An IoT-Based Life Cycle Assessment Platform of Wind Turbines

Abstract

:1. Introduction

- The existing life cycle assessment process mainly relies on software system databases, which are from the average data of various industries, or manually collecting from literature or on site. The real time, dynamic, and accuracy of evaluation data are far from satisfactory. Therefore, the results of LCA are not accurate enough.

- The existing LCA software are commercial, and they are for many products. As a result, the process is not specifically for wind turbines.

- The existing LCA methods mainly include problem-oriented midpoint methods and damage-oriented endpoint methods, having their limitations.

- The existing LCA systems and enterprise information systems (EIS) are independent of each other and cannot be effectively integrated together, and the data of enterprise information systems cannot be effectively utilized.

- The IoT technology is applied to achieve the real-time, intelligent collection of energy consumption and environmental impact data in the entire life cycle of wind turbines. Therefore, the databases of the platform have the function of updating and expanding, which ensures the objectivity and accuracy of the assessment results. Additionally, the status and location of wind turbines and their components can be monitored with the support of IoT technology.

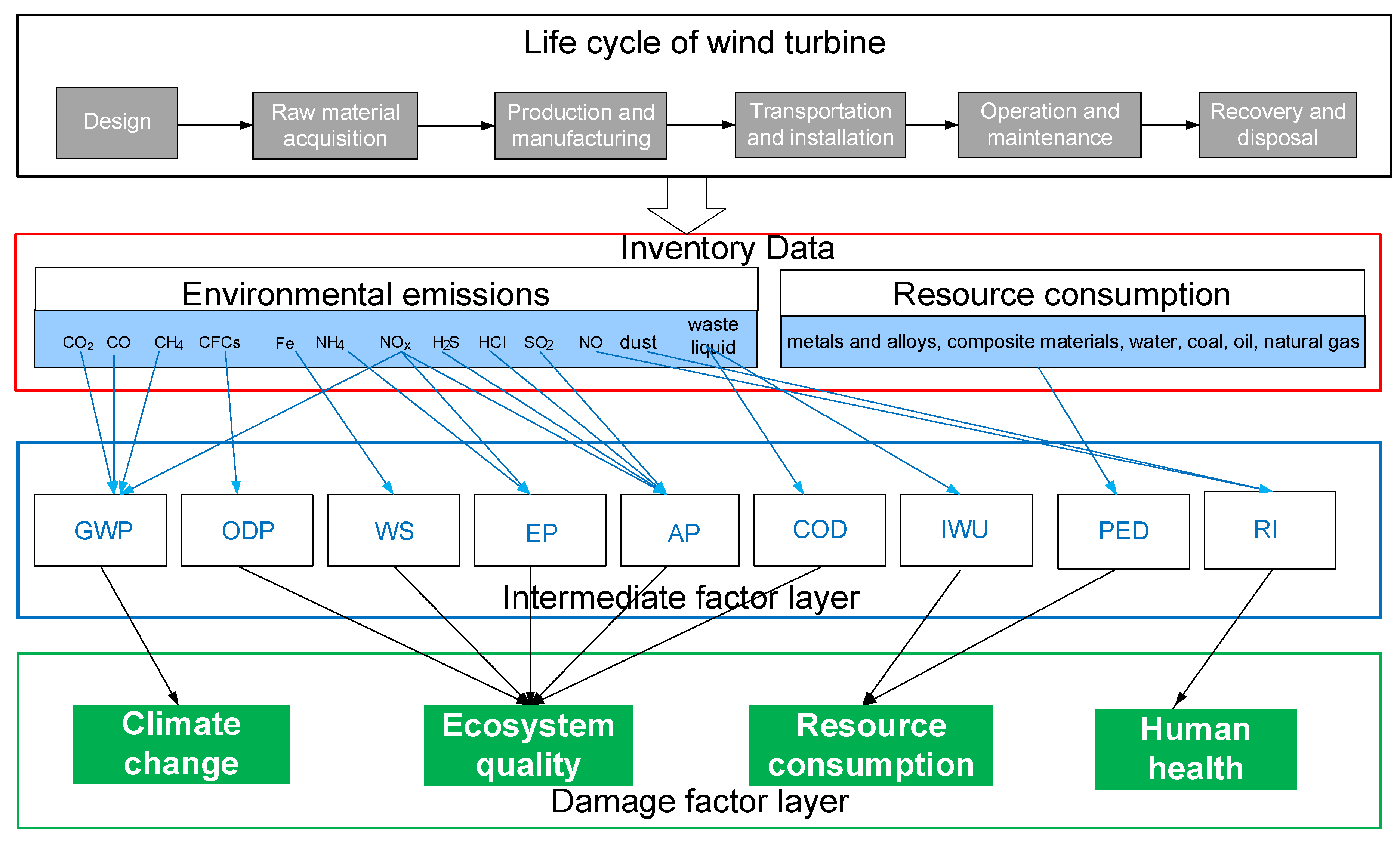

- A novel LCA architecture based on IoT is proposed, which achieves the energy consumption assessment and environmental impact assessment of wind turbine from parts to products, including the stages of design, raw material acquisition, production and manufacturing, transportation and installation, operation and maintenance, and recovery and disposal.

- An LCA model for wind turbines is proposed based on IMPACT 2002+ [8], which combined the midpoint method with the endpoint method. Compared with other methods, the proposed model reduces the complexity and uncertainty of the evaluation process.

- Based on ONS and DS of IoT technology, the effective integration method between the proposed platform and the existing EIS is innovated, thereby constructing an open and extensible platform for life cycle assessment.

2. Background and Related Work

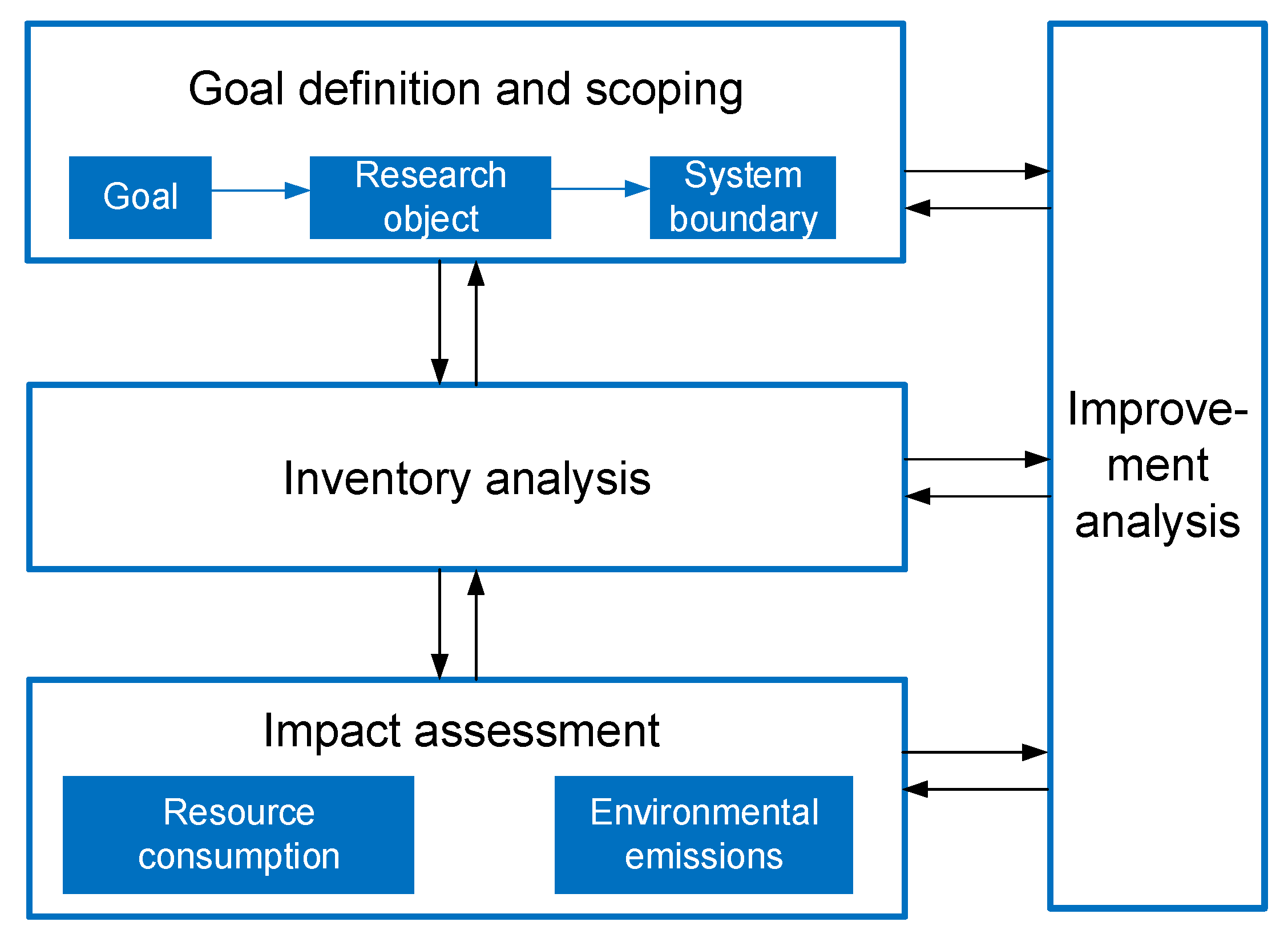

2.1. Life Cycle Assessment (LCA)

2.1.1. Development of LCA

2.1.2. Software of LCA

- Simapro is developed by the University of Leiden, the Netherlands. It provides abundant databases and a variety of evaluation methods. The database in the manufacturing phase is the most detailed. It is also the most popular LCA software in the world.

- GaBi is developed by Institut fur Kunststoffprufung und Kunst—stoffkunde from Stuttgart, Germany. It has the latest wide-range comprehensive database and provides sensitivity analysis.

- LCAiT (LCA Inventory Tool) is developed by Chalmers Industrieknik in Göteborg, Sweden. Although it has fewer own databases, it can connect with external databases. It is suitable for people who understand the flow of material and energy.

- eBalance is developed by IKE Environmental Technology Co. Ltd. from Chengdu, China. It includes three databases: Chinese Life Cycle Database, European Reference Life Cycle Database, and Ecoinvent Database. It supports China’s localized evaluation of energy conservation and emission reduction.

- Pira Environmental Management System (PEMS) is developed by Pira International, UK. The parameters in the database are from Europe, which cannot be modified or edited.

2.1.3. Quantification of LCA

2.2. LCA of Wind Turbines

2.3. IoT in LCA

3. System Design

3.1. Goal Definition and Scoping

3.1.1. Goal Definition

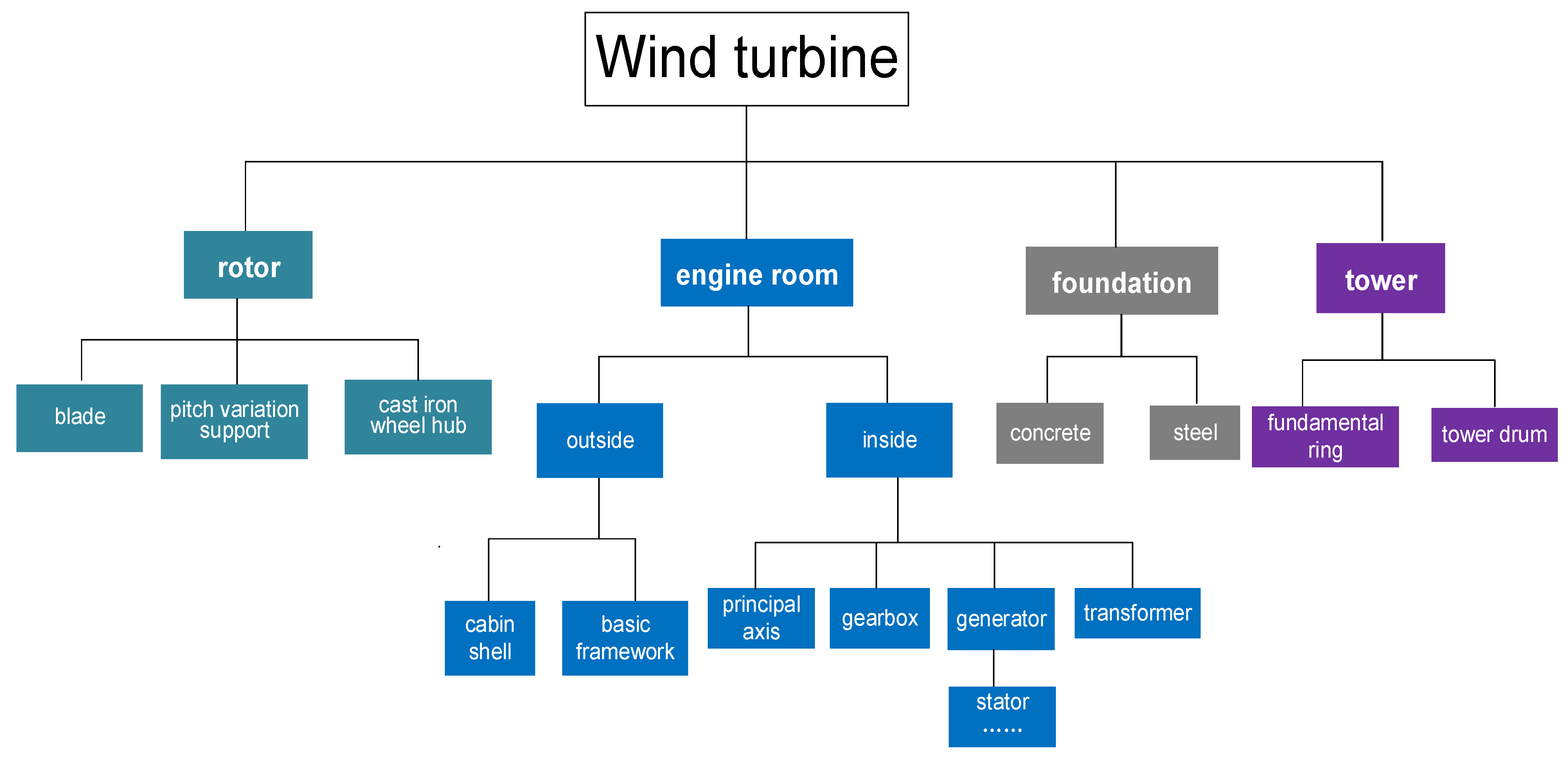

3.1.2. Research Objects

3.1.3. System Boundary

3.2. Architecture of the LCA Platform

3.3. Data Acquisition Layer

3.3.1. Design Stage

3.3.2. Raw Material Acquisition Stage

3.3.3. Production and Manufacturing Stage

3.3.4. Transportation and Installation Stage

3.3.5. Operation and Maintenance Stage

3.3.6. Recovery and Disposal Stage

3.4. Data Transmission Layer

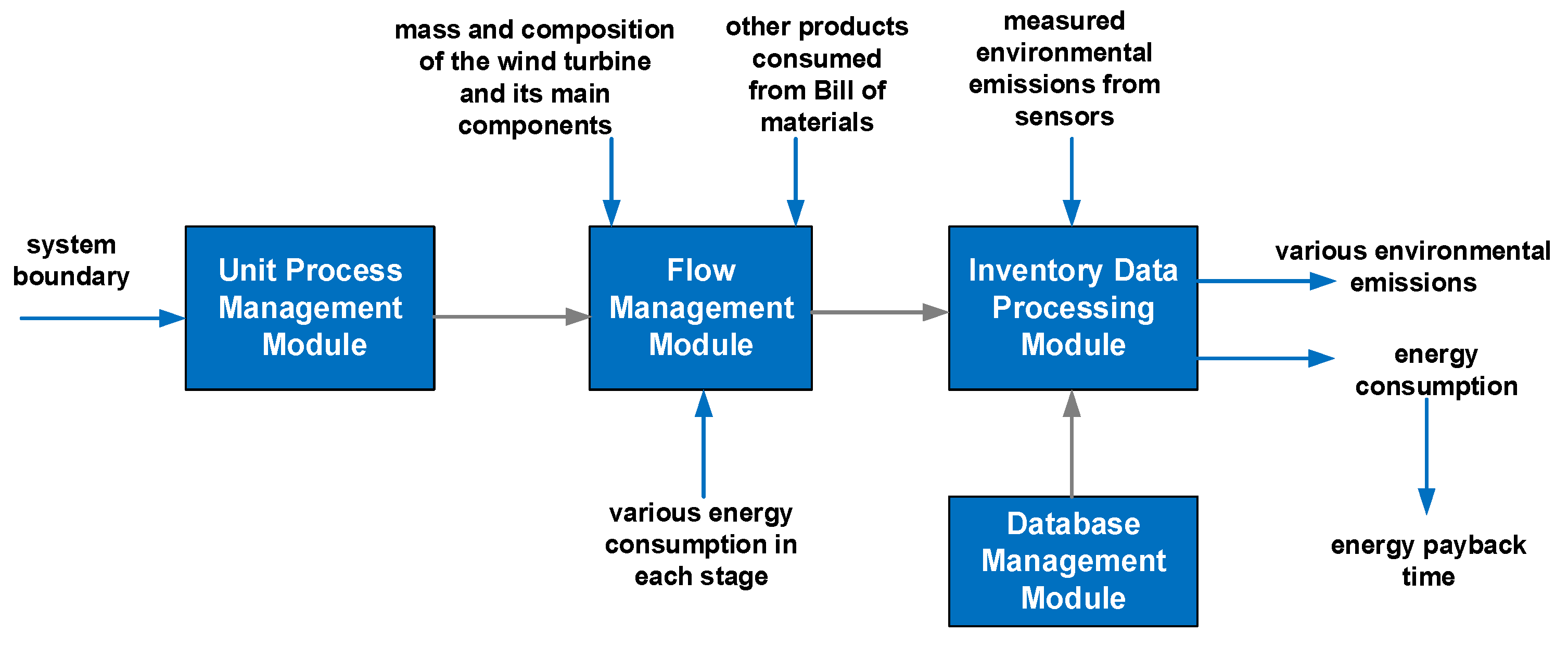

3.5. Platform Layer

3.5.1. Unit Process Management Module

3.5.2. Flow Management Module

3.5.3. Database Management Module

- LCA basic database: the existing mature database, including Ecoinvent, European Reference Life Cycle Database (ELCD), Chinese Life Cycle Database (CLCD), GaBi Databases, NREL-USLCI Database, etc. The resource consumption and environmental emission of unit mass materials in the raw material acquisition stage, unit power consumption in the production and manufacturing stage, unit oil consumption in the transportation stage, and materials with different disposal methods in the scrapping stage can be obtained from these databases.

- Material list database: mostly utilizing the name and unit of the International Reference Life Cycle Data System (ILCD), and adding the material list according to the characteristics of the wind turbine.

- Enterprise information database: storing the enterprise information involved in the life cycle of the wind turbine, including enterprise name, organization code, enterprise identification, identification rules, enterprise address, legal person information, responsible person information, enterprise website, and other fundamental data of the enterprise. The information of the database is obtained through enterprise registration and filing mainly.

- Product information database: storing the fundamental data, operation and maintenance data, and environmental emissions and energy consumption data in the life cycle of wind turbines. The fundamental data contain the structural information of all kinds of wind turbines and defines the structural relationship between the wind turbine and its components and between the components. In this database, the fundamental data are mainly obtained through integration with EIS, and the operation and maintenance data and environmental emissions and energy consumption data are obtained by real-time monitoring of IoT technology. Based on the database, the usability and real-time performance of LCA can be significantly improved.

3.5.4. Inventory Data Processing Module

- LCIA index management: it mainly stores the types of evaluation indicators, conversion coefficients between different types of indicators, and environmental impact assessment standards of relevant industries or regions. It supports the calculation of LCIA characteristic indicators, normalized indicators, and weighted comprehensive indicators. Consequently, it is an important module for data normalization and environmental impact factor unification.

- Online modeling: Based on linking all types of life cycle inventory results via 14 midpoint categories to four damage categories, a feasible approach combining midpoint and damage is proposed, which is the IMPACT2002+ methodology [8]. Based on the IMPACT 2002+, the LCA model for wind turbines is established, as shown in Figure 6. Compared with other methods, the proposed model reduces the complexity and uncertainty of the evaluation process and guides the next optimization.

3.6. Application Layer

3.6.1. Life Cycle Impact Assessment (LCIA)

3.6.2. Improvement Analysis

4. Prototype System Implementation

- The enterprise registers in the system and inputs the information of name, identification, address, website, responsible person information, relevant qualifications, etc.

- The decomposition of the wind turbine studied is determined, and the process flow is identified through the Unit Process Management Module. Additionally, then, the relevant parameters and the main information of key components for life cycle assessment will be input. Then, the material flow and energy flow information of each unit can be added, modified, deleted, and viewed through the Flow Management Module.

- Based on the installation of various sensors, the relevant energy consumption and environmental emission data will be collected. Meanwhile, the operation data will be monitored, including wind speed, vibration, noise, engine speed, pitch angle, etc. According to these data, the output power characteristic curve is formed, which can be used to calculate the annual power generation of the wind turbine. Moreover, the real-time fault data and the fault rate curve of wind turbines are collected and formed. On this basis, the residual life prediction of the main components of wind turbines is carried out.

- In addition to the real-time monitoring data, the Bill of Materials is acquired by integrating with the information systems of enterprises. Additionally, other data are obtained by the Database Management Module in the system.

- Based on the online modeling and LCIA index management, the inventory data will be processed through the Inventory Data Processing Module. Based on inventory data, the energy consumption and environmental emission data at all stages of wind turbines are calculated systematically, and the evaluation results are analyzed visually. On this basis, the life cycle assessment report of wind turbines is formed.

5. Discussion

5.1. Workload and Accuracy of the Platform

5.1.1. Comparison of the Workload

5.1.2. Estimation of the Accuracy

5.2. Characteristics of the Platform

5.2.1. LCA of Wind Turbines Oriented

5.2.2. Flexible Expansibility

5.2.3. Real-Time Data Updating

5.2.4. Effective Utilization of Data

5.2.5. Ease of Use

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Serrano-González, J.; Lacal-Arántegui, R. Technological evolution of onshore wind turbines—A market-based analysis. Wind Energy 2016, 19, 2171–2187. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez, E.; Ortego, A.; Topham, E.; Valero, A. Is the future development of wind energy compromised by the availability of raw materials? J. Phys. Conf. Ser. 2018, 1102, 012028. [Google Scholar] [CrossRef]

- Santos-Alamillos, F.J.; Thomaidis, N.S.; Usaola-García, J.; Ruiz-Arias, J.A.; Pozo-Vázquez, D. Exploring the mean-variance portfolio optimization approach for planning wind repowering actions in Spain. Renew. Energy 2017, 106, 335–342. [Google Scholar] [CrossRef]

- Miorandi, D.; Sicari, S.; De Pellegrini, F.; Chlamtac, I. Internet of things: Vision, applications and research challenges. Ad Hoc Netw. 2012, 10, 1497–1516. [Google Scholar] [CrossRef] [Green Version]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Huang, J.; Meng, Y.; Gong, X.; Liu, Y.; Duan, Q. A Novel Deployment Scheme for Green Internet of Things. IEEE Internet Things J. 2014, 1, 196–205. [Google Scholar] [CrossRef]

- Bandyopadhyay, D.; Sen, J. Internet of Things: Applications and Challenges in Technology and Standardization. Wirel. Pers. Commun. 2011, 58, 49–69. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef] [Green Version]

- Hauschild, M.Z.; Rosenbaum, R.K. Chapter 3: LCA History, Life Cycle Assessment—Theory and Practice; Springer International Publishing: Cham, Switzerland, 2018; p. 18. [Google Scholar]

- ISO 14044:2006/AMD 2:2020 Environmental Management—Life Cycle Assessment—Requirements and Guidelines—Amendment 2. Available online: https://www.iso.org/standard/76122.html (accessed on 14 December 2020).

- ISO 14040: 2006 Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/standard/37456.html (accessed on 14 December 2020).

- Boyden, A.; Soo, V.K.; Doolan, M. The Environmental Impacts of Recycling Portable Lithium-Ion Batteries. Procedia CIRP 2016, 48, 188–193. [Google Scholar] [CrossRef] [Green Version]

- Geng, S.; Wang, Y.; Zuo, J.; Zhou, Z.; Du, H.; Mao, G. Building life cycle assessment research: A review by bibliometric analysis. Renew. Sustain. Energy Rev. 2017, 76, 176–184. [Google Scholar] [CrossRef]

- Wulf, C.; Kaltschmitt, M. Life cycle assessment of biohydrogen production as a transportation fuel in Germany. Bioresour. Technol. 2013, 150, 466–475. [Google Scholar] [CrossRef] [PubMed]

- Foelster, A.-S.; Andrew, S.; Kroeger, L.; Bohr, P.; Dettmer, T.; Boehme, S.; Herrmann, C. Electronics recycling as an energy efficiency measure—A Life Cycle Assessment (LCA) study on refrigerator recycling in Brazil. J. Clean. Prod. 2016, 129, 30–42. [Google Scholar] [CrossRef]

- Duan, N.; Cheng, S. Outline and Contrast Analysis of Life Cycle Assessment Methodologies. J. Anhui Agric. Sci. 2008, 36, 13923–13925. [Google Scholar]

- Hauschild, M.Z.; Rosenbaum, R.K. Chapter 40: Overview of Existing LCIA Methods—Annex to Chapter 10, Life Cycle Assessment—Theory and Practice; Springer International Publishing: Cham, Switzerland, 2018; pp. 1152–1175. [Google Scholar]

- Suhariyanto, T.T.; Wahab, D.A.; Rahman, M.A. Multi-Life Cycle Assessment for sustainable products: A systematic review. J. Clean. Prod. 2017, 165, 677–696. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, X.; Xiang, Y.; Wang, X.; Zhao, X.; Ren, N. HIT.WATER scheme: An integrated LCA-based decision-support platform for evaluation of wastewater discharge limits. Sci. Total. Environ. 2019, 655, 1427–1438. [Google Scholar] [CrossRef]

- Yao, L.; Liu, T.; Mahdi, M.; Ni, J. An integrated method of life-cycle assessment and system dynamics for waste mobile phone management and recycling in China. J. Clean. Prod. 2018, 187, 852–862. [Google Scholar] [CrossRef]

- Morbidoni, A.; Favi, C.; Germani, M. CAD-Integrated LCA Tool: Comparison with dedicated LCA Software and Guidelines for the Improvement. Presented at the 18th CIRP International Conference on Life Cycle Engineering, Braunschweig, Germany, 7 March 2011. [Google Scholar]

- Demir, N.; Taşkın, A. Life cycle assessment of wind turbines in Pınarbaşı-Kayseri. J. Clean. Prod. 2013, 54, 253–263. [Google Scholar] [CrossRef]

- Uddin, M.S.; Kumar, S. Energy, emissions and environmental impact analysis of wind turbine using life cycle assessment technique. J. Clean. Prod. 2014, 69, 153–164. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, L.; Wang, C. Energy consumption and greenhouse gas emission of an offshore wind farm in China: A hybrid life cycle assessment perspective. Acta Sci. Circumstantiae 2017, 37, 786–792. [Google Scholar]

- Lloberas-Valls, J.; Benveniste Perez, G.; Gomis-Bellmunt, O. Life-Cycle Assessment Comparison between 15-MW Second-Generation High-Temperature Superconductor and Permanent-Magnet Direct-Drive Synchronous Generators for Offshore Wind Energy Applications. IEEE Trans. Appl. Supercond. 2015, 25, 1–9. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Rezk, H.; Mustafa, R.J.; Al-Dhaifallah, M. Evaluating the Environmental Impacts and Energy Performance of a Wind Farm System Utilizing the Life-Cycle Assessment Method: A Practical Case Study. Energies 2019, 12, 3263. [Google Scholar] [CrossRef] [Green Version]

- Chipindula, J.; Botlaguduru, V.; Du, H.; Kommalapati, R.R.; Huque, Z. Life Cycle Environmental Impact of Onshore and Offshore Wind Farms in Texas. Sustainability 2018, 10, 2022. [Google Scholar] [CrossRef] [Green Version]

- Moghadam, F.K.; Nejad, A.R. Evaluation of PMSG-based drivetrain technologies for 10-MW floating offshore wind turbines: Pros and cons in a life cycle perspective. Wind Energy 2020, 23, 1542–1563. [Google Scholar] [CrossRef]

- Mendecka, B.; Lombardi., L. Life cycle environmental impacts of wind energy technologies: A review of simplified models and harmonization of the results. Renew. Sustain. Energy Rev. 2019, 111, 462–480. [Google Scholar] [CrossRef]

- Martínez, E.; Latorre-Biel, J.I.; Jiménez, E.; Sanz, F.; Blanco, J. Life cycle assessment of a wind farm repowering process. Renew. Sustain. Energy Rev. 2018, 93, 260–271. [Google Scholar] [CrossRef]

- Marx, H.; Forin, S.; Finkbeiner, M. Organizational Life Cycle Assessment of a Service Providing SME for Renewable Energy Projects (PV and Wind) in the United Kingdom. Sustainability 2020, 12, 4475. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Zhou, Z.; Garvlehn, M.P.; Bi, F. Comparative Assessment of the Environmental Impacts of Hydro-Electric, Nuclear and Wind Power Plants in China: Life Cycle Considerations. Energy Procedia 2018, 152, 1009–1014. [Google Scholar] [CrossRef]

- Crawford, R.H. Life cycle energy and greenhouse emissions analysis of wind turbines and the effect of size on energy yield. Renew. Sustain. Energy Rev. 2009, 13, 2653–2660. [Google Scholar] [CrossRef]

- Xu, L.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Mishra, S.; Singh, S.P. Carbon management framework for sustainable manufacturing using life cycle assessment, IoT and carbon sequestration. Benchmarking Int. J. 2019. ahead-of-print. [Google Scholar] [CrossRef]

- Du, J.; Li, H.; Liang, T. The Research of Mode of Renewable Resource Management Based on the Internet of Things and the Life Cycle Assessment. Chin. Agric. Sci. Bull. 2014, 30, 294–299. [Google Scholar]

- Tao, F.; Wang, Y.; Zuo, Y.; Yang, H.; Zhang, M. Internet of Things in product life-cycle energy management. J. Ind. Inf. Integr. 2016, 1, 26–39. [Google Scholar] [CrossRef]

- Tao, F.; Zuo, Y.; Xu, L.D.; Lv, L.; Zhang, L. Internet of Things and BOM-Based Life Cycle Assessment of Energy-Saving and Emission-Reduction of Products. IEEE Trans. Ind. Inform. 2014, 10, 1252–1261. [Google Scholar]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- GS1 General Specification. Available online: https://www.gs1.org/standards/barcodes-epcrfid-id-keys/gs1-general-specifications (accessed on 14 December 2020).

- Object Name Service (ONS) Version 2.0.1. Available online: https://www.gs1.org/standards/epcis/epcis-ons/2-0-1 (accessed on 14 December 2020).

- Huang, X.; Zhong, M.; Li, Y.; Yang, H. Research on comprehensive performance evaluation technology of wind turbine based on Analytic Hierarchy Process. Iop Conf. Ser. Earth Environ. Sci. 2018, 153, 042024. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Mo, Q.; Zhou, Z.; Deng, F.; Tang, L. The calculation of small wind turbine energy pay back time based on LCA. Renew. Energy Resour. 2015, 33, 667–671. [Google Scholar]

- Alsema, E.A.; Frankl, P.; Kato, K. Energy Pay-Back Time of Photovoltaic Energy Systems: Present Status and Prospects. In Proceedings of the 2nd World Conference on Photovoltaic Solar Energy Conversion, Vienna, Austria, 6–10 July 1998. [Google Scholar]

| Users | Goal Definition | Research Object | System Boundary |

|---|---|---|---|

| Enterprises | Product development and improvement, green design | Wind turbine/main components | Raw material acquisition stage, production and manufacturing stage, recovery and disposal stage |

| The third-party certification department | Green certification | Wind farm/wind turbine/main components | Raw material acquisition stage, production and manufacturing stage, installation stage, operation and maintenance stage, recovery and disposal stage |

| Government | Standard-setting and policymaking | Wind farm/wind turbine | Design stage, raw material acquisition stage, production and manufacturing stage, transportation and installation stage, operation and maintenance stage, recovery and disposal stage |

| Components | Steel | Iron | Copper | Aluminum | Silicon | Glass Fiber | Epoxy Resin | Concrete | |

|---|---|---|---|---|---|---|---|---|---|

| Tower frames | Fundamental ring | √ | |||||||

| Tower drum | √ | ||||||||

| Rotor | Blade | √ | √ | ||||||

| Hub | √ | ||||||||

| Pitch variation support | √ | √ | |||||||

| Engine room | Shell | √ | √ | ||||||

| Framework | √ | ||||||||

| Generator | √ | √ | √ | ||||||

| Gearbox | √ | √ | √ | ||||||

| Principal axis | √ | ||||||||

| Transformer | √ | √ | √ | ||||||

| Foundation | √ | √ | |||||||

| Stage | Influencing Factor 1 | Influencing Factor 2 |

|---|---|---|

| Design stage | Design tool

| Design test

|

| Raw material acquisition stage | Metal material manufacturing

| Chemical products manufacturing

|

| Production and manufacturing stage | Communal facilities

| Manufacturing equipment

|

| Transportation and installation stage | Transportation

| Installation

|

| Operation and maintenance stage | Installation test

| Maintenance

|

| Recovery and disposal stage | Recovery

| Waste disposal

|

| Resource and Environment Indicators | Abbreviation | Influencing Factors | Functional Units | |

|---|---|---|---|---|

| 1 | Global warming potential | GWP | CO2, etc. | kg CO2 eq |

| 2 | Solid waste | WS | steel, iron, glass fiber, etc. | kg |

| 3 | Eutrophication potential | EP | NH4, NOx, etc. | kg PO43− eq |

| 4 | Acidification potential | AP | SO2, NO2, H2S, HCl, etc. | kg SO2 eq |

| 5 | Chemical oxygen demand | COD | waste liquid draining | kg |

| 6 | Respirable inorganic | RI | dust, NO, etc. | kg PM2.5eq |

| 7 | Industrial water consumption | IWU | source of water | kg |

| 8 | Primary energy demand | PED | coal, oil, natural gas, etc. | MJ |

| 9 | Ozone depletion potential | ODP | CFCs | kg CFC-11eq |

| Data Preprocessing | Goal Definition and Scoping | Inventory Analysis | Impact Assessment | the LCA Workload | |||

|---|---|---|---|---|---|---|---|

| Data Collection | Data Analysis | Data Calculation | |||||

| The existing software | 70% | 10% | 20% | 100% | 100% | 100% | 100% |

| The proposed system | 20% | 8% | 20% | 30% | 80% | 100% | 62.4% |

| weights | 30% | 20% | 40% | 10% | 100% | ||

| LCA System | Architecture | Data Sources | Real-Time Data Acquisition | Integration with EIS | Accuracy of Results | Wind Turbines Oriented |

|---|---|---|---|---|---|---|

| Gabi/Simapro/eBalance | C/S | Manual collection | N | N | Usual | N |

| The proposed platform | B/S | Automatic collection | Y | Y | High | Y |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, J.; Zou, Z.; Chen, G.; Sun, Y.; Liu, R.; Zheng, L. An IoT-Based Life Cycle Assessment Platform of Wind Turbines. Sensors 2021, 21, 1233. https://doi.org/10.3390/s21041233

An J, Zou Z, Chen G, Sun Y, Liu R, Zheng L. An IoT-Based Life Cycle Assessment Platform of Wind Turbines. Sensors. 2021; 21(4):1233. https://doi.org/10.3390/s21041233

Chicago/Turabian StyleAn, Jinjing, Zhuo Zou, Guoping Chen, Yaojie Sun, Ran Liu, and Lirong Zheng. 2021. "An IoT-Based Life Cycle Assessment Platform of Wind Turbines" Sensors 21, no. 4: 1233. https://doi.org/10.3390/s21041233