Chalcogenide Glass-Capped Fiber-Optic Sensor for Real-Time Temperature Monitoring in Extreme Environments

Abstract

1. Introduction

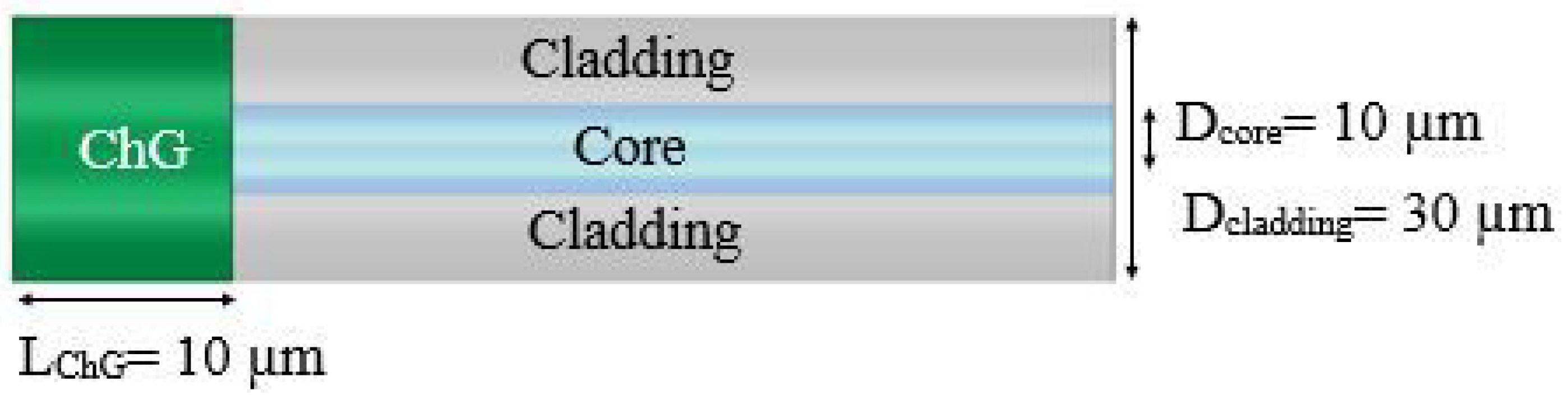

2. Sensor Design

2.1. Determination of the Optical Constants of In-House Synthesized ChGs

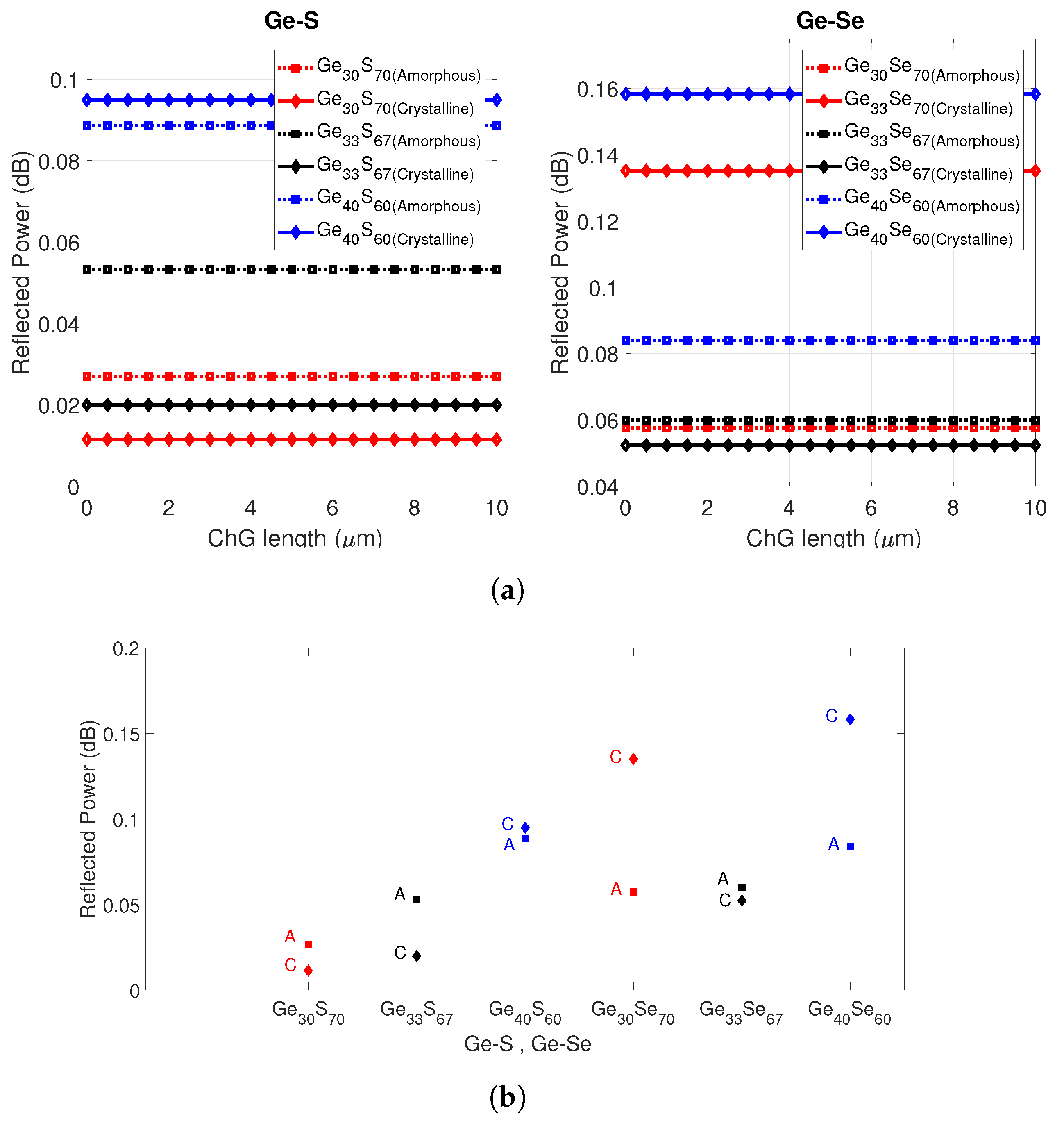

2.2. Fiber Sensor Modeling

3. Sensor Fabrication and Testing

- (a)

- Dip-coating method: The sensor devices were made by dip coating the fiber in ChG nanoparticle ink [39,40]. The coatings were left to dry for 24 h at room temperature. Then, the coatings were further cured using a hot chuck in a two-step process: (1) the coated fiber was heated at 100 C for 2 h to slowly dry the solvent, cyclohexanone, without creating cracks in the film, and (2) the fiber tip was placed on a hot plate and heated at 350 C for 15 min to decompose the surfactants in the ink, Ethyl Cellulose. Once cooled, the fiber tip was dip-coated with spin-on-glass for isolation of the sensor from an oxygen containing ambient. After drying at room temperature for 24 h, the coated fiber was heated at 300 C for 3 h to cure the spin-on-glass.

- (b)

- Thermal evaporation: The ChGs on the tip of the fibers were also coated using thermal evaporation in a Cressington 308R coating system at 10 mbar vacuum with an evaporation rate of 0.35 Å/s. The fiber was not heated during the film preparation. The thickness of the deposited film was estimated using the output from a quartz crystal microbalance. To check the composition of the deposited coating, ChG was also deposited on a single crystalline silicon substrate along with the fiber. Compared to the composition of the source material, the thin film had ±1.5% compositional deviation as measured by an Energy Dispersive Spectroscopy (EDS) study. Once the deposition was completed, the fiber tip was dip-coated with spin-on-glass. After drying at room temperature for 24 h, the coated fibers were heated at 300 C for 3 h to completely cure the spin-on-glass. This vapor phase deposition process to form ChG layer on fiber tip is a standard process that leads to highly conformal and uniform in thickness coating. The thermally deposited sensors were used to benchmark the performance of the dip-coated devices.

4. Experimental Setup

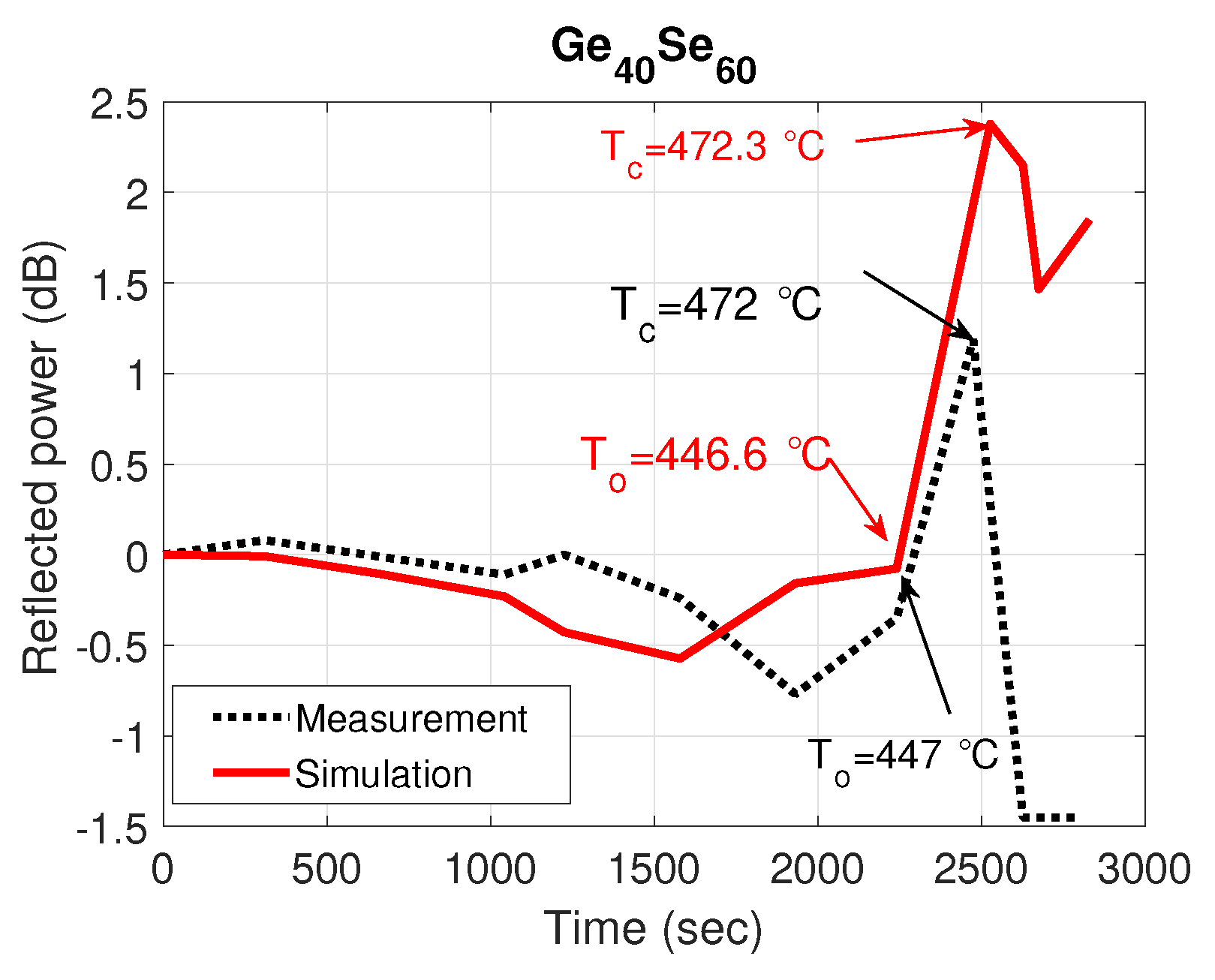

5. Results and Discussion

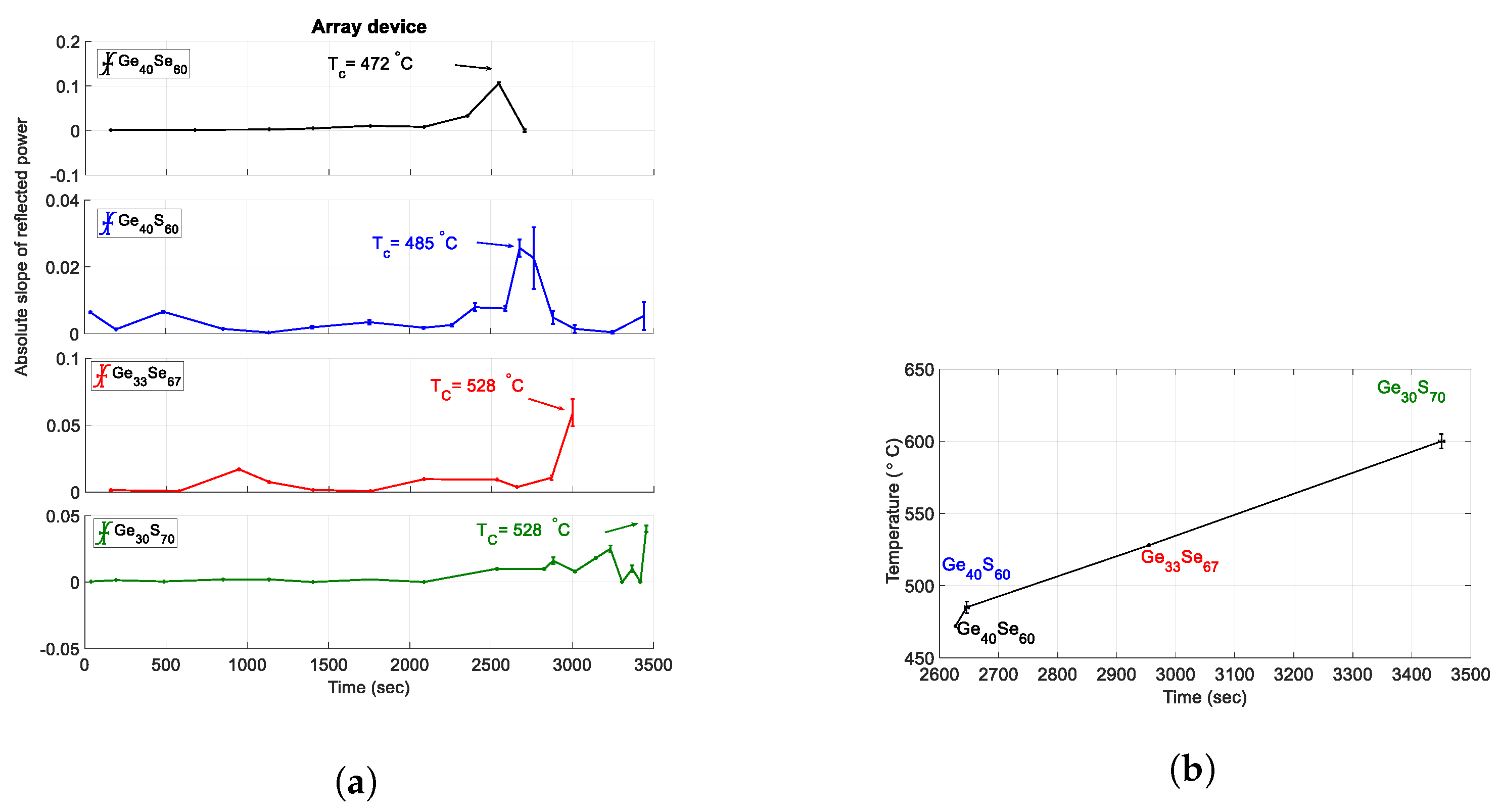

6. Temperature Profile Estimation Using Array Sensor

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ChG | Chalcogenide Glass |

| RTD | Resistance Temperature Detectors |

| OFS | Optical Fiber Sensors |

| T | Glass Transition Temperature |

| T | Crystallization Onset Temperature |

| T | Glass Peak Crystallization Temperature |

| DSC | Differential Scanning Calorimetry |

| SMF | Single-Mode Fiber |

References

- Locatelli, G.; Mancini, M.; Todeschini, N. Generation IV nuclear reactors: Current status and future prospects. Energy Policy 2013, 61, 1503–1520. [Google Scholar] [CrossRef]

- Kallman, B. The Very High Temperature Reactor. Available online: http://large.stanford.edu/courses/2013/ph241/kallman1/ (accessed on 13 March 2013).

- Kelly, J.E. Generation IV International Forum: A decade of progress through international cooperation. Prog. Nucl. Energy 2014, 77, 240–246. [Google Scholar] [CrossRef]

- Daw, J.; Rempe, J.; Knudson, D.; Unruh, T.; Chase, B.; Davis, K.; Palmer, A. Temperature monitoring options available at the Idaho national laboratory advanced test reactor. In Proceedings of the 9th International Temperature Symposium on Temperature—Its Measurement, Los Angeles, CA, USA, 19–23 March 2012; Volume 1552, pp. 970–975. [Google Scholar]

- Hashemian, H. Nuclear power plant instrumentation and control. In Nuclear Power Control, Reliability and Human Factors; Intech: Vienna, Austria, 2011; pp. 49–66. [Google Scholar]

- Scervini, M.; Rae, C.; Lindley, B. Transmutation of thermocouples in thermal and fast nuclear reactors. In Proceedings of the 3rd International Conference on Advancements in Nuclear Instrumentation, Measurement Methods and their Applications (ANIMMA), Marseille, France, 23–27 June 2013; pp. 1–8. [Google Scholar]

- Bentley, R.E. Handbook of Temperature Measurement Vol. 3: The Theory and Practice of Thermoelectric Thermometry; Springer Science & Business Media: New York, NY, USA, 1998; Volume 3. [Google Scholar]

- Bucholtz, F.; Udd, E. Fiber optic magnetic sensors. In Fiber Optic Sensors: An Introduction for Engineers and Scientists; A Wiley-Interscience Publication: New York, NY, USA, 1991; pp. 369–382. [Google Scholar]

- Golnabi, H. Design and operation of a fiber optic sensor for liquid level detection. Opt. Lasers Eng. 2004, 41, 801–812. [Google Scholar] [CrossRef]

- Pal, B.P. Fundamentals of Fibre Optics in Telecommunication and Sensor Systems; Bohem Press: New Delhi, India, 1992. [Google Scholar]

- Zhao, Y.; Li, P.; Pu, Z. MJ internal thread used for aerospace and its noncontact test method with a fiber optic sensor. Opt. Eng. Sens. Nanotechnol. 1999, 3740, 501–504. [Google Scholar]

- Zhao, Y.; Li, P.; Pu, Z. Shape measurement based on fiber-optic technique for complex internal surface. Measurement 2001, 30, 289–295. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, P.; Wang, C.; Pu, Z. A novel fiber-optic sensor used for small internal curved surface measurement. Sens. Actuators A Phys. 2000, 86, 211–215. [Google Scholar] [CrossRef]

- Udd, E. Fiber optic smart structures. In E. Udd and WB Spillman, Fiber Opic Sensors and Introduction for Engineers and Scientists; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Grattan, K.; Sun, T. Fiber optic sensor technology: An overview. Sens. Actuators A Phys. 2000, 82, 40–61. [Google Scholar] [CrossRef]

- Wei, T.; Lan, X.; Xiao, H.; Han, Y.; Tsai, H.L. Optical fiber sensors for high temperature harsh environment sensing. In Proceedings of the I2MC—IEEE Instrumentation and Measurement Technology Conference, Hangzhou, China, 10–12 May 2011; pp. 1–4. [Google Scholar]

- Zakery, A.; Elliott, S. Optical properties and applications of chalcogenide glasses: A review. J. Non-Cryst. Solids 2003, 330, 1–12. [Google Scholar] [CrossRef]

- Tanaka, K.; Shimakawa, K. Amorphous Chalcogenide Semiconductors and Related Materials; Springer Science & Business Media: New York, NY, USA, 2011. [Google Scholar]

- Wang, R.; Madden, S.; Zha, C.; Rode, A.V.; Luther-Davies, B. Annealing induced phase transformations in amorphous As2S3 films. J. Appl. Phys. 2006, 100, 063524. [Google Scholar] [CrossRef]

- Wang, R.; Rode, A.V.; Madden, S.J.; Zha, C.; Jarvis, R.; Luther-Davies, B. Structural relaxation and optical properties in amorphous Ge33As12Se55 films. J. Non-Cryst. Solids 2007, 353, 950–952. [Google Scholar] [CrossRef]

- Burr, G.W.; Brightsky, M.J.; Sebastian, A.; Cheng, H.Y.; Wu, J.Y.; Kim, S.; Sosa, N.E.; Papandreou, N.; Lung, H.L.; Pozidis, H.; et al. Recent progress in phase-change memory technology. IEEE J. Etcas 2016, 6, 146–162. [Google Scholar]

- Waser, R. Redox-based resistive switching memories. J. Nanosci. 2012, 12, 7628–7640. [Google Scholar] [CrossRef] [PubMed]

- Abdollahramezani, S.; Hemmatyar, O.; Taghinejad, H.; Krasnok, A.; Kiarashinejad, Y.; Zandehshahvar, M.; Alù, A.; Adibi, A. Tunable nanophotonics enabled by chalcogenide phase-change materials. Nanophotonics 2020, 9, 1189–1241. [Google Scholar] [CrossRef]

- Adam, J.L.; Zhang, X. Chalcogenide Glasses: Preparation, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Adler, D.; Shur, M.; Silver, M.; Ovshinsky, S. Threshold Switching in Chalcogenide-Glass Thin Films. In Disordered Materials; Springer: Boston, MA, USA, 1991; pp. 66–87. [Google Scholar]

- Barik, A.; Bapna, M.; Drabold, D.; Adarsh, K. Ultrafast light induced unusually broad transient absorption in the sub-bandgap region of GeSe2 thin film. Sci. Rep. 2014, 4, 3686. [Google Scholar] [CrossRef]

- Naitoh, M.; Katayama, H.; Harada, M.; Suganuma, M.; Okamura, Y.; Tange, Y.; Rogers, K.; Guimond, Y. The radiation tolerance of chalcogenide glasses. In Proceedings of the Infrared Technology and Applications XXXVI, Orlando, FL, USA, 5–9 April 2010; Volume 7660, p. 766028. [Google Scholar]

- Shpotyuk, M.; Shpotyuk, M.; Ubizskii, S. Radiation-induced optical effects in chalcogenide semiconductor glasses. In Proceedings of the Fifth International Conference on Radiation and Applications in Various Fields of Research, Budva, Montenegro, 11 June 2017. [Google Scholar]

- Macko, P.; Lukášik, D. Electrical and optical properties of neutron irradiated the GeS8 glass. Solid State Commun. 1981, 39, 239–243. [Google Scholar] [CrossRef]

- Sarsembinov, S.S.; Abdulgafarov, E.; Tumanov, M.; Rogachev, N. Radiation-induced defects influence on the electrical, photoelectrical and optical properties of chalcogenide glasses. J. Non-Cryst. Solids 1980, 35, 877–882. [Google Scholar] [CrossRef]

- Ahmed Simon, A.A.; Jones, L.; Sakaguchi, Y.; Kunold, H.; van Rooyen, I.; Mitkova, M. Effect of Ion Irradiation on Amorphous and Crystalline Ge–Se and Their Application as Phase Change Temperature Sensor. Phys. Status Solidi (b) 2020, 2000429. [Google Scholar] [CrossRef]

- Edmond, J.; Male, J.; Chester, P. On the suitability of liquid semiconductors for resistance thermometry in nuclear reactors. J. Phys. E Sci. Instrum. 1968, 1, 373. [Google Scholar] [CrossRef]

- Simon, A.A.A.; Badamchi, B.; Subbaraman, H.; Sakaguchi, Y.; Mitkova, M. Phase change in Ge-Se chalcogenide glasses and its implications on optical temperature-sensing devices. J. Mater. Sci. Mater. Electron. 2020, 31, 11211–11226. [Google Scholar] [CrossRef]

- Sakaguchi, Y.; Tenne, D.; Mitkova, M. Structural development in Ge-rich Ge–S glasses. J. Non-Cryst. Solids 2009, 355, 1792–1796. [Google Scholar] [CrossRef][Green Version]

- Lin, C.; Tao, H.; Wang, Z.; Wang, B.; Zang, H.; Zheng, X.; Zhao, X. Defect configurations in Ge–S chalcogenide glasses studied by Raman scattering and positron annihilation technique. J. Non-Cryst. Solids 2009, 355, 438–440. [Google Scholar] [CrossRef]

- Mitkova, M.; Sakaguchi, Y.; Tenne, D.; Bhagat, S.K.; Alford, T.L. Structural details of Ge-rich and silver-doped chalcogenide glasses for nanoionic nonvolatile memory. Phys. Status Solidi (a) 2010, 207, 621–626. [Google Scholar] [CrossRef]

- Feng, X.; Bresser, W.; Boolchand, P. Direct evidence for stiffness threshold in chalcogenide glasses. Phys. Rev. Lett. 1997, 78, 4422. [Google Scholar] [CrossRef]

- Fiberguide Industries. Buffer Removal Techniques for Optical Fiber. 2008. Available online: https://www.fiberguide.com/supplier-resources/application-notes/ (accessed on 17 September 2020).

- Simon, A.A.A.; Rahmot Ullah, S.M.; Badamchi, B.; Subbaraman, H.; Mitkova, M. Materials Characterization of Thin Films Printed with Ge20Se80 Ink. Microsc. Microanal. 2019, 25, 2606–2607. [Google Scholar] [CrossRef]

- Simon, A.A.A.; Kadrager, K.; Badamchi, B.; Subbaraman, H.; Mitkova, M. Temperature Sensing in Nuclear Facilities: Application of the Phase Change Effect of Chalcogenide Glasses. In Proceedings of the Nuclear Plant Instrumentation, Control, and Human-Machine Interface Technologies, Orlando, FL, USA, 9–14 February 2019. [Google Scholar]

- Sakaguchi, Y.; Hanashima, T.; Ohara, K.; Simon, A.A.A.; Mitkova, M. Structural transformation in GexS100−x (10≤ x≤ 40) network glasses: Structural varieties in short-range, medium-range, and nanoscopic scale. Phys. Rev. Mater. 2019, 3, 035601. [Google Scholar] [CrossRef]

- Málek, J.; Klikorka, J. Crystallization kinetics of glassy GeS2. J. Therm. Anal. 1987, 32, 1883–1893. [Google Scholar] [CrossRef]

- Dittmar, G.; Schäfer, H. Die kristallstruktur von germaniumdiselenid. Acta Crystallogr. Sect. Struct. Crystallogr. Cryst. Chem. 1976, 32, 2726–2728. [Google Scholar] [CrossRef]

- Fouad, S. On the glass transition temperature and related parameters in the glassy GexSe1−x system. Phys. B Condens. Matter 2001, 293, 276–282. [Google Scholar] [CrossRef]

- Inoue, K.; Matsuda, O.; Murase, K. Raman spectra of tetrahedral vibrations in crystalline germanium dichalcogenides, GeS2 and GeSe2, in high and low temperature forms. Solid State Commun. 1991, 79, 905–910. [Google Scholar] [CrossRef]

- Eymard, R.; Otto, A. Optical and electron-energy-loss spectroscopy of GeS, GeSe, SnS, and SnSe single crystals. Phys. Rev. B 1977, 16, 1616. [Google Scholar] [CrossRef]

- Saffarini, G. The effect of compositional variations on the glass-transition and crystallisation temperatures in Ge-Se-In glasses. Appl. Phys. A 2002, 74, 283–285. [Google Scholar] [CrossRef]

| Composition | Refractive Index | Temperature (°C) | |||

|---|---|---|---|---|---|

| Amorphous | Crystalline | T | T | T | |

| GeS | 2.17406 + i0 | 1.77269 + i0.11865 | 402 | 572 | 605 |

| GeS | 2.67680 + i0 | 2.72309 + i0.17664 | 355 | 408 | 413 |

| 480 | 489 | ||||

| GeS | 2.31779 + i8.28 | 1.92455 + i0.02458 | 435 | 644 | 694 |

| GeSe | 2.37646 + i4.06 | 3.12455 + i0.25837 | 334.8 | 440.9 | 470.4 |

| GeSe | 2.63104 + i0.00575 | 3.10991 + i0.211 | 343.7 | 446.6 | 472.3 |

| GeSe | 2.38753 + i0.00402 | 2.30756 + i0.02011 | 396.3 | 485.4 | 527.7 |

| Temperature (°C) | Refractive Index | Temperature (°C) | Refractive Index |

|---|---|---|---|

| 25 | 2.717 + i0.00547 | 400 | 2.70088 + i0.01636 |

| 100 | 2.171516 + i0.00575 | 450 | 3.35909 + i0.25735 |

| 150 | 2.695050 + i0.00547 | 472 | 3.29764 + i0.09341 |

| 200 | 2.66978 + i0.00513 | 479 | 3.1099 + i0.2211 |

| 250 | 2.63104 + i0.00575 | 484 | 3.14107 + i0.22572 |

| 300 | 2.59792 + i0.00563 | 500 | 3.2688 + i0.21606 |

| 350 | 2.70057 + i0.00938 |

| Composition | Fabrication | T | T | Time | T | T | Time | Error |

|---|---|---|---|---|---|---|---|---|

| (°C) | (°C) | T | (°C) | (°C) | T | T (°C) | ||

| GeSe | Dip-coated | 446.6 | 460 | 2589 | 472.3 | 472 | 2627 | 0.3 |

| Evaporated | 446.6 | 447 | 2462 | 472.3 | 472 | 2627 | 0.3 | |

| GeSe | Dip-coated | 485.4 | 485 | 2646 | 527.7 | 528 | 2950 | 0.3 |

| Evaporated | 485.4 | 450 | 2527 | 527.7 | 485 | 2646 | 42.7 | |

| GeSe | Dip-coated | 440.9 | 400 | 2241 | 470.4 | 450 | 2527 | 20.5 |

| Evaporated | 440.9 | 447 | 2462 | 470.4 | 460 | 2589 | 10.4 | |

| GeS | Dip-coated | 480 | 450 | 2527 | 489 | 485 | 2646 | 4 |

| GeS | Dip-coated | 572 | 574 | 2830 | 605 | 600 | 3399 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badamchi, B.; Simon, A.-A.A.; Mitkova, M.; Subbaraman, H. Chalcogenide Glass-Capped Fiber-Optic Sensor for Real-Time Temperature Monitoring in Extreme Environments. Sensors 2021, 21, 1616. https://doi.org/10.3390/s21051616

Badamchi B, Simon A-AA, Mitkova M, Subbaraman H. Chalcogenide Glass-Capped Fiber-Optic Sensor for Real-Time Temperature Monitoring in Extreme Environments. Sensors. 2021; 21(5):1616. https://doi.org/10.3390/s21051616

Chicago/Turabian StyleBadamchi, Bahareh, Al-Amin Ahmed Simon, Maria Mitkova, and Harish Subbaraman. 2021. "Chalcogenide Glass-Capped Fiber-Optic Sensor for Real-Time Temperature Monitoring in Extreme Environments" Sensors 21, no. 5: 1616. https://doi.org/10.3390/s21051616

APA StyleBadamchi, B., Simon, A.-A. A., Mitkova, M., & Subbaraman, H. (2021). Chalcogenide Glass-Capped Fiber-Optic Sensor for Real-Time Temperature Monitoring in Extreme Environments. Sensors, 21(5), 1616. https://doi.org/10.3390/s21051616