A Novel Method Based on Headspace-Ion Mobility Spectrometry for the Detection and Discrimination of Different Petroleum Derived Products in Seawater

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.1.1. Water Samples

2.1.2. PDP Samples

2.1.3. Petroleum Products in Water Samples

2.2. HS-GC-IMS Acquisition

2.2.1. Optimization of the Conditions

2.3. Data Treatment

2.3.1. IMS Sum Spectrum

2.3.2. Data Analysis

3. Results and Discussion

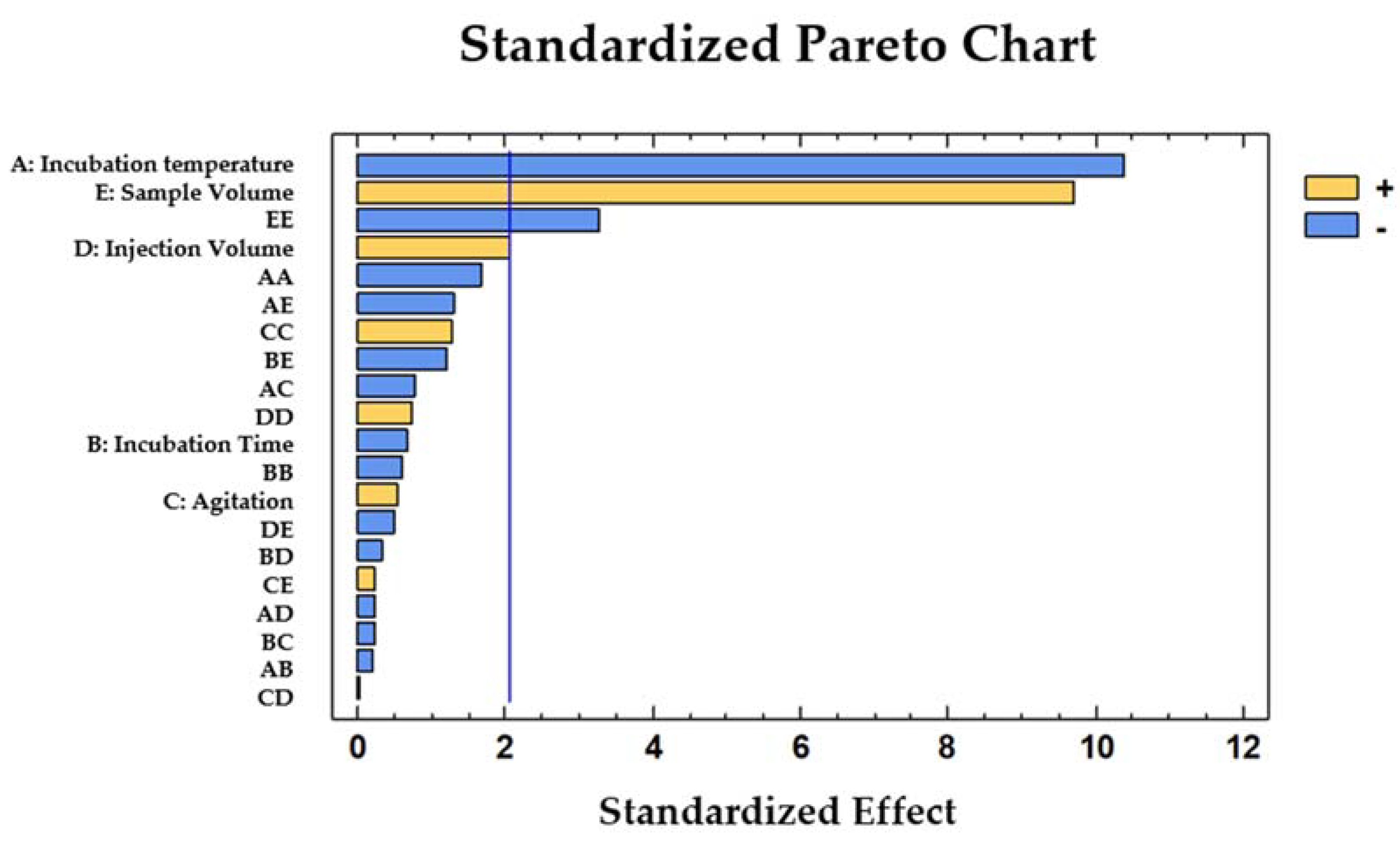

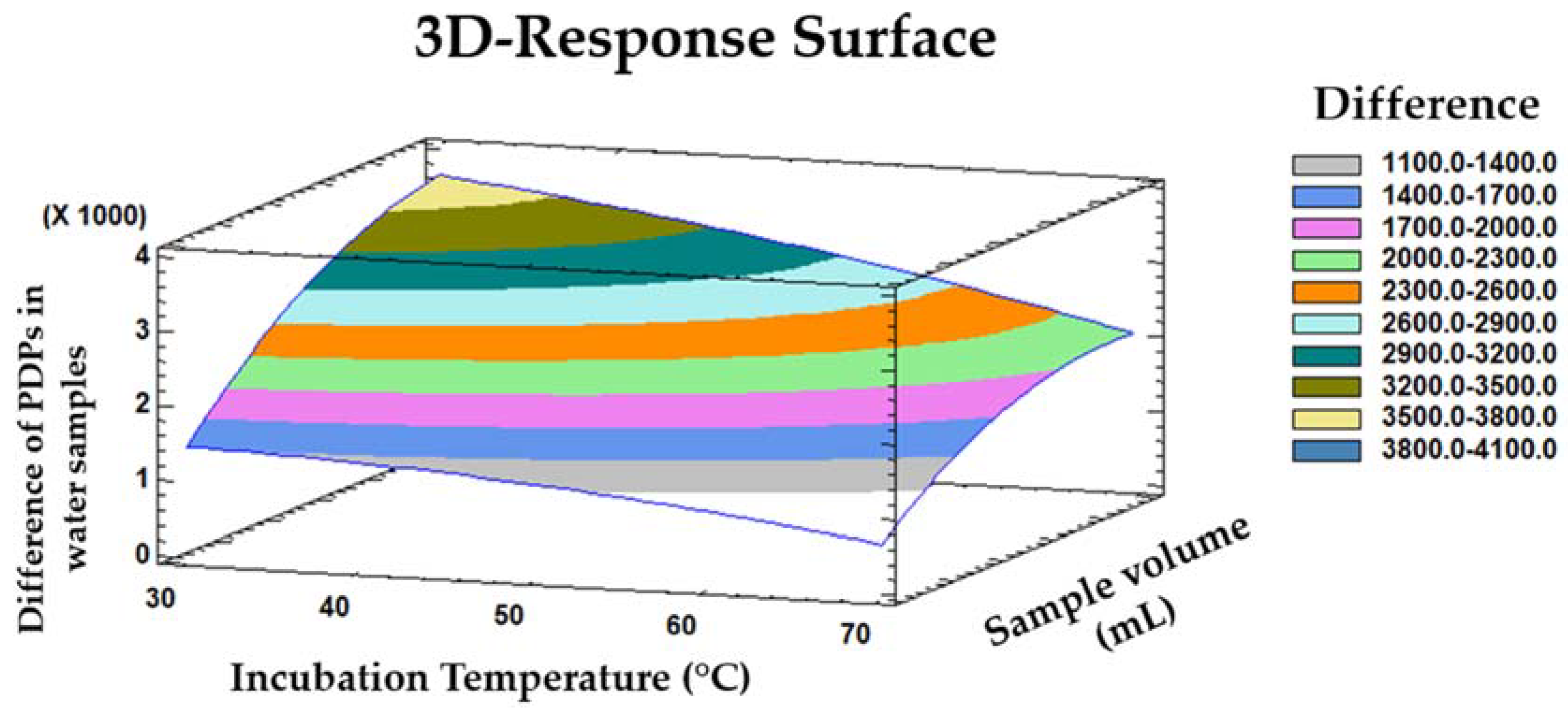

3.1. Optimization of the Method

β25X2X5 + β34X3X4 + β35X3X5 + β45X4X5 + β11X12 + β22X22 + β33X32 + β44X42 + β55X52

3.2. Repeatability and Intermediate Precision of the Method

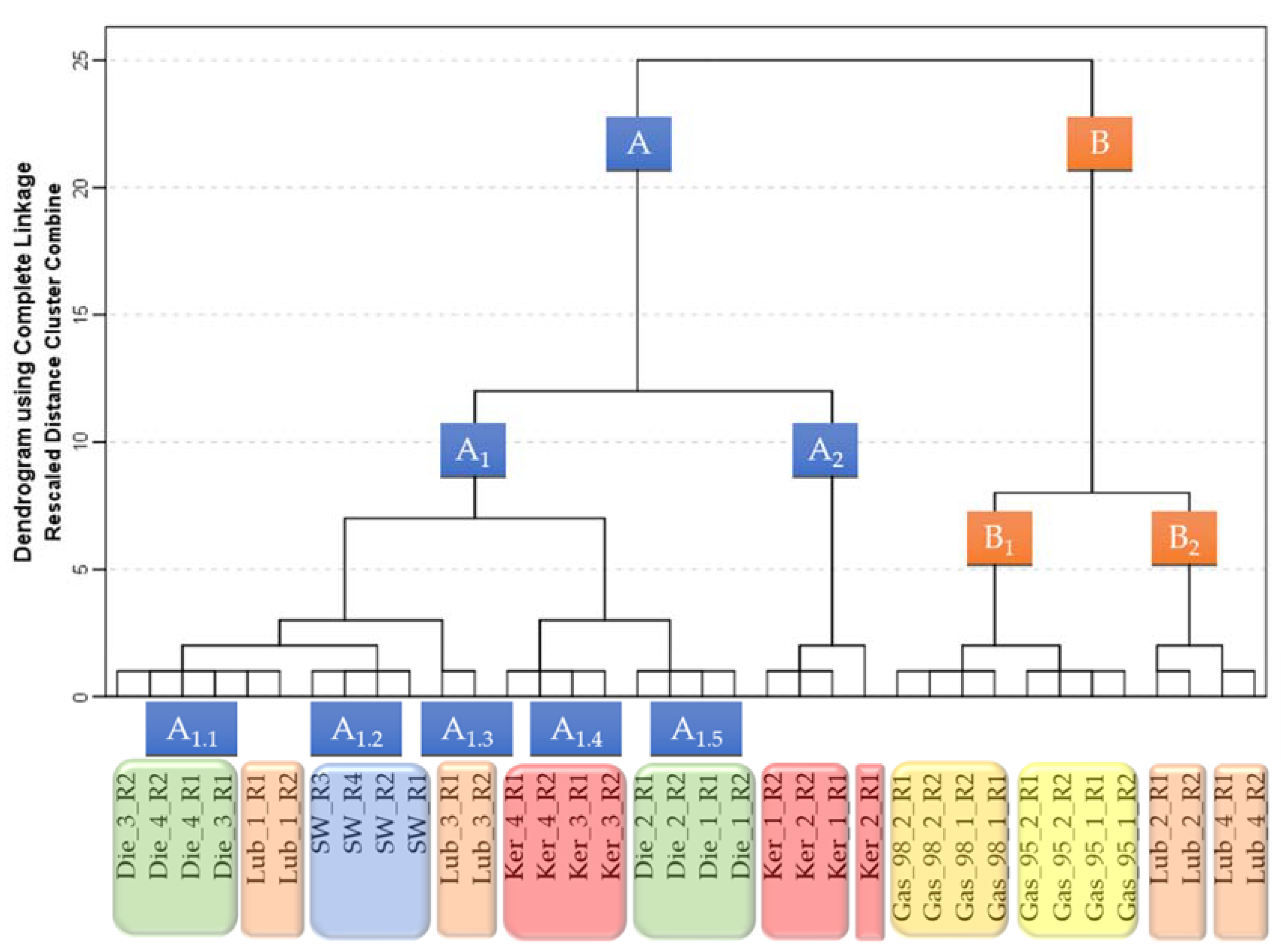

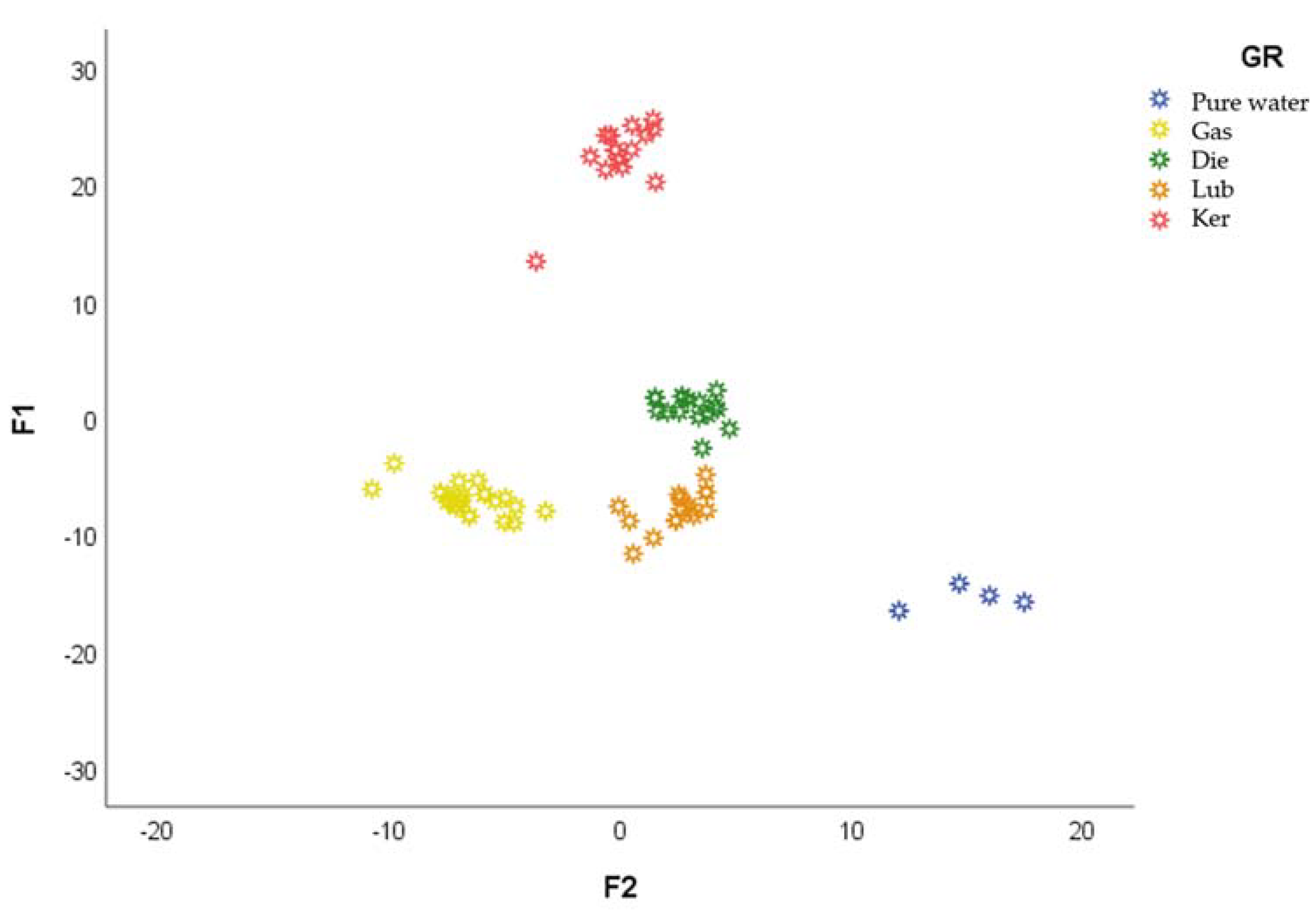

3.3. Analysis of the PDPs in Water Samples

3.4. Application to Natural Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Experiment | Incubation Time (min) | Incubation Temperature (°C) | Agitation (rpm) | Injection Volume (mL) | Sample Volume (mL) | Measured Response | Predicted Response | Relative Error (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 15 | 50 | 750 | 0.75 | 0.50 | 1995.15 | 1927.07 | 3.47 |

| 2 | 15 | 50 | 250 | 0.50 | 1.50 | 3136.79 | 2913.67 | 7.38 |

| 3 | 15 | 50 | 500 | 0.75 | 1.50 | 3006.22 | 2999.02 | 0.24 |

| 4 | 15 | 50 | 500 | 1.00 | 0.50 | 2072.53 | 2066.15 | 0.31 |

| 5 | 15 | 50 | 250 | 0.75 | 0.50 | 1838.73 | 1922.00 | 4.43 |

| 6 | 15 | 50 | 750 | 0.50 | 1.50 | 3059.73 | 2771.06 | 9.90 |

| 7 | 15 | 30 | 500 | 1.00 | 1.50 | 3432.70 | 3422.67 | 0.29 |

| 8 | 15 | 50 | 750 | 1.00 | 1.50 | 3022.98 | 3032.90 | 0.33 |

| 9 | 5 | 50 | 500 | 1.00 | 1.50 | 2975.55 | 2919.55 | 1.90 |

| 10 | 15 | 50 | 500 | 0.50 | 0.50 | 1648.85 | 1688.52 | 2.38 |

| 11 | 15 | 50 | 250 | 1.00 | 1.50 | 3084.64 | 2960.11 | 4.12 |

| 12 | 15 | 30 | 250 | 0.75 | 1.50 | 3287.25 | 3184.06 | 3.19 |

| 13 | 25 | 50 | 750 | 0.75 | 1.50 | 2736.63 | 2717.00 | 0.72 |

| 14 | 5 | 50 | 500 | 0.75 | 0.50 | 1588.39 | 1654.55 | 4.08 |

| 15 | 25 | 50 | 250 | 0.75 | 1.50 | 2640.63 | 2710.54 | 2.61 |

| 16 | 5 | 50 | 500 | 0.50 | 1.50 | 2637.91 | 2584.23 | 2.06 |

| 17 | 15 | 70 | 750 | 0.75 | 1.50 | 1778.89 | 1954.30 | 9.40 |

| 18 | 15 | 50 | 500 | 0.75 | 1.50 | 2874.66 | 2699.02 | 6.30 |

| 19 | 15 | 50 | 500 | 0.75 | 1.50 | 2874.66 | 2699.02 | 6.30 |

| 20 | 25 | 70 | 500 | 0.75 | 1.50 | 1786.34 | 1791.53 | 0.29 |

| 21 | 5 | 50 | 750 | 0.75 | 1.50 | 2759.58 | 2860.95 | 3.61 |

| 22 | 25 | 50 | 500 | 0.50 | 1.50 | 2366.48 | 2580.10 | 8.64 |

| 23 | 15 | 70 | 500 | 1.00 | 1.50 | 2189.53 | 2067.82 | 5.72 |

| 24 | 5 | 70 | 500 | 0.75 | 1.50 | 1715.84 | 1723.96 | 0.47 |

| 25 | 15 | 30 | 500 | 0.75 | 2.50 | 3472.08 | 3696.63 | 6.26 |

| 26 | 5 | 50 | 500 | 0.75 | 2.50 | 3517.25 | 3472.00 | 1.29 |

| 27 | 15 | 70 | 250 | 0.75 | 1.50 | 2012.62 | 2081.60 | 3.37 |

| 28 | 5 | 30 | 500 | 0.75 | 1.50 | 3283.33 | 3171.70 | 3.46 |

| 29 | 15 | 70 | 500 | 0.75 | 2.50 | 2230.74 | 2075.06 | 7.23 |

| 30 | 15 | 50 | 500 | 0.75 | 1.50 | 2454.59 | 2699.02 | 9.49 |

| 31 | 15 | 50 | 500 | 1.00 | 2.50 | 3057.82 | 3155.22 | 3.14 |

| 32 | 25 | 50 | 500 | 0.75 | 0.50 | 1751.32 | 1874.11 | 6.77 |

| 33 | 25 | 30 | 500 | 0.75 | 1.50 | 3448.04 | 3133.49 | 9.56 |

| 34 | 25 | 50 | 500 | 1.00 | 1.50 | 2541.73 | 2753.04 | 7.98 |

| 35 | 15 | 50 | 250 | 0.75 | 2.50 | 2836.79 | 3074.55 | 8.04 |

| 36 | 15 | 30 | 500 | 0.75 | 0.50 | 2085.95 | 2157.35 | 3.37 |

| 37 | 25 | 50 | 500 | 0.75 | 2.50 | 3070.42 | 2781.79 | 9.86 |

| 38 | 15 | 50 | 750 | 0.75 | 2.50 | 3113.24 | 3199.66 | 2.74 |

| 39 | 15 | 70 | 500 | 0.50 | 1.50 | 1745.15 | 1873.68 | 7.10 |

| 40 | 15 | 50 | 500 | 0.75 | 1.50 | 2361.75 | 2499.02 | 5.65 |

| 41 | 15 | 30 | 500 | 0.50 | 1.50 | 2868.33 | 3108.54 | 8.04 |

| 42 | 15 | 30 | 750 | 0.75 | 1.50 | 3438.30 | 3441.54 | 0.09 |

| 43 | 15 | 50 | 500 | 0.50 | 2.50 | 2881.15 | 3024.59 | 4.86 |

| 44 | 15 | 70 | 500 | 0.75 | 0.50 | 1498.05 | 1489.21 | 0.59 |

| 45 | 15 | 50 | 500 | 0.75 | 1.50 | 2622.25 | 2699.02 | 2.89 |

| 46 | 5 | 50 | 250 | 0.75 | 1.50 | 2546.31 | 2737.23 | 7.23 |

References

- Selley, R.C.; Sonnenberg, S.A. Petroleum Exploration: Past, Present, and Future. In Elements of Petroleum Geology; Academic Press; Elsevier: Cambridge, UK, 2015; pp. 1–526. [Google Scholar]

- Kim, D.; Jung, H.-S. Mapping Oil Spills from Dual-Polarized SAR Images Using an Artificial Neural Network: Application to Oil Spill in the Kerch Strait in November 2007. Sensors 2018, 18, 2237. [Google Scholar] [CrossRef] [Green Version]

- Armenio, E.; ben Meftah, M.; de Padova, D.; de Serio, F.; Mossa, M. Monitoring Systems and Numerical Models to Study Coastal Sites. Sensors 2019, 19, 1552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, G.; Li, Y.; Liu, B.; Wu, P.; Chen, C. Marine Oil Slick Detection Based on Multi-Polarimetric Features Matching Method Using Polarimetric Synthetic Aperture Radar Data. Sensors 2019, 19, 5176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mishra, A.K.; Kumar, G.S. Weathering of Oil Spill: Modeling and Analysis. Aquat. Proc. 2015, 4, 435–442. [Google Scholar] [CrossRef]

- Walker, A.; Stern, C.; Scholz, D.; Nielsen, E.; Csulak, F.; Gaudiosi, R. Consensus Ecological Risk Assessment of Potential Transportation-related Bakken and Dilbit Crude Oil Spills in the Delaware Bay Watershed, USA. J. Mar. Sci. Eng. 2016, 4, 23. [Google Scholar] [CrossRef] [Green Version]

- Guo, G.; Liu, B.; Liu, C. Thermal Infrared Spectral Characteristics of Bunker Fuel Oil to Determine Oil-Film Thickness and API. J. Mar. Sci. Eng. 2020, 8, 135. [Google Scholar] [CrossRef] [Green Version]

- Pauzi Zakaria, M.; Okuda, T.; Takada, H. Polycyclic Aromatic Hydrocarbon (PAHs) and Hopanes in Stranded Tar-balls on the Coasts of Peninsular Malaysia: Applications of Biomarkers for Identifying Sources of Oil Pollution. Mar. Pollut. Bull. 2001, 42, 1357–1366. [Google Scholar] [CrossRef]

- Fingas, M. The Basics of Oil Spill Cleanup, 3rd ed.; CRC Press: Cleveland, OH, USA, 2013; pp. 1–286. ISBN 9781439862469. [Google Scholar]

- Zakaria, M.P.; Takada, H. Case study. In Oil Spill Environmental Forensics; Academic Press; Elsevier: Cambridge, UK, 2007; pp. 505–536. [Google Scholar]

- Asano, T.; Burton, F.; Leverenz, H.; Tsuchihashi, R.; Tchobanoglous, G. Water Reuse: Issues, Technologies, and Applications, 1st ed.; McGraw-Hill Education: New York, NY, USA, 2007; pp. 1–1616. ISBN 9780071459273. [Google Scholar]

- Mackie, A.; Woszczynski, M.; Farmer, H.; Walsh, M.E.; Gagnon, G.A. Water Reclamation and Reuse. Water Environ. Res. 2009, 81, 1406–1418. [Google Scholar] [CrossRef]

- Tran, V.T.; Xu, X.; Mredha, M.T.I.; Cui, J.; Vlassak, J.J.; Jeon, I. Hydrogel bowls for cleaning oil spills on water. Water Res. 2018, 145, 640–649. [Google Scholar] [CrossRef]

- Ejofodomi, O.; Ofualagba, G. Detection and Classification of Land Crude Oil Spills Using Color Segmentation and Texture Analysis. J. Imaging Sci. Technol. 2017, 3, 47. [Google Scholar] [CrossRef] [Green Version]

- Beiras, R. Hydrocarbons and Oil Spills. In Marine Pollution, 1st ed.; Academic Press; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–408. [Google Scholar]

- Pintor, A.M.A.; Vilar, V.J.P.; Botelho, C.M.S.; Boaventura, R.A.R. Oil and grease removal from wastewaters: Sorption treatment as an alternative to state-of-the-art technologies. A critical review. Chem. Eng. J. 2016, 297, 229–255. [Google Scholar] [CrossRef]

- Abdullah, M.; Atta, A.; Allohedan, H.; Alkhathlan, H.; Khan, M.; Ezzat, A. Green Synthesis of Hydrophobic Magnetite Nanoparticles Coated with Plant Extract and Their Application as Petroleum Oil Spill Collectors. Nanomaterials 2018, 8, 855. [Google Scholar] [CrossRef] [Green Version]

- Jha, M.; Levy, J.; Gao, Y. Advances in Remote Sensing for Oil Spill Disaster Management: State-of-the-Art Sensors Technology for Oil Spill Surveillance. Sensors 2008, 8, 236–255. [Google Scholar] [CrossRef] [Green Version]

- Leifer, I.; Lehr, W.J.; Simecek-Beatty, D.; Bradley, E.; Clark, R.; Dennison, P.; Hu, Y.; Matheson, S.; Jones, C.E.; Holt, B.; et al. State of the art satellite and airborne marine oil spill remote sensing: Application to the BP Deepwater Horizon oil spill. Remote Sens. Environ. 2012, 124, 185–209. [Google Scholar] [CrossRef] [Green Version]

- Speight, J.G. The Chemistry and Technology of Petroleum, 5th ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 1–953. ISBN 9780429108662. [Google Scholar]

- Ederington, L.H.; Fernando, C.S.; Hoelscher, S.A.; Lee, T.K.; Linn, S.C. Characteristics of petroleum product prices: A survey. J. Commod. Mark. 2019, 14, 1–15. [Google Scholar] [CrossRef]

- Walters, C.C.; Wang, F.C.; Higgins, M.B.; Madincea, M.E. Universal Biomarker Analysis: Aromatic hydrocarbons. Org. Geochem. 2018, 124, 205–214. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 9377-2:2000—Water Quality—Determination of Hydrocarbon Oil Index—Part 2: Method Using Solvent Extraction and Gas Chromatography; ISO: Geneva, Switzerland, 2000; Available online: https://www.iso.org/standard/27604.html (accessed on 26 December 2020).

- OSPAR Commission. Offshore Industry Series Assessment of the OSPAR Report on Discharges, Spills and Emissions to Air from Offshore Installations; OSPAR Convention, Oslo and Paris Comission; 2010. Available online: https://www.ospar.org/documents?v=7351 (accessed on 26 December 2020).

- Langenfeld, J.J.; Hawthorne, S.B.; Miller, D.J. Quantitative Analysis of Fuel-Related Hydrocarbons in Surface Water and Wastewater Samples by Solid-Phase Microextraction. Anal. Chem. 1996, 68, 144–155. [Google Scholar] [CrossRef]

- Tankiewicz, M.; Morrison, C.; Biziuk, M. Application and optimization of headspace solid-phase microextraction (HS-SPME) coupled with gas chromatography–flame-ionization detector (GC–FID) to determine products of the petroleum industry in aqueous samples. Microchem. J. 2013, 108, 117–123. [Google Scholar] [CrossRef]

- Falkova, M.; Vakh, C.; Shishov, A.; Zubakina, E.; Moskvin, A.; Moskvin, L.; Bulatov, A. Automated IR determination of petroleum products in water based on sequential injection analysis. Talanta 2016, 148, 661–665. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. SW-846 Test Method 8440: Total Recoverable Petroleum Hydrocarbons by Infrared Spectrophotometry. Available online: https://www.epa.gov/hw-sw846/sw-846-test-method-8440-total-recoverable-petroleum-hydrocarbons-infrared-spectrophotometry (accessed on 2 November 2020).

- Ferreiro-González, M.; Aliaño-González, M.J.; Barbero, G.F.; Palma, M.; Barroso, C.G. Characterization of petroleum-based products in water samples by HS-MS. Fuel 2018, 222, 506–512. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, Q.; Chen, H.; Yue, W.; Teng, Y. Source Apportionment of Heavy Metals in Sediments and Soils in an Interconnected River-Soil System Based on a Composite Fingerprint Screening Approach. J. Hazard. Mater. 2021, 411, 125125. [Google Scholar] [CrossRef] [PubMed]

- Kaplan, I.R.; Lu, S.T.; Alimi, H.M.; MacMurphey, J. Fingerprinting of High Boiling Hydrocarbon Fuels, Asphalts and Lubricants. Environ. Forensics 2001, 2, 231–248. [Google Scholar] [CrossRef]

- Boehm, P.D.; Burns, W.A.; Page, D.S.; Bence, A.E.; Mankiewicz, P.J.; Brown, J.S.; Douglas, G.S. Total Organic Carbon, an Important Tool in an Holistic Approach to Hydrocarbon Source Fingerprinting. Environ. Forensics 2002, 3, 243–250. [Google Scholar] [CrossRef]

- Taiwo, A.M.; Musa, M.O.; Oguntoke, O.; Afolabi, T.A.; Sadiq, A.Y.; Akanji, M.A.; Shehu, M.R. Spatial Distribution, Pollution Index, Receptor Modelling and Health Risk Assessment of Metals in Road Dust from Lagos Metropolis, Southwestern Nigeria. Environ. Adv. 2020, 2, 100012. [Google Scholar] [CrossRef]

- Aliaño-González, M.; Ferreiro-González, M.; Barbero, G.; Ayuso, J.; Palma, M.; Barroso, C. Study of the Weathering Process of Gasoline by eNose. Sensors 2018, 18, 139. [Google Scholar] [CrossRef] [Green Version]

- Aliaño-González, M.; Ferreiro-González, M.; Barbero, G.; Ayuso, J.; Álvarez, J.; Palma, M.; Barroso, C. An Electronic Nose Based Method for the Discrimination of Weathered Petroleum-Derived Products. Sensors 2018, 18, 2180. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aliaño-González, M.J.; Ferreiro-González, M.; Espada-Bellido, E.; Barbero, G.F.; Palma, M. Novel method based on ion mobility spectroscopy for the quantification of adulterants in honeys. Food Control 2020, 114, 107236. [Google Scholar] [CrossRef]

- Piotr Konieczka, P.; Aliaño-González, M.J.; Ferreiro-González, M.; Barbero, G.F.; Palma, M. Characterization of Arabica and Robusta Coffees by Ion Mobility Sum Spectrum. Sensors 2020, 20, 3123. [Google Scholar] [CrossRef] [PubMed]

- Cao, S.; Sun, J.; Yuan, X.; Deng, W.; Zhong, B.; Chun, J. Characterization of Volatile Organic Compounds of Healthy and Huanglongbing-Infected Navel Orange and Pomelo Leaves by HS-GC-IMS. Molecules 2020, 25, 4119. [Google Scholar] [CrossRef]

- García-Nicolás, M.; Arroyo-Manzanares, N.; Arce, L.; Hernández-Córdoba, M.; Viñas, P. Headspace Gas Chromatography Coupled to Mass Spectrometry and Ion Mobility Spectrometry: Classification of Virgin Olive Oils as a Study Case. Foods 2020, 9, 1288. [Google Scholar] [CrossRef]

- Aliaño-González, M.J.; Ferreiro-González, M.; Barbero, G.F.; Palma, M. Novel method based on ion mobility spectrometry sum spectrum for the characterization of ignitable liquids in fire debris. Talanta 2019, 199, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Aliaño-González, M.; Ferreiro-González, M.; Barbero, G.; Palma, M.; Barroso, C. Application of Headspace Gas Chromatography-Ion Mobility Spectrometry for the Determination of Ignitable Liquids from Fire Debris. Separations 2018, 5, 41. [Google Scholar] [CrossRef] [Green Version]

- Du, Z.; Sun, T.; Zhao, J.; Wang, D.; Zhang, Z.; Yu, W. Development of a plug-type IMS-MS instrument and its applications in resolving problems existing in in-situ detection of illicit drugs and explosives by IMS. Talanta 2018, 184, 65–72. [Google Scholar] [CrossRef]

- Mullen, M.; Giordano, B.C. Combined secondary electrospray and corona discharge ionization (SECDI) for improved detection of explosive vapors using drift tube ion mobility spectrometry. Talanta 2020, 209, 120544. [Google Scholar] [CrossRef]

- Kostarev, V.A.; Kotkovskii, G.E.; Chistyakov, A.A.; Akmalov, A.E. Enhancement of Characteristics of Field Asymmetric Ion Mobility Spectrometer with Laser Ionization for Detection of Explosives in Vapor Phase. Chemosensors 2020, 8, 91. [Google Scholar] [CrossRef]

- Thompson, R.; Perry, J.D.; Stanforth, S.P.; Dean, J.R. Rapid detection of hydrogen sulfide produced by pathogenic bacteria in focused growth media using SHS-MCC-GC-IMS. Microchem. J. 2018, 140, 232–240. [Google Scholar] [CrossRef] [Green Version]

- Zimmer-Faust, A.G.; Thulsiraj, V.; Lee, C.M.; Whitener, V.; Rugh, M.; Mendoza-Espinosa, L.; Jay, J.A. Multi-tiered approach utilizing microbial source tracking and human associated-IMS/ATP for surveillance of human fecal contamination in Baja California, Mexico. Sci. Total Environ. 2018, 640, 475–484. [Google Scholar] [CrossRef] [PubMed]

- Márquez-Sillero, I.; Aguilera-Herrador, E.; Cárdenas, S.; Valcárcel, M. Ion-mobility spectrometry for environmental analysis. TrAC Trends Anal. Chem. 2011, 30, 677–690. [Google Scholar] [CrossRef]

- Calle, J.L.P.; Ferreiro-González, M.; Aliaño-González, M.J.; Barbero, G.F.; Palma, M. Characterization of biodegraded ignitable liquids by headspace-ion mobility spectrometry. Sensors 2020, 20, 6005. [Google Scholar] [CrossRef]

- Sun, T.; Wang, D.; Tang, Y.; Xing, X.; Zhuang, J.; Cheng, J.; Du, Z. Fabric-phase sorptive extraction coupled with ion mobility spectrometry for on-site rapid detection of PAHs in aquatic environment. Talanta 2019, 195, 109–116. [Google Scholar] [CrossRef]

- Yukioka, S.; Tanaka, S.; Suzuki, Y.; Fujii, S.; Echigo, S. A new method to search for per- and polyfluoroalkyl substances (PFASs) by linking fragmentation flags with their molecular ions by drift time using ion mobility spectrometry. Chemosphere 2020, 239, 124644. [Google Scholar] [CrossRef]

- Gabelica, V.; Marklund, E. Fundamentals of ion mobility spectrometry. Curr. Opin. Chem. Biol. 2018, 42, 51–59. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Borsdorf, H.; Eiceman, G.A. Ion Mobility Spectrometry: Principles and Applications. Appl. Spectrosc. Rev. 2006, 41, 323–375. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, D.; Dong, Y.; Ju, H.; Wu, C.; Lin, S. Characteristic Volatiles Fingerprints and Changes of Volatile Compounds in Fresh and Dried Tricholoma Matsutake Singer by HS-GC-IMS and HS-SPME-GC–MS. J. Chromatogr. B 2018, 1099, 46–55. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Yang, R.; Zhang, H.; Wang, S.; Chen, D.; Lin, S. Development of a Flavor Fingerprint by HS-GC–IMS with PCA for Volatile Compounds of Tricholoma Matsutake Singer. Food Chem. 2019, 290, 32–39. [Google Scholar] [CrossRef]

- Wang, F.; Gao, Y.; Wang, H.; Xi, B.; He, X.; Yang, X.; Li, W. Analysis of Volatile Compounds and Flavor Fingerprint in Jingyuan Lamb of Different Ages Using Gas Chromatography–Ion Mobility Spectrometry (GC–IMS). Meat Sci. 2021, 175, 108449. [Google Scholar] [CrossRef]

- Pastor Sánchez, G. Empleo de Diferentes Metodologías Tradicionales para el Análisis de Distintas Propiedades Físico-Químicas del Petróleo. Master’s Thesis, University of Cadiz, Cádiz, Spain, 2018. [Google Scholar]

- Ministerio de Medio Ambiente, y Medio Rural y Marino. Real Decreto 60/2011 Sobre las Normas de Calidad Ambiental en el Ámbito de la Política de Aguas. 2011. Available online: https://www.boe.es/eli/es/rd/2011/01/21/60 (accessed on 6 July 2020).

- Snow, N.H.; Slack, G.C. Head-space analysis in modern gas chromatography. TrAC Trends Anal. Chem. 2002, 21, 608–617. [Google Scholar] [CrossRef]

| Acronym | Location |

|---|---|

| RS_1 | Seawater sample from El Rinconcillo Beach. Algeciras. Spain (36°09’48.7” N 5°26’22.8” W). Collected on: 28/02/2018. |

| RS_2 | Seawater sample from the port near El Rinconcillo Beach. Algeciras. Spain (36°09’45.1” N 5°26’06.9” W). Collected on: 13/01/2018. |

| RS_3 | Seawater sample taken between grounded boats. La Caleta Beach. Cadiz. Spain (36°31’54.7” N 6°18’21.9” W). Collected on: 14/03/2018. |

| RS_4 | Seawater sample from Punta Candor Beach. Cadiz. Spain (36°38’32.1” N 6°23’34.5” W). Collected on: 29/01/2018. |

| RS_5 | Seawater sample from La Calita Beach in Puerto Sherry. El Puerto de Santa Maria. Spain (36°34’60.0” N 6°16’05.1” W). Collected on: 15/04/2018. |

| RS_6 | Seawater sample from Puerto Sherry. El Puerto de Santa María. Spain (36°34’50.0” N 6°15’03.4” W). Collected on: 08/02/2018. |

| RS_7 | Seawater sample from Cadiz harbor. Cadiz. Spain (36°32’01.6” N 6°17’31.5” W). Collected on: 23/03/2018. |

| Group | Acronym | Description |

|---|---|---|

| Gasoline (Gas) | Gas_95_1 | Gasoline 95 octane. Collected on: 28/06/2018. REPSOL Gas Station El Puerto de Santa Maria. Spain. |

| Gas_95_2 | Gasoline 95 octane. Collected on: 29/06/2018. Carrefour Gas Station Jerez de la Frontera. Spain. | |

| Gas_98_1 | Gasoline 98 octane. Collected on: 19/09/2018. REPSOL Gas Station Cordoba. Spain. | |

| Gas_98_2 | Gasoline 98 octane. Collected on: 20/07/2018. Carrefour Gas Station Jerez de la Frontera. Spain. | |

| Diesel (Dies) | Dies_1 | Automotive diesel fuel (A)-diesel e+ neotech. Collected on: 27/05/2018. REPSOL Gas Station Torre del Mar. Spain. |

| Dies_2 | Automotive diesel fuel (A)-diesel e+ neotech. Collected on: 20/06/2018. REPSOL Gas Station Torre del Mar. Spain. | |

| Dies_3 | Industrial diesel fuel (B)-diesel e+. Collected on: 05/05/2018. REPSOL Gas Station Port Caleta de Velez. Spain. | |

| Dies_4 | Industrial diesel fuel (B)-diesel e+. Collected on: 10/06/2018. CEPSA Gas Station Port Caleta de Velez. Spain. | |

| Lubricant (LUB) | LUB_1 | Engine lubricant 2T. Cepsa Store. Spain. Collected on: 17/05/2018. |

| LUB_2 | Engine lubricant 2T. Racing Store. Spain. Collected on: 10/08/2018. | |

| LUB_3 | Boat lubricant. Cadiz Port. Spain. Collected on: 14/07/2018. | |

| LUB_4 | Boat lubricant. Cadiz Port. Spain. Origin unknown. Collected on: 24/05/2018. | |

| Kerosene (Ker) | Ker_1 | Aviation kerosene. Collected on: 17/06/2018. Malaga airport. Spain. |

| Ker_2 | Aviation kerosene. Collected on: 25/07/2018. Malaga airport. Spain. | |

| Ker_3 | Aviation kerosene. Collected on: 02/06/2018. Airfield La Axarquia-Leoni Benabu. Malaga. Spain. | |

| Ker_4 | Aviation kerosene. Collected on: 22/07/2018. Airfield La Axarquia-Leoni Benabu. Malaga. Spain. |

| Variable | −1 | 0 | 1 |

|---|---|---|---|

| Incubation time (min) | 5 | 15 | 25 |

| Incubation temperature (°C) | 30 | 50 | 70 |

| Agitation (rpm) | 250 | 500 | 750 |

| Injection volume (mL) | 0.5 | 0.75 | 1 |

| Sample volume (mL) | 0.5 | 1.5 | 2.5 |

| Variable | Factor | Coefficient | F-Value | p-Value |

|---|---|---|---|---|

| Incubation temperature | X1 | −1294.850 | 107.740 | 0.000 |

| Incubation time | X2 | −85.321 | 0.470 | 0.500 |

| Agitation | X3 | 65.092 | 0.270 | 0.606 |

| Injection volume | X4 | 254.135 | 4.150 | 0.052 |

| Sample volume | X5 | 1212.570 | 94.490 | 0.000 |

| Incubation temperature: Incubation temperature | X12 | −284.903 | 2.850 | 0.104 |

| Incubation temperature: Incubation time | X1X2 | −47.107 | 0.040 | 0.852 |

| Incubation temperature: Agitation | X1X3 | −192.386 | 0.590 | 0.448 |

| Incubation temperature: Injection volume | X1X4 | −59.996 | 0.060 | 0.812 |

| Incubation temperature: Sample volume | X1X5 | −326.713 | 1.710 | 0.202 |

| Incubation time: Incubation time | X22 | −102.797 | 0.370 | 0.548 |

| Incubation time: Agitation | X2X3 | −58.636 | 0.060 | 0.816 |

| Incubation time: Injection volume | X2X4 | −81.193 | 0.110 | 0.748 |

| Incubation time: Sample volume | X2X5 | −304.884 | 1.490 | 0.233 |

| Agitation: Agitation | X32 | 217.615 | 1.660 | 0.209 |

| Agitation: Injection volume | X3X4 | 7.701 | 0.000 | 0.976 |

| Agitation: Sample volume | X3X5 | 60.019 | 0.060 | 0.812 |

| Injection volume: Injection volume | X42 | 123.217 | 0.530 | 0.473 |

| Injection volume: Sample volume | X4X5 | −123.500 | 0.250 | 0.625 |

| Sample volume: Sample volume | X52 | −554.015 | 10.760 | 0.003 |

| Concentration (µL·L−1) | Pure Water | Gas | Die | Lub | Ker |

|---|---|---|---|---|---|

| 8 | 4 (100%) | 8 (100%) | 8 (100%) | 8 (100%) | 8 (100%) |

| 4 | 4 (100%) | 8 (100%) | 8 (100%) | 8 (100%) | 8 (100%) |

| 2 | 4 (100%) | 8 (100%) | 8 (100%) | 8 (100%) | 8 (100%) |

| 0.8 | 4 (100%) | 8 (100%) | 7 (87.5%) | 100 (100%) | 8 (100%) |

| 0.4 | 4 (100%) | 8 (100%) | 7 (87.5%) | 7 (87.5%) | 8 (100%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaén-González, L.; Aliaño-González, M.J.; Ferreiro-González, M.; Barbero, G.F.; Palma, M. A Novel Method Based on Headspace-Ion Mobility Spectrometry for the Detection and Discrimination of Different Petroleum Derived Products in Seawater. Sensors 2021, 21, 2151. https://doi.org/10.3390/s21062151

Jaén-González L, Aliaño-González MJ, Ferreiro-González M, Barbero GF, Palma M. A Novel Method Based on Headspace-Ion Mobility Spectrometry for the Detection and Discrimination of Different Petroleum Derived Products in Seawater. Sensors. 2021; 21(6):2151. https://doi.org/10.3390/s21062151

Chicago/Turabian StyleJaén-González, Lucas, Ma José Aliaño-González, Marta Ferreiro-González, Gerardo F. Barbero, and Miguel Palma. 2021. "A Novel Method Based on Headspace-Ion Mobility Spectrometry for the Detection and Discrimination of Different Petroleum Derived Products in Seawater" Sensors 21, no. 6: 2151. https://doi.org/10.3390/s21062151