Surface-Mounted Bare and Packaged Fiber Bragg Grating Sensors for Measuring Rock Strain in Uniaxial Testing

Abstract

:1. Introduction

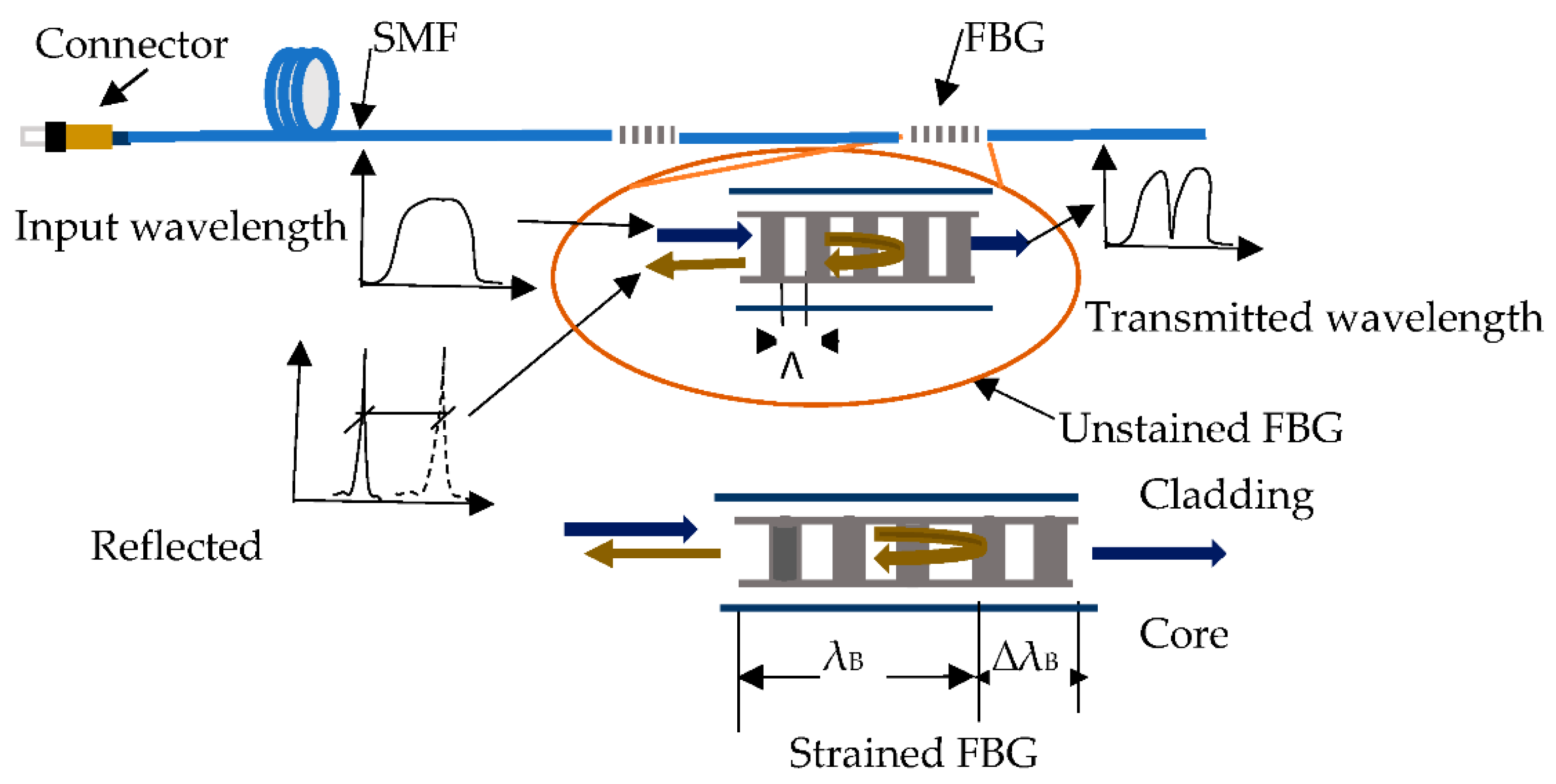

2. Principle, Calibration and Packaging of FBG for Strain Sensing

2.1. Principle of FBG Strain Sensing Technology

2.2. FBG Strain Calibration

2.3. Preparation, Packaging and Attachment of C-FBG Strain Sensors

3. Materials and Methods

4. Results and Discussion

4.1. Laboratory Experiment

4.2. Finite Element Modeling (FEM)

4.3. Study of the Effect of Frictional Coefficient (FC) between Steel Plates and Specimen

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamdi, P. Characterization of Brittle Damage in Rock from the Micro to Macro Scale. Ph.D. Thesis, Simon Fraser University, Burnaby, BC, Canada, 10 August 2015. [Google Scholar]

- Roshan, H.; Masoumi, H.; Hagan, P. On size-dependent uniaxial compressive strength of sedimentary rocks in reservoir geomechanics. In Proceedings of the 50th US Rock Mechanics/Geomechanics Symposium, ARMA, Houston, TX, USA, 26–29 June 2016; pp. 2322–2327. [Google Scholar]

- Nicksiar, M.; Martin, C.D. Crack initiation stress in low porosity crystalline and sedimentary rocks. Eng. Geol. 2013, 154, 64–76. [Google Scholar] [CrossRef]

- Miranda, T.; Sousa, L.R.; Gomes, A.T.; Tinoco, J.; Ferreira, C. Geomechanical characterization of volcanic rocks using empirical systems and data mining techniques. J. Rock Mech. Geotech. Eng. 2017, 10, 138–150. [Google Scholar] [CrossRef]

- Hoek, E.; Martin, C.D. Fracture initiation and propagation in intact rock–a review. J. Rock Mech. Geotech. Eng. 2014, 6, 287–300. [Google Scholar] [CrossRef] [Green Version]

- Bieniawski, Z.T.; Bernede, M.J. Suggested methods for determining the uniaxial compressive strength and deformability of rock materials. Part 1. Suggested method for determination of the uniaxial compressive strength of rock materials. Int. J. Rock Mech. Min. Sci. 1979, 16, 137. [Google Scholar] [CrossRef]

- ASTM. D3148-02 Standard Test Method for Elastic Moduli of Intact Rock Core Specimens in Uniaxial Compression; ASTM International: West Conshohocken, PA, USA, 2002; Available online: https://www.astm.org/Standards/D3148.htm (accessed on 22 February 2021).

- Dautriat, J.; Bornert, M.; Gland, N.; Dimanov, A.; Raphanel, J. Localized deformation induced by heterogeneities in porous carbonate analysed by multi-scale digital image correlation. Tectonophysics 2011, 503, 100–116. [Google Scholar] [CrossRef]

- Bartmann, K.; Alber, M. Experimental Determination of Crack Initiation and Crack Damage of Two Granites. Procedia Eng. 2017, 191, 119–126. [Google Scholar] [CrossRef]

- Roshan, H.; Masoumi, H.; Regenauer-Lieb, K. Frictional behaviour of sandstone: A sample-size dependent triaxial investigation. J. Struct. Geol. 2017, 94, 154–165. [Google Scholar] [CrossRef]

- Shen, J.; Jimenez, R.; Karakus, M.; Xu, C. A simplified failure criterion for intact rocks based on rock type and uniaxial compressive strength. Rock Mech. Rock Eng. 2014, 47, 357–369. [Google Scholar] [CrossRef]

- Bahaaddini, M.; Hosseinpour Moghadam, E. Evaluation of empirical approaches in estimating the deformation modulus of rock masses. Bull. Eng. Geol. Environ. 2019, 78, 3493–3507. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E.K. Pre-Peak and Post-Peak Rock Strain Characteristics During Uniaxial Compression by 3D Digital Image Correlation. Rock Mech. Rock Eng. 2016, 49, 2541–2554. [Google Scholar] [CrossRef]

- Lin, Q.; Labuz, J.F. Fracture of sandstone characterized by digital image correlation. Int. J. Rock Mech. Min. Sci. 2013, 60, 235–245. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A. Specimen aspect ratio and progressive field strain development of sandstone under uniaxial compression by three-dimensional digital image correlation. J. Rock Mech. Geotech. Eng. 2017, 9, 599–610. [Google Scholar] [CrossRef]

- Schmidt-Hattenberger, C.; Naumann, M.; Borm, G. Fiber Bragg grating strain measurements in comparison with additional techniques for rock mechanical testing. IEEE Sens. J. 2003, 3, 50–55. [Google Scholar] [CrossRef]

- Park, J.; Kwon, Y.S.; Ko, M.O.; Jeon, M.Y. Dynamic fiber Bragg grating strain sensor interrogation with real-time measurement. Opt. Fiber Technol. 2017, 38, 147–153. [Google Scholar] [CrossRef]

- Di Sante, R. Fibre optic sensors for structural health monitoring of aircraft composite structures: Recent advances and applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.C.; Tee, B.P.; Chong, M.F.; Ku Mahamud, K.M.; Mohamad, H. Structural Assessment for an old Steel Railway Bridge Under Static and Dynamic Loads Using Fibre Optic Sensors. In Proceedings of the International Conference on Smart Infrastructure and Construction 2019 (ICSIC): Driving data-informed decision-making, Churchill College, Cambridge, UK, 8 July 2019; pp. 729–736. [Google Scholar]

- Sun, Y.; Li, Q.; Yang, D.; Fan, C.; Sun, A. Investigation of the dynamic strain responses of sandstone using multichannel fiber-optic sensor arrays. Eng. Geol. 2016, 213, 1–10. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q.; Fan, C. Laboratory core flooding experiments in reservoir sandstone under different sequestration pressures using multichannel fiber Bragg grating sensor arrays. Int. J. Greenh. Gas Control 2017, 60, 186–198. [Google Scholar] [CrossRef]

- Torres, B.; Payá-Zaforteza Ignacio, I.; Calderón, P.A.; Adam, J.M. Analysis of the strain transfer in a new FBG sensor for Structural Health Monitoring. Eng. Struct. 2011, 33, 539–548. [Google Scholar] [CrossRef] [Green Version]

- Xu, D.S.; Borana, L.; Yin, J.H. Measurement of small strain behavior of a local soil by fiber Bragg grating-based local displacement transducers. Acta Geotech. 2013, 9, 935–943. [Google Scholar] [CrossRef]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain measurements of composite laminates with embedded fibre bragg gratings: Criticism and opportunities for research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef] [Green Version]

- Hong, C.Y.; Zhang, Y.F.; Zhang, M.X.; Leung, L.M.G.; Liu, L.Q. Application of FBG sensors for geotechnical health monitoring, a review of sensor design, implementation methods and packaging techniques. Sens. Actuators Phys. 2016, 244, 184–197. [Google Scholar] [CrossRef]

- Yang, Y.W.; Bhalla, S.; Wang, C.; Soh, C.K.; Zhao, J. Monitoring of rocks using smart sensors. Tunn. Undergr. Sp. Technol. 2007, 22, 206–221. [Google Scholar] [CrossRef]

- Ferdinand, P. The Evolution of Optical Fiber Sensors Technologies During the 35 Last Years and Their Applications in Structure Health Monitoring. In Proceedings of the EWSHM-7th European Workshop on Structural Health Monitoring, IFFSTTAR, Inria, Université de Nantes, Nantes, France, 8 July 2014. [Google Scholar]

- Zhao, Y.; Zhang, N.; Si, G. A fiber bragg grating-based monitoring system for roof safety control in underground coal mining. Sensors 2016, 16, 1759. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castro-Caicedo, A.; Torres, P.; Lain, R. Packaging and testing of fiber Bragg gratings for use as strain sensor in rock specimens. In Proceedings of the 8th Iberoamerican Optics Meeting and 11th Latin American Meeting on Optics, Lasers, and Applications, Porto, Portugal, 18 November 2013; p. 87852R. [Google Scholar]

- Castro-Caicedo, A.; Nieto-Callejas, M.J.; Torres, P. Fiber Bragg grating strain sensor for hard rocks. In Proceedings of the International Conference on Optical Fibre Sensors (OFS24), Curitiba, Brazil, 28 September 2015; p. 963449. [Google Scholar]

- Hill, K.O.; Meltz, G. Fiber Bragg Grating Technology Fundementals and Overview. IEEE J. Light. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef] [Green Version]

- Morey, W.; Meltz, G.; Glenn, H.; Glenn, W. Fiber optic Bragg grating sensors. Proc. SPIE Fiber Opt. Laser Sens. 1989, 1169, 98–107. [Google Scholar] [CrossRef]

- Meltz, G.; Morey, W.W.; Glenn, W.H. Formation of Bragg gratings in optical fibers by a transverse holographic method. Opt. Lett. 1989, 14, 823–825. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Li, Q.; Fan, C.; Yang, D.; Li, X.; Sun, A. Fiber-optic monitoring of evaporation-induced axial strain of sandstone under ambient laboratory conditions. Environ. Earth Sci. 2017, 76, 379. [Google Scholar] [CrossRef]

- Isah, B.W.; Mohamad, H.; Ahmad, N.R.; Harahap, I.S.H. Preliminary view of a smart technique for materials testing in the laboratory using FBG sensor. In Proceedings of the International Conference on Civil, Offshore & Environmental Engineering 2018 (ICCOEE 2018), Kuala Lumpur, Malaysia, 17 September 2018. [Google Scholar]

- Our Products-Smartscan. Smart Fibres. Available online: https://www.smartfibres.com/products/smartscan (accessed on 26 January 2021).

- Isah, B.W.; Mohamad, H.; Ahmad, N.R. Rock stiffness measurements fibre Bragg grating sensor (FBGs) and the effect of cyanoacrylate and epoxy resin as adhesive materials. Ain Shams Eng. J. 2020. [Google Scholar] [CrossRef]

- Geotechnical Monitoring Instruments. Available online: http://www.jooshin.kr/?act=shop.goods_view&GS=419&GC=GD02 (accessed on 1 July 2019).

- Acar, M.C.; Gündüz, Z.; Kara, H.B. Modulus of Elasticity Determination of Rocks Using Comressometer, Strain Gauge and Lvdt. Proc. ACE 2014, 11, 2–7. [Google Scholar]

- Isah, B.W.; Mohamad, H.; Harahap, I.S.H. Measurement of small-strain stiffness of soil in a triaxial setup: Review of local instrumentation. Int. J. Adv. Appl. Sci. 2018, 5, 15–26. [Google Scholar] [CrossRef] [Green Version]

- Hazzard, J.F.; Young, R.P.; Maxwell, S.C. Micromechanical modeling of cracking and failure in brittle rocks. J. Geophys. Res. Solid Earth 2000, 105, 16683–16697. [Google Scholar] [CrossRef]

- Mardalizad, A.; Scazzosi, R.; Manes, A.; Giglio, M. Testing and numerical simulation of a medium strength rock material under unconfined compression loading. J. Rock Mech. Geotech. Eng. 2018, 10, 197–211. [Google Scholar] [CrossRef]

- ASTM. D7012-14 Standard Test Method for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens Under Varying States of Stress and Temperatures; ASTM International: West Conshohocken, PA, USA, 2014; pp. 4–11. Available online: https://webstore.ansi.org/standards/astm/astmd701214 (accessed on 22 February 2021).

- Carbon Fibre Sheet, 300 mm × 300 mm × 1.3 mm | RS Components. Available online: https://my.rs-online.com/web/p/carbon-fibre-sheets/7648707/ (accessed on 17 July 2020).

- VT-802/VT-802NT 502 Super Glue-Vital Technical. Available online: https://vitaltechnical.com/product/vt-802-vt-802nt-502-super-glue/ (accessed on 11 January 2020).

- Li, J.; Neumann, H.; Ramalingam, R. Design, fabrication, and testing of fiber Bragg grating sensors for cryogenic long-range displacement measurement. Cryogenics 2015, 68, 36–43. [Google Scholar] [CrossRef]

- Wan, K.T.; Leung, C.K.Y.; Olson, N.G. Investigation of the strain transfer for surface-attached optical fiber strain sensors. Smart Mater. Struct. 2008, 17, 35037. [Google Scholar] [CrossRef]

| S/N | L (mm) | BW@−3dB (nm) | SLSR (dB) | Reflectivity (%) | |

|---|---|---|---|---|---|

| 1 | 10 | 1530.0 | 0.171 | 15 | 95 |

| 2 | 10 | 1533.7 | 0.187 | 13 | 95 |

| 3 | 10 | 1537.0 | 0.184 | 15 | 95 |

| 4 | 10 | 1540.3 | 0.169 | 16 | 95 |

| 5 | 10 | 1544.0 | 0.205 | 14 | 95 |

| 6 | 10 | 1547.6 | 0.184 | 13 | 95 |

| 7 | 10 | 1551.1 | 0.183 | 16 | 95 |

| 8 | 10 | 1554.5 | 0.204 | 15 | 95 |

| 9 | 10 | 1558.0 | 0.199 | 15 | 95 |

| S/N | UCS (MPa) | Modulus | FBGPack | FBGBare | SG | LVDT |

|---|---|---|---|---|---|---|

| UC1 | Et (MPa) | 30,070 | 27,300 | 27,700 | 20,240 | |

| 48.98 | Eav (MPa) | 29,310 | 27,630 | 28,280 | 20,230 | |

| Es (MPa) | 33,547 | 33,320 | 33,456 | 21,769 | ||

| UC2 | Et (MPa) | 23,820 | 23,030 | 22,220 | 16,770 | |

| 45.8 | Eav (MPa) | 23,790 | 22,070 | 21,970 | 16,840 | |

| Es (MPa) | 23,130 | 23,131 | 21,810 | 15,793 | ||

| UC10 | Et (MPa) | 32,520 | 31,560 | - | 28,150 | |

| 52.56 | Eav (MPa) | 32,820 | 31,890 | - | 28,080 | |

| Es (MPa) | 35,990 | 35,892 | - | 25,022 | ||

| UC13 | Et (MPa) | 29,010 | 27,560 | 29,050 | 22,350 | |

| 51.25 | Eav (MPa) | 28,800 | 26,880 | 28,250 | 21,810 | |

| Es (MPa) | 28,444 | 26,947 | 26,148 | 18,920 | ||

| UC26 | Et (MPa) | 19,300 | 20,420 | 19,300 | 17,100 | |

| 32.81 | Eav (MPa) | 19,135 | 20,290 | 19,130 | 17,350 | |

| Es (MPa) | 20,500 | 18,222 | 19,294 | 13,015 | ||

| UC31 | Et (MPa) | 29,750 | 28,780 | 29,870 | 22,610 | |

| 63.27 | Eav (MPa) | 28,860 | 27,230 | 28,050 | 21,990 | |

| Es (MPa) | 30,170 | 27,002 | 28,590 | 17,416 |

| Specimen | m FBGPack | m FBGBare | m LVDT |

|---|---|---|---|

| UC1 | 1.08 | 0.98 | 0.73 |

| UC2 | 1.07 | 1.04 | 0.76 |

| UC10 | - | - | - |

| UC13 | 0.99 | 0.95 | 0.77 |

| UC26 | 1 | 1.05 | 0.89 |

| UC31 | 1.00 | 0.96 | 0.76 |

| Specimen | FBGPack | FBGBare | SG |

|---|---|---|---|

| UC1 | 0.3 | 0.23 | 0.21 |

| UC2 | 0.3 | 0.24 | 0.3 |

| UC10 | 0.27 | 0.25 | |

| UC13 | 0.32 | 0.29 | 0.32 |

| UC26 | 0.25 | 0.23 | 0.22 |

| UC31 | 0.21 | 0.23 | 0.22 |

| Limestone | Steel | Cyano | CFRP | FBGs | |

|---|---|---|---|---|---|

| E (GPa) | 29.75 | 200 | 1.88 | 70 | 73 |

| 0.21 | 0.3 | 0.2 | 0.32 | 0.2 | |

| UCS (MPa) | 63.27 | - | - | - | - |

| (MPa) | 6.10 | 460 | 23.3 | 504.3 | |

| (GPa) | 17.1 | 166.67 | 1.04 | 64.82 | 43.45 |

| G (GPa) | 12.3 | 76.92 | 0.78 | 26.52 | 29.92 |

| (kg/m3) | 2800 | 7850 | - | 1600 | 2600 |

| Division | Length (mm) | Y (mm) | X (mm) |

|---|---|---|---|

| Class 1 | 15 | 0.2 | 0.05 |

| 15 | 0.2 | 0.1 | |

| 15 | 0.2 | 0.2 | |

| Class 2 | 20 | 0.2 | 0.05 |

| 20 | 0.2 | 0.1 | |

| 20 | 0.2 | 0.2 | |

| Class 3 | 30 | 0.2 | 0.05 |

| 30 | 0.2 | 0.1 | |

| 30 | 0.2 | 0.2 |

| Specimen | Analysis | Et (GPa) | Eav (GPa) | Es (GPa) |

|---|---|---|---|---|

| UC31 | FEMRock | 30,560 | 30,450 | 30,170 |

| FEMFBG | 31,340 | 31,440 | 32,192 | |

| FBGBare | 28,780 | 27,230 | 27,002 | |

| FBGPack | 29,750 | 28,860 | 30,170 | |

| SG | 29,870 | 28,050 | 28,590 |

| Packaging Length (mm) | STC at x = 0.05 (%) | STC at x = 0.1 (%) | STC at x = 0.2 (%) |

|---|---|---|---|

| 15 | 82.24 | 81.55 | 80.33 |

| 20 | 90.14 | 89.44 | 88.5 |

| 30 | 93.64 | 92.87 | 91.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Isah, B.W.; Mohamad, H. Surface-Mounted Bare and Packaged Fiber Bragg Grating Sensors for Measuring Rock Strain in Uniaxial Testing. Sensors 2021, 21, 2926. https://doi.org/10.3390/s21092926

Isah BW, Mohamad H. Surface-Mounted Bare and Packaged Fiber Bragg Grating Sensors for Measuring Rock Strain in Uniaxial Testing. Sensors. 2021; 21(9):2926. https://doi.org/10.3390/s21092926

Chicago/Turabian StyleIsah, Balarabe Wada, and Hisham Mohamad. 2021. "Surface-Mounted Bare and Packaged Fiber Bragg Grating Sensors for Measuring Rock Strain in Uniaxial Testing" Sensors 21, no. 9: 2926. https://doi.org/10.3390/s21092926

APA StyleIsah, B. W., & Mohamad, H. (2021). Surface-Mounted Bare and Packaged Fiber Bragg Grating Sensors for Measuring Rock Strain in Uniaxial Testing. Sensors, 21(9), 2926. https://doi.org/10.3390/s21092926