Capacitive Humidity Sensor Based on Carbon Black/Polyimide Composites

Abstract

:1. Introduction

2. Experimental Details

2.1. Preparation of Carbon Black/Polyimide Composite

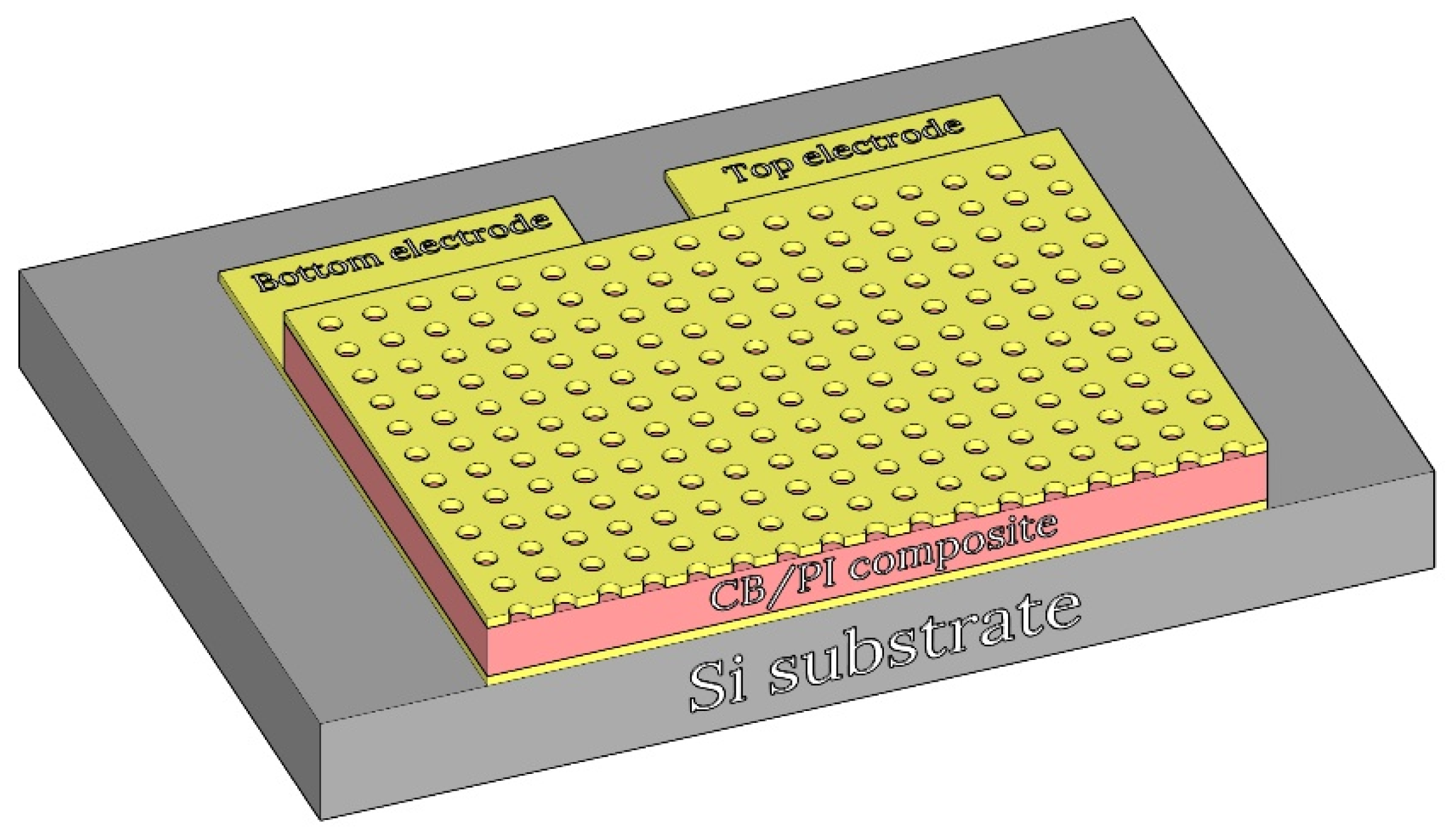

2.2. Sensor Design

2.3. Fabrication of the Sensor

2.4. Measurement System

3. Results and Discussion

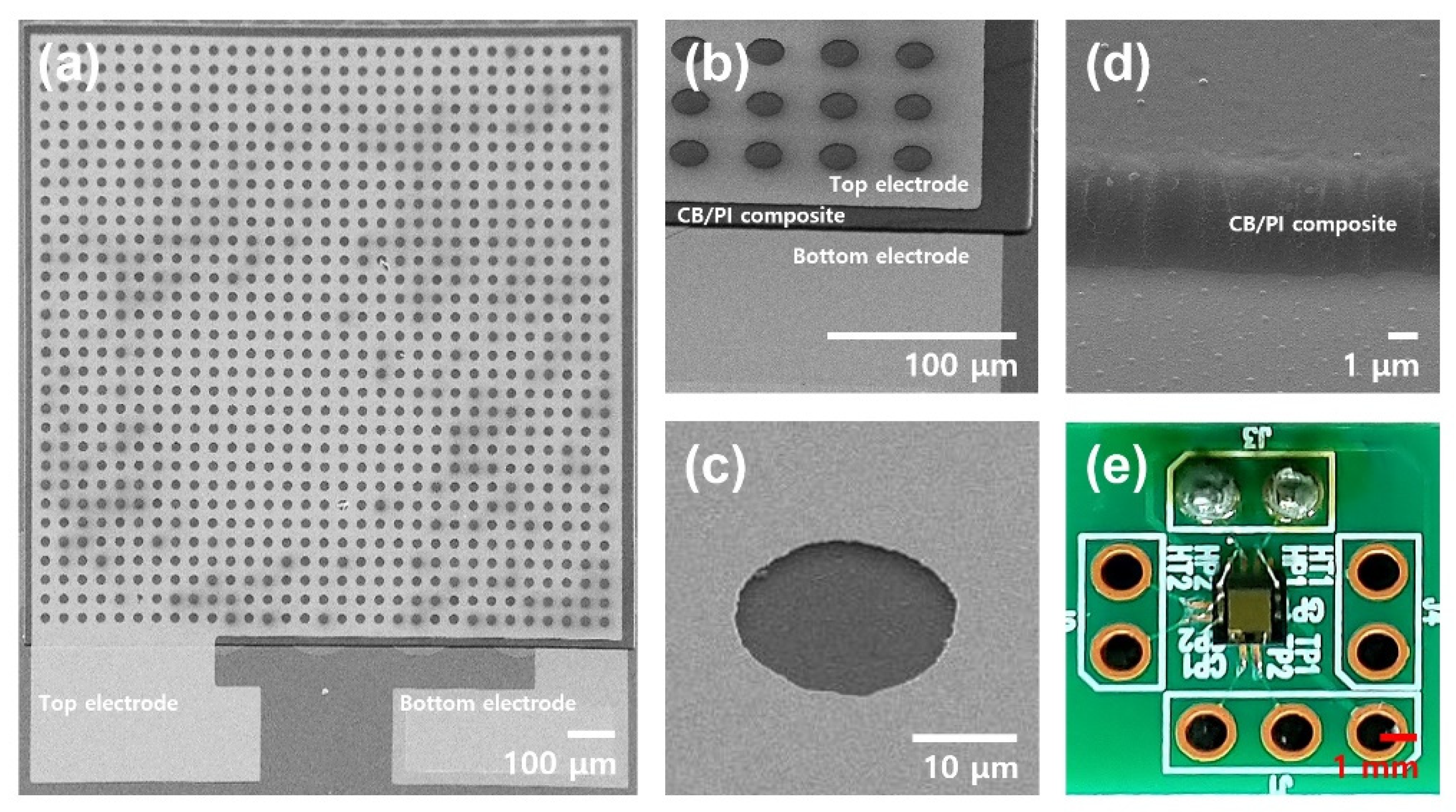

3.1. Imaging

3.2. Sensor Characteristics

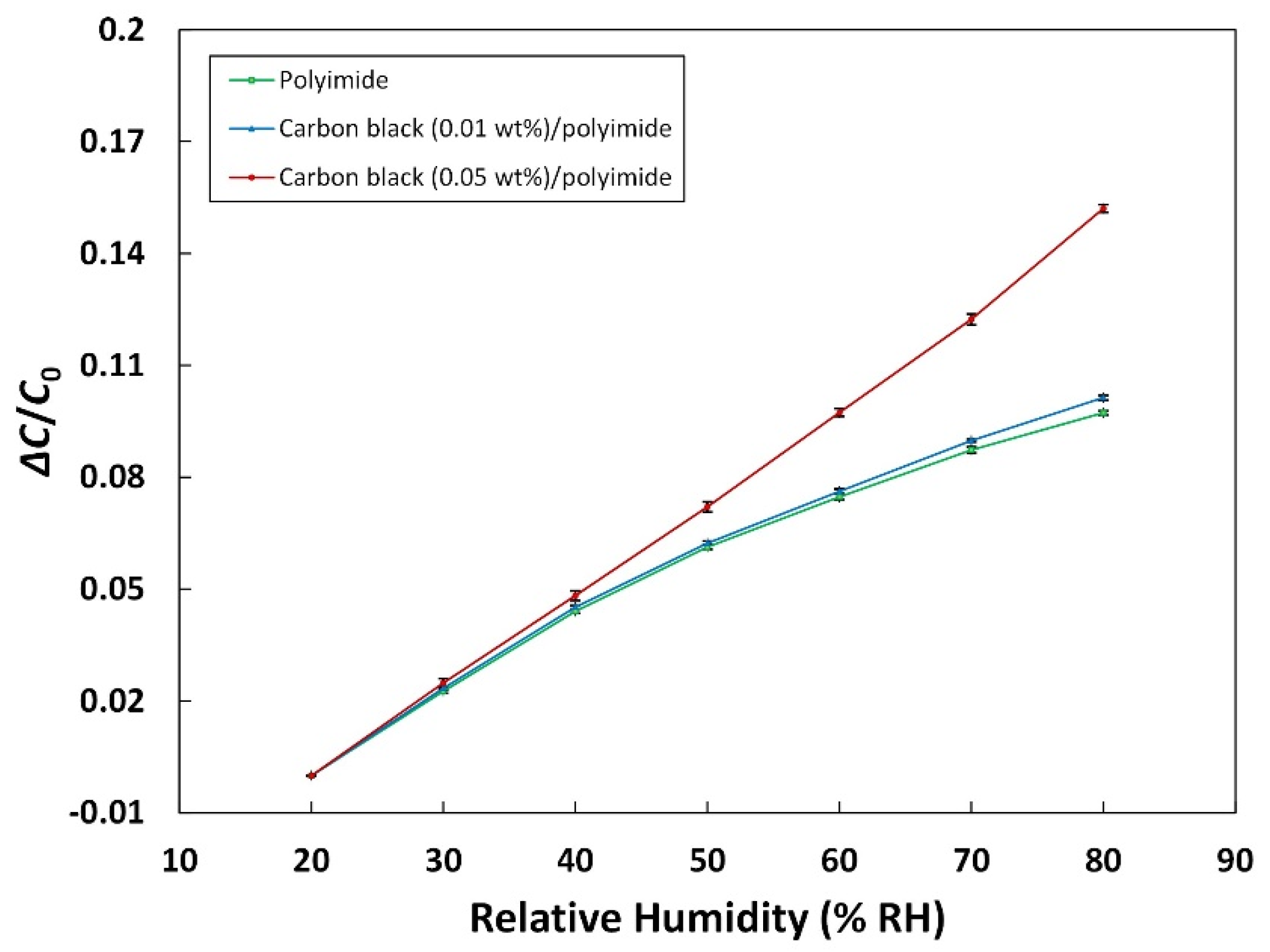

3.2.1. Sensitivity

3.2.2. Hysteresis

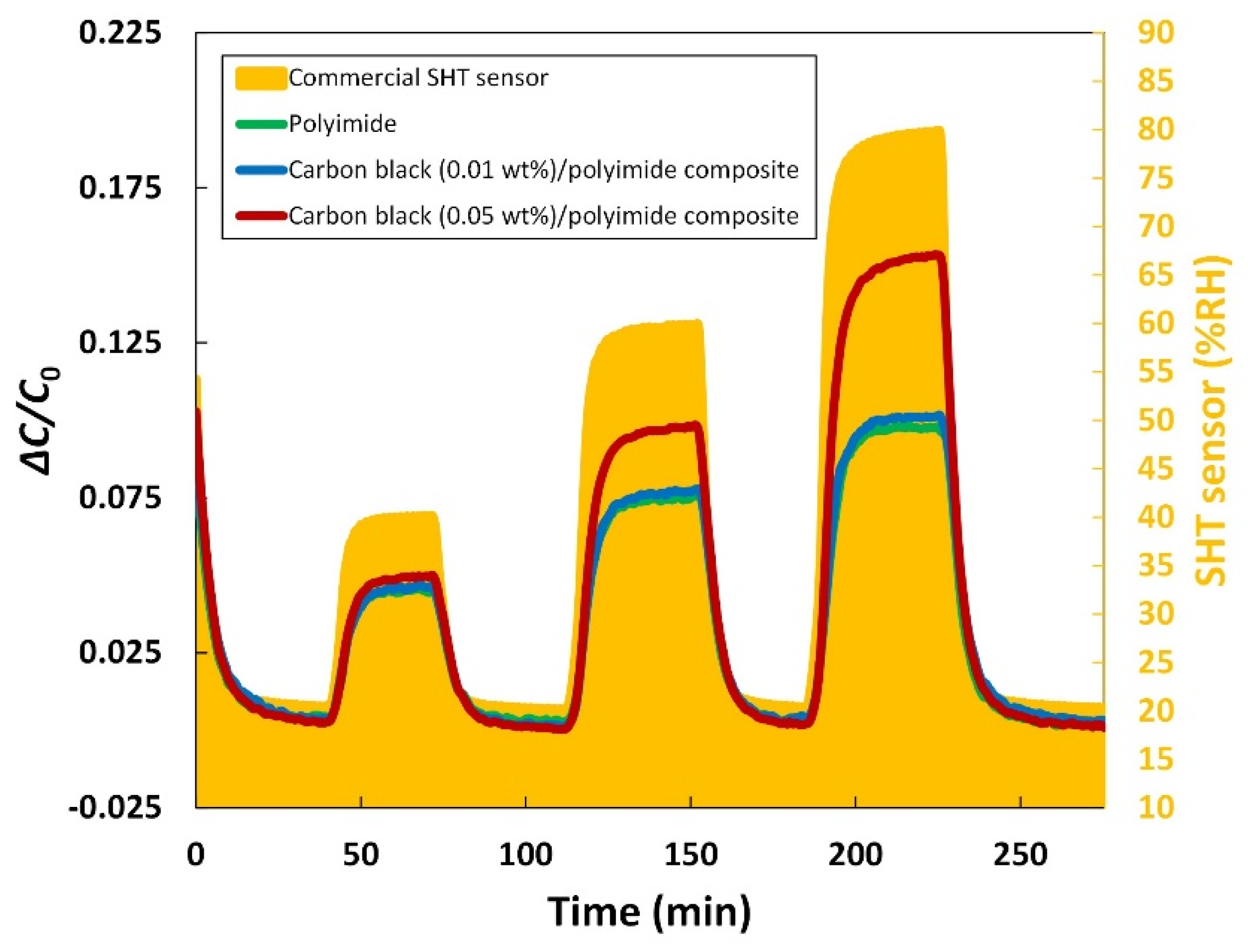

3.2.3. Dynamic Response

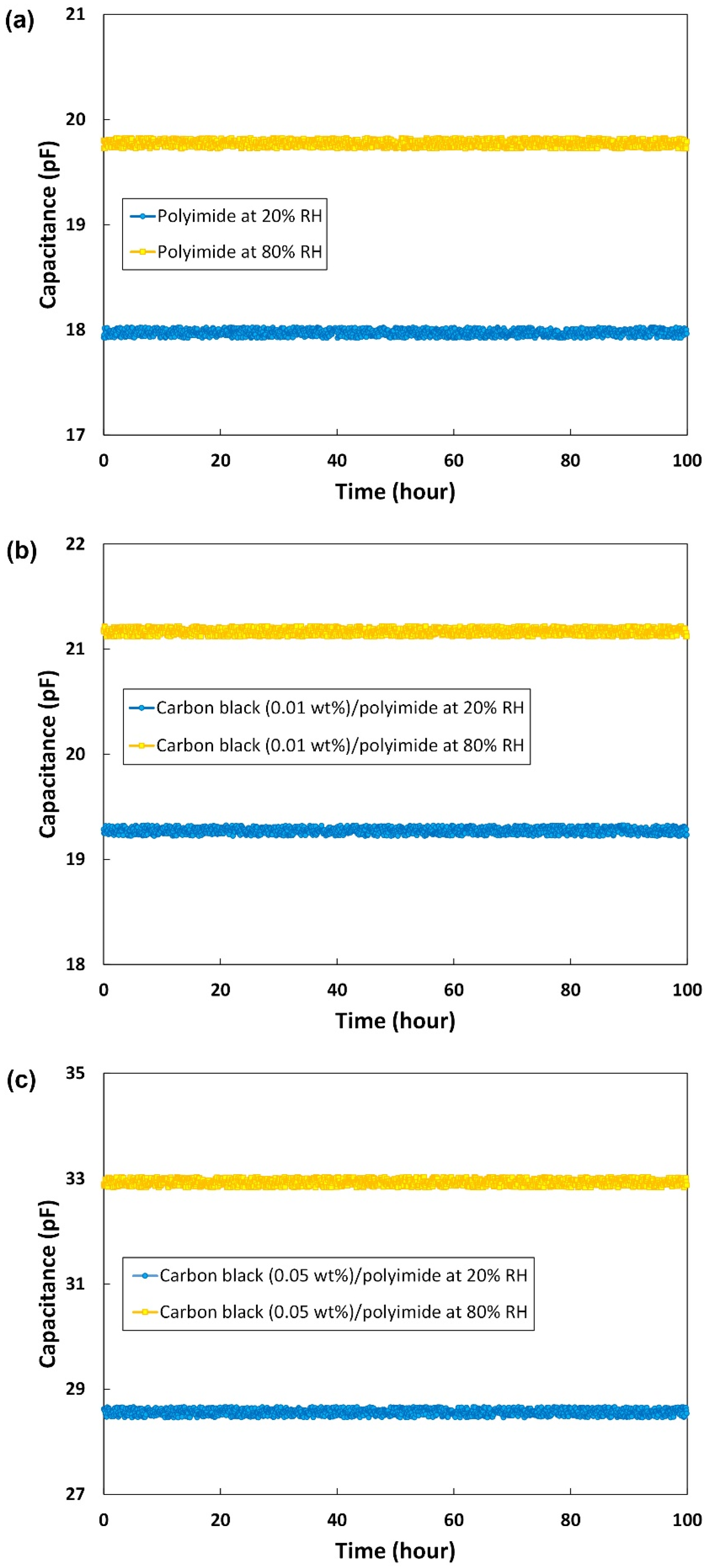

3.2.4. Long-Term Stability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hernández-Rivera, D.; Rodríguez-Roldán, G.; Mora-Martínez, R.; Suaste-Gómez, E. A Capacitive Humidity Sensor Based on an Electrospun PVDF/Graphene Membrane. Sensors 2017, 17, 1009. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.-Y.; Lee, G.-B. Humidity Sensors: A Review. Sens. Lett. 2005, 3, 1–15. [Google Scholar] [CrossRef]

- Kim, Y.; Jung, B.; Lee, H.; Kim, H.; Lee, K.; Park, H. Capacitive Humidity Sensor Design Based on Anodic Aluminum Oxide. Sens. Actuators B Chem. 2009, 141, 441–446. [Google Scholar] [CrossRef]

- Lokman, A.; Arof, H.; Harun, S.W.; Harith, Z.; Rafaie, H.A.; Nor, R.M. Optical Fiber Relative Humidity Sensor Based on Inline Mach-Zehnder Interferometer with ZnO Nanowires Coating. IEEE Sens. J. 2015, 16, 312–316. [Google Scholar] [CrossRef]

- Kang, U.; Wise, K.D. A High-Speed Capacitive Humidity Sensor with on-Chip Thermal Reset. IEEE Trans. Electron Devices 2000, 47, 702–710. [Google Scholar] [CrossRef]

- Farahani, H.; Wagiran, R.; Hamidon, M.N. Humidity Sensors Principle, Mechanism, and Fabrication Technologies: A Comprehensive Review. Sensors 2014, 14, 7881–7939. [Google Scholar] [CrossRef] [Green Version]

- Schubert, P.J.; Nevin, J.H. A Polyimide-Based Capacitive Humidity Sensor. IEEE Trans. Electron Devices 1985, 32, 1220–1223. [Google Scholar] [CrossRef]

- Boudaden, J.; Steinmaßl, M.; Endres, H.; Drost, A.; Eisele, I.; Kutter, C.; Müller-Buschbaum, P. Polyimide-Based Capacitive Humidity Sensor. Sensors 2018, 18, 1516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoo, K.-P.; Lim, L.-T.; Min, N.-K.; Lee, M.J.; Lee, C.J.; Park, C.-W. Novel Resistive-Type Humidity Sensor Based on Multiwall Carbon Nanotube/Polyimide Composite Films. Sens. Actuators B Chem. 2010, 145, 120–125. [Google Scholar] [CrossRef]

- Peng, X.; Chu, J.; Aldalbahi, A.; Rivera, M.; Wang, L.; Duan, S.; Feng, P. A Flexible Humidity Sensor Based on KC–MWCNTs Composites. Appl. Surf. Sci. 2016, 387, 149–154. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Hong, L.; Chen, Y.; Wang, H.; Lu, X.; Yang, M. Poly (4-Vinylpyridine)/Carbon Black Composite as a Humidity Sensor. Sens. Actuators B Chem. 2007, 123, 554–559. [Google Scholar] [CrossRef]

- Su, P.-G.; Wang, C.-S. In Situ Synthesized Composite Thin Films of MWCNTs/PMMA Doped with KOH as a Resistive Humidity Sensor. Sens. Actuators B Chem. 2007, 124, 303–308. [Google Scholar] [CrossRef]

- Fei, T.; Jiang, K.; Jiang, F.; Mu, R.; Zhang, T. Humidity Switching Properties of Sensors Based on Multiwalled Carbon Nanotubes/Polyvinyl Alcohol Composite Films. J Appl. Polym. Sci. 2014, 131, 39726. [Google Scholar] [CrossRef]

- Thomas, P.J.; Hellevang, J.O. A High Response Polyimide Fiber Optic Sensor for Distributed Humidity Measurements. Sens. Actuators B Chem. 2018, 270, 417–423. [Google Scholar] [CrossRef]

- Kim, J.-H.; Hong, S.-M.; Moon, B.-M.; Kim, K. High-Performance Capacitive Humidity Sensor with Novel Electrode and Polyimide Layer Based on MEMS Technology. Microsyst. Technol. 2010, 16, 2017–2021. [Google Scholar] [CrossRef]

- Lee, H.; Lee, S.; Jung, S.; Lee, J. Nano-Grass Polyimide-Based Humidity Sensors. Sens. Actuators B Chem. 2011, 154, 2–8. [Google Scholar] [CrossRef]

- Saeidi, N.; Blake, A.; Colinge, C.; Burke, M.; Quinn, A.J.; Demosthenous, A.; Donaldson, N. The Effects of Fabrication Process on the Performance of a CMOS Based Capacitive Humidity Sensor. ECS Trans. 2011, 35, 71. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, M.J.; Kang, M.-S.; Yoo, K.-P.; Kwon, K.-H.; Singh, V.R.; Min, N.K. Fabrication of High-Speed Polyimide-Based Humidity Sensor using Anisotropic and Isotropic Etching with ICP. Thin Solid Films 2009, 517, 3879–3882. [Google Scholar] [CrossRef]

- Suzuki, T.; Tanner, P.; Thiel, D.V. O2 Plasma Treated Polyimide-Based Humidity Sensors. Analyst 2002, 127, 1342–1346. [Google Scholar] [CrossRef]

- Kondalkar, V.V.; Ryu, G.; Lee, Y.; Lee, K. Development of Highly Sensitive and Stable Humidity Sensor for Real-Time Monitoring of Dissolved Moisture in Transformer-Insulating Oil. Sens. Actuators B Chem. 2019, 286, 377–385. [Google Scholar] [CrossRef]

- Rivadeneyra, A.; Fernández-Salmerón, J.; Banqueri, J.; López-Villanueva, J.A.; Capitan-Vallvey, L.F.; Palma, A.J. A Novel Electrode Structure Compared with Interdigitated Electrodes as Capacitive Sensor. Sens. Actuators B Chem. 2014, 204, 552–560. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Q.; Sheng, W.; Wang, X.; Zhang, K.; Du, L.; Zhou, J. Humidity Sensors with Shielding Electrode Under Interdigitated Electrode. Sensors 2019, 19, 659. [Google Scholar] [CrossRef] [Green Version]

- Sen, A.K.; Darabi, J. Modeling and Optimization of a Microscale Capacitive Humidity Sensor for HVAC Applications. IEEE Sens. J. 2008, 8, 333–340. [Google Scholar] [CrossRef]

- Choi, K.S.; Kim, D.S.; Yang, H.J.; Ryu, M.S.; Chang, S.P. A Highly Sensitive Humidity Sensor with a Novel Hole Array Structure using a Polyimide Sensing Layer. RSC Adv. 2014, 4, 32075–32080. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, L.; Wang, L. Numerical Study of the Structural Parameter Effects on the Dynamic Characteristics of a Polyimide Film Micro-Capacitive Humidity Sensor. IEEE Sens. J. 2016, 16, 5979–5986. [Google Scholar] [CrossRef]

- Itoh, E.; Yuan, Z. Comparative Study of all-Printed Polyimide Humidity Sensors with Single-and Multiwalled Carbon Nanotube Gas-Permeable Top Electrodes. Jpn. J. Appl. Phys. 2017, 56, 05EC03. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Li, B.; Chen, W. A CMOS MEMS Humidity Sensor Enhanced by a Capacitive Coupling Structure. Micromachines 2016, 7, 74. [Google Scholar] [CrossRef] [Green Version]

- Lazarus, N.; Fedder, G.K. Designing a Robust High-Speed CMOS-MEMS Capacitive Humidity Sensor. J. Micromech. Microeng. 2012, 22, 085021. [Google Scholar] [CrossRef]

- Lee, M.J.; Min, N.-K.; Yoo, K.-P.; Kwak, K.-Y.; Kwon, K.-H. Microhotplate-Based High-Speed Polyimide Capacitive Humidity Sensors. Sens. Lett. 2009, 7, 517–522. [Google Scholar] [CrossRef]

- Zhao, C.-L.; Qin, M.; Huang, Q.-A. A Fully Packaged CMOS Interdigital Capacitive Humidity Sensor with Polysilicon Heaters. IEEE Sens. J. 2011, 11, 2986–2992. [Google Scholar] [CrossRef]

- Dai, C.-L. A Capacitive Humidity Sensor Integrated with Micro Heater and Ring Oscillator Circuit Fabricated by CMOS–MEMS Technique. Sens. Actuators B Chem. 2007, 122, 375–380. [Google Scholar] [CrossRef]

- Gu, L.; Huang, Q.-A.; Qin, M. A Novel Capacitive-Type Humidity Sensor using CMOS Fabrication Technology. Sens. Actuators B Chem. 2004, 99, 491–498. [Google Scholar] [CrossRef]

- He, H.; Zhong, M.; Konkolewicz, D.; Yacatto, K.; Rappold, T.; Sugar, G.; David, N.E.; Matyjaszewski, K. Carbon Black Functionalized with Hyperbranched Polymers: Synthesis, Characterization, and Application in Reversible CO 2 Capture. J. Mater. Chem. A 2013, 1, 6810–6821. [Google Scholar] [CrossRef]

- Guloglu, G.E.; Hamidi, Y.K.; Altan, M.C. Moisture Absorption of Composites with Interfacial Storage. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105908. [Google Scholar] [CrossRef]

- Kwon, J.; Kim, J.; Park, D.; Seo, J.; Han, P.; Han, H. Water Sorption Behavior in Polyimide Thin Films Controlled by Inorganic Additives. Macromol. Res. 2014, 22, 431–435. [Google Scholar] [CrossRef]

- Matsuguchi, M.; Umeda, S.; Sadaoka, Y.; Sakai, Y. Characterization of Polymers for a Capacitive-Type Humidity Sensor Based on Water Sorption Behavior. Sens. Actuators B Chem. 1998, 49, 179–185. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Cho, J.-H.; Lee, H.-M.; Hong, S.-M. Capacitive Humidity Sensor Based on Carbon Black/Polyimide Composites. Sensors 2021, 21, 1974. https://doi.org/10.3390/s21061974

Kim J, Cho J-H, Lee H-M, Hong S-M. Capacitive Humidity Sensor Based on Carbon Black/Polyimide Composites. Sensors. 2021; 21(6):1974. https://doi.org/10.3390/s21061974

Chicago/Turabian StyleKim, Jihong, Jang-Hoon Cho, Hyung-Man Lee, and Sung-Min Hong. 2021. "Capacitive Humidity Sensor Based on Carbon Black/Polyimide Composites" Sensors 21, no. 6: 1974. https://doi.org/10.3390/s21061974

APA StyleKim, J., Cho, J.-H., Lee, H.-M., & Hong, S.-M. (2021). Capacitive Humidity Sensor Based on Carbon Black/Polyimide Composites. Sensors, 21(6), 1974. https://doi.org/10.3390/s21061974