Passive Wireless Dual-Tag UHF RFID Sensor System for Surface Crack Monitoring

Abstract

:1. Introduction

2. Sensing Tag Setup and Wireless Transmission

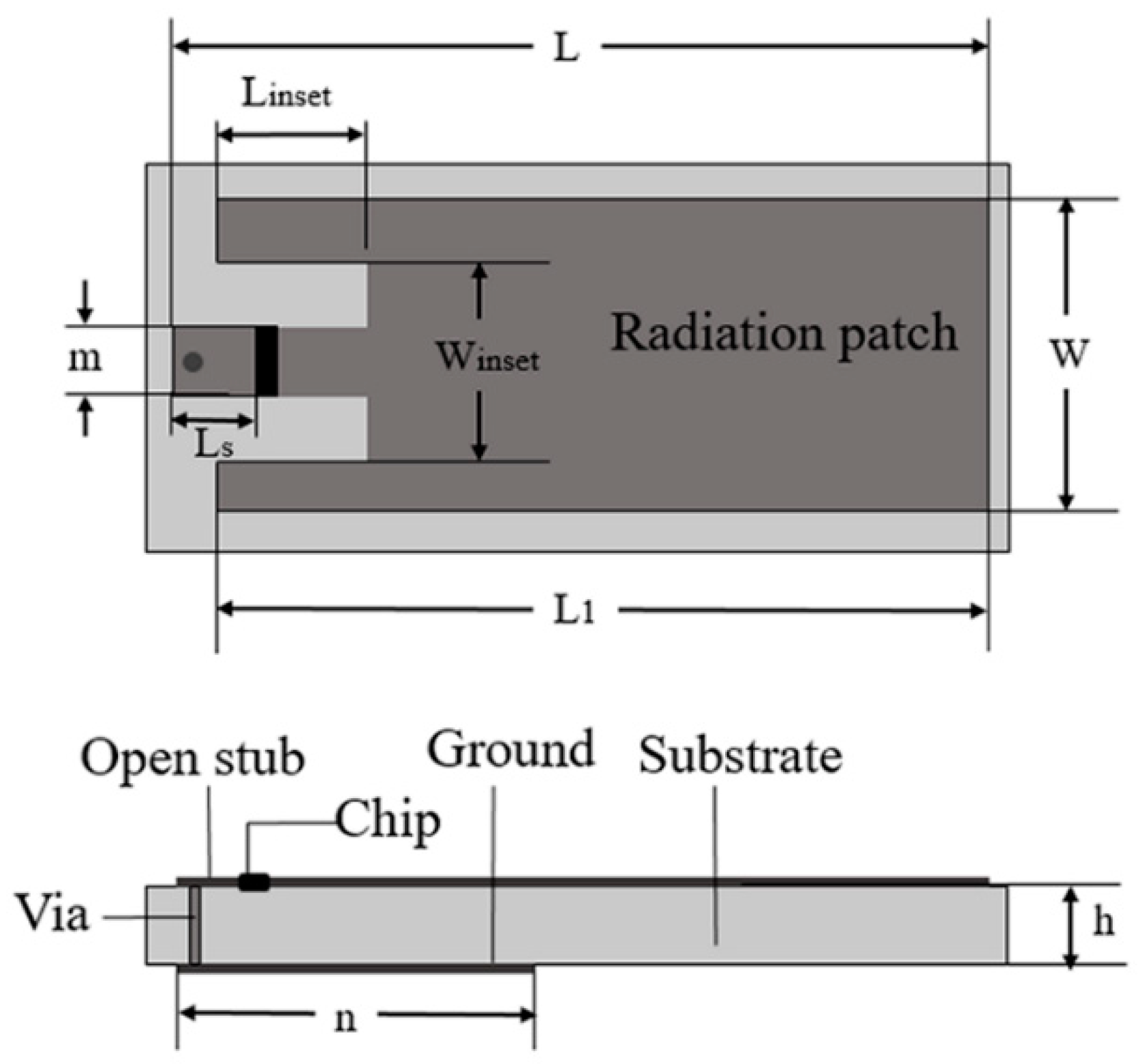

2.1. Sensing Tag Setup

2.2. Wireless Transmission

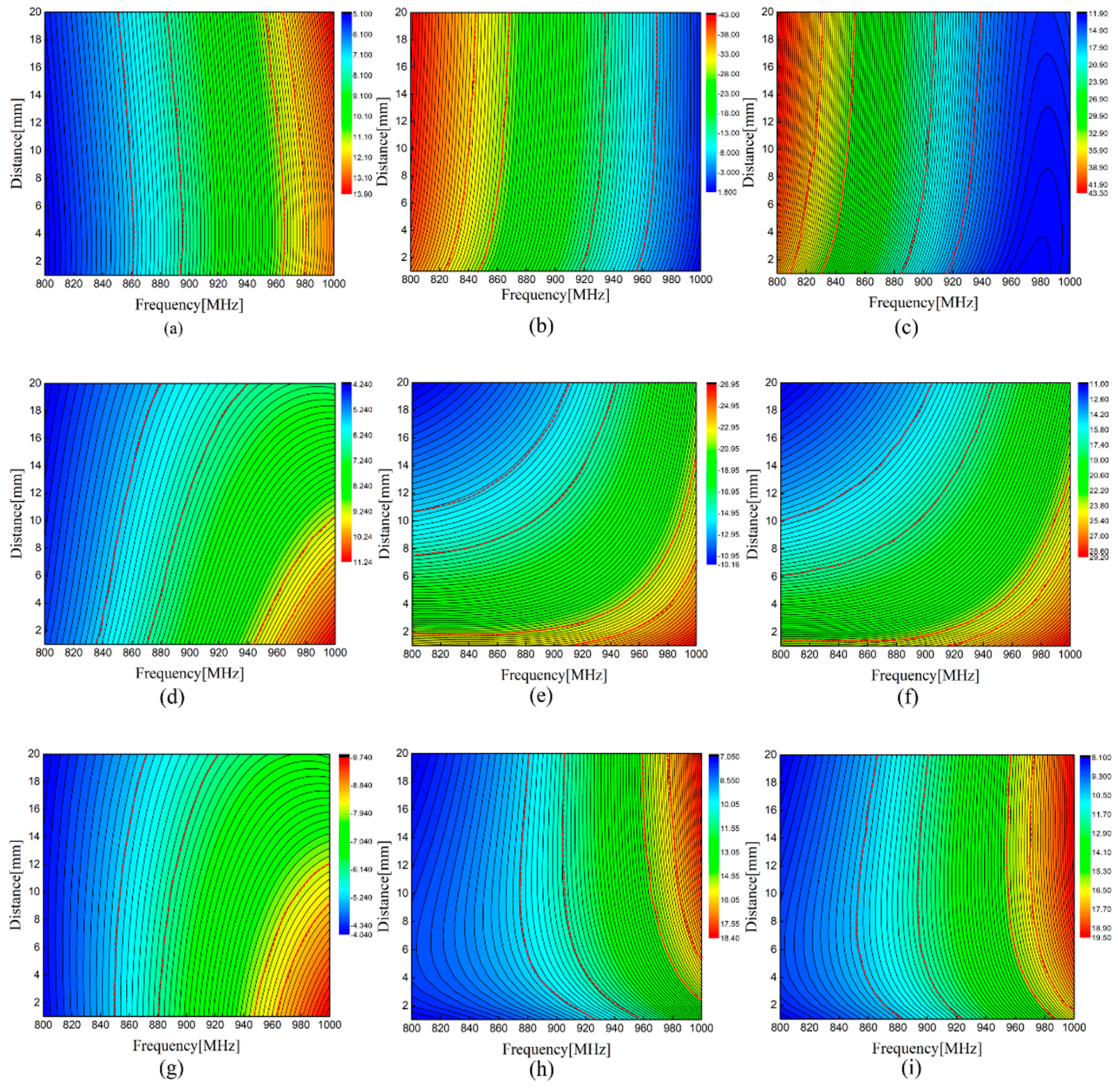

3. Mode Analysis

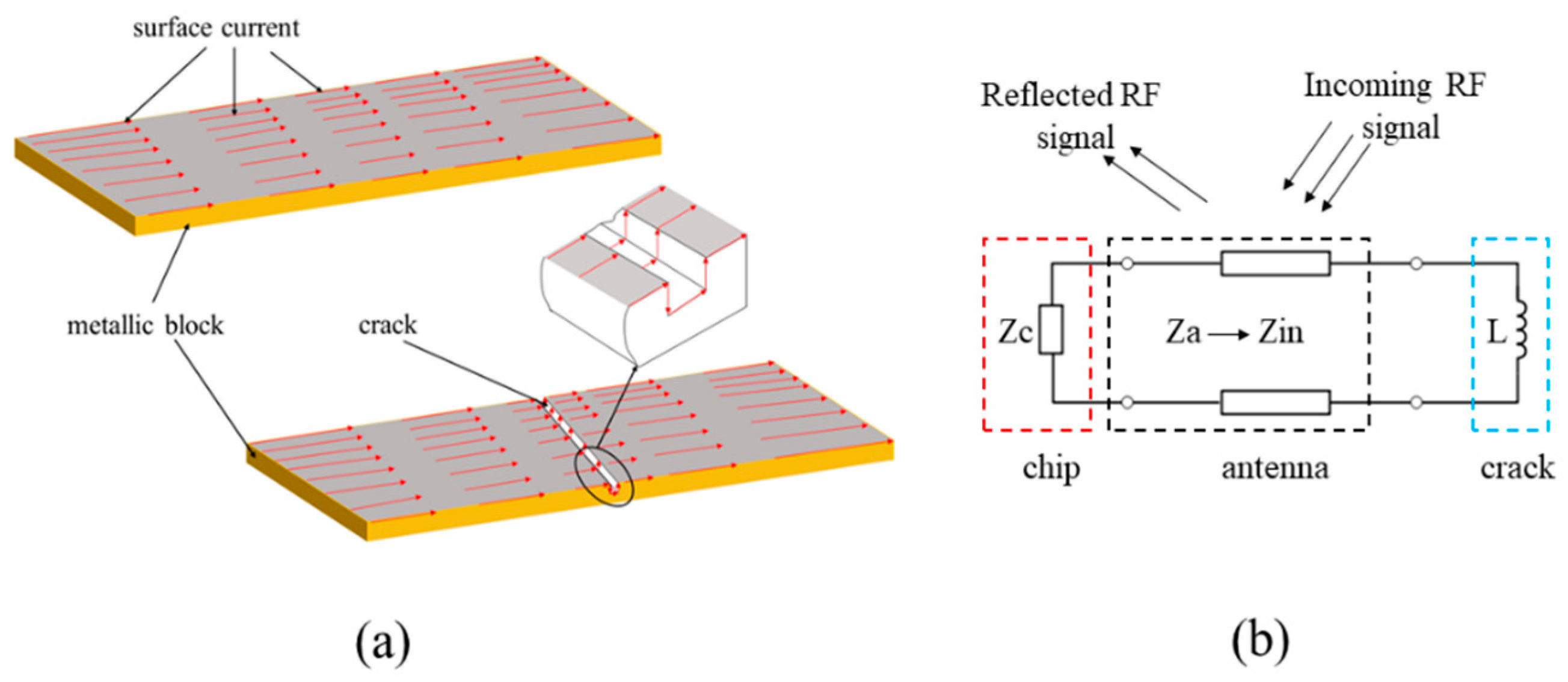

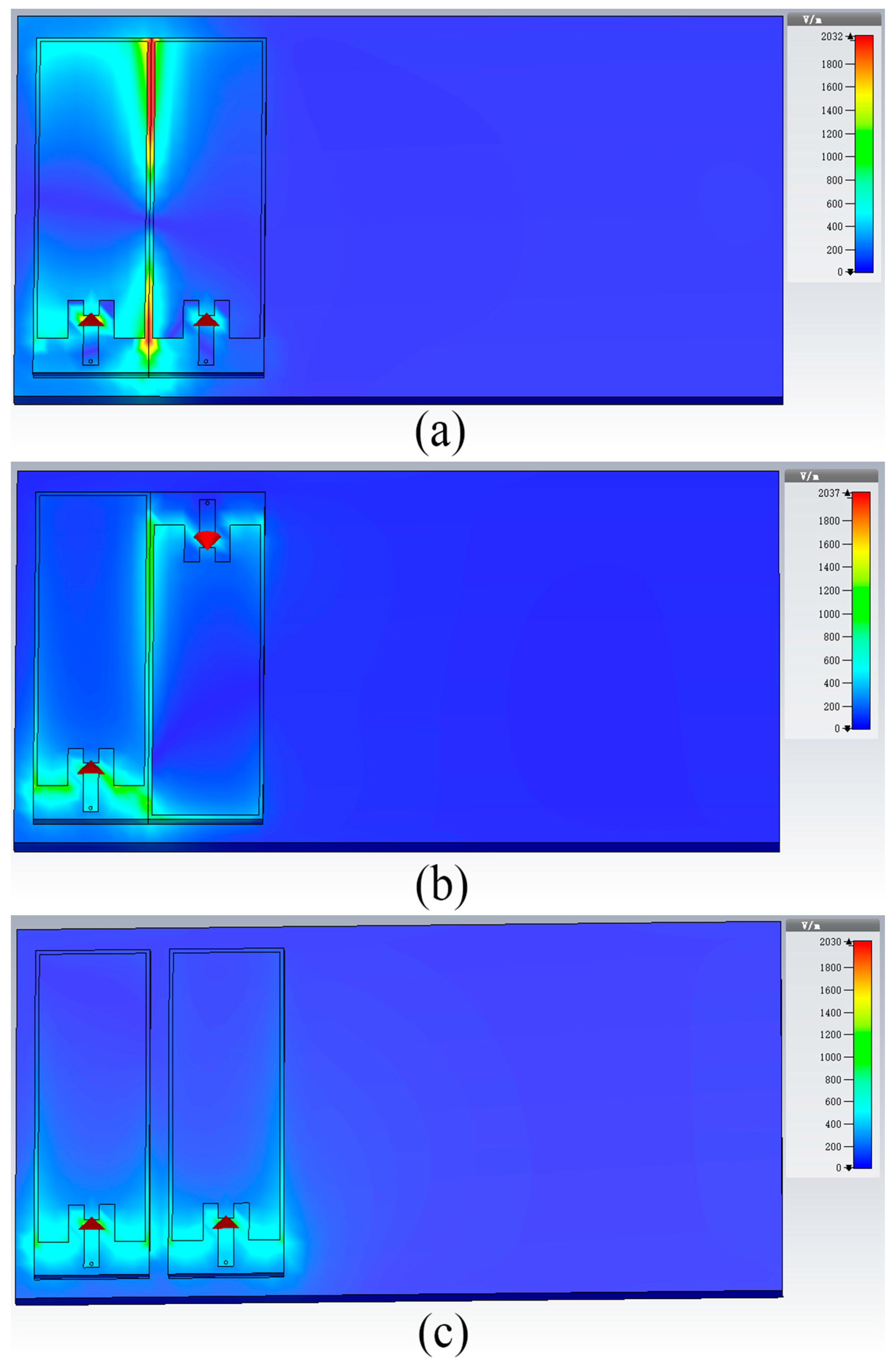

3.1. Crack Sensing Mode Analysis

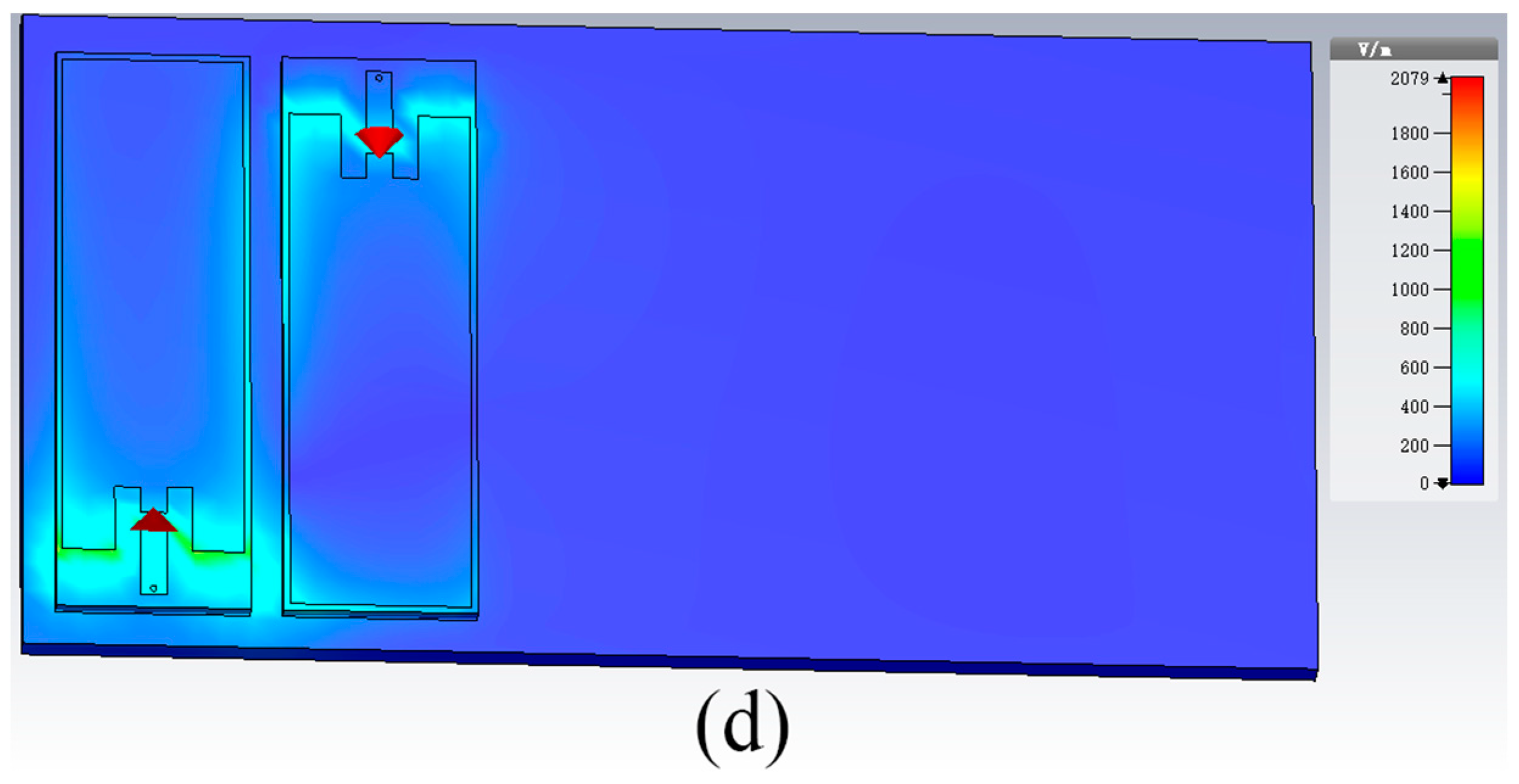

3.2. Dual-Tag Mutual Coupling Mode Analysis

4. Experimental Studies and Results

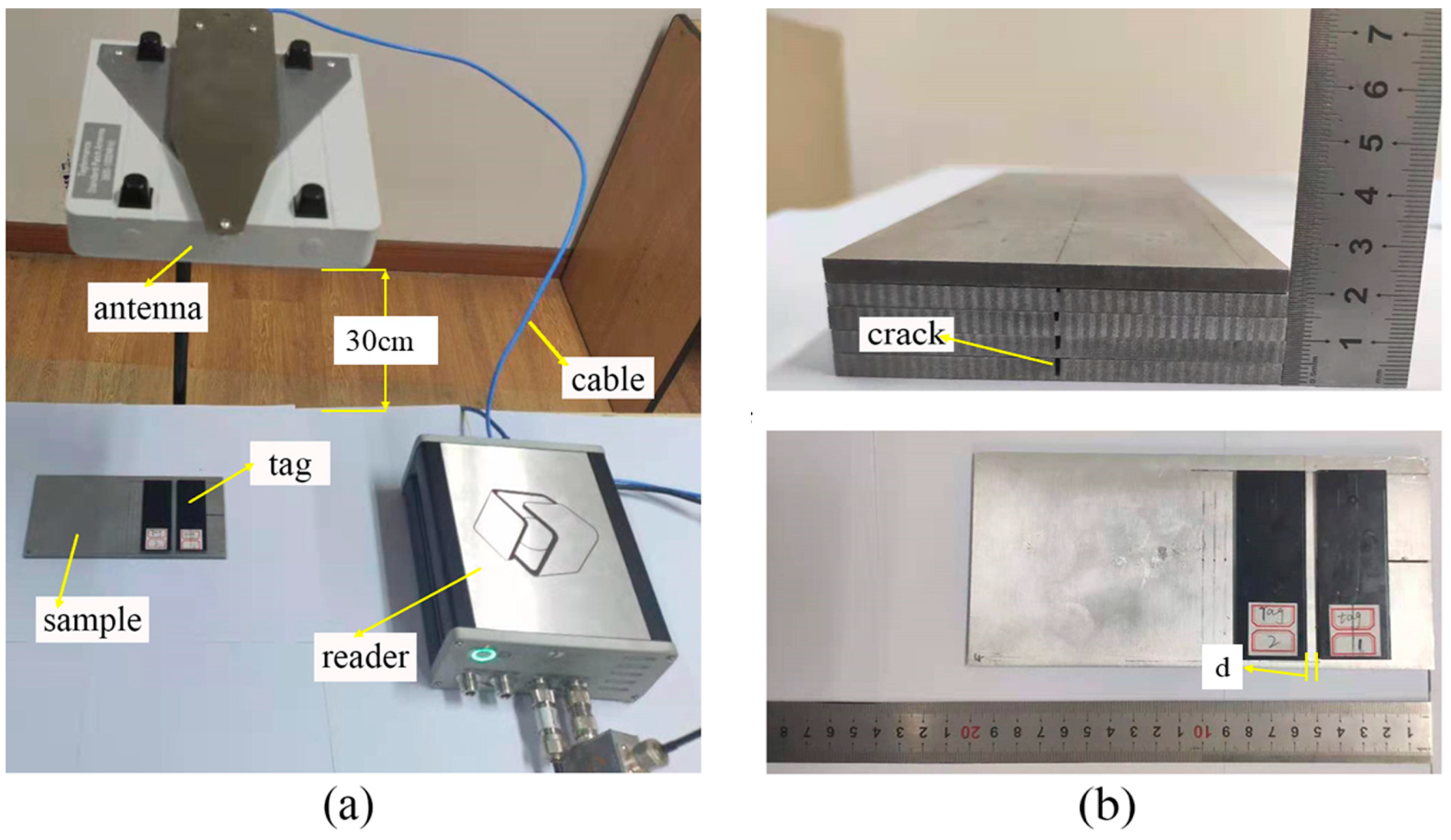

4.1. Test Setup

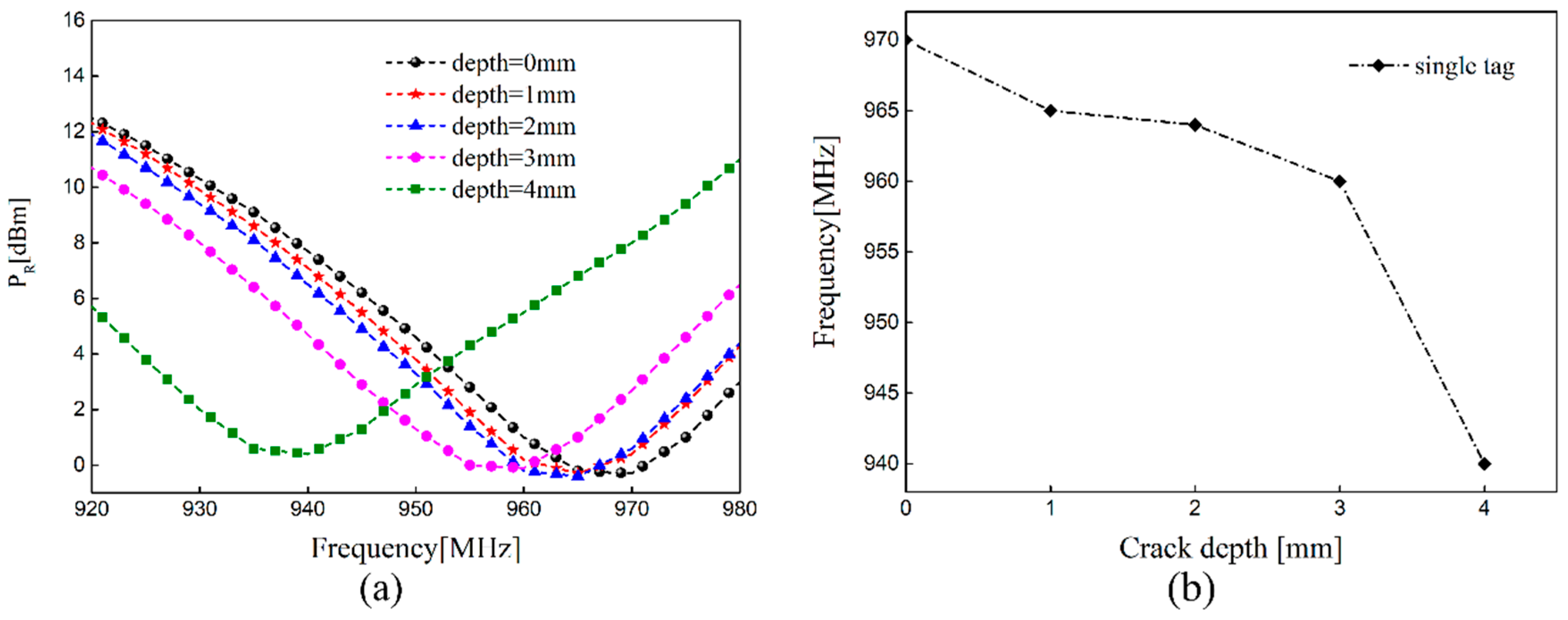

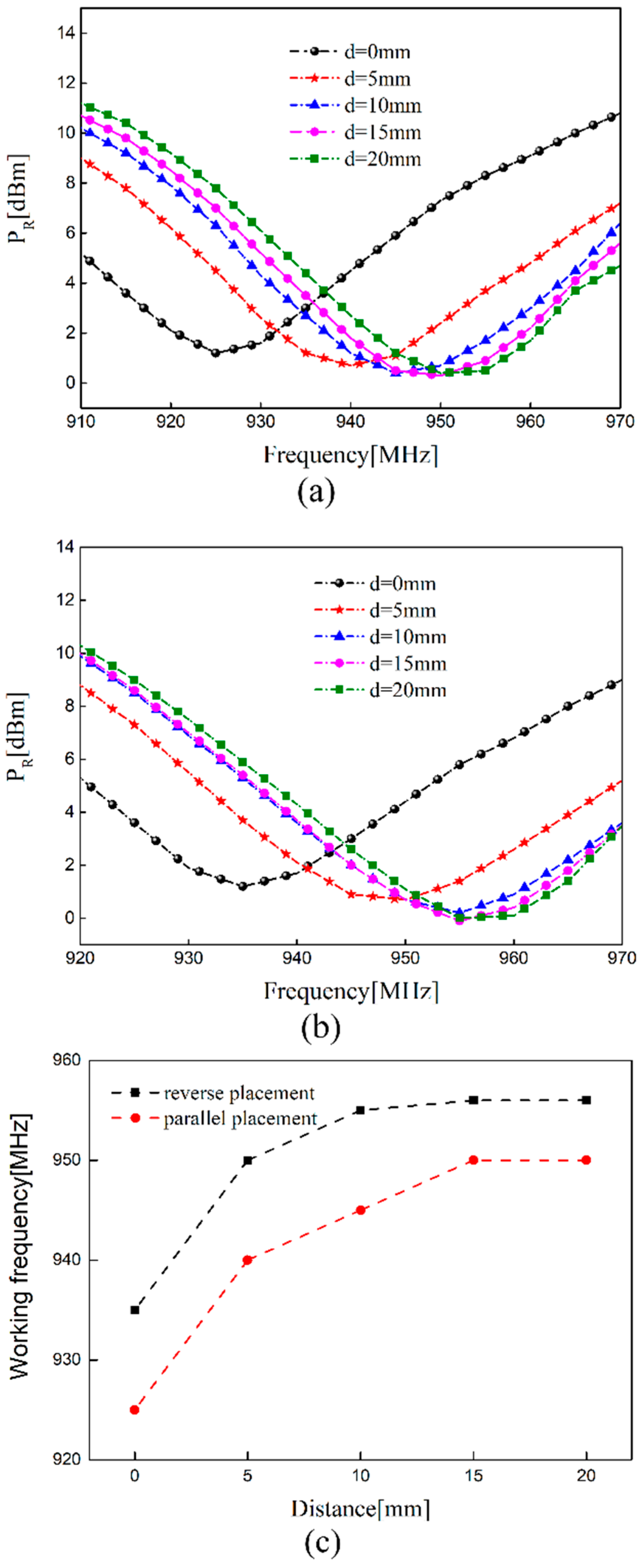

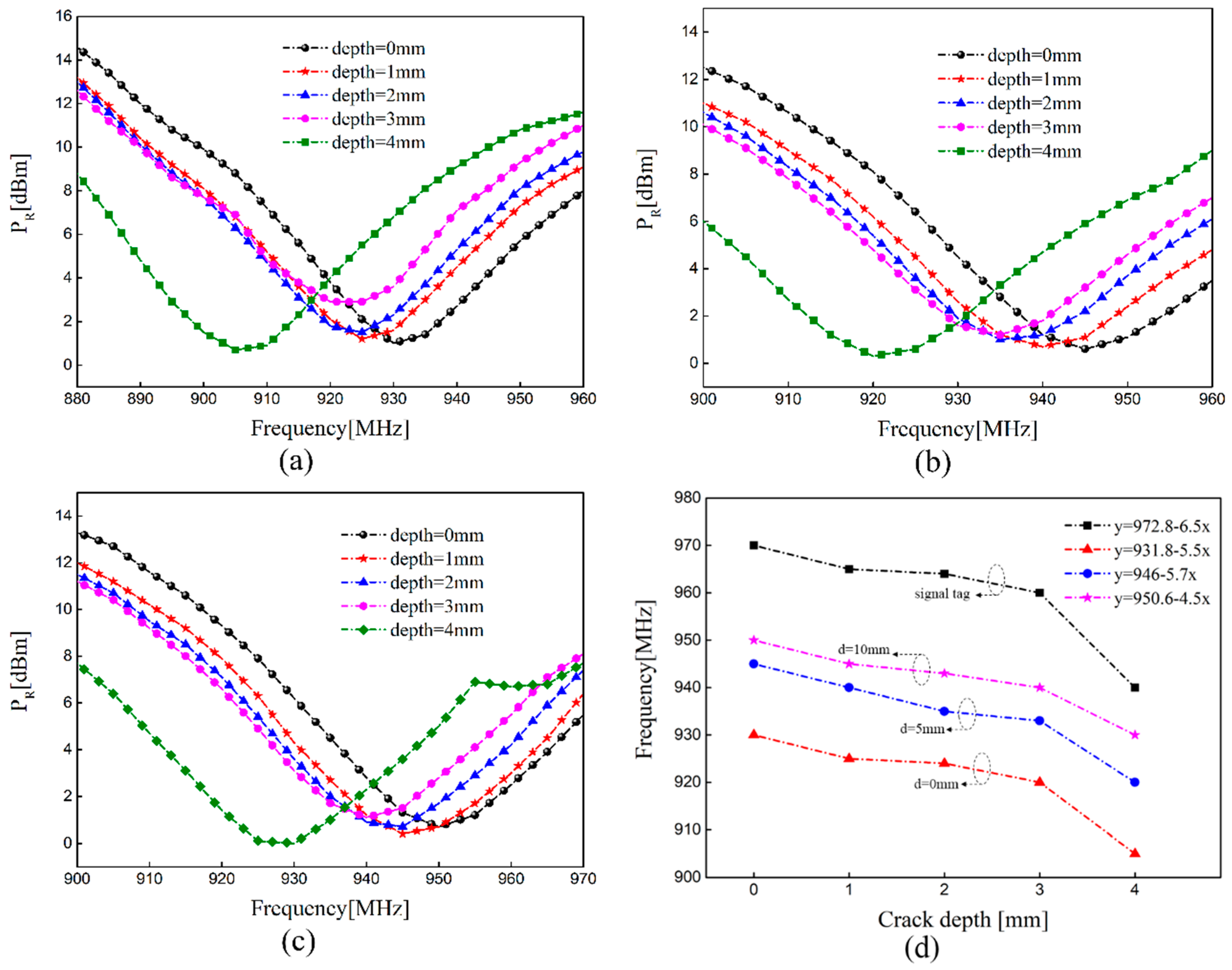

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Giagopoulos, D.; Arailopoulos, A.; Dertimanis, V.; Papadimitriou, C.; Chatzi, E.; Grompanopoulos, K. Structural health monitoring and fatigue damage estimation using vibration measurements and finite element model updating. Struct. Health Monit. 2019, 18, 1189–1206. [Google Scholar] [CrossRef]

- Zerbst, U.; Madia, M.; Klinger, C.; Bettge, D.; Murakami, Y. Defects as a root cause of fatigue failure of metallic components. III: Cavities, dents, corrosion pits, scratches. Eng. Fail. Anal. 2019, 97, 759–776. [Google Scholar] [CrossRef]

- Joseph, R.; Giurgiutiu, V. Analytical and Experimental Study of Fatigue-Crack-Growth AE Signals in Thin Sheet Metals. Sensors 2020, 20, 5835. [Google Scholar] [CrossRef] [PubMed]

- Bose, A.K.; Zhang, X.Z.; Maddipatla, D.; Masihi, S.; Panahi, M.; Narakathu, B.B.; Bazuin, B.J.; Williams, J.D.; Mitchell, M.F.; Atashbar, M.Z. Screen-Printed Strain Gauge for Micro-Strain Detection Applications. IEEE Sens. J. 2020, 20, 12652–12660. [Google Scholar] [CrossRef]

- Zhang, W.; Zhuang, W.; Dong, M.; Zhu, L.; Meng, F. Dual-Parameter Optical Fiber Sensor for Temperature and Pressure Discrimination Featuring Cascaded Tapered-FBG and Ball-EFPI. IEEE Sens. J. 2019, 19, 5645–5652. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Zolfaghari, A.; Kolahan, F. Reliability and sensitivity of magnetic particle nondestructive testing in detecting the surface cracks of welded components. Nondestruct. Test. Eval. 2018, 33, 290–300. [Google Scholar] [CrossRef]

- Rosario, P.; Louis, M.V.; Jasper, B.; Richard, B.; Ludovic, F.; Ludovic, G.C.; Frederic, S. Phased Array Ultrasonic Nondestructive Tests of Soldered Current-Carrying Bus-Bar Splices of Superconducting Magnets. IEEE Trans. Appl. Supercon. 2018, 28, 9000708. [Google Scholar]

- Zeng, Z.W.; Liao, Y.F.; Liu, X.H.; Junming Lin, J.M.; Dai, Y.H. Detection of Fiber Fracture in Unidirectional CFRP by Remote Field Eddy-Current Testing. IEEE Trans. Instrum. Meas. 2020, 69, 5755–5762. [Google Scholar] [CrossRef]

- Brigitte, G.; Nemkumar, B.; Noboru, Y. Use of infrared thermal imaging to detect corrosion of epoxy coated and uncoated rebar in concrete. Constr. Build. Mater. 2020, 263, 120162. [Google Scholar]

- Zhang, J.; Tian, G.Y.; Marindra, A.; Sunny, A.; Zhao, A.B. A Review of Passive RFID Tag Antenna-Based Sensors and Systems for Structural Health Monitoring Applications. Sensors 2017, 17, 265. [Google Scholar] [CrossRef]

- Li, J.; Feng, G.; Wei, W.; Luo, C.; Cheng, L.; Wang, H.; Song, H.; Zhong, M. PSOTrack: A RFID-Based System for Random Moving Objects Tracking in Unconstrained Indoor Environment. IEEE Internet Things 2018, 5, 4632–4641. [Google Scholar] [CrossRef]

- Yi, X.H.; Cho, C.; Cook, B.; Wang, Y.; Tentzeris, M.M. Design and simulation of a slotted patch antenna sensor for wireless strain sensing. In Proceedings of the SPIE Smart Structures and Materials and Nondestructive Evaluation and Health Monitoring Conference, San Diego, CA, USA, 10–14 March 2013. [Google Scholar] [CrossRef]

- Sunny, A.I.; Zhang, J.; Tian, G.Y.; Tang, C.; Rafique, W.; Zhao, A.; Fan, M. Temperature Independent Defect Monitoring Using Passive Wireless RFID Sensing System. IEEE Sens. J. 2018, 19, 1525–1532. [Google Scholar] [CrossRef] [Green Version]

- Geetha, C.; Krishna, P.L.; Jeby, P.; Jayaganthan, R.; Velmurugan, R.; Kavitha, A. Reusable Passive Wireless RFID Sensor for Strain Measurement on Metals. IEEE Sens. J. 2018, 18, 5143–5150. [Google Scholar]

- Abubakar, S.; Jun, O.; Yang, F.; Hassan, T.C.; Muhammad, A.I.; Akram, A.; Qammer, H.A. Low-Cost Inkjet-Printed UHF RFID Tag-Based System for Internet of Things Applications Using Characteristic Modes. IEEE Internet Things 2019, 6, 3962–3975. [Google Scholar]

- Yi, X.H.; Cho, C.; Cooper, J.; Wang, Y.; Tentzeris, M.M.; Leon, R.T. Passive wireless antenna sensor for strain and crack sensing –electromagnetic modeling, simulation, and testing. Smart. Mater. Struct. 2013, 22, 085009. [Google Scholar] [CrossRef]

- Kalansuriya, P.; Bhattacharyya, R.; Sarma, S. RFID tag antenna-based sensing for pervasive surface crack detection. IEEE Sens. J. 2013, 13, 1564–1570. [Google Scholar] [CrossRef]

- Martínez-Castro, R.E.; Jang, S.; Nicholas, J.; Bansal, R. Experimental assessment of an RFID-based crack sensor for steel structures. Smart. Mater. Struct. 2017, 26, 085035. [Google Scholar] [CrossRef]

- Dobmann, G.; Altpeter, I.; Sklarczyk, C.; Pinchuk, R. Non-destructive testing with micro- and MM-waves -where we are -where we go. Weld. World. 2012, 56, 111–120. [Google Scholar] [CrossRef]

- Nadakuduti, J.; Chen, G.; Zoughi, R. Semiempirical electromagnetic modeling of crack detection and sizing in cement-based materials using near-field microwave methods. IEEE Trans. Instrum. Meas. 2006, 55, 588–597. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Tian, G.Y.; Zhao, A.B. Passive RFID sensor systems for crack detection & characterization. NDT E Int. 2017, 86, 89–99. [Google Scholar]

- Caizzone, S.; DiGiampaolo, E.; Marrocco, G. Wireless crack monitoring by stationary phase measurements from coupled RFID tags. IEEE Trans. Antennas Propag. 2014, 62, 6412–6419. [Google Scholar] [CrossRef] [Green Version]

- Caizzone, S.; Emidio, D. Wireless passive RFID crack width sensor for structural health monitoring. IEEE Sens. J. 2015, 15, 6767–6774. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Dong, L.; Wang, H.; Di, Y.; Xie, X.; Wang, P.; Zhang, M. Reducing disturbance of crack location on crack depth-sensing tag. Sensor Rev. 2019, 39, 449–455. [Google Scholar] [CrossRef]

- Mo, L.F.; Qin, C.F. Planar UHF RFID Tag Antenna with Open Stub Feed for Metallic Objects. IEEE Trans. Antennas Propag. 2010, 58, 3037–3043. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, G.Y. UHF RFID Tag Antenna-Based Sensing for Corrosion Detection & Characterization Using Principal Component Analysis. IEEE Trans. Antennas Propag. 2016, 64, 4405–4414. [Google Scholar]

- Zhang, J.; Huang, B.; Zhang, G.; Tian, G.Y. Wireless Passive Ultra High Frequency RFID Antenna Sensor for Surface Crack Monitoring and Quantitative Analysis. Sensors 2018, 18, 2130. [Google Scholar] [CrossRef] [Green Version]

- Shi, G.L.; He, Y.G.; Yin, B.Q.; She, P.L.; Zeng, W.B.; Ali, F. Analysis of Mutual Couple Effect of UHF RFID Antenna for the Internet of Things Environment. IEEE Access. 2019, 7, 81451–81465. [Google Scholar] [CrossRef]

- Zhang, Q.; Crisp, M.J.; Penty, R.V.; White, I.H. Reduction of proximity effects on UHF passive RFID systems by using tags with polarization diversity. IEEE Trans. Antennas Propag. 2015, 63, 2264–2271. [Google Scholar] [CrossRef]

- Haus, H.A.; Huang, W. Coupled-mode theory. Proc. IEEE 1991, 79, 1505–1518. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Dong, L.; Wang, H.; Li, G.; Di, Y.; Xie, X.; Huang, D. Passive Wireless Dual-Tag UHF RFID Sensor System for Surface Crack Monitoring. Sensors 2021, 21, 882. https://doi.org/10.3390/s21030882

Wang P, Dong L, Wang H, Li G, Di Y, Xie X, Huang D. Passive Wireless Dual-Tag UHF RFID Sensor System for Surface Crack Monitoring. Sensors. 2021; 21(3):882. https://doi.org/10.3390/s21030882

Chicago/Turabian StyleWang, Peng, Lihong Dong, Haidou Wang, Guolu Li, Yuelan Di, Xiangyu Xie, and Dong Huang. 2021. "Passive Wireless Dual-Tag UHF RFID Sensor System for Surface Crack Monitoring" Sensors 21, no. 3: 882. https://doi.org/10.3390/s21030882

APA StyleWang, P., Dong, L., Wang, H., Li, G., Di, Y., Xie, X., & Huang, D. (2021). Passive Wireless Dual-Tag UHF RFID Sensor System for Surface Crack Monitoring. Sensors, 21(3), 882. https://doi.org/10.3390/s21030882