An Improved Timed Elastic Band (TEB) Algorithm of Autonomous Ground Vehicle (AGV) in Complex Environment

Abstract

:1. Introduction

2. Proposed TEB Algorithm

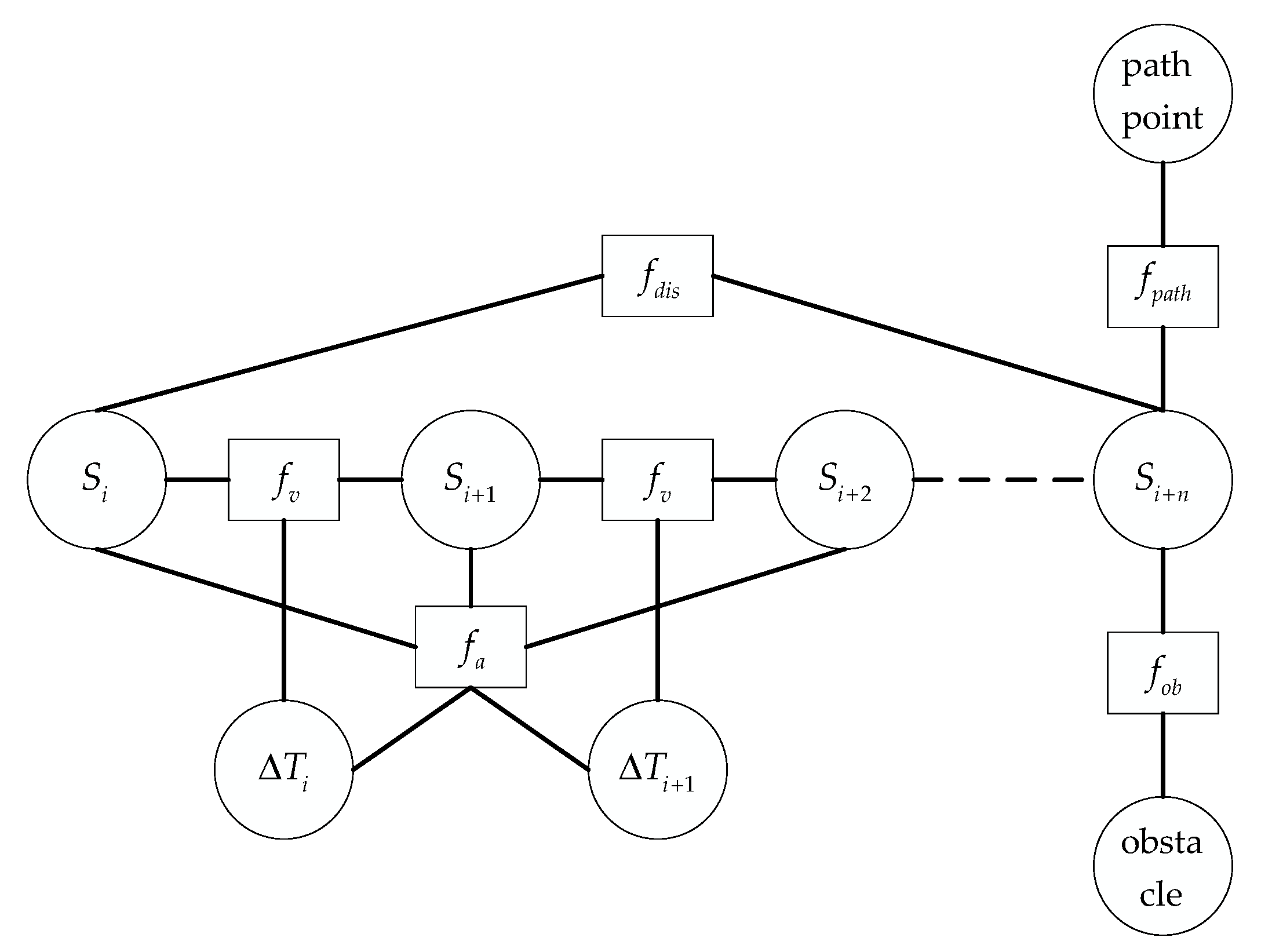

2.1. Timed Elastic Band Algorithm Model Construction

2.2. AGV Local Path Planning Based on Improved TEB Algorithm

2.2.1. A* Algorithm Is Fused to Introduce the Shortest Distance Constraint

2.2.2. Implementation of AGV Local Path Planning Based on Improved TEB Algorithm

3. Simulation Experiment and Real Robot Experiment

3.1. Simulation Experiment

3.2. Real Robot Experiment

4. Results Analysis

4.1. Simulated Experiment Results Analysis

4.2. Practical Experiment Results Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferrer, G.; Garrell, A.; Sanfeliu, A. Social-aware robot navigation in urban environments. In Proceedings of the 2013 European Conference on Mobile Robots, Barcelona, Spain, 25–27 September 2013; pp. 331–336. [Google Scholar]

- Chen, W.; Wu, X.; Lu, Y. An improved path planning method based on artificial potential field for a mobile robot. Cybern. Inf. Technol. 2015, 15, 181–191. [Google Scholar] [CrossRef] [Green Version]

- Seddaoui, A.; Saaj, C.M. Collision-free optimal trajectory generation for a space robot using genetic algorithm. Acta Astronaut. 2021, 179, 311–321. [Google Scholar] [CrossRef]

- Saranrittichai, P.; Niparnan, N.; Sudsang, A. Robust local obstacle avoidance for mobile robot based on dynamic window approach. In Proceedings of the 2013 10th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Krabi, Thailand, 15–17 May 2013; pp. 1–4. [Google Scholar]

- Chen, Y.; Liang, J.; Wang, Y.; Pan, Q.; Tan, J.; Mao, J. Autonomous mobile robot path planning in unknown dynamic environments using neural dynamics. Soft Comput. 2020, 24, 13979–13995. [Google Scholar] [CrossRef]

- Song, Q.; Zhao, Q.; Wang, S.; Liu, Q.; Chen, X. Dynamic path planning for unmanned vehicles based on fuzzy logic and improved ant colony optimization. IEEE Access 2020, 8, 62107–62115. [Google Scholar] [CrossRef]

- Fei, X. Research on robot obstacle avoidance and path planning based on improved artificial potential field method. Comput. Sci. 2016, 43, 293–296. [Google Scholar]

- Mai, X.; Li, D.; Ouyang, J.; Luo, Y. An improved dynamic window approach for local trajectory planning in the environment with dense objects. In Proceedings of the Journal of Physics Conference Series; IOP Publishing: Bristol, UK, 2021; p. 012003. [Google Scholar]

- Wang, X.-Y.; Yang, L.; Zhang, Y.; Meng, S. Robot path planning based on improved ant colony algorithm with potential field heuristic. Control. Decis. 2018, 33, 50–56. [Google Scholar]

- Lee, J.; Kang, B.Y.; Kim, D.W. Fast genetic algorithm for robot path planning. Electron. Lett. 2013, 49, 1449–1451. [Google Scholar] [CrossRef]

- Rösmann, C.; Feiten, W.; Wösch, T.; Hoffmann, F.; Bertram, T. Trajectory modification considering dynamic constraints of autonomous robots. In Proceedings of the ROBOTIK 2012, 7th German Conference on Robotics, Munich, Germany, 21–22 May 2012; pp. 1–6. [Google Scholar]

- Quinlan, S.; Khatib, O. Elastic bands: Connecting path planning and control. In Proceedings of the IEEE International Conference on Robotics and Automation, Atlanta, GA, USA, 2–6 May 1993; pp. 802–807. [Google Scholar]

- Rösmann, C.; Feiten, W.; Wösch, T.; Hoffmann, F.; Bertram, T. Efficient trajectory optimization using a sparse model. In Proceedings of the 2013 European Conference on Mobile Robots, Barcelona, Spain, 25–27 September 2013; pp. 138–143. [Google Scholar]

- Rösmann, C.; Hoffmann, F.; Bertram, T. Integrated online trajectory planning and optimization in distinctive topologies. Robot. Auton. Syst. 2017, 88, 142–153. [Google Scholar] [CrossRef]

- Rösmann, C.; Oeljeklaus, M.; Hoffmann, F.; Bertram, T. Online trajectory prediction and planning for social robot navigation. In Proceedings of the 2017 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Munich, Germany, 3–7 July 2017; pp. 1255–1260. [Google Scholar]

- Nguyen, L.A.; Pham, T.D.; Ngo, T.D.; Truong, X.T. A Proactive Trajectory Planning Algorithm for Autonomous Mobile Robots in Dynamic Social Environments. In Proceedings of the 2020 17th International Conference on Ubiquitous Robots (UR), Kyoto, Japan, 22–26 June 2020; pp. 309–314. [Google Scholar]

- Han, Y.; Cheng, Y.; Xu, G. Trajectory tracking control of AGV based on sliding mode control with the improved reaching law. IEEE Access 2019, 7, 20748–20755. [Google Scholar] [CrossRef]

- Kümmerle, R.; Grisetti, G.; Strasdat, H.; Konolige, K.; Burgard, W. G20: A general framework for graph optimization. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 3607–3613. [Google Scholar]

| Constraint Parameters | Values |

|---|---|

| Maximum X linear velocity (m/s) | 0.4 |

| Maximum backward linear velocity (m/s) | 0.2 |

| Maximum angular velocity (rad/s) | 0.3 |

| Maximum X linear acceleration (m/s2) | 0.5 |

| Maximum angular acceleration (rad/s2) | 0.5 |

| Obstruction expansion radius (m) | 0.6 |

| Minimum distance to obstacle (m) | 0.25 |

| the weight of shortest distance constraint | 30 |

| Starting Point | Starting Time | End Time | Total Time Spent | |

|---|---|---|---|---|

| Traditional TEB algorithm planning time | (6.496,−2.52) | 10:43:02.8 | 10:43:40.0 | 37.2s |

| Improved TEB algorithm planning time | (6.490,−2.50) | 10:49:39.0 | 10:50:15.0 | 36s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Ma, X.; Peng, T.; Wang, H. An Improved Timed Elastic Band (TEB) Algorithm of Autonomous Ground Vehicle (AGV) in Complex Environment. Sensors 2021, 21, 8312. https://doi.org/10.3390/s21248312

Wu J, Ma X, Peng T, Wang H. An Improved Timed Elastic Band (TEB) Algorithm of Autonomous Ground Vehicle (AGV) in Complex Environment. Sensors. 2021; 21(24):8312. https://doi.org/10.3390/s21248312

Chicago/Turabian StyleWu, Jiafeng, Xianghua Ma, Tongrui Peng, and Haojie Wang. 2021. "An Improved Timed Elastic Band (TEB) Algorithm of Autonomous Ground Vehicle (AGV) in Complex Environment" Sensors 21, no. 24: 8312. https://doi.org/10.3390/s21248312

APA StyleWu, J., Ma, X., Peng, T., & Wang, H. (2021). An Improved Timed Elastic Band (TEB) Algorithm of Autonomous Ground Vehicle (AGV) in Complex Environment. Sensors, 21(24), 8312. https://doi.org/10.3390/s21248312