An Easily Fabricated High Performance Fabry-Perot Optical Fiber Humidity Sensor Filled with Graphene Quantum Dots

Abstract

1. Introduction

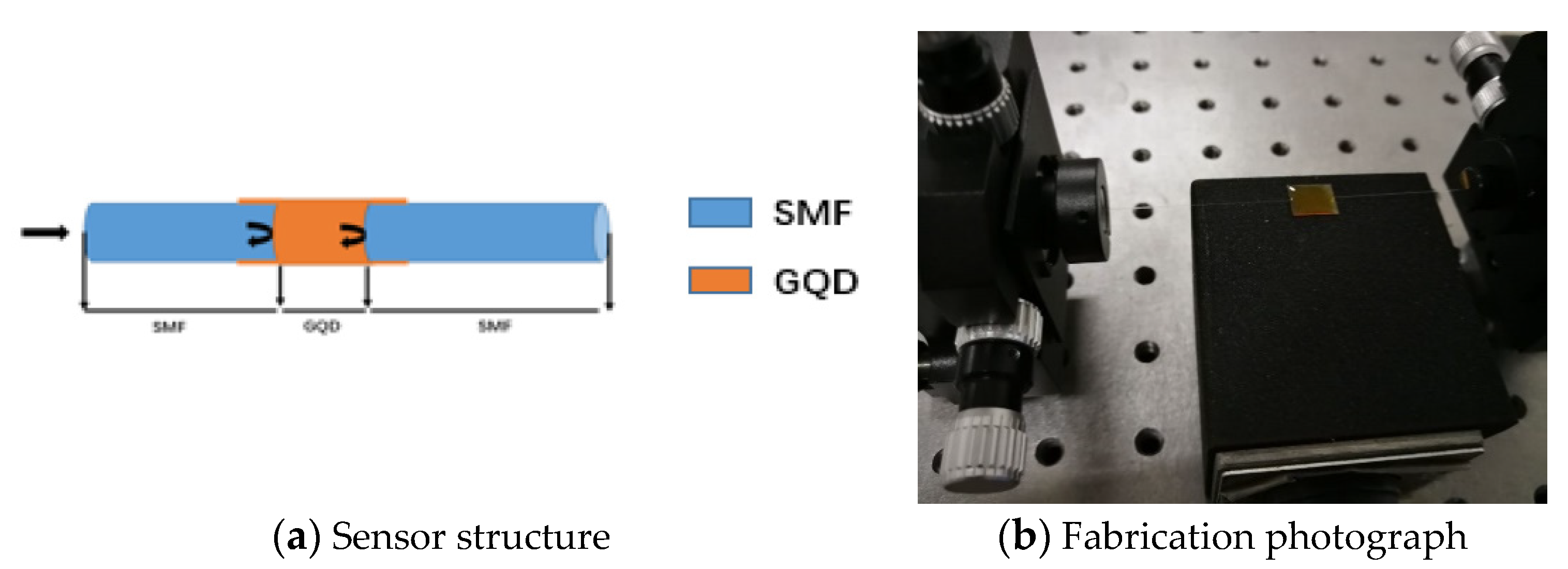

2. Sensor Fabrication and Sensing Principle

3. Experiments

3.1. Experimental Setup

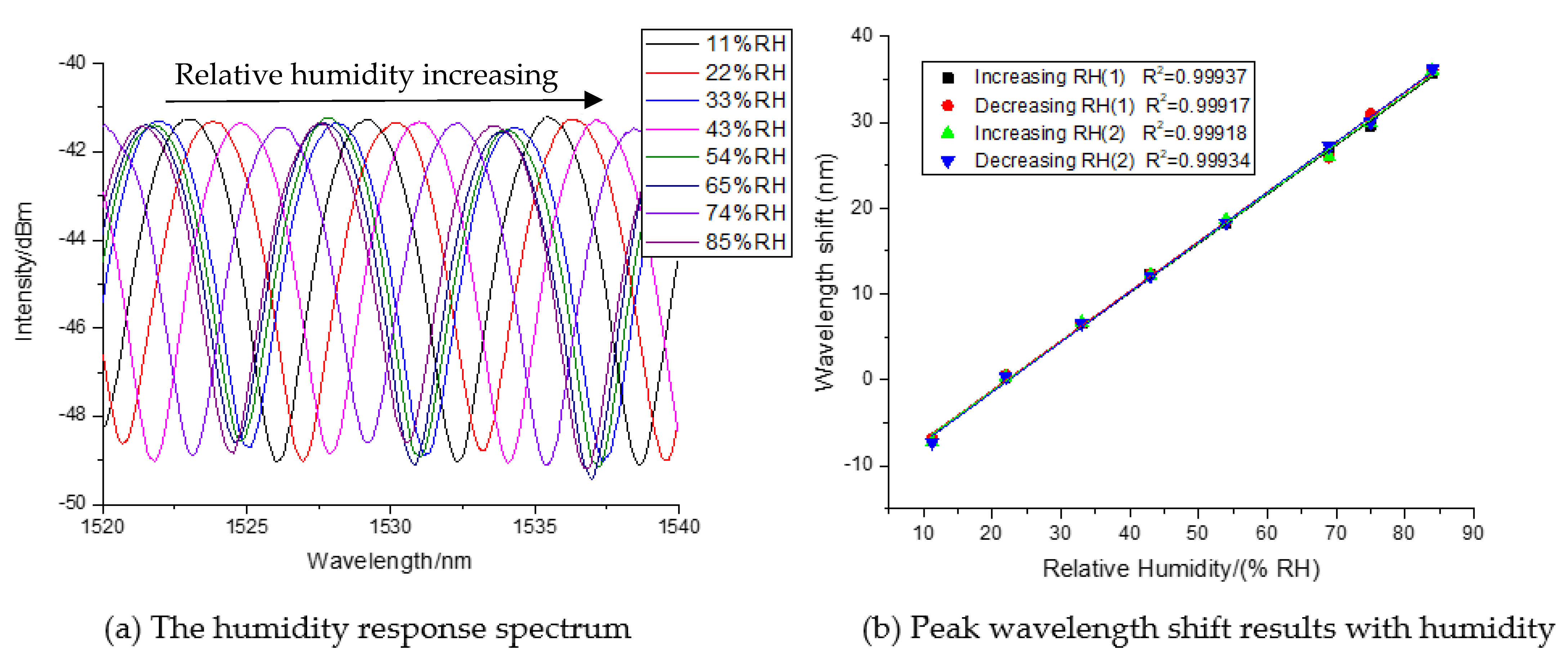

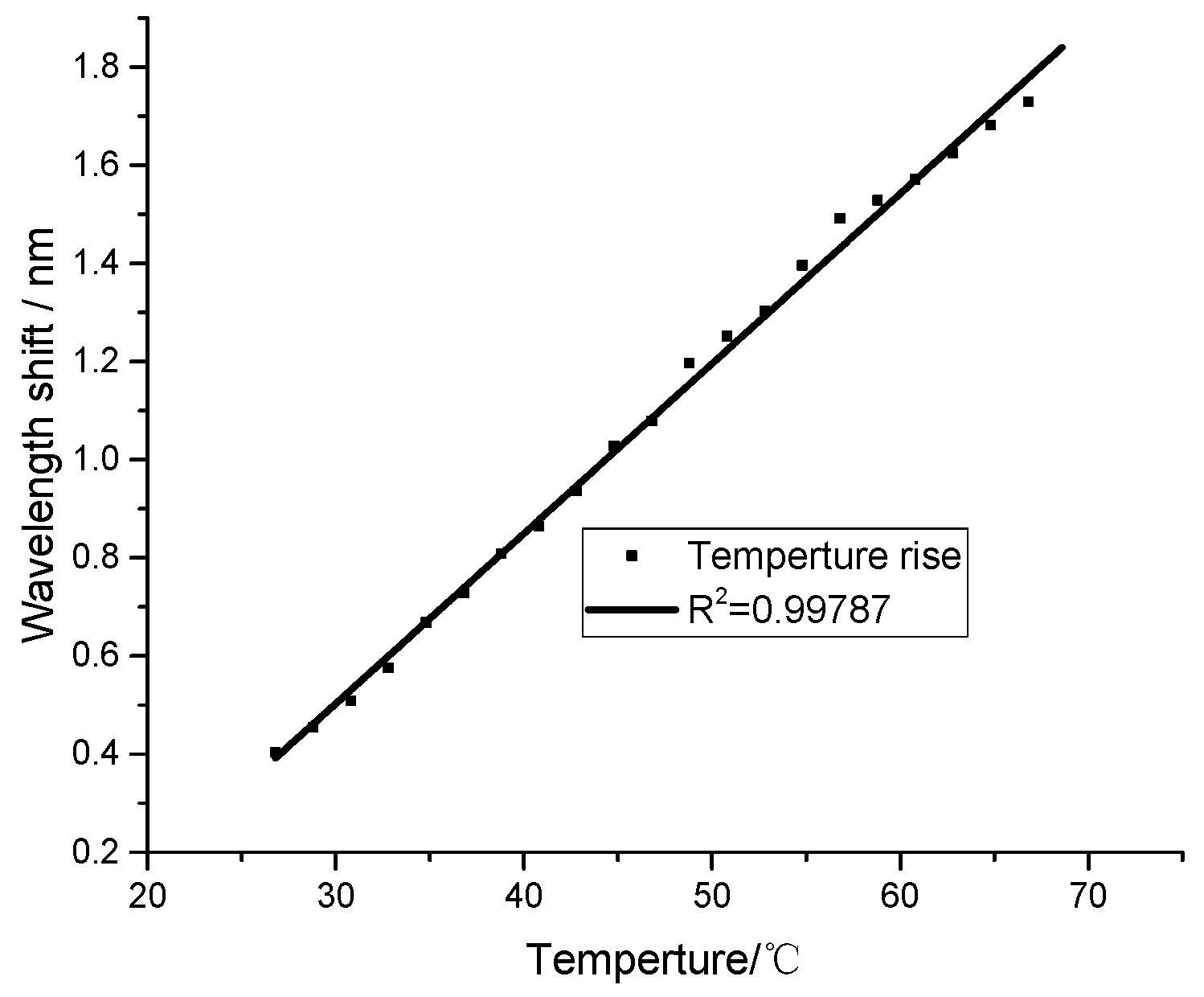

3.2. Humidity Responding Experiments and Discussions

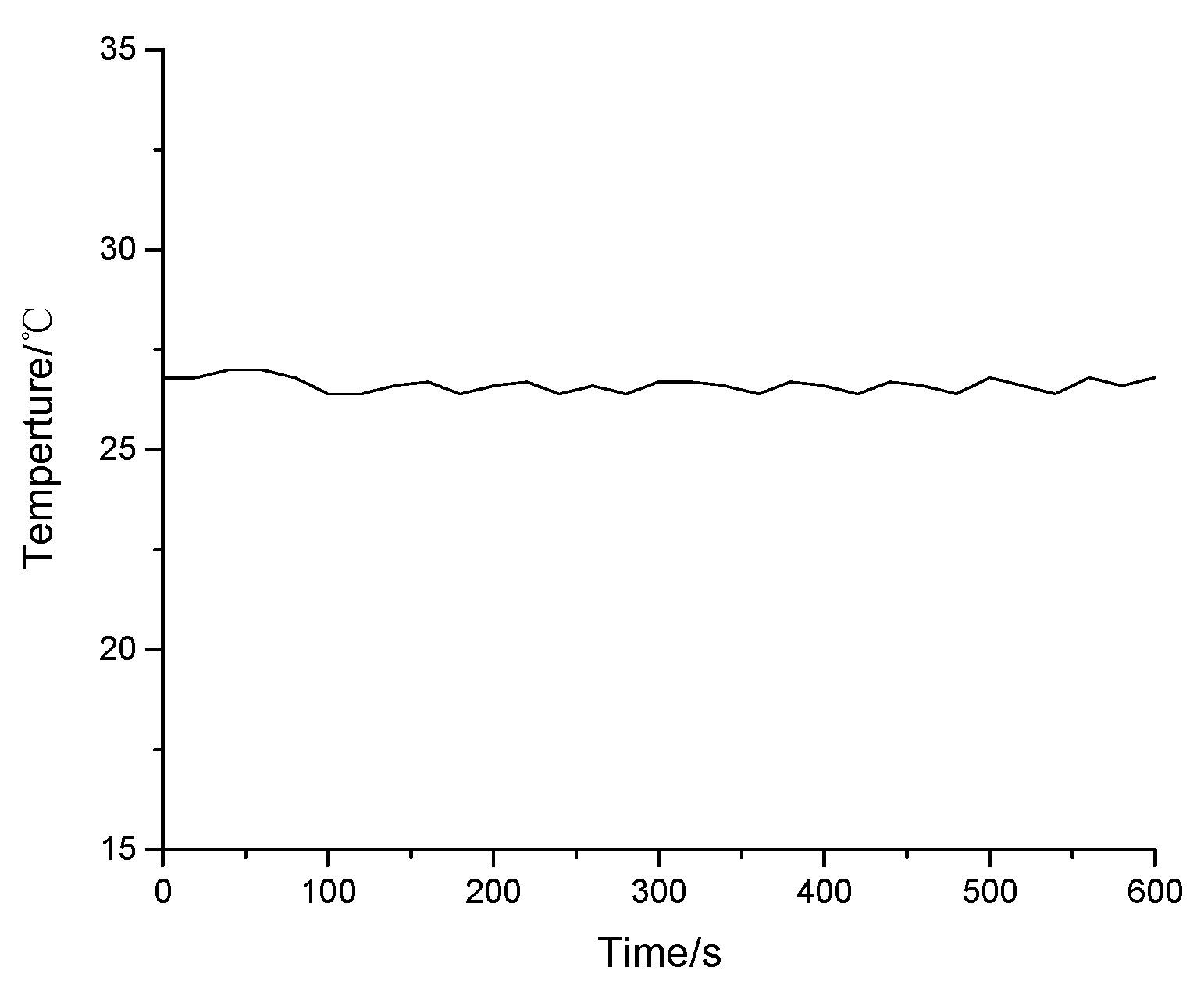

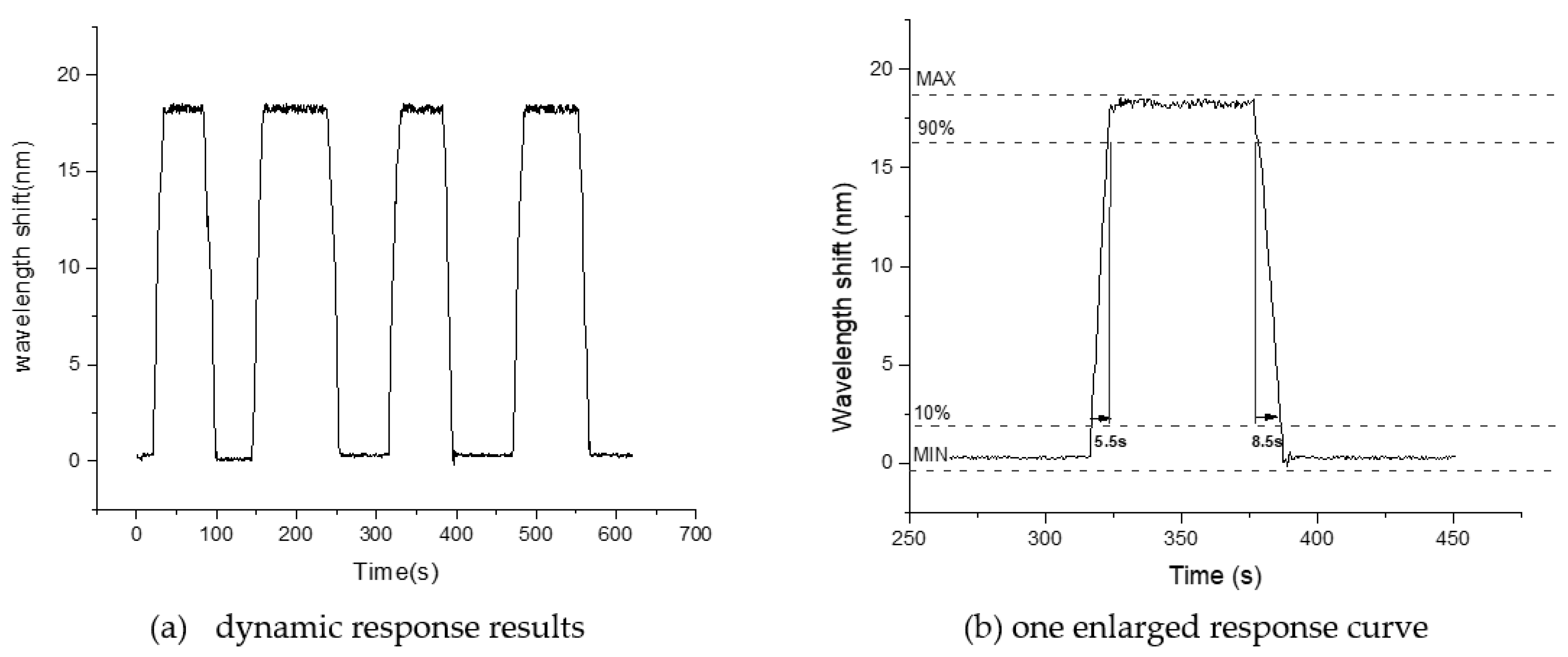

3.3. Dynamic Responding of the Sensor

3.4. The Cavity Length Influence

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jali, M.H.; Rahim, H.R.; Johari, M.A.; Hamid, S.S.; Yusof, H.H.; Thokchom, S.; Wang, P.; Harun, S.W. Optical characterization of different waist diameter on microfiber loop resonator humidity sensor. Sens. Actuators A Phys. 2019, 285, 200–209. [Google Scholar] [CrossRef]

- Shin, J.C.; Yoon, M.S.; Han, Y.G. Relative humidity sensor based on an optical microfiber knot resonator with a polyvinyl alcohol overlay. J. Lightwave Technol. 2016, 34, 4511–4515. [Google Scholar] [CrossRef]

- Wang, P.; Gu, F.; Zhang, L.; Tong, L. Polymer microfiber rings for high-sensitivity optical humidity sensing. Appl. Opt. 2011, 50, G7. [Google Scholar] [CrossRef]

- Zhang, L.; Gu, F.; Lou, J.; Yin, X.; Tong, L. Fast detection of humidity with a subwavelength-diameter fiber taper coated with gelatin film. Opt. Express 2008, 16, 13349. [Google Scholar] [CrossRef]

- Story, P.R.; Galipeau, D.W.; Mileham, R.D. A study of low-cost sensors for measuring low relative humidity. Sens. Actuators B Chem. 1995, 25, 681–685. [Google Scholar] [CrossRef]

- Sakai, Y.; Matsuguchi, M.; Hurukawa, T. Humidity sensor using cross-linked polychloromethyl styrene. Sens. Actuators B Chem. 2000, 66, 135–138. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.Q.; Lv, R.Q.; Xia, F.; Song, A.N. Small in-fiber Fabry-Perot low-frequency acoustic pressure sensor with PDMS diaphragm em-bedded in hollow-core fiber. Sens. Actuators A Phys. 2018, 270, 162–169. [Google Scholar] [CrossRef]

- Tong, R.J.; Zhao, Y.; Chen, M.Q.; Peng, Y. Relative humidity sensor based on small up-tapered photonic crystal fiber Mach–Zehnder interferometer. Sens. Actuators A Phys. 2018, 280, 24–30. [Google Scholar] [CrossRef]

- Brook, T.E.; Taib, M.N. Extending the range of a fiber-optic relative-humidity sensor. Sens. Actuators B Chem. 1997, 38, 272–276. [Google Scholar] [CrossRef]

- Su, D.; Qiao, X.; Rong, Q.; Sun, H.; Zhang, J.; Bai, Z.; Du, Y.; Feng, D.; Wang, Y.; Hu, M.; et al. A fiber Fabry-Perot interferometer based on a PVA coating for humidity measurement. Opt. Commun. 2013, 311, 107–110. [Google Scholar] [CrossRef]

- Tan, Y.Z.; Sun, L.P. Temperature-insensitive humidity sensor based on a silica Fiber taper interferometer. IEEE Photon. Technol. Lett. 2013, 25, 2201–2204. [Google Scholar] [CrossRef]

- Sun, L.; Yuliya, S. Investigation of humidity and temperature response of a silica gel coated microfiber coupler. IEEE Photon. J. 2016, 8, 1–7. [Google Scholar] [CrossRef]

- Aldaba, A.L.; Torres, D.L.; Elosua, C.; Auguste, J.L.; Jamier, R.; Roy, P.; Arregui, F.J.; Amo, M.L. SnO2-MOF-Fabry-Perot optical sensor for relative humidity measurements. Sens. Actuators B Chem. 2018, 257, 189–199. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, R.J.; Chen, M.Q.; Xia, F. Relative. Relative humidity sensor based on hollow core fiber filled with GQDs-PVA. Sens. Actuators B Chem. 2019, 284, 96–102. [Google Scholar] [CrossRef]

- Zebian, H.Y.; Taher, H.J. Relative humidity sensor based on no-core multimode interferometer coated with Al2O3-PVA composite films. Opt. Fiber Technol. 2020, 54, 102110. [Google Scholar] [CrossRef]

- Hromadka, J.; Hazlan, N.N.; Hernandez, F.U.; Correia, R.; Norris, A.; Morgan, S.P.; Korposh, S. Simultaneous in situ temperature and relative humidity monitoring in mechanical ventilators using an array of functionalised optical fibre long period grating sensors. Sens. Actuators B Chem. 2019, 286, 306–314. [Google Scholar] [CrossRef]

- Konstantaki, M.; Pissadakis, S.; Piside-polishedas, S.; Madamopoulos, N.; Vainos, N.A. Optical fiber long-period grating humidity sensor with poly ethylene oxide, /cobalt chloride coating. Appl. Opt. 2006, 45, 4567–4571. [Google Scholar] [CrossRef]

- Kronenberg, P.; Rastogi, P.K.; Giaccari, P.; Limberger, H.G. Relative Humidity sensor with optical fiber Bragg grating. Opt. Lett. 2002, 27, 1385–1387. [Google Scholar] [CrossRef]

- Gupta, B.D. A novel probe for a fiber optic humidity sensor. Sens. Actuators B Chem. 2001, 80, 132–135. [Google Scholar] [CrossRef]

- Ahmad, H.; Rahman, M.T.; Sakeh, S.N.A.; Razak, M.Z.A.; Zulkifli, M.Z. Humidity sensor based on microfiber resonator with reduced graphene oxide. Optik 2016, 127, 3158–3161. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, J.; Cai, X.; Tan, S.; Yu, J.; Lu, H.; Luo, Y.; Liao, G.; Li, S.; Tang, J.; et al. Reduced graphene oxide for fiber-optic humidity sensing. Opt. Express 2014, 22, 31555–31567. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zhu, W.G.; Li, Z.H.; Chen, G.; Chen, L.; Zhou, J.; Lin, H.; Guan, J.; Fang, W.; Liu, X.; et al. High-performance fibre-optic humidity sensor based on a side-polished fibre wavelength selectively coupled with grapheme oxide film. Sens. Actuators B Chem. 2018, 255, 57–69. [Google Scholar] [CrossRef]

- Du, B.B.; Yang, D.X.; She, X.Y.; Dong, M.; Jiang, Y.; Lu, F. MoS2-based all-fiber humidity sensor for monitoring human breath with fast response and recovery. Sens. Actuators B Chem. 2017, 251, 180–184. [Google Scholar] [CrossRef]

- Li, T.; Dong, X.; Chan, C.C.; Ni, K.; Zhang, S.; Shum, P.P. Humidity sensor with a PVA-coated photonic crystal fiber interferometer. IEEE Sens. J. 2013, 13, 2214–2216. [Google Scholar] [CrossRef]

- Bariain, C.; Matias, I.R.; Arregui FIManuel, L.A. Optical fiber humidity sensor based on a tapered fiber coated with agarose gel. Sens. Actuators B Chem. 2000, 69, 127–131. [Google Scholar] [CrossRef]

- Alizadeh, T.; Shokri, M. A new humidity sensor based upon grapheme quantum dots prepared via carbonization of citric acid. Sens. Actuators B Chem. 2016, 222, 728–773. [Google Scholar] [CrossRef]

- Consales, M.; Berruti, G.; Borriello, A.; Giordano, M.; Buontempo, S.; Breglio, G.; Makovec, A.; Petagna, P.; Cusanoet, A. Nanoscale TiO2-coated LPGs as radiation-tolerant humidity sensors for high-energy physics applications. Opt. Lett. 2014, 39, 4128–4131. [Google Scholar] [CrossRef]

- Chu, R.; Guan, C.; Bo, Y.; Shi, J.; Zhu, Z.; Li, P.; Yang, J.; Yuan, L. All-optical graphene-oxide humidity sensor based on a side-polished symmetrical twin-core fiber Michelson interferometer. Sens. Actuators B Chem. 2019, 284, 623–627. [Google Scholar] [CrossRef]

- Shen, C.; Lou, W.; Shentu, F.; Wang, Y.; Tong, L. Tilted fiber Bragg gratings and its fiber humidity and twist sensing applications. In Proceedings of the International Conference on Optical Communications and Networks, Hangzhou, China, 24–27 September 2016; pp. 1–3. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, C. Fiber optic humidity sensor based on the graphene oxide/PVA composite film. Opt. Commun. 2016, 372, 229–234. [Google Scholar] [CrossRef]

- Habibah, M.; Nabihah, H. Optical based relative humidity sensor using tapered optical fiber coated with graphene oxide. In Proceedings of the 4th International Conference on Fundamental and Applied Sciences, Kuala Lumpur, Malaysia, 15–17 August 2016; Volume 1787, pp. 1–6. [Google Scholar] [CrossRef]

| Method | Humidity Sensitive Material | RH/% | Sensitivity | Response and Recovery Time/s | Reference |

|---|---|---|---|---|---|

| Microstructured polymer fiber bragg grating | Polycarbonate | 20~90 | 0.00731 nm/%RH | 10.5, 25 | [8] |

| Long-period grating | Titanium dioxide | 0~10 10~20 | 1.027 nm/%RH 1.453 nm/%RH | 19, 27.1 | [27] |

| Side-polished twin-core fiber | Graphene-oxide | 40~75 60~62.1 | 2.72 nm/%RH 3.76 dB/%RH | 3.6, 6.4 | [28] |

| wheel side-polishing and evaporation | graphene-oxide | 32~85 85~97.6 | 0.145 nm/%RH 0.915 nm/%RH | 2.73, 7.27 | [22] |

| F-P interferometer | PVA-GQDs | 11.3~83.4 | 0.11725 nm/%RH | 4.3, 11.5 | [14] |

| F-P interferometer | GQDs | 11~84 | 0.567 nm/%RH | 5.5, 8.5 | Our work |

| Material | Measurement Range (%RH) | Sensitivity | Correlation Coefficient | Reference |

|---|---|---|---|---|

| Graphene oxide | 10–80 | 0.129 dB/%RH | 99% | [29] |

| Graphene oxide | 32–85 | 0.145 nm/%RH | 99.6% | [22] |

| 85–97.6 | 0.915 nm/%RH | 98.7% | ||

| Reduced graphene oxide | 30–50 | 0.0537 nm/%RH | 96.33% | [20] |

| Reduced graphene oxide | 75–95 | 0.31 dB/%RH | 98.2% | [21] |

| Graphene oxide/PVA | 25–80 | 0.193 dB/%RH | 99.1% | [30] |

| Graphene oxide/PVA | 40–60 | 0.0128 dB m/%RH | 96.786% | [31] |

| PVA/GQDs | 11.3–81.34 | 0.11725 nm/%RH | 99.83% | [14] |

| GODs | 11-85 | 0.567 nm/%RH | 99.92% | Our work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, N.; Tian, W.; Zhang, H.; Yu, X.; Yin, X.; Du, Y.; Li, D. An Easily Fabricated High Performance Fabry-Perot Optical Fiber Humidity Sensor Filled with Graphene Quantum Dots. Sensors 2021, 21, 806. https://doi.org/10.3390/s21030806

Wang N, Tian W, Zhang H, Yu X, Yin X, Du Y, Li D. An Easily Fabricated High Performance Fabry-Perot Optical Fiber Humidity Sensor Filled with Graphene Quantum Dots. Sensors. 2021; 21(3):806. https://doi.org/10.3390/s21030806

Chicago/Turabian StyleWang, Ning, Wenhao Tian, Haosheng Zhang, Xiaodan Yu, Xiaolei Yin, Yonggang Du, and Dailin Li. 2021. "An Easily Fabricated High Performance Fabry-Perot Optical Fiber Humidity Sensor Filled with Graphene Quantum Dots" Sensors 21, no. 3: 806. https://doi.org/10.3390/s21030806

APA StyleWang, N., Tian, W., Zhang, H., Yu, X., Yin, X., Du, Y., & Li, D. (2021). An Easily Fabricated High Performance Fabry-Perot Optical Fiber Humidity Sensor Filled with Graphene Quantum Dots. Sensors, 21(3), 806. https://doi.org/10.3390/s21030806