3.1.1. Field Distribution in the Sample Compartment

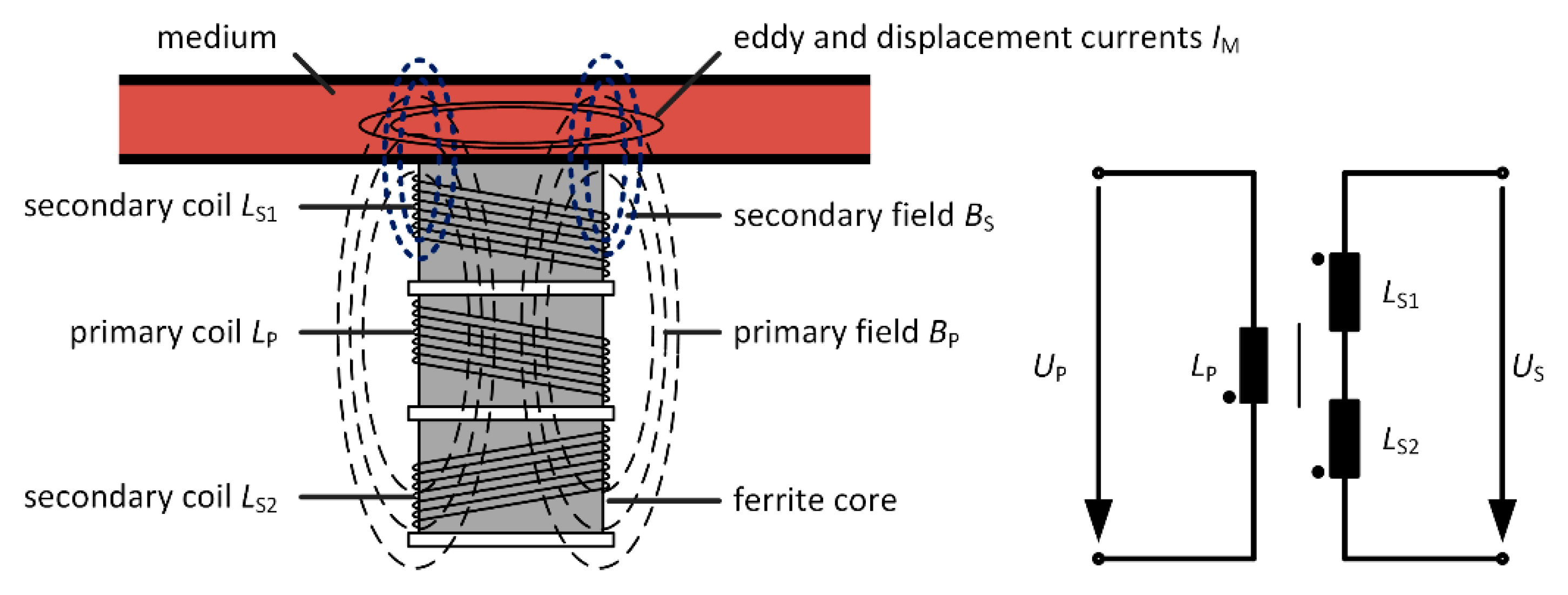

The magnitude of the electromagnetic field generated by the excited primary coil

LP decreases in

z-direction. As the density of the eddy and displacement currents

IM, measured by the secondary coils

LS1 and

LS2, are directly related to the electromagnetic field inside the medium according to Maxwell’s law [

43], the current density within the medium also decreases along the

z-direction. Thus, above a certain height

hM of the sample compartment, the induced current density is too low for a measurable contribution to the secondary magnetic field and hence to the output voltage

US. Therefore, a further increase of

hM does not improve sensitivity. The penetration depth of electromagnetic field and thus the eddy currents in the sample is typically described by solving the field diffusion equation of a planar electromagnetic wave, propagating e.g., in

z-direction and reaching a conducting half space at

z = 0. Solving this diffusion equation results in Equation (4) [

43,

44,

45], where this is valid for

z ≥ 0. For

z < 0,

J(

z) is zero.

Here,

J(

z) is the current density depending on the distance in

z-direction.

J(0) is the initial value of the current density for

z = 0. By replacing

J with the magnetic field

B or electrical field

E, Equation (4) also describes the decrease of this parameter inside a medium. For eddy current sensors, the parameter

δS is typically called standard depth of penetration or skin depth in the scientific literature [

46]. At

z =

δS the current density has attenuated to 1/

e or about 37% respectively of the initial value at

z = 0. The standard depth of penetration

δS only depends on material parameters such as the conductivity

κ and the permeability

μ as well as frequency

f of the field and can be calculated according to Equation (5) [

43].

For typical applications of the differential transformer, the conductivity measured in Siemens per meter is in the single-digit range. For example, the conductivity of blood for monitoring the sodium concentration is between 1 S/m and 2 S/m [

42]. In the case of water quality monitoring, the conductivity can be slightly higher, e.g., about 5 S/m for seawater [

47]. The magnetic properties

μ of a sample is the product of the permeability of free space

μ0 and the relative permeability

μr of the corresponding medium, where usually for the application presented here the relative permeability can be considered as

μr = 1, so that

μ =

μ0 applies. For a differential transformer driven at a frequency

f of 155 kHz, Equation (5) would yield a standard depth of penetration

δS of about 0.9 m to 1.3 m for conductivities between 1 S/m and 2 S/m, respectively. However, these depths of penetration are not to be expected in practical applications.

In order to calculate the true depth of penetration

δT, Dodd et al. has described the depth of penetration of an eddy current sensor for non-destructive material testing using an analytical solution of the vector potential

A [

48]. The excited coil is an axisymmetric circular coil with a rectangular cross-section in the plane of the symmetry axis and radial axis. The mean coil radius

rP,M is the arithmetic mean value between the outer and inner radius of the coil. Since these sensors have similarities to the differential transformer with respect to the depth of penetration, the findings can be transferred. The very complex description using the vector potential

A was analyzed by Mottl [

49]. It was found that a calculation of the standard depth of penetration

δS according to Equation (5) is valid as long as the ratio between the mean coil radius

rP,M of the excited coil and the calculated standard depth of penetration

δS is greater than 10 (

rP,M/

δS > 10). For a smaller ratio, the actual depth of penetration deviates from that in Equation (5). The reason is the assumption of planar waves to derive Equation (4). A planar wave implies, among other things, that the electromagnetic field has a constant amplitude along the propagation direction and is not attenuated without the presence of a medium. The attenuation of planar waves is solely due to the properties of the medium. To obtain an understanding why the true depth of penetration

δT can be significantly lower and to have a much easier approach to estimate the

δT than in [

48], we use the Biot–Savart law. This allows to determine the magnetic field

B(

z) of a coil that is rotationally symmetric to the

z-axis, along the

z-direction. Since the Biot–Savart law neglects the spatial expansion of the coil, it is assumed for a coil with a rectangular cross-section that all

nP windings are concentrated at the mean radius

rP,M. In this case, the

B(

z)-field along the symmetry axis (

z-axis) of a coil excited with the current

IP can be described by Equation (6).

Equation (6) shows that the

B-field decreases with increasing distance

z from coil origin (

z = 0). The decrease depends on the mean coil radius

rP,M. Calculating the

B-field of a coil in free space and without the presence of any sample according to Equation (6) at the position

z =

δS and normalizing the

B-field to the initial value of the

B-field at the position

z = 0, yields Equation (7).

By plotting Equation (7) versus the ratio

rP,M/

δS,

Figure 5 is obtained, where

rP,M/

δS can be varied by changing the primary coil radius

rP,M and the standard depth of penetration

δS depending on the sample conductivity and the excitation frequency according to Equation (5).

For values of

rP,M/

δS ≥ 10, it can be seen that the ratio

BP(

δS)/

BP(0) tends towards the value 1, meaning that the

B-field in free space can be seen almost constant up to

z =

δS, meeting the conditions to be considered as a planar wave and supporting the results obtained from [

49]. Hence, the attenuation within the medium can be described by Equations (4) and (5), as the medium is the dominant reason for lowering the current density or field strengths. To reach the standard depths of penetration

δS of about 1 m for the above-calculated sodium monitoring in blood would require a technically unreasonable coil radius of about 10 m. The mean coil radius

rP,M of the differential transformer used here is about 9.55 mm, giving a ratio

rP,M/

δS of about 10

−2. At this point, Equation (7) approaches zero, indicating that the

B-field of the coil has nearly decreased to zero at

z =

δS (with

δS ≈ 1 m) only due to the coil geometry. Thus, it can be assumed that the decrease of the field is dominated by the coil geometry of the excited coil while the attenuation due to the electromagnetic properties of the medium has a negligible impact on the field distribution. In order to estimate the true depth of penetration

δT in the case that the decrease of the

B-field is dominated by the coil geometry, we present a very simple approach using the Biot–Savart law.

δT is defined similar to δ

S as the depth of penetration, at which the

B-field and thus also the current density

J has declined to the value 1/

e i.e., 37% relative to the initial value at

z = 0. Therefore, the ratio

BP(

δT +

d0)/

BP(

d0) is determined by using Equation (6) and is set equal to 1/

e.

d0 is the distance in

z-direction between the primary coil and the medium, see

Figure 3, and is about 11.25 mm for the differential transformer used here. As a result, Equation (8) is obtained.

Solving Equation (8) for the true depth of penetration

δT leads to Equation (9), enabling the depth of penetration of eddy current sensors to be estimated in a simple way. This equation is valid for

rP,M/

δS < 10

−1, since here the decrease of the field strength of the

B-field is mainly caused by the coil geometry and the attenuation due to the medium can be neglected.

Calculating the true depth of penetration δT for the differential transformer used here with rP,M = 9.55 mm and d0 = 11.25 mm, Equation (9) results in δT = 7 mm, which is significantly lower than the δS of approximately 1 m due to the relatively low conductivity of the medium κ (e.g., blood) and excitation frequency f according to Equation (5).

In order to confirm the calculated

δT, numerical computer simulations are conducted using the CST-EM Studio model described in

Section 2.3. Subsequently, these simulations are validated by measurements. Besides the true depth of penetration

δT of the eddy currents and the resulting current distribution of the current density

JM within the medium, the dependence of the sensitivity on the height

hM of the medium is of particular interest. Since the sensitivity is proportional to the total eddies and displacement currents

IM induced into the medium, i.e., to the integral of

JM along the

z-axis and

JM decreases with increasing

hM, it can be expected that

Sκ initially rises with increasing height

hM of the medium and starts to saturate at a certain point. As the eddy current density has decreased to 37% of the initial value at

δT, the sensitivity

Sκ can only increase by 37% by further increasing

hM, i.e.,

Sκ has reached 67% of the maximum value. Considering an exponentially decreasing depth of penetration, the point 3∙

δS is called the effective depth of penetration. At this point, the current density is already attenuated by about 95%. Therefore, all currents induced above the effective depth of penetration have only a negligible effect. The definition of the effective depth of penetration is also assumed here for the true depths of penetration determined according to Equation (9), so that 3∙

δT applies to the effective depth of penetration. A calculated true depth of penetration

δT of 7 mm, results in an effective depth of penetration 3∙

δT = 21 mm.

Now, simulations according to the model from

Section 2.3 help to verify whether this relationship between the true depths of penetration of the current density is consistent with the dependence of sensitivity on the height

hM of the medium or sample compartment, respectively. First, the height

hM of the sample compartment is set to 50 mm, the outer radius

rM,outer to 47 mm and the inner radius to 0 mm. The conductivity

κ of the medium is set to 2 S/m and the primary coil is excited with 1 V

PP and 155 kHz.

Figure 6 shows the resulting curve of the current density within the sample in

z-direction (orange solid line versus the upper

x-axis, normalized to the initial

JM at the bottom of the medium). The intersection of the horizontal black dotted line at 0.37 with the vertical black dotted line gives a simulated true depth of penetration of

δT = 7.4 mm. The height

hM of the medium is now varied from 0 mm to 50 mm, in order to proof that the depth of penetration can also be determined based on the sensitivity of the differential transformer. Each height

hM is simulated for 1 S/m and 2 S/m, allowing the sensitivity to be determined using Equation (3). The simulated sensitivity

Sκ is shown in

Figure 6 (blue solid line versus the lower

x-axis). The sensitivity is normalized to the maximum

Sκ,max of 114.8 μV/S/m. As can be seen, the sensitivity first rises rapidly with increasing

hM and then saturates, as expected. 63% of the maximum sensitivity

Sκ,max, is reached at the simulated

δT of the induced current density

JM is 7.4 mm. Thus, the true depth of penetration

δT of the eddy and displacement currents and the sensitivity

Sκ of the differential transformer are proportional to each other, and

δT can therefore be derived from the sensitivity, which is a considerable advantage for determination of

δT by measurements, since the sensitivity is much easier to measure than

JM within the medium. This simulated true depth of penetration

δT is close to the calculated

δT of 7 mm by Equation (9), which is also shown as the green dashed line in

Figure 6.

In order to validate the simulations, the depth of penetration was also measured, using the differential transformer described in

Section 2.1. The differential transformer is driven with a peak-to-peak input voltage of 1 V

pp and a frequency

f of 155 kHz. The medium was positioned above the differential transformer within a compartment having a radius of 47 mm. Similar to the simulation; the medium height

hM was varied from 0 mm to 50 mm. As described in

Section 2.2, the sample solution is DI-water containing NaCl with a concentration of

c1 = 100 mmol/L and

c2 = 150 mmol/L, so that the sensitivity

Sc can be calculated according to Equation (2) for each height

hM. The results are shown in

Figure 6 as red dots. The measured sensitivity is normalized to the maximum measured

Sc,max of 38.74 mV/mol/L. The measured values are in good agreement with the simulated values validating the simulation and the mathematical model from Equation (9).

Furthermore, an important issue is whether the increased sensitivity can improve the precision and thus the

SNR of the differential transformer. Therefore, we determined the noise of the output signal by the standard deviation of the imaginary part of

US, which is averaged 512 times giving a measured value about every 11 s.

Table 1 gives the noise measured for different heights

hM and a concentration of 150 mmol/L NaCl. The standard deviation of the measured concentration can be calculated by the standard deviation of

Im{

Us} divided by the respective sensitivity

Sc.

Table 1 reveals that there is no correlation between

hM and the noise of the imaginary part of

US. Thus, comparing the standard deviation of

cstd can be reduced from 0.81 mmol/L to 0.44 mmol/L by increasing

hM due to the increasing sensitivity

Sc. The relative error bars normalized to

Sc,max are illustrated in

Figure 6.

In summary, the true depth of penetration δT of the differential transformer used here cannot be calculated using Equation (5) due to the small ratio rP,M/δS of the primary coil radius to the standard depth of penetration. As a result of the relatively small coil radius rP,M and the low conductivity of the medium, the magnetic field of the coil and thus the currents induced into the medium have already approached zero before reaching δS due to the coil properties. δS only depends on the frequency f of the excited coil and the material properties of the medium, such as the conductivity κ and permeability μ. Therefore, we introduced Equation (9) estimating the true depth of penetration δT when rP,M/δS is below 10−1. With Equation (9), the true depth of penetration δT of the differential transformer used here, was calculated to 7 mm. The simulation model, validated by measurements, showed a depth of penetration of about 7.4 mm. Hence, Equation (9) is well suited for estimating δT. The true depth of penetration δT is particularly important for the design of the measuring chamber, when the sample volume is limited by the application. For hM ≤ δT, the sensitivity can be significantly improved by increasing hM. However, by further increasing hM the effect of hM on Sκ and Sc decreases, e.g., for hM > 3∙δT, increasing hM does not noticeably increase the sensitivity. Since the noise of the output signal Im{US} has shown no inherent correlation with the medium height hM, an increase in sensitivity by increasing hM is associated with an improvement in signal-to-noise ratio SNR.

3.1.2. Impact of the Radius of the Sample Compartment on the Sensitivity

In this section, the impact of the radius of the sample compartment and thus the radius

rM of the medium is discussed. In [

37], we have derived Equation (10) in order to improve the sensitivity of the differential transformer by an optimized distance

dPCB between the three planar PCB coils, see

Figure 3. This mathematical model can be used to increase the sensitivity and the signal-to-noise ratio

SNR by optimizing the magnetic coupling between the coils and the medium.

dM is the distance between the medium and the upper secondary coil

LS1, see

Figure 3. The factor

C summarizes further constants as well as geometrical factors of the ferrite core, the angular frequency and the primary voltage, which will not be discussed here any further. Considering Equation (10), additional to the distance

dPCB the mean medium radius

rM,M is relevant.

rM,M is defined as the geometric mean value between the inner radius

rM,inner and the outer radius

rM,outer of the cylindrically shaped sample compartment, representing the boundaries of the medium. Plotting Equation (10) for

rM,inner = 0 mm versus

rM,outer and setting a distance

dPCB between the PCB coils to 8 mm and

dM to 1 mm leads to

Figure 7. Setting

rM,inner to zero yields

rM,outer = 2∙

rM,M.

For deriving Equation (10), the medium was considered as a coil with one winding carrying the total induced eddy and displacement currents

IM at

rM,M and thus causing a secondary field

BS. Hence,

BS can be determined by using the Biot–Savart law according to Equation (6) [

37] and

Figure 7 and therefore Equation (10) can be interpreted accordingly. First, the amplitude of the secondary field

BS increases squared to radius

rM,M. Thus, the factor

r2M,M in Equation (10) dominates the influence on the sensitivity

Sκ for small radii, leading to an increased sensitivity increasing

rM,M. However, at a certain value of

rM,M, the secondary field reaches the lower secondary coil

LS2, see Equation (6), resulting in a progressive penetration of

BS of both secondary coils

LS1 and

LS2 with increasing

rM,M. Hence, a reduction of

Sκ can be observed. The loss of sensitivity due progressive penetration of

BS of both secondary coils

LS1 and

LS2 is described in Equation (10) by the term in parentheses. However, Equation (10) only considers the geometrical effect of

rM,M. The total current intensity of the eddy and displacement currents

IM was determined in [

37] using Faraday’s law and the total impedance

ZM of the medium. The dependence of

ZM on the height

hM and the mean radius

rM,M of the medium was neglected. Furthermore, the complex distribution of the primary field

BP was simplified and assumed to be just oriented in positive

z-direction within the ferrite core. These simplifications leads to a constant induced current

IM within the medium independent of the radius

rM,outer. A constant current

IM independent of the radius would imply a current density

JM evenly distributed along the radius

rM. The amplitude of

JM changes as a function of

rM,outer. However, the current

IM is expected to grow progressively with increasing size of the medium as

ZM decreases. After a certain value of

rM,outer, less current is induced in the outer area with a large radius of the medium due to the complex field distribution of

BP. As a result, the current

IM should saturate.

Therefore, using the differential transformer model from

Section 2.3, we simulate the current distribution

JM within the medium at a conductivity

κ of the medium of 2 S/m at an excitation of the primary coil of 1 V

PP and a frequency of 155 kHz.

Figure 8a shows a cross sectional view in the

x-

y-plane from the top. The simulated current density is represented by arrows and rotates around the

z-axis. The color gradient indicates the intensity of

JM.

Figure 8b shows a cross sectional view in the

y-

z-plane. Again, the intensity

JM is given by the color gradient.

Figure 9 shows the resulting current density distribution

JM,x of the

x-component of the induced eddy and displacement current densities along the cutting line A-A located at a height of 1 mm inside the medium as depicted in

Figure 8. The outer radius

rM,outer of the medium is 200 mm (

Figure 9, red solid line) and 50 mm (

Figure 9, blue dotted line), respectively, and the height

hM is 10 mm. These parameters represent the boundaries of the sample compartment.

Figure 9 reveals a point symmetry of the current density

JM,x to the origin, representing the center of the radially symmetric medium. Starting from the origin of the medium (x = y = 0 mm), the absolute value of the current density increases with increasing radius

rM and reaches a maximum at about 7 mm. Then, the absolute current density decreases until

JM,x approaches zero. Comparing the current densities

JM,x for sample boundaries of

rM,outer = 50 mm and

rM,outer = 200 mm, the current density

JM,x is almost independent of

rM,outer until the outer boundary

rM,outer is reached. Beyond this boundary, it is evident that the current is forced to zero. Hence, the initial assumption for Equation (10) of a evenly distributed

JM along the radius with an amplitude depending on the boundary of the sample compartment

rM,outer is not fulfilled. Thus, the total current of the induced eddy and displacement currents

IM is also not constant for different radii of the medium as long as

JM has not fully decreased to zero for very high

rM,outer. Furthermore, a possible influence of different radii

rS,outer of the secondary coils

LS1 and

LS2 is not considered in this Equation (10).

In order to determine the exact impact of the radius

rM,outer and of the outer radius

rS,outer of the secondary coils on the sensitivity, simulations are executed using the model from

Section 2.3, followed by validation of the model via measurements. As for the previous simulations of the current distribution,

hM is set to 10 mm. The outer radius

rM,outer of the medium is varied from 0 mm to 100 mm. In order to determine the sensitivity

Sκ according to Equation (3), each step is simulated at a conductivity of

κ = 1 S/m and

κ = 2 S/m. The inner radius

rM,inner is fixed to zero. The results are shown in

Figure 10 as a blue solid line, normalized to the maximum sensitivity of 88 μV/S/m. As expected, the simulation shows an increasing sensitivity with increasing radius

rM,outer. However, at a certain value,

Sκ saturates and does not decrease.

A possible reason for the sensitivity

Sκ not decreasing after a certain radius

rM,outer as shown in

Figure 7 could be the more complex shape of the current density

JM within the medium. For larger radii of

rM,outer,

JM decreases towards zero after its maximum at about 7 mm and thus contributes less to the secondary field

BS. In addition, due to the inhomogeneous distribution of

JM, the mean radius

rM,M of the medium cannot be calculated simply from the geometric mean value of

rM,inner and

rM,outer. As

JM decreases for larger

rM,outer,

rM,M increases much slower than expected, causing less penetration of

BS into the lower secondary coil

LS2, as

BS does not extend that far along the

z-direction, see Equation (6). This results in a saturation of

Sκ instead of a reduction for larger

rM,outer. For small

rM,outer, the simulated characteristic of the sensitivity of the differential transformer corresponds in good approximation to the expected behavior shown in

Figure 7 and can therefore be approximated well by a quadratic function

f(

rM,outer) =

a∙

r2M,outer (

Figure 10, black dashed line). Fitting in the range of

rM,outer = 0 mm to

rM,outer = 26 mm leads to

a = 102.4 × 10

−6 mVS/(mol∙mm

2) having a coefficient of determination R

2 of 0.9925. For

rM,outer > 26 mm,

f(

rM,outer) increasingly deviates from

Sκ. This value of

rM,outer is indicated by the black dotted line in

Figure 10 and represents the outer radius

rs,outer of the secondary coils

LS1 and

LS2. The impact of the secondary coil radius

rS,outer will be investigated in more detail later. First, the simulation results have to be validated by measurements.

Therefore, similar to

Section 3.1.1, the differential transformer described in

Section 2.1 is driven with a voltage

UP of 1 V

PP at a frequency

f of 155 kHz. The medium is placed above the differential transformer and is located in sample compartments with fixed height

hM of 10 mm and variable diameters of 15 mm, 43 mm, 50 mm, 80 mm, 94 mm, and 115 mm. The sample solutions inside the compartments contain NaCl with concentrations of

c1 = 100 mmol/L and

c2 = 150 mmol/L, enabling the calculation of sensitivity

Sc for each radius. The measured results are normalized to the maximum sensitivity of

Sc = 31 mV/mol/L and are shown in

Figure 10 as red dots. As can be seen, the results correspond well with the simulations, meaning the simulation model can be considered as validated. Similar to the simulations, the sensitivity initially increases with increasing radius of the medium. As in

Section 3.1.1, we also investigate whether the precision can be enhanced by the increased sensitivity. Therefore, the noise of the output voltage was determined by the standard deviations of

Im{

US} at different radii

rM,outer. The results can be found in

Table 2.

Table 2 reveals no correlation between the noise and

rM,outer. The standard deviation of the concentration

cstd was calculated by dividing the standard deviation of

Im{

US} by the respective sensitivity

Sc. Due to the initial low sensitivity at

rM = 7.5 mm, the standard deviation of concentration

cstd is 11.9 mmol/L. Comparing this to a radius of 57 mm,

cstd is only 0.57 mmol/L, which is a significant improvement in the precision of the differential transformer. The relative error bars normalized to

Sc,max are also illustrated in

Figure 10.

As already mentioned, the increase of both the simulated sensitivity

Sκ as well as the measured sensitivity

Sc saturate at an outer radius of the medium

rM,outer of about 26 mm. This corresponds exactly to the outer radius

rS,outer of the secondary coils

LS1 and

LS2. Therefore, the validated simulation model is used to investigate how

rS,outer affects

Sκ and if there is a correlation between

rS,outer and the saturation radius. In this simulation,

rS,outer is used as parameter between 15 mm and 150 mm. Thereby, only the radius

rS,outer of the secondary coils are changed. The number of windings

nS of

LS1 and

LS2 are kept constant at 542. This means, for example, that the windings at

rS,outer = 15 mm spread over a much smaller area than at

rS,outer = 150 mm. The results of this simulation are shown in

Figure 11.

As depicted in

Figure 11, the initial increase of

Sκ can approximated by a quadratic function

f(

rM,outer) =

a∙

r2M,outer for all secondary coil radii

rS,outer. However, for very large

rS,outer of—e.g., 150 mm—a reasonable fit can only be realized up to

rM,outer of about 40 mm, since the simulated

Sκ increasingly deviates from

f(

rM,outer) for larger

rM,outer. This is probably due to the increasing decline of

JM at larger radii. Furthermore, the simulations indicate a decrease of the initial slop of

Sκ, i.e., the factor

a of the quadratic function

f(

rM,outer) becomes smaller, for larger secondary coil radii

rS,outer. Hence, the sensitivity curve is shifted towards larger medium radii

rM,outer indicated by the arrow in

Figure 11. A possible reason for this could be the reduction of the number of windings

nS of the secondary coils effectively involved in the magnetic coupling with the secondary field

BS. Since the divergence of magnetic fields must always be zero, the field lines are closed. The secondary field

BS propagates from the medium inside the ferrite core in negative

z-direction, towards the secondary coils. At larger radial distance to the ferrite core, the field lines turn back in positive

z-direction. The outer windings of the secondary coils with large

rS,outer are thus penetrated by both the outgoing and returning field and causing a reduced net flux, so that no voltage is induced. These outer windings are effectively not involved in the coupling with the secondary field. By replacing the secondary inductance

LS with the proportionality

LS ~

nS2 in Equation (10), Equation (11) is obtained. Equation (11) indicates a dependency of the winding ratio between the primary coil

nP and the secondary coil

nS. Comparable to an ordinary transformer, lowering the effective

nS cause a reduction in the sensitivity.

Nevertheless, the respective outer secondary coil radius

rS,outer always corresponds very well with saturation radius regarding the sensitivity

Sκ, meaning that there is a direct correlation between

rS,outer and the saturation. A possible reason for this could be the reduced contribution of the circular currents with very large radius

rM to the secondary magnetic field

BS at the origin of the medium at x = y = 0 mm propagating over the ferrite core in negative

z-direction. Equation (6) supports this assumption, since the contribution of the circular currents to

BS at the origin decreases with

rM−1. However, leakage fields occur in the immediate surroundings of currents circulating at the outer boundary of the medium, although with decreasing amplitude due to the declining current density

JM. These leakage fields predominantly close directly around the current path and do not noticeably penetrate the ferrite core. Due to the small distance between the medium and the secondary coil

LS1, only

LS1 is penetrated by these leakage fields. If the outer radius

rM,outer of the medium exceeds the outer radius

rS,outer of the secondary coil, such additional currents with larger radius

rM than

rS,outer couple increasingly less with

LS1, leading to the saturation of the sensitivity. Therefore, an increase of

rS,outer leads to more leakage fields being collected by

LS1 and thus to an increased maximum sensitivity

Sκ,max. This increase in maximum sensitivity

Sκ,max can be observed up to an

rS,outer of 70 mm. However, for higher

rS,outer Sκ,max starts to decreases again as shown in

Figure 12. Here, the maximum simulated sensitivity

Sκ,max is plotted versus the outer radius

rS,outer of the secondary coils

LS1 and

LS2.

Again, this decrease in the maximum sensitivity Sκ,max for higher secondary radii rS,outer can be described by the reduction in the effective number of windings nS involved in the coupling. At large radii, the current within the medium has nearly approached zero. Therefore, an increase of rM,outer has only a negligible effect, since almost no current exists. If the outer secondary coil radius rS,outer exceeds the radius in the medium where almost no current flows, the effective number of windings nS is irrevocably reduced due to the same effect described before. Thus, to obtain an optimum design of the differential transformer in terms of sensitivity, the secondary coil radius rS,outer and radius of the medium must be carefully adjusted to each other. For example, a restricted radius rM,outer of the sample due to a limited sample volume needs a secondary coil radius close to rM,outer. If rM,outer is not limited by the application, the secondary coil radius rS,outer have to be carefully adjusted to achieve high maximum sensitivity Sκ,max.

In the section above, the dependence of the sensitivities Sκ and Sc of the differential transformer on the radius of the medium has been analyzed. A good approximation of the initial increase of the sensitivities Sκ and Sc by increasing rM,outer with a quadratic function was found. Thus, an increase of rM,outer has significant impact on the sensitivity. For a constant number of windings of the secondary coils, the slope of this approximating function depends on the radius rS,outer of the secondary coil. Increasing rS,outer to rS,outer ≥ rM,outer results in the outer windings of the secondary coil not participating in the magnetic coupling between the medium and the secondary coil. Hence, the effective number of windings nS of the secondary coil decreases, causing a decrease in sensitivity. The same effect of uncoupled windings nS also occurs when rS,outer is increased over the radius where only negligible eddy and displacement currents circulate even for rS,outer < rM,outer. If the radius rM,outer of the medium exceeds the radius of the secondary coil, the sensitivity saturates, i.e., a further increase of rM,outer has no effect on Sκ and Sc. Thus, if rM,outer exceeds rS,outer, the maximum sensitivity is reached. In experimental investigations, an increase of rM,outer seems useful, since the sensitivity significantly increases, but no correlation of the noise to rM,outer is observed. Thus, increasing the sensitivity by increasing rM,outer is a reasonable solution to improve the signal-to-noise ratio SNR.