRef] [PubMed]

- Mills, A.; Hawthorne, D.; Burns, L.; Hazafy, D. Novel temperature-activated humidity-sensitive optical sensor. Sens. Actuators B Chem. 2017, 240, 1009–1015. [Google Scholar] [CrossRef] [Green Version]

- Bumbudsanpharoke, N.; Kwon, S.; Lee, W.; Ko, S. Optical response of photonic cellulose nanocrystal film for a novel humidity indicator. Int. J. Biol. Macromol. 2019, 140, 91–97. [Google Scholar] [CrossRef]

- Lazarova, K.; Bozhilova, S.; Novakov, C.; Christova, D.; Babeva, T. Amphiphilic Poly(vinyl Alcohol) Copolymers Designed for Optical Sensor Applications-Synthesis and Properties. Coatings 2020, 10, 460. [Google Scholar] [CrossRef]

- Mathew, J.; Semenova, Y.; Rajan, G.; Wang, P.; Farrell, G. Improving the sensitivity of a humidity sensor based on fiber bend coated with a hygroscopic coating. Opt. Laser Technol. 2011, 43, 1301–1305. [Google Scholar] [CrossRef]

- Feng, J.; Peng, L.; Wu, C.; Sun, X.; Hu, S.; Lin, C.; Dai, J.; Yang, J.; Xie, Y. Giant moisture responsiveness of VS2 ultrathin nanosheets for novel touchless positioning interface. Adv. Mater. 2012, 24, 1969–1974. [Google Scholar] [CrossRef]

- Szendrei, K.; Ganter, P.; Sanchez-Sobrado, O.; Eger, R.; Kuhn, A.; Lotsch, B.V. Touchless Optical Finger Motion Tracking Based on 2D Nanosheets with Giant Moisture Responsiveness. Adv. Mater. 2015, 27, 6341–6348. [Google Scholar] [CrossRef]

- Yu, L.; Xu, H.; Monro, T.M.; Lancaster, D.G.; Xie, Y.; Zeng, H.; Chen, G.Y.; Liu, X. Ultrafast colorimetric humidity-sensitive polyelectrolyte coating for touchless control. Mater. Horiz. 2017, 4, 72–82. [Google Scholar] [CrossRef]

- Posch, H.E.; Wolfbeis, O.S. Optical Sensors, 13: Fibre-Optic Humidity Sensor Based on Fluorescence Quenching. Sens. Actuators 1988, 15, 77–83. [Google Scholar] [CrossRef]

- Lukosz, W.; Stamm, C. Integrated Optical Interferometer as Relative-Humidity Sensor and Differential Refractometer. Sens. Actuators A-Phys. 1991, 25, 185–188. [Google Scholar] [CrossRef]

- Sadaoka, Y.; Matsuguchi, M.; Sakai, Y.; Murata, Y.U. Optical Humidity Sensing Characteristics of Nafion-Dyes Composite Thin-Films. Sens. Actuators B-Chem. 1992, 7, 443–446. [Google Scholar] [CrossRef]

- Ando, M.; Kobayashi, T.; Haruta, M. Humidity-sensitive optical absorption of Co3O4 film. Sens. Actuators B-Chem. 1996, 32, 157–160. [Google Scholar] [CrossRef]

- Arregui, F.J.; Liu, Y.J.; Matias, I.R.; Claus, R.O. Optical fiber humidity sensor using a nano Fabry-Perot cavity formed by the ionic self-assembly method. Sens. Actuators B-Chem. 1999, 59, 54–59. [Google Scholar] [CrossRef]

- Bariain, C.; Matias, I.R.; Arregui, F.J.; Lopez-Amo, M. Optical fiber humidity sensor based on a tapered fiber coated with agarose gel. Sens. Actuators B-Chem. 2000, 69, 127–131. [Google Scholar] [CrossRef]

- Arregui, F.J.; Cooper, K.L.; Liu, Y.J.; Matias, I.R.; Claus, R.O. Optical fiber humidity sensor with a fast response time using the ionic self-assembly method. Ieice Trans. Electron. 2000, E83C, 360–365. [Google Scholar]

- Kronenberg, P. Relative humidity sensor with optical fiber Bragg gratings. Opt. Lett. 2002, 27, 1385–1387. [Google Scholar] [CrossRef]

- Jindal, R. High dynamic range fiber optic relative humidity sensor. Opt. Eng. 2002, 41, 1093–1096. [Google Scholar] [CrossRef]

- Gaston, A.; Lozano, I.; Perez, F.; Auza, F.; Sevilla, J. Evanescent wave optical-fiber sensing (temperature, relative humidity, and ph sensors). IEEE Sens. J. 2003, 3, 806–811. [Google Scholar] [CrossRef] [Green Version]

- Muto, S. A plastic optical fibre sensor for real-time humidity monitoring. Meas. Sci. Technol. 2003, 14, 746–750. [Google Scholar] [CrossRef]

- Gastón, A. Optical fiber relative-humidity sensor with polyvinyl alcohol film. Appl. Opt. 2004, 43, 4127–4132. [Google Scholar] [CrossRef]

- Alvarez-Herrero, A.; Guerrero, H.; Levy, D. High-Sensitivity Sensor of Low Relative Humidity Based on Overlay on Side-Polished Fibers. IEEE Sens. J. 2004, 4, 52–56. [Google Scholar] [CrossRef]

- Xu, L. Optical fiber humidity sensor based on evanescent-wave scattering. Opt. Lett. 2004, 29, 1191–1193. [Google Scholar] [CrossRef] [Green Version]

- Shukla, S.K.; Parashar, G.K.; Mishra, A.P.; Misra, P.; Yadav, B.C.; Shukla, R.K.; Bali, L.M.; Dubey, G.C. Nano-like magnesium oxide films and its significance in optical fiber humidity sensor. Sens. Actuators B Chem. 2004, 98, 5–11. [Google Scholar] [CrossRef]

- Tan, K.M.; Tay, C.M.; Tjin, S.C.; Chan, C.C.; Rahardjo, H. High relative humidity measurements using gelatin coated long-period grating sensors. Sens. Actuators B Chem. 2005, 110, 335–341. [Google Scholar] [CrossRef]

- Zanjanchi, M.A.; Sohrabnezhad, S. Evaluation of methylene blue incorporated in zeolite for construction of an optical humidity sensor. Sens. Actuators B Chem. 2005, 105, 502–507. [Google Scholar] [CrossRef]

- Yeo, T.L.; Sun, T.; Grattan, K.T.V.; Parry, D.; Lade, R.; Powell, B.D. Characterisation of a polymer-coated fibre Bragg grating sensor for relative humidity sensing. Sens. Actuators B Chem. 2005, 110, 148–156. [Google Scholar] [CrossRef]

- Yeo, T.L.; Tong, S.; Grattan, K.T.V.; Parry, D.; Lade, R.; Powell, B.D. Polymer-coated fiber Bragg grating for relative humidity sensing. IEEE Sens. J. 2005, 5, 1082–1089. [Google Scholar] [CrossRef]

- Corres, J.M.; Bravo, J.; Matias, I.R.; Arregui, F.J. Nonadiabatic tapered single-mode fiber coated with humidity sensitive nanofilms. IEEE Photonics Technol. Lett. 2006, 18, 935–937. [Google Scholar] [CrossRef]

- Corres, J.M.; Arregui, F.J.; Matias, I.R. Design of Humidity Sensors Based on Tapered Optical Fibers. J. Lightwave Technol. 2006, 24, 4329–4336. [Google Scholar] [CrossRef]

- Bedoya, M.; Díez, M.T.; Moreno-Bondi, M.C.; Orellana, G. Humidity sensing with a luminescent Ru(II) complex and phase-sensitive detection. Sens. Actuators B Chem. 2006, 113, 573–581. [Google Scholar] [CrossRef]

- Barry, R.A. Humidity-Sensing Inverse Opal Hydrogels. Langmuir 2006, 22, 1369–1374. [Google Scholar] [CrossRef] [PubMed]

- Yeo, T.L.; Eckstein, D.; McKinley, B.; Boswell, L.F.; Sun, T.; Grattan, K.T.V. Demonstration of a fibre-optic sensing technique for the measurement of moisture absorption in concrete. Smart Mater. Struct. 2006, 15, N40–N45. [Google Scholar] [CrossRef]

- Yeo, T.L.; Cox, M.A.C.; Boswell, L.F.; Sun, T.; Grattan, K.T.V. Optical fiber sensors for monitoring ingress of moisture in structural concrete. Rev. Sci. Instrum. 2006, 77, 055108. [Google Scholar] [CrossRef]

- Corres, J.M.; Arregui, F.J.; Matías, I.R. Sensitivity optimization of tapered optical fiber humidity sensors by means of tuning the thickness of nanostructured sensitive coatings. Sens. Actuators B Chem. 2007, 122, 442–449. [Google Scholar] [CrossRef]

- Matias, I.R.; Arregui, F.J.; Corres, J.M.; Bravo, J. Evanescent Field Fiber-Optic Sensors for Humidity Monitoring Based on Nanocoatings. IEEE Sens. J. 2007, 7, 89–95. [Google Scholar] [CrossRef]

- Gu, F. Polymer Single-nanowire Optical Sensors. Nano Lett. 2008, 8, 2757–2761. [Google Scholar] [CrossRef]

- Zhang, L. Fast Detection of Humidity with a Subwavelength-diameter Fiber Taper Coated with Gelatin Film. Opt. Express 2008, 16, 13349. [Google Scholar] [CrossRef]

- Vijayan, A.; Fuke, M.; Hawaldar, R.; Kulkarni, M.; Amalnerkar, D.; Aiyer, R.C. Optical fibre based humidity sensor using Co-polyaniline clad. Sens. Actuators B Chem. 2008, 129, 106–112. [Google Scholar] [CrossRef]

- Corres, J.M.; Matias, I.R.; Hernaez, M.; Bravo, J.; Arregui, F.J. Optical Fiber Humidity Sensors Using Nanostructured Coatings of SiO$_{2}$ Nanoparticles. IEEE Sens. J. 2008, 8, 281–285. [Google Scholar] [CrossRef]

- Corres, J.M.; del Villar, I.; Matias, I.R.; Arregui, F.J. Two-Layer Nanocoatings in Long-Period Fiber Gratings for Improved Sensitivity of Humidity Sensors. IEEE Trans. Nanotechnol. 2008, 7, 394–400. [Google Scholar] [CrossRef]

- Venugopalan, T.; Yeo, T.L.; Sun, T.; Grattan, K.T.V. LPG-Based PVA Coated Sensor for Relative Humidity Measurement. IEEE Sens. J. 2008, 8, 1093–1098. [Google Scholar] [CrossRef]

- Viegas, D.; Goicoechea, J.; Santos, J.L.; Araujo, F.M.; Ferreira, L.A.; Arregui, F.J.; Matias, I.R. Sensitivity improvement of a humidity sensor based on silica nanospheres on a long-period fiber grating. Sensors 2009, 9, 519–527. [Google Scholar] [CrossRef]

- Shukla, S.K.; Tiwari, A.; Parashar, G.K.; Mishra, A.P.; Dubey, G.C. Exploring fiber optic approach to sense humid environment over nano-crystalline zinc oxide film. Talanta 2009, 80, 565–571. [Google Scholar] [CrossRef]

- Xiujuan, Y.; Childs, P.; Min, Z.; Yanbiao, L.; Jian, J.; Wei, J. Relative Humidity Sensor Based on Cascaded Long-Period Gratings With Hydrogel Coatings and Fourier Demodulation. IEEE Photonics Technol. Lett. 2009, 21, 1828–1830. [Google Scholar] [CrossRef]

- Yinping, M.; Bo, L.; Hao, Z.; Yuan, L.; Haibin, Z.; Hua, S.; Weihua, Z.; Qida, Z. Relative Humidity Sensor Based on Tilted Fiber Bragg Grating With Polyvinyl Alcohol Coating. IEEE Photonics Technol. Lett. 2009, 21, 441–443. [Google Scholar] [CrossRef]

- Estella, J.; de Vicente, P.; Echeverría, J.C.; Garrido, J.J. A fibre-optic humidity sensor based on a porous silica xerogel film as the sensing element. Sens. Actuators B Chem. 2010, 149, 122–128. [Google Scholar] [CrossRef]

- Fuke, M.V.; Kanitkar, P.; Kulkarni, M.; Kale, B.B.; Aiyer, R.C. Effect of particle size variation of Ag nanoparticles in Polyaniline composite on humidity sensing. Talanta 2010, 81, 320–326. [Google Scholar] [CrossRef]

- Akita, S.; Sasaki, H.; Watanabe, K.; Seki, A. A humidity sensor based on a hetero-core optical fiber. Sens. Actuators B Chem. 2010, 147, 385–391. [Google Scholar] [CrossRef]

- Wang, P. Polymer Microfiber Rings for High-sensitivity Optical Humidity Sensing. SPIE-OSA-IEEE Asia Commun. Photonics 2011, 155, 258–263. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhang, T.; Rao, Y.; Gong, Y. Miniature interferometric humidity sensors based on silica/polymer microfiber knot resonators. Sens. Actuators B Chem. 2011, 155, 258–263. [Google Scholar] [CrossRef]

- Buvailo, A.; Xing, Y.; Hines, J.; Borguet, E. Thin polymer film based rapid surface acoustic wave humidity sensors. Sens. Actuators B Chem. 2011, 156, 444–449. [Google Scholar] [CrossRef]

- Popp, J.; Wang, B.; Zhang, F.; Pang, F.; Wang, T. An optical fiber humidity sensor based on optical absorption. In Optical Sensors and Biophotonics III; SPIE: Shanghai, China, 2011. [Google Scholar]

- Gu, B. Optical fiber relative humidity sensor based on FBG incorporated thin-core fiber modal interferometer. Opt. Express 2011, 19, 4140–4146. [Google Scholar] [CrossRef]

- Zamarreño, C.R.; Hernaez, M.; Sanchez, P.; Del Villar, I.; Matias, I.R.; Arregui, F.J. Optical Fiber Humidity Sensor Based on Lossy Mode Resonances Supported by TiO2/PSS Coatings. Procedia Eng. 2011, 25, 1385–1388. [Google Scholar] [CrossRef]

- Fu, M.-Y. Fiber-Optic Humidity Sensor Based on an Air-Gap Long Period Fiber Grating. Opt. Rev. 2011, 18, 93–95. [Google Scholar] [CrossRef]

- Xuan, R.; Wu, Q.; Yin, Y.; Ge, J. Magnetically assembled photonic crystal film for humidity sensing. J. Mater. Chem. 2011, 21, 3672–3676. [Google Scholar] [CrossRef]

- Wong, W.C.; Chan, C.C.; Chen, L.H.; Li, T.; Lee, K.X.; Leong, K.C. Polyvinyl alcohol coated photonic crystal optical fiber sensor for humidity measurement. Sens. Actuators B Chem. 2012, 174, 563–569. [Google Scholar] [CrossRef]

- Liang, H.; Jin, Y.; Wang, J.; Dong, X. Relative humidity sensor based on polarization maintaining fiber loop mirror with polymer coating. Microw. Opt. Technol. Lett. 2012, 54, 2364–2366. [Google Scholar] [CrossRef]

- Mathew, J.; Semenova, Y.; Farrell, G. A fiber bend based humidity sensor with a wide linear range and fast measurement speed. Sens. Actuators A Phys. 2012, 174, 47–51. [Google Scholar] [CrossRef]

- Chen, L.H.; Li, T.; Chan, C.C.; Menon, R.; Balamurali, P.; Shaillender, M.; Neu, B.; Ang, X.M.; Zu, P.; Wong, W.C.; et al. Chitosan based fiber-optic Fabry–Perot humidity sensor. Sens. Actuators B Chem. 2012, 169, 167–172. [Google Scholar] [CrossRef]

- Chen, L.H.; Chan, C.C.; Li, T.; Shaillender, M.; Neu, B.; Balamurali, P.; Menon, R.; Zu, P.; Ang, X.M.; Wong, W.C.; et al. Chitosan-Coated Polarization Maintaining Fiber-Based Sagnac Interferometer for Relative Humidity Measurement. IEEE J. Sel. Top. Quantum Electron. 2012, 18, 1597–1604. [Google Scholar] [CrossRef]

- Mohd Noor, M.Y.; Khalili, N.; Skinner, I.; Peng, G.D. Optical relative humidity sensor based on a hollow core-photonic bandgap fiber. Meas. Sci. Technol. 2012, 23, 085103. [Google Scholar] [CrossRef]

- Mohan, P.; Shinta, R.; Fujiwara, J.; Takahashi, H.; Mott, D.; Matsumura, Y.; Mizutani, G.; Iwami, K.; Umeda, N.; Maenosono, S. Boehmite nanorod/gold nanoparticle nanocomposite film for an easy-to-use optical humidity sensor. Sens. Actuators B Chem. 2012, 168, 429–435. [Google Scholar] [CrossRef]

- Aneesh, R. Titanium dioxide nanoparticle based optical fiber humidity sensor with linear response and enhanced sensitivity. Appl. Opt. 2012, 51, 2164–2171. [Google Scholar] [CrossRef]

- Correia, S.F.; Antunes, P.; Pecoraro, E.; Lima, P.P.; Varum, H.; Carlos, L.D.; Ferreira, R.A.; Andre, P.S. Optical fiber relative humidity sensor based on a FBG with a di-ureasil coating. Sensors 2012, 12, 8847–8860. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, S.; Verma, N.; Yadav, B.C.; Prakash, R. A comparative study on surface morphological investigations of ferric oxide for LPG and opto-electronic humidity sensors. Appl. Surf. Sci. 2012, 258, 8780–8789. [Google Scholar] [CrossRef]

- Li, T.; Dong, X.; Chan, C.C.; Zhao, C.-L.; Zu, P. Humidity Sensor Based on a Multimode-Fiber Taper Coated With Polyvinyl Alcohol Interacting With a Fiber Bragg Grating. IEEE Sens. J. 2012, 12, 2205–2208. [Google Scholar] [CrossRef]

- Zhang, W.; Webb, D.J.; Peng, G.D. Investigation into Time Response of Polymer Fiber Bragg Grating Based Humidity Sensors. J. Lightwave Technol. 2012, 30, 1090–1096. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y. Growth of well-arrayed ZnO nanorods on thinned silica fiber and application for humidity sensing. Opt. Express 2012, 20, 19405. [Google Scholar] [CrossRef] [PubMed]

- Makovec, A.; Berruti, G.; Consales, M.; Giordano, M.; Petagna, P.; Buontempo, S.; Breglio, G.; Szillasi, Z.; Beni, N.; Cusano, A. Radiation hard polyimide-coated FBG optical sensors for relative humidity monitoring in the CMS experiment at CERN. J. Instrum. 2014, 9, C03040. [Google Scholar] [CrossRef]

- Rajan, G.; Noor, Y.M.; Liu, B.; Ambikairaja, E.; Webb, D.J.; Peng, G.-D. A fast response intrinsic humidity sensor based on an etched singlemode polymer fiber Bragg grating. Sens. Actuators A Phys. 2013, 203, 107–111. [Google Scholar] [CrossRef]

- An, J. Relative humidity sensor based on SMS fiber structure with polyvinyl alcohol coating. Optik 2013, 124, 6178–6181. [Google Scholar] [CrossRef]

- Mathew, J.; Semenova, Y.; Farrell, G. Effect of coating thickness on the sensitivity of a humidity sensor based on an Agarose coated photonic crystal fiber interferometer. Opt. Express 2013, 21, 6313–6320. [Google Scholar] [CrossRef]

- Mathew, J.; Semenova, Y.; Farrell, G. Fiber Optic Hybrid Device for Simultaneous Measurement of Humidity and Temperature. IEEE Sens. J. 2013, 13, 1632–1636. [Google Scholar] [CrossRef]

- Hu, J.; Wu, P.; Deng, D.; Jiang, X.; Hou, X.; Lv, Y. An optical humidity sensor based on CdTe nanocrystals modified porous silicon. Microchem. J. 2013, 108, 100–105. [Google Scholar] [CrossRef]

- Alwis, L.; Sun, T.; Grattan, K.T. Design and performance evaluation of polyvinyl alcohol/polyimide coated optical fibre grating-based humidity sensors. Rev. Sci. Instrum. 2013, 84, 025002. [Google Scholar] [CrossRef]

- Alwis, L.; Sun, T.; Grattan, K.T.V. Fibre optic long period grating-based humidity sensor probe using a Michelson interferometric arrangement. Sens. Actuators B Chem. 2013, 178, 694–699. [Google Scholar] [CrossRef]

- Xia, L.; Li, L.; Li, W.; Kou, T.; Liu, D. Novel optical fiber humidity sensor based on a no-core fiber structure. Sens. Actuators A Phys. 2013, 190, 1–5. [Google Scholar] [CrossRef]

- Alwis, L.; Sun, T.; Grattan, K.V. Analysis of Polyimide-Coated Optical Fiber Long-Period Grating-Based Relative Humidity Sensor. IEEE Sens. J. 2013, 13, 767–771. [Google Scholar] [CrossRef]

- Jaroszewicz, L.R.; Sanchez, P.; Zamarreño, C.R.; Hernaez, M.; del Villar, I.; Matias, I.R.; Arregui, F.J. Humidity sensor fabricated by deposition of SnO2layers onto optical fibers. In Fifth European Workshop on Optical Fibre Sensors; SPIE: Krakow, Poland, 2013. [Google Scholar]

- Voznesenskiy, S.S.; Sergeev, A.A.; Mironenko, A.Y.; Bratskaya, S.Y.; Kulchin, Y.N. Integrated-optical sensors based on chitosan waveguide films for relative humidity measurements. Sens. Actuators B Chem. 2013, 188, 482–487. [Google Scholar] [CrossRef]

- Zheng, S.; Zhu, Y.; Krishnaswamy, S. Fiber humidity sensors with high sensitivity and selectivity based on interior nanofilm-coated photonic crystal fiber long-period gratings. Sens. Actuators B Chem. 2013, 176, 264–274. [Google Scholar] [CrossRef]

- Miao, Y. Agarose gel-coated LPG based on two sensing mechanisms for relative humidity measurement. Appl. Opt. 2013, 52, 90–95. [Google Scholar] [CrossRef]

- Cheng, Y. Optical coatings on fiber for relative-humidity sensing applications. Chin. Opt. Lett. 2013, 11, S10404. [Google Scholar]

- Churenkov, A.V. Resonant micromechanical fiber optic sensor of relative humidity. Measurement 2014, 55, 33–38. [Google Scholar] [CrossRef]

- Batumalay, M.; Harun, S.W.; Ahmad, F.; Nor, R.M.; Zulkepely, N.R.; Ahmad, H. Study of a fiber optic humidity sensor based on agarose gel. J. Mod. Opt. 2014, 61, 244–248. [Google Scholar] [CrossRef]

- López-Higuera, J.M.; Jones, J.D.C.; López-Amo, M.; Santos, J.L.; Ni, H.; Wang, M.; Chen, W. Relative humidity optical fiber sensors. In Proceedings of the 23rd International Conference on Optical Fibre Sensors, Santander, Spain, 2–6 June 2014. [Google Scholar]

- Verma, N.; Singh, S.; Srivastava, R.; Yadav, B.C. Fabrication of iron titanium oxide thin film and its application as opto-electronic humidity and liquefied petroleum gas sensors. Opt. Laser Technol. 2014, 57, 181–188. [Google Scholar] [CrossRef]

- Korenko, B.; Rothhardt, M.; Hartung, A.; Bartelt, H. Novel Fiber-Optic Relative Humidity Sensor with Thermal Compensation. IEEE Sens. J. 2015, 15, 5450–5454. [Google Scholar] [CrossRef]

- Huang, C.; Xie, W.; Yang, M.; Dai, J.; Zhang, B. Optical Fiber Fabry–Perot Humidity Sensor Based on Porous Al2O3 Film. IEEE Photonics Technol. Lett. 2015, 27, 2127–2130. [Google Scholar] [CrossRef]

- Harith, Z.; Irawati, N.; Batumalay, M.; Rafaie, H.A.; Harun, S.W.; Nor, R.M.; Ahmad, H. Relative Humidity Sensor Employing Optical Fibers Coated with ZnO Nanostructures. Indian J. Sci. Technol. 2015, 8, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.F.; Zhang, Y. Humidity sensor based on optical fiber attached with hydrogel spheres. Opt. Laser Technol. 2015, 74, 16–19. [Google Scholar] [CrossRef]

- Swanson, A.J.; Raymond, S.G.; Janssens, S.; Breukers, R.D.; Bhuiyan, M.D.H.; Lovell-Smith, J.W.; Waterland, M.R. Development of novel polymer coating for FBG based relative humidity sensing. Sens. Actuators A Phys. 2016, 249, 217–224. [Google Scholar] [CrossRef]

- Urrutia, A.; Goicoechea, J.; Ricchiuti, A.L.; Barrera, D.; Sales, S.; Arregui, F.J. Simultaneous measurement of humidity and temperature based on a partially coated optical fiber long period grating. Sens. Actuators B Chem. 2016, 227, 135–141. [Google Scholar] [CrossRef] [Green Version]

- Lokman, A.; Arof, H.; Harun, S.W.; Harith, Z.; Rafaie, H.A.; Nor, R.M. Optical Fiber Relative Humidity Sensor Based on Inline Mach–Zehnder Interferometer with ZnO Nanowires Coating. IEEE Sens. J. 2016, 16, 312–316. [Google Scholar] [CrossRef]

- Woyessa, G.; Nielsen, K.; Stefani, A.; Markos, C.; Bang, O. Temperature insensitive hysteresis free highly sensitive polymer optical fiber Bragg grating humidity sensor. Opt. Express 2016, 24, 1206–1213. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, H.; Hussin, N.; Ahmad, F.; Ambran, S.; Harun, S.W. Optical based relative humidity sensor using tapered optical fiber coated with graphene oxide. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2016. [Google Scholar]

- Ascorbe, J.; Corres, J.M.; Matias, I.R.; Arregui, F.J. High sensitivity humidity sensor based on cladding-etched optical fiber and lossy mode resonances. Sens. Actuators B Chem. 2016, 233, 7–16. [Google Scholar] [CrossRef] [Green Version]

- Shin, J.C.; Yoon, M.-S.; Han, Y.-G. Relative Humidity Sensor Based on an Optical Microfiber Knot Resonator With a Polyvinyl Alcohol Overlay. J. Lightwave Technol. 2016, 34, 4511–4515. [Google Scholar] [CrossRef]

- Shili, L. Optical Fiber Humidity Sensor Based On PVA-Coated M-Z Interferometer. In Proceedings of the 15th International Conference on Optical Communications and Networks (ICOCN), Hangzhou, China, 24–27 September 2016. [Google Scholar]

- Ghadiry, M.; Gholami, M.; Lai, C.K.; Ahmad, H.; Chong, W.Y. Ultra-Sensitive Humidity Sensor Based on Optical Properties of Graphene Oxide and Nano-Anatase TiO2. PLoS ONE 2016, 11, e0153949. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Shen, C.; Lou, W.; Shentu, F. Fiber optic humidity sensor based on the graphene oxide/PVA composite film. Opt. Commun. 2016, 372, 229–234. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, C.; Lou, W.; Shentu, F.; Zhong, C.; Dong, X.; Tong, L. Fiber optic relative humidity sensor based on the tilted fiber Bragg grating coated with graphene oxide. Appl. Phys. Lett. 2016, 109, 031107. [Google Scholar] [CrossRef]

- Luo, Y.; Chen, C.; Xia, K.; Peng, S.; Guan, H.; Tang, J.; Lu, H.; Yu, J.; Zhang, J.; Xiao, Y.; et al. Tungsten disulfide (WS2) based all-fiber-optic humidity sensor. Opt. Express 2016, 24, 8956–8966. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.Y.; Wu, X.; Kang, Y.Q.; Yu, L.; Monro, T.M.; Lancaster, D.G.; Liu, X.; Xu, H. Ultra-fast Hygrometer based on U-shaped Optical Microfiber with Nanoporous Polyelectrolyte Coating. Sci. Rep. 2017, 7, 7943. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, B.-K.; Tan, C.-H. A Simple Relative Humidity Sensor Employing Optical Fiber Coated with Lithium Chloride. Phys. Sci. Int. J. 2017, 16, 1–6. [Google Scholar] [CrossRef]

- Massaroni, C.; Caponero, M.A.; D’Amato, R.; Lo Presti, D.; Schena, E. Fiber Bragg Grating Measuring System for Simultaneous Monitoring of Temperature and Humidity in Mechanical Ventilation. Sensors 2017, 17, 749. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, H.; Irawati, N.; Ahmad, F.; Haniff Ibrahim, M.; Ambran, S.; Azizi Abdul Rahman, M.; Wadi Harun, S. Optical Humidity Sensor Based on Tapered Fiber with Multi-walled Carbon Nanotubes Slurry. Indones. J. Electr. Eng. Comput. Sci. 2017, 6, 97–103. [Google Scholar] [CrossRef]

- Limodehi, H.E.; Legare, F. Fiber optic humidity sensor using water vapor condensation. Opt. Express 2017, 25, 15313–15321. [Google Scholar] [CrossRef]

- Shi, J.; Xu, D.; Xu, W.; Wang, Y.; Yan, C.; Zhang, C.; Yan, D.; He, Y.; Tang, L.; Zhang, W.; et al. Humidity Sensor Based on Fabry–Perot Interferometer and Intracavity Sensing of Fiber Laser. J. Lightwave Technol. 2017, 35, 4789–4795. [Google Scholar] [CrossRef]

- Chung, Y.; Jin, W.; Lee, B.; Canning, J.; Nakamura, K.; Yuan, L.; Dissanayake, K.P.W.; Wu, W.; Nguyen, H.; Sun, T.; et al. Graphene oxide coated long period grating based fibre optic humidity sensor. In Proceedings of the 25th International Conference on Optical Fiber Sensors, Jeju Island, Korea, 24–28 April 2017. [Google Scholar]

- Woyessa, G.; Pedersen, J.K.; Fasano, A.; Nielsen, K.; Markos, C.; Rasmussen, H.K.; Bang, O. Zeonex-PMMA microstructured polymer optical FBGs for simultaneous humidity and temperature sensing. Opt. Lett. 2017, 42, 1161–1164. [Google Scholar] [CrossRef]

- Szendrei, K.; Jiménez-Solano, A.; Lozano, G.; Lotsch, B.V.; Míguez, H. Fluorescent Humidity Sensors Based on Photonic Resonators. Adv. Opt. Mater. 2017, 5, 1700663. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Sun, T.; Peng, J.; Dai, J.; Yang, M. Humidity Sensor Based on Fiber BraggGratingCoated With DifferentPore-FoamingAgentDopedPolyimides. IEEE Photonics Technol. Lett. 2017, 29, 1963–1966. [Google Scholar] [CrossRef]

- Chiu, Y.D.; Wu, C.W.; Chiang, C.C. Tilted Fiber Bragg Grating Sensor with Graphene Oxide Coating for Humidity Sensing. Sensors 2017, 17, 2129. [Google Scholar] [CrossRef] [PubMed]

- Harith, Z.; Batumalay, M.; Irawati, N.; Harun, S.W.; Arof, H.; Ahmad, H. Relative humidity sensor employing tapered plastic optical fiber coated with seeded Al-doped ZnO. Optik 2017, 144, 257–262. [Google Scholar] [CrossRef]

- Wang, Z. Optical Fiber Humidity Sensor Based On Cascaded Peanut-Shape Structure. In Proceedings of the 2017 16th International Conference on Optical Communications and Networks (ICOCN), Wuzhen, China, 7–10 August 2017. [Google Scholar]

- Ma, Q.F.; Tou, Z.Q.; Ni, K.; Lim, Y.Y.; Lin, Y.F.; Wang, Y.R.; Zhou, M.H.; Shi, F.F.; Niu, L.; Dong, X.Y.; et al. Carbon-nanotube/Polyvinyl alcohol coated thin core fiber sensor for humidity measurement. Sens. Actuators B Chem. 2018, 257, 800–806. [Google Scholar] [CrossRef]

- Wang, B.; Tian, J.; Hu, L.; Yao, Y. High Sensitivity Humidity Fiber-Optic Sensor Based on All-Agar Fabry–Perot Interferometer. IEEE Sens. J. 2018, 18, 4879–4885. [Google Scholar] [CrossRef]

- Gu, B.; Aung, C.Y.; Chong, P.H.J.; Guan, Y.L.; Yong, K.-T. Reversible and Fast Responsive Optical Fiber Relative Humidity Sensor Based on Polyelectrolyte Self-Assembly Multilayer Film. IEEE Sens. J. 2018, 18, 1081–1086. [Google Scholar] [CrossRef]

- Bian, C.; Hu, M.; Wang, R.; Gang, T.; Tong, R.; Zhang, L.; Guo, T.; Liu, X.; Qiao, X. Optical fiber humidity sensor based on the direct response of the polyimide film. Appl. Opt. 2018, 57, 356–361. [Google Scholar] [CrossRef]

- Li, C.; Yu, X.; Zhou, W.; Cui, Y.; Liu, J.; Fan, S. Ultrafast miniature fiber-tip Fabry-Perot humidity sensor with thin graphene oxide diaphragm. Opt. Lett. 2018, 43, 4719–4722. [Google Scholar] [CrossRef]

- Limodehi, H.E.; Mozafari, M.; Amiri, H.; Légaré, F. Multi-channel fiber optic dew and humidity sensor. Opt. Fiber Technol. 2018, 41, 89–94. [Google Scholar] [CrossRef]

- Chai, J.; Liu, Q.; Liu, J.; Zhang, D. Optical fiber sensors based on novel polyimide for humidity monitoring of building materials. Opt. Fiber Technol. 2018, 41, 40–47. [Google Scholar] [CrossRef]

- Dissanayake, K.P.W.; Wu, W.; Nguyen, H.; Sun, T.; Grattan, K.T.V. Graphene-Oxide-Coated Long-Period Grating-Based Fiber Optic Sensor for Relative Humidity and External Refractive Index. J. Lightwave Technol. 2018, 36, 1145–1151. [Google Scholar] [CrossRef]

- Liang, L.; Li, M.; Liu, N.; Sun, H.; Rong, Q.; Hu, M. A high-sensitivity optical fiber relative humidity sensor based on microsphere WGM resonator. Opt. Fiber Technol. 2018, 45, 415–418. [Google Scholar] [CrossRef]

- Jagtap, S.; Rane, S.; Arbuj, S.; Rane, S.; Gosavi, S. Optical fiber based humidity sensor using Ag decorated ZnO nanorods. Microelectron. Eng. 2018, 187–188, 1–5. [Google Scholar] [CrossRef]

- Yuan, T.; Qi, X.; Liu, Z.; Yang, J.; Guan, C.; Long, Q.; Cao, J.; Luo, M.; Yang, X.; Yuan, L. Humidity sensor based on micro optical fiber array fabricated by electrospinning. Opt. Commun. 2018, 427, 517–521. [Google Scholar] [CrossRef]

- Mahapure, P.D.; Gangal, S.A.; Aiyer, R.C.; Gosavi, S.W. Combination of polymeric substrates and metal-polymer nanocomposites for optical humidity sensors. J. Appl. Polym. Sci. 2019, 136, 47035. [Google Scholar] [CrossRef]

- Zhao, Y.; Yuan, Y.; Gan, W.; Yang, M. Optical fiber Fabry–Perot humidity sensor based on polyimide membrane: Sensitivity and adsorption kinetics. Sens. Actuators A Phys. 2018, 281, 48–54. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, Y.; Cao, S.Q.; Huang, Y.J.; Zhang, L.F.; Zhang, F.; Liao, C.R.; Wang, Y.P. Mechanism and Characteristics of Humidity Sensing with Polyvinyl Alcohol-Coated Fiber Surface Plasmon Resonance Sensor. Sensors 2018, 18, 9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, G.Y.; Wu, X.; Codemard, C.A.; Yu, L.; Liu, X.; Xu, H.; Monro, T.M.; Lancaster, D.G. Optical hygrometer using light-sheet skew-ray probed multimode fiber with polyelectrolyte coating. Sens. Actuators B Chem. 2019, 296, 126685. [Google Scholar] [CrossRef]

- Le, A.D.D.; Hwang, J.; Yusuf, M.; Park, K.H.; Park, S.; Kim, J. Simultaneous Measurement of Humidity and Temperature with Cytop-reduced Graphene Oxide-overlaid Two-mode Optical Fiber Sensor. Sens. Actuators B Chem. 2019, 298, 126841. [Google Scholar] [CrossRef]

- Vaz, A.; Barroca, N.; Ribeiro, M.; Pereira, A.; Frazao, O. Optical Fiber Humidity Sensor Based on Polyvinylidene Fluoride Fabry–Perot. IEEE Photonics Technol. Lett. 2019, 31, 549–552. [Google Scholar] [CrossRef]

- Tan, C.; Huang, X.; Lei, H.; Zhang, L.; Chen, J.; Meng, H. A new optical fiber dew point humidity sensor based on the virtual instrument. Rev. Sci. Instrum. 2019, 90, 015115. [Google Scholar] [CrossRef] [PubMed]

- Maciak, E. Low-Coherence Interferometric Fiber Optic Sensor for Humidity Monitoring Based on Nafion((R)) Thin Film. Sensors 2019, 19, 629. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, J.; Sun, H.; Hong, D.; Li, L.; Yang, Y.; Yong, X.; Zhang, C.; Cui, J. An optical fiber relative humidity sensor based on hollow-core fiber and hydroxypropyl methylcellulose hydrogel film. Optik 2019, 195, 163172. [Google Scholar] [CrossRef]

- Xu, K.; Li, H.; Liu, Y.; Wang, Y.; Tian, J.; Wang, L.; Du, J.; He, Z.; Song, Q. Optical Fiber Humidity Sensor Based on Water Absorption Peak Near 2-μm Waveband. IEEE Photonics J. 2019, 11, 1–8. [Google Scholar] [CrossRef]

- Dehghani Sanij, M.; Bahrampour, A.; Bahrampour, A.R. Resonant Light Scattering Toward Optical Fiber Humidity Sensors. Photonic Sens. 2019, 9, 60–68. [Google Scholar] [CrossRef] [Green Version]

- Hernaez, M.; Acevedo, B.; Mayes, A.G.; Melendi-Espina, S. High-performance optical fiber humidity sensor based on lossy mode resonance using a nanostructured polyethylenimine and graphene oxide coating. Sens. Actuators B Chem. 2019, 286, 408–414. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Xue, S.; Liu, L.; Li, Z.; Wang, H.; Tan, C.; Yang, J.; Hu, X.; Jiang, X.-F.; Cheng, Y.; et al. A highly stable optical humidity sensor. Sens. Actuators B Chem. 2019, 287, 329–337. [Google Scholar] [CrossRef]

- Arrizabalaga, O.; Velasco, J.; Zubia, J.; Sáez de Ocáriz, I.; Villatoro, J. Miniature interferometric humidity sensor based on an off-center polymer cap onto optical fiber facet. Sens. Actuators B Chem. 2019, 297, 126700. [Google Scholar] [CrossRef]

- Chu, R.; Guan, C.; Bo, Y.; Shi, J.; Zhu, Z.; Li, P.; Yang, J.; Yuan, L. All-optical graphene-oxide humidity sensor based on a side-polished symmetrical twin-core fiber Michelson interferometer. Sens. Actuators B Chem. 2019, 284, 623–627. [Google Scholar] [CrossRef]

- Syuhada, A.; Shamsudin, M.S.; Daud, S.; Krishnan, G.; Harun, S.W.; Abd Aziz, M.S. Single-Mode Modified Tapered Fiber Structure Functionalized With GO-PVA Composite Layer for Relative Humidity Sensing. Photonic Sens. 2019, 11, 314–324. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Prado, A.; Frizera, A.; Pontes, M.J. Smartphone Integrated Polymer Optical Fiber Humidity Sensor: Towards a Fully Portable Solution for Healthcare. IEEE Sens. Lett. 2019, 3, 1–4. [Google Scholar] [CrossRef]

- Resen, D.A. A New Technique to Sense Humidity Based on Optical Heterodyne detection. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 042029. [Google Scholar] [CrossRef]

- Procek, M.; Opilski, Z.; Márquez Maqueda, A.; Muñoz Berbel, X.; Aznar-Cervantes, S.D.; Luis Cenis, J.; Domínguez Horna, C.; Struk, P.; Pustelny, T. Silk fibroin thin films for optical humidity sensing. In Proceedings of the 14th Conference on Integrated Optics: Sensors, Sensing Structures, and Methods, Szcyrk-Gliwice, Poland, 13 September 2019. [Google Scholar]

- Squillaci, M.A.; Zhong, X.; Peyruchat, L.; Genet, C.; Ebbesen, T.W.; Samori, P. 2D hybrid networks of gold nanoparticles: Mechanoresponsive optical humidity sensors. Nanoscale 2019, 11, 19315–19318. [Google Scholar] [CrossRef] [Green Version]

- Johari, M.A.M.; Pour, M.P.; Al Noman, A.; Khudus, M.I.M.A.; Jali, M.H.B.; Maslinda, M.S.; Ali, U.U.M.; Harun, S.W. Effect of PMMA and PVA coating on the performance of optical microbottle resonator humidity sensors. Microw. Opt. Technol. Lett. 2019, 62, 993–998. [Google Scholar] [CrossRef]

- Sidhu, N.K.; Sohi, P.A.; Kahrizi, M. Polymer based optical humidity and temperature sensor. J. Mater. Sci. Mater. Electron. 2019, 30, 3069–3077. [Google Scholar] [CrossRef]

- Zakaria, R.; Zainuddin, N.A.M.; Leong, T.C.; Rosli, R.; Rusdi, M.F.; Harun, S.W.; Sadegh Amiri, I. Investigation of Surface Plasmon Resonance (SPR) in MoS2- and WS2-Protected Titanium Side-Polished Optical Fiber as a Humidity Sensor. Micromachines 2019, 10, 465. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Novais, S.; Ferreira, M.S.; Pinto, J.L.; Lieberman, R.A.; Baldini, F.; Homola, J. Humidity sensor based on optical fiber coated with agarose gel. In Optical Sensors 2019; SPIE: Prague, Czech Republic, 2019. [Google Scholar]

- Liu, Y.; Li, P.; Zhang, N.; Zhang, X.; Chen, S.; Liu, Z.; Guang, J.; Peng, W. Fiber-optic evanescent field humidity sensor based on a micro-capillary coated with graphene oxide. Opt. Mater. Express 2019, 9, 4418–4428. [Google Scholar] [CrossRef]

- Shrivastav, A.M.; Gunawardena, D.S.; Liu, Z.Y.; Tam, H.Y. Microstructured optical fiber based Fabry-Perot interferometer as a humidity sensor utilizing chitosan polymeric matrix for breath monitoring. Sci. Rep. 2020, 10, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Kaur, B.; Popescu, V.A. On the role of different 2D materials/heterostructures in fiber-optic SPR humidity sensor in visible spectral region. Opt. Mater. 2020, 102, 109824. [Google Scholar] [CrossRef]

- Bian, C.; Cheng, Y.; Zhu, W.; Tong, R.; Hu, M.; Gang, T. A Novel Optical Fiber Mach–Zehnder Interferometer Based on the Calcium Alginate Hydrogel Film for Humidity Sensing. IEEE Sens. J. 2020, 20, 5759–5765. [Google Scholar] [CrossRef]

- Bian, C.; Wang, J.; Bai, X.; Hu, M.; Gang, T. Optical fiber based on humidity sensor with improved sensitivity for monitoring applications. Opt. Laser Technol. 2020, 130, 106342. [Google Scholar] [CrossRef]

- Dominguez-Flores, C.E.; Rodriguez-Quiroz, O.; Monzon-Hernandez, D.; Ascorbe, J.; Corres, J.M.; Arregui, F.J. Dual-Cavity Fiber Fabry-Perot Interferometer Coated With SnO2 for Relative Humidity and Temperature Sensing. IEEE Sens. J. 2020, 20, 14195–14201. [Google Scholar] [CrossRef]

- Zhang, E.; Lu, D.; Zhang, S.; Gui, X.; Guan, H.; Zhang, Z.; Lin, Y.; Ming, J.; Hong, J.; Dong, J.; et al. High-sensitivity fiber-optic humidity sensor based on microfiber overlaid with niobium disulfide. J. Mater. Sci. 2020, 55, 16576–16587. [Google Scholar] [CrossRef]

- Hamza, F.H.; Mohammed, A.Z.; Mahdi, B.R. Construction of optical fiber humidity sensor by laser technique. AIP Conf.Proc. 2020, 2213, 020305. [Google Scholar]

- Wen, H.-Y.; Liu, Y.-C.; Chiang, C.-C. The use of doped conductive bionic muscle nanofibers in a tennis racket–shaped optical fiber humidity sensor. Sens. Actuators B Chem. 2020, 320, 128340. [Google Scholar] [CrossRef]

- Shihang, H. Optical Fiber Humidity Sensor Based on Graphene Oxide. Acad. J. Eng. Technol. Sci. 2020, 3, 19–27. [Google Scholar]

- Kim, H.J.; Shin, H.Y.; Pyeon, C.H.; Kim, S.; Lee, B. Fiber-optic humidity sensor system for the monitoring and detection of coolant leakage in nuclear power plants. Nucl. Eng. Technol. 2020, 52, 1689–1696. [Google Scholar] [CrossRef]

- Yu, H.S.; Yu, N.C.; Rim, J.A.; Jo, M.J. Widely sensitive optical humidity module by using acrylic resin and a position sensitivity detector. Opt. Quantum Electron. 2020, 52, 1–11. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Sun, H.; Yang, Y.; Ye, Y.; Cui, J.; He, W.; Yong, X.; Xie, Y. An optical fiber sensor based on carboxymethyl cellulose/carbon nanotubes composite film for simultaneous measurement of relative humidity and temperature. Opt. Commun. 2020, 467, 125740. [Google Scholar] [CrossRef]

- Li, J.-X.; Tong, Z.-R.; Zhao, X.-D.; Zhang, W.-H.; Qin, J. Simultaneous measurement of temperature and humidity based on spherical structure optical fiber interferometer. Optoelectron. Lett. 2020, 16, 256–261. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, J.; Li, Z.; Hou, M.; Dong, G.; Liu, T.; Sun, T.; Grattan, K.T.V. Quasi-Distributed Fiber Optic Temperature and Humidity Sensor System for Monitoring of Grain Storage in Granaries. IEEE Sens. J. 2020, 20, 9226–9233. [Google Scholar] [CrossRef]

- Hsieh, M.-C.; Liao, C.-H.; Lin, J.-Y. Optical relative humidity sensor based on a polyvinyl alcohol film and a phase-enhancement total-internal-reflection heterodyne interferometer. Sens. Actuators A Phys. 2020, 316, 112412. [Google Scholar] [CrossRef]

- Lokman, M.Q.; Burhanuddin, H.M.; Riza, M.A.; Rosli, N.N.; Hashim, N.H.; Sepeai, S.; Ludin, N.A.; Teridi, M.A.M.; Ahmad, F.; Ibrahim, M.A. Humidity sensing of thin film perovskite nanostructure for improved sensitivity and optical performance. J. Mater. Res. Technol. 2020, 9, 13274–13281. [Google Scholar] [CrossRef]

- Zhong, N.; Xin, X.; Liu, H.; Yu, X.; Chang, H.; Tang, B.; Zhong, D.; Zhao, M.; Zhang, H.; Zhao, J. Plastic optical fiber sensor for temperature-independent high-sensitivity detection of humidity. Appl. Opt. 2020, 59, 5708–5713. [Google Scholar] [CrossRef] [PubMed]

- Siddiq, N.A.; Chong, W.Y.; Pramono, Y.H.; Muntini, M.S.; Asnawi, A.; Ahmad, H. All-Optical Humidity Sensor Using SnO2 Nanoparticle Drop Coated on Straight Channel Optical Waveguide. Photonic Sens. 2020, 10, 123–133. [Google Scholar] [CrossRef] [Green Version]

- Di Palma, P.; Sansone, L.; Taddei, C.; Campopiano, S.; Giordano, M.; Iadicicco, A. Relative Humidity Sensor Based on Tip of Multimode Optical Fiber Integrated with Photonic Crystal of Hydrogel Coated Polystyrene Nanoparticles. In Sensors and Microsystems; Springer: Naples, Italy, 2020; pp. 403–408. [Google Scholar]

- Liu, Z.; Zhang, M.; Zhang, Y.; Xu, Y.; Zhang, Y.; Yang, X.; Zhang, J.; Yang, J.; Yuan, L. Spider silk-based tapered optical fiber for humidity sensing based on multimode interference. Sens. Actuators A Phys. 2020, 313, 112179. [Google Scholar] [CrossRef]

- Grogan, C.; McGovern, F.R.; Staines, R.; Amarandei, G.; Naydenova, I. Cantilever-Based Sensor Utilizing a Diffractive Optical Element with High Sensitivity to Relative Humidity. Sensors 2021, 21, 1673. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Zhou, Q.; Wang, B.; Tian, J.; Yao, Y. High-sensitivity relative humidity fiber-optic sensor based on an internal-external Fabry-Perot cavity Vernier effect. Opt. Express 2021, 29, 11854–11868. [Google Scholar] [CrossRef]

- He, C.; Korposh, S.; Correia, R.; Liu, L.; Hayes-Gill, B.R.; Morgan, S.P. Optical fibre sensor for simultaneous temperature and relative humidity measurement: Towards absolute humidity evaluation. Sens. Actuators B Chem. 2021, 344, 130154. [Google Scholar] [CrossRef]

- Owji, E.; Mokhtari, H.; Ostovari, F.; Darazereshki, B.; Shakiba, N. 2D materials coated on etched optical fibers as humidity sensor. Sci. Rep. 2021, 11, 1771. [Google Scholar] [CrossRef]

- Burhanuddin, H.M. Optical Based Humidity Sensor by Using Zinc Oxide-PVA In Micro Cavity. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1051, 012026. [Google Scholar] [CrossRef]

- Wang, J.-K.; Ying, Y.; Hu, N.; Cheng, S.-Y. Double D-shaped optical fiber temperature and humidity sensor based on ethanol and polyvinyl alcohol. Optik 2021, 242, 166972. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, X.; Qian, M.; Xiang, Z.; Hu, X. An optical fiber sensor based on polyimide coated fiber Bragg grating for measurement of relative humidity. Opt. Fiber Technol. 2021, 61, 102406. [Google Scholar] [CrossRef]

- Rashed, G.I.; Zhang, J.; Xie, Y.; Zhang, Z.; Lv, L.; Tan, Z.; Kheshti, M. Research on Optical Fiber Sensor for Environmental Temperature and Humidity of Transmission Line. E3S Web Conf. 2021, 252, 02014. [Google Scholar] [CrossRef]

- Lazarova, K.; Bozhilova, S.; Ivanova, S.; Christova, D.; Babeva, T. Flexible and Transparent Polymer-Based Optical Humidity Sensor. Sensors 2021, 21, 3674. [Google Scholar] [CrossRef]

- Chen, M.-Q.; Zhao, Y.; Wei, H.-M.; Zhu, C.-L.; Krishnaswamy, S. 3D printed castle style Fabry-Perot microcavity on optical fiber tip as a highly sensitive humidity sensor. Sens. Actuators B Chem. 2021, 328, 128981. [Google Scholar] [CrossRef]

- Wang, N.; Tian, W.; Zhang, H.; Yu, X.; Yin, X.; Du, Y.; Li, D. An Easily Fabricated High Performance Fabry-Perot Optical Fiber Humidity Sensor Filled with Graphene Quantum Dots. Sensors 2021, 21, 806. [Google Scholar] [CrossRef]

- Al-Hayali, S.K.; Salman, A.M.; Al-Janabi, A.H. High sensitivity balloon-like interferometric optical fiber humidity sensor based on tuning gold nanoparticles coating thickness. Measurement 2021, 170, 108703. [Google Scholar] [CrossRef]

- Largani, S.R.H.; Wen, H.-Y.; Liu, Y.-C.; Chiang, C.-C. Humidity and temperature sensing by monitoring changeable length and diameter of bent fiber optics attached to Faraday mirror reflector. Opt. Fiber Technol. 2021, 65, 102633. [Google Scholar] [CrossRef]

- Cheng, X.; Hu, J.; Zhu, K.; Zhao, Z. High-resolution polymer optical fibre humidity sensor utilizing single-passband microwave photonic filter. Measurement 2021, 179, 109462. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Shao, Y.; Liao, C.; Wang, Y. Highly Sensitive Surface Plasmon Resonance Humidity Sensor Based on a Polyvinyl-Alcohol-Coated Polymer Optical Fiber. Biosensors 2021, 11, 461. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Lai, M.; Zhao, Z.; Yang, Y.; Li, J.; Song, H.; He, J.; Ma, Y.; Liu, B. Fiber optic evanescent wave humidity sensor based on SiO2/TiO2 bilayer films. Appl. Opt. 2021, 60, 2158–2165. [Google Scholar] [CrossRef]

- Ying, Y.; Cheng, S.; Hu, N.; Gao, Z.; Guo, X.; Si, G. Temperature and humidity sensor based on a double D-shaped optical fiber with incorporated toluene and polyethylene. Instrum. Sci. Technol. 2021, 49, 404–415. [Google Scholar] [CrossRef]

- Mogera, U.; Sagade, A.A.; George, S.J.; Kulkarni, G.U. Ultrafast response humidity sensor using supramolecular nanofibre and its application in monitoring breath humidity and flow. Sci. Rep. 2014, 4, 4103. [Google Scholar] [CrossRef] [Green Version]

- Borini, S.; White, R.; Wei, D.; Astley, M.; Haque, S.; Spigone, E.; Harris, N.; Kivioja, J.; Ryhanen, T. Ultrafast Graphene Oxide Humidity Sensors. ACS Nano 2013, 7, 11166–11173. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Tang, W.; Shen, C.; Wang, X. High sensitivity and fast response graphene oxide capacitive humidity sensor with computer-aided design. Comput. Mater. Sci. 2016, 111, 289–293. [Google Scholar] [CrossRef]

- Smith, A.D.; Elgammal, K.; Niklaus, F.; Delin, A.; Fischer, A.C.; Vaziri, S.; Forsberg, F.; Rasander, M.; Hugosson, H.; Bergqvist, L.; et al. Resistive graphene humidity sensors with rapid and direct electrical readout. Nanoscale 2015, 7, 19099–19109. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Tong, J.; Xia, B.; Xue, Q. Ultrahigh performance humidity sensor based on layer-by-layer self-assembly of graphene oxide/polyelectrolyte nanocomposite film. Sens. Actuators B Chem. 2014, 203, 263–270. [Google Scholar] [CrossRef]

- Le, X.; Wang, X.; Pang, J.; Liu, Y.; Fang, B.; Xu, Z.; Gao, C.; Xu, Y.; Xie, J. A high performance humidity sensor based on surface acoustic wave and graphene oxide on AlN/Si layered structure. Sens. Actuators B Chem. 2018, 255, 2454–2461. [Google Scholar] [CrossRef]

- Bi, H.; Yin, K.; Xie, X.; Ji, J.; Wan, S.; Sun, L.; Terrones, M.; Dresselhaus, M.S. Ultrahigh humidity sensitivity of graphene oxide. Sci. Rep. 2013, 3, 2714. [Google Scholar] [CrossRef] [Green Version]

- Rahim, I.; Shah, M.; Khan, A.; Luo, J.; Zhong, A.; Li, M.; Ahmed, R.; Li, H.; Wei, Q.; Fu, Y. Capacitive and resistive response of humidity sensors based on graphene decorated by PMMA and silver nanoparticles. Sens. Actuators B Chem. 2018, 267, 42–50. [Google Scholar] [CrossRef]

- Zheng, Z.; Yao, Y.; Sun, Y.; Yeow, J.T.W. Development of a highly sensitive humidity sensor based on the capacitive micromachined ultrasonic transducer. Sens. Actuators B Chem. 2019, 286, 39–45. [Google Scholar] [CrossRef]

- Yang, H.; Ye, Q.; Zeng, R.; Zhang, J.; Yue, L.; Xu, M.; Qiu, Z.J.; Wu, D. Stable and Fast-Response Capacitive Humidity Sensors Based on a ZnO Nanopowder/PVP-RGO Multilayer. Sensors 2017, 17, 2415. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Chen, X.; Guo, H.; Wu, Z.; Li, X. Humidity sensing behaviors of graphene oxide-silicon bi-layer flexible structure. Sens. Actuators B Chem. 2012, 161, 1053–1058. [Google Scholar] [CrossRef]

- Qiang, T.; Wang, C.; Liu, M.-Q.; Adhikari, K.K.; Liang, J.-G.; Wang, L.; Li, Y.; Wu, Y.-M.; Yang, G.-H.; Meng, F.-Y.; et al. High-Performance porous MIM-type capacitive humidity sensor realized via inductive coupled plasma and reactive-Ion etching. Sens. Actuators B Chem. 2018, 258, 704–714. [Google Scholar] [CrossRef]

- Sun, N.; Ye, Z.; Kuang, X.L.; Liu, W.J.; Li, G.F.; Bai, W.; Tang, X.D. High sensitivity capacitive humidity sensors based on Zn1-xNixO nanostructures and plausible sensing mechanism. J. Mater. Sci. Mater. Electron. 2019, 30, 1724–1738. [Google Scholar] [CrossRef]

- Burman, D.; Santra, S.; Pramanik, P.; Guha, P.K. Pt decorated MoS2 nanoflakes for ultrasensitive resistive humidity sensor. Nanotechnology 2018, 29, 115504. [Google Scholar] [CrossRef]

- Feng, J.; Kang, X.; Zuo, Q.; Yuan, C.; Wang, W.; Zhao, Y.; Zhu, L.; Lu, H.; Chen, J. Fabrication and Evaluation of a Graphene Oxide-Based Capacitive Humidity Sensor. Sensors 2016, 16, 314. [Google Scholar] [CrossRef] [Green Version]

- Ogawa, K.; Tsuchiya, S.; Kawakami, H.; Tsutsui, T. Humidity-Sensing Effects of Optical Fibers with Microporous Sio2 Cladding. Electron. Lett. 1988, 24, 42–43. [Google Scholar] [CrossRef]

- Michie, W.C.; Culshaw, B.; McKenzie, I.; Konstantakis, M.; Graham, N.B.; Moran, C.; Santos, F.; Bergqvist, E.; Carlstrom, B. Distributed Sensor for Water and Ph Measurements Using Fiber Optics and Swellable Polymeric Systems. Opt. Lett. 1995, 20, 103–105. [Google Scholar] [CrossRef]

- Kharaz, A. A distributed optical-fiber sensing system for multi-point humidity measurment. Sens. Actuators A Phys. 1995, 46, 491–493. [Google Scholar] [CrossRef]

- Bai, W.; Yang, M.; Dai, J.; Yu, H.; Wang, G.; Qi, C. Novel polyimide coated fiber Bragg grating sensing network for relative humidity measurements. Opt. Express 2016, 24, 3230–3237. [Google Scholar] [CrossRef] [PubMed]

- Liehr, S.; Breithaupt, M.; Krebber, K. Distributed Humidity Sensing in PMMA Optical Fibers at 500 nm and 650 nm Wavelengths. Sensors 2017, 17, 738. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thomas, P.J.; Hellevang, J.O. A fully distributed fibre optic sensor for relative humidity measurements. Sens. Actuators B Chem. 2017, 247, 284–289. [Google Scholar] [CrossRef]

- Thomas, P.J.; Hellevang, J.O. A high response polyimide fiber optic sensor for distributed humidity measurements. Sens. Actuators B Chem. 2018, 270, 417–423. [Google Scholar] [CrossRef]

- Zhou, N.; Wang, P.; Shi, Z.X.; Gao, Y.X.; Yang, Y.X.; Wang, Y.P.; Xie, Y.; Cai, D.W.; Guo, X.; Zhang, L.; et al. Au nanorod-coupled microfiber optical humidity sensors. Opt. Express 2019, 27, 8180–8185. [Google Scholar] [CrossRef]

- Chen, G.Y.; Wu, X.; Schartner, E.P.; Shahnia, S.; Bourbeau Hebert, N.; Yu, L.; Liu, X.; Shahraam, A.V.; Newson, T.P.; Ebendorff-Heidepriem, H.; et al. Short-Range Non-Bending Fully Distributed Water/Humidity Sensors. J. Lightwave Technol. 2019, 37, 2014–2022. [Google Scholar] [CrossRef]

- Stajanca, P.; Hicke, K.; Krebber, K. Distributed Fiberoptic Sensor for Simultaneous Humidity and Temperature Monitoring Based on Polyimide-Coated Optical Fibers. Sensors 2019, 19, 5279. [Google Scholar] [CrossRef] [Green Version]

- Wright, R.; Badar, M.; Egbu, J.C.; Lu, P.; Buric, M.P.; Ohodnicki, P.R.; Sanders, G.A.; Lieberman, R.A.; Scheel, I.U. Fully distributed optical fiber sensor for water and humidity monitoring. In Fiber Optic Sensors and Applications XVI; SPIE: Baltimore, MD, USA, 2019. [Google Scholar]

| Paper | Limit of Detection | Response Time | Sensitivity | Dynamic Range |

|---|---|---|---|---|

| 2020, Anuj K. Sharma et al. [168] | 0.0041%RH | 171.11 dB/%RH for 99%RH | 0%RH–100%RH | |

| 2021, Xin Cheng et al. [200] | 0.0119%RH | 84 MHz/%RH between 45%RH and 95%RH range | 45%RH–95%RH | |

| 2019, Oskar Arrizabalaga et al. [155] | 0.04%RH | 148 pm/%RH between 10%RH and 95%RH | 10%RH–95%RH | |

| 2019, George Y. Chen et al. [145] | 0.099%RH or 0.007%RH | 115 ms | 0.04 dB/%RH between 10%RH–60%RH and 80%RH–94%RH, or 0.57 dB/%RH between 60%RH and 80%RH | 10%RH–94%RH |

| 2013, Jinesh Mathew et al. [86] | 0.07%RH | 75 ms | 64 pm/%RH between 25%RH and 40%RH 137 pm/%RH between 40%RH and 90%RH | 25%RH–90%RH |

| 1991, W. Lukosz et al. [23] | 0.1%RH | 100 ms | ||

| 2012, W. Zhang et al. [81] | 0.12%RH | 12 min | 33.6 pm/%RH between 30%RH and 90%RH | 30%RH–90%RH |

| 2012, Wei Chang Wong et al. [70] | 0.5%RH, 0.14%RH or 0.04%RH | 300 ms | 0.04 nm/%RH, 0.15 nm/%RH, 0.60 nm/%RH at 50%RH, 70%RH, 90%RH | 50%RH–80%RH |

| 2017, Habibah Mohamed et al. [121] | 0.177%RH | 5.17 μW/% between 45%RH and 80%RH | 45%RH–80%RH | |

| 2004, Alberto Alvarez-Herrero et al. [34] | 0.2%RH | 10 s | 460 pm/%RH between 1%RH and 15%RH | 1%RH–80%RH |

| Paper | Limit of Detection | Response Time | Sensitivity | Dynamic Range |

|---|---|---|---|---|

| 2017, George Y. Chen et al. [118] | 1.6%RH | 3 ms | 2.7%/%RH between 60%RH and 80%RH | 0%RH–100%RH |

| 2008, Fuxing Gu et al. [49] | 30 ms | 35%RH–88%RH | ||

| 2012, Jinesh Mathew et al. [72] | 50 ms | 0.1 dB/%RH between 35%RH and 75%RH | 25%RH–90%RH | |

| 2019, Miguel Hernaez et al. [153] | 50 ms | 20%RH–90%RH | ||

| 2018, Cheng Li et al. [135] | 3.1%RH 0.4%RH | 60 ms | 82 pm/%RH between 10%RH and 70%RH 630 pm/%RH between 70%RH and 90%RH | 10%RH–90%RH |

| 2008, Lei Zhang et al. [50] | 70 ms | 9%RH–94%RH | ||

| 2017, Jia Shi et al. [124] | 5%RH | 72 ms | 0.202 dB/%RH between 25%RH and 95%RH | 25%RH–95%RH |

| 2013, Jinesh Mathew et al. [87] | 0.07%RH | 75 ms | 64 pm/%RH between 25%RH and 40%RH 137 pm/%RH between 40%RH and 90%RH | 25%RH–90%RH |

| 1991, W. Lukosz et al. [23] | 0.1%RH | 100 ms | ||

| 2009, Diana Viegas et al. [55] | 100 ms | 20%RH–80%RH |

| Reference | Response Time | Sensitivity |

|---|---|---|

| 2014, U. Mogera et al. [204] | 8 ms | ~10,000 |

| 2013, Stefano Borini et al. [205] | 30 ms | |

| 2016, Rui Guo [206] | 0.4 s | 7.68 nF/%RH |

| 2015, Anderson D. Smith et al. [207] | 0.6 s | 0.31() |

| 2014, Dongzhi Zhang et al. [208] | <1 s | 1552.3 pF/%RH |

| 2018, Xianhao Le et al. [209] | 8 s | 42.08 kHz/%RH |

| 2013, Hengchang Bi et al. [210] | 10.5 s | 37800%() |

| 2018, Ishrat Rahim et al. [211] | 10 s | 154 nF/%RH |

| 2019, Zhou Zheng et al. [212] | 10 s | 2.9 kHz (22.5–43.2%RH) 11.5 kHz (43.2–93.6%RH) |

| 2017, Hui Yang et al. [213] | 12 s | 0.022() |

| 2012, Yao Yao et al. [214] | 19 s | 29 µV/%RH |

| 2018, Tian Qiang et al. [215] | 25 s | 1.24 pF/%RH |

| 2019, Ning Sun et al. [216] | 27 s | 177791.63%() |

| 2018, Debasree Burman et al. [217] | 92 s | 4000() |

| 2016, Jinfeng Feng et al. [218] | 4.2() |

| Material | Usage |

|---|---|

| Polyimide | [183,193,228] |

| Polyvinyl alcohol (PVA) | [54,115,162] |

| GO | [9,185,218] |

| Hydrogel | [150,169,185] |

| Agarose | [99,120,165] |

| Gelatin | [37,50] |

| Chitosan | [73,167,188] |

| Poly(diallyldimethylammonium) (PDDA)/poly R-478 | [222] |

| Poly(allylamine hydrochloride) (PAH) and poly(acrylic acid)(PAA) | [92] |

| Hydroxyethylcellulose (HEC)/polyvinylidenefluoride (PVDF) | [91] |

| Zinc oxide (ZnO) | [129,140,216] |

| Tin(IV) oxide (SnO2) | [93,184] |

| Titanium dioxide (TiO2) | [77] |

| Methylene blue/hydroxypropyl cellulose | [149] |

| Photonic cellulose nanocrystals | [16] |

| Poly(vinyl alcohol-co-vinyl acetal)s | [17] |

| Silica gel | [59,78] |

| Silk fibroin | [160] |

| Gold nanoparticles linked by polyethylene glycol | [198] |

| Poly methyl meth acrylate (PMMA) | [162,211,223] |

| Molybdenum disulfide (MoS2) or tungsten disulfide (WS2)-protected titanium | [164,190] |

| Calcium alginate (CaAlg) hydrogel | [169] |

| Niobium disulfide | [169] |

| Sodium silica | [82] |

| Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate in PSS (PEDOT:PSS) in polyvinyl alcohol (PVA) | [67] |

| Polyvinylidene fluoride in dimethyl sulfoxide (DMSO) and hydroxyethyl cellulose (HEC) | [147] |

| Acrylic resin | [177] |

| Carboxymethyl cellulose (CMC)/carbon nanotubes (CNTs) | [178] |

| nickel-doped zinc thin oxide (NZTO) perovskite | [56] |

| Polystyrene (PS) in poly(N-isopropylacrylamide) (PNIPAM) | [185] |

| Spider dragline silk | [186] |

| Polydimethylsiloxane (PDMS) | [187] |

| Poly(allylamine hydrochloride) (PAH)/silica (SiO2) nanoparticles | [17] |

| Graphene quantum dots | [197] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, X.; Zhao, L.; Xu, L.; Wang, Y.; Liu, K.; Wang, Y.; Chen, G.Y.; Liu, T.; Wang, Y. Review of Optical Humidity Sensors. Sensors 2021, 21, 8049. https://doi.org/10.3390/s21238049

Rao X, Zhao L, Xu L, Wang Y, Liu K, Wang Y, Chen GY, Liu T, Wang Y. Review of Optical Humidity Sensors. Sensors. 2021; 21(23):8049. https://doi.org/10.3390/s21238049

Chicago/Turabian StyleRao, Xing, Lin Zhao, Lukui Xu, Yuhang Wang, Kuan Liu, Ying Wang, George Y. Chen, Tongyu Liu, and Yiping Wang. 2021. "Review of Optical Humidity Sensors" Sensors 21, no. 23: 8049. https://doi.org/10.3390/s21238049

APA StyleRao, X., Zhao, L., Xu, L., Wang, Y., Liu, K., Wang, Y., Chen, G. Y., Liu, T., & Wang, Y. (2021). Review of Optical Humidity Sensors. Sensors, 21(23), 8049. https://doi.org/10.3390/s21238049