A New Acoustic-Based Approach for Assessing Induced Adulteration in Bovine Milk

Abstract

:1. Introduction

2. New Instrumentation System to Assess Bovine Milk Adulteration

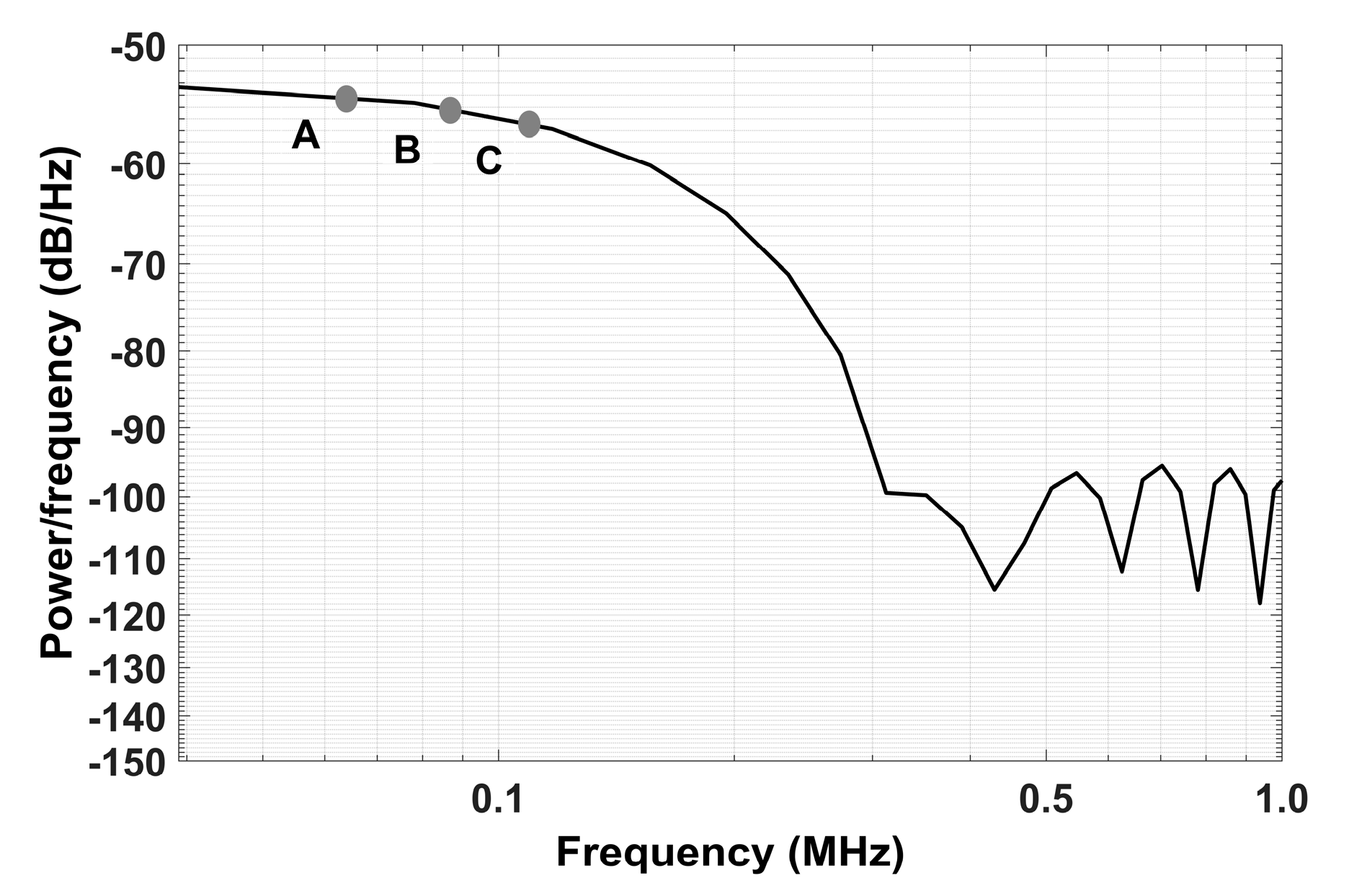

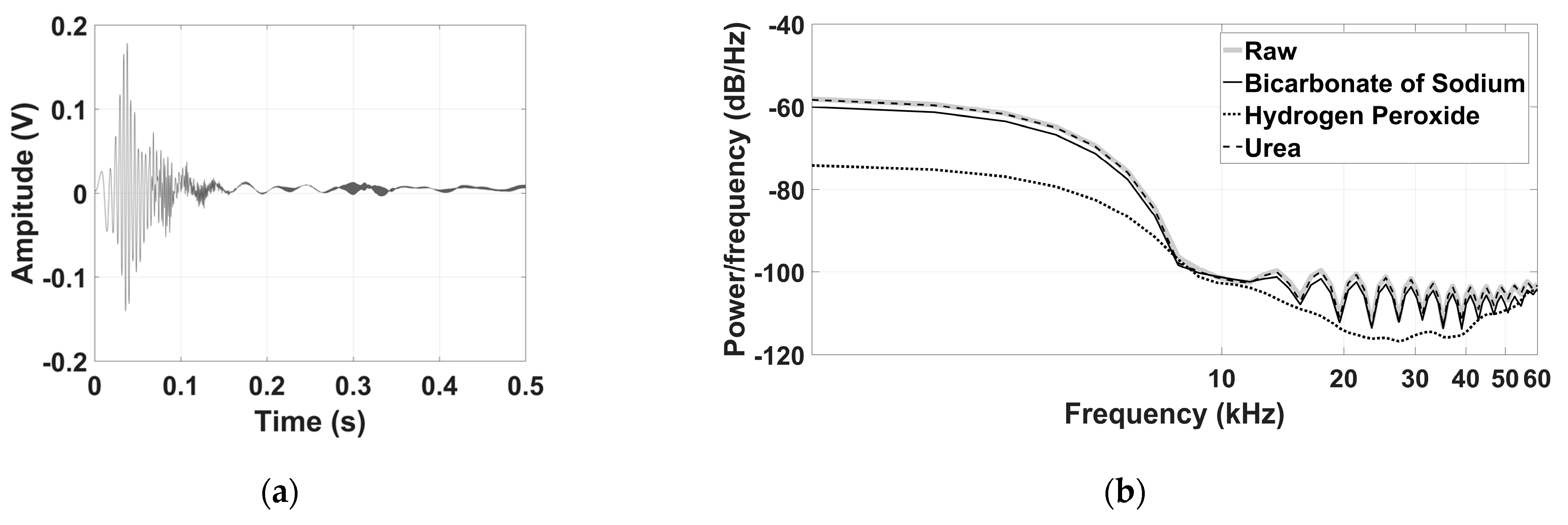

2.1. Acoustic Liquid Characterization

2.2. Statistical Index Approach

2.3. Chromatic Clustering Technique

3. Experimental Setup

4. Results and Discussion

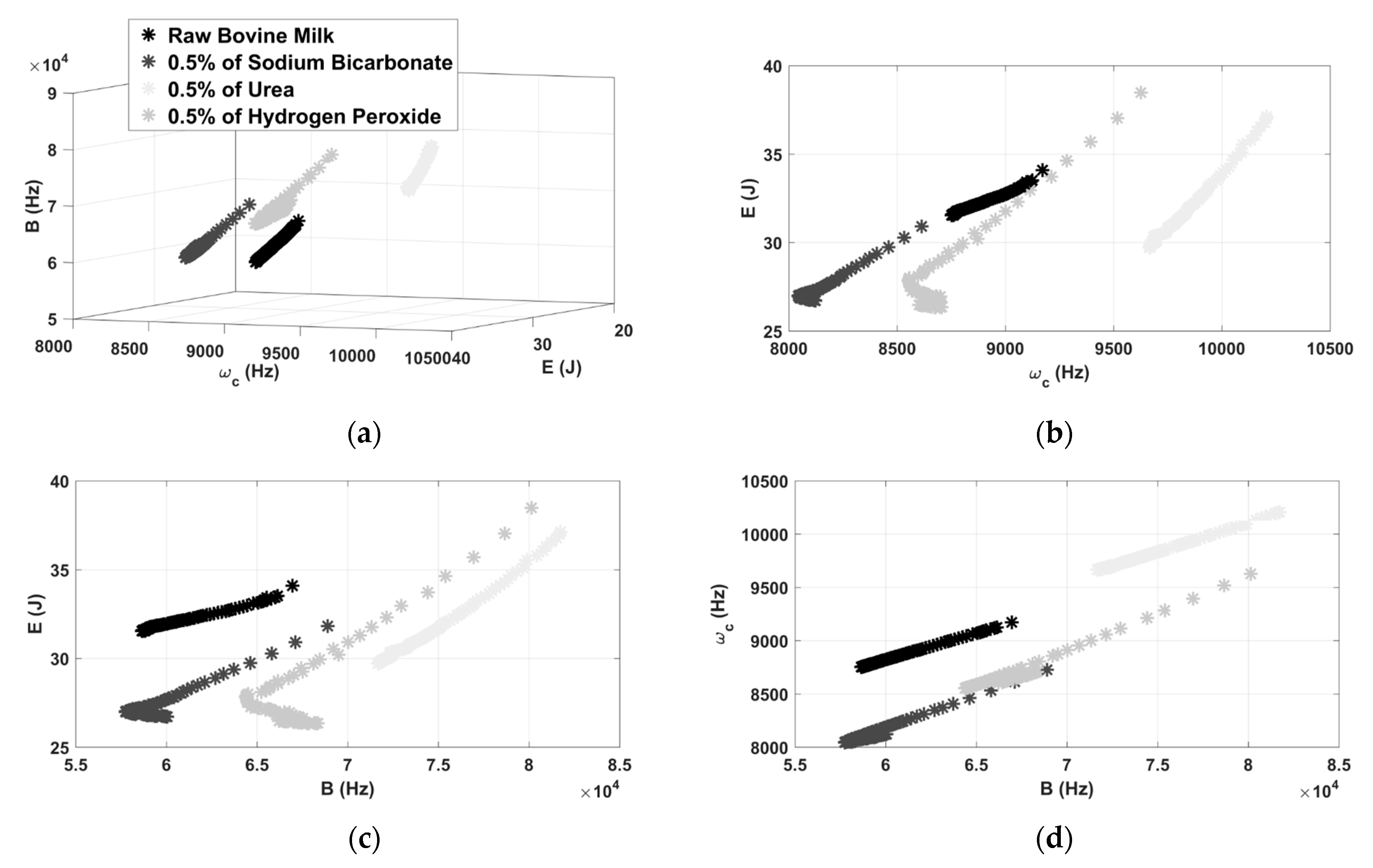

4.1. Statistical Indexes Results

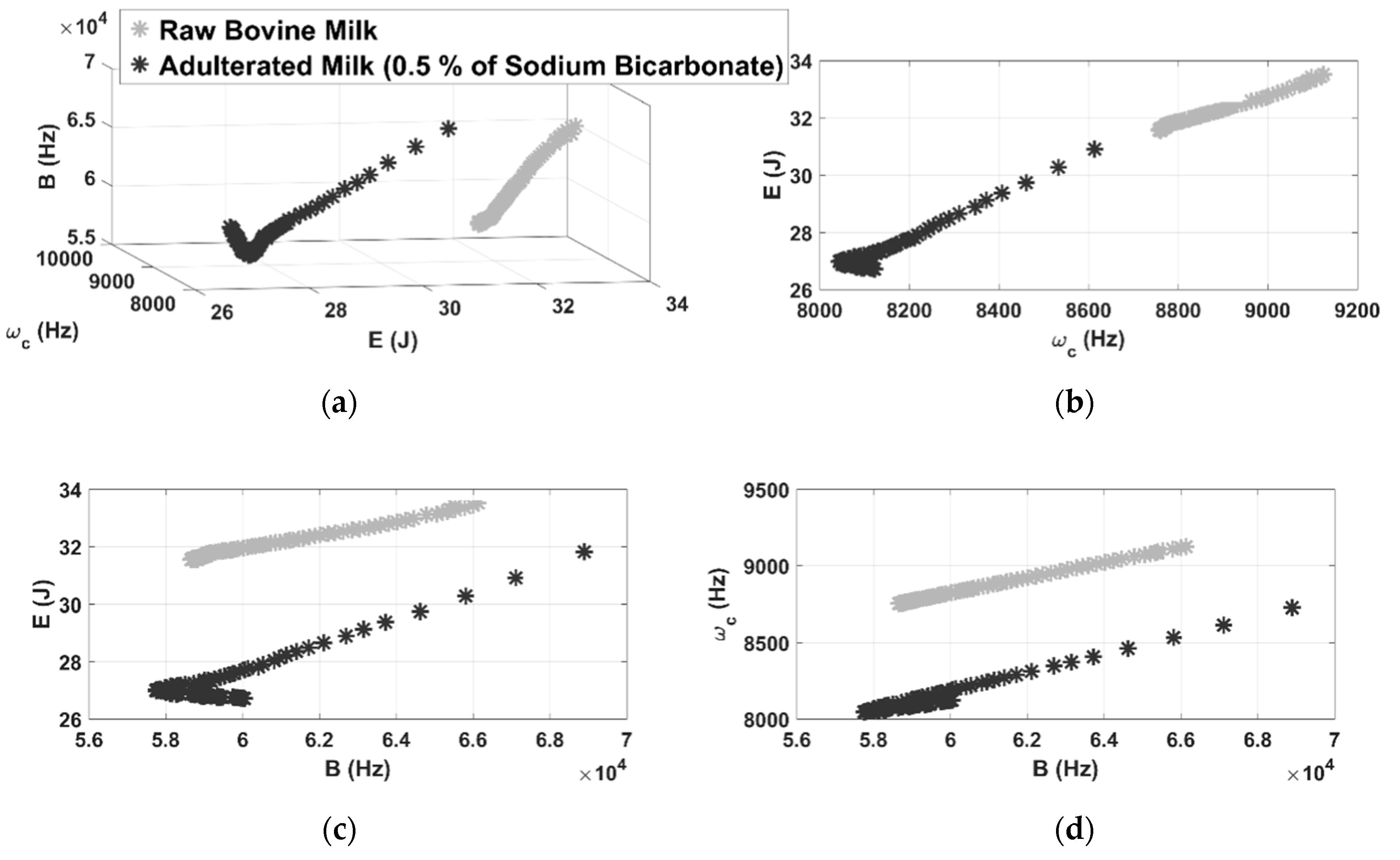

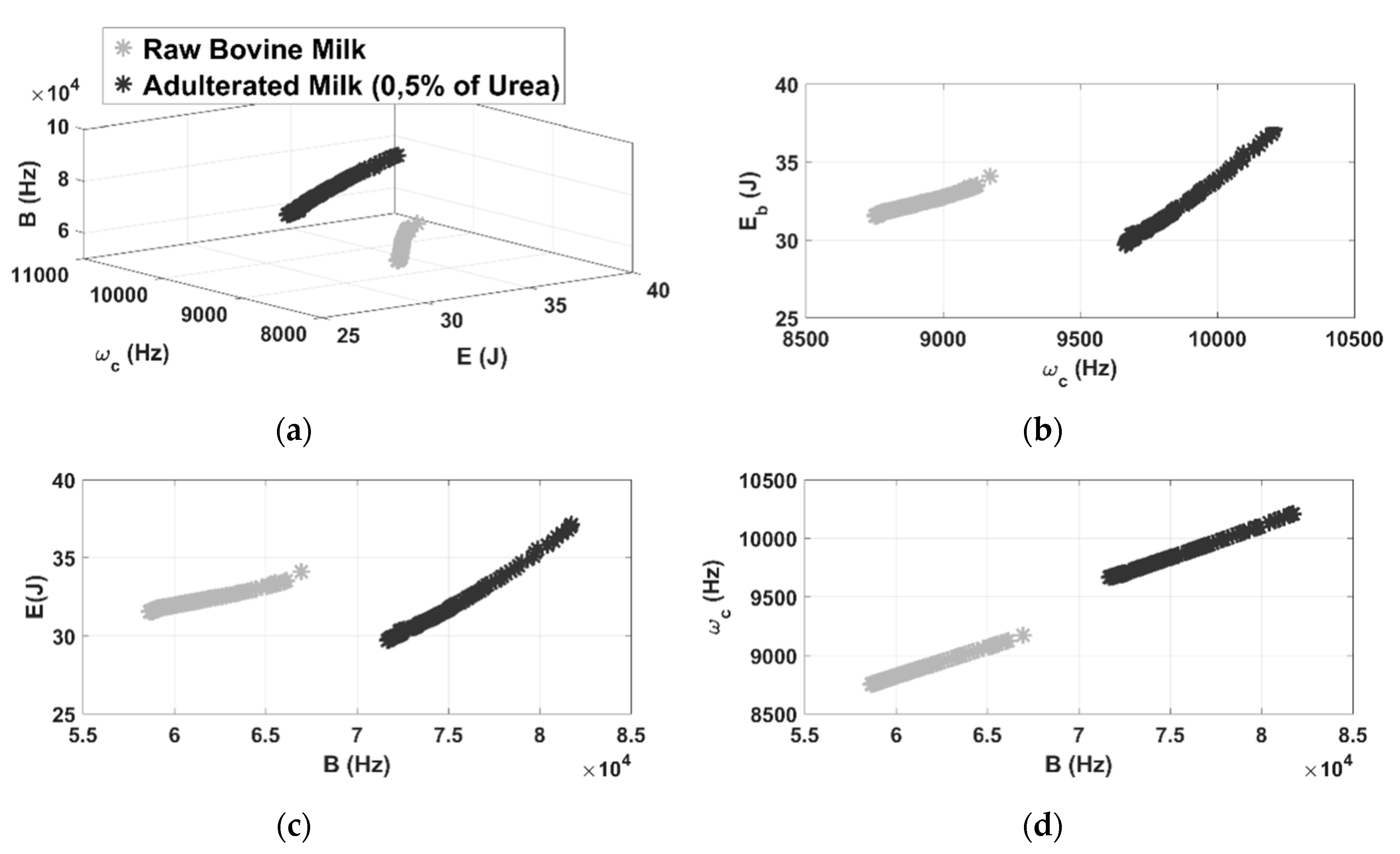

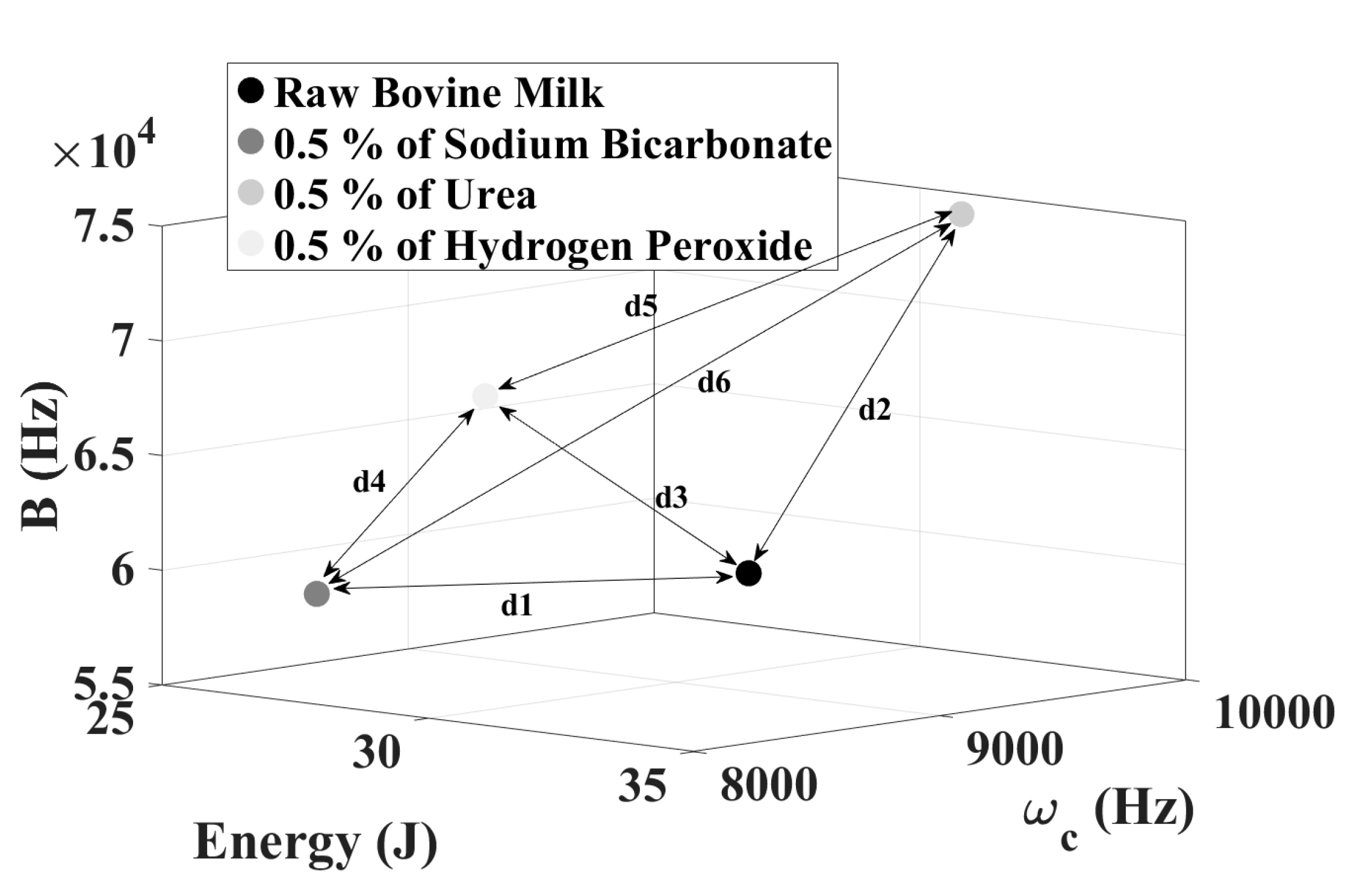

4.2. Chromatic Technique Applied in Data Separation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Afzal, A.; Mahmood, M.S.; Hussain, I. Adulteration and microbiological quality of milk (A Review). Pak. J. Nutr. 2011, 10, 1195–1202. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, L.S.; Gentilin, F.A.; de França, J.A.; Felicio, A.L.D.S.M.; Franca, M.B.D.M. Development of a Hardware Platform for Detection of Milk Adulteration Based on Near-Infrared Diffuse Reflection. IEEE Trans. Instrum. Meas. 2016, 65, 1698–1706. [Google Scholar] [CrossRef]

- Karuppuswami, S.; Kaur, A.; Arangali, H.; Chahal, P.P. A Hybrid Magnetoelastic Wireless Sensor for Detection of Food Adulteration. IEEE Sens. J. 2017, 17, 1706–1714. [Google Scholar] [CrossRef]

- Chakraborty, M.; Biswas, K. Limit of Detection for Five Common Adulterants in Milk: A Study With Different Fat Percent. IEEE Sens. J. 2018, 18, 2395–2403. [Google Scholar] [CrossRef]

- Das, S.; Sivaramakrishna, M.; Biswas, K.; Goswami, B. Performance study of a ‘constant phase angle based impedance sensor to detect milk adulteration. Sens. Actuators A Phys. 2011, 167, 273–278. [Google Scholar] [CrossRef]

- Durante, G.; Becari, W.; Lima, F.A.; Peres, H.E. Electrical impedance sensor for real-time detection of bovine milk adulteration. IEEE Sens. J. 2016, 16, 861–865. [Google Scholar] [CrossRef]

- Mabrook, M.F.; Petty, M.C. A novel technique for the detection of added water to full fat milk using single frequency admittance measurements. Sci. Dir. Sens. 2016, 96, 215–218. [Google Scholar] [CrossRef]

- Jawaid, S.; Talpur, F.N.; Sherazi, S.T.H.; Nizamani, S.M.; Khaskheli, A.A. Rapid detection of melamine adulteration in dairy milk by SB-ATR–Fourier transform infrared spectroscopy. Food Chem. 2013, 141, 3066–3071. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, A.S.; Merkuleva, A.D.; Andreev, S.V.; Sakharov, K.A. Method for determination of hydrogen peroxide in adulterated milk using high performance liquid chromatography. Food Chem. 2019, 283, 431–436. [Google Scholar] [CrossRef] [PubMed]

- Trimboli, F.; Costanzo, N.; Lopreiato, V.; Ceniti, C.; Morittu, V.M.; Spina, A.; Britti, D. Detection of buffalo milk adulteration with cow milk by capillary electrophoresis analysis. J. Dir. Sci. 2019, 102, 5962–5970. [Google Scholar] [CrossRef]

- Veríssimo, M.I.S.; Gamelas, J.A.F.; Fernandes, A.J.S.; Evtuguin, D.V.; Gomes, M.T.S. A new formaldehyde optical sensor: Detecting milk adulteration. Food Chem. 2020, 318, 126–461. [Google Scholar] [CrossRef]

- Gupta, P.; Sadat, A.; Khan, M.J.R. An Optoelectromechanical Sensor for Detecting Adulteration in Anhydrous Milk Fat. IEEE Sens. J. 2014, 14, 2930–2931. [Google Scholar] [CrossRef]

- Sinha, D.N.; Kaduchak, G. Noninvasive determination of sound speed and attenuation in liquids. Exp. Methods Phys. Sci. 2001, 39, 307–333. [Google Scholar] [CrossRef]

- Castro, B.A.; Baptista, F.G.; Ciampa, F. New signal processing approach for structural health monitoring in noisy environments based on impedance measurements. Measurement 2019, 137, 155–167. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. Structural Health Monitoring: A Machine Learning Perspective; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2013; ISBN 9781119994336. [Google Scholar]

- Junior, P.; D’Addona, D.M.; Teti, R. Dressing tool condition monitoring through impedance-base sensors: PZT diaphragm transducer response and EMI sensing technique. Sensors 2018, 18, 4455. [Google Scholar] [CrossRef] [Green Version]

- Priev, A.; Boktov, S.; Barenholz, Y. Rapid Ultrasonic Milk Analyzer for the Indian Market. Int. J. Sci. Res. (IJSR) 2015, 26–29. [Google Scholar] [CrossRef]

- Junior, M.M.S.; Ulson, J.A.C.; Castro, B.A.; Ardila-Rey, J.A.; Campos, F.D.S.; Ferreira, L.T. Analysis of Piezoelectric Sensors in Adulteration of Bovine Milk Using the Chromatic Technique. In Proceedings of the 5th International Electronic Conference on Sensors and Applications, On-line, 15–30 November 2019; Volume 4, pp. 1–6. [Google Scholar]

- Castro, B.A.; Baptista, F.G.; Ciampa, F. A comparison of signal processing techniques for impedance-based damage characterization in carbon fibers under noisy inspections. Mater. Today Proc. 2020, 1–5. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Rong, M.; Xie, D.; Ding, D.; Wang, Z. UHF signal processing and pattern recognition of partial discharge in gas-insulated switchgear using chromatic methodology. Sensors 2017, 17, 177. [Google Scholar] [CrossRef] [Green Version]

- Jones, G.R.; Russel, P.C.; Vourdas, A.; Cosgrave, J.; Stergioulas, L.; Haber, R. The Gabor transform basis of chromatic monitoring. Meas. Sci. Technol. 2000, 11, 489–498. [Google Scholar] [CrossRef]

- Ardila-Rey, J.A.; Montaña, J.; Castro, B.A.; Schürch, R.; Ulson, J.A.C.; Muhammad-Sukki, F.; Bani, N.A. A comparison of inductive sensors in the characterizations of partial discharges and electrical noise using the chromatic technique. Sensors 2018, 18, 1021. [Google Scholar] [CrossRef] [Green Version]

- Cheng, R.S.; Verdu, S. Capacity of root-mean square bandlimited Gaussian multiuser channels. IEEE Trans. Inf. Theory 1991, 37, 453–465. [Google Scholar] [CrossRef]

- Castro, B.A.; Baptista, F.G.; Ardila-Rey, J.A.; Ciampa, F. Chromatic technique to distinguish damage from noise in structure health monitoring based on impedance measurements. IOP Meas. Sc. Technol. 2019, 30, 1–11. [Google Scholar] [CrossRef]

- Murata Electronics. Piezoelectric Sound Components. Available online: https://www.murata.com/~/media/webrenewal/support/library/catalog/products/sound/p37e.ashx?la=en-sg (accessed on 11 December 2019).

- Castro, B.A.; Baptista, F.G.; Ciampa, F. Impedance-based Structural Health Monitoring Under Low Signal-to-Noise Ratio Conditions. In Proceedings of the 9th European Workshop on Structural Health Monitoring, Manchester, UK, 10–13 July 2018; pp. 1–12. [Google Scholar]

- Freitas, E.S.; Baptista, F.G. Experimental analysis of the feasibility of low-cost piezoelectric diaphragm in impedance-based SHM applications. Sens. Actuators A Phys. 2016, 238, 220–228. [Google Scholar] [CrossRef] [Green Version]

- Meitzler, A.H. IEEE Standard on Piezoelectricity: An American National Standard; IEEE-ANSI: New York, NY, USA, 1987; p. 176. [Google Scholar]

- ASTM E976–10. Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response; ASTM International: West Conshohocken, PA, USA, 2010; Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/E976-10.htm (accessed on 1 January 2021).

- Marchi, M.; Baptista, F.G.; Aguiar, P.R.; Bianchi, E.C. Grinding process monitoring based on electromechanical impedance measurements. Meas. Sci. Technol. 2015, 167, 273–278. [Google Scholar] [CrossRef]

- Lucas, G.B.; Castro, B.A.; Rocha, M.A.; Andreoli, A.L. Three-phase induction motor loading estimation based on Wavelet Transform and low-cost piezoelectric sensors. Measurement 2020, 164, 4–10. [Google Scholar] [CrossRef]

| Milk Samples | ||||

|---|---|---|---|---|

| CT | Raw | Sodium Bicarbonate | Urea | Hydrogen Peroxide |

| E | 0.6 | 0.9 | 1.2 | 1.34 |

| 116.9 | 118.9 | 157.6 | 190.8 | |

| 2336.9 | 1885.6 | 2935.4 | 2477.5 | |

| Milk Samples | ||||

|---|---|---|---|---|

| CT | Raw | Sodium Bicarbonate | Urea | Hydrogen Peroxide |

| E | 32.1 | 27.3 | 31.63 | 27.8 |

| 8850.2 | 8133.1 | 9815.1 | 8708.9 | |

| 60,597.1 | 59,427.2 | 74,605.6 | 67,286.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Messias dos Santos Junior, M.; Albuquerque de Castro, B.; Ardila-Rey, J.A.; de Souza Campos, F.; Merino de Medeiros, M.I.; Covolan Ulson, J.A. A New Acoustic-Based Approach for Assessing Induced Adulteration in Bovine Milk. Sensors 2021, 21, 2101. https://doi.org/10.3390/s21062101

Messias dos Santos Junior M, Albuquerque de Castro B, Ardila-Rey JA, de Souza Campos F, Merino de Medeiros MI, Covolan Ulson JA. A New Acoustic-Based Approach for Assessing Induced Adulteration in Bovine Milk. Sensors. 2021; 21(6):2101. https://doi.org/10.3390/s21062101

Chicago/Turabian StyleMessias dos Santos Junior, Marcos, Bruno Albuquerque de Castro, Jorge Alfredo Ardila-Rey, Fernando de Souza Campos, Maria Izabel Merino de Medeiros, and José Alfredo Covolan Ulson. 2021. "A New Acoustic-Based Approach for Assessing Induced Adulteration in Bovine Milk" Sensors 21, no. 6: 2101. https://doi.org/10.3390/s21062101