Review on Sensing Technology Adoption in the Construction Industry

Abstract

1. Introduction

2. Current Status of Sensing Technologies in Construction

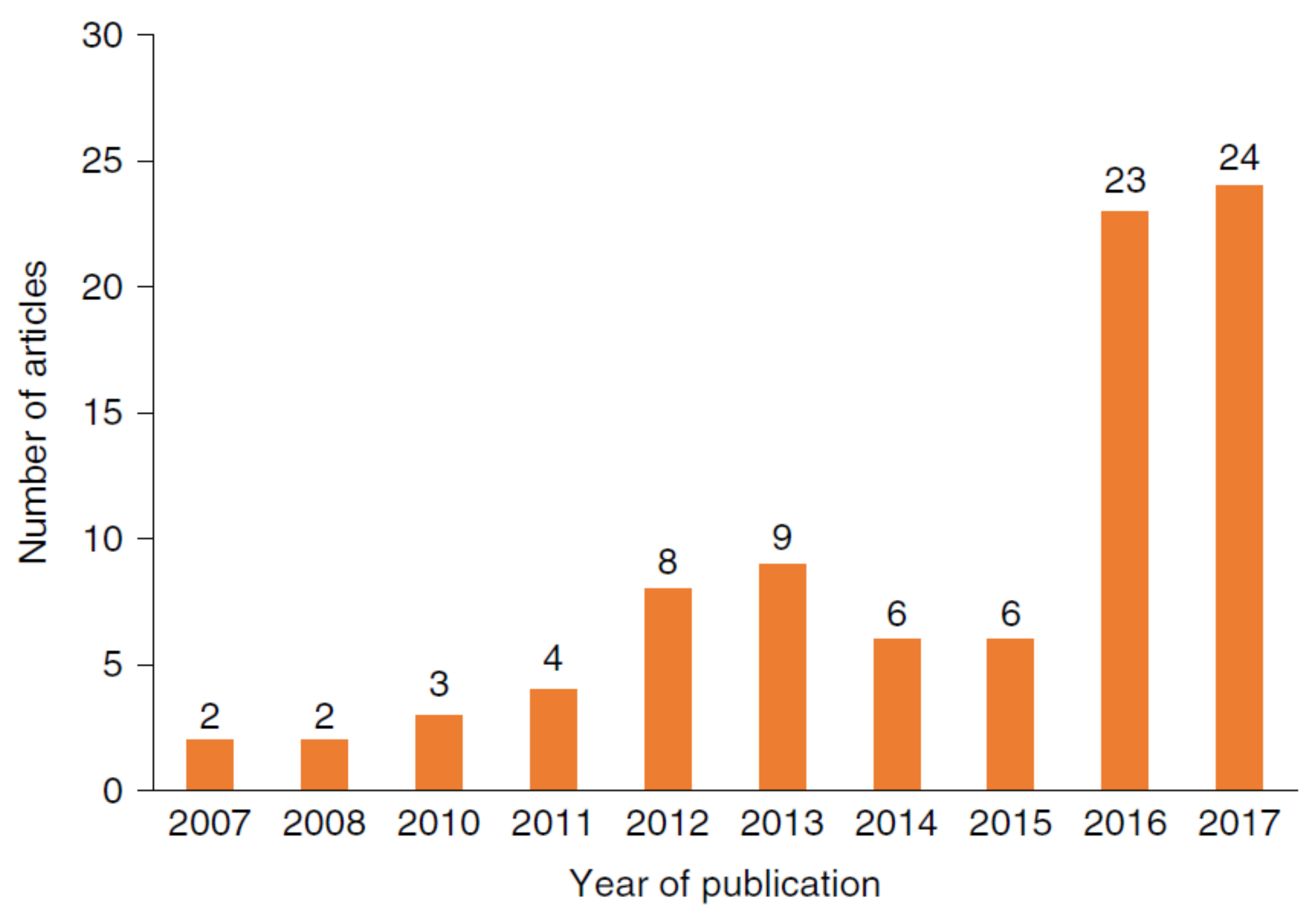

2.1. Methods and Material for Literature Review

2.2. Sensing Technologies in Construction Safety Enhancement

2.2.1. Location-Based Sensing Technologies

Global Positioning System (GPS) Technology

Radio Frequency Identification (RFID) Technology

Ultra-Wideband (UWB) Technology

2.2.2. Vision-Based Sensing Technologies

2.2.3. Wireless Sensor Networks (WSN) Technologies

2.3. Sensing Technologies in Occupational Health and Safety (OHS) Enhancement

2.3.1. Physiological Sensors

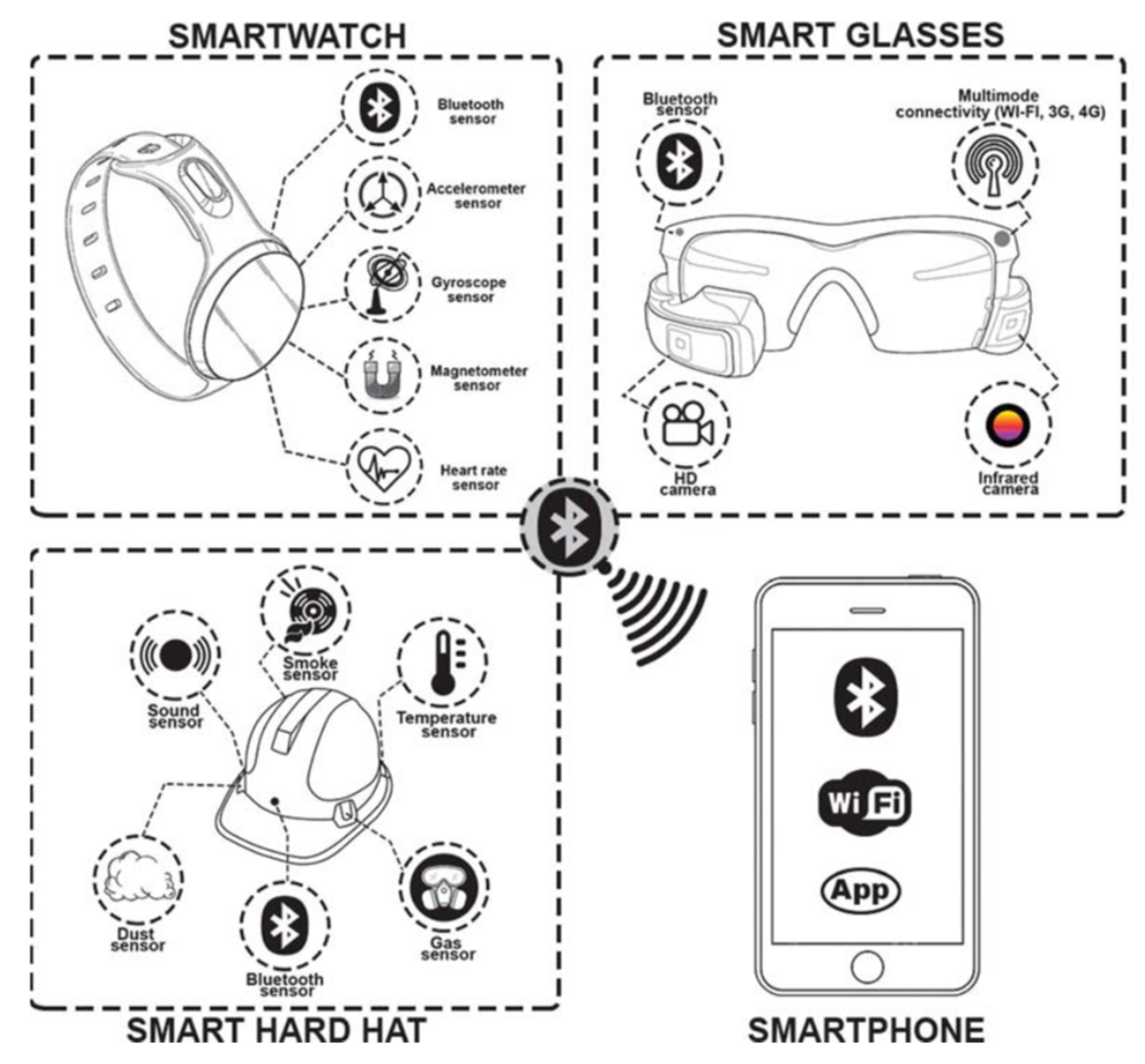

2.3.2. Integrated Sensors in Personal Protective Equipment (PPE)

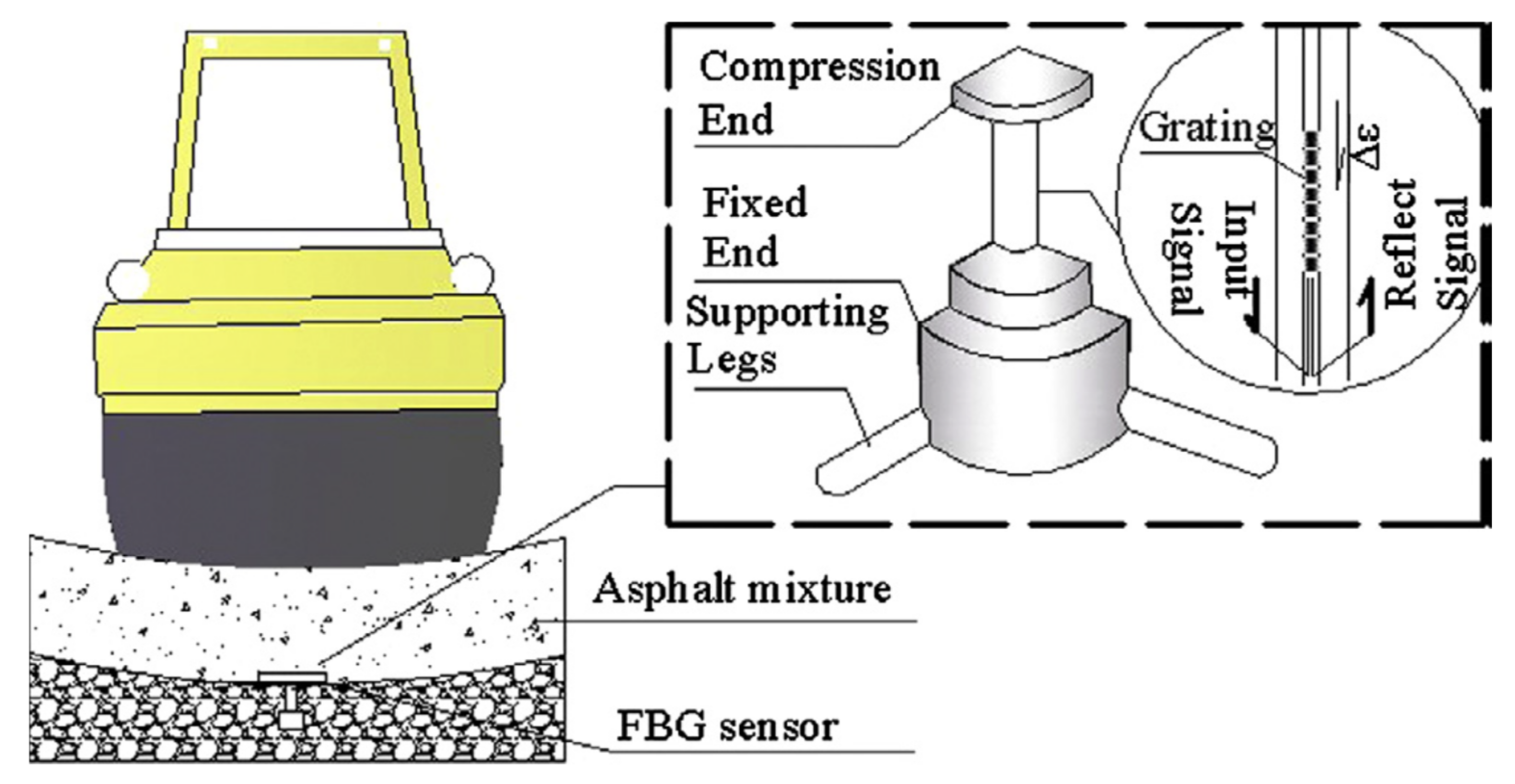

2.4. Sensing Technologies in Construction Quality Enhancement

2.5. Sensing Technologies in Construction Productivity Enhancement

2.5.1. Location-Based Sensing Technologies to Improve Productivity

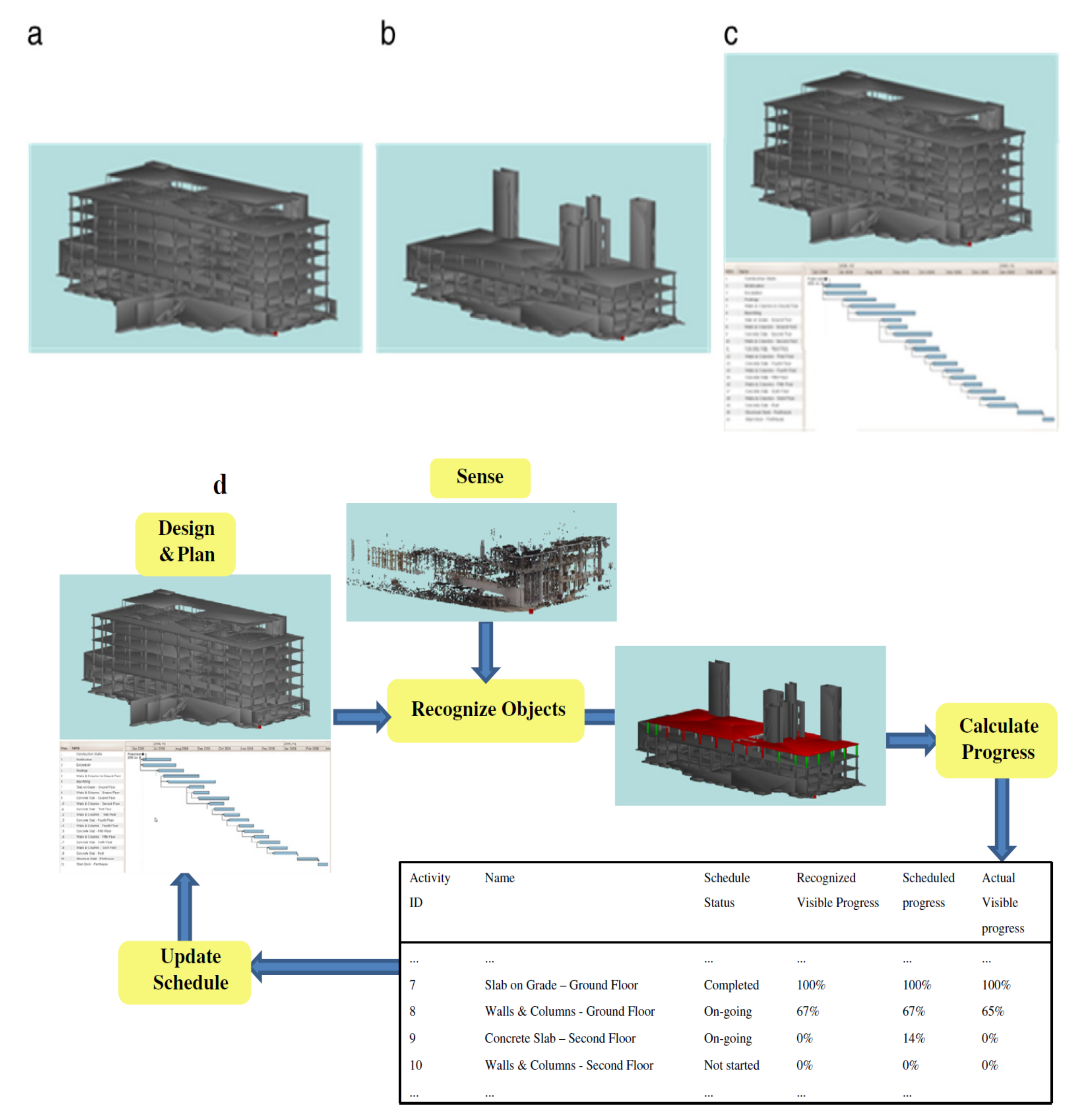

2.5.2. Vision-Based Sensing Technologies to Improve Productivity

3. Factors in the Determination of Sensing Technologies Adoption

3.1. Perceptions of Construction Managers toward Sensing Technologies

3.1.1. Benefits of Sensing Technologies Adoption

3.1.2. Barriers to Sensing Technologies Adoption

3.2. Acceptance of Construction Workers toward Sensing Technologies

4. Future Research

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Martínez-Rojas, M.; Marín, N.; Vila, M.A. The role of information technologies to address data handling in construction project management. J. Comput. Civ. Eng. 2016, 30, 04015064. [Google Scholar] [CrossRef]

- Behzadan, A.H.; Aziz, Z.; Anumba, C.J.; Kamat, V.R. Ubiquitous location tracking for context-specific information delivery on construction sites. Autom. Constr. 2008, 17, 737–748. [Google Scholar] [CrossRef]

- Shen, X.; Lu, M. A framework for indoor construction resources tracking by applying wireless sensor networks. Rev. Can. De Génie Civ. 2012, 39, 1083–1088. [Google Scholar] [CrossRef]

- Sardroud, J.M. Perceptions of automated data collection technology use in the construction industry. J. Civ. Eng. Manag. 2014, 21, 54–66. [Google Scholar] [CrossRef]

- Li, X.; Yang, H.; Zhang, J.; Qian, G.; Yu, H.; Cai, J. Time-domain analysis of tamper displacement during dynamic compaction based on automatic control. Coatings 2021, 11, 1092. [Google Scholar] [CrossRef]

- Moselhi, O.; Bardareh, H.; Zhu, Z. Automated Data Acquisition in Construction with Remote Sensing Technologies. Appl. Sci. 2020, 10, 2846. [Google Scholar] [CrossRef]

- Odubiyi, T.B.; Aigbavboa, C.O.; Thwala, W.D. Information and communication technology application challenges in the construction industry: A narrative review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012025. [Google Scholar] [CrossRef]

- Vähä, P.; Heikkilä, T.; Kilpeläinen, P.; Järviluoma, M.; Gambao, E. Extending automation of building construction—Survey on potential sensor technologies and robotic applications. Autom. Constr. 2013, 36, 168–178. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Wong, J.K.-W.; Oladinrin, O.T.; Ge, J.X.; Seo, J.; Wong, A.Y.L. Sensing and warning-based technology applications to improve occupational health and safety in the construction industry: A literature review. Eng. Constr. Archit. Manag. 2019, 26, 1534–1552. [Google Scholar] [CrossRef]

- Taneja, S.; Akinci, B.; Garrett, J.; Soibelman, L.; Ergen, E.; Pradhan, A.; Tang, P.; Berges, M.; Atasoy, G.; Liu, X.; et al. Sensing and Field Data Capture for Construction and Facility Operations. J. Constr. Eng. Manag.-ASCE 2011, 137, 870–881. [Google Scholar] [CrossRef]

- Sepasgozaar, S.M.E.; Shirowzhan, S.; Wang, C. A Scanner Technology Acceptance Model for Construction Projects. Procedia Eng. 2017, 180, 1237–1246. [Google Scholar] [CrossRef]

- Li, H.; Chan, G.; Wong, J.K.W.; Skitmore, M. Real-time locating systems applications in construction. Autom. Constr. 2016, 63, 37–47. [Google Scholar] [CrossRef]

- Lu, W.; Huang, G.Q.; Li, H. Scenarios for applying RFID technology in construction project management. Autom. Constr. 2011, 20, 101–106. [Google Scholar] [CrossRef]

- Zhou, W.; Whyte, J.; Sacks, R. Construction safety and digital design: A review. Autom. Constr. 2012, 22, 102–111. [Google Scholar] [CrossRef]

- Wu, C.; Wu, P.; Wang, J.; Jiang, R.; Chen, M.; Wang, X. Critical review of data-driven decision-making in bridge operation and maintenance. Struct. Infrastruct. Eng. 2020, 1–24. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Bernold, L.E. Factors influencing the decision of technology adoption in construction. In ICSDEC 2012: Developing the Frontier of Sustainable Design, Engineering, and Construction; Fort Worth, TX, USA, 7–9 November 2012, American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 654–661. [Google Scholar]

- Sepasgozar, S.M.E.; Davis, S. Construction Technology Adoption Cube: An Investigation on Process, Factors, Barriers, Drivers and Decision Makers Using NVivo and AHP Analysis. Buildings 2018, 8, 74. [Google Scholar] [CrossRef]

- Schall, M.C.; Sesek, R.F.; Cavuoto, L.A. Barriers to the Adoption of Wearable Sensors in the Workplace: A Survey of Occupational Safety and Health Professionals. Hum. Factors 2018, 60, 351–362. [Google Scholar] [CrossRef]

- Usman, N.; Said, I. Information and communication technology innovation for construction site management. Am. J. Appl. Sci. 2012, 9, 1259. [Google Scholar]

- Soltanmohammadlou, N.; Sadeghi, S.; Hon, C.K.H.; Mokhtarpour-Khanghah, F. Real-time locating systems and safety in construction sites: A literature review. Saf. Sci. 2019, 117, 229–242. [Google Scholar] [CrossRef]

- Cheng, T.; Teizer, J. Modeling Tower Crane Operator Visibility to Minimize the Risk of Limited Situational Awareness. J. Comput. Civ. Eng. 2014, 28, 04014004. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, Z. Numerical modeling of response of CFRP–Concrete interfaces subjected to fatigue loading. J. Compos. Constr. 2021, 25, 04021043. [Google Scholar] [CrossRef]

- Skitmore, M.H.; Luo, X.; Huang, T. Quantifying Hazard Exposure Using Real-Time Location Data of Construction Workforce and Equipment. J. Constr. Eng. Manag. 2016, 142, 4016031. [Google Scholar]

- Huang, H.; Huang, M.; Zhang, W.; Yang, S. Experimental study of predamaged columns strengthened by HPFL and BSP under combined load cases. Struct. Infrastruct. Eng. 2021, 17, 1210–1227. [Google Scholar] [CrossRef]

- Zhao, X.; Gu, B.; Gao, F.; Chen, S. Matching Model of Energy Supply and Demand of the Integrated Energy System in Coastal Areas. J. Coast. Res. 2020, 103, 983. [Google Scholar] [CrossRef]

- Teizer, J.; Cheng, T. Proximity hazard indicator for workers-on-foot near miss interactions with construction equipment and geo-referenced hazard areas. Autom. Constr. 2015, 60, 58–73. [Google Scholar] [CrossRef]

- Zhao, X.; Xia, H.; Pan, L.; Song, H.; Niu, W.; Wang, R.; Li, R.; Bian, X.; Guo, Y.; Qin, Y. Drought monitoring over Yellow River basin from 2003–2019 using reconstructed MODIS land surface temperature in Google Earth Engine. Remote Sens. 2021, 13, 3748. [Google Scholar] [CrossRef]

- Wang, J.; Razavi, S.N. Low False Alarm Rate Model for Unsafe-Proximity Detection in Construction. J. Comput. Civ. Eng. 2016, 30, 04015005. [Google Scholar] [CrossRef]

- Huang, H.; Xue, C.; Zhang, W.; Guo, M. Torsion design of CFRP-CFST columns using a data-driven optimization approach. Eng. Struct. 2022, 251, 113479. [Google Scholar] [CrossRef]

- Zekavat, P.R.; Moon, S.; Bernold, L.E. Securing a wireless site network to create a BIM-allied work-front. Int. J. Adv. Robot. Syst. 2014, 11, 132. [Google Scholar] [CrossRef]

- Yan, J.; Meng, Y.; Yang, X.; Luo, X.; Guan, X. Privacy-Preserving Localization for Underwater Sensor Networks via Deep Reinforcement Learning. IEEE Trans. Inf. Forensics Secur. 2020, 16, 1880–1895. [Google Scholar] [CrossRef]

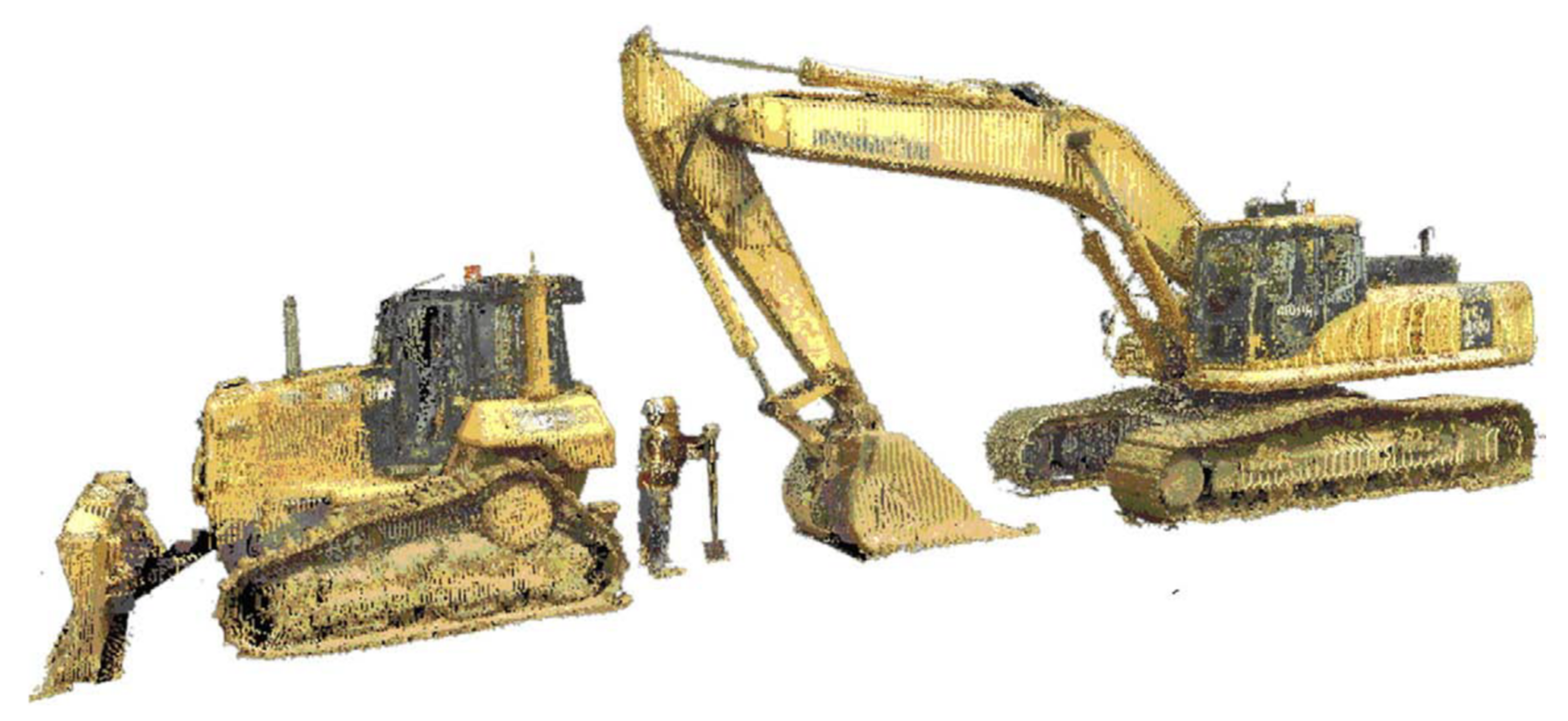

- Cheng, T.; Teizer, J. Real-time resource location data collection and visualization technology for construction safety and activity monitoring applications. Autom. Constr. 2013, 34, 3–15. [Google Scholar] [CrossRef]

- Majrouhi Sardroud, J. Influence of RFID technology on automated management of construction materials and components. Sci. Iran. 2012, 19, 381–392. [Google Scholar] [CrossRef]

- Lee, G.; Cho, J.; Ham, S.; Lee, T.; Lee, G.; Yun, S.-H.; Yang, H.-J. A BIM- and sensor-based tower crane navigation system for blind lifts. Autom. Constr. 2012, 26, 1–10. [Google Scholar] [CrossRef]

- Akhavian, R.; Behzadan, A.H. Construction equipment activity recognition for simulation input modeling using mobile sensors and machine learning classifiers. Adv. Eng. Inform. 2015, 29, 867–877. [Google Scholar] [CrossRef]

- Valero, E.; Adán, A.; Cerrada, C. Evolution of RFID applications in construction: A literature review. Sensors 2015, 15, 15988–16008. [Google Scholar] [CrossRef]

- Sun, C.; Jiang, F.; Jiang, S. Research on RFID Applications in Construction Industry. J. Netw. 2013, 8, 1221. [Google Scholar] [CrossRef]

- Wu, C.; Wang, X.; Chen, M.; Kim, M.J. Differential received signal strength based RFID positioning for construction equipment tracking. Adv. Eng. Inform. 2019, 42, 100960. [Google Scholar] [CrossRef]

- Razavi, S.N.; Montaser, A.; Moselhi, O. RFID deployment protocols for indoor construction. Constr. Innov. 2012, 12, 239–258. [Google Scholar] [CrossRef]

- Ding, L.; Li, S.; Gao, H.; Liu, Y.J.; Huang, L.; Deng, Z. Adaptive Neural Network-Based Finite-Time Online Optimal Tracking Control of the Nonlinear System With Dead Zone. IEEE Trans. Cybern. 2019, 51, 382–392. [Google Scholar] [CrossRef]

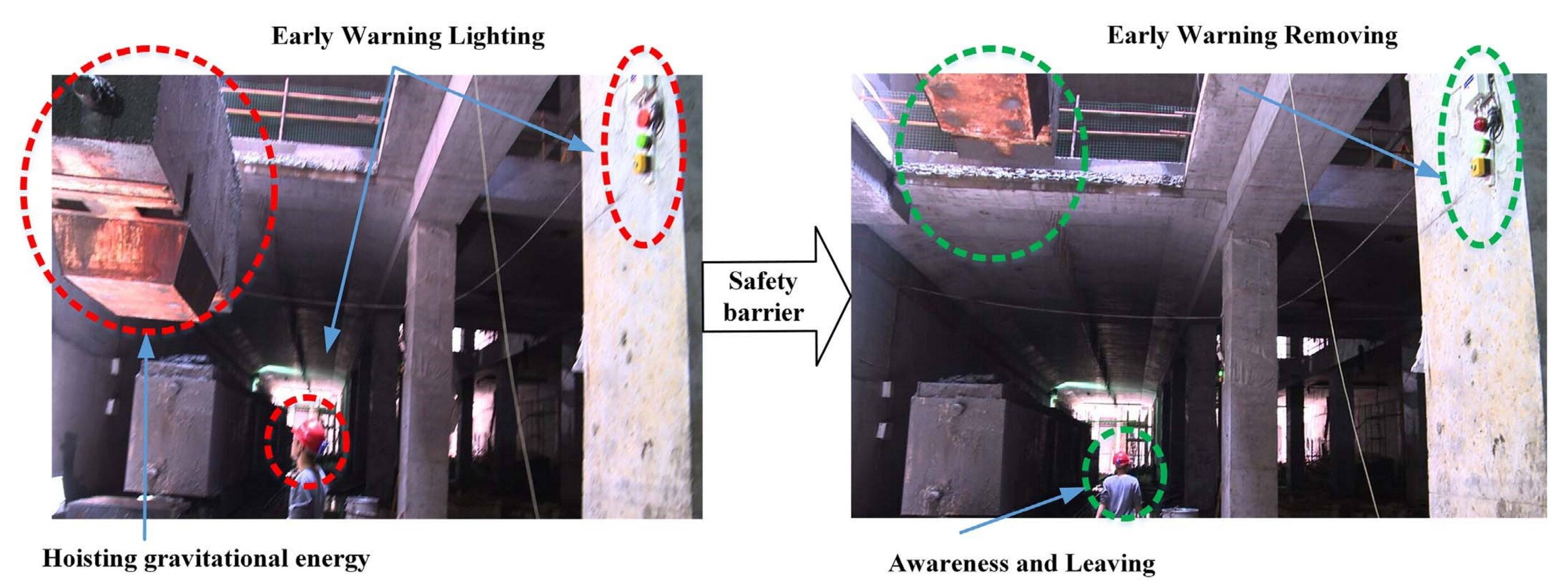

- Zhou, C.; Ding, L.Y. Safety barrier warning system for underground construction sites using Internet-of-Things technologies. Autom. Constr. 2017, 83, 372–389. [Google Scholar] [CrossRef]

- Yang, H.; Chew, D.A.S.; Wu, W.; Zhou, Z.; Li, Q. Design and implementation of an identification system in construction site safety for proactive accident prevention. Accid. Anal. Prev. 2012, 48, 193–203. [Google Scholar] [CrossRef]

- Brilakis, I.; Lee, S.; Becerik-Gerber, B. Application of Sensing Technology in the Prevention of Backing Accidents in Construction Work Zones. In ASCE International Workshop on Computing in Civil Engineering; Los Angeles, CA, USA, 23–25 June 2013, American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 557–564. [Google Scholar] [CrossRef]

- Ding, L.Y.; Zhou, C.; Deng, Q.X.; Luo, H.B.; Ye, X.W.; Ni, Y.Q.; Guo, P. Real-time safety early warning system for cross passage construction in Yangtze Riverbed Metro Tunnel based on the internet of things. Autom. Constr. 2013, 36, 25–37. [Google Scholar] [CrossRef]

- Marks, E.D.; Teizer, J. Method for testing proximity detection and alert technology for safe construction equipment operation. Constr. Manag. Econ. 2013, 31, 636–646. [Google Scholar] [CrossRef]

- Wu, W.; Yang, H.; Chew, D.A.S.; Yang, S.-H.; Gibb, A.G.F.; Li, Q. Towards an autonomous real-time tracking system of near-miss accidents on construction sites. Autom. Constr. 2010, 19, 134–141. [Google Scholar] [CrossRef]

- Kanan, R.; Elhassan, O.; Bensalem, R. An IoT-based autonomous system for workers’ safety in construction sites with real-time alarming, monitoring, and positioning strategies. Autom. Constr. 2018, 88, 73–86. [Google Scholar] [CrossRef]

- Fang, Y.; Cho, Y.K.; Zhang, S.; Perez, E. Case Study of BIM and Cloud-Enabled Real-Time RFID Indoor Localization for Construction Management Applications. J. Constr. Eng. Manag. 2016, 142, 5016003. [Google Scholar] [CrossRef]

- Ko, C.-H. RFID 3D location sensing algorithms. Autom. Constr. 2010, 19, 588–595. [Google Scholar] [CrossRef]

- Lee, K.-P.; Lee, H.-S.; Park, M.; Kim, H.; Han, S. A real-time location-based construction labor safety management system. J. Civ. Eng. Manag. 2014, 20, 724–736. [Google Scholar] [CrossRef]

- Hwang, S. Ultra-wide band technology experiments for real-time prevention of tower crane collisions. Autom. Constr. 2012, 22, 545–553. [Google Scholar] [CrossRef]

- Zhang, C.; Hammad, A.; Rodriguez, S. Crane Pose Estimation Using UWB Real-Time Location System. J. Comput. Civ. Eng. 2012, 26, 625–637. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, M.; Tang, Y.; Ding, Q.; Wang, C.; Huang, X.; Chen, D.; Yan, F. Angular velocity measurement with improved scale factor based on a wideband-tunable optoelectronic oscillator. IEEE Trans. Instrum. Meas. 2021, 70, 1–9. [Google Scholar] [CrossRef]

- Teizer, J.; Venugopal, M.; Walia, A. Ultrawideband for Automated Real-Time Three-Dimensional Location Sensing for Workforce, Equipment, and Material Positioning and Tracking. Transp. Res. Rec. J. Transp. Res. Board 2008, 2081, 56–64. [Google Scholar] [CrossRef]

- Maalek, R.; Sadeghpour, F. Accuracy assessment of Ultra-Wide Band technology in tracking static resources in indoor construction scenarios. Autom. Constr. 2013, 30, 170–183. [Google Scholar] [CrossRef]

- Cheng, T.; Venugopal, M.; Teizer, J.; Vela, P.A. Performance evaluation of ultra wideband technology for construction resource location tracking in harsh environments. Autom. Constr. 2011, 20, 1173–1184. [Google Scholar] [CrossRef]

- Alarifi, A.; Al-Salman, A.; Alsaleh, M.; Alnafessah, A.; Al-Hadhrami, S.; Al-Ammar, M.; Al-Khalifa, H. Ultra Wideband Indoor Positioning Technologies: Analysis and Recent Advances. Sensors 2016, 16, 707. [Google Scholar] [CrossRef] [PubMed]

- Shahi, A.; Aryan, A.; West, J.S.; Haas, C.T.; Haas, R.C.G. Deterioration of UWB positioning during construction. Autom. Constr. 2012, 24, 72–80. [Google Scholar] [CrossRef]

- Aslani, F.; Gunawardena, Y.; Dehghani, A. Behaviour of concrete filled glass fibre-reinforced polymer tubes under static and flexural fatigue loading. Constr. Build. Mater. 2019, 212, 57–76. [Google Scholar] [CrossRef]

- Teizer, J. 3D range imaging camera sensing for active safety in construction. J. Inf. Technol. Constr. (ITcon) 2008, 13, 103–117. [Google Scholar]

- Zekavat, P.R.; Moon, S.; Bernold, L.E. Performance of short and long range wireless communication technologies in construction. Autom. Constr. 2014, 47, 50–61. [Google Scholar] [CrossRef]

- Mi, C.; Huang, Y.; Fu, C.; Zhang, Z.; Postolache, O. Vision-Based Measurement: Actualities and Developing Trends in Automated Container Terminals. IEEE Instrum. Meas. Mag. 2021, 24, 65–76. [Google Scholar] [CrossRef]

- Xu, S.; Wang, J.; Shou, W.; Ngo, T.; Sadick, A.-M.; Wang, X. Computer vision techniques in construction: A critical review. Arch. Comput. Methods Eng. 2021, 28, 3383–3397. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Wu, G.; Wang, X. A novel differential search algorithm and applications for structure design. Appl. Math. Comput. 2015, 268, 246–269. [Google Scholar] [CrossRef]

- Xu, D.-S.; Huang, M.; Zhou, Y. One-dimensional compression behavior of calcareous sand and marine clay mixtures. Int. J. Geomech. 2020, 20, 0402013. [Google Scholar] [CrossRef]

- Teizer, J.; Allread, B.S.; Fullerton, C.E.; Hinze, J. Autonomous pro-active real-time construction worker and equipment operator proximity safety alert system. Autom. Constr. 2010, 19, 630–640. [Google Scholar] [CrossRef]

- Mingyuan, Z.; Tianzhuo, C.; Xuefeng, Z. Applying Sensor-Based Technology to Improve Construction Safety Management. Sensors 2017, 17, 1841. [Google Scholar] [CrossRef]

- Sun, J.; Lin, S.; Zhang, G.; Sun, Y.; Zhang, J.; Chen, C.; Morsy, A.M.; Wang, X. The effect of graphite and slag on electrical and mechanical properties of electrically conductive cementitious composites. Constr. Build. Mater. 2021, 281, 122606. [Google Scholar] [CrossRef]

- Dehghani, A.; Aslani, F.; Panah, N.G. Effects of initial SiO2/Al2O3 molar ratio and slag on fly ash-based ambient cured geopolymer properties. Constr. Build. Mater. 2021, 293, 123527. [Google Scholar] [CrossRef]

- Sun, L.; Li, C.; Zhang, C.; Liang, T.; Zhao, Z. The Strain Transfer Mechanism of Fiber Bragg Grating Sensor for Extra Large Strain Monitoring. Sensors 2019, 19, 1851. [Google Scholar] [CrossRef]

- Li, J.; Qin, Q.; Sun, J.; Ma, Y.; Li, Q. Mechanical and conductive performance of electrically conductive cementitious composite using graphite, steel slag, and GGBS. Struct. Concr. 2020. [Google Scholar] [CrossRef]

- Aslani, F.; Sun, J.; Huang, G. Mechanical behavior of fiber-reinforced self-compacting rubberized concrete exposed to elevated temperatures. J. Mater. Civ. Eng. 2019, 31, 04019302. [Google Scholar] [CrossRef]

- Dehghani, A.; Mozafari, A.R.; Aslani, F. Evaluation of the efficacy of using engineered cementitious composites in RC beam-column joints. Structures 2020, 27, 151–162. [Google Scholar] [CrossRef]

- Aslani, F.; Deghani, A.; Gunawardena, Y. Experimental investigation of the behavior of concrete-filled high-strength glass fiber-reinforced polymer tubes under static and cyclic axial compression. Struct. Concr. 2020, 21, 1497–1522. [Google Scholar] [CrossRef]

- Afzal, M.H.B.; Kabir, S.; Sidek, O. An In-depth Review: Structural Health Monitoring using Fiber Optic Sensor. IETE Tech. Rev. 2012, 29, 105–113. [Google Scholar] [CrossRef]

- Aslani, F.; Sun, J.; Bromley, D.; Ma, G. Fiber-reinforced lightweight self-compacting concrete incorporating scoria aggregates at elevated temperatures. Struct. Concr. 2019, 20, 1022–1035. [Google Scholar] [CrossRef]

- Hu, L.; Wang, Y.; Feng, P.; Wang, H.; Qiang, H. Debonding development in cracked steel plates strengthened by CFRP laminates under fatigue loading: Experimental and boundary element method analysis. Thin-Walled Struct. 2021, 166, 108038. [Google Scholar] [CrossRef]

- Ye, X.W.; Ni, Y.Q.; Yin, J.H. Safety Monitoring of Railway Tunnel Construction Using FBG Sensing Technology. Adv. Struct. Eng. 2013, 16, 1401–1409. [Google Scholar] [CrossRef]

- Aslani, F.; Hou, L.; Nejadi, S.; Sun, J.; Abbasi, S. Experimental analysis of fiber-reinforced recycled aggregate self-compacting concrete using waste recycled concrete aggregates, polypropylene, and steel fibers. Struct. Concr. 2019, 20, 1670–1683. [Google Scholar] [CrossRef]

- Hu, L.; Feng, P.; Zhao, X.-L. Fatigue design of CFRP strengthened steel members. Thin-Walled Struct. 2017, 119, 482–498. [Google Scholar] [CrossRef]

- Chen, F.; Zhong, Y.; Gao, X.; Jin, Z.; He, X. Non-uniform model of relationship between surface strain and rust expansion force of reinforced concrete. Sci. Rep. 2021, 11, 8741. [Google Scholar] [CrossRef]

- Hayatdavoodi, A.; Dehghani, A.; Aslani, F.; Alahi, F.N. The development of a novel analytical model to design composite steel plate shear walls under eccentric shear. J. Build. Eng. 2021, 44, 103281. [Google Scholar] [CrossRef]

- Chen, F.; Jin, Z.; Wang, E.; Wang, L.; Jiang, Y.; Guo, P.; Gao, X.; He, X. Relationship model between surface strain of concrete and expansion force of reinforcement rust. Sci. Rep. 2021, 11, 4208. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Roy, K.; Uzzaman, A.; Raftery, G.; Lim, J.B. Axial strength of back-to-back cold-formed steel channels with edge-stiffened holes, un-stiffened holes and plain webs. J. Constr. Steel Res. 2020, 174, 106313. [Google Scholar] [CrossRef]

- Ibrahim, M.; Moselhi, O. Wireless Sensor Networks Configurations for Applications in Construction. Procedia Eng. 2014, 85, 260–273. [Google Scholar] [CrossRef]

- Paya-Marin, M.A.; Roy, K.; Chen, J.-F.; Masood, R.; Lawson, R.M.; Gupta, B.S.; Lim, J.B. Large-scale experiment of a novel non-domestic building using BPSC systems for energy saving. Renew. Energy 2020, 152, 799–811. [Google Scholar] [CrossRef]

- Naticchia, B.; Vaccarini, M.; Carbonari, A. A monitoring system for real-time interference control on large construction sites. Autom. Constr. 2013, 29, 148–160. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Triaxial Shear Behavior of Basalt Fiber-Reinforced Loess Based on Digital Image Technology. KSCE J. Civ. Eng. 2021, 25, 3714–3726. [Google Scholar] [CrossRef]

- Sun, Y.; Li, G.; Zhang, J.; Sun, J.; Huang, J.; Taherdangkoo, R. New Insights of Grouting in Coal Mass: From Small-Scale Experiments to Microstructures. Sustainability 2021, 13, 9315. [Google Scholar] [CrossRef]

- Zhu, Z.; Park, M.-W.; Koch, C.; Soltani, M.; Hammad, A.; Davari, K. Predicting movements of onsite workers and mobile equipment for enhancing construction site safety. Autom. Constr. 2016, 68, 95–101. [Google Scholar] [CrossRef]

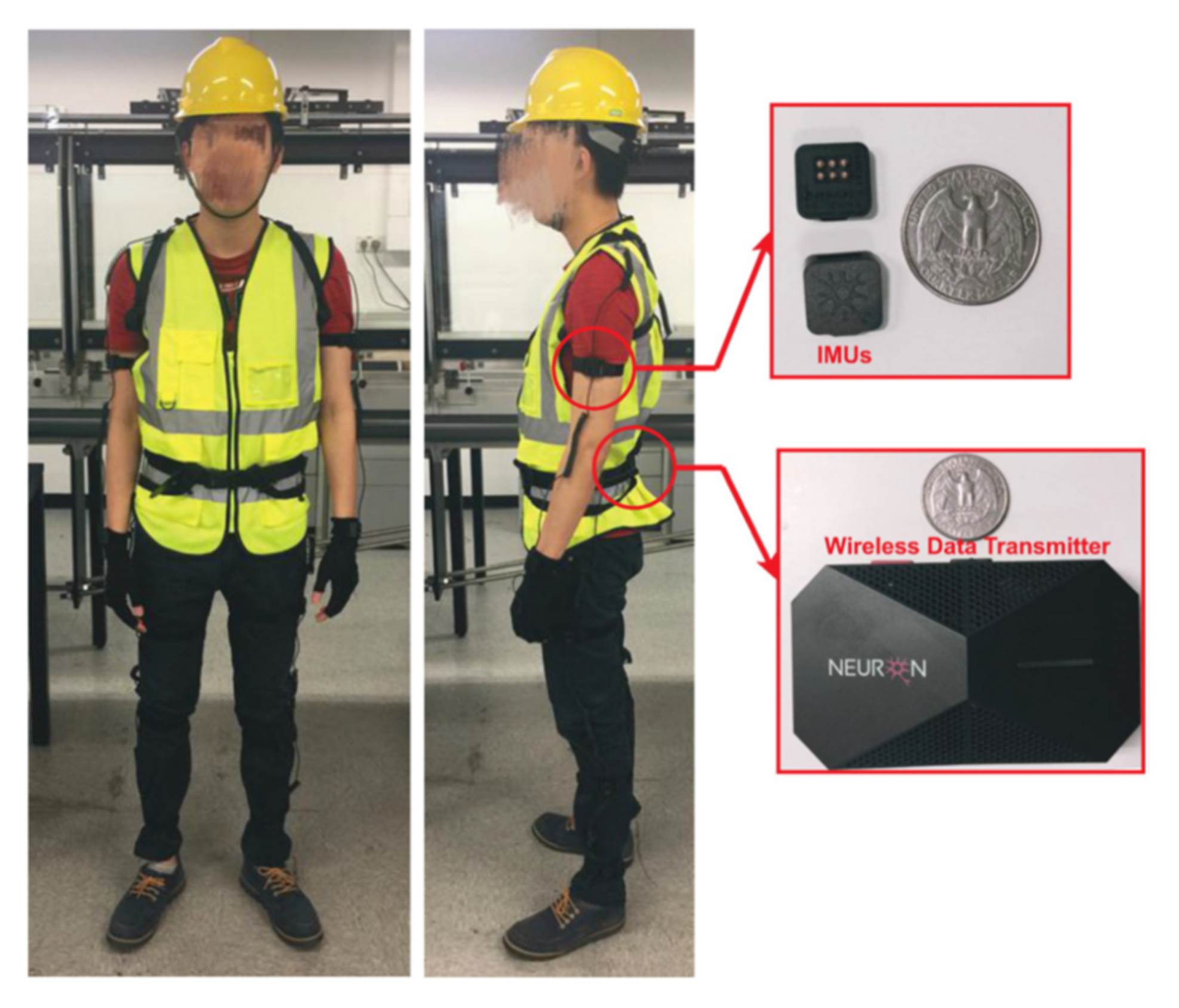

- Nath, N.D.; Akhavian, R.; Behzadan, A.H. Ergonomic analysis of construction worker’s body postures using wearable mobile sensors. Appl. Ergon. 2017, 62, 107–117. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.; Hallowell, M. Wearable technology for personalized construction safety monitoring and trending: Review of applicable devices. Autom. Constr. 2018, 85, 96–106. [Google Scholar] [CrossRef]

- Guo, H.; Yu, Y.; Xiang, T.; Li, H.; Zhang, D. The availability of wearable-device-based physical data for the measurement of construction workers’ psychological status on site: From the perspective of safety management. Autom. Constr. 2017, 82, 207. [Google Scholar] [CrossRef]

- Kamišalić, A.; Fister, J.I.; Turkanović, M.; Karakatič, S. Sensors and Functionalities of Non-Invasive Wrist-Wearable Devices: A Review. Sensors. 2018, 18, 1714. [Google Scholar] [CrossRef]

- Mneymneh, B.E.; Abbas, M.; Khoury, H. Automated Hardhat Detection for Construction Safety Applications. Procedia Eng. 2017, 196, 895–902. [Google Scholar] [CrossRef]

- Ray, S.J.; Teizer, J. Real-time construction worker posture analysis for ergonomics training. Adv. Eng. Inform. 2012, 26, 439–455. [Google Scholar] [CrossRef]

- Han, S.; Lee, S. A vision-based motion capture and recognition framework for behavior-based safety management. Autom. Constr. 2013, 35, 131–141. [Google Scholar] [CrossRef]

- Hu, T.; Wang, S.; She, B.; Zhang, M.; Huang, X.; Cui, Y.; Khuri, J.; Hu, Y.; Fu, X.; Wang, X. Human Mobility Data in the COVID-19 Pandemic: Characteristics, Applications, and Challenges. Int. J. Digit. Earth 2021, 14, 1126–1147. [Google Scholar] [CrossRef]

- Ahn, C.R.; Lee, S.; Sun, C.; Jebelli, H.; Yang, K.; Choi, B. Wearable Sensing Technology Applications in Construction Safety and Health. J. Constr. Eng. Manag. 2019, 145, 03119007. [Google Scholar] [CrossRef]

- Wang, D.; Chen, J.; Zhao, D.; Dai, F.; Zheng, C.; Wu, X. Monitoring workers’ attention and vigilance in construction activities through a wireless and wearable electroencephalography system. Autom. Constr. 2017, 82, 122–137. [Google Scholar] [CrossRef]

- Jebelli, H.; Hwang, S.; Lee, S. Feasibility of Field Measurement of Construction Workers’ Valence Using a Wearable EEG Device. In Proceedings of ASCE International Workshop on Computing in Civil Engineering 2017, Seattle, WA, USA, 25–27 June 2017; pp. 99–106. [Google Scholar]

- Lee, W.; Lin, K.-Y.; Seto, E.; Migliaccio, G.C. Wearable sensors for monitoring on-duty and off-duty worker physiological status and activities in construction. Autom. Constr. 2017, 83, 341–353. [Google Scholar] [CrossRef]

- Hwang, S.; Lee, S. Wristband-type wearable health devices to measure construction workers’ physical demands. Autom. Constr. 2017, 83, 330–340. [Google Scholar] [CrossRef]

- Yi, W.; Chan, A.P.C.; Wang, X.; Wang, J. Development of an early-warning system for site work in hot and humid environments: A case study. Autom. Constr. 2016, 62, 101–113. [Google Scholar] [CrossRef]

- Wang, L.; Yuan, J.; Wu, C.; Wang, X. Practical algorithm for stochastic optimal control problem about microbial fermentation in batch culture. Optim. Lett. 2019, 13, 527–541. [Google Scholar] [CrossRef]

- Aryal, A.; Ghahramani, A.; Becerik-Gerber, B. Monitoring fatigue in construction workers using physiological measurements. Autom. Constr. 2017, 82, 154–165. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Edwards, D.J.; Pärn, E.A.; Seo, J.; Wong, A.Y.L. Biomechanical analysis of risk factors for work-related musculoskeletal disorders during repetitive lifting task in construction workers. Autom. Constr. 2017, 83, 41–47. [Google Scholar] [CrossRef]

- Umer, W.; Li, H.; Szeto, G.P.Y.; Wong, A.Y. Low-cost ergonomic intervention for mitigating physical and subjective discomfort during manual rebar tying. J. Constr. Eng. Manag. 2017, 143, 04017075. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, J.; Ahn, C. Construction worker’s awkward posture recognition through supervised motion tensor decomposition. Autom. Constr. 2017, 77, 67–81. [Google Scholar] [CrossRef]

- Yang, K.; Ahn, C.R.; Vuran, M.C.; Kim, H. Collective sensing of workers’ gait patterns to identify fall hazards in construction. Autom. Constr. 2017, 82, 166–178. [Google Scholar] [CrossRef]

- Jebelli, H.; Ahn, C.R.; Stentz, T.L. Comprehensive Fall-Risk Assessment of Construction Workers Using Inertial Measurement Units: Validation of the Gait-Stability Metric to Assess the Fall Risk of Iron Workers. J. Comput. Civ. Eng. 2016, 30, 4015034. [Google Scholar] [CrossRef]

- Dong, S.; Li, H.; Yin, Q. Building information modeling in combination with real time location systems and sensors for safety performance enhancement. Saf. Sci. 2018, 102, 226. [Google Scholar] [CrossRef]

- Sung Hun, K.; Changwon, W.; Se Dong, M.; Seung Hyun, L. Safety Helmet Wearing Management System for Construction Workers Using Three-Axis Accelerometer Sensor. Appl. Sci. 2018, 8, 2400. [Google Scholar] [CrossRef]

- Naticchia, B.; Fava, G.; Carbonari, A.; Quaquero, E. Preliminary Tests on a Wireless Sensor Network for Pervasive Dust Monitoring in Construction Sites. Open Environ. Eng. J. 2014, 7, 10–18. [Google Scholar] [CrossRef]

- Smaoui, N.; Kim, K.; Gnawali, O.; Lee, Y.-J.; Suh, W. Respirable Dust Monitoring in Construction Sites and Visualization in Building Information Modeling Using Real-time Sensor Data. Sens. Mater. 2018, 30, 1775. [Google Scholar] [CrossRef]

- Adjiski, V.; Despodov, Z.; Mirakovski, D.; Movski, D. System architecture to bring smart personal protective equipment wearables and sensors to transform safety at work in the underground mining industry. Rudarsko-Geolosko-Naftni Zbornik 2019, 34, 37–44. [Google Scholar] [CrossRef]

- Yiqiu, T.; Haipeng, W.; Shaojun, M.; Huining, X. Quality control of asphalt pavement compaction using fibre Bragg grating sensing technology. Constr. Build. Mater. 2014, 54, 53–59. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Liu, S.; Dehghani, A.; Xiang, X.; Wei, J.; Wang, X. Mechanical, chemical and hydrothermal activation for waste glass reinforced cement. Constr. Build. Mater. 2021, 301, 124361. [Google Scholar] [CrossRef]

- Song, Z.P.; Zhang, D.; Shi, B.; Chen, S.E.; Shen, M.F. Integrated distributed fiber optic sensing technology-based structural monitoring of the pound lock. Struct. Control Health Monit. 2017, 24, e1954. [Google Scholar] [CrossRef]

- Hu, L.L.; Zhao, X.L.; Feng, P. Fatigue behavior of cracked high-strength steel plates strengthened by CFRP sheets. J. Compos. Constr. 2016, 20, 04016043. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, B.; Han, S.; Chen, H.; Wei, Z. Upscaling evapotranspiration from the instantaneous to the daily time scale: Assessing six methods including an optimized coefficient based on worldwide eddy covariance flux network. J. Hydrol. 2021, 596, 126135. [Google Scholar] [CrossRef]

- Moon, S.; Zekavat, P.R.; Bernold, L.E. Dynamic quality control of process resource to improve concrete supply chain. J. Constr. Eng. Manag. 2017, 143, 04016130. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, Y.; Li, G.; Wang, Y.; Sun, J.; Li, J. Machine-learning-assisted shear strength prediction of reinforced concrete beams with and without stirrups. Eng. Comput. 2020, 5, 1–15. [Google Scholar] [CrossRef]

- Akinci, B.; Boukamp, F.; Gordon, C.; Huber, D.; Lyons, C.; Park, K. A formalism for utilization of sensor systems and integrated project models for active construction quality control. Autom. Constr. 2006, 15, 124–138. [Google Scholar] [CrossRef]

- Kim, M.-K.; Cheng, J.C.P.; Sohn, H.; Chang, C.-C. A framework for dimensional and surface quality assessment of precast concrete elements using BIM and 3D laser scanning. Autom. Constr. 2015, 49, 225–238. [Google Scholar] [CrossRef]

- Chi, H.-L.; Wang, J.; Wang, X.; Truijens, M.; Yung, P. A conceptual framework of quality-assured fabrication, delivery and installation processes for liquefied natural gas (LNG) plant construction. J. Intell. Robot. Syst. 2015, 79, 433–448. [Google Scholar] [CrossRef]

- Razavi, S.N.; Haas, C.T. Using reference RFID tags for calibrating the estimated locations of construction materials. Autom. Constr. 2011, 20, 677–685. [Google Scholar] [CrossRef]

- Grau, D.; Caldas, C.H.; Haas, C.T.; Goodrum, P.M.; Gong, J. Assessing the impact of materials tracking technologies on construction craft productivity. Autom. Constr. 2009, 18, 903–911. [Google Scholar] [CrossRef]

- Sun, J.; Ma, Y.; Li, J.; Zhang, J.; Ren, Z.; Wang, X. Machine learning-aided design and prediction of cementitious composites containing graphite and slag powder. J. Build. Eng. 2021, 43, 102544. [Google Scholar] [CrossRef]

- Zekavat, P.R.; Mortaheb, M.M.; Han, S.; Bernold, L. Comparative study of GPS-integrated concrete supply management using discrete event simulation. J. Constr. Eng. Proj. Manag. 2014, 4, 31–40. [Google Scholar] [CrossRef][Green Version]

- Khoury, H.M.; Kamat, V.R. Evaluation of position tracking technologies for user localization in indoor construction environments. Autom. Constr. 2009, 18, 444–457. [Google Scholar] [CrossRef]

- Fan, P.; Deng, R.; Qiu, J.; Zhao, Z.; Wu, S. Well logging curve reconstruction based on kernel ridge regression. Arab. J. Geosci. 2021, 14, 1559. [Google Scholar] [CrossRef]

- Soleimanifar, M. IntelliSensorNet: A Positioning Technique Integrating Wireless Sensor Networks and Artificial Neural Networks for Critical Construction Resource Tracking; Lu, M., Ed.; ProQuest Dissertations Publishing: Morrisville, NC, USA, 2011. [Google Scholar]

- Shin, T.-H.; Chin, S.; Yoon, S.-W.; Kwon, S.-W. A service-oriented integrated information framework for RFID/WSN-based intelligent construction supply chain management. Autom. Constr. 2011, 20, 706–715. [Google Scholar] [CrossRef]

- Sun, J.; Huang, Y.; Aslani, F.; Ma, G. Properties of a double-layer EMW-absorbing structure containing a graded nano-sized absorbent combing extruded and sprayed 3D printing. Constr. Build. Mater. 2020, 261, 120031. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Zhou, W. RFID Enabled Knowledge-Based Precast Construction Supply Chain. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 499–514. [Google Scholar] [CrossRef]

- Razavi, S.N.; Haas, C.T. Reliability-Based Hybrid Data Fusion Method for Adaptive Location Estimation in Construction. J. Comput. Civ. Eng. 2012, 26, 1–10. [Google Scholar] [CrossRef]

- Kim, C.; Kim, H.; Ryu, J.; Kim, C. Ubiquitous Sensor Network for Construction Material Monitoring. J. Constr. Eng. Manag. 2011, 137, 158–165. [Google Scholar] [CrossRef]

- Ma, G.; Sun, J.; Aslani, F.; Huang, Y.; Jiao, F. Review on electromagnetic wave absorbing capacity improvement of cementitious material. Constr. Build. Mater. 2020, 262, 120907. [Google Scholar] [CrossRef]

- Ren, Z.; Anumba, C.J.; Tah, J. RFID-facilitated construction materials management (RFID-CMM)—A case study of water-supply project. Adv. Eng. Inform. 2011, 25, 198–207. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Yao, X.; Ren, Z.; Zhang, G.; Zhang, C.; Chen, X.; Ma, W.; Wang, X. Machine-Learning-Aided Prediction of Flexural Strength and ASR Expansion for Waste Glass Cementitious Composite. Appl. Sci. 2021, 11, 6686. [Google Scholar] [CrossRef]

- Olatunji, O.; Akanmu, A. An adaptive cyber-physical system’s approach to construction progress monitoring and control. 2014. In ASCE Monograph on Building Information Modelling: Application and Practices in the AEC Industry; American Society of Engineers: Reston, VA, USA, 2014. [Google Scholar]

- Young, D.; Haas, C.T.; Goodrum, P.; Caldas, C. Improving Construction Supply Network Visibility by Using Automated Materials Locating and Tracking Technology. J. Constr. Eng. Manage.-ASCE 2011, 137, 976–984. [Google Scholar] [CrossRef]

- Sun, J.; Huang, Y.; Aslani, F.; Ma, G. Electromagnetic wave absorbing performance of 3D printed wave-shape copper solid cementitious element. Cem. Concr. Compos. 2020, 114, 103789. [Google Scholar] [CrossRef]

- Wang, J.; Shou, W.; Wang, X.; Wu, P. Developing and evaluating a framework of total constraint management for improving workflow in liquefied natural gas construction. Constr. Manag. Econ. 2016, 34, 859–874. [Google Scholar] [CrossRef]

- Moon, S.; Xu, S.; Hou, L.; Wu, C.; Wang, X.; Tam, V.W.Y. RFID-Aided Tracking System to Improve Work Efficiency of Scaffold Supplier: Stock Management in Australasian Supply Chain. J. Constr. Eng. Manag. 2018, 144, 4017115. [Google Scholar] [CrossRef]

- Park, M.-W.; Koch, C.; Brilakis, I. Three-Dimensional Tracking of Construction Resources Using an On-Site Camera System. J. Comput. Civ. Eng. 2012, 26, 541–549. [Google Scholar] [CrossRef]

- Park, M.-W.; Makhmalbaf, A.; Brilakis, I. Comparative study of vision tracking methods for tracking of construction site resources. Autom. Constr. 2011, 20, 905–915. [Google Scholar] [CrossRef]

- Turkan, Y.; Bosche, F.; Haas, C.T.; Haas, R. Automated progress tracking using 4D schedule and 3D sensing technologies. Autom. Constr. 2012, 22, 414–421. [Google Scholar] [CrossRef]

- Song, L.; Mohammed, T.; Stayshich, D.; Eldin, N. A Cost Effective Material Tracking and Locating Solution for Material Laydown Yard. Procedia Eng. 2015, 123, 538–545. [Google Scholar] [CrossRef][Green Version]

- Siu, M.-F.; Lu, M.; AbouRizk, S. Combining photogrammetry and robotic total stations to obtain dimensional measurements of temporary facilities in construction field. Vis. Eng. 2013, 1, 4. [Google Scholar] [CrossRef]

- Siddiqui, H. UWB RTLS for Construction Equipment Localization: Experimental Performance Analysis and Fusion with Video Data. Ph.D. Thesis, Concordia University, Montreal, Canada, 2014. [Google Scholar]

- Xu, D.; Liu, Q.; Qin, Y.; Chen, B. Analytical approach for crack identification of glass fiber reinforced polymer–sea sand concrete composite structures based on strain dissipations. Struct. Health Monit. 2020. [Google Scholar] [CrossRef]

- Sepasgozar, S.M. Technology Adoption in Construction; The University of New South Wales Sydney: Sydney, Australia, 2015. [Google Scholar]

- Mitropoulos, P.; Tatum, C.B. Technology Adoption Decisions in Construction Organizations. J. Constr. Eng. Manag. 1999, 125, 330–338. [Google Scholar] [CrossRef]

- Hong, Y.; Sepasgozar, S.; Ahmadian, A.; Akbarnezhad, A. Factors influencing BIM Adoption in Small and Medium Sized Construction Organizations. In Proceedings of the International Symposium on Automation and Robotics in Construction, ISARC, Auburn, AL, USA, 18–21 July 2016; Volume 33, p. 1. [Google Scholar]

- Alreshidi, E.; Mourshed, M.; Rezgui, Y. Factors for effective BIM governance. J. Build. Eng. 2017, 10, 89–101. [Google Scholar] [CrossRef]

- Singh, V.; Gu, N.; Wang, X. A theoretical framework of a BIM-based multi-disciplinary collaboration platform. Autom. Constr. 2011, 20, 134–144. [Google Scholar] [CrossRef]

- Ma, W.; Wang, X.; Wang, J.; Xiang, X.; Sun, J. Generative Design in Building Information Modelling (BIM): Approaches and Requirements. Sensors 2021, 21, 5439. [Google Scholar] [CrossRef]

- Aslani, F.; Dehghani, A.; Wang, L. The effect of hollow glass microspheres, carbon nanofibers and activated carbon powder on mechanical and dry shrinkage performance of ultra-lightweight engineered cementitious composites. Constr. Build. Mater. 2021, 280, 122415. [Google Scholar] [CrossRef]

- Lu, N.; Wang, H.; Wang, K.; Liu, Y. Maximum Probabilistic and Dynamic Traffic Load Effects on Short-to-Medium Span Bridges. Comput. Modeling Eng. Sci. 2021, 127, 345–360. [Google Scholar] [CrossRef]

- Mitropoulos, P.; Tatum, C.B. Forces Driving Adoption of New Information Technologies. J. Constr. Eng. Manag. 2000, 126, 340–348. [Google Scholar] [CrossRef]

- Luo, Y.; Zheng, H.; Zhang, H.; Liu, Y. Fatigue reliability evaluation of aging prestressed concrete bridge accounting for stochastic traffic loading and resistance degradation. Adv. Struct. Eng. 2021, 24, 3021–3029. [Google Scholar] [CrossRef]

- Goodrum, P.M.; Haas, C.T.; Caldas, C.; Zhai, D.; Yeiser, J.; Homm, D. Model to Predict the Impact of a Technology on Construction Productivity. J. Constr. Eng. Manag. 2011, 137, 678–688. [Google Scholar] [CrossRef]

- Doloi, H. Rationalizing the Implementation of Web-Based Project Management Systems in Construction Projects Using PLS-SEM. J. Constr. Eng. Manag. 2014, 140, 4014026. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. A Concept for Automated Construction Progress Monitoring: Technologies Adoption for Benchmarking Project Performance Control. Arab. J. Sci. Eng. 2018, 44, 4993–5008. [Google Scholar] [CrossRef]

- Akinbile, B.F.; Oni, O.Z. Assessment of the Challenges and Benefits of Information Communication Technology (ICT) on Construction Industry in OYO State Njgeria. Ann. Fac. Eng. Hunedoara 2016, 14, 161–166. [Google Scholar]

- Tang, Y.; Feng, W.; Chen, Z.; Nong, Y.; Guan, S.; Sun, J. Fracture behavior of a sustainable material: Recycled concrete with waste crumb rubber subjected to elevated temperatures. J. Clean. Prod. 2021, 318, 128553. [Google Scholar] [CrossRef]

- Dehghani, A.; Hayatdavoodi, A.; Aslani, F. The ultimate shear capacity of longitudinally stiffened steel-concrete composite plate girders. J. Constr. Steel Res. 2021, 179, 106550. [Google Scholar] [CrossRef]

- Sun, Y.; Li, G.; Zhang, J.; Sun, J.; Xu, J. Development of an ensemble intelligent model for assessing the strength of cemented paste backfill. Adv. Civ. Eng. 2020, 2020, 1643529. [Google Scholar] [CrossRef]

- Häikiö, J.; Kallio, J.; Mäkelä, S.-M.; Keränen, J. IoT-based safety monitoring from the perspective of construction site workers. Int. J. Occup. Environ. Saf. 2020, 4, 1–14. [Google Scholar] [CrossRef]

- Aghimien, D.; Aigbavboa, C.; Oke, A.; Koloko, N. Digitalisation in construction industry: Construction professionals perspective. In Proceedings of the Fourth Australasia and South-East Asia Structural Engineering and Construction Conference, Brisbane, Australia, 3–5 December 2018. [Google Scholar]

- Sun, J.; Wang, X.; Zhang, J.; Xiao, F.; Sun, Y.; Ren, Z.; Zhang, G.; Liu, S.; Wang, Y. Multi-objective optimisation of a graphite-slag conductive composite applying a BAS-SVR based model. J. Build. Eng. 2021, 44, 103223. [Google Scholar] [CrossRef]

- Heller, A.; Orthmann, C. Wireless technologies for the construction sector—Requirements, energy and cost efficiencies. Energy Build. 2014, 73, 212–216. [Google Scholar] [CrossRef]

- Ozorhon, B.; Oral, K. Drivers of innovation in construction projects. J. Constr. Eng. Manag. 2017, 143, 04016118. [Google Scholar] [CrossRef]

- Aslani, F.; Deghani, A.; Asif, Z. Development of lightweight rubberized geopolymer concrete by using polystyrene and recycled crumb-rubber aggregates. J. Mater. Civ. Eng. 2020, 32, 04019345. [Google Scholar] [CrossRef]

- Ahmed, V.; Aziz, Z.; Tezel, A.; Riaz, Z. Challenges and drivers for data mining in the AEC sector. Eng. Constr. Archit. Manag. 2018, 25, 1436–1453. [Google Scholar] [CrossRef]

- Sun, J.; Huang, Y.; Aslani, F.; Wang, X.; Ma, G. Mechanical enhancement for EMW-absorbing cementitious material using 3D concrete printing. J. Build. Eng. 2021, 41, 102763. [Google Scholar] [CrossRef]

- Sun, J.; Aslani, F.; Wei, J.; Wang, X. Electromagnetic absorption of copper fiber oriented composite using 3D printing. Constr. Build. Mater. 2021, 300, 124026. [Google Scholar] [CrossRef]

- Sun, J.; Aslani, F.; Lu, J.; Wang, L.; Huang, Y.; Ma, G. Fresh and mechanical behaviour of developed fibre-reinforced lightweight engineered cementitious composites for 3D concrete printing containing hollow glass microspheres. Ceram. Int. 2021, 47, 27107–27121. [Google Scholar] [CrossRef]

- Sweis, G.J.; Sweis, R.J.; Al-Shboul, M.A.; Al-Dweik, G.A. The Impact of Information Technology (IT) Adoption on the Quality of Construction Projects: The Case of Jordan. Int. J. Inf. Technol. Proj. Manag. (IJITPM) 2015, 6, 26–40. [Google Scholar] [CrossRef]

- Didehvar, N.; Teymourifard, M.; Mojtahedi, M.; Sepasgozar, S. An Investigation on Virtual Information Modeling Acceptance Based on Project Management Knowledge Areas. Buildings 2018, 8, 80. [Google Scholar] [CrossRef]

- Golizadeh, H.; Hosseini, M.R.; Edwards, D.J.; Abrishami, S.; Taghavi, N.; Banihashemi, S. Barriers to adoption of RPAs on construction projects: A task–technology fit perspective. Constr. Innov. 2019, 19, 149–169. [Google Scholar] [CrossRef]

- Dithebe, K.; Aigbavboa, C.O.; Thwala, W.D.; Malabela, A.T. Descriptive perspective on factors affecting the complete adoption of information technology systems in the construction firms. J. Phys. Conf. Ser. 2019, 1378, 22045. [Google Scholar] [CrossRef]

- Olaniyan, R. Barriers to Technology Adoption Among Construction Project Managers in Nigeria; ProQuest Dissertations Publishing: Morrisville, NC, USA, 2019. [Google Scholar]

- Amusan, L.; Oloniju, L.I.; Akomolafe, M.; Makinde, A.; Peter, N.J.; Farayola, H.; Osawaru, F. Adopting information and communication technology in construction industry. Int. J. Mech. Eng. Technol. (IJMET) 2018, 9, 739–746. [Google Scholar]

- Adriaanse, A.; Voordijk, H.; Dewulf, G. Adoption and Use of Interorganizational ICT in a Construction Project. J. Constr. Eng. Manag. 2010, 136, 1003–1014. [Google Scholar] [CrossRef]

- Rogers, J.; Chong, H.Y.; Preece, C. Adoption of Building Information Modelling technology (BIM): Perspectives from Malaysian engineering consulting services firms. Eng. Constr. Archit. Manag. 2015, 22, 424–445. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, X. Broadband cancellation method in an adaptive co-site interference cancellation system. Int. J. Electron. 2021. [Google Scholar] [CrossRef]

- Elshafey, A.; Saar, C.C.; Aminudin, E.B.; Gheisari, M.; Usmani, A. Technology acceptance model for Augmented Reality and Building Information Modeling integration in the construction industry. J. Inf. Technol. Constr. 2020, 25, 161–172. [Google Scholar] [CrossRef]

- Mettler, T.; Wulf, J. Physiolytics at the workplace: Affordances and constraints of wearables use from an employee’s perspective. Inf. Syst. J. 2018, 29, 245–273. [Google Scholar] [CrossRef]

- Choi, B.; Hwang, S.; Lee, S. What drives construction workers’ acceptance of wearable technologies in the workplace?: Indoor localization and wearable health devices for occupational safety and health. Autom. Constr. 2017, 84, 31–41. [Google Scholar] [CrossRef]

- Davis, F.D. Perceived Usefulness, Perceived Ease of Use, and User Acceptance of Information Technology. MIS Q. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Son, H.; Park, Y.; Kim, C.; Chou, J.-S. Toward an understanding of construction professionals’ acceptance of mobile computing devices in South Korea: An extension of the technology acceptance model. Autom. Constr. 2012, 28, 82–90. [Google Scholar] [CrossRef]

- Lee, S.; Yu, J.; Jeong, D. BIM Acceptance Model in Construction Organizations. J. Manag. Eng. 2015, 31, 04014048. [Google Scholar] [CrossRef]

- Dehghani, A.; Aslani, F. Fatigue performance and design of concrete-filled steel tubular joints: A critical review. J. Constr. Steel Res. 2019, 162, 105749. [Google Scholar] [CrossRef]

| Benefit | Reference |

|---|---|

| proximity detection of workers on foot and construction equipment | [26] |

| unsafe proximity detection identification | [28,29] |

| construction equipment management | [30,31] |

| situational awareness improvement of on-site workers | [32] |

| construction resources identification | [33] |

| enhancement of tower crane navigation systems | [34] |

| construction equipment activity recognition | [35,36] |

| Benefit | Reference |

|---|---|

| risky behavior of workers recognition | [41] |

| accidents and collision prevention | [42,43,44] |

| proximity detection alert systems | [45] |

| storage of safety information | [46] |

| controls of workers and vehicles to specific positions | [47] |

| indoor localization of mobile and stationary construction resources | [48,49] |

| detection of construction workers localization | [50] |

| Benefit | Reference |

|---|---|

| improvement on a communication platform for tower crane operations | [61,81,82] |

| environmental and structural health monitoring | [78,83,84] |

| recognition and detection of construction operation | [85,86] |

| access control of restricted areas and examination of proper personal protective equipment | [87] |

| automated monitoring of construction processes | [88,89] |

| Method | Reference |

|---|---|

| object detection methods | [95] |

| movement prediction of workers | [90] |

| posture estimation and classification | [96] |

| identification of potential bodily work-related ergonomic risks | [91] |

| identification of unsafe behavior | [97,98] |

| Benefit | Reference |

|---|---|

| construction waste management and machinery maintenance records | [13] |

| identification of construction material and resources | [33] |

| recognition of construction staff location | [131] |

| automatic progress reports | [134,135] |

| operational cost reduction in precast construction supply chain | [136] |

| material localization, monitoring, and tracking | [137,138,139] |

| active information flow between construction progress and material monitoring staff | [140,141] |

| applications in time and schedule management | [142] |

| supply network visibility | [143,144] |

| asset management and supply chain management | [145,146] |

| Benefit | Reference |

|---|---|

| cost reduction | [164,165,166] |

| time-saving and improved productivity | [167,168,169] |

| reduced risk of injury and illness | [170] |

| increase employees’ wellness and satisfaction | [171] |

| better document quality | [172,173] |

| better facilities management | [174] |

| process and performance improvement | [175,176] |

| improved leadership and decision support systems | [177] |

| mechanical enhancement on concrete printing | [178,179,180] |

| improved quality of construction project delivery | [181] |

| Barriers | Reference | Barriers | Reference |

|---|---|---|---|

| cost-related | people-related | ||

| operating cost | [164] | lack of well-trained staff | [167] |

| cost of training and employing professionals | [177] | compliance of employees | [166] |

| cost of maintenance | [184] | legal or ethical concerns | [171] |

| implementation cost | [185] | resistance to change | [182] |

| uncertain cost-benefit relation | [186] | company culture | [187] |

| lack of government support | [188] | ||

| technology-related | other barriers | ||

| operational difficulties | [19,189] | manufacturing requirements | [18] |

| power supply issues | [174] | change in the process | [182] |

| data management issues | [177] | site-related issues | [183] |

| lack of proper IT infrastructure | [182] | temporary nature of construction | [187] |

| technology immaturity | [183] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arabshahi, M.; Wang, D.; Sun, J.; Rahnamayiezekavat, P.; Tang, W.; Wang, Y.; Wang, X. Review on Sensing Technology Adoption in the Construction Industry. Sensors 2021, 21, 8307. https://doi.org/10.3390/s21248307

Arabshahi M, Wang D, Sun J, Rahnamayiezekavat P, Tang W, Wang Y, Wang X. Review on Sensing Technology Adoption in the Construction Industry. Sensors. 2021; 21(24):8307. https://doi.org/10.3390/s21248307

Chicago/Turabian StyleArabshahi, Mona, Di Wang, Junbo Sun, Payam Rahnamayiezekavat, Weichen Tang, Yufei Wang, and Xiangyu Wang. 2021. "Review on Sensing Technology Adoption in the Construction Industry" Sensors 21, no. 24: 8307. https://doi.org/10.3390/s21248307

APA StyleArabshahi, M., Wang, D., Sun, J., Rahnamayiezekavat, P., Tang, W., Wang, Y., & Wang, X. (2021). Review on Sensing Technology Adoption in the Construction Industry. Sensors, 21(24), 8307. https://doi.org/10.3390/s21248307