An Open-Source Test Environment for Effective Development of MARG-Based Algorithms

Abstract

:1. Introduction

1.1. Relative Localization

1.2. Contribution of the Paper

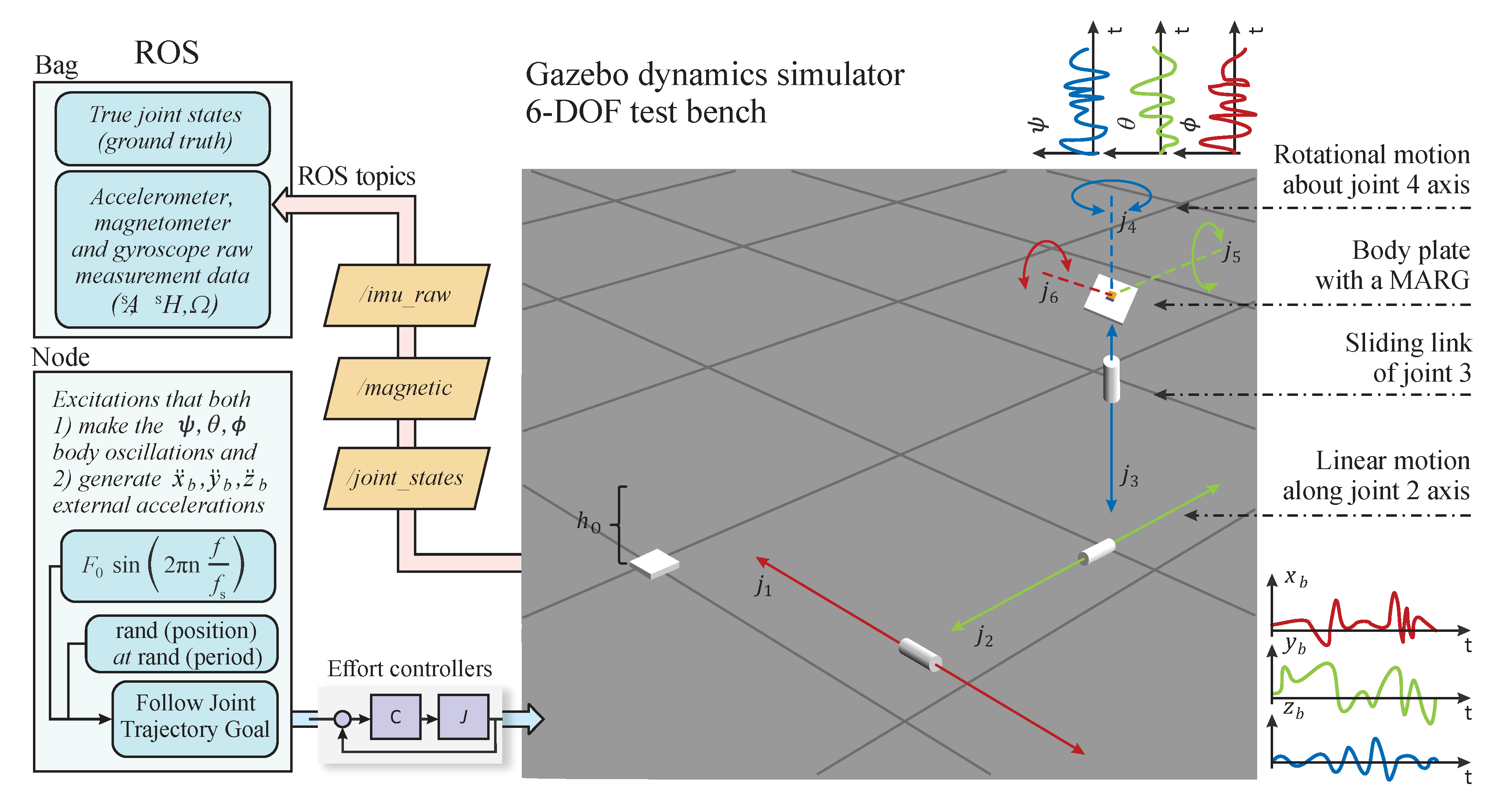

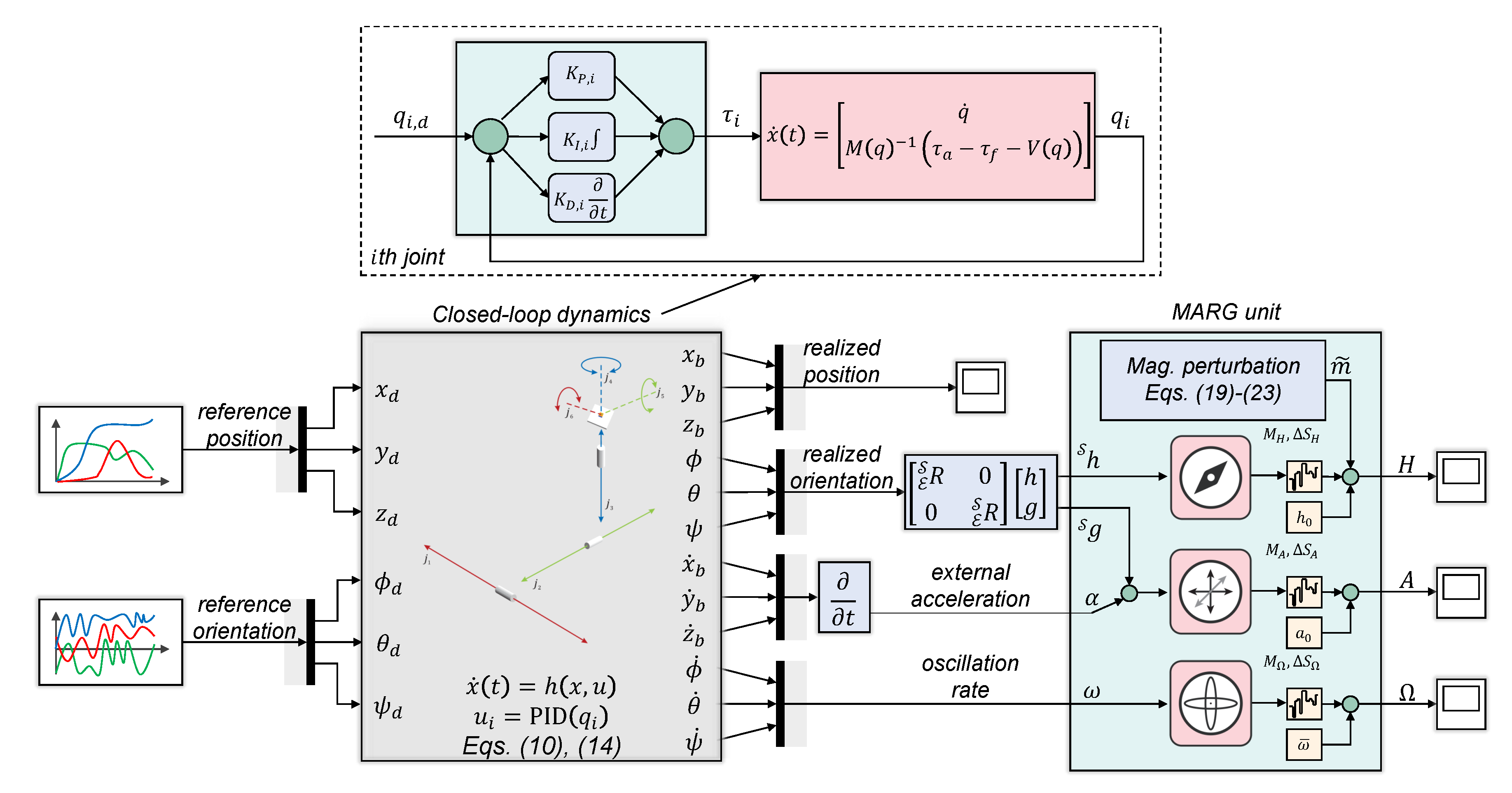

2. Test Environment

2.1. Model Equations

2.2. Control Synthesis

2.3. MARG System

2.4. Magnetic Perturbation Generator

- Generate an artificial signal by combining five fundamental waveforms. In this algorithm, a square signal, a sawtooth wave, two sinusoidal signals and a triangle wave are combined to generate the artificial signal m of length , where denotes the time window, in which magnetic perturbation is to be generated, while is the sampling frequency. Namely, initialize for , and then let denote the length of each waveform; moreover, a vector containing the start locations of each waveform is generated via a random permutation. As a result, the artificial signal (m) is produced with Equation (19), where is the random amplitude of the ith waveform, , while and denote the random frequencies of the sinusoidal signals in range. The first row of Figure 5 shows the generated artificial signal, where s, and .

- Use the artificial signal (m) and calculate the analytic signal , , where denotes the real part and is the original signal, while represents the imaginary part, and is the original signal with phase shift, obtained via Hilbert transformation. In this step, the fast Fourier transform (FFT) of m is calculated, a zero vector h of length is created and offset (scaling) values are applied, and, finally, the inverse FFT of the element-wise product of m and h is obtained [43]; see Equation (20). Then, the artificial perturbation is generated as the sum of the imaginary part and absolute value of the analytic signal , where the sequence of absolute values is reversed in time (see the outcome of this step in the second row of Figure 5):

- Extract the continuous linear trend of the artificial perturbation signal by subtracting a straight line from , where denotes the best linear fit to in the least squares sense:Then, apply low-pass filtration to the detrended signal () via a second order Butterworth infinite impulse response (IIR) filter to obtain the output ():where ; moreover, and filter coefficients are obtained based on the cutoff frequency of the filter. In this algorithm, the cutoff frequency was selected to be . The output of the algorithm is shown in the third row of Figure 5.

2.5. Implementation Results

3. Case Study: Evaluation and Tuning of Attitude Filters

3.1. Algorithms

3.1.1. Explicit Complementary Filter

3.1.2. Gradient Descent-Based Attitude Filter

3.1.3. Attitude Estimation with Extended Kalman Filter (EKF)

3.2. Experimental Results

4. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Usage of the package in MATLAB/Simulink

Appendix B. Usage of the package in ROS/Gazebo

References

- Odry, Á.; Kecskes, I.; Sarcevic, P.; Vizvari, Z.; Toth, A.; Odry, P. A Novel Fuzzy-Adaptive Extended Kalman Filter for Real-Time Attitude Estimation of Mobile Robots. Sensors 2020, 20, 803. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Odry, Á.; Fullér, R.; Rudas, I.J.; Odry, P. Kalman filter for mobile-robot attitude estimation: Novel optimized and adaptive solutions. Mech. Syst. Signal Process. 2018, 110, 569–589. [Google Scholar] [CrossRef]

- Colorado, J.; Perez, M.; Mondragon, I.; Mendez, D.; Parra, C.; Devia, C.; Martinez-Moritz, J.; Neira, L. An integrated aerial system for landmine detection: SDR-based Ground Penetrating Radar onboard an autonomous drone. Adv. Robot. 2017, 31, 791–808. [Google Scholar] [CrossRef]

- Zhang, T.; Liao, Y. Attitude measure system based on extended Kalman filter for multi-rotors. Comput. Electron. Agric. 2017, 134, 19–26. [Google Scholar] [CrossRef]

- Roh, M.S.; Kang, B.S. Dynamic Accuracy Improvement of a MEMS AHRS for Small UAVs. Int. J. Precis. Eng. Manuf. 2018, 19, 1457–1466. [Google Scholar] [CrossRef]

- Odry, Á.; Fullér, R.; Rudas, I.J.; Odry, P. Fuzzy control of self-balancing robots: A control laboratory project. Comput. Appl. Eng. Educ. 2020, 28, 512–535. [Google Scholar] [CrossRef]

- Martínez-Prado, M.A.; Rodríguez-Reséndiz, J.; Gómez-Loenzo, R.A.; Herrera-Ruiz, G.; Franco-Gasca, L.A. An FPGA-based open architecture industrial robot controller. IEEE Access 2018, 6, 13407–13417. [Google Scholar] [CrossRef]

- Hashim, H.A.; Eltoukhy, A.E.E. Landmark and IMU Data Fusion: Systematic Convergence Geometric Nonlinear Observer for SLAM and Velocity Bias. IEEE Trans. Intell. Transp. Syst. 2021, 1–10. [Google Scholar]

- Wen, X.; Liu, C.; Huang, Z.; Su, S.; Guo, X.; Zuo, Z.; Qu, H. A First-Order Differential Data Processing Method for Accuracy Improvement of Complementary Filtering in Micro-UAV Attitude Estimation. Sensors 2019, 19, 1340. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, S.; Lyu, P.; Lai, J.; Yuan, C.; Wang, B. A fault-tolerant attitude estimation method for quadrotors based on analytical redundancy. Aerosp. Sci. Technol. 2019, 93, 105290. [Google Scholar] [CrossRef]

- Khankalantary, S.; Rafatnia, S.; Mohammadkhani, H. An adaptive constrained type-2 fuzzy Hammerstein neural network data fusion scheme for low-cost SINS/GNSS navigation system. Appl. Soft Comput. 2019, 86, 105917. [Google Scholar] [CrossRef]

- Lee, J.K.; Park, E.J.; Robinovitch, S.N. Estimation of attitude and external acceleration using inertial sensor measurement during various dynamic conditions. IEEE Trans. Instrum. Meas. 2012, 61, 2262–2273. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cruz-Miguel, E.E.; García-Martínez, J.R.; Rodríguez-Reséndiz, J.; Carrillo-Serrano, R.V. A New Methodology for a Retrofitted Self-tuned Controller with Open-Source FPGA. Sensors 2020, 20, 6155. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Shan, S. Dot Product Equality Constrained Attitude Determination from Two Vector Observations: Theory and Astronautical Applications. Aerospace 2019, 6, 102. [Google Scholar] [CrossRef] [Green Version]

- Markley, F.L.; Crassidis, J.L. Fundamentals of Spacecraft Attitude Determination and Control; Springer: New York, NY, USA, 2014; Volume 33. [Google Scholar]

- Liu, F.; Li, J.; Wang, H.; Liu, C. An improved quaternion Gauss–Newton algorithm for attitude determination using magnetometer and accelerometer. Chin. J. Aeronaut. 2014, 27, 986–993. [Google Scholar] [CrossRef] [Green Version]

- Fourati, H.; Manamanni, N.; Afilal, L.; Handrich, Y. A nonlinear filtering approach for the attitude and dynamic body acceleration estimation based on inertial and magnetic sensors: Bio-logging application. IEEE Sens. J. 2010, 11, 233–244. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Zhou, Z.; Fourati, H.; Cheng, Y. A super fast attitude determination algorithm for consumer-level accelerometer and magnetometer. IEEE Trans. Consum. Electron. 2018, 64, 375–381. [Google Scholar] [CrossRef]

- Mahony, R.; Hamel, T.; Pflimlin, J.M. Nonlinear complementary filters on the special orthogonal group. IEEE Trans. Autom. Control 2008, 53, 1203–1218. [Google Scholar] [CrossRef] [Green Version]

- Madgwick, S.O.; Harrison, A.J.; Vaidyanathan, R. Estimation of IMU and MARG orientation using a gradient descent algorithm. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics (ICORR), Zurich, Switzerland, 27 June–1 July 2011; pp. 1–7. [Google Scholar]

- Wilson, S.; Eberle, H.; Hayashi, Y.; Madgwick, S.O.; McGregor, A.; Jing, X.; Vaidyanathan, R. Formulation of a new gradient descent MARG orientation algorithm: Case study on robot teleoperation. Mech. Syst. Signal Process. 2019, 130, 183–200. [Google Scholar] [CrossRef]

- Valenti, R.G.; Dryanovski, I.; Xiao, J. Keeping a good attitude: A quaternion-based orientation filter for IMUs and MARGs. Sensors 2015, 15, 19302–19330. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Zhou, Z.; Chen, J.; Fourati, H.; Li, R. Fast complementary filter for attitude estimation using low-cost MARG sensors. IEEE Sens. J. 2016, 16, 6997–7007. [Google Scholar] [CrossRef]

- Fan, B.; Li, Q.; Liu, T. Improving the accuracy of wearable sensor orientation using a two-step complementary filter with state machine-based adaptive strategy. Meas. Sci. Technol. 2018, 29, 115104. [Google Scholar] [CrossRef]

- Gośliński, J.; Nowicki, M.; Skrzypczyński, P. Performance comparison of EKF-based algorithms for orientation estimation on Android platform. IEEE Sens. J. 2015, 15, 3781–3792. [Google Scholar] [CrossRef]

- Li, W.; Wang, J. Effective adaptive Kalman filter for MEMS-IMU/magnetometers integrated attitude and heading reference systems. J. Navig. 2013, 66, 99–113. [Google Scholar] [CrossRef] [Green Version]

- Mazza, C.; Donati, M.; McCamley, J.; Picerno, P.; Cappozzo, A. An optimized Kalman filter for the estimate of trunk orientation from inertial sensors data during treadmill walking. Gait Posture 2012, 35, 138–142. [Google Scholar] [CrossRef]

- Feng, K.; Li, J.; Zhang, X.; Shen, C.; Bi, Y.; Zheng, T.; Liu, J. A new quaternion-based Kalman filter for real-time attitude estimation using the two-step geometrically-intuitive correction algorithm. Sensors 2017, 17, 2146. [Google Scholar] [CrossRef] [Green Version]

- Kownacki, C. Optimization approach to adapt Kalman filters for the real-time application of accelerometer and gyroscope signals’ filtering. Digit. Signal Process. 2011, 21, 131–140. [Google Scholar] [CrossRef]

- Wu, J. MARG Attitude Estimation Using Gradient-Descent Linear Kalman Filter. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1777–1790. [Google Scholar] [CrossRef]

- Mourcou, Q.; Fleury, A.; Franco, C.; Klopcic, F.; Vuillerme, N. Performance evaluation of smartphone inertial sensors measurement for range of motion. Sensors 2015, 15, 23168–23187. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cavallo, A.; Cirillo, A.; Cirillo, P.; De Maria, G.; Falco, P.; Natale, C.; Pirozzi, S. Experimental comparison of sensor fusion algorithms for attitude estimation. IFAC Proc. Vol. 2014, 47, 7585–7591. [Google Scholar] [CrossRef] [Green Version]

- Kuti, J.; Galambos, P.; Györök, G. Adaptive Odometry and IMU Sensor Fusion for KUKA youBot Mobile Robot Using Analytical Time Update. In Proceedings of the 2019 IEEE 23rd International Conference on Intelligent Engineering Systems (INES), Gödöllő, Hungary, 25–27 April 2019; pp. 257–262. [Google Scholar]

- Odry, Á. An Open-Source Test Environment for Effective Development of MARG-Based Algorithms Supplementary Material. Available online: http://appl-dsp.com/faekf/ (accessed on 7 February 2021).

- Sciavicco, L.; Siciliano, B. Modelling and Control of Robot Manipulators; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Haidegger, T.; Kovács, L.; Precup, R.E.; Preitl, S.; Benyó, B.; Benyó, Z. Cascade control for telerobotic systems serving space medicine. IFAC Proc. Vol. 2011, 44, 3759–3764. [Google Scholar] [CrossRef] [Green Version]

- Haidegger, T.; Kovács, L.; Preitl, S.; Precup, R.E.; Benyó, B.; Benyo, Z. Controller design solutions for long distance telesurgical applications. Int. J. Artif. Intell. 2011, 6, 48–71. [Google Scholar]

- Aggarwal, P. MEMS-Based Integrated Navigation; Artech House: Norwood, MA, USA, 2010. [Google Scholar]

- Papafotis, K.; Sotiriadis, P.P. MAG.I.C.AL.—A Unified Methodology for Magnetic and Inertial Sensors Calibration and Alignment. IEEE Sens. J. 2019. [Google Scholar] [CrossRef]

- Sarcevic, P.; Kincses, Z.; Pletl, S. Online human movement classification using wrist-worn wireless sensors. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 89–106. [Google Scholar] [CrossRef]

- Sarcevic, P. Examining the Efficiency of Magnetometers in Movement Classification Systems. In Proceedings of the 2020 IEEE 14th International Symposium on Applied Computational Intelligence and Informatics (SACI), Timisoara, Romania, 21–23 May 2020; pp. 241–246. [Google Scholar]

- Zmitri, M.; Fourati, H.; Prieur, C. Magnetic Field Gradient-Based EKF for Velocity Estimation in Indoor Navigation. Sensors 2020, 20, 5726. [Google Scholar] [CrossRef]

- Marple, L. Computing the discrete-time “analytic” signal via FFT. IEEE Trans. Signal Process. 1999, 47, 2600–2603. [Google Scholar] [CrossRef]

- Furrer, F.; Burri, M.; Achtelik, M.; Siegwart, R. Robot Operating System (ROS): The Complete Reference (Volume 1); Springer: Cham, Switzerland, 2016; pp. 595–625. [Google Scholar]

- Meyer, J.; Sendobry, A.; Kohlbrecher, S.; Klingauf, U.; Von Stryk, O. Comprehensive simulation of quadrotor uavs using ros and gazebo. In Proceedings of the International conference on simulation, modeling, and programming for autonomous robots, Tsukuba, Japan, 5–8 November 2012; pp. 400–411. [Google Scholar]

- Kok, M.; Hol, J.D.; Schön, T.B. Using inertial sensors for position and orientation estimation. Found. Trends Signal Process. 2017, 11, 1–153. [Google Scholar] [CrossRef] [Green Version]

- Gunther, M.; Dryanovski, I. IMU Tools for ROS. Available online: wiki.ros.org/imutools (accessed on 7 February 2021).

- Lu, D.V.; Ferguson, M.; Hoy, A.; Meeussen, W. Robot Pose EKF. Available online: wiki.ros.org/robotposeekf (accessed on 7 February 2021).

- Madgwick, S. An Efficient Orientation Filter for Inertial and Inertial/Magnetic Sensor Arrays. 2010. Available online: https://forums.parallax.com/uploads/attachments/41167/106661.pdf (accessed on 7 February 2021).

- MathWorks. Estimate Orientation through Inertial Sensor Fusion. Available online: www.mathworks.com/help/fusion/ug/estimate-orientation-through-inertial-sensor-fusion.html (accessed on 7 February 2021).

- Michel, T.; Genevès, P.; Fourati, H.; Layaïda, N. Attitude estimation for indoor navigation and augmented reality with smartphones. Pervasive Mob. Comput. 2018, 46, 96–121. [Google Scholar] [CrossRef] [Green Version]

- Jouybari, A.; Amiri, H.; Ardalan, A.A.; Zahraee, N.K. Methods comparison for attitude determination of a lightweight buoy by raw data of IMU. Measurement 2019, 135, 348–354. [Google Scholar] [CrossRef]

- Sarabandi, S.; Thomas, F. A survey on the computation of quaternions from rotation matrices. J. Mech. Robot. 2019, 11, 021006. [Google Scholar] [CrossRef] [Green Version]

- Odry, Á.; Kecskés, I.; Burkus, E.; Odry, P. Protective Fuzzy Control of a Two-Wheeled Mobile Pendulum Robot: Design and Optimization. WSEAS Trans. Syst. Control 2017, 12, 297–306. [Google Scholar]

| Parameter | Symbol (Unit) | Value |

|---|---|---|

| Mass of link 1 and 2 | , (kg) | 500 |

| Mass of link 3 | (kg) | 200 |

| Mass of the body plate | (g) | 200 |

| Inertia of the body plate (, ) | , (kg) | 60 |

| Inertia of the body plate () | (kg) | 40 |

| Viscous friction coefficient (joint 1–3) | , , (Ns/m) | 100 |

| Viscous friction coefficient (joint 4–6) | , , (Nms/rad) | |

| Static friction (joint 1–3) | , , (N) | 0 |

| Static friction (joint 4–6) | , , (Nm) | 0 |

| Parameter | Symbol (Unit) | Value |

|---|---|---|

| External acceleration executed by joint 1–3 | (g) | 30 |

| Oscillation rate executed by joint 4–6 | (rad/s) | 40 |

| Overshoot for joint 1–3 | (%) | 20 |

| Settling time for joint 1–3 | (s) | 1 |

| Overshoot for joint 4–6 | (%) | 40 |

| Settling time for joint 4–6 | (s) |

| ECF | GDA | EKF | ||||

|---|---|---|---|---|---|---|

| Initial | Tuned | Initial | Tuned | Initial | Tuned | |

| F | 0.5237 | 0.1471 | 1.1950 | 0.1812 | 0.2891 | 0.1033 |

| MSE () | 0.4405 | 0.1831 | 1.2361 | 0.2349 | 0.2351 | 0.0856 |

| STD () | 0.6307 | 0.4275 | 0.9103 | 0.4835 | 0.4848 | 0.2881 |

| MSE () | 0.3713 | 0.0773 | 0.5610 | 0.0977 | 0.1068 | 0.0676 |

| STD () | 0.5996 | 0.2756 | 0.7410 | 0.3069 | 0.3184 | 0.2593 |

| MSE () | 0.8784 | 0.2248 | 2.4607 | 0.2589 | 0.9618 | 0.1906 |

| STD () | 0.6384 | 0.4476 | 1.0554 | 0.4871 | 0.9774 | 0.4115 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Odry, Á. An Open-Source Test Environment for Effective Development of MARG-Based Algorithms. Sensors 2021, 21, 1183. https://doi.org/10.3390/s21041183

Odry Á. An Open-Source Test Environment for Effective Development of MARG-Based Algorithms. Sensors. 2021; 21(4):1183. https://doi.org/10.3390/s21041183

Chicago/Turabian StyleOdry, Ákos. 2021. "An Open-Source Test Environment for Effective Development of MARG-Based Algorithms" Sensors 21, no. 4: 1183. https://doi.org/10.3390/s21041183