Characterization and Improvement of Heat Resistance of a Polymer-Ceramic Pressure-Sensitive Paint at High Temperatures

Abstract

1. Introduction

2. Materials and Methods

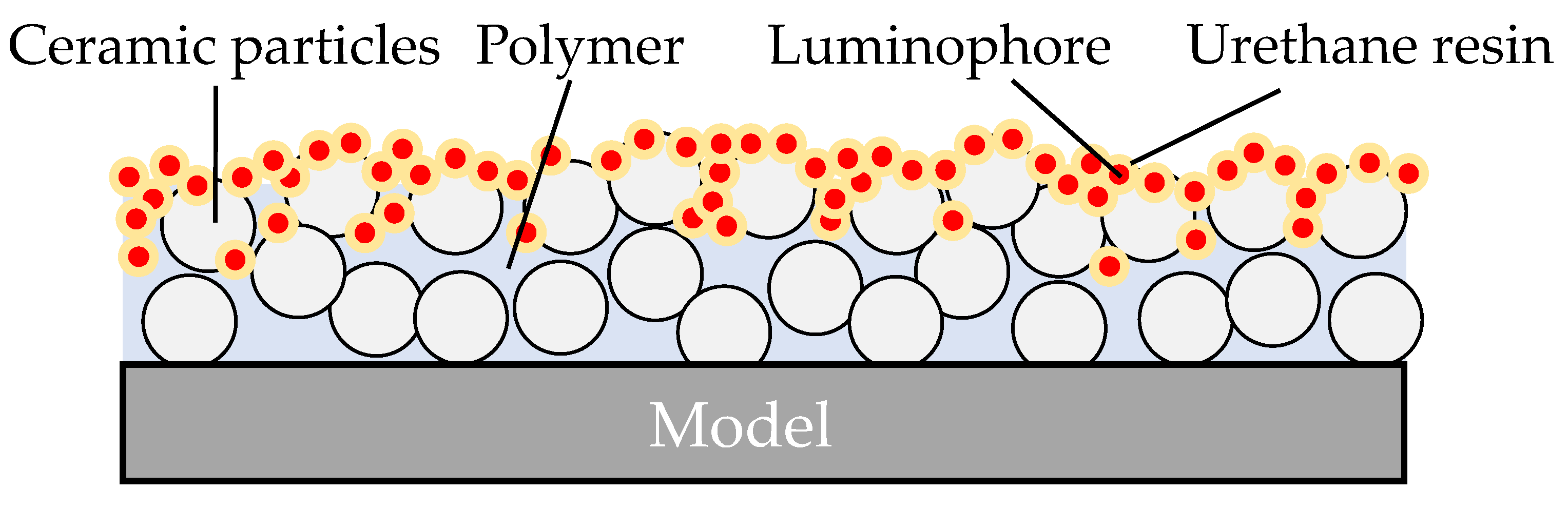

2.1. Materials and Preparation

2.2. Performance Test

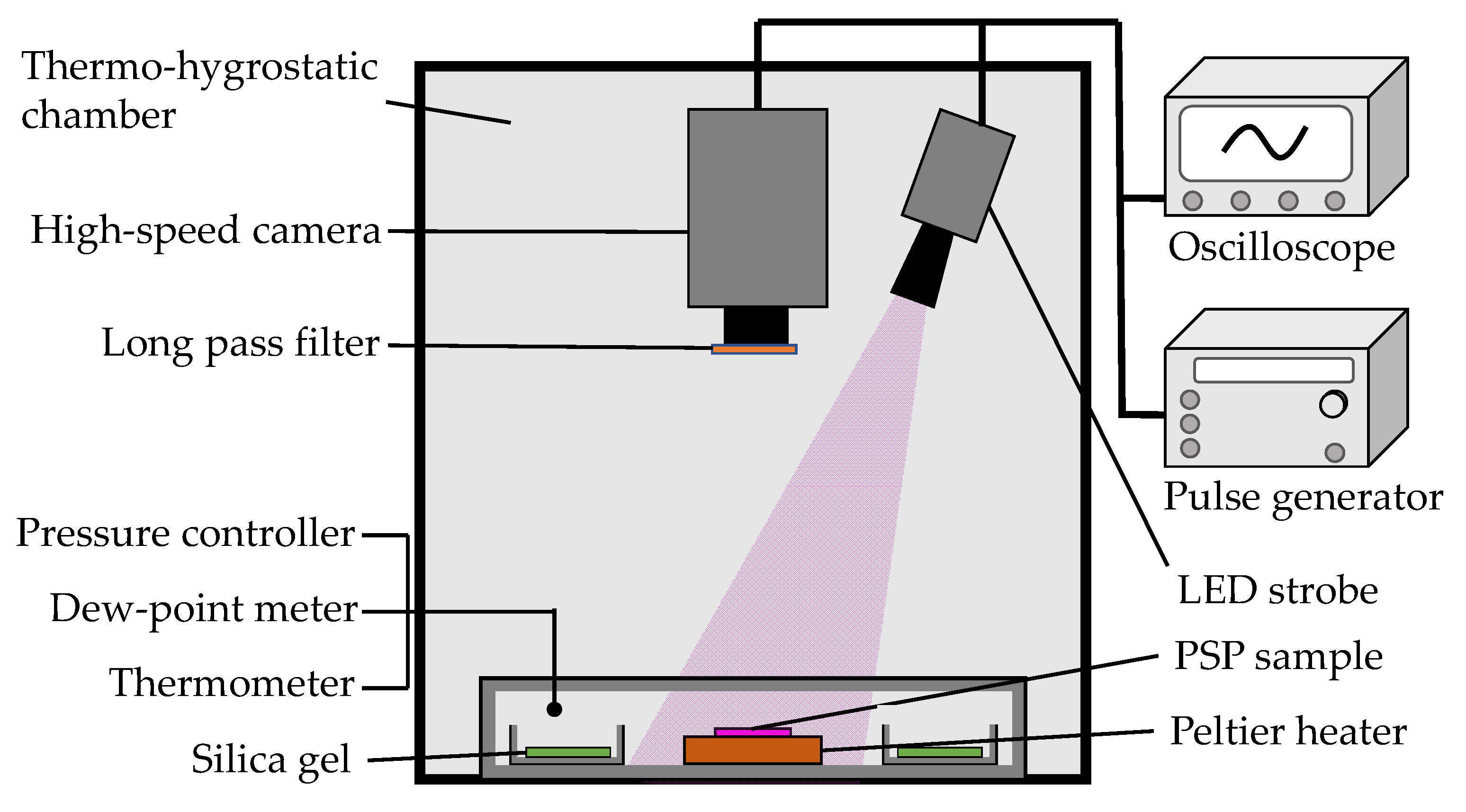

2.2.1. Pressure and Temperature Sensitivity

2.2.2. Thermal and Photostability

2.2.3. Luminescence Spectra

2.2.4. Luminescence Intensity

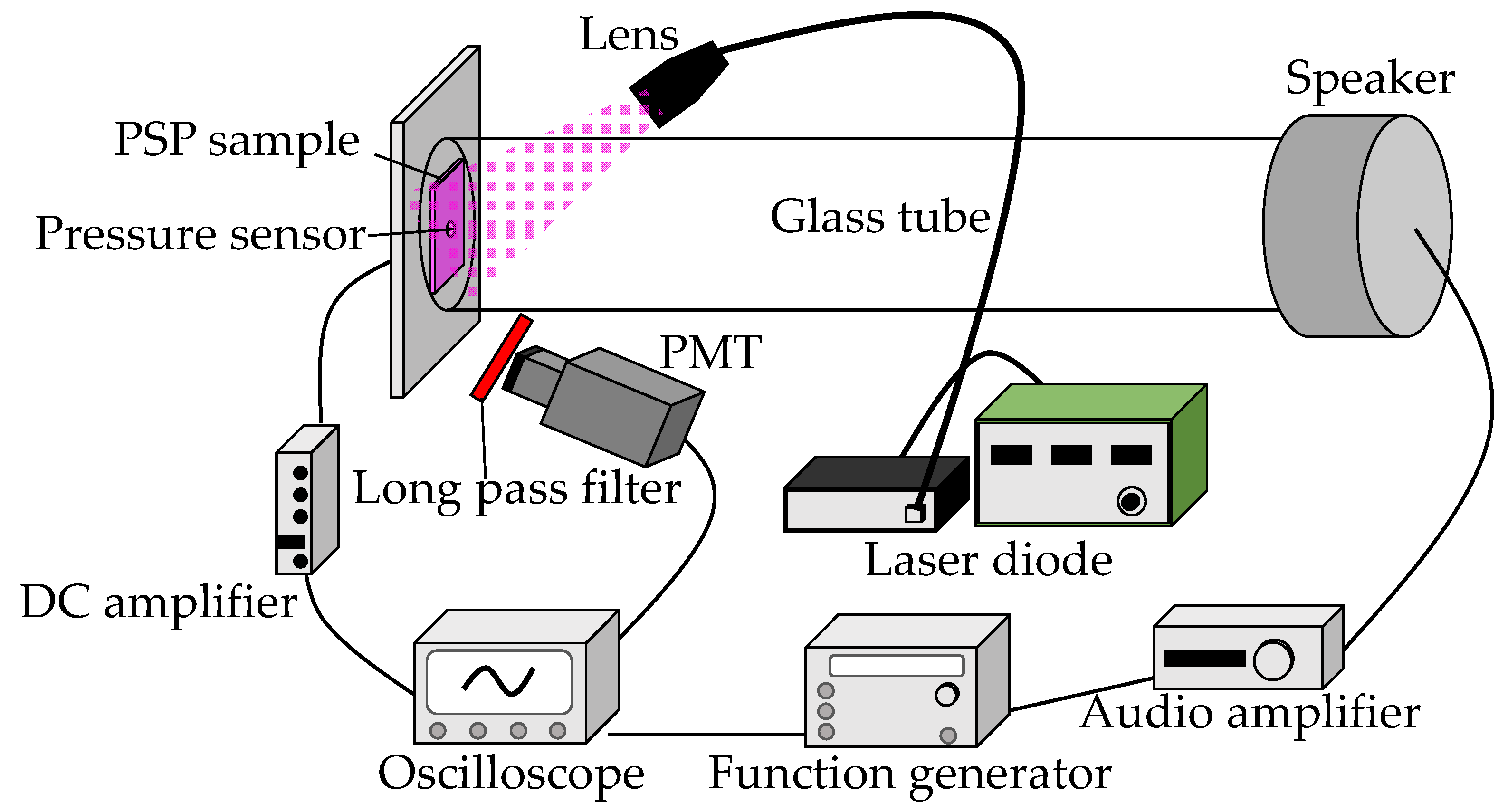

2.2.5. Frequency Response

2.3. Glass Transition of Polymers

3. Results and Discussion

3.1. Characterization of Standard PC-PSP

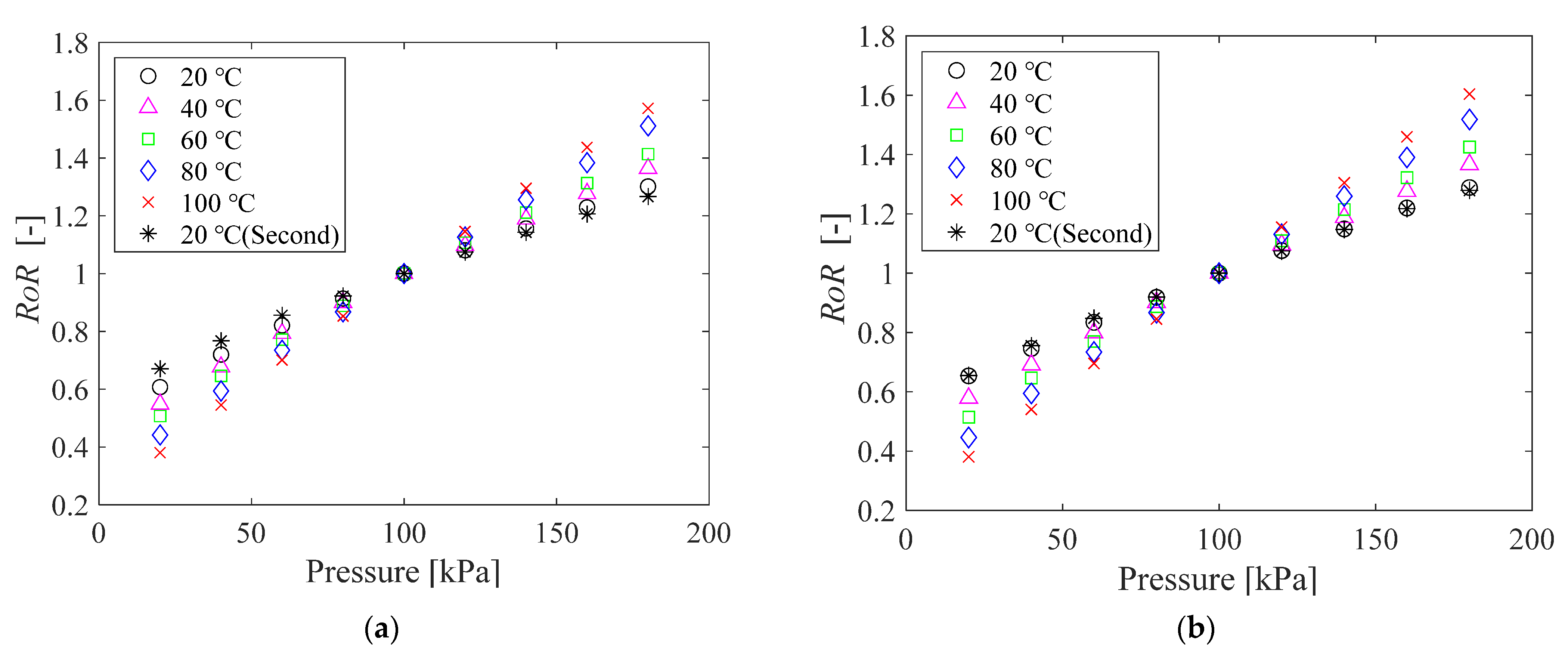

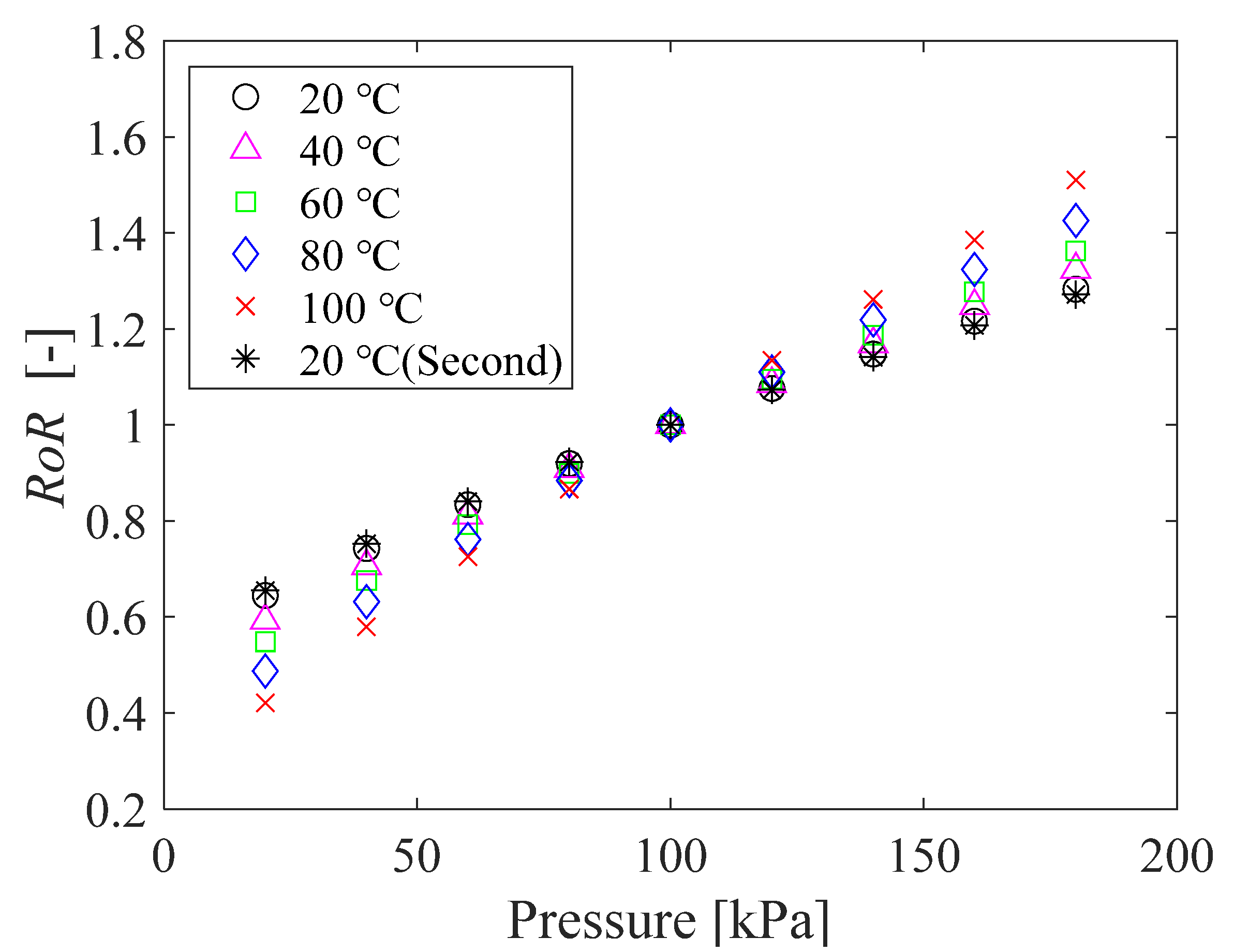

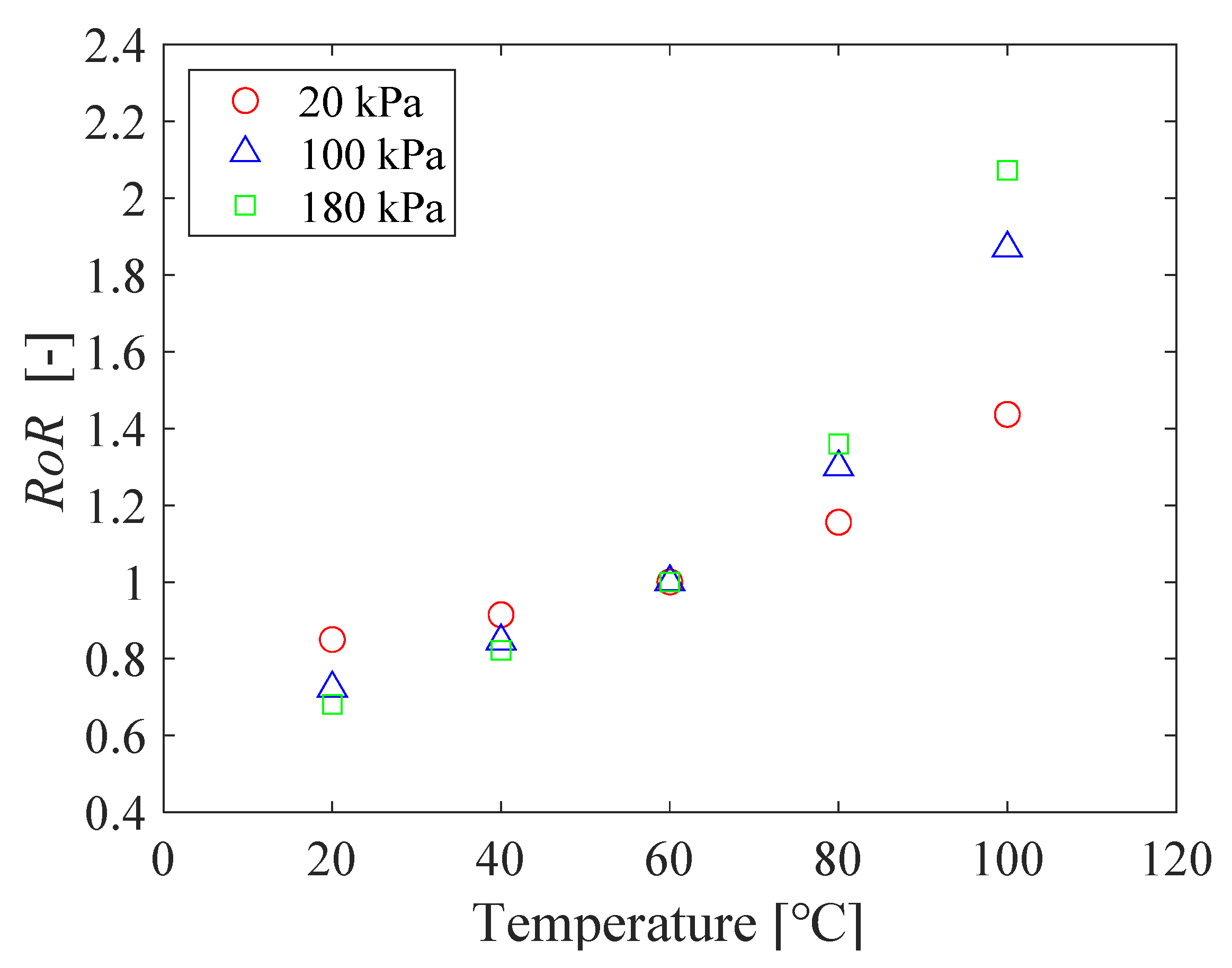

3.1.1. Pressure and Temperature Sensitivity

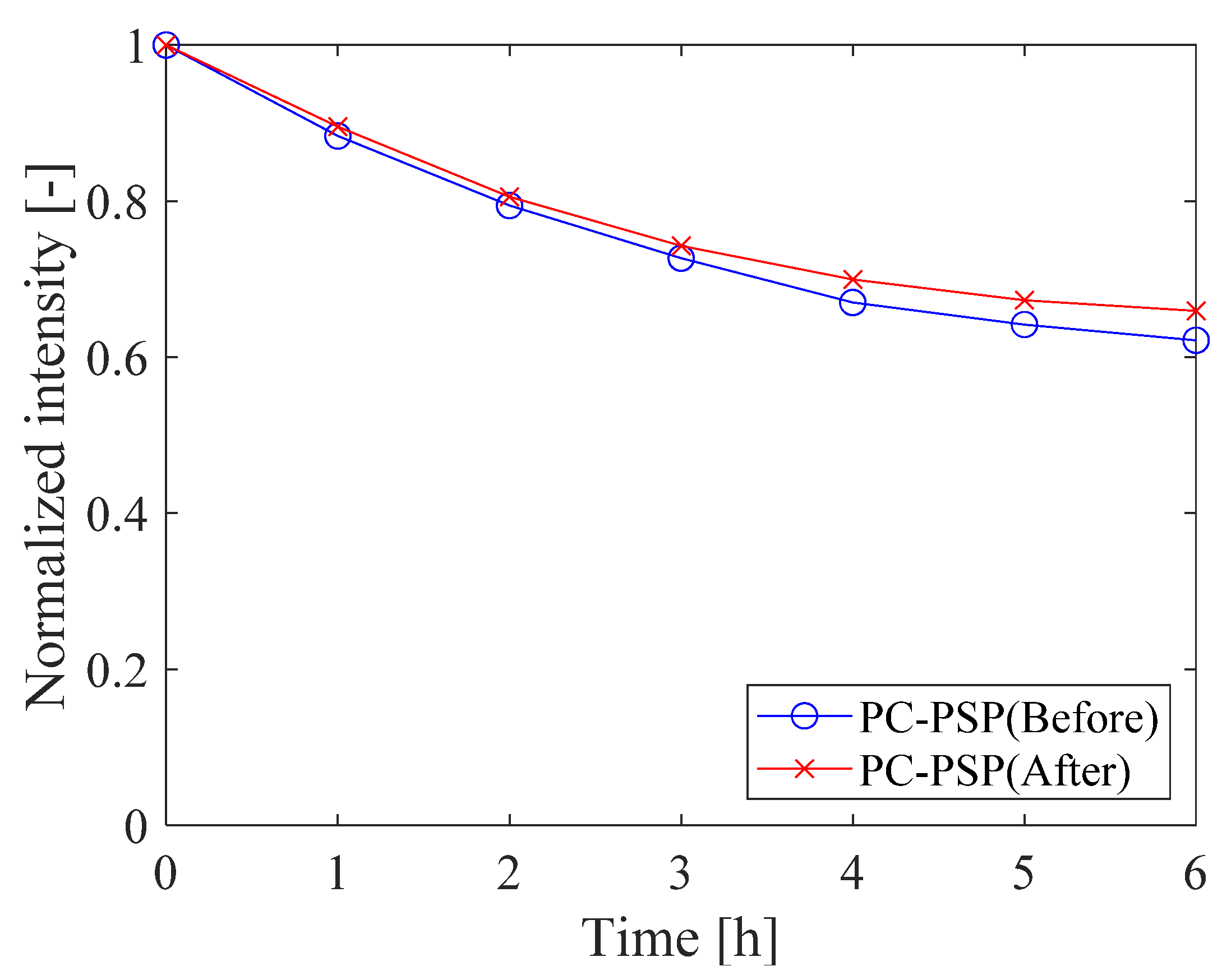

3.1.2. Thermal and Photostability

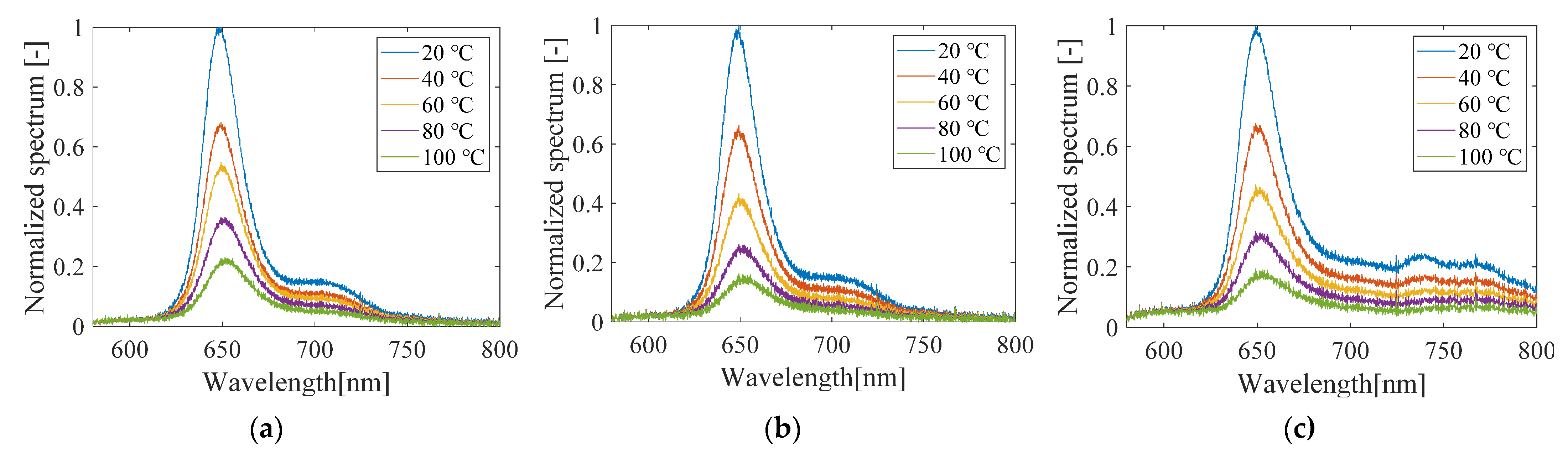

3.1.3. Luminescence Spectra

3.2. Glass Transition Temperature of Polymers

3.3. Characterization of PC-PSP with Added Urethane Resin

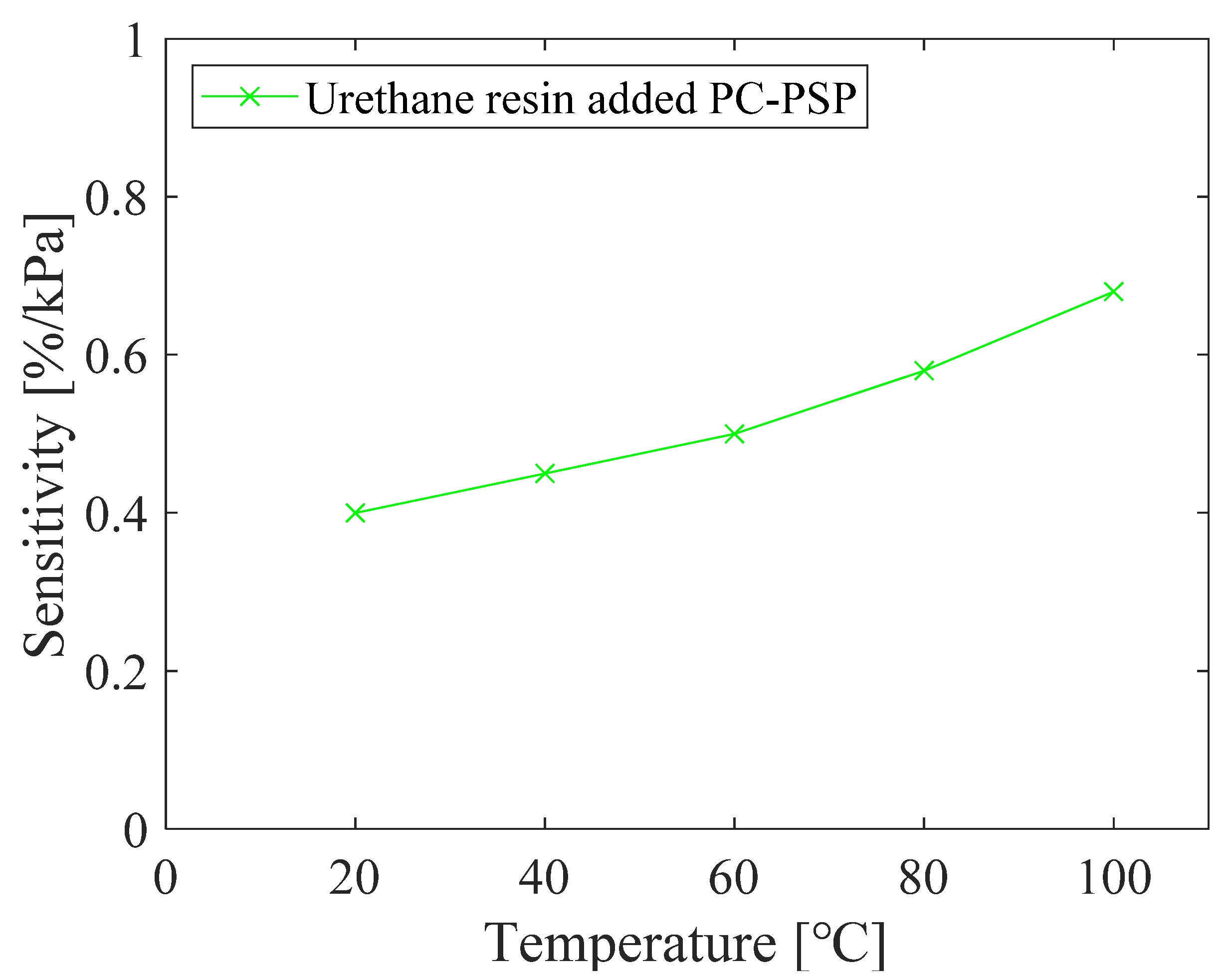

3.3.1. Pressure and Temperature Sensitivity

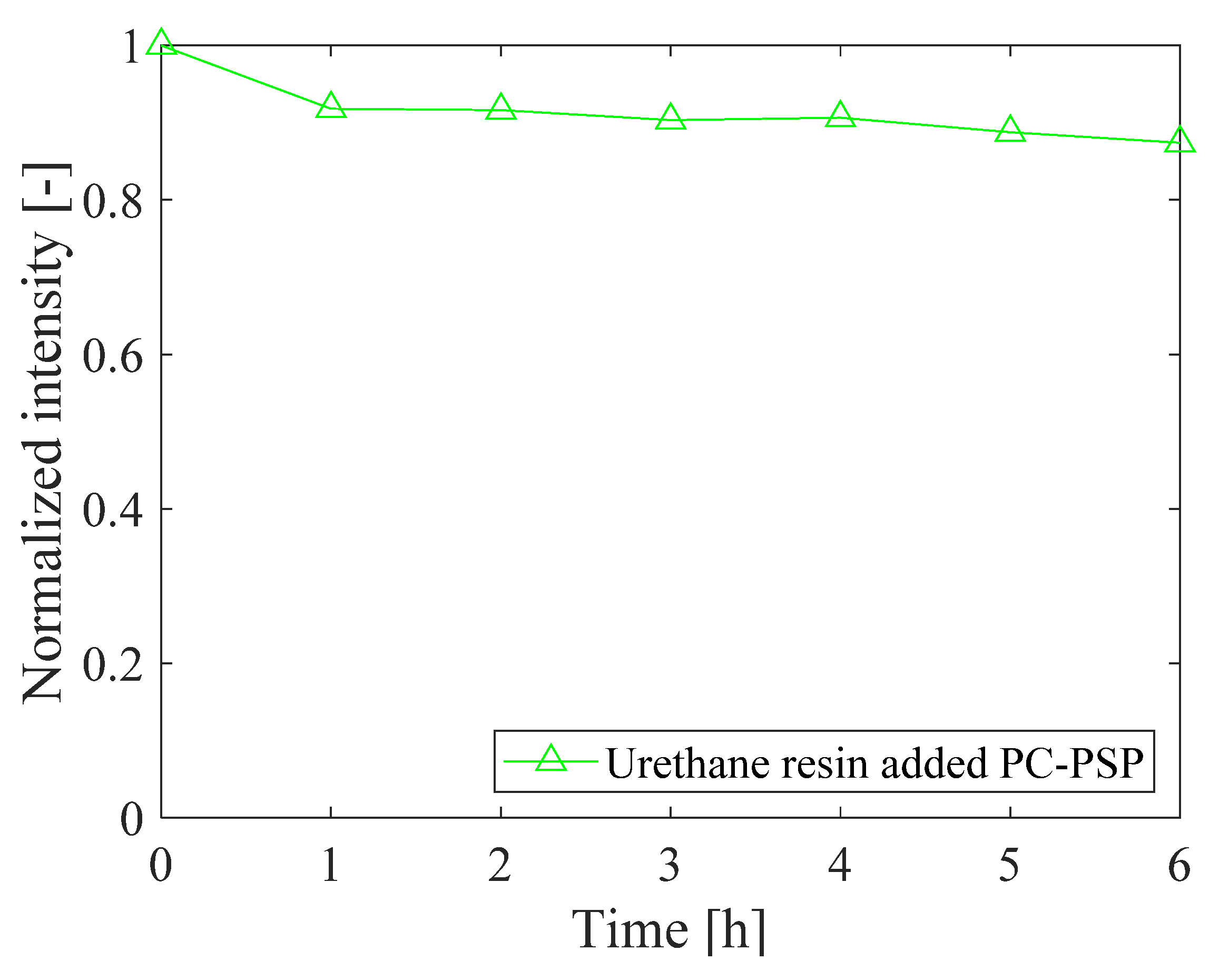

3.3.2. Thermal and Photostability

3.3.3. Luminescence Spectra

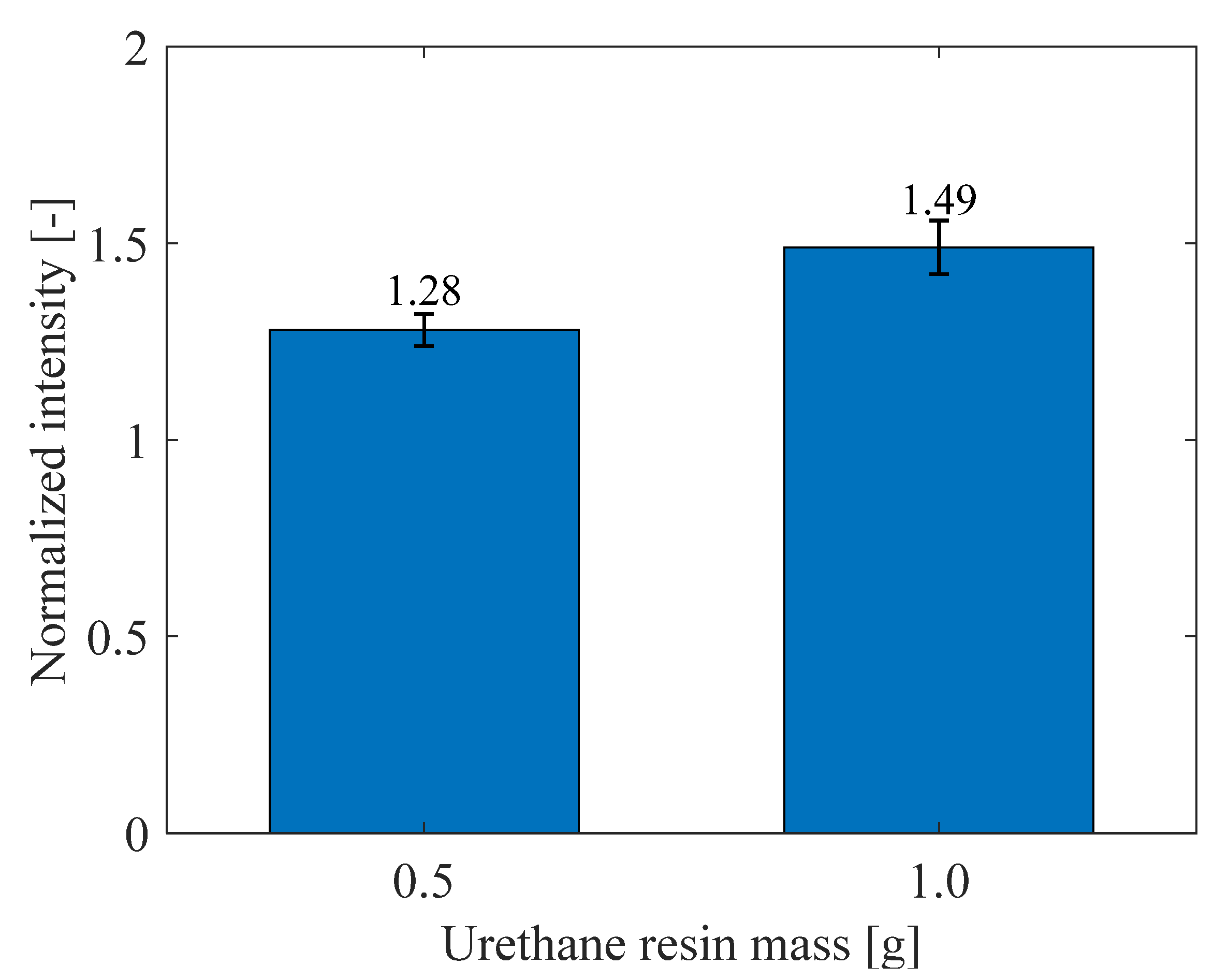

3.3.4. Increase in Luminescence Intensity

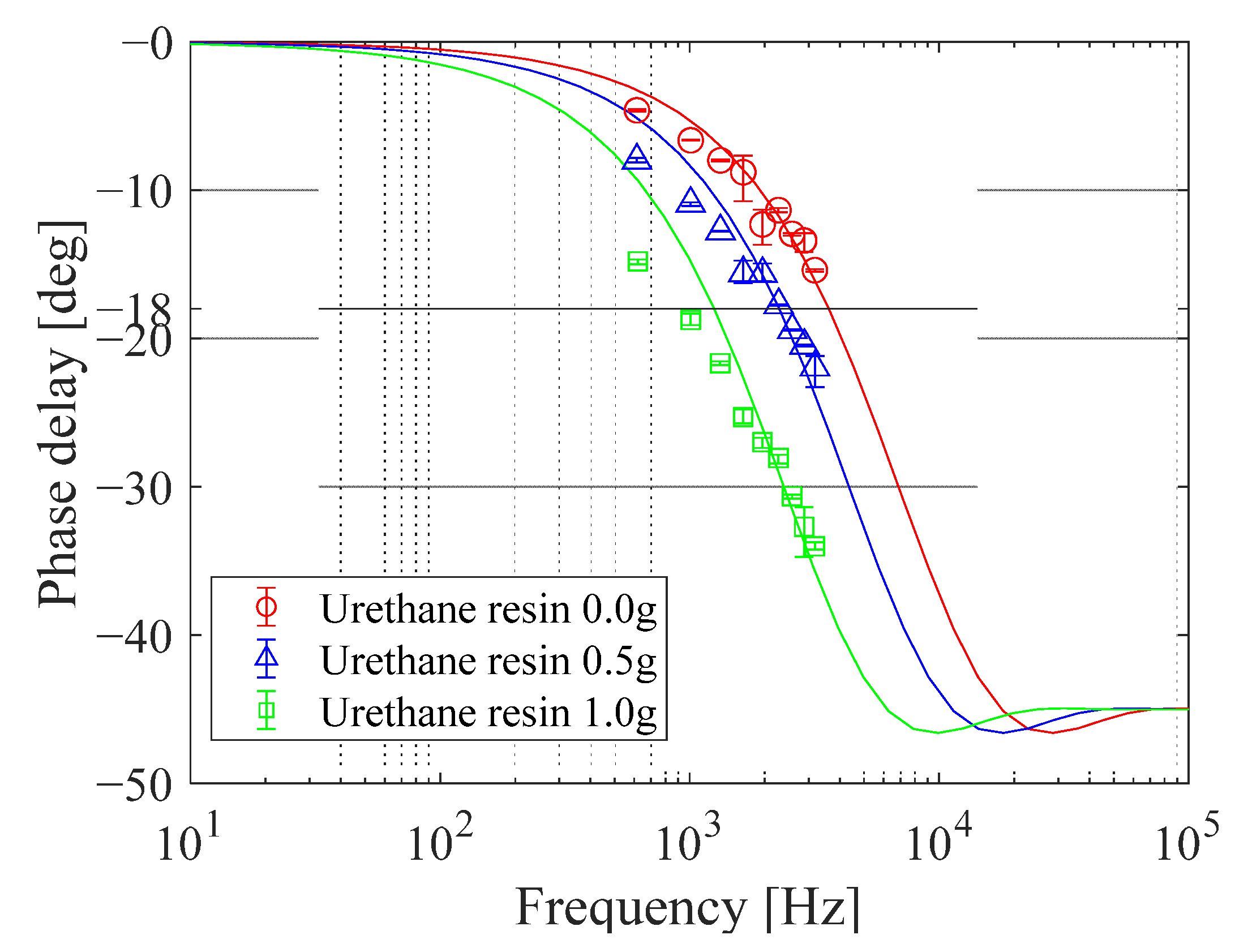

3.3.5. Frequency Response

4. Conclusions

- The standard PC-PSP has good pressure and temperature sensitivity even at 100 °C. The sensitivity is also almost the same for both.

- While the sensitivity is good, a significant decrease in luminescence intensity occurs at high temperatures. For example, after 1 h of excitation at 100 °C, the luminescence intensity decreases to 0.04. Such a rapid decrease in luminescence intensity at high temperatures makes it difficult to measure the pressure correctly using the intensity-based method of using intensities measured at distant times as reference values. The lifetime-based method should be used if PC-PSP is exposed to high temperatures.

- Subsequent measurements on thermal and photostability as well as luminescence spectra reveal that the main cause of the degradation at high temperature is the photodegradation of PtTFPP due to direct exposure of the dye molecules to atmosphere.

- The effect of glass transition of the polymer does not play a significant role in the lifetime-based PSP measurements, but a very small jump in pressure sensitivity is measured near the glass transition temperature.

- The addition of urethane resin significantly suppresses the photodegradation of PC-PSPs and increases the luminescence intensity at atmospheric pressure, but slightly reduces the pressure sensitivity and time response. These trade-off factors need to be considered when determining the recipe for PC-PSPs to be applied to actual measurements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Bell, J.H.; Schairer, E.T.; Hand, L.A.; Mehta, R.D. Surface pressure measurements using luminescent coatings. Annu. Rev. Fluid Mech. 2001, 33, 155–206. [Google Scholar] [CrossRef]

- Liu, T.; Sullivan, J.P.; Asai, K.; Klein, C.; Egami, Y. Pressure and Temperature Sensitive Paints, 2nd ed.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Gregory, J.W.; Asai, K.; Kameda, M.; Liu, T.; Sullivan, J.P. A review of pressure-sensitive paint for high-speed and unsteady aerodynamics. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2008, 222, 249–290. [Google Scholar] [CrossRef]

- Gregory, J.W.; Sakaue, H.; Liu, T.; Sullivan, J.P. Fast pressure-sensitive paint for flow and acoustic diagnostics. Annu. Rev. Fluid Mech. 2014, 46, 303–330. [Google Scholar] [CrossRef]

- Peng, D.; Liu, Y. Fast pressure-sensitive paint for understanding complex flows: From regular to harsh environments. Exp. Fluids 2020, 61, 8. [Google Scholar] [CrossRef]

- Asai, K.; Kanda, H.; Cunningham, C.T.; Erausquin, R.; Sullivan, J.P. Surface pressure measurements in a cryogenic wind tunnel by using luminescent coatings. In Proceedings of the 17th International Congress on Instrumentation in Aerospace Simulation Facilities (ICIASF 97) Record, Pacific Grove, CA, USA, 29 September–2 October 1997; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 1997; pp. 105–114. [Google Scholar]

- Sakaue, H.; Sullivan, J.P. Time response of anodized aluminum pressure-sensitive paint. AIAA J. 2001, 39, 1944–1949. [Google Scholar] [CrossRef]

- Kameda, M.; Tezuka, N.; Hangai, T.; Asai, K.; Nakakita, K.; Amao, Y. Adsorptive pressure-sensitive coatings on porous anodized aluminium. Meas. Sci. Technol. 2004, 15, 489–500. [Google Scholar] [CrossRef]

- Scroggin, A.M.; Slamovich, E.B.; Crafton, J.W.; Lachendro, N.; Sullivan, J.P. Porous polymer/ceramic composites for luminescence-based temperature and pressure measurement. MRS Proc. 1999, 560, 347–352. [Google Scholar] [CrossRef]

- Gregory, J.W.; Sullivan, J.P.; Wanis, S.S.; Komerath, N.M. Pressure-sensitive paint as a distributed optical microphone array. J. Acoust. Soc. Am. 2006, 119, 251–261. [Google Scholar] [CrossRef] [PubMed]

- Kameda, M.; Seki, H.; Makoshi, T.; Amao, Y.; Nakakita, K. A fast-response pressure sensor based on a dye-adsorbed silica nanoparticle film. Sens. Actuators B Chem. 2012, 171, 343–349. [Google Scholar] [CrossRef]

- Sugioka, Y.; Numata, D.; Asai, K.; Koike, S.; Nakakita, K.; Nakajima, T. Polymer/ceramic pressure-sensitive paint with reduced roughness for unsteady measurement in transonic flow. AIAA J. 2018, 56, 2145–2156. [Google Scholar] [CrossRef]

- Funderburk, M.L.; Narayanaswamy, V. Spectral signal quality of fast pressure sensitive paint measurements in turbulent shock-wave/boundary layer interactions. Exp. Fluids 2019, 60, 154. [Google Scholar] [CrossRef]

- Navarra, K.R.; Rabe, D.C.; Fonov, S.D.; Goss, L.P.; Hah, C. The application of pressure- and temperature-sensitive paints to an advanced compressor. J. Turbomach. 2001, 123, 823–829. [Google Scholar] [CrossRef]

- Pastuhoff, M.; Tillmark, N.; Alfredsson, P.H. Measuring surface pressure on rotating compressor blades using pressure sensitive paint. Sensors 2016, 16, 344. [Google Scholar] [CrossRef] [PubMed]

- Peng, D.; Jiao, L.; Yu, Y.; Liu, Y.; Oshio, T.; Kawakubo, T.; Yakushiji, A. Single-shot lifetime-based PSP and TSP measurements on turbocharger compressor blades. Exp. Fluids 2017, 58, 127. [Google Scholar] [CrossRef]

- Kitamura, T.; Kameda, M.; Watanabe, W.; Horimoto, K.; Akimoto, K.; Akahori, A. Measurement of unsteady pressure field in a turbocharger compressor using pressure-sensitive paint. Proceedings of ASME Turbo Expo 2018: Turbomachinery Technical Conference & Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar] [CrossRef]

- Li, R.; Gao, L.; Zheng, T.; Yang, G. Experimental investigation on static/dynamic characteristics of a fast-response pressure sensitive paint. Chin. J. Aeronaut. 2018, 31, 1198–1205. [Google Scholar] [CrossRef]

- Peng, D.; Gu, F.; Zhong, Z.; Liu, Y. Thermal stability improvement of sprayable fast-responding pressure-sensitive paint for measurement above 100 °C. Chin. J. Aeronaut. 2021, 34, 320–326. [Google Scholar] [CrossRef]

- Borisov, S.M.; Lehner, P.; Klimant, I. Novel optical trace oxygen sensors based on platinum(II) and palladium(II) complexes with 5,10,15,20-meso-tetrakis-(2,3,4,5,6-pentafluorphenyl)-porphyrin covalently immobilized on silica-gel particles. Anal. Chim. Acta 2011, 690, 108–115. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Matsui, T.; Kitagawa, Y.; Nakanishi, T.; Seki, T.; Ito, H.; Nakasaka, Y.; Masuda, T.; Fushimi, K. Near-IR luminescent YbIII coordination polymers composed of pyrene derivatives for thermostable oxygen sensors. Chem. Eur. J. 2019, 25, 12308. [Google Scholar] [CrossRef]

- Kameda, M.; Yoshida, M.; Sekiya, T.; Nakakita, K. Humidity effects in the response of a porous pressure-sensitive paint. Sens. Actuators B Chem. 2015, 208, 399–405. [Google Scholar] [CrossRef]

- Goss, L.G.; Trump, D.D.; Sarka, B.; Lydick, L.N.; Baker, W.M. Multi-dimensional time-resolved pressure-sensitive-paint techniques—A numerical and experimental comparison. In Proceedings of the 38th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2000. [Google Scholar] [CrossRef]

- Kameda, M. Effect of luminescence lifetime on the frequency response of fast-response pressure-sensitive paints. Trans. Jpn. Soc. Mech. Eng. Part B 2012, 78, 1942–1950. [Google Scholar] [CrossRef]

- Sergeeva, N.N.; Senge, M.O. Photochemical transformations involving porphyrins and phthalocyanines. In CRC Handbook of Organic Photochemistry and Photobiology; Griesbeck, A., Oelgemöller, M., Ghetti, F., Eds.; CRC Press: Boca Raton, FL, USA, 2012; pp. 831–876. [Google Scholar] [CrossRef][Green Version]

- Zhang, R.; Mallon, P.E.; Chen, H.; Huang, C.M.; Zhang, J.; Li, Y.; Wu, Y.; Sandreczki, T.C.; Jean, Y.C. Characterization of photodegradation of a polyurethane coating by positron annihilation spectroscopy: Correlation with cross-link density. Prog. Org. Coat. 2001, 42, 244–252. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. SpringerPlus 2013, 2, 398. [Google Scholar] [CrossRef]

- Thran, A.; Kroll, G.; Faupel, F. Correlation between fractional free volume and diffusivity of gas molecules in glassy polymers. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 3344–3358. [Google Scholar] [CrossRef]

| Normalized Intensity [-] | ||

|---|---|---|

| Heat Treatment | 20 °C (First) | 20 °C (Second) |

| Before | 1.0 | 1.0 |

| After | 0.43 | 0.38 |

| Glass Transition Temperature [°C] | |||

|---|---|---|---|

| Polymer | Polymer Only | Polymer + PtTFPP | Polymer + PtTFPP (Photodegraded) |

| PolyIBM | 64.7 | 69.3 | 69.5 |

| Urethane resin | 86.7 | 94.2 | 82.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Furuya, T.; Nakai, T.; Imai, M.; Kameda, M. Characterization and Improvement of Heat Resistance of a Polymer-Ceramic Pressure-Sensitive Paint at High Temperatures. Sensors 2021, 21, 8177. https://doi.org/10.3390/s21248177

Furuya T, Nakai T, Imai M, Kameda M. Characterization and Improvement of Heat Resistance of a Polymer-Ceramic Pressure-Sensitive Paint at High Temperatures. Sensors. 2021; 21(24):8177. https://doi.org/10.3390/s21248177

Chicago/Turabian StyleFuruya, Takenori, Takumi Nakai, Masato Imai, and Masaharu Kameda. 2021. "Characterization and Improvement of Heat Resistance of a Polymer-Ceramic Pressure-Sensitive Paint at High Temperatures" Sensors 21, no. 24: 8177. https://doi.org/10.3390/s21248177

APA StyleFuruya, T., Nakai, T., Imai, M., & Kameda, M. (2021). Characterization and Improvement of Heat Resistance of a Polymer-Ceramic Pressure-Sensitive Paint at High Temperatures. Sensors, 21(24), 8177. https://doi.org/10.3390/s21248177