Fast γ Photon Imaging for Inner Surface Defects Detecting

Abstract

1. Introduction

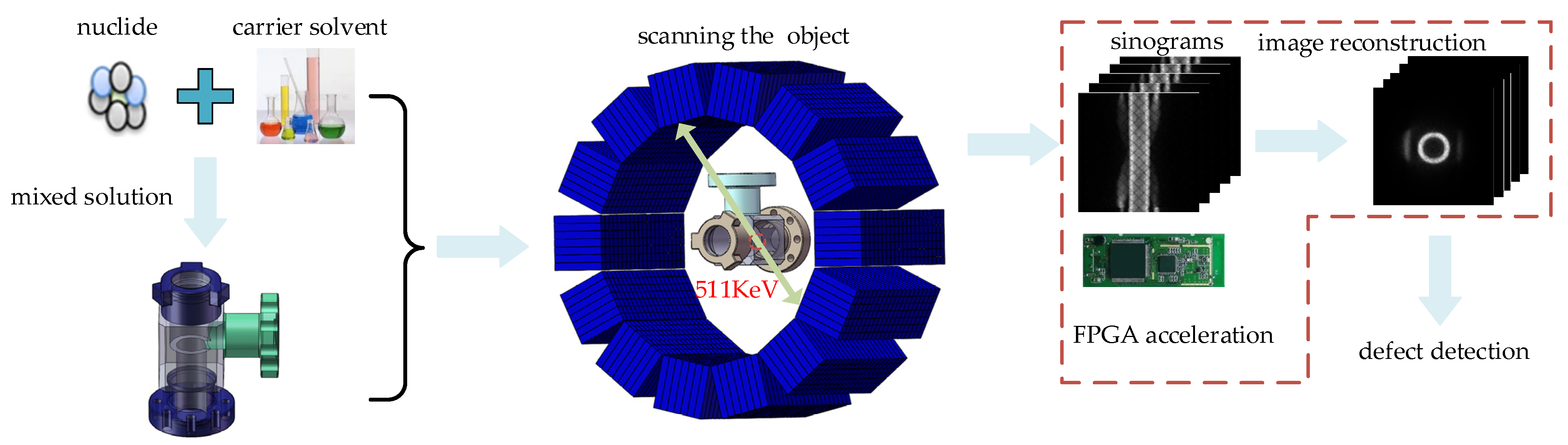

2. Tomographic Images Reconstructed in FPGA

2.1. Image Reconstruction Algorithms

2.1.1. Obtaining the Initial Image by Using FBP

2.1.2. Optimizing Image Reconstruction Algorithms of BPML

2.2. BPML Algorithms Built in FPGA

3. Implementation of Edge Detection in FPGA

4. Experiments

4.1. Preparation for Experiments

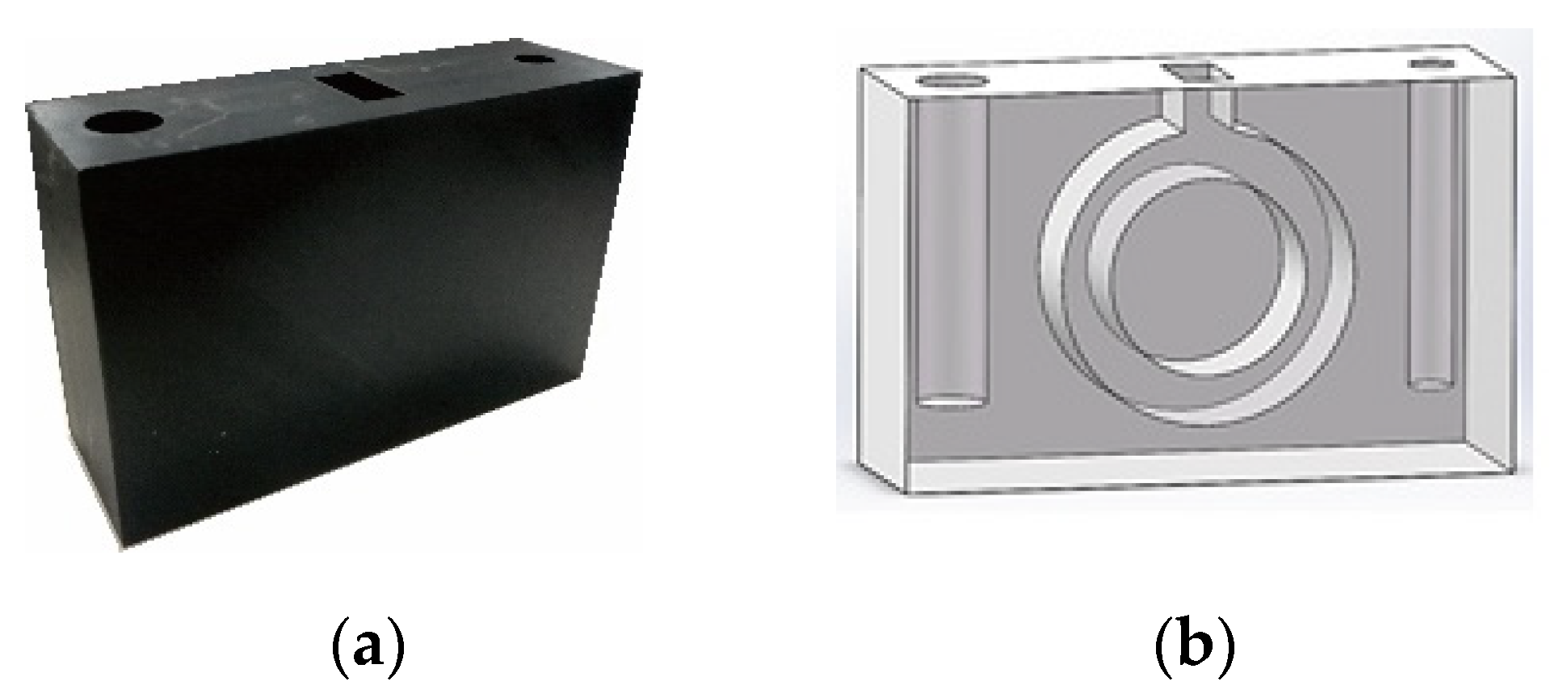

4.2. A Experiment for a Model

4.2.1. Completing the Experiment

4.2.2. Algorithm Execution Time Analysis

4.2.3. Internal Imaging Experiment of Hydraulic Parts

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Fukaya, S.; Kojima, S.; Natsume, M. Observation of CFRP Microscopic Damages by Penetrant Testing. Trans. JSME 2020, 86, 20-00191. (In Japanese) [Google Scholar] [CrossRef]

- Prem, N.; Schale, F.; Zimmermann, K.; Gowda, D.K.; Odenbach, S. Synthesis and Characterization of the Properties of Thermosensitive Elastomers with Thermoplastic and Magnetic Particles for Application in Soft Robotics. J. Appl. Polym. Sci. 2021, 138, 51296. [Google Scholar] [CrossRef]

- Machado, M.A.; Antin, K.; Rosado, L.S.; Vilaça, P.; Santos, T.G. High-speed inspection of delamination defects in unidirectional CFRP by non-contact eddy current testing. Compos. Part B Eng. 2021, 224, 109167. [Google Scholar] [CrossRef]

- Yang, X.; Jia, F.; Ren, Q. Direction of Technique Development of PET/CT. China Med. Devices 2012, 27, 51–52, 56. [Google Scholar]

- Choi, Y.; Cong, J. Acceleration of EM-Based 3D CT Reconstruction using FPGA. IEEE Trans. Biomed. Circuits Syst. 2016, 10, 754–767. [Google Scholar] [CrossRef]

- Fan, X.; Wang, H.; Yun, M.; Sun, X.; Cao, X.; Liu, S.; Chai, P.; Li, D.; Liu, B.; Wang, L.; et al. PET Image Reconstruction with a System Matrix Containing Point Spread Function Derived from Single Photon Incidence Response. Chin. Phys. B 2015, 24, 542–550. [Google Scholar] [CrossRef]

- Alkhorayef, M.; Sulieman, A.; Alsager, O.A.; Alrumayan, F.; Alkhomashi, N. Investigation of using Positronium and its Annihilation for Hypoxia PET Imaging. Radiat. Phys. Chem. 2021, 188, 109690. [Google Scholar] [CrossRef]

- de Klerk, D.N.; Govender, I.; Mainza, A.N. Geometric Features of Tumbling Mill Flows: A Positron Emission Particle Tracking Investigation. Chem. Eng. Sci. 2019, 206, 41–49. [Google Scholar] [CrossRef]

- Jiantang, L.; Min, Z.; Hui, X. A Positron Injection-Based 3D Imaging Test Method for Inner Cavities in Complex Parts. Insight 2016, 58, 617–622. [Google Scholar] [CrossRef]

- Jiang, T.; Zhao, M.; Yao, M.; Guo, R.; Sun, T.; Zhao, Z.; Xiao, H.; Li, Y. Outline Feature Extraction of Positron Image Based on a 3D Anisotropic Convolution Operator. IEEE Access 2020, 8, 150586–150598. [Google Scholar] [CrossRef]

- Langford, S.; Wiggins, C.; Tenpenny, D.; Ruggles, A. Positron Emission Particle Tracking (PEPT) for Fluid Flow Measurements. Nucl. Eng. Des. 2016, 302, 81–89. [Google Scholar] [CrossRef]

- Hao, C.; Zhao, M.; Yao, M.; Guo, R.; Zhu, M.; Hui, X. Positron Emission Tomography of Not-Full-Ring Sensors arrangement: Simulation and Verification for internal imaging of hydraulic cylinder. IEEE Access 2020, 8, 208096–208106. [Google Scholar] [CrossRef]

- Buffler, A.; Cole, K.; Leadbeater, T.W.; van Heerden, M.R. Positron Emission Particle Tracking: A Powerful Technique for Flow Studies. Int. J. Mod. Phys. Conf. Ser. 2018, 48, 1860113. [Google Scholar] [CrossRef]

- Gonzalez-Montoro, A.; Pierce, L.A.; Hunter, W.C.J.; Gonzalez, A.J.; Miyaoka, R.S. Validation of Photon Collimation Techniques for Monolithic PET Detector Calibration. IEEE Trans. Radiat. Plasma Med Sci. 2020, 5, 783–792. [Google Scholar] [CrossRef]

- Wasfy, W.; Zheng, H. General Structure Design for Fast Image Processing Algorithms Based upon FPGA DSP Slice. Phys. Procedia 2012, 33, 690–697. [Google Scholar] [CrossRef][Green Version]

- Njiki, M.; Elouardi, A.; Bouaziz, S.; Casula, O.; Roy, O. A Multi-FPGA Architecture-Based Real-Time TFM Ultrasound Imaging. J. Real-Time Image Process. 2019, 16, 505–521. [Google Scholar] [CrossRef]

- Muji, S.Z.M.; Amirulah, R.; Ambar, R.; Rahim, R.A.; Rahiman, M.H.F. Development of Image Reconstruction using FPGA. In Proceedings of the 2016 6th IEEE International Conference on Control System, Computing and Engineering (ICCSCE), Penang, Malaysia, 25–27 November 2016. [Google Scholar] [CrossRef]

- Payal, A.; Rajesh, M. High Speed CT Image Reconstruction Using FPGA. Int. J. Comput. Appl. 2011, 22, 7–10. [Google Scholar] [CrossRef]

- Wieczorek, H. The Image Quality of FBP and MLEM Reconstruction. Phys. Med. Biol. 2010, 55, 3161–3176. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Luo, S.; Yang, Z.; Wu, G. A Novel Iterative CT Reconstruction Approach Based on FBP Algorithm. PLoS ONE 2015, 10, e0138498. [Google Scholar] [CrossRef]

- Yao, M.; Lin, Q.; Zhao, M.; Guo, R. Acceleration of PET-Based Industrial Internal Defect Image Reconstruction using FPGA. AIP Adv. 2020, 10, 065104. [Google Scholar] [CrossRef]

- Yao, M.; Zhang, Y.; Zhao, M.; Guo, R.; Xu, J. Research on Combustion Flow Field Imaging Method Based on Ray Casting Algorithm. AIP Adv. 2019, 9, 055022. [Google Scholar] [CrossRef]

- Wang, B.; Liu, H. FBP-net for direct reconstruction of dynamic PET images. Phys. Med. Biol. 2020, 65, 235008. [Google Scholar] [CrossRef]

- Siddiqui, F.; Amiri, S.; Minhas, U.; Deng, T.; Woods, R.; Rafferty, K.; Crookes, D. FPGA-Based Processor Acceleration for Image Processing Applications. J. Imaging 2019, 5, 16. [Google Scholar] [CrossRef]

- Tiejun, L.; Kefan, M.; Jianmin, Z. An Parallel FPGA SAT Solver Based on Multi-Thread and Pipeline. Chin. J. Electron. 2021, 30, 1008–1016. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, W.; Wang, W.; Cao, S. Edge-detection algorithm based on multi-scale adaptive gradient. Comput. Eng. Des. 2014, 7, 16. [Google Scholar]

- Shi, G.; Wei, Q.; Meng, F. Image edge detection algorithm based on Canny operator. Mod. Electron. Tech. 2015, 38, 92–93, 97. [Google Scholar]

- Shen, D.; Hou, J.; Xu, E.; Zhang, L. Sobel-based edge detection algorithm for multi-direction template. Mod. Electron. Tech. 2015, 38, 91–93. [Google Scholar]

| Parameters | Values |

|---|---|

| detector inner diameter | 190 mm |

| axial length | 108 mm |

| spatial resolution | 0.99 mm |

| Energy resolution | 12.83% at 511 KeV |

| Time resolution | 1.53 ns |

| sensitivity | 7.12% at 350–650 KeV |

| Platform (Type, Frequency) | Consumption Time for Reconstructing 52 Slices | |||

|---|---|---|---|---|

| One Iteration | Two Iterations | Three Iterations | Four Iterations | |

| FPGA (XC7A100T, 125 MHz) | 5.37 | 10.79 | 16.12 | 22.95 |

| CPU (Core i7-4790, 3.6 GHz) | 259.38 | 362.73 | 458.75 | 561.54 |

| Acceleration ratio | 48.3× | 33.6× | 28.5× | 24.4× |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, M.; Luo, G.; Zhao, M.; Guo, R.; Liu, J. Fast γ Photon Imaging for Inner Surface Defects Detecting. Sensors 2021, 21, 8134. https://doi.org/10.3390/s21238134

Yao M, Luo G, Zhao M, Guo R, Liu J. Fast γ Photon Imaging for Inner Surface Defects Detecting. Sensors. 2021; 21(23):8134. https://doi.org/10.3390/s21238134

Chicago/Turabian StyleYao, Min, Guangdong Luo, Min Zhao, Ruipeng Guo, and Jian Liu. 2021. "Fast γ Photon Imaging for Inner Surface Defects Detecting" Sensors 21, no. 23: 8134. https://doi.org/10.3390/s21238134

APA StyleYao, M., Luo, G., Zhao, M., Guo, R., & Liu, J. (2021). Fast γ Photon Imaging for Inner Surface Defects Detecting. Sensors, 21(23), 8134. https://doi.org/10.3390/s21238134